In-plane compression properties of negative Poisson's ratio sandwich structure filled with foam concrete

-

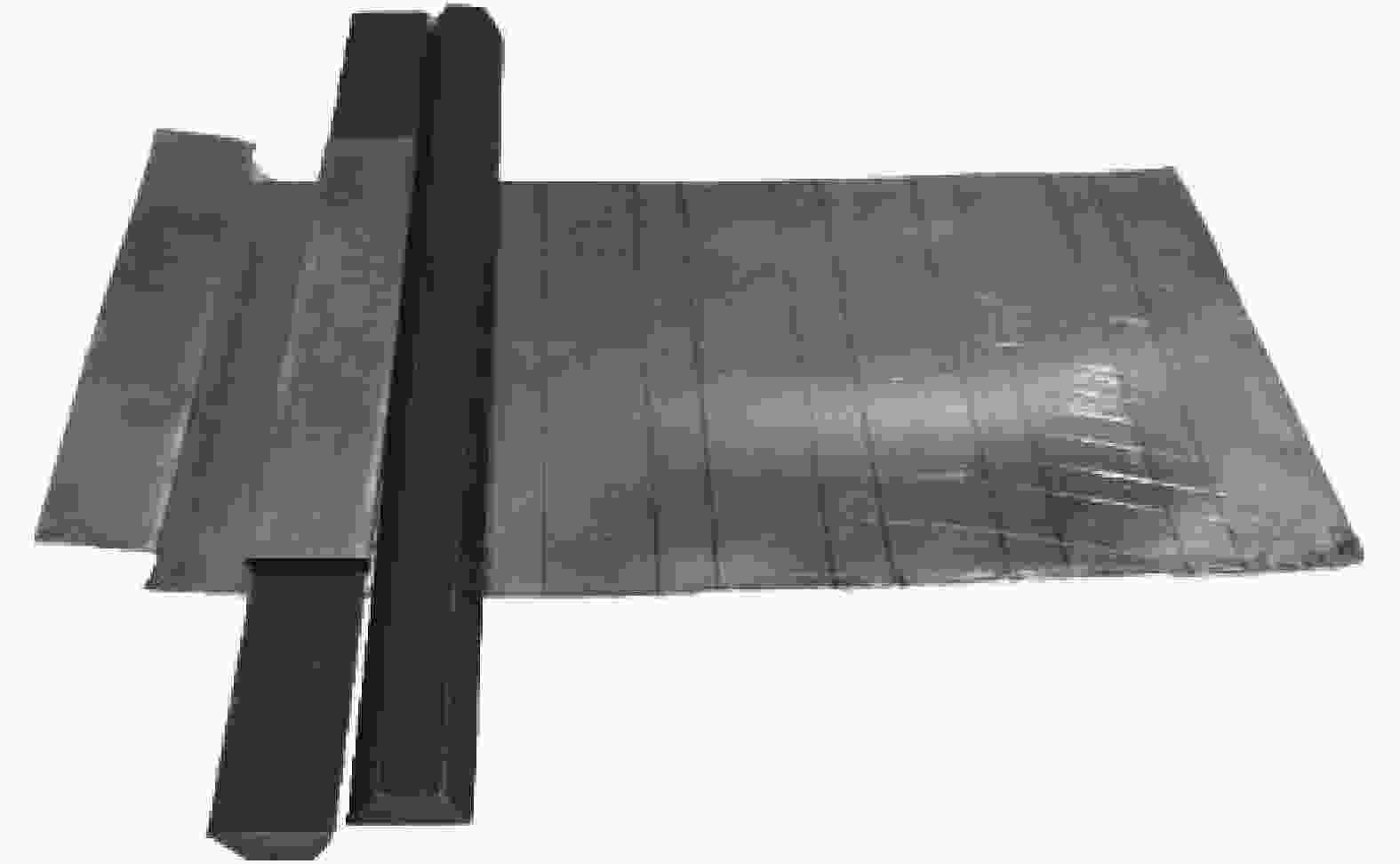

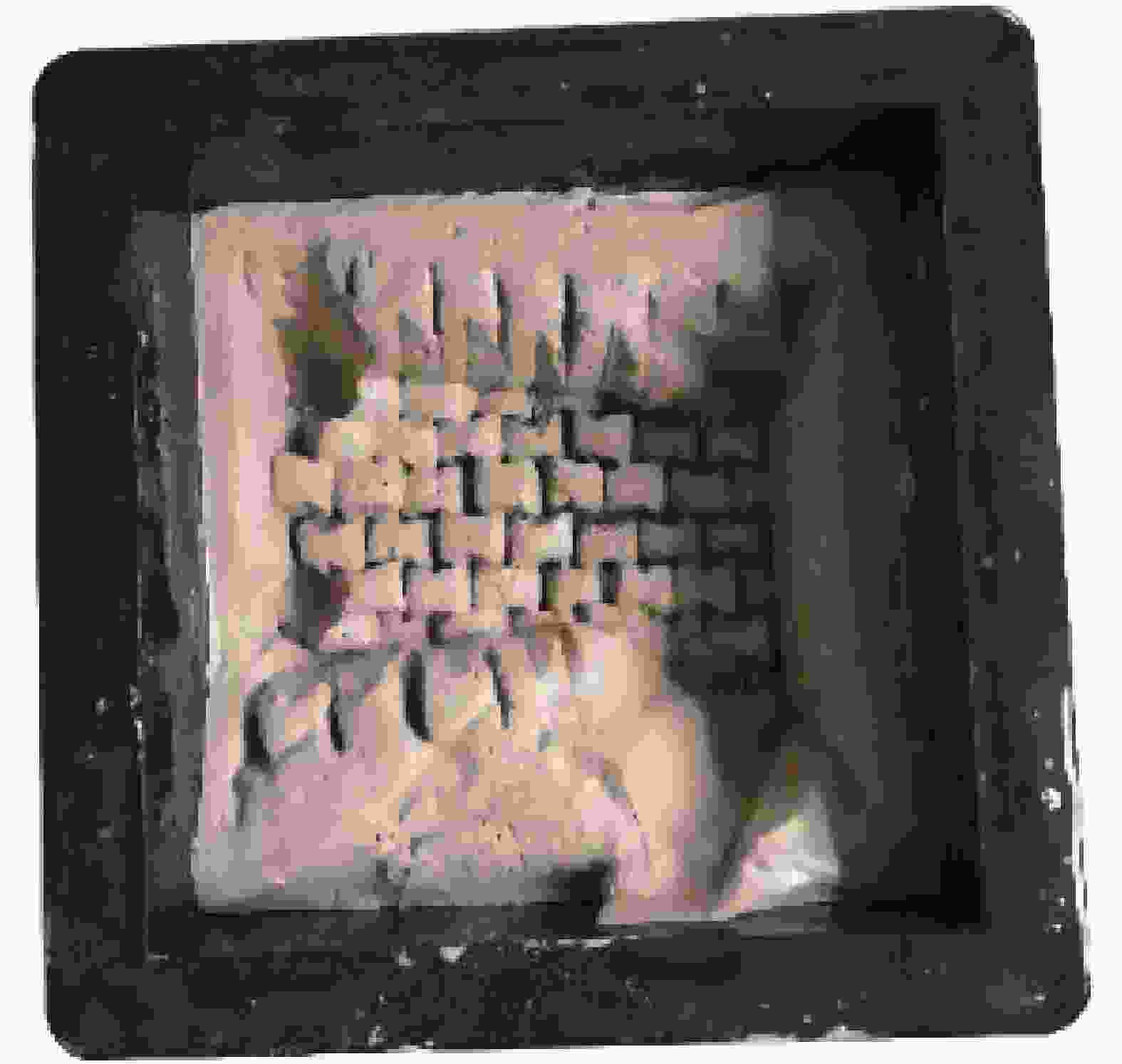

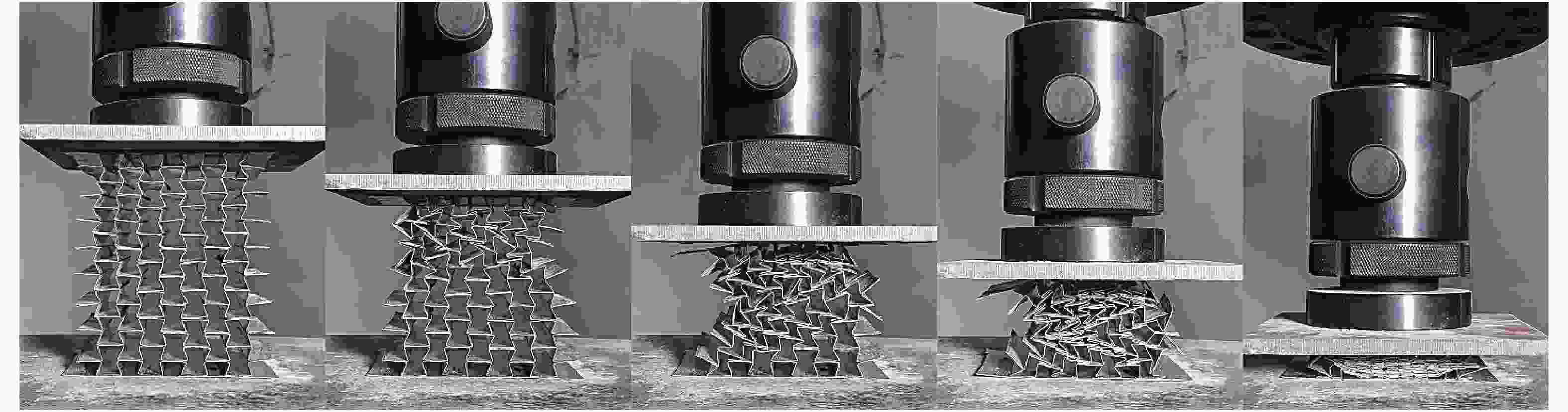

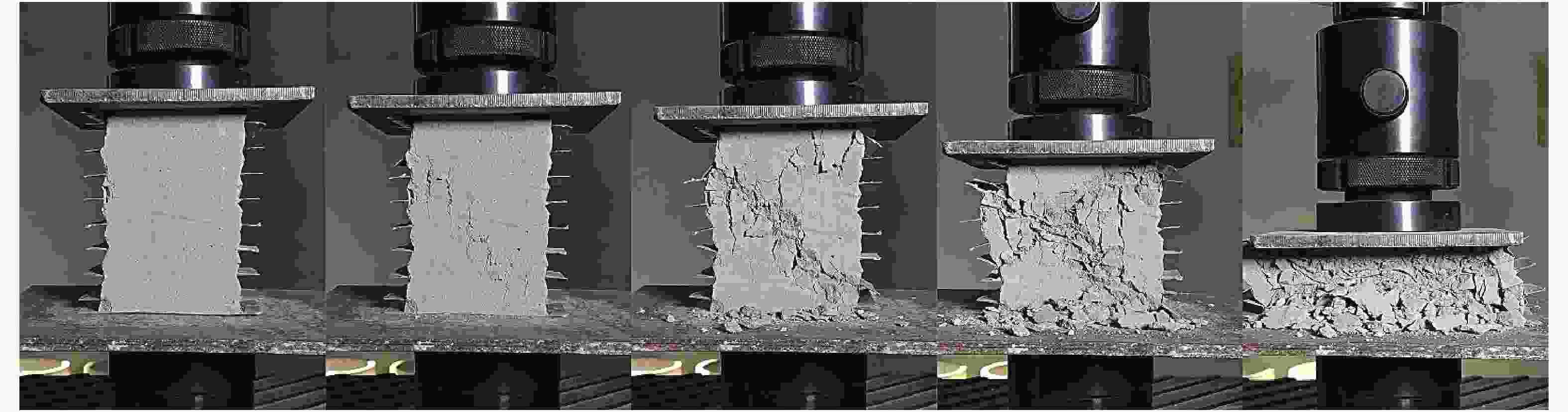

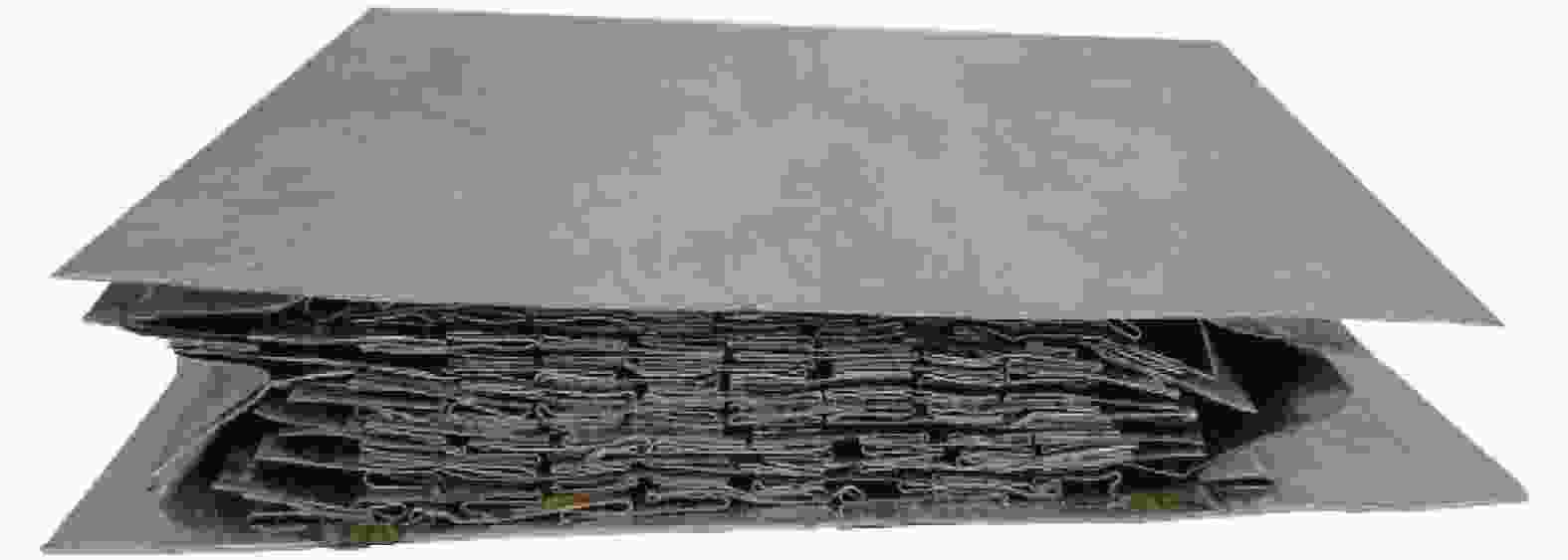

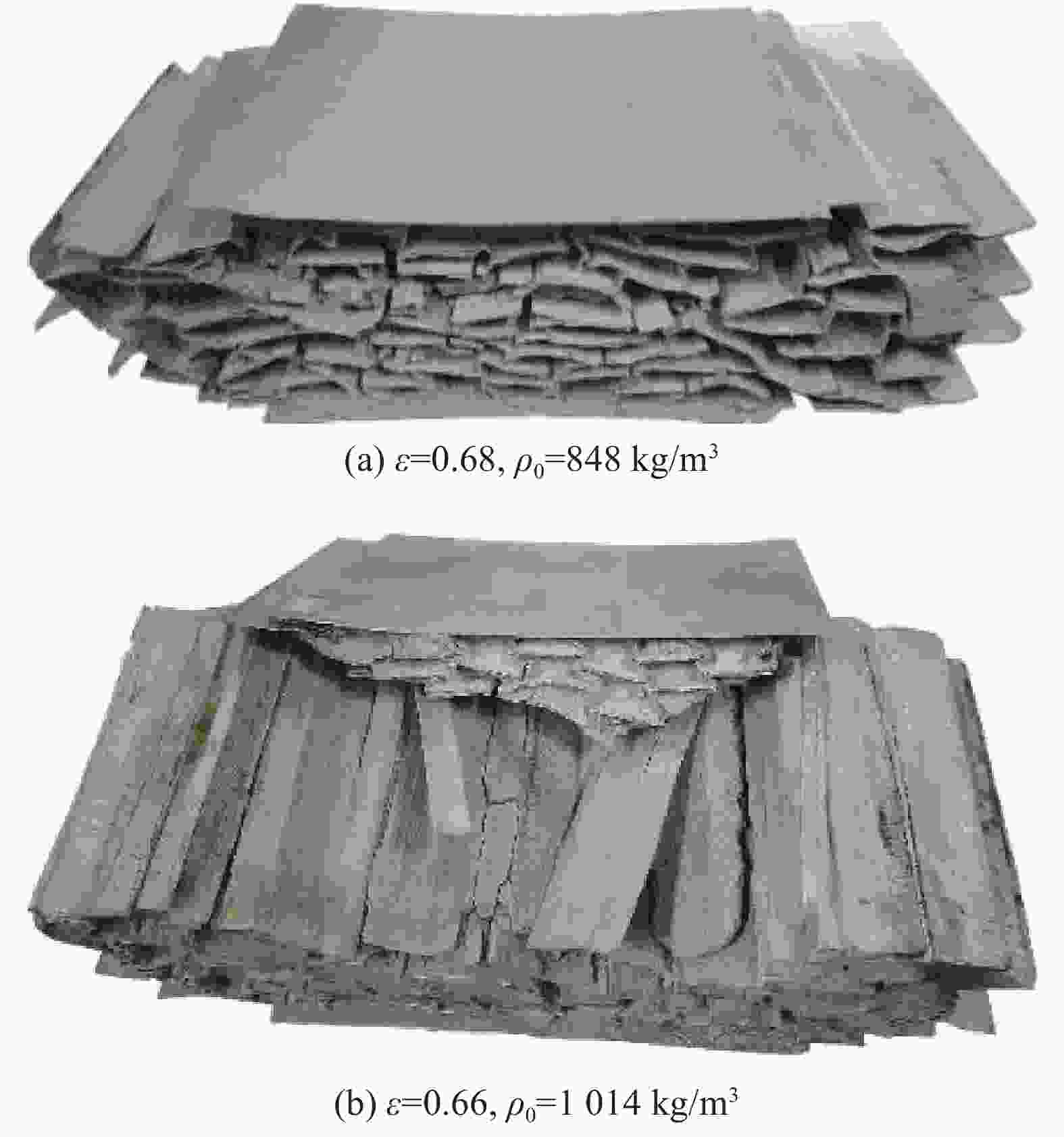

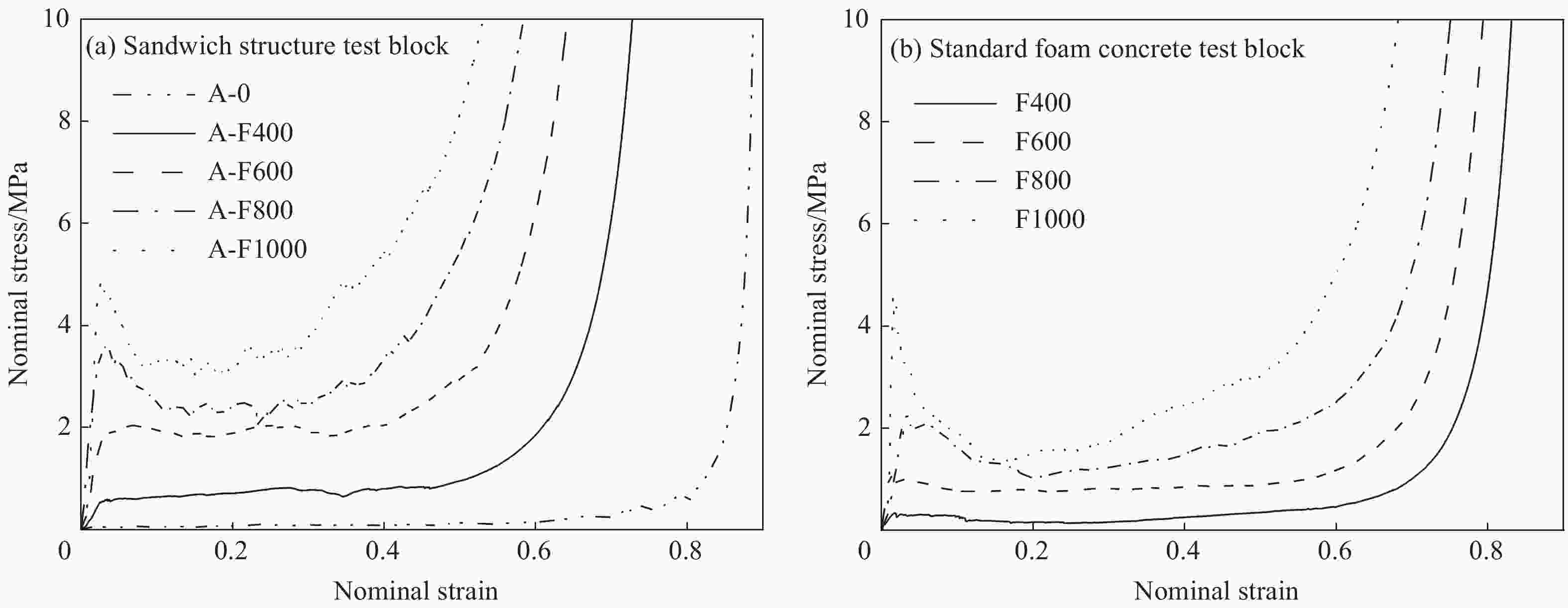

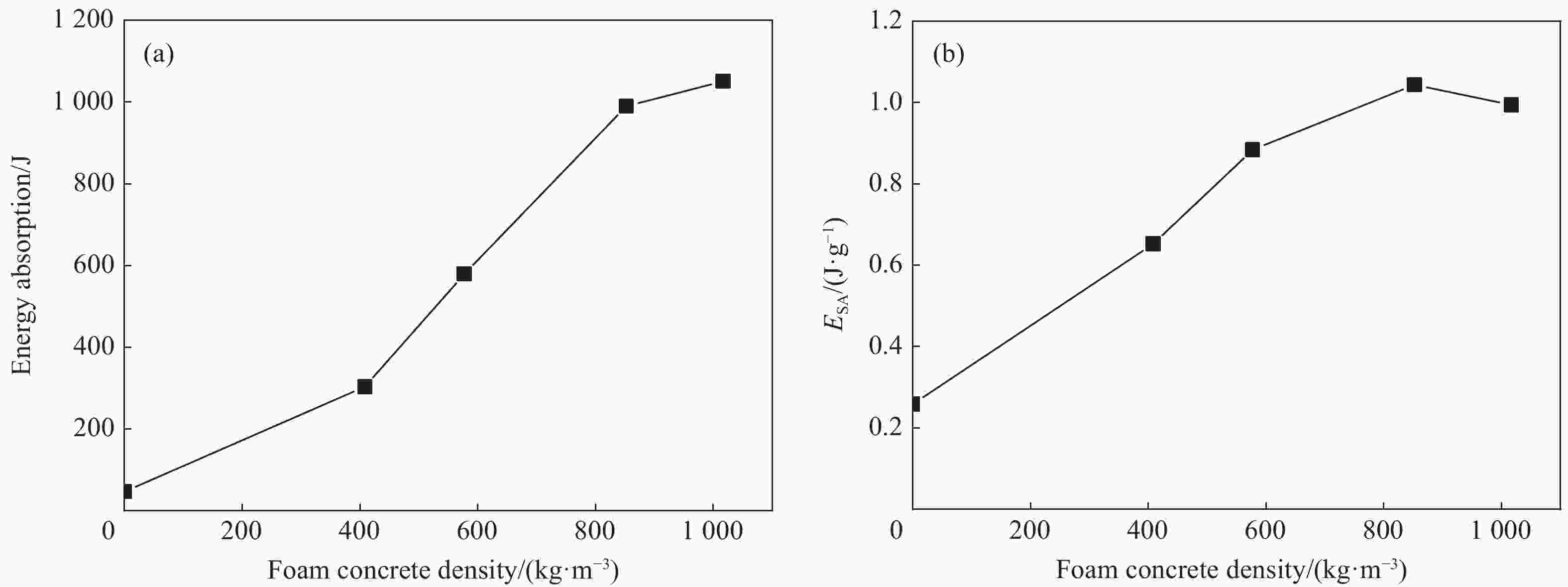

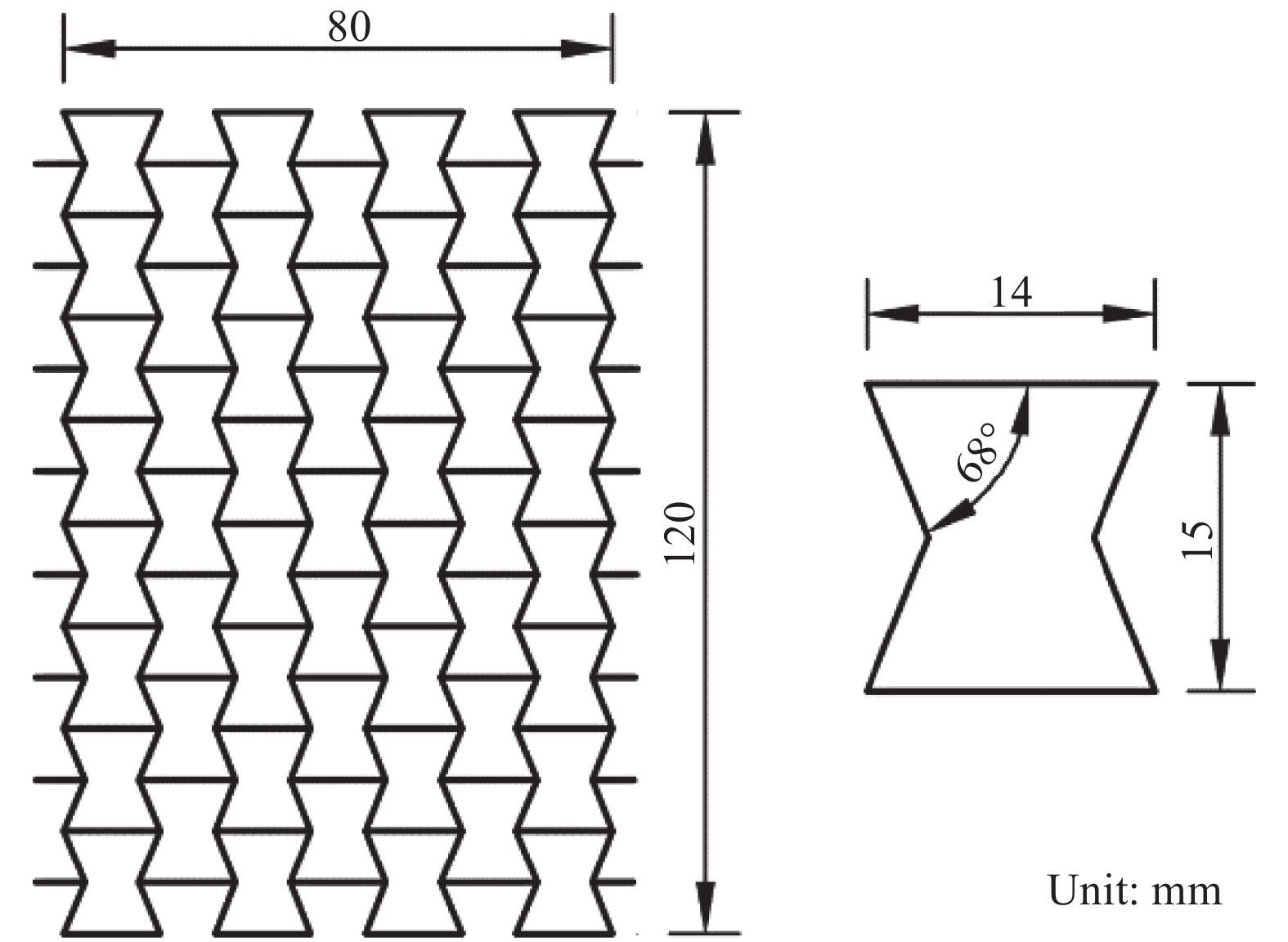

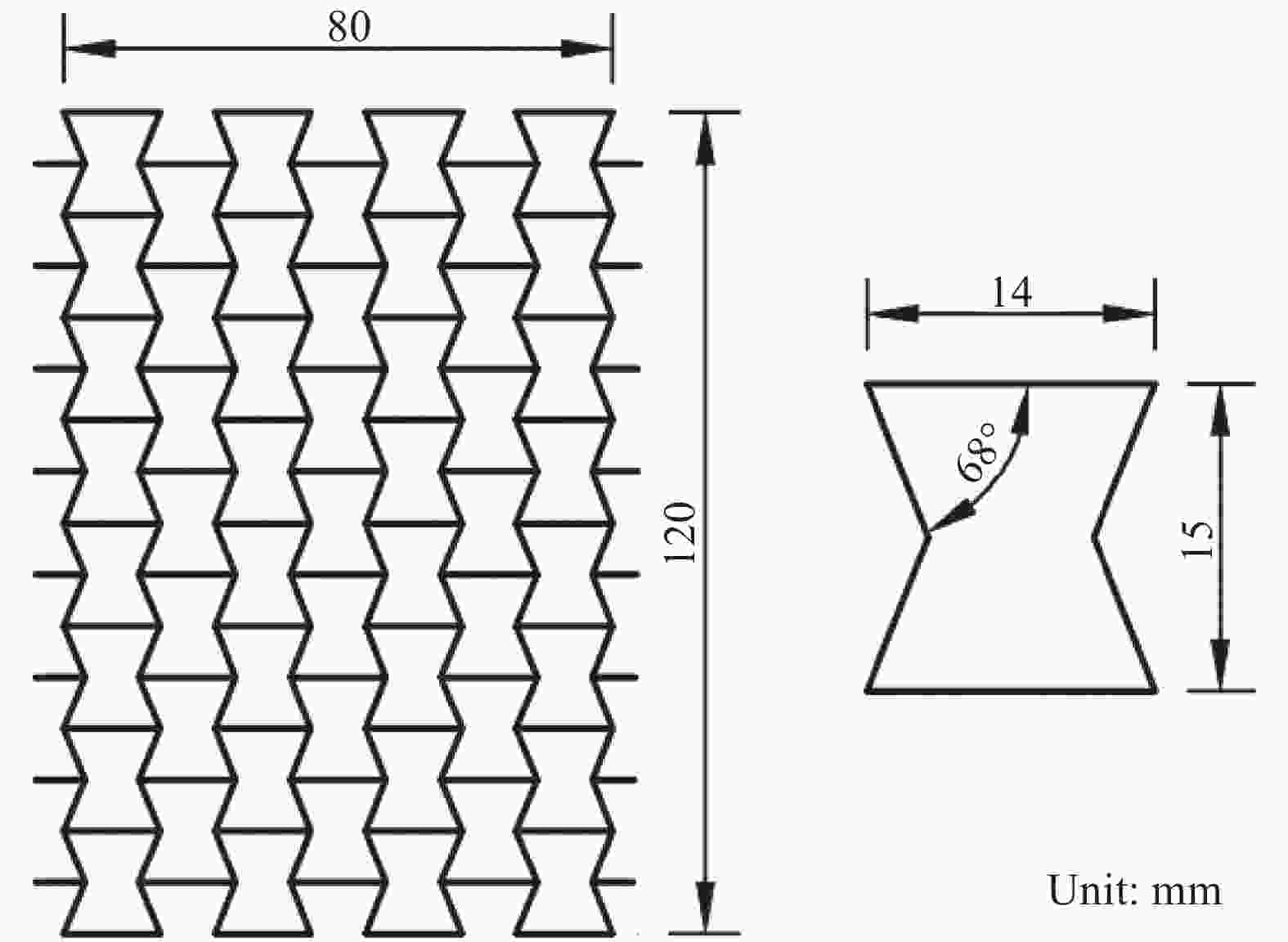

摘要: 为改善负泊松比三明治结构的受压破坏模式且提高其缓冲吸能能力,提出一种填充泡沫混凝土的新型复合三明治结构。在负泊松比结构中填充不同密度(409 kg/m3、575 kg/m3、848 kg/m3、1 014 kg/m3)的泡沫混凝土得到负泊松比填充结构,并对无填充负泊松比结构、负泊松比填充结构和泡沫混凝土对照试块在准静态压缩下的破坏模式和吸能特性进行比较。根据荷载-位移关系和破坏模式得到以下结论:当填充物密度较小时,负泊松比填充结构能够将填充物的泊松比限制在较小的数值,胞元表现出内凹的变形模式,结构发生逐渐被压实的压缩破坏;当填充物密度较大时,结构发生“X”型剪切破坏,塑性铰区域和剪切带附近的胞壁发生断裂破坏;泡沫混凝土填充物的密度越大,填充结构的压实应变越小,吸收的能量越多,但当填充物密度超过一定值后,填充物密度的增加对负泊松比填充结构能量吸收能力的提升作用不再明显,结构的比吸能降低。Abstract: New composite sandwich structures filled with foam concrete were proposed to improve the failure mode subjected to compression and enhance the energy absorption capacity. The composite structures were made by filling foam concrete of different densities (409 kg/m3, 575 kg/m3, 848 kg/m3, 1 014 kg/m3) into negative Poisson's ratio aluminum structures. The failure modes and energy absorption capacities of the specimens subjected to quasi-static compression were compared among the empty auxetic structures, the auxetic structures filled with foam concrete as well as the standalone foam concrete control specimens. Based on the load-displacement relationship and failure mode, the findings can be reached: With foam concrete of relatively low density filled, the Poisson’s ratio of the auxetic composite structures is limited to a small value, leading to auxetic deformation of the cells and progressive compression mode of the whole structures. With foam concrete of relatively high density filled, the structures exhibit X-type shear failure, in which the cell walls around plastic hinges and shear bands fracture. The energy absorption increases, and the densification strain of the composite structures decreases, with increasing density of the foam concrete. However, with filler density greater than a certain value, the enhancement of energy absorption of the composite structures becomes less remarkable, and the specific energy absorption decreases, with increasing density of the filled foam concrete.

-

表 1 负泊松比填充泡沫混凝土结构质量和几何参数

Table 1. Mass and geometric parameters of auxetic aluminum structures filled with foam concrete

Sample Density of foam concrete /(kg·m−3) Density of sandwich structure /(kg·m−3) Equivalent bottom area/mm2 Height/mm A-0 — 219 6 642 124 A-F400 409 566 6 561 125 A-F600 575 780 6 723 125 A-F800 848 1 059 7 047 127 A-F1000 1 014 1 172 7 047 128 表 2 不同泡沫混凝土试件准静态压缩试验能量吸收指标

Table 2. Energy absorption of different foam concrete specimens subjected to quasi-static compression

Sample Densification strain Initial peak force/kN Mean crushing force/kN Initial peak strength/MPa Mean crushing

strength /MPaEnergy absorption /J ESA/

(J·g−1)CFE A-0 0.545 0.422 0.525 0.064 0.079 46.740 0.259 1.244 A-F400 0.460 4.198 4.553 0.640 0.694 303.390 0.653 1.085 A-F600 0.401 13.782 12.538 2.050 1.865 579.680 0.884 0.910 A-F800 0.372 25.444 18.061 3.611 2.563 989.930 1.044 0.710 A-F1000 0.289 33.991 23.481 4.824 3.332 1 050.910 0.994 0.691 F-400 0.600 3.374 2.504 0.337 0.250 150.230 0.367 0.742 F-600 0.565 10.897 8.356 1.090 0.836 472.131 0.820 0.767 F-800 0.526 22.723 14.500 2.272 1.450 762.652 0.898 0.638 F-1000 0.494 46.472 20.751 4.647 2.075 1 025.100 1.011 0.447 Notes: ESA—Specific energy absorption; CFE—Crushing force efficiency. -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] WANG Z Q, ZHOU Y B, WANG X H, et al. Multi-objective optimization design of a multi-layer honeycomb sandwich structure under blast loading[J]. Proceedings of the Institution of Mechanical Engineers Part D: Journal of Automobile Engineering,2016,231(10):1449-1458. [3] 冀宾, 韩涵, 宋林郁, 等. 面内压缩超轻质点阵夹芯板的优化、试验与仿真[J]. 复合材料学报, 2019, 36(4):1045-1051.JI Bin, HAN Han, SONG Linyu, et al. Optimization, experiment and simulation of lightweight lattice sandwich plates under in-plane compression load[J]. Acta Materiae Compositae Sinica,2019,36(4):1045-1051(in Chinese). [4] 周昊, 郭锐, 刘荣忠, 等. 碳纤维增强聚合物复合材料方形蜂窝夹层结构水下爆炸动态响应数值模拟[J]. 复合材料学报, 2019, 36(5):1226-1234.ZHOU Hao, GUO Rui, LIU Rongzhong, et al. Simulations on dynamic responses of carbon fiber reinforced polymer composite sandwich plates with square honeycomb cores subjected to water blast[J]. Acta Materiae Compositae Sinica,2019,36(5):1226-1234(in Chinese). [5] LI Z J, CHEN W S, HAO H. Blast mitigation performance of cladding using square dome-shape kirigami folded structure as core[J]. International Journal of Mechanical Sciences,2018,145:83-95. [6] ZHANG J X, ZHOU R F, WANG M S, et al. Dynamic response of double-layer rectangular sandwich plates with metal foam cores subjected to blast loading[J]. International Journal of Impact Engineering,2018,122:265-275. [7] PRAWOTO Y. Seeing auxetic materials from the mechanics point of view: A structural review on the negative Poisson's ratio[J]. Computational Materials Science,2012,58:140-153. [8] LOVE A E H. A treatise on the mathematical theory of elasticity[M]. New York: Dover Publications, 1944. [9] FROST H J, ASHBY M F. Deformation-mechanism maps: The plasticity and creep of metals and ceramics[M]. New York: Pergamon Press, 1982. [10] XIAO D B, CHEN X Q, LI Y, et al. The structure response of sandwich beams with metallic auxetic honeycomb cores under localized impulsive loading-experiments and finite element analysis[J]. Materials <italic>&</italic> Design,2019,176:107840. [11] HU L L, LUO Z R, ZHANG Z Y, et al. Mechanical property of reentrant anti-trichiral honeycombs under large deformation[J]. Composites Part B: Engineering,2018,163:107-120. [12] ZHANG J J, LU G X, RUAN D, et al. Tensile behavior of an auxetic structure: Analytical modeling and finite element analysis[J]. Composite Structures,2018,136:143-154. [13] AMRAN Y H M, FARZADNIA N, ABANG-ALI A A. Properties and applications of foamed concrete: A review[J]. Construction and Building Materials,2015,101:990-1005. [14] CHICA L, ALZATE A. Cellular concrete review: New trends for application in construction[J]. Construction and Building Materials,2019,200:637-647. [15] SU B Y, ZHOU Z W, LI Z Q, et al. Experimental investigation on the mechanical behavior of foamed concrete under uniaxial and triaxial loading[J]. Construction and Building Materials,2019,209:41-51. [16] FLORES-JOHNSON E A, LI Q M. Structural behaviour of composite sandwich panels with plain and fibre-reinforced foamed concrete cores and corrugated steel faces[J]. Composite Structures,2012,94(5):1555-1563. [17] FLECK N A, DESHPANDE V S. The resistance of clamped sandwich beams to shock loading[J]. Journal of Applied Mechanics,2004,71(3):386-401. [18] LIU Q, FU J, MA J, et al. Axial and lateral crushing responses of aluminum honeycombs filled with EPP foam[J]. Composites Part B: Engineering,2017,130:236-247. [19] 罗伟铭, 少卿, 孙建虎, 等. 蜂窝填砂复合夹芯结构的低速冲击响应试验研究[J]. 振动与冲击, 2018, 37(10):50-56.LUO Weiming, SHAO Qing, SUN Jianhu, et al. Experimental investigation on the low velocity impact responses of sand-filled aluminum honeycomb composite sandwich structures[J]. Journal of Vibration and Shock,2018,37(10):50-56(in Chinese). [20] MOZAFARI H, MOLATEFI H, CRUPI V, et al. In-plane compressive response and crushing of foam filled aluminum honeycombs[J]. Journal of Composite Materials,2014,49(26):3215-3228. [21] NIA A A, SADEGHI M Z. The effects of foam filling on compressive response of hexagonal cell aluminum honeycombs under axial loading-experimental study[J]. Materials & Design,2010,31(3):1216-1230. [22] LIU J F, CHEN W S, HAO H, et al. Dynamic fracture of aramid paper honeycomb subjected to impact loading[J]. Composite Structures,2019,220:736-748. [23] TAN P J, HARRIGAN J J, REID S R. Inertia effects in uniaxial dynamic compression of a closed cell aluminium alloy foam[J]. Materials Science and Technology,2002,18(5):480-488. -

下载:

下载: