Preparation and properties of carbon fiber/bismaleimide resin composites with high heat resistance

-

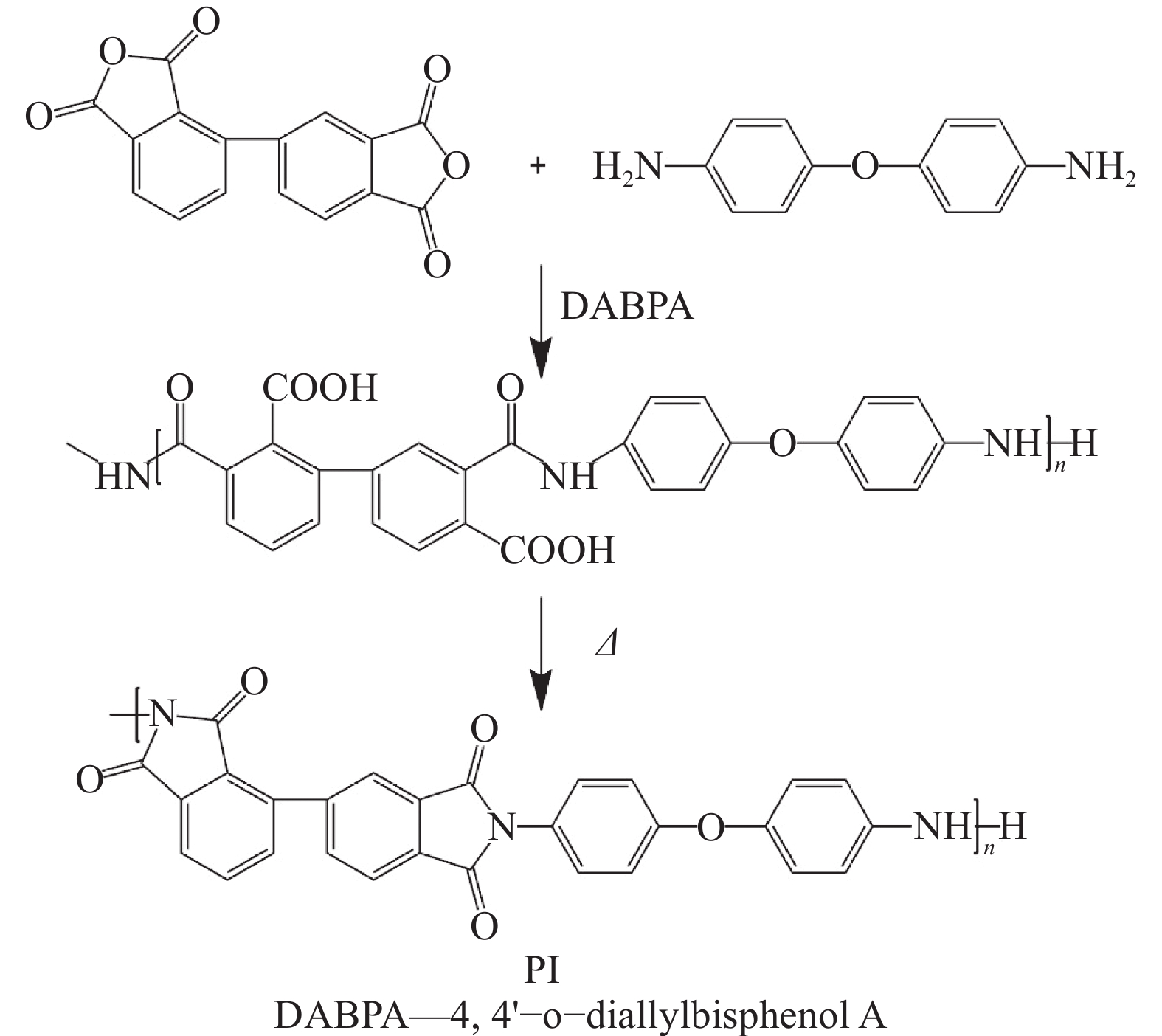

摘要: 采用前原位聚合的热塑性聚酰亚胺(PI)改性4,4′-二氨基二苯甲烷双马来酰亚胺(BDM)/4,4′-邻二烯丙基双酚A(DABPA)树脂体系,制备了一种耐高温的改性双马来酰亚胺(BDPI)树脂,研究了BDPI树脂的微观形貌和耐热性能;通过前原位自增强技术制备了T800H碳纤维/BDPI预浸料,通过SEM研究了T800H/BDPI预浸料表面形貌,评价了T800H/BDPI复合材料高低温力学性能和断面微观形貌。结果表明:BDPI树脂满足预浸料加工工艺要求,BDM微米颗粒均匀铺覆于T800H/BDPI预浸料表面,粒径分布为30~70 μm,BDPI树脂固化物的玻璃化转变温度(Tg)为367℃,5%热失重温度(Td5)为452℃;T800H/BDPI单向复合材料0°拉伸强度、0°拉伸模量和层间剪切强度分别为2 440 MPa、148 GPa和107 MPa,280℃其力学性能保持率分别为66.4%、87.2%和44.1%。Abstract: The 4,4′-diaminodiphenylmethane bismaleimide (BDM)/4,4′-o-diallylbisphenol A (DABPA) resin system was modified by synthesized thermoplastic polyimide (PI) via pre-in situ polymerization, used to prepare modified bismaleimide resin with high heat resistance (BDPI). The micromorphology and heat resistance of BDPI resin were investigated. The T800H carbon fiber/BDPI prepreg was fabricated through pre-in situ self-strengthening technology. The surface morphology of T800H/BDPI prepreg was studied by SEM. The mechanical properties and fracture morphology of T800H/BDPI composites at room temperature and high temperature were evaluated. The results show that the BDPI resin is suitable for prepreg processing technology, and the BDM microparticles with 30–70 μm size are well covered on the surface of T800H/BDPI prepreg. The glass transition temperature (Tg) and 5% mass loss temperature (Td5) of the cured BDPI resin reach 367℃ and 452℃, respectively. The 0° tensile strength, 0° tensile modulus and interlaminar shear strength of T800H/BDPI unidirectional composites are 2 440 MPa, 148 GPa and 107 MPa, respectively, the retention of which are approximately 66.4%, 87.2% and 44.1% at 280℃, respectively.

-

Key words:

- bismaleimide /

- carbon fiber /

- prepreg /

- composites /

- heat resistance /

- mechanical property

-

表 1 常温(RT)和280℃下T800H/BD和T800H/BDPI单向复合材料的力学性能

Table 1. Mechanical properties of T800H/BD and T800H/BDPI unidirectional composites at room temperature(RT) and 280℃

Property T800H/BD T800H/BDPI RT 280℃ Property retention/% RT 280℃ Property retention/% 0° flexural strength/MPa 1 620±62 953±50 58.8 1 810±71 1 140±57 63.0 0° flexural modulus/GPa 139±3.1 126±1.8 90.6 152±2.9 147±2.9 96.7 0° Tensile strength/MPa 2 120±113 1 278±156 60.3 2 440±120 1 620±125 66.4 0° tensile modulus/GPa 137±2.6 117±19.5 85.4 148±2.5 129±21.6 87.2 90° tensile strength/MPa 27±4.5 17±3.1 63.0 29±4.6 21±3.4 72.4 90° tensile modulus/GPa 8.0±1.0 3.7±0.7 46.2 8.4±0.6 4.5±0.9 53.6 Interlaminar shear strength/MPa 88.1±3.5 26.5±3.8 30.1 107±5.6 47.2±4.8 44.1 -

[1] 王慧杰. 航空复合材料树脂基体的现状及发展[J]. 复合材料学报, 1995, 12(4):35-38. doi: 10.3321/j.issn:1000-3851.1995.04.005WANG H J. Present state and future development of the resin matrix in aircraft composite materials[J]. Acta Materiae Compositae Sinica,1995,12(4):35-38(in Chinese). doi: 10.3321/j.issn:1000-3851.1995.04.005 [2] 王德志, 王鑫, 刘立柱, 等. 双马来酰亚胺共聚改性及性能[J]. 复合材料学报, 2017, 34(5):1088-1094.WANG D Z, WANG X, LIU L Z, et al. Preparation and properties of the modified bismaleimide systems[J]. Acta Materiae Compositae Sinica,2017,34(5):1088-1094(in Chinese). [3] 陈宇飞, 郭红缘, 耿成宝, 等. 聚醚醚酮和烯丙基化合物改性双马来酰亚胺复合材料微观结构及力学性能[J]. 复合材料学报, 2018, 35(11):3081-3087.CHEN Y F, GUO H Y, GENG C B, et al. Microstructure and mechanical properties of bismaleimide composites modified with poly(ether ether ketone) and allyl compounds[J]. Acta Materiae Compositae Sinica,2018,35(11):3081-3087(in Chinese). [4] 王汝敏, 郑水蓉, 张军君, 等. 低温固化双马来酰亚胶树脂基体研究: 引发剂的作用[J]. 玻璃钢/复合材料, 1995(6):2-4.WANG R M, ZHENG S R, ZHANG J J, et al. Study on low temperature cured bismaleimide resin matrix: Roles of initiators[J]. Fiber Reinforced Plastics/Composites,1995(6):2-4(in Chinese). [5] LUO H Y, ROY S, LU H B. Dynamic compressive behavior of unidirectional IM7/5250-4 laminate after thermal oxidation[J]. Composites Science and Technology,2012,72(2):159-166. doi: 10.1016/j.compscitech.2011.10.012 [6] 李兵, 洪旭辉, 王晓蔚. 改性双马来酰亚胺树脂预浸料及成形工艺[J]. 宇航材料工艺, 1994(2):29-32.LI B, HONG X H, WANG X W. Modified bismaleimide resin prepreg and forming process[J]. Aerospace Materials & Technology,1994(2):29-32(in Chinese). [7] 刘志真, 郭恩玉, 邢军, 等. “离位”增韧技术在碳纤维/RTM聚酰亚胺复合材料中的应用[J]. 复合材料学报, 2010, 27(6):1-8.LIU Z Z, GUO E Y, XING J, et al. Application of carbon fiber/RTMable polyimide composites by ex-situ toughness method[J]. Acta Materiae Compositae Sinica,2010,27(6):1-8(in Chinese). [8] 董留洋, 刘锋, 张永胜, 等. 聚醚酰亚胺对共聚双马来酰亚胺树脂的增韧作用[J]. 热固性树脂, 2012, 27(6):15-18.DONG L Y, LIU F, ZHANG Y S, et al. Toughening effect of polyetherimide on the bismaleimide resin copolymer[J]. Thermosetting Resin,2012,27(6):15-18(in Chinese). [9] GOPALA A, WU H, HEIDEN P. Investigation of readily processable thermoplastic-toughened thermosets III: Toughening BMIs and epoxy with a comb-shaped imide oligomer[J]. Journal of Applied Polymer Science,1998,70(5):943-951. doi: 10.1002/(SICI)1097-4628(19981031)70:5<943::AID-APP15>3.0.CO;2-U [10] 李玲. 聚酰亚胺齐聚物改性高性能树脂基体的研究[D]. 西安: 西北工业大学, 2002.LI L. Research on the imide oligomer modified high performance matrix resins[D]. Xi’an: Northwestern Polytechnical University, 2002(in Chinese). [11] 张宝艳. 新型耐高温双马来酰亚胺树脂体系研究[C]//第十四届全国复合材料学术会议论文集. 北京: 中国宇航出版社, 2006: 309-313.ZHANG B Y. A novel bismaleimide resin for high service temperature[C]//Proceedings of the 14th National Conference on Composite Materials. Beijing: China Astronautic Publishing House, 2006: 309-313(in Chinese). [12] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People’s Republic of China. Test methods for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [13] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料弯曲性能试验方法: GB/T 3356—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People’s Republic of China. Test methods for flexural properties of orientational fiber reinforced polymer matrix composite materials: GB/T 3356—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [14] 中华人民共和国工业和信息化部. 纤维增强塑料短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国建材工业出版社, 2010.Ministry of Industry and Information Technology of the People’s Republic of China. Fiber-reinforced plastics composites-determination of apparent interlaminar shear strength by short-beam method: JC/T 773—2010[S]. Beijing: China Building Materials Press, 2010(in Chinese). [15] 耿洪斌, 黄培, 时钧. 聚酰胺酸在不同热处理过程中的热环化[J]. 高分子材料科学与工程, 2005, 21(3):192-195. doi: 10.3321/j.issn:1000-7555.2005.03.048GENG H B, HUANG P, SHI J. The thermal imidization behavior of a certain polyamide for the different kinds of treatment[J]. Polymeric Materials Science and Engineering,2005,21(3):192-195(in Chinese). doi: 10.3321/j.issn:1000-7555.2005.03.048 [16] XIONG X H, CHEN P, YU Q, et al. Synthesis and properties of chain-extended bismaleimide resins containing phthalide cardo structure[J]. Polymer International,2010,59(12):1665-1672. doi: 10.1002/pi.2900 [17] XIONG X, CHEN P, ZHANG J, et al. Cure kinetics and thermal properties of novel bismaleimide containing phthalide cardo structure[J]. Thermochimica Acta,2011,514(1-2):44-50. [18] 陈建林, 万隆, 刘小磐, 等. 二元胺改性双马来酰亚胺树脂的固化工艺[J]. 热固性树脂, 2005, 20(5):1-4. doi: 10.3969/j.issn.1002-7432.2005.05.001CHEN J L, WAN L, LIU X P, et al. The thermosetting process of diamine-modified bismaleimide resin[J]. Thermosetting Resin,2005,20(5):1-4(in Chinese). doi: 10.3969/j.issn.1002-7432.2005.05.001 [19] 刘燕峰, 包建文, 益小苏, 等. 基于异构联苯二酐的热塑性聚酰亚胺性能研究[J]. 工程塑料应用, 2012, 40(3):9-13.LIU Y F, BAO J W, YI X S, et al. Properties study of thermoplastic polyimides based on isomeric biphenyl dianhydrides[J]. Engineering Plastics Application,2012,40(3):9-13(in Chinese). [20] 姚逸伦, 张朋, 包建文, 等. 耐高温高韧性聚酰亚胺树脂分子量与性能关系[J]. 复合材料学报, 2016, 33(9):1973-1980.YAO Y L, ZHANG P, BAO J W, et al. Relation between molecular weight and properties of high temperature and high toughness polyimide resin[J]. Acta Materiae Compositae Sinica,2016,33(9):1973-1980(in Chinese). [21] RIKIO Y, SYOUGO Y, SHOICHIRO Y, et al. Molecular design of heat resistant polyimides having excellent processability and high glass transition temperature[J]. High Performance Polymers,2001,13(2):61-72. doi: 10.1088/0954-0083/13/2/306 [22] LIU D W, LI G, LI B, et al. In-situ toughened CFRP composites by shear-calender orientation and fiber-bundle filtration of PA microparticles at prepreg interlayer[J]. Composites Part A: Applied Science and Manufacturing,2016,84:165-174. doi: 10.1016/j.compositesa.2016.01.015 -

下载:

下载: