Surface modification of carbon fiber(CF) deposited graphene oxide(GO) by electrophorestic deposition and interfacial properties of GO-CF/epoxy composites

-

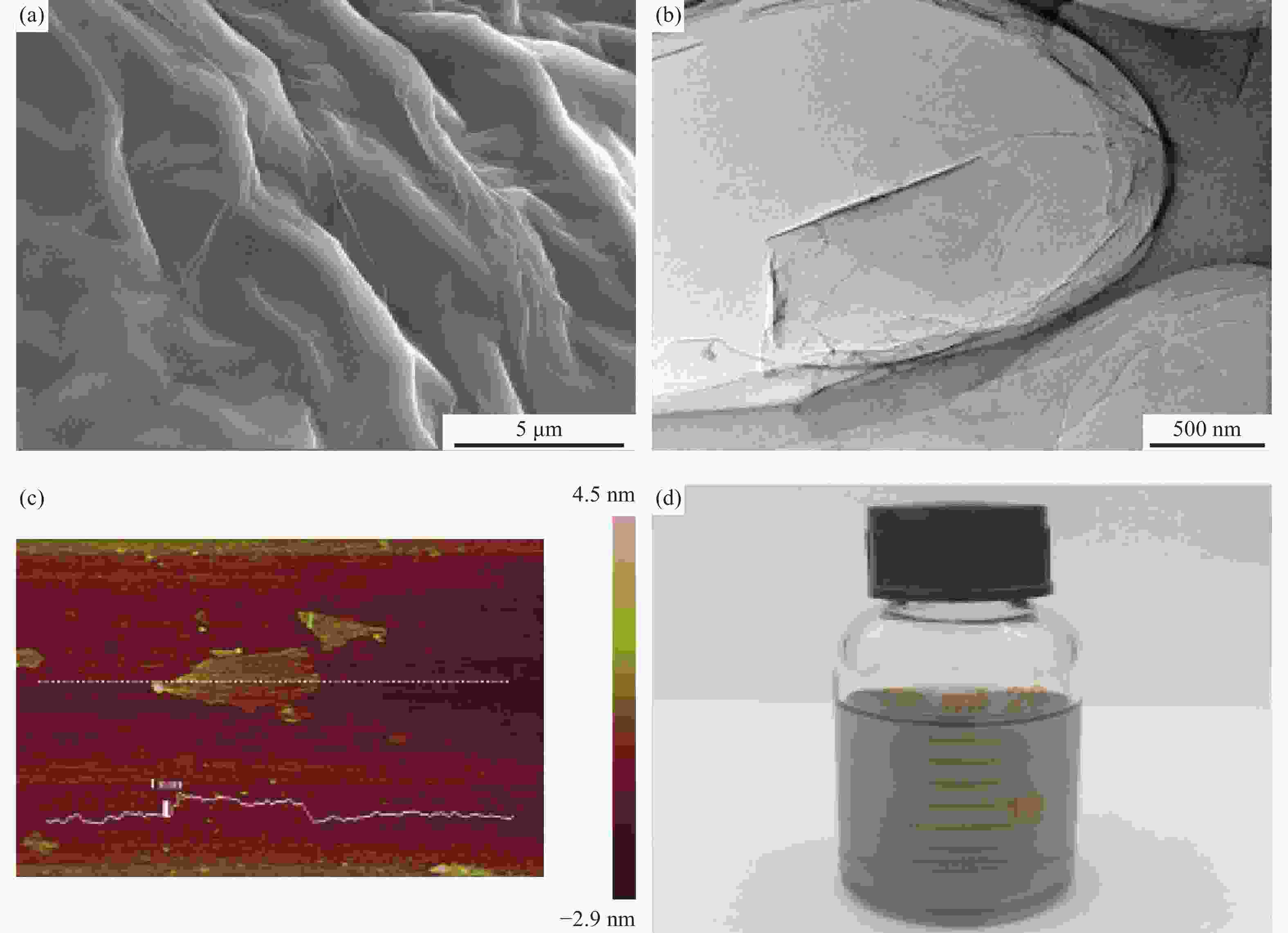

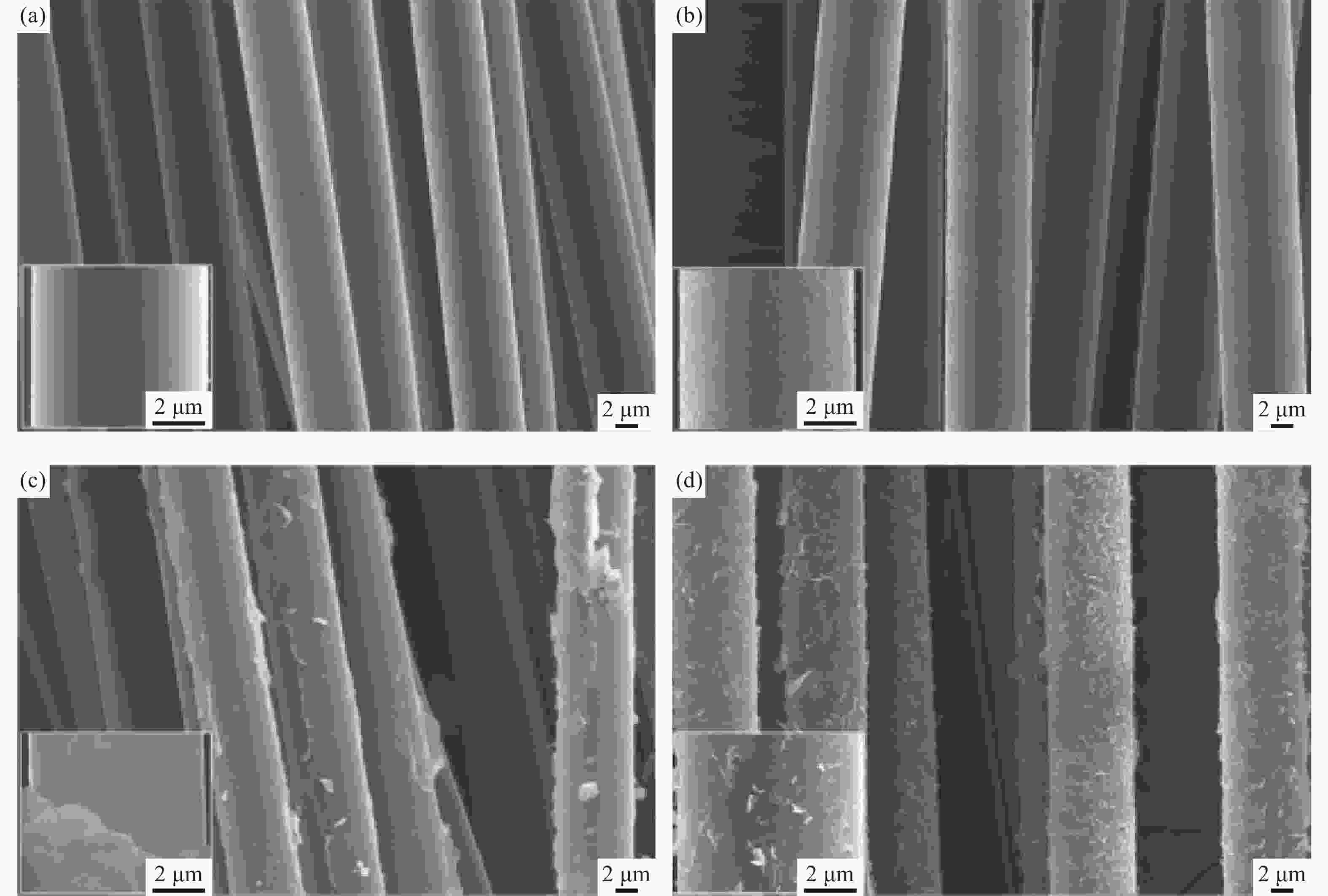

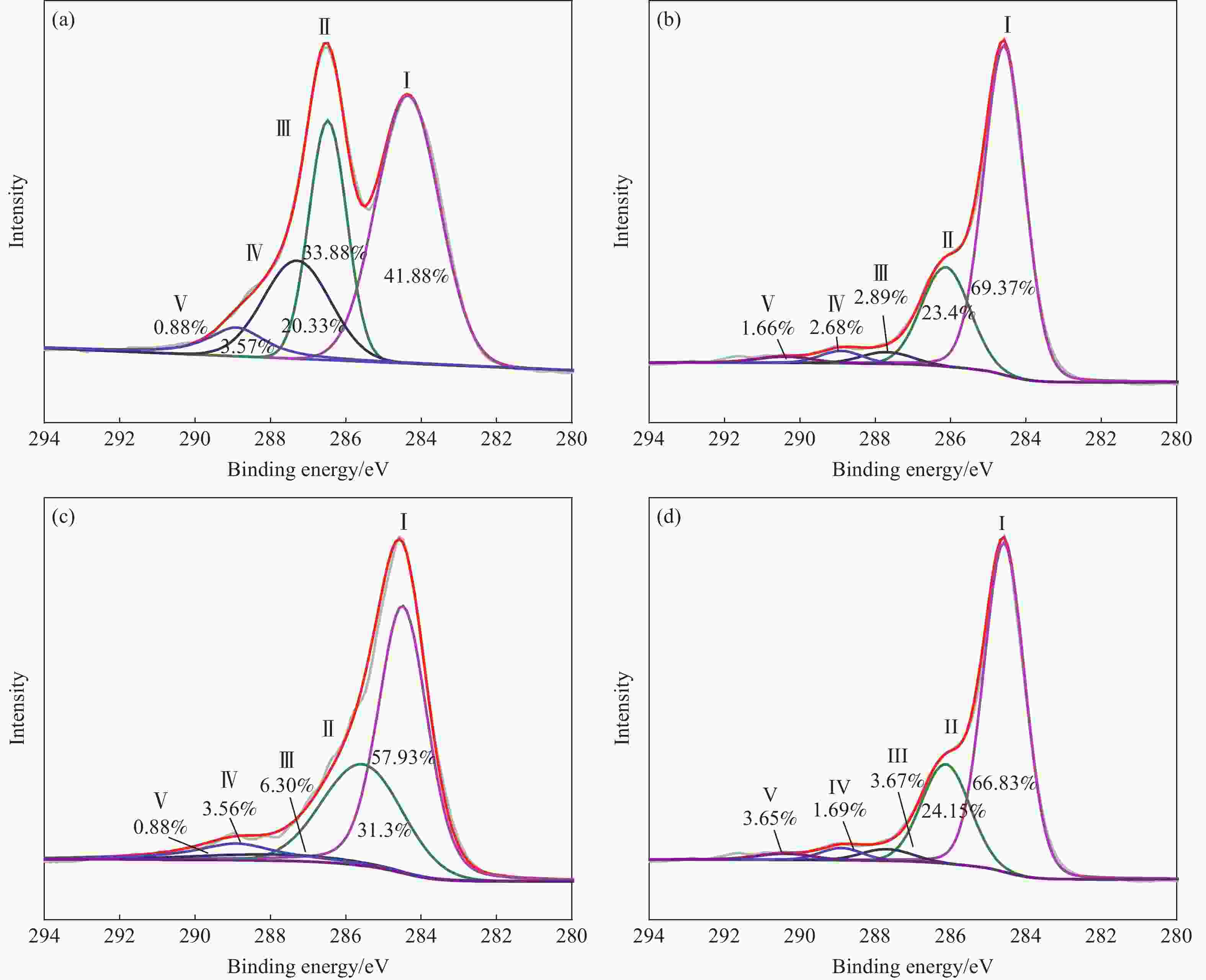

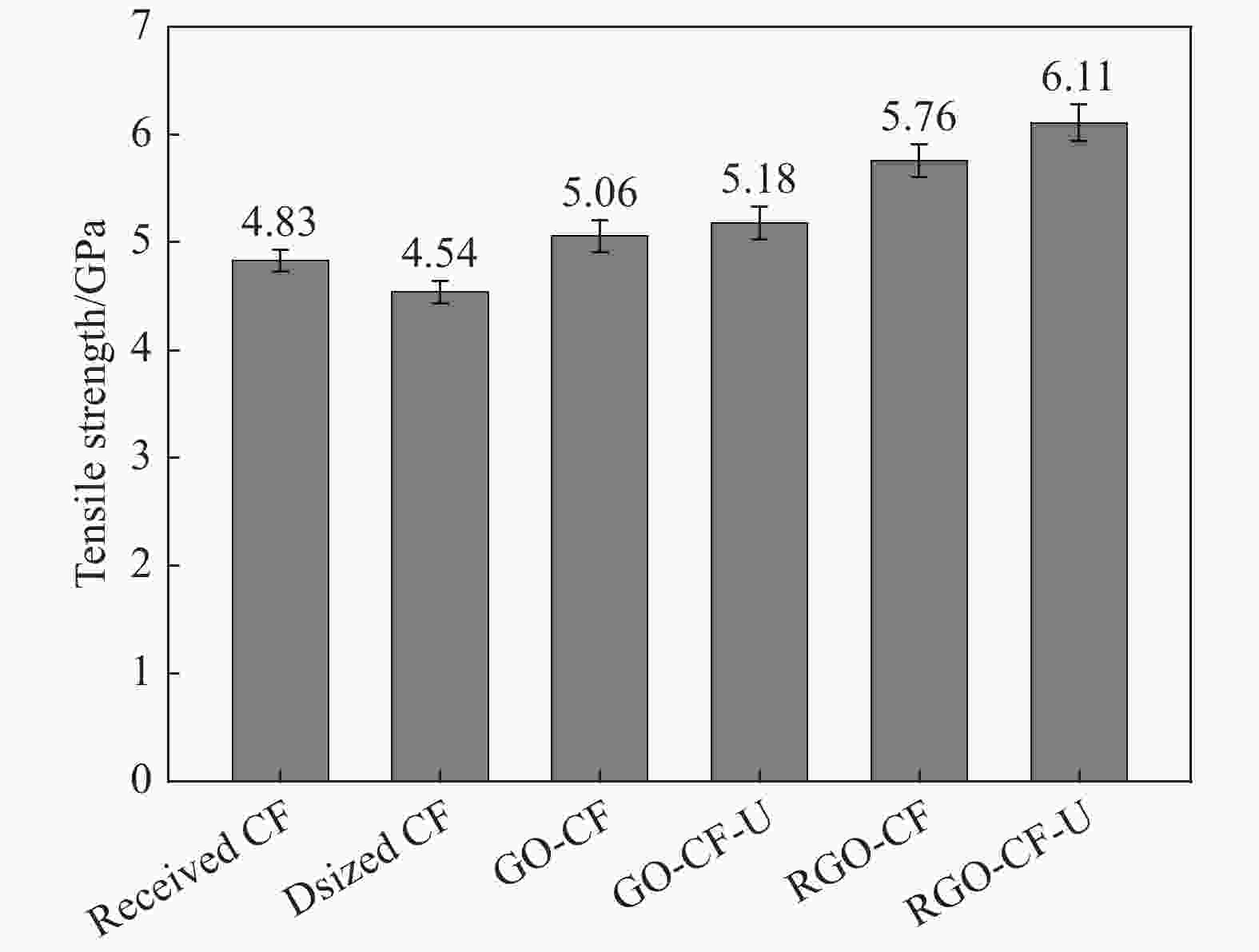

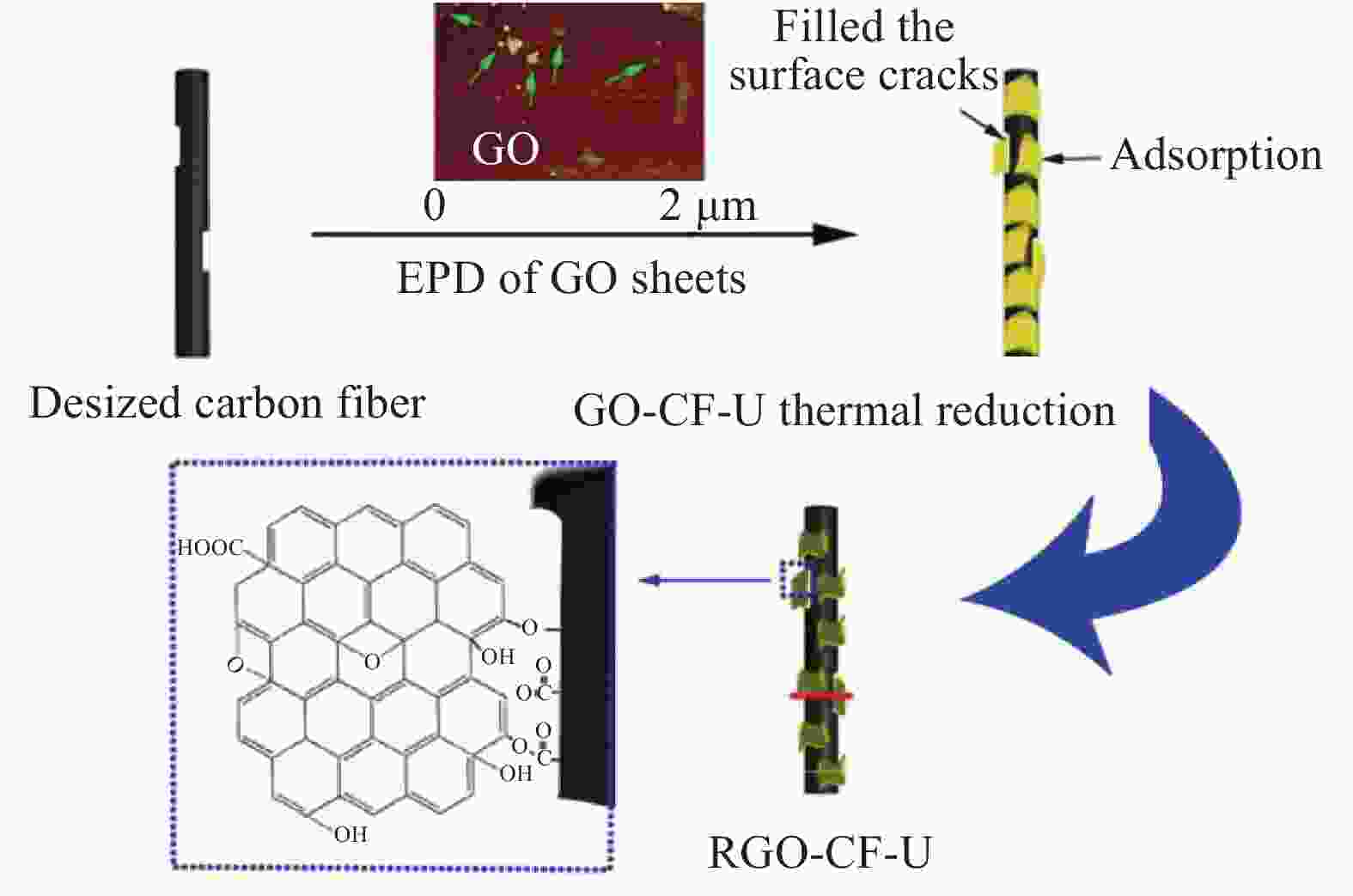

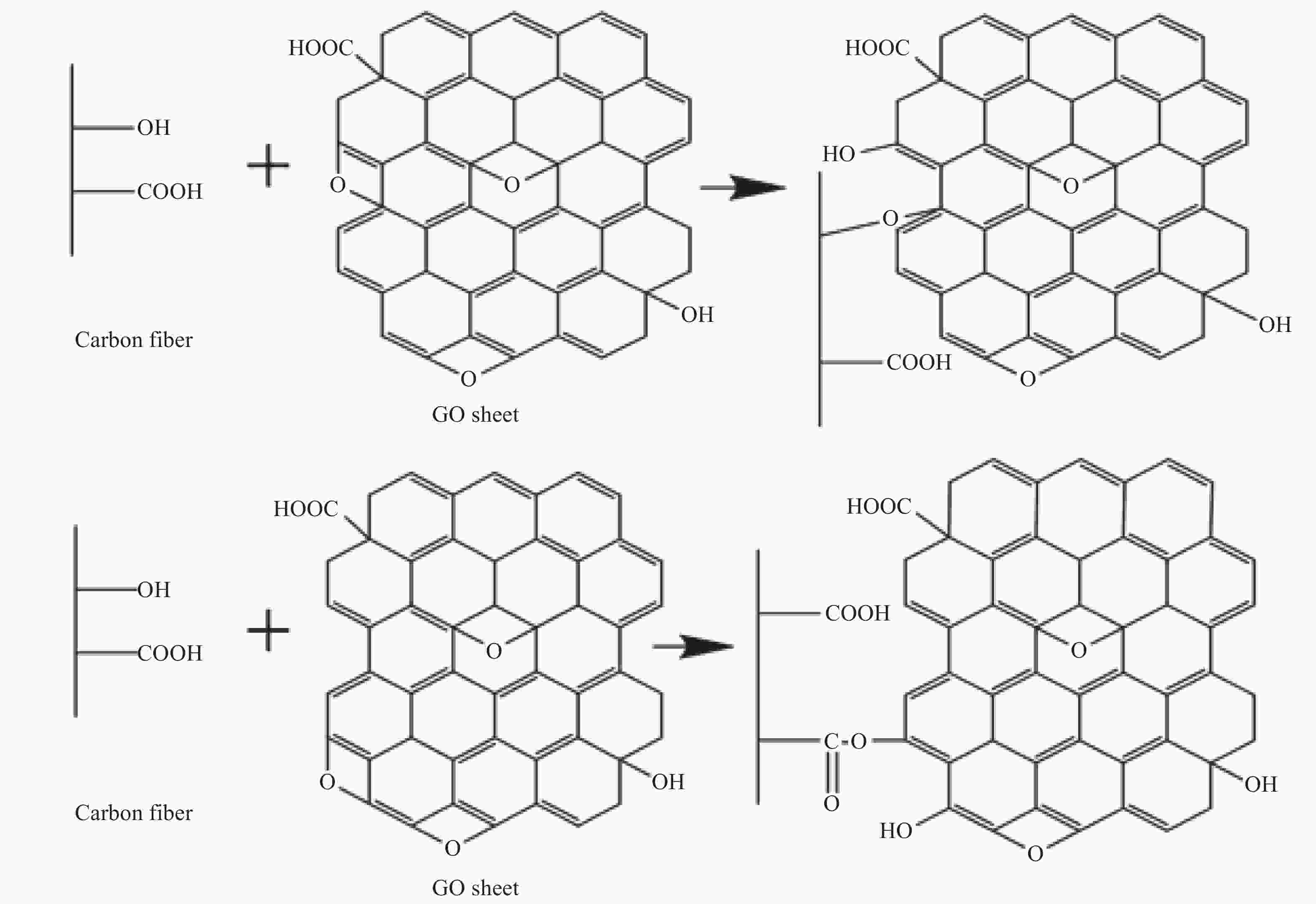

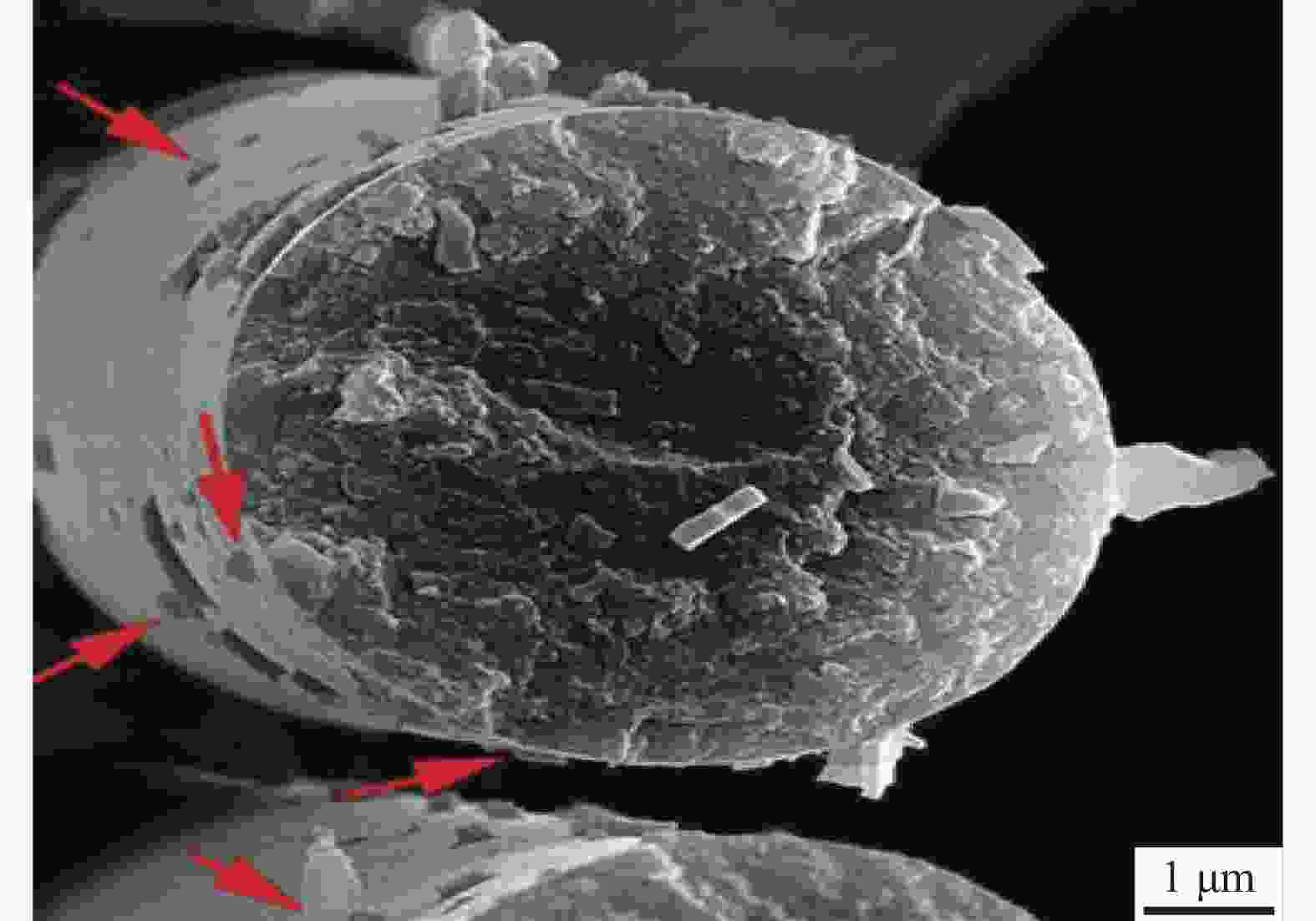

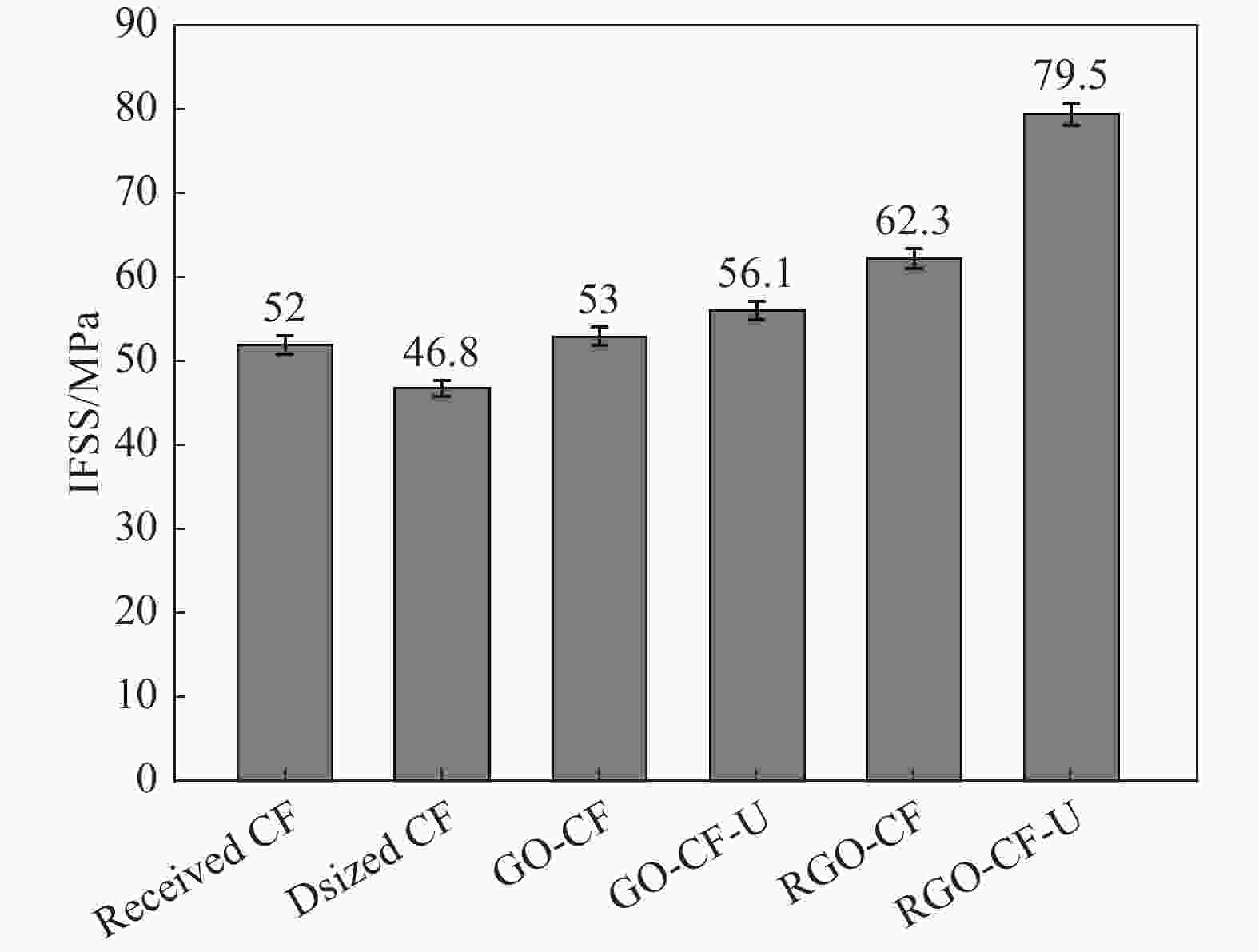

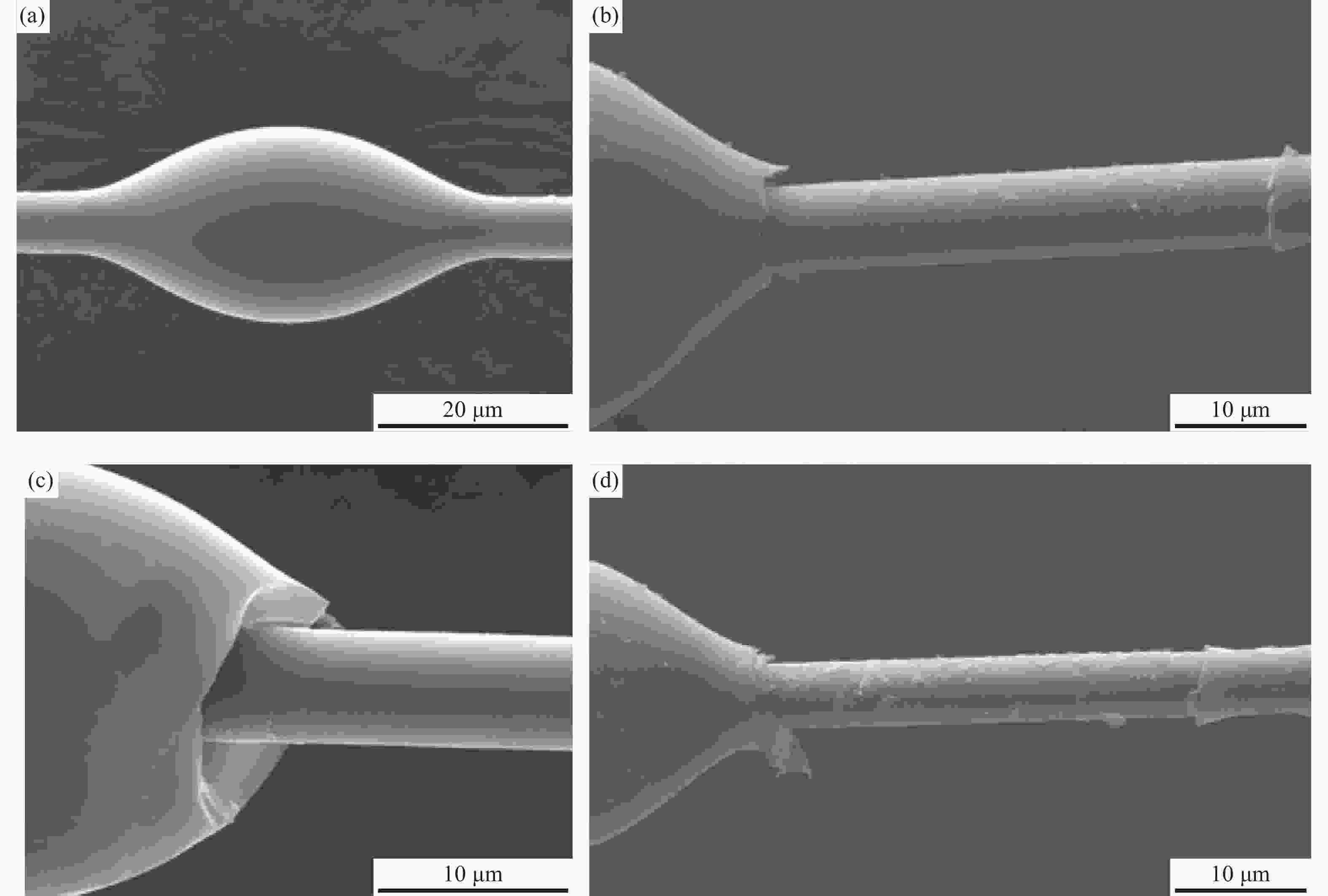

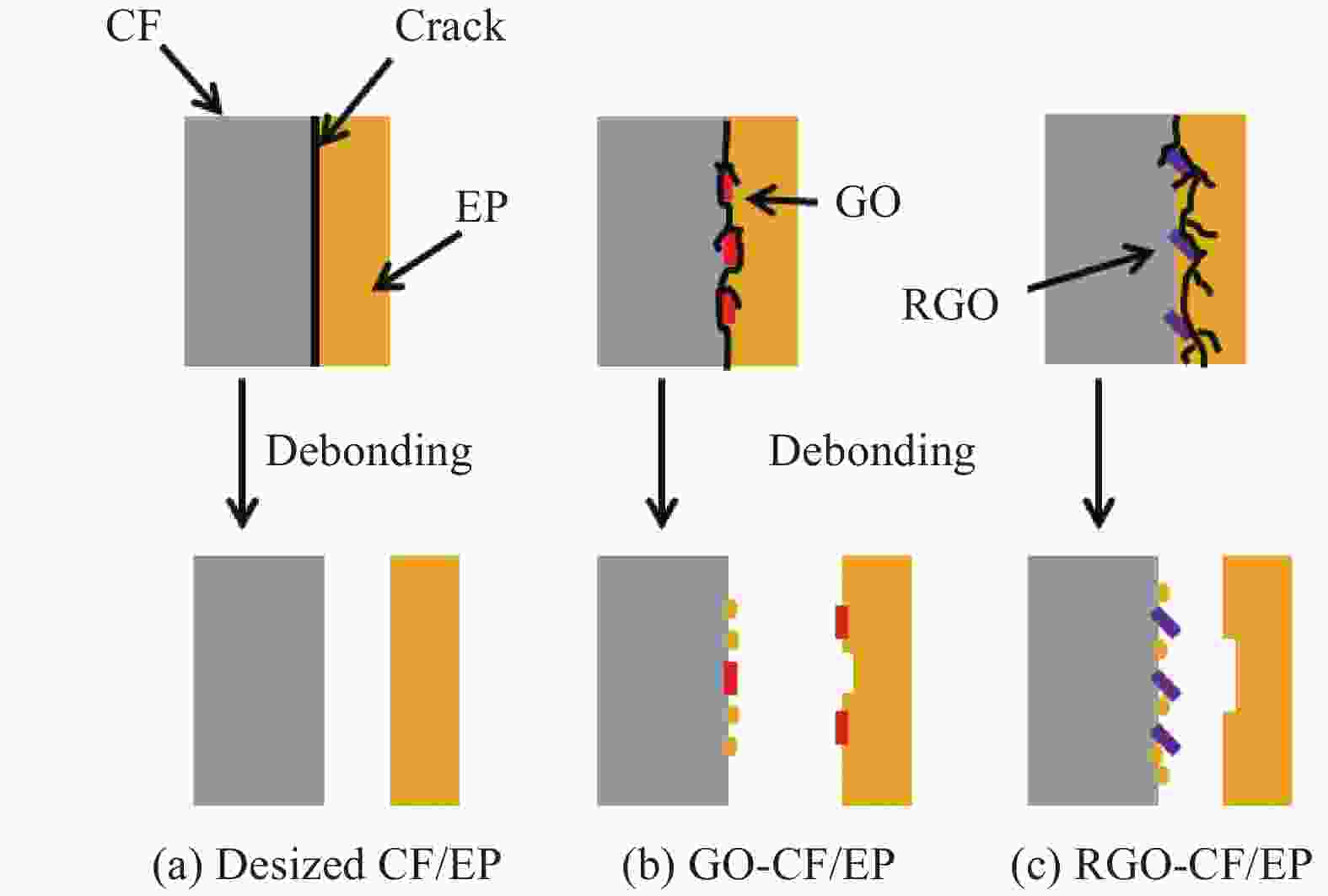

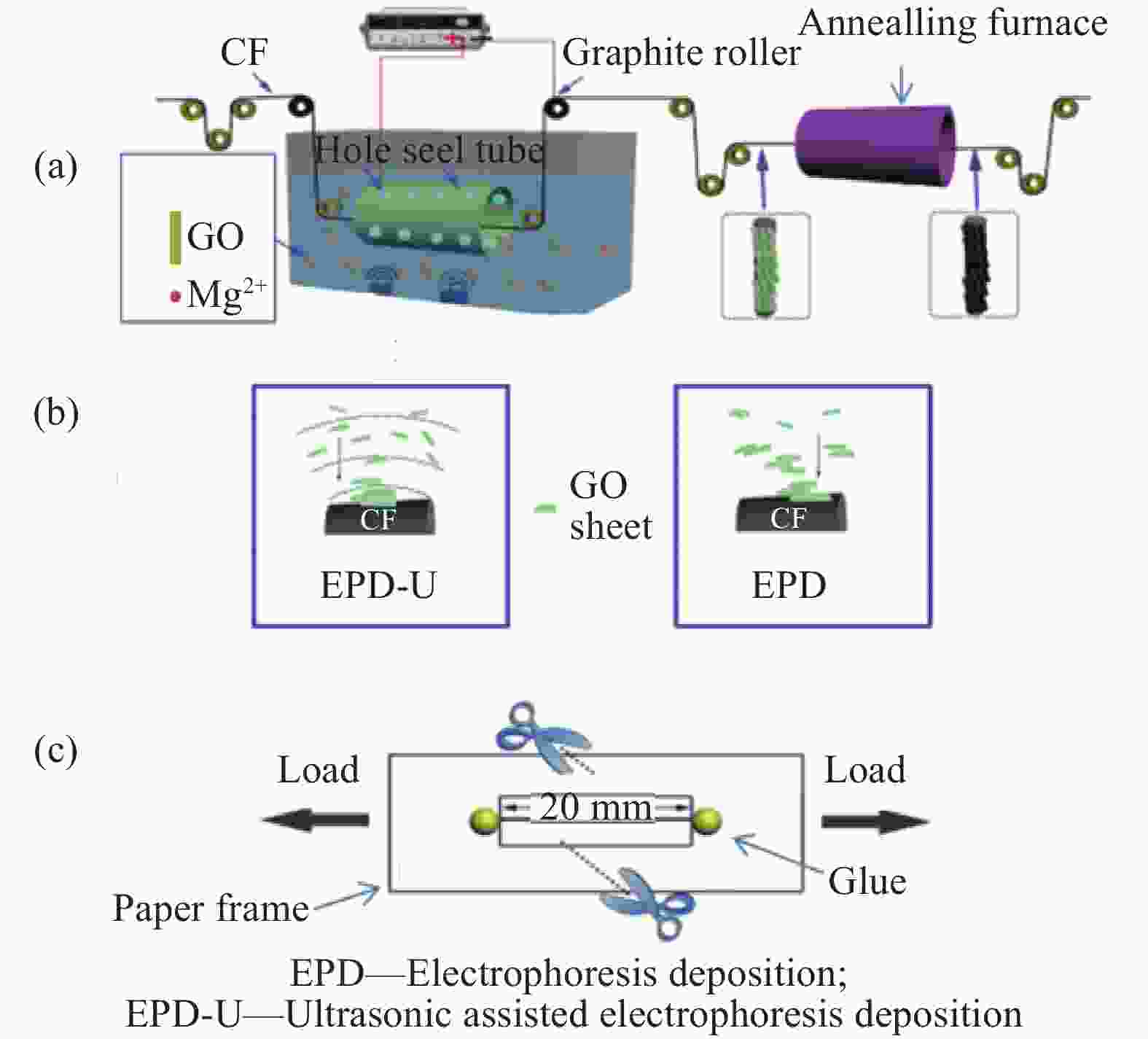

摘要: 采用超声辅助电泳沉积法,以异丙醇作为溶剂,在连续碳纤维(CF)表面沉积一层氧化石墨烯(GO),对CF表面进行改性。再经200℃高温处理来增强(GO)与CF之间的黏合性,从而增加CF/环氧树脂(EP)复合材料的界面结合强度。利用SEM和AFM对改性前后CF的表面形貌及微观结构变化进行了表征,通过XPS对改性前后CF表面官能团的变化进行了检测。结果表明,在CF表面沉积GO并经200℃处理后,有效地部分还原了GO(RGO),填补或桥联了CF表面缺陷,使改性后CF的拉伸强度提高了34.58%。同时,高温处理使RGO与CF之间生成牢固的化学键,从而提高了RGO与CF之间的结合强度,最终使RGO-CF/EP复合材料的界面剪切强度(IFSS)提高了69.9%。Abstract: The graphene oxide(GO) was deposited on the surface of continuous carbon fiber(CF) by ultrasonic assisted electrophoresis deposition in isopropyl alcohol for the modification of the surface of CF. Then the adhesion between GO and CF was enhanced by high temperature treatment under 200℃, which would increase the interfacial bonding strength of CF/epoxy(EP) composites. The surface morphology and microstructure of the CF before and after modification were characterized by SEM and AFM, and the changes of the surface functional groups of CF before and after modification were tested by XPS. The results show that the tensile strength of the modified CF is increased by 34.58% after deposition of GO and treatment under 200℃. The reason for the improvement is that some partially reduced GO sheets fill or bridge the defects on the surface of CF. At the same time, the adhesion between RGO and CF is enhanced by the linkage of chemical bond after high temperature treatment. And the interfacial shear strength (IFSS) of RGO-CF/EP composites is increased by 69.9%.

-

Key words:

- carbon fiber /

- graphene oxide /

- composite /

- interface property /

- electrophoresis deposition /

- surface topography

-

表 1 改性碳纤维(CF)的电泳沉积和热处理参数

Table 1. Electrophoresis deposition and heat treatment parameters for modified carbon fiber(CF)

Sample CGO/

(mg·mL−1)Voltage/

(V·cm−1)Time/

minUltra-

sonicAnnealing(200℃) GO-CF 0.1 160 1 No No GO-CF-U 0.1 160 1 Yes No RGO-CF 0.1 160 1 No Yes RGO-CF-U 0.1 160 1 Yes Yes Notes: GO—Graphene oxide; CGO—Concentration of GO; GO-CF—Electrophoretic deposition GO on CF; GO-CF-U—Deposition GO on CF by ultrasonic assisted electrophoresis deposition; RGO-CF—Electrophoretic deposition RGO on CF; RGO-CF-U —Deposition GO on CF by ultrasonic assisted electrophoresis deposition; RGO—Reduced graphene oxide. 表 2 GO、脱浆CF、GO-CF-U、RGO-CF-U的表面元素组成

Table 2. Composition of surface elements of GO, desized CF, GO-CF-U, RGO-CF-U

Sample Element mass fraction/wt% O/C C O Desized CF 87.37 12.63 0.1445 GO 69.46 30.54 0.4397 GO-CF-U 77.03 22.97 0.2982 RGO-CF-U 84.99 15.01 0.1766 -

[1] YANG Y, LU C X, SU X L, et al. Effects of emulsion sizing with nano-SiO2 on interfacial properties of carbon fibers/epoxy composites[J]. Journal of Materials Science,2007,42(15):6347-6352. doi: 10.1007/s10853-006-1198-x [2] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [3] 方奕欣, 陈蔚, 蒋震宇, 等. 碳纤维和SiO2纳米颗粒增强环氧树脂复合材料的压缩性能[J]. 复合材料学报, 2019, 36(6):1343-1352.FANG Yixin, CHEN Wei, JIANG Zhenyu, et al. Compression properties of epoxy resin composites reinforced by carbon fiber and SiO2 nanoparticles[J]. Acta Materias Compositae Sinica,2019,36(6):1343-1352(in Chinese). [4] 董慧民, 益小苏, 安学峰, 等. 纤维增强热固性聚合物基复合材料层间增韧研究进展[J]. 复合材料学报, 2014, 31(2):273-285.DONG Huimin, YI Xiaosu, AN Xuefeng, et al. Research progress in interlayer toughening of fiber-reinforced thermosetting polymer matrix composites[J]. Acta Materias Compositae Sinica,2014,31(2):273-285(in Chinese). [5] WANG Y L, PILLAI S K R, CHE J F, et al. High interlaminar shear strength enhancement of carbon fiber/epoxy composite through fiber and matrix-anchored carbon nanotube networks[J]. ACS Applied Materials & Interfaces,2017,9(10):8960-8966. [6] SUN H F, MEMON S A, GU Y, et al. Degradation of carbon fiber reinforced polymer from cathodic protection process on exposure to NaOH and simulated pore water solutions[J]. Materials and Structures,2016,49(12):5273-5283. doi: 10.1617/s11527-016-0859-8 [7] 李君, 矫维成, 闫美玲, 等. 碳纳米材料接枝碳纤维的复合材料界面增效研究进展[J]. 玻璃钢/复合材料, 2018(7):108-113. doi: 10.3969/j.issn.1003-0999.2018.07.018LI Ju, JIAO Weicheng, YAN Meilin, et al. Research status analysis of FRP reinforced concrete structures[J]. Fiber Reinforced Plastics/Composites,2018(7):108-113(in Chinese). doi: 10.3969/j.issn.1003-0999.2018.07.018 [8] HUANG S Y, WU G P, ZHANG S C, et al. Electrophoretic deposition and thermal annealing of a graphene oxide thin film on carbon fiber surfaces[J]. Carbon,2013,52:605-620. [9] ZHANG X Q, FAN X Y. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials & Interfaces,2012,4(3):1543-1552. [10] WU Z S, PEI S F, LIU B L, et al. Field emission of single-layer graphene films prepared by electrophoretic deposition[J]. Advanced Materials,2009,21(17):1756-1760. doi: 10.1002/adma.200802560 [11] QIN W Z, VAUTRARD F, DRZAL L T, et al. Mechanical and electrical properties of carbon fiber composites with incorporation of graphene nanoplatelets at the fiber-matrix interphase[J]. Composites Part B: Engineering,2015,69(8):335-341. [12] CHEN J L, WANG K, ZHAO Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface[J]. Composites Science and Technology,2018,154:175-186. [13] 杨平军, 袁剑民, 何莉萍, 等. 碳纤维表面改性及其对碳纤维/树脂界面影响的研究进展[J]. 材料导报, 2017, 31(7):129-136.YANG Pingjun, YUAN Jianmin, HE Lipin, et al. Carbon fibers surface modification and effects on the interfaces between fibers and resin matrices: A Review[J]. Materials Review,2017,31(7):129-136(in Chinese). [14] LI F, LIU Y, QU C B, et al. Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating[J]. Polymer,2015,59:155-165. [15] LI Y, PENG Q, HE X, et al. Synthesis and characterization of a new hierarchical reinforcement by chemically grafting graphene oxide onto carbon fibers[J]. Journal of Materials Chemistry,2012,22(36):18748-18752. doi: 10.1039/c2jm32596a [16] 李伟, 岳远志, 朱婷婷, 等. 硅烷修饰的氧化石墨烯对碳纤维/BMI复合材料的界面改性研究[J]. 高校化学工程学报, 2017, 31(3):738-742. doi: 10.3969/j.issn.1003-9015.2017.00.031LI Wei, YUE Yuanzhi, ZHU Tingting, et al. Interfacial modification of carbon fiber/BMI composites with silane modified graphene oxide[J]. Journal of Chemical Engineering of Chinese Universities,2017,31(3):738-742(in Chinese). doi: 10.3969/j.issn.1003-9015.2017.00.031 [17] WANG C, LI Y, TONG L, et al. The role of grafting force and surface wettability in interfacial enhancement of carbon nanotube/carbon fiber hierarchical composites[J]. Carbon,2014,69:239-246. [18] 胡涛, 赵东林, 程兴旺, 等. 氧化石墨烯增强环氧树脂复合材料的制备及其力学性能研究[J]. 北京化工学报(自然科学版), 2018, 45(6):29-33.HU Tao, ZHAO Donglin, CHENG Xingwang, et al. Preparation and mechanical properties of graphene oxide reinforced epoxy composites[J]. Journal of Beijing University of Chemical Technology (Natural Science Edition),2018,45(6):29-33(in Chinese). [19] 张成, 刘兆政, 孙明娟, 等. 低温等离子体碳纤维表面处理技术研究[J]. 材料导报, 2018, 32(32):294-296.ZHANG Cheng, LIU Zhaozheng, SUN Minjuan, et al. Surface treatment on carbon fiber by cold plasma[J]. Materials Review,2018,32(32):294-296(in Chinese). [20] BATTISTI A, OJOS D E L, GHISLENI R, et al. Single fiber push-out characterization of interfacial properties of hierarchical CNT-carbon fiber composites prepared by electrophoretic deposition[J]. Composites Science and Technology,2014,95:121-127. [21] DENG C, JIANG J, LIU F, et al. Influence of grapheme oxide coatings on carbon fiber by ultrasonically assisted electrophoretic deposition on its composite interfacial property[J]. Surface and Coatings Technology,2015,272:176-181. [22] QIN W, VAUTARD F, DRZAL L T, et al. Mechanical and electrical properties of carbon fiber composites with incorporation of graphene nanoplatelets at the fiber-matrix interphase[J]. Composites Part B: Engineering,2015,69:335-341. [23] STANKOVICH S, DIKINI D A, DOMMETT G H B, et al. Graphene-based composite materials[J]. Nature,2006,442(13):282-286. [24] ZHANG S, LIU W B, HAO L F, et al. Preparation of carbon nanotube/carbon fiber hybrid fiber by combining electrophoretic deposition and sizing process for enhancing interfacial strength in carbon fiber composites[J]. Composites Science and Technology,2018,88:120-125. [25] ZHANG R L, GAO B, MA Q H, et al. Directly grafting grapheme oxide onto carbon fiber and the effect on the mechanical properties of carbon fiber composites[J]. Materials & Design,2016,93:364-369. [26] FENG J J, WANG X Q, TIAN Y, et al. Electrophoretic deposition of graphene oxide onto carbon fibers for in-tube solid-phase microextraction[J]. Journal of Chromatography A,2017,1517:209-214. [27] ASTM International. Standard Test method for tensile strength and Young’s modulus for high-modulus single-filament materials: ASTM D3379—75[S]. West Conshohocken: ASTM International, 1989. [28] WEIBULL W. A statistical distribution function of wide applicability[J]. Journal of Applied Mechanics,1951,18:293-297. [29] NING H, LI J, HU N, et al. Interlaminar mechanical properties of carbon fiber reinforced plastic laminates modified with graphene oxide interleaf[J]. Carbon,2015,91:224-233. [30] YUAN X M, ZHU B, CAI X, et al. Micro-configuration controlled interfacial adhesion by grafting graphene oxide onto carbon fibers[J]. Composites Part A: Applied Science and Manufacturing,2018,111:83-93. [31] AKHAVAN O, GHADERI E. Toxicity of graphene and graphene oxide nanowalls against bacteria[J]. ACS Nano,2010,4(10):5731-5736. [32] LI Z, YOUNG R, WILSON N R, et al. Effect of the orientation of graphene-based nanoplatelets upon the Young’s modulus of nanocomposites[J]. Composites Science and Technology,2016,123:125-133. [33] MA L C, MENG L H, WU G S, et al. Effects of bonding types of carbon fibers with branched polyethyleneimine on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites[J]. Composites Science and Technology,2015,117:289-297. [34] MA L C, MENG L H, WU G S, et al. Improving the interfacial properties of carbon fiber-reinforced expoxy composites by grafting of branched polyethyleneimine on carbon fiber surface in supercritical methanol[J]. Composites Science and Technology,2015,114:64-71. [35] ZHANG J, YANG H, SHEN G, at al. Reduction of graphene oxide via L-ascorbic acid[J]. Chemistry Communication,2010,46(7):1112-1114. doi: 10.1039/B917705A [36] LEE W, LEE J U, CHA H J, et al. Partially reduced graphene oxide as a multi-functional sizing agent for carbon fiber composites by electrophoretic deposition[J]. RSC Advance,2013,3(48):25609-25613. doi: 10.1039/c3ra44155e [37] DENG C, JIANG J J, LIU F, et al. Effects of electrophoretically deposited graphene oxide coatings on interfacial properties of carbon fiber composite[J]. Journal of Matererials Science,2015,50(17):5886-5892. doi: 10.1007/s10853-015-9138-2 [38] CHEN J, ZHAO D, JIN X, et al. Modifying glass fibers with grapheme oxide: Towards high-performance polymer composites[J]. Composites Science and Technology,2014,97:41-45. [39] 张雪, 刘媛, 杨斌, 等. 碳纤维表面改性对复合材料性能的影响[J]. 功能高分子学报, 2017, 30(4):444-449.ZHANG Xue, LIU Yuan, YANG Bin, et al. Effect of carbon fiber surface modification on properties of composites[J]. Journal of Functional Polymers,2017,30(4):444-449(in Chinese). [40] WANG C, GE H, LIU H, et al. Microstructure and properties of carbon fiber sized with pickering emulsion based on graphene oxide sheet and its composite with epoxy resin[J]. Journal of Applied polymer,2015,132(29):42285. [41] DOWNEY M A, DRZAL L T. Toughening of carbon fiber-reinforced epoxy polymer composites utilizing fiber surface treatment and sizing[J]. Composites Part A: Applied Science and Manufacturing,2016,90:687-698. -

下载:

下载: