Preparation and thermophysical properties of aligned graphite flake/Cu composites

-

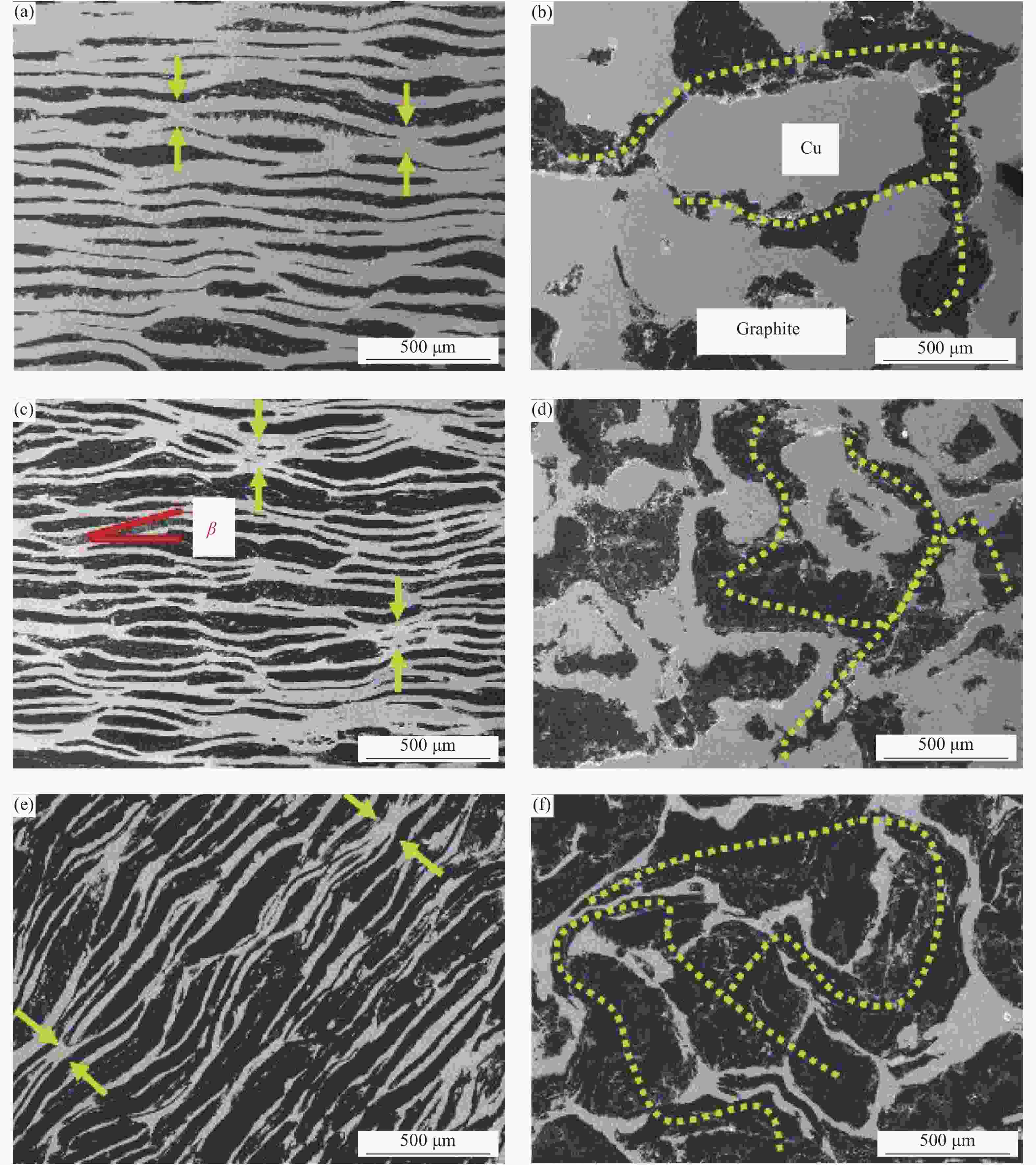

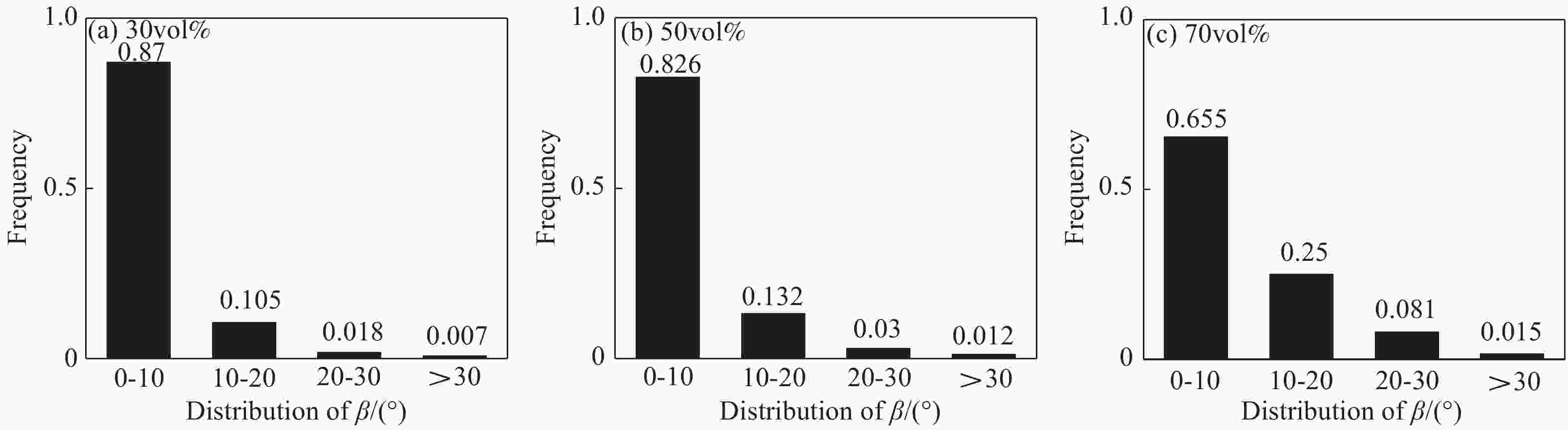

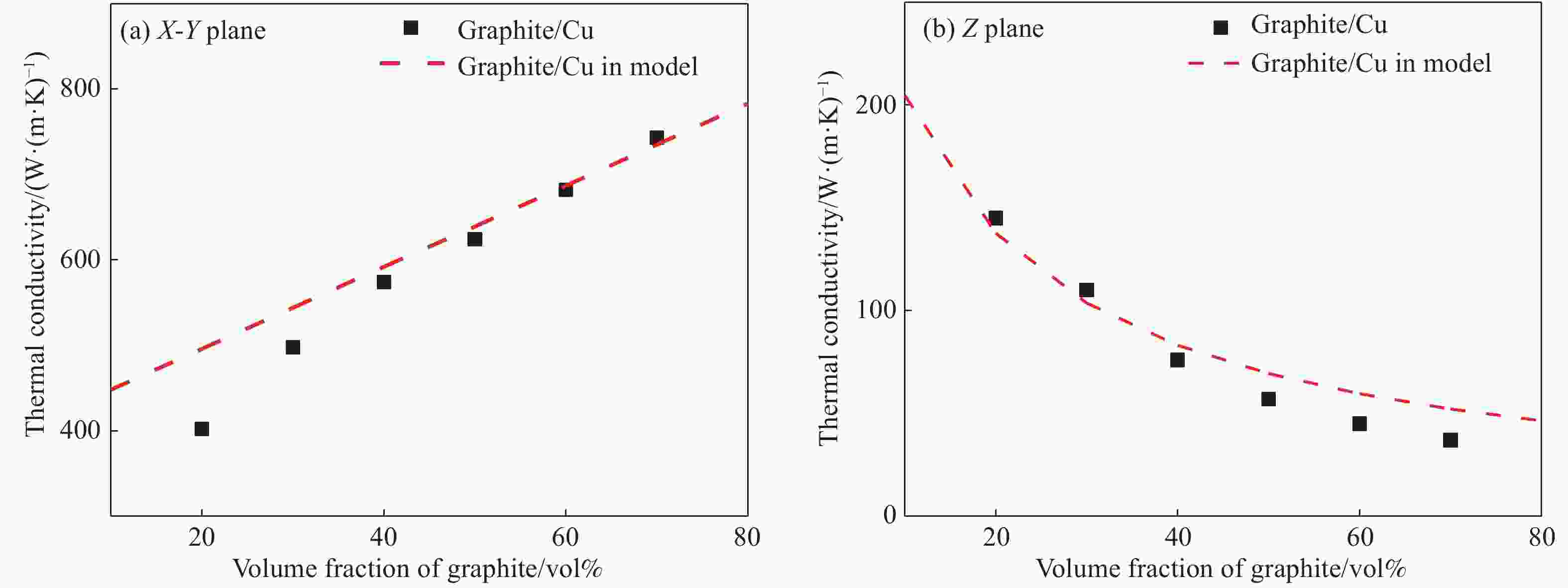

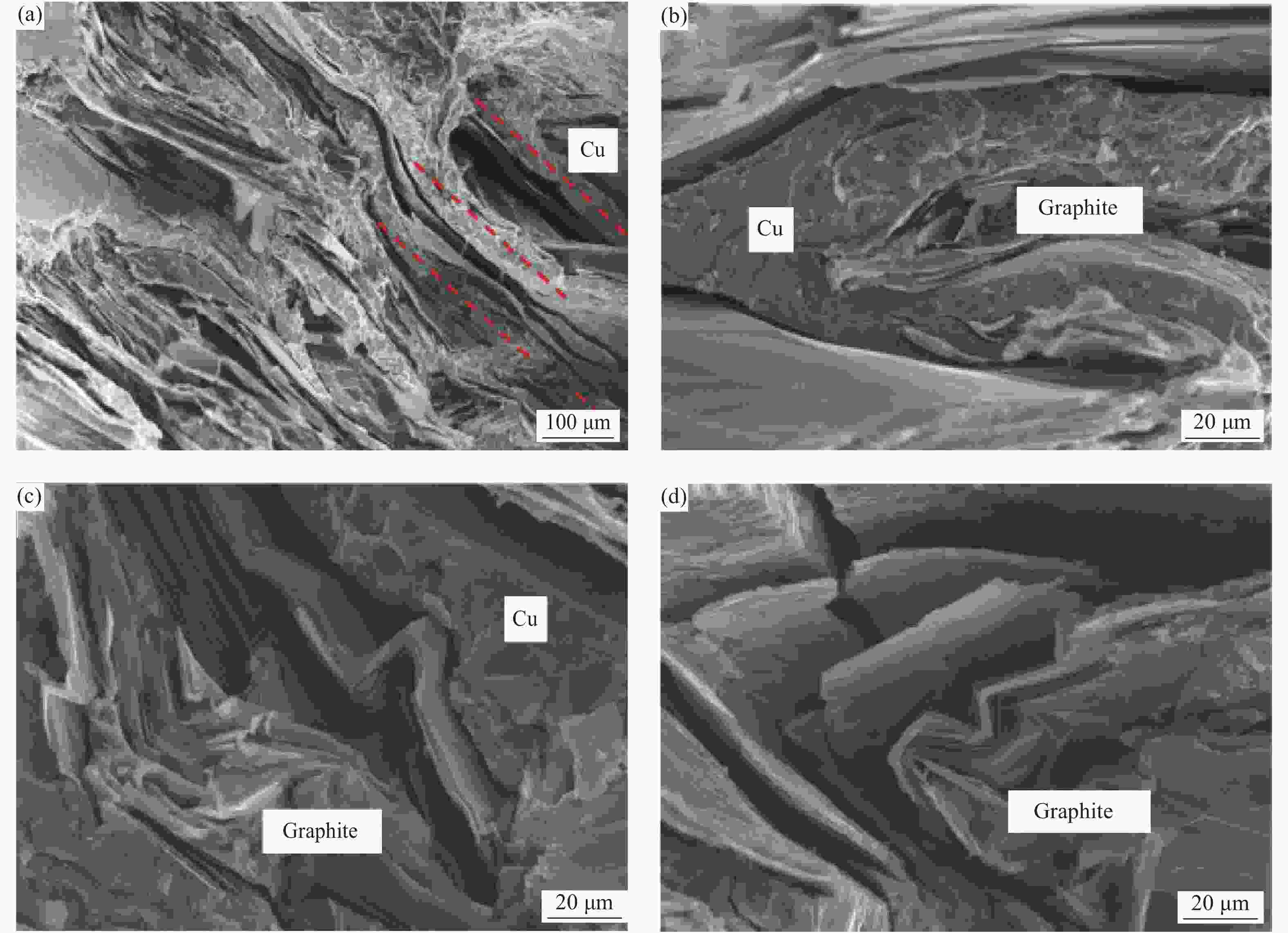

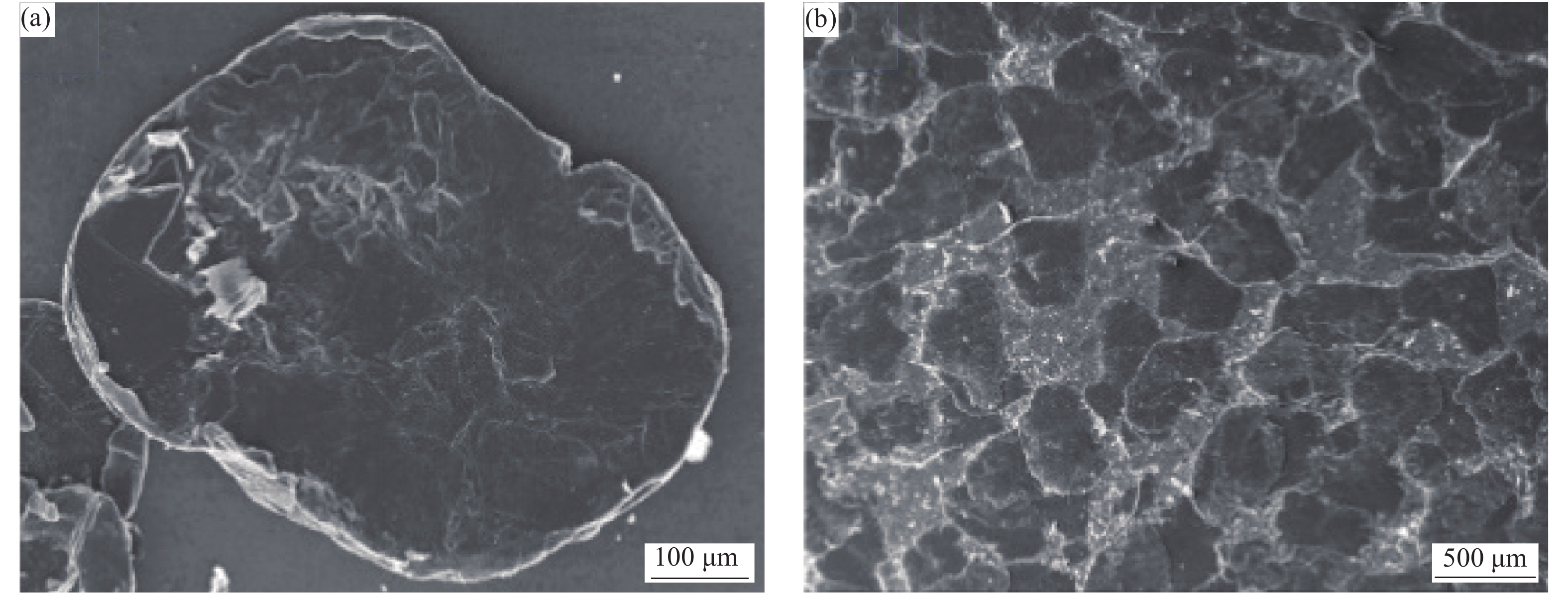

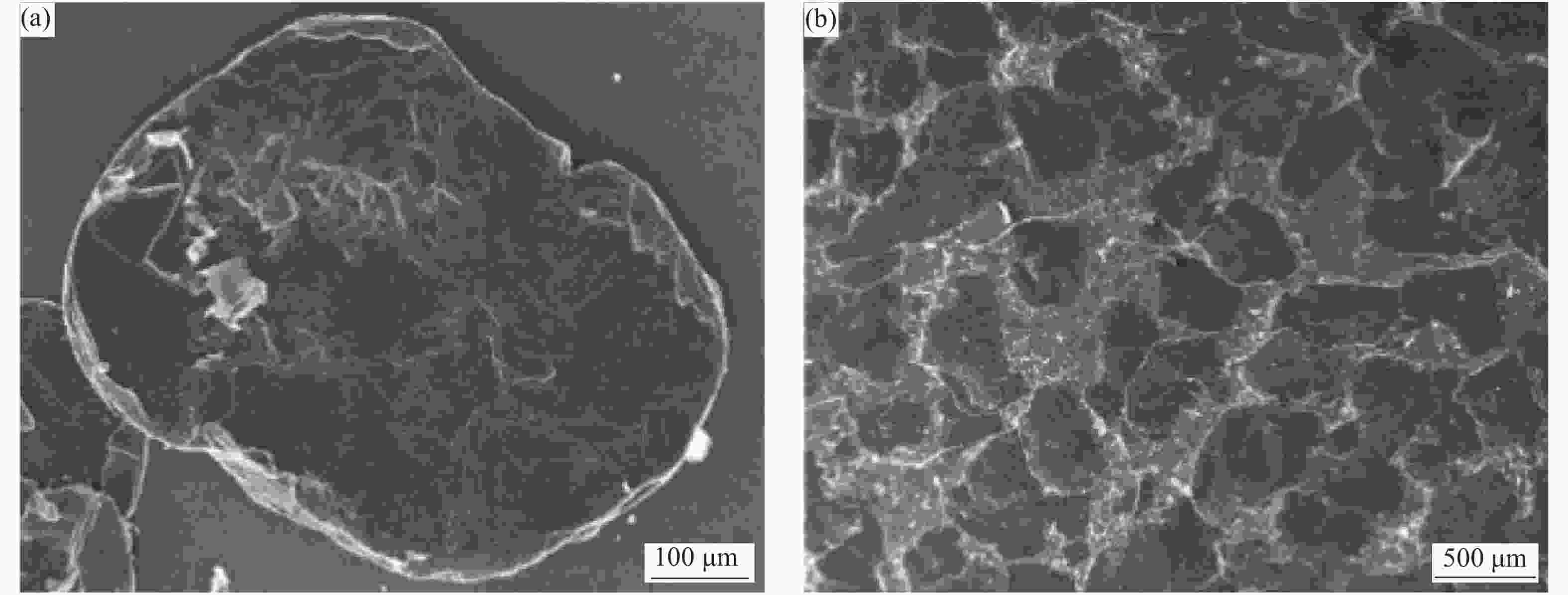

摘要: 为了制备出具有优良热物理性能的石墨/铜复合材料,采用流延法将天然鳞片石墨定向排列在铜箔表面,并使用真空热压法制备具有层状结构的高定向石墨/铜复合材料。使用XRD和SEM等表征方法分析样品的微观形貌和成分,结果表明,在高温的作用下,流延所使用的溶剂充分挥发,热压后石墨仍高定向排列在相邻的两层铜箔之间,并相互搭接;部分熔化的铜在压力作用下渗透到石墨层的孔隙处,铜层之间相互贯穿。这种结构使石墨/铜复合材料具有优良的热物理性能。当石墨体积分数为20vol%~70vol%时,石墨/铜复合材料在高导热平面内热导率高达402~743 W/(m·K),抗弯强度达到126~48 MPa。深入讨论了石墨/铜复合材料的热传导机制,并建立了导热预测模型。Abstract: In order to prepare graphite/Cu composites with excellent thermodynamic properties, the natural graphite flakes were highly oriented on the surface of copper foil by tape casting method. The high-oriented graphite flake/Cu composites with layered structure were prepared by vacuum hot-pressing method. The phases and morphology of graphite flake/Cu composites were characterized by XRD and SEM. The results show that the solvent used for casting is fully volatilized after heat-treated process. The aligned graphite flakes between two copper foil layers overlap each other and partially melted copper penetrates other copper layers across the pores of the graphite layer. This structure allows the graphite/Cu composite to achieve excellent thermophysical properties. As the volume fraction of graphite is 20vol% to 70vol%, the thermal conductivity of the graphite flake/Cu composite increases from 402 W/(m·K) to 743 W/(m·K) in high thermal conductivity plane, while the bending strength is 126~48 MPa.The heat transfer mechanism of graphite flake/Cu composites is discussed deeply and a thermal conductivity prediction model has been established.

-

表 1 石墨和铜的物理参数

Table 1. Physical parameters of graphite and Cu

表 2 不同石墨体积分数的石墨/铜复合材料的热物理性能和弯曲强度

Table 2. Thermophysical properties and bending strengths of graphite/Cu composites with different graphite volume fractions

Volume fraction of graphite/vol% Density/

(kg·m−3)Specific heat capacity/(J·(kg·K)−1) Thermal diffusion

coefficient/(mm2·s−1)Thermal conductivity/

(W/(m·K))Bending strength/MPa X-Y Z X-Y Z 20 7 452 409 132 47 402 143 126 30 6 818 421 173 38 497 109 115 40 6 124 436 215 28 574 75 101 50 5 493 455 250 23 625 58 85 60 4 811 478 296 19 681 44 66 70 4 160 509 351 17 743 36 48 -

[1] MALLIK S, EKERE N, BEST C, et al. Investigation of thermal management materials for automotive electronic control units[J]. Applied Thermal Engineering,2011,31(2):355-362. [2] 张晓辉, 王强. 电子封装用金属基复合材料的研究现状[J]. 微纳米电子技术, 2018, 55(1):18-25, 44.ZHANG Xiaohui, WANG Qiang. Research status of metal matrix composites for electronic packaging[J]. Micro-nanoelectronic Technology,2018,55(1):18-25, 44(in Chinese). [3] 朱敏, 孙忠新, 高锋. 电子封装用金属基复合材料的研究现状[J]. 材料导报, 2013, 27(2):181-183.ZHU Min, SUN Zhongxin, GAO Feng. Research status of metal matrix composites for electronic packaging[J]. Materials Reports,2013,27(2):181-183(in Chinese). [4] 申胜飞, 李茜. 5G通信技术关键材料发展研究[J]. 科技中国, 2019(8):50-59.SHEN Shengfei, LI Qian. Research on key materials development of 5G communication technology[J]. Science and Technology of China,2019(8):50-59(in Chinese). [5] 黄凯, 白华, 朱英彬, 等. 石墨表面化学镀Cu对天然鳞片石墨/Al复合材料热物理性能的影响[J]. 复合材料学报, 2018, 35(4):920-926.HUANG Kai, BAI Hua, ZHU Yinbin, et al. Thermal conductivity and mechanical properties of flake graphite/Al composite with electroless Cu plating on graphite surface[J]. Acta Materiae Compositae Sinica,2018,35(4):920-926(in Chinese). [6] 吴赵兵, 张永刚, 颜克文. 某型基站大功率模块散热优化设计[J]. 电子世界, 2014(16):180-181. doi: 10.3969/j.issn.1003-0522.2014.16.177WU Zhaobing, ZHANG Yonggang, YAN Kewen. Optimization design of heat dissipation for a high-power module of a base station[J]. Electronics World,2014(16):180-181(in Chinese). doi: 10.3969/j.issn.1003-0522.2014.16.177 [7] MIZUUCHI K, INOUE K, AGARI Y, et al. Processing of Al/SiC composites in continuous solid–liquid coexistent state by SPS and their thermal properties[J]. Composites Part B: Engineering,2012,43(4):2012-2019. doi: 10.1016/j.compositesb.2012.02.004 [8] 王俊伟, 张现周, 薛晨, 等. 石墨表面镀Si对石墨/Al复合材料热物理性能的影响[J]. 复合材料学报, 2017, 34(4):608-615.WANG Junwei, ZHANG Xianzhou, XUE Chen, et al. Effects of Si coated on graphite surface on the thermal and mechanical properties of graphite/Al composites[J]. Acta Materiae Compositae Sinica,2017,34(4):608-615(in Chinese). [9] KOVÁČIK J Š, EMMER S, BIELEK J. Thermal conductivity of Cu-graphite composites[J]. International Journal of Thermal Sciences,2015,90:298-302. doi: 10.1016/j.ijthermalsci.2014.12.017 [10] HU F, JIE D, ZHENG Y. Morphological effect of fillers on graphite reinforced polydicyclopentadiene based composites[J]. Polymer Composites,2014,35(10):1918-1925. doi: 10.1002/pc.22850 [11] YUAN G, LI X, DONG Z, et al. Graphite blocks with preferred orientation and high thermal conductivity[J]. Carbon,2012,50(1):175-182. doi: 10.1016/j.carbon.2011.08.017 [12] 徐群峰, 游志恒, 高鹏, 等. 石墨/铜复合材料的热学性能比较[J]. 热加工工艺, 2017, 46(10):136-138+142.XU Qunfeng, YOU Zhiheng, GAO Peng, et al. Comparison of thermal properties of graphite/Cu composite[J]. Hot Working Technology,2017,46(10):136-138+142(in Chinese). [13] ZHU Y, BAI H, XUE C, et al. Thermal conductivity and mechanical properties of a flake graphite/Cu composite with a silicon nano-layer on a graphite surface[J]. RSC Advances,2016,6(100):98190-98196. doi: 10.1039/C6RA17804A [14] CHU K, WANG X H, WANG F, et al. Largely enhanced thermal conductivity of graphene/Cu composites with highly aligned graphene network[J]. Carbon,2018,127:102-112. doi: 10.1016/j.carbon.2017.10.099 [15] ZHOU C, HUANG W, CHEN Z, et al. In-plane thermal enhancement behaviors of Al matrix composites with oriented graphite flake alignment[J]. Composites Part B: Engineering,2015,70:256-262. doi: 10.1016/j.compositesb.2014.11.018 [16] LI W, LIU Y, WU G. Preparation of graphite flakes/Al with preferred orientation and high thermal conductivity by squeeze casting[J]. Carbon,2015,95:545-551. doi: 10.1016/j.carbon.2015.08.063 [17] ZHOU C, JI G, CHEN Z, et al. Fabrication, interface characterization and modeling of oriented graphite flakes/Si/Al composites for thermal management applications[J]. Materials <italic>&</italic> Design,2014,63:719-728. [18] CHEN Wang, HUA Bai, CHEN Xue, et al. On the influence of carbide coating on the thermal conductivity and flexural strength of X (X = SiC, TiC) coated graphite/Al composites[J]. RSC Advances,2016,6(109):107483-107490. doi: 10.1039/C6RA21754K [19] TRUONG H V, ZINSEMISTER G E. Experimental study of heat transfer in layered composites[J]. International Journal of Heat <italic>&</italic> Mass Transfer,1978,21(7):905-909. [20] PROGELHOF R C, THRONE J L, RUETSCH R R. Methods for predicting the thermal conductivity of composite systems: A review[J]. Polymer Engineering and Science,1976,16(9):615-625. doi: 10.1002/pen.760160905 [21] NAN C W, BIRRINGER R, CLARKE D R, et al. Effective thermal conductivity of particulate composites with interfacial thermal resistance[J]. Journal of Applied Physics,1997,81(10):6692-6699. doi: 10.1063/1.365209 [22] SWARTZ E T, POHL R O. Thermal boundary resistance[J]. Reviews of Modern Physics,1989,61(3):605. doi: 10.1103/RevModPhys.61.605 [23] BAI H, XUE C, LYU J L, et al. Thermal conductivity and mechanical properties of flake graphite/copper composite with a boron carbide-boron nano-layer on graphite surface[J]. Composites Part A: Applied Science and Manufacturing,2018,106:42-51. doi: 10.1016/j.compositesa.2017.11.019 -

下载:

下载: