Optimization design and validation of algae powder-penicillin residue/low density polyethylene composites formulation by response surface methodology

-

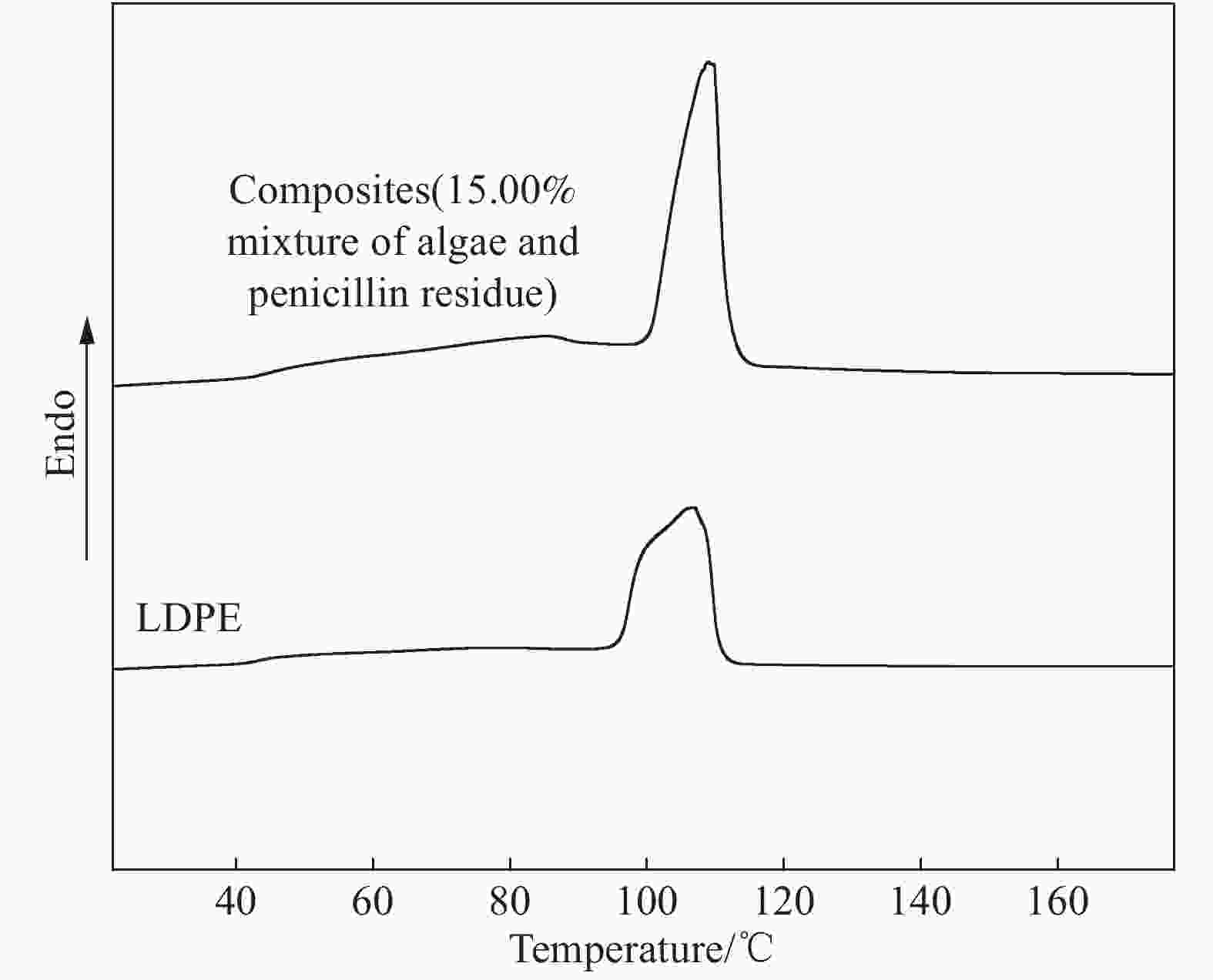

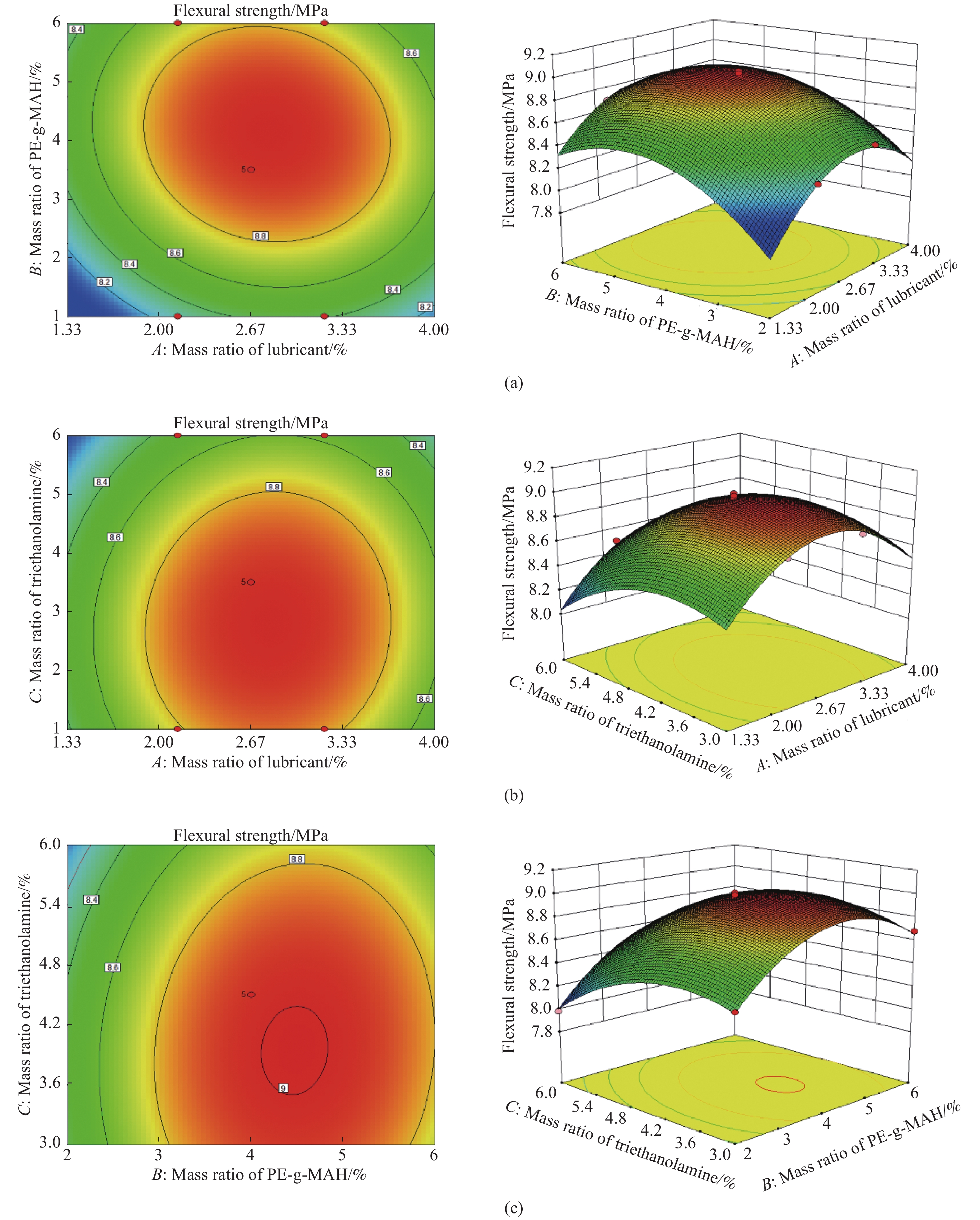

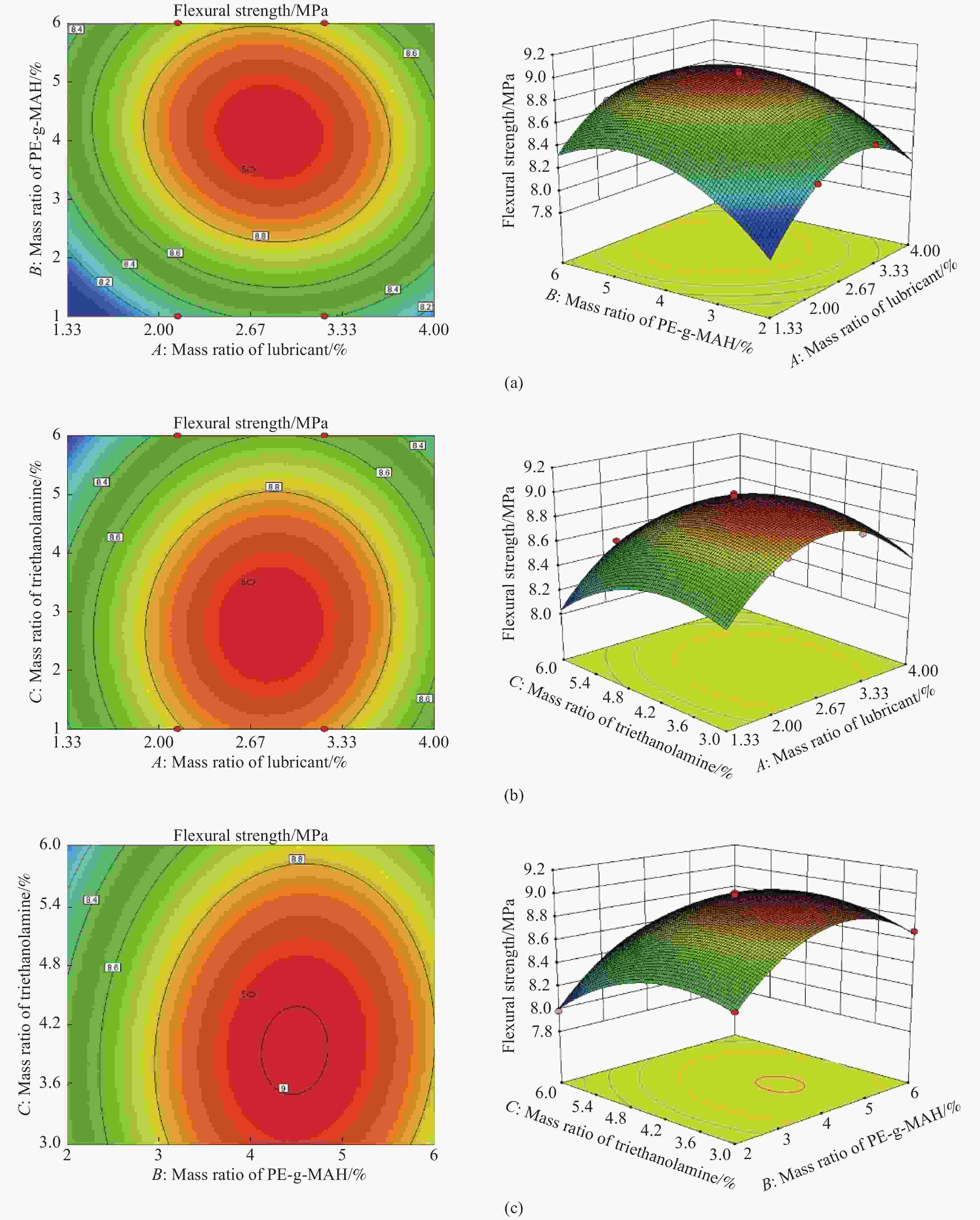

摘要: 为了实现水华蓝藻和青霉素菌渣的资源化利用,并进一步提升蓝藻粉-青霉素菌渣/低密度聚乙烯(LDPE)复合材料的力学性能,以菌渣与蓝藻粉共混物、LDPE为原料,通过响应面法优化实验方案,研究聚乙烯蜡(PE-wax)和白油、马来酸酐接枝聚乙烯(PE-g-MAH)、三乙醇胺对蓝藻粉-青霉素菌渣/LDPE复合材料力学性能的影响。当蓝藻粉-菌渣共混粉末与LDPE的质量比为15.00%和85.00%时,响应面回归方程的方差分析结果表明,PE-g-MAH和三乙醇胺两因素间的交互作用显著,润滑剂与PE-g-MAH、润滑剂与三乙醇胺之间的交互作用不显著;回归方程预测的最佳工艺参数如下:润滑剂、PE-g-MAH、三乙醇胺的质量比分别为3.08%、4.33%和4.23%,此条件下蓝藻粉-青霉素菌渣/LDPE复合材料的拉伸强度、弯曲强度和弯曲模量分别为12.30 MPa、9.03 MPa和220.00 MPa,相较于未添加助剂时的蓝藻粉-青霉素菌渣/LDPE复合材料分别提高了10.81%、29.74%和34.97%。Abstract: In order to realize the resource utilization of bloom algae and penicillin residue and further improve the mechanical properties of algae powder-penicillin residue/low density polyethylene (LDPE) composites, the mixture of penicillin residue with algae powder from Chao Lake and LDPE were used as the raw materials. The experimental scheme was designed by the response surface method, and the effects of the addition of polyethylene wax (PE-wax) and white oil, maleic anhydride grafted polyethylene (PE-g-MAH) and triethanolamine on the mechanical properties of the algae powder-penicillin residue/LDPE composites were studied. When the mass ratios of mixture of penicillin residue with algae powder and LDPE are 15.00% and 85.00%, the results of variance analysis of response surface regression equation show that the interaction between PE-g-MAH and triethanolamine is significant, but the interaction between lubricant and PE-g-MAH, lubricant and triethanolamine is not significant. The optimum process parameters predicted by the response surface regression model are as follows: when the mass ratios of lubricant, PE-g-MAH and triethanolamine are 3.08%, 4.33% and 4.23%, the tensile strength, flexural strength and flexural modulus of the algae powder-penicillin residue/LDPE composites are 12.30 MPa, 9.03 MPa and 220.00 MPa, respectively, which are increased by 10.81%, 29.74% and 34.97%, compared with the algae powder-penicillin residue/LDPE composites without additives.

-

Key words:

- response surface method /

- algae /

- penicillin residue /

- model prediction /

- interaction

-

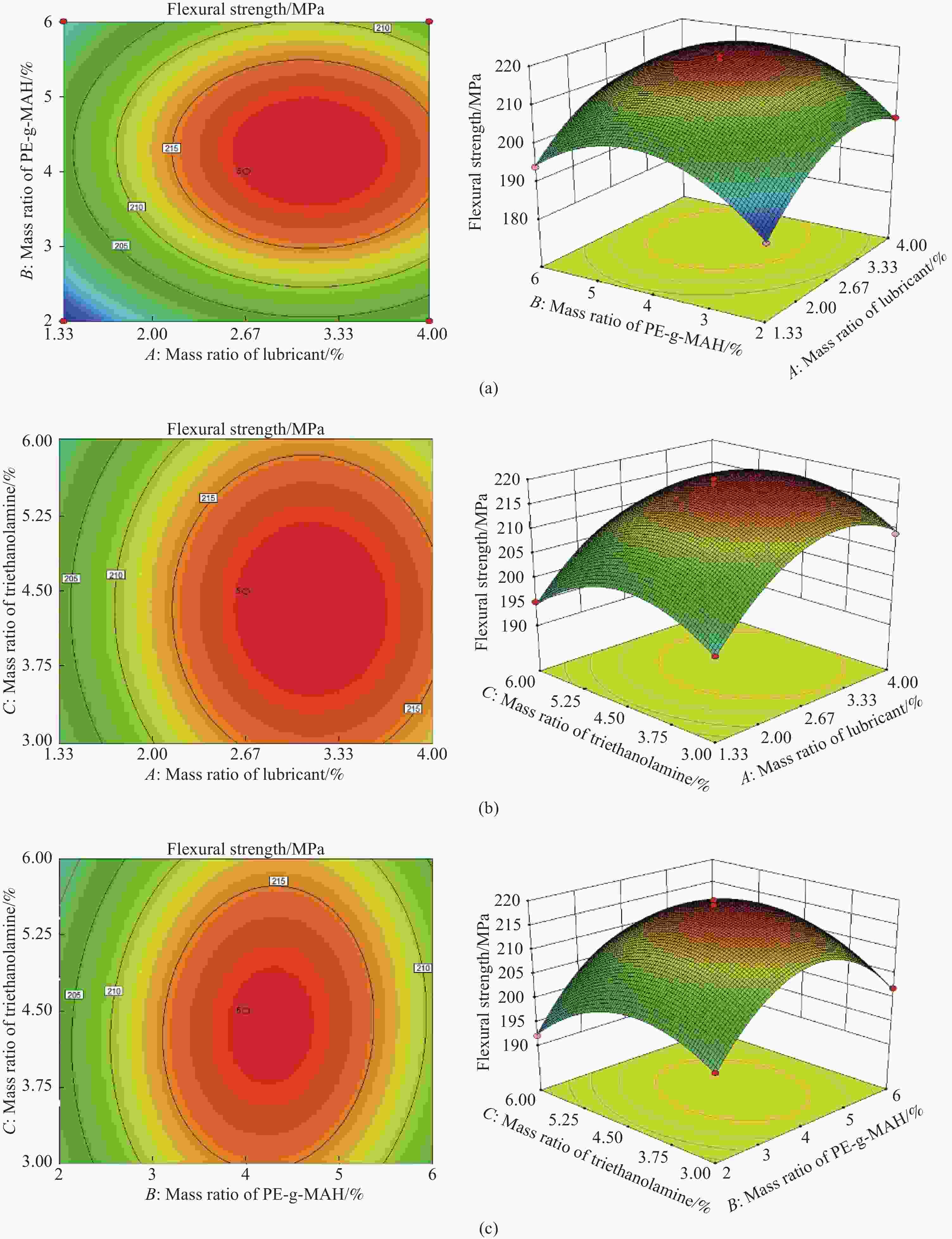

图 1 响应因子分别为润滑剂与马来酸酐接枝聚乙烯(PE-g-MAH) (a)、润滑剂与三乙醇胺(b)、PE-g-MAH与三乙醇胺(c)时蓝藻粉-青霉素菌渣/LDPE复合材料以弯曲强度为响应变量时的等高线和曲面图

Figure 1. Contour and surface graph with flexural strength of algae powder-penicillin residue/LDPE composites as response variable when the response factors are lubricant and maleic anhydride grafted polyethylene (PE-g-MAH) (a), lubricant and triethanolamine (b), PE-g-MAH and triethanolamine (c)

图 2 响应因子分别为润滑剂与PE-g-MAH (a)、润滑剂与三乙醇胺(b)、PE-g-MAH与三乙醇胺(c)时,蓝藻粉-青霉素菌渣/LDPE复合材料弯曲模量为响应变量时的等高线和曲面图

Figure 2. Contour and surface graph with flexural modulus of algae powder-penicillin residue/LDPE composites as response variable when the response factors are lubricant and PE-g-MAH (a), lubricant and triethanolamine (b), PE-g-MAH and triethanolamine (c)

表 1 响应面法优化蓝藻粉-青霉素菌渣/低密度聚乙烯(LDPE)复合材料力学性能实验的因素水平

Table 1. Response surface design of factors and levels by response surface method to optimize the mechanical properties of algae powder-penicillin residue/low density polyethylene (LDPE) composites

Level A: Polyethylene wax and white oil mass ratio/% B:PE-g-MAH mass ratio/% C: Triethanolamine mass ratio/% −1 1.33 2.00 3.00 0 2.67 4.00 4.50 1 4.00 6.00 6.00 Notes:Total mass of algae powder blended with penicillin residue and LDPE is 100%, the mass ratio of other materials is the mass to the total mass of algae powder blended with penicillin residue and LDPE. 表 2 响应面法优化蓝藻粉-青霉素菌渣/LDPE复合材料力学性能实验的设计与结果

Table 2. Response surface design of experiments and results to optimize the mechanical properties of algae powder-penicillin residue/LDPE composites

Run Factors Flexural

strength/MPaFlexural

modulus/MPaA/% B/% C/% 1 2.67 2.00 6.00 7.98 192.00 2 4.00 4.00 3.00 8.81 209.00 3 1.33 4.00 6.00 8.50 195.00 4 1.33 4.00 3.00 8.78 197.00 5 2.67 4.00 4.50 8.99 219.00 6 4.00 2.00 4.50 8.43 201.00 7 2.67 4.00 4.50 8.93 218.00 8 4.00 4.00 6.00 8.58 206.00 9 2.67 2.00 3.00 8.38 198.00 10 2.67 6.00 6.00 8.45 201.00 11 2.67 4.00 4.50 8.97 219.00 12 4.00 6.00 4.50 8.73 206.00 13 1.33 6.00 4.50 8.69 194.00 14 2.67 6.00 3.00 8.68 202.00 15 1.33 2.00 4.50 8.29 187.00 16 2.67 4.00 4.50 9.01 220.00 17 2.67 4.00 4.50 8.95 218.00 表 3 响应面法优化蓝藻粉-青霉素菌渣/LDPE复合材料力学性能实验中回归方程的方差分析

Table 3. Variance analysis of response surface experimental regression equation of optimization of the mechanical properties of algae powder-penicillin residue/LDPE composites

Source Flexural strength Flexural modulus F value P value Significance F value P value Significance Model 146.92 < 0.0001 ** 313.83 < 0.0001 ** A 10.48 0.0143 * 461.73 < 0.0001 ** B 269.15 < 0.0001 ** 120.19 < 0.0001 ** C 161.87 < 0.0001 ** 27.69 0.0012 ** AB 2.49 0.1585 1.54 0.2548 AC 0.62 0.4559 0.38 0.5548 BC 7.20 0.0314 * 9.62 0.0173 * A2 20.56 0.0027 ** 542.33 < 0.0001 ** B2 558.95 < 0.0001 ** 1036.58 < 0.0001 ** C2 226.80 < 0.0001 ** 404.28 < 0.0001 ** Lack of FIT 1.01 0.4761 0.83 0.5413 R2 0.9947 0.9975 R2Adj 0.9880 0.9943 CV 0.37 0.39 Notes: F—Ratio of the mean square between groups to the mean square within groups; P—Confidence interval of F; Lack of FIT— Misfit term; R2—Multivariate correlation coefficient; R2Adj—Correction coefficient; CV—Coefficient of variation; *—Significant at P<0.05; **—Extremely significant at P<0.01. -

[1] ELANDER R P. Industrial production of beta-lactam antibiotics[J]. Appl Microbiol Biotechnol,2003,61(5-6):385-392. doi: 10.1007/s00253-003-1274-y [2] WISE R. Antimicrobial resistance: Priorities for action[J]. Journal of Antimicrobial Chemotherapy,2002,49(4):585-586. doi: 10.1093/jac/49.4.585 [3] 李再兴, 田宝阔, 左剑恶, 等. 抗生素菌渣处理处置技术进展[J]. 环境工程, 2012, 30(2):72-75.LI Z X, TIAN B K, ZUO J E, et al. Progress in treat and disposal technology of antibiotic bacterial residues[J]. Environmental Engineering,2012,30(2):72-75(in Chinese). [4] 付欢, 刘惠玲, 王璞. 高效降解青霉素菌的筛选鉴定及降解效果研究[J]. 环境保护科学, 2015, 41(1):42-45. doi: 10.3969/j.issn.1004-6216.2015.01.009FU H, LIU H L, WANG P. Screening and identification of penicillin-degrading bacteria and its degradation effects[J]. Environmental Protection Science,2015,41(1):42-45(in Chinese). doi: 10.3969/j.issn.1004-6216.2015.01.009 [5] GUO B, GONG L, DUAN E, et al. Characteristics of penicillin bacterial residue[J]. Journal of the Air <italic>&</italic> Waste Management Association,2012,62(4):485-488. [6] 张红娟. 抗生素菌渣堆肥化处理研究[D]. 郑州: 郑州大学, 2010.ZHANG H J. Research of the composting treatment of antibioticmushroom dregs[D]. Zhengzhou: Zhengzhou University, 2010 (in Chinese). [7] HILDEGARD E, KREUTZFELDT R. Process for the preparation of penicillin free mycelium masses from penicillin production culturesformed by fermentation, and the use as animal feeds and fertilizens: United States, 4601908[P]. 1986-07-22. [8] BANERJEE R K, SRINIVASAN K V. Recycling-reuse of penicillin mycelium as fish pond manure[J]. Biological Wastes,1988,23(2):107-116. doi: 10.1016/0269-7483(88)90068-7 [9] 张红娟, 郭夏丽, 王岩. 林可霉素菌渣与牛粪联合堆肥实验研究[J]. 环境工程学报, 2011, 5(1):231-234.ZHANG H J, GUO X L, WANG Y. Study on co-composting of lincomycin fermentation dregs and cattle manure[J]. Chinese Journal of Environmental Engineering,2011,5(1):231-234(in Chinese). [10] 苏建文, 王俊超, 许尚营, 等. 红霉素菌渣厌氧消化实验研究[J]. 中国沼气, 2013, 31(5):25-28. doi: 10.3969/j.issn.1000-1166.2013.05.005SU J W, WANG J C, XU S Y, et al. Anaerobic digestion of bacterial residues from erythromycin production[J]. China Biogas,2013,31(5):25-28(in Chinese). doi: 10.3969/j.issn.1000-1166.2013.05.005 [11] 张晔. 抗生素菌渣与煤粉配合成浆性能及燃烧动力学研究[D]. 淮南: 安徽理工大学, 2010.ZHANG Y. Study on performance and combustion kinetics of synthetic pulp of pntibiotic slag and coal powder[D]. Huainan: Anhui University of Science & Technology, 2010 (in Chinese). [12] 高勤. 土霉素菌渣活性炭的制备及应用研究[D]. 石家庄: 河北科技大学, 2012.GAO Q. Study on preparation and application of oxytetracycline bacterial residue-activation carbon[D]. Shijiazhuang: Hebei University of Science and Technology, 2012 (in Chinese). [13] 邵雪玲, 佐藤実 , 山口敏康, 等. 蓝藻Trichodesmium thiebautii营养成分分析[J]. 华中农业大学学报, 2001, 20(3):279-282. doi: 10.3321/j.issn:1000-2421.2001.03.021SHAO X L, SATO M, YAMAGUCHI T, et al. Nutritious components analysis on Trichodesmium thiebautii[J]. Journal of Huazhong Agricultural University,2001,20(3):279-282(in Chinese). doi: 10.3321/j.issn:1000-2421.2001.03.021 [14] 赵冰冰, 张发宇, 陈裕, 等. 四步盐析提取巢湖新鲜蓝藻中藻蓝蛋白及其稳定性[J]. 环境工程学报, 2016, 10(5):2302-2308. doi: 10.12030/j.cjee.2016050ZHAO B B, ZHANG F Y, CHEN Y, et al. Extraction by four steps’ salting-out and stability of phycocyanin from fresh blue algae in Lake Chaohu[J]. Chinese Journal of Environmental Engineering,2016,10(5):2302-2308(in Chinese). doi: 10.12030/j.cjee.2016050 [15] 牛娜, 罗学刚, 李纪伟, 等. 胶原蛋白/低密度聚乙烯复合材料的制备与性能[J]. 复合材料学报, 2014, 31(4):944-948.NIU N, LUO X G, LI J W, et al. Preparation and performance of hydrolyzed collagen/low density polyethylene composites[J]. Acta Materiae Compositae Sinica,2014,31(4):944-948(in Chinese). [16] 盛旭敏, 李又兵, 王选伦, 等. 食用级淀粉/低密度聚乙烯复合材料研究[J]. 重庆理工大学学报, 2011, 25(2): 37-42.SHENG X M, LI Y B, WANG X L, et al. Study on composite material of LDPE and edible starch[J]. Journal of Chongqing University of Technology, 2011, 25(2): 37-42(in Chinese). [17] 陈李红. 天然蛋白质可降解热塑膜及纺织浆料的制备与性能研究[D]. 上海: 东华大学, 2013.CHEN L H. Research on preparation and performance of biodegradable thermoplastic films and textile sizes from natural proteins[D]. Shanghai: Donghua University, 2013 (in Chinese). [18] CHALERMTHAI B, CHAN W Y, BASTIDAS-OYANEDEL J R, et al. Preparation and characterization of whey protein-based polymers produced from residual dairy streams[J]. Polymers,2019,11(4):722-732. doi: 10.3390/polym11040722 [19] 彭旭锵. PP/超细羽绒粉体共混改性及可纺性研究[D]. 武汉: 武汉科技学院, 2007.PENG X Q. Study on blending modification and spinnability of PP/superfine down powder[D]. Wuhan: Wuhan University of Science and Engineering, 2007(in Chinese). [20] 朱凌波, 李新功, 杨凯, 等. 几种不同改性剂对稻草/丙烯腈-丁二烯-苯乙烯复合材料性能的影响[J]. 复合材料学报, 2018, 35(7):1791-1799.ZHU L B, LI X G, YANG K, et al. Performance enhancement of straw / acrylonitrile-butadiene-styrene composites modified by several different kinds of modifiers[J]. Acta Materiae Compositae Sinica,2018,35(7):1791-1799(in Chinese). [21] 中国国家标准化管理委员会. 塑料拉伸性能的测定: GB/T 1040.2—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Plastic the measurement of tensile properties: GB/T 1040.2—2006[S]. Beijing: Standards Press of China, 2006 (in Chinese). [22] 中国国家标准化管理委员会. 塑料弯曲性能试验方法: GB/T 9341—2000[S]. 北京: 中国标准出版社, 2000.Standardization Administration of the People’s Republic of China. Plastic determination of flexural properties: GB/T 9341—2000[S]. Beijing: Standards Press of China, 2000 (in Chinese). [23] VUONG Q V, GOLDING J B, NGUYEN M H, et al. Production of caffeinated and decaffeinated green tea catechin powders from underutilised old tea leaves[J]. Journal of Food Engineering,2012,110:1-8. [24] ZHANG Q A, YUE X F, FAN X H, et al. Response surface optimization of ultrasound-assisted oil extraction from autoclaved almond powder[J]. Food Chemistry,2009,116:513-518. [25] 熊勇, 李冬梅, 刘江波, 等. 响应面法分析优化藻蓝蛋白色素提取工艺的研究[J]. 中国食品添加剂, 2018(11):107-112.XIONG Y, LI D M, LIU J B, et al. Optimization of the extraction technology of phycocyanin from Spirulina using response surface methodology[J]. China Food Additives,2018(11):107-112(in Chinese). [26] NAKA K, NAKANMURA T, OHKI A, et al. Chitin-graft-poly(2-methyl-2-oxazoline) enhanced solubility and activity of catalase in organic solvent[J]. International Journal of Biological Macromolecules,1998,23(4):14-17. [27] PAWLAK A, MUCHA A. Thermogravimetric and FTIR studies of chitosan blends[J]. Thermochimica Acta,2003,296(1-2):14-17. -

下载:

下载: