Microcreep properties of carbon fiber reinforced resin composites

-

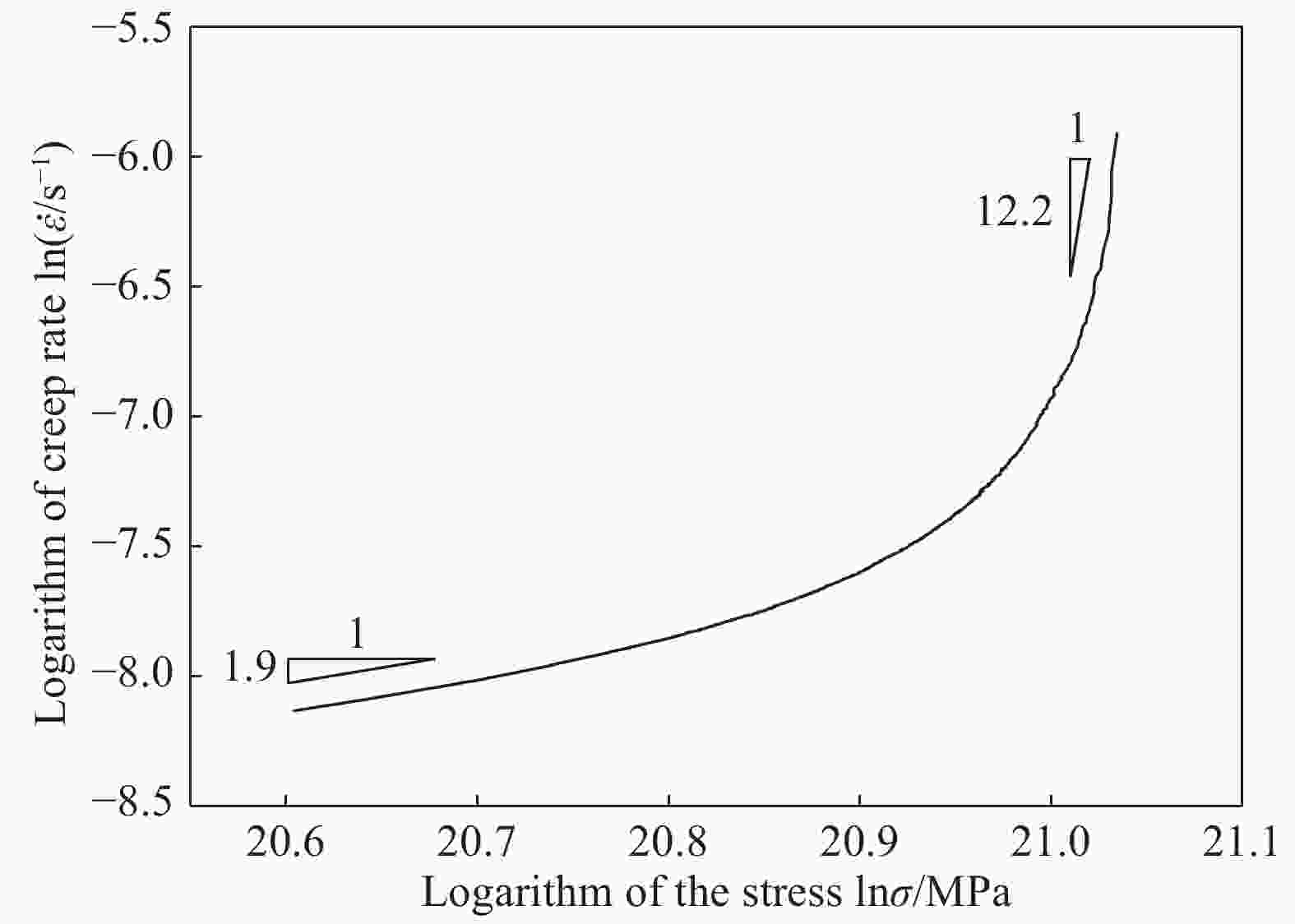

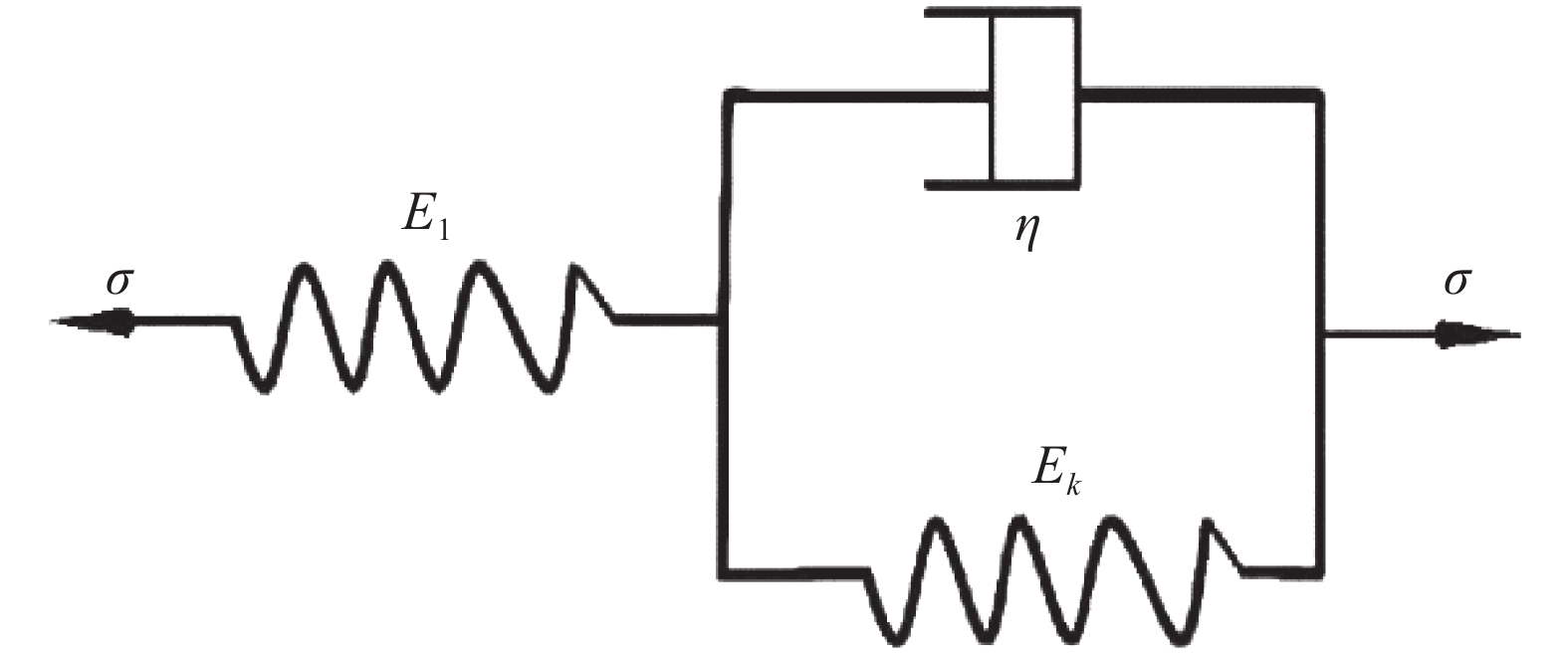

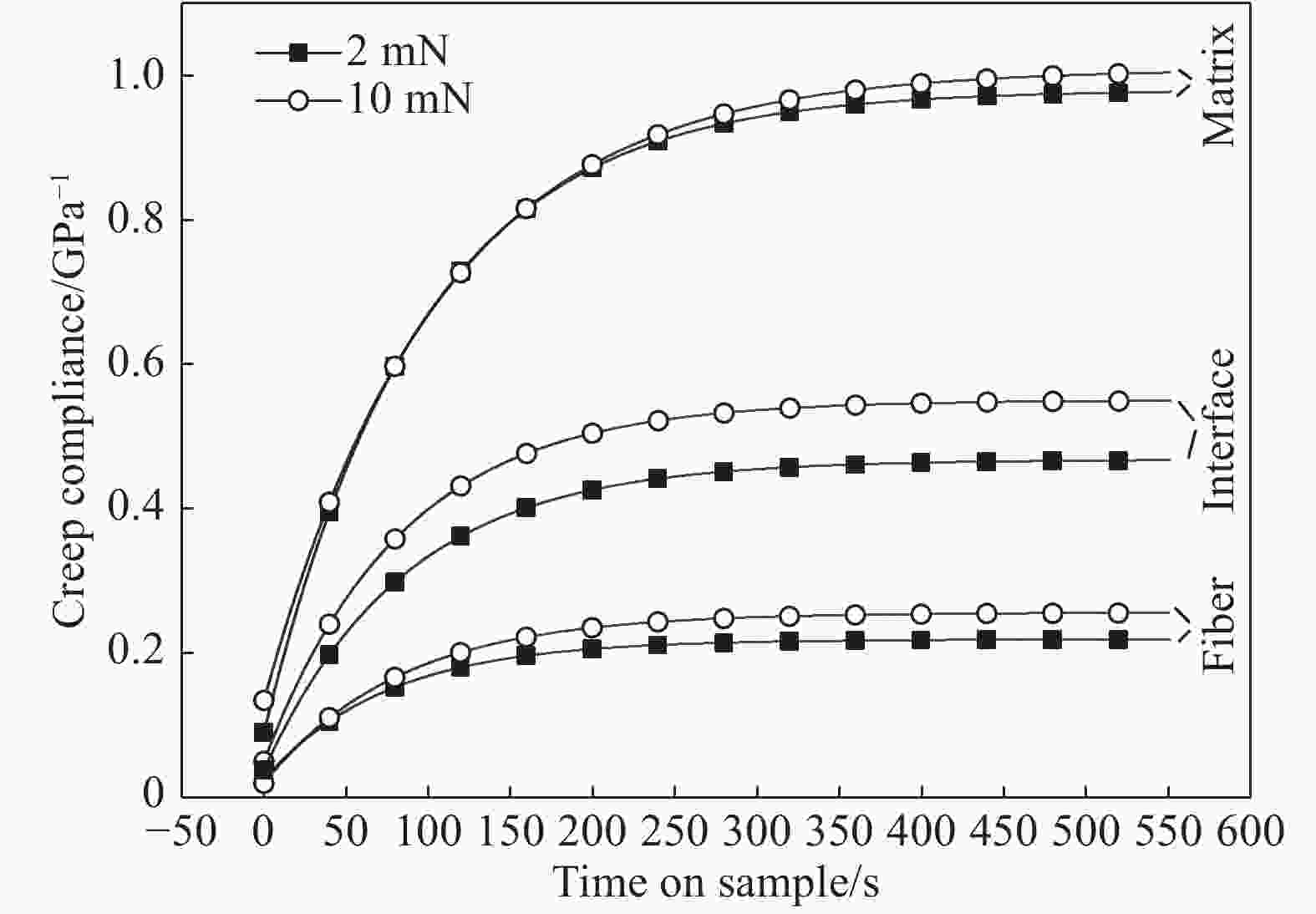

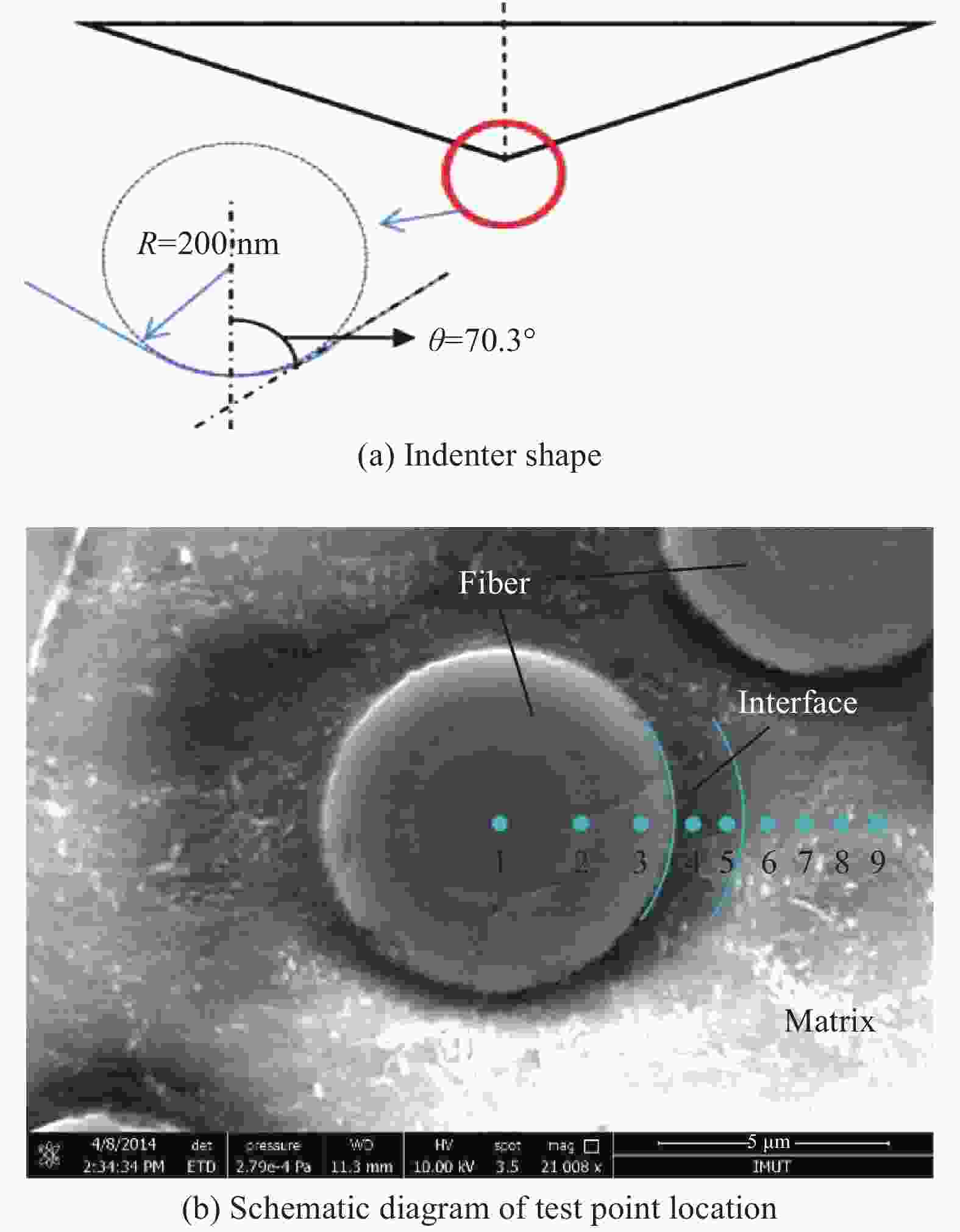

摘要: 碳纤维增强树脂复合材料以其优异的性能,在各领域得到广泛应用。由于树脂基体具有黏弹性,使其合成的复合材料也表现出黏弹性行为。蠕变是材料黏弹性行为中最典型的一类现象,因此对碳纤维增强树脂复合材料细观蠕变性能的研究具有重要意义。室温下利用纳米压痕技术对碳纤维增强树脂复合材料中的基体、界面及纤维相在不同峰值载荷下的细观蠕变行为进行分析。结果表明:在相同的蠕变时间下,最大载荷为2 mN和10 mN的纤维蠕变位移约为基体蠕变位移的1/3和1/2,界面的蠕变位移介于两者之间;稳态蠕变阶段的蠕变速率小于0.1%;基体、界面、纤维的蠕变应力指数分别为3.6、2.9和2.1。同时根据Kelvin-Voigt模型得到了基体、界面及纤维的第一、第二复数模量、黏度系数及蠕变柔量。

-

关键词:

- 碳纤维增强树脂复合材料 /

- 纳米压痕技术 /

- 细观蠕变 /

- 蠕变应力指数 /

- Kelvin-Voigt模型

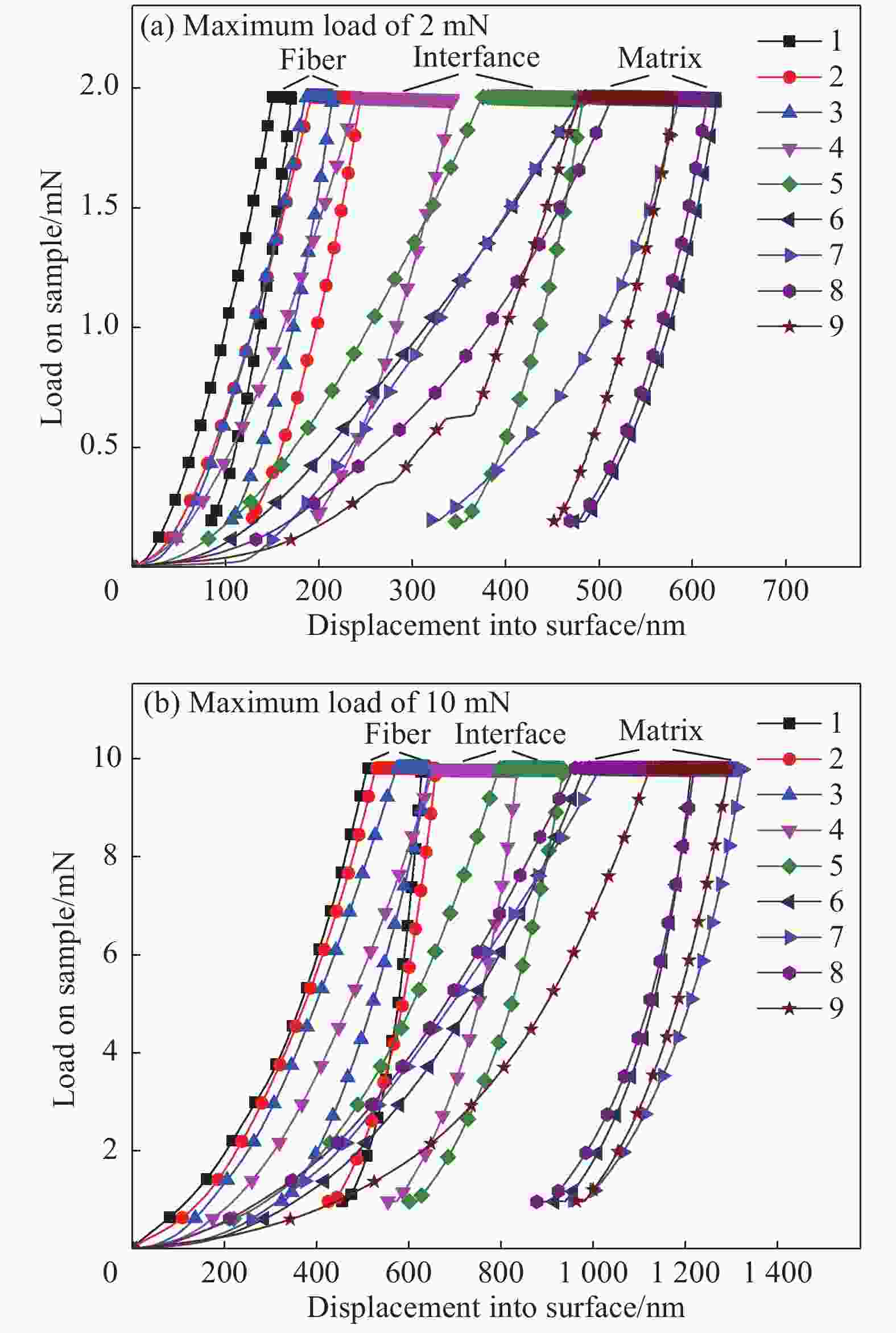

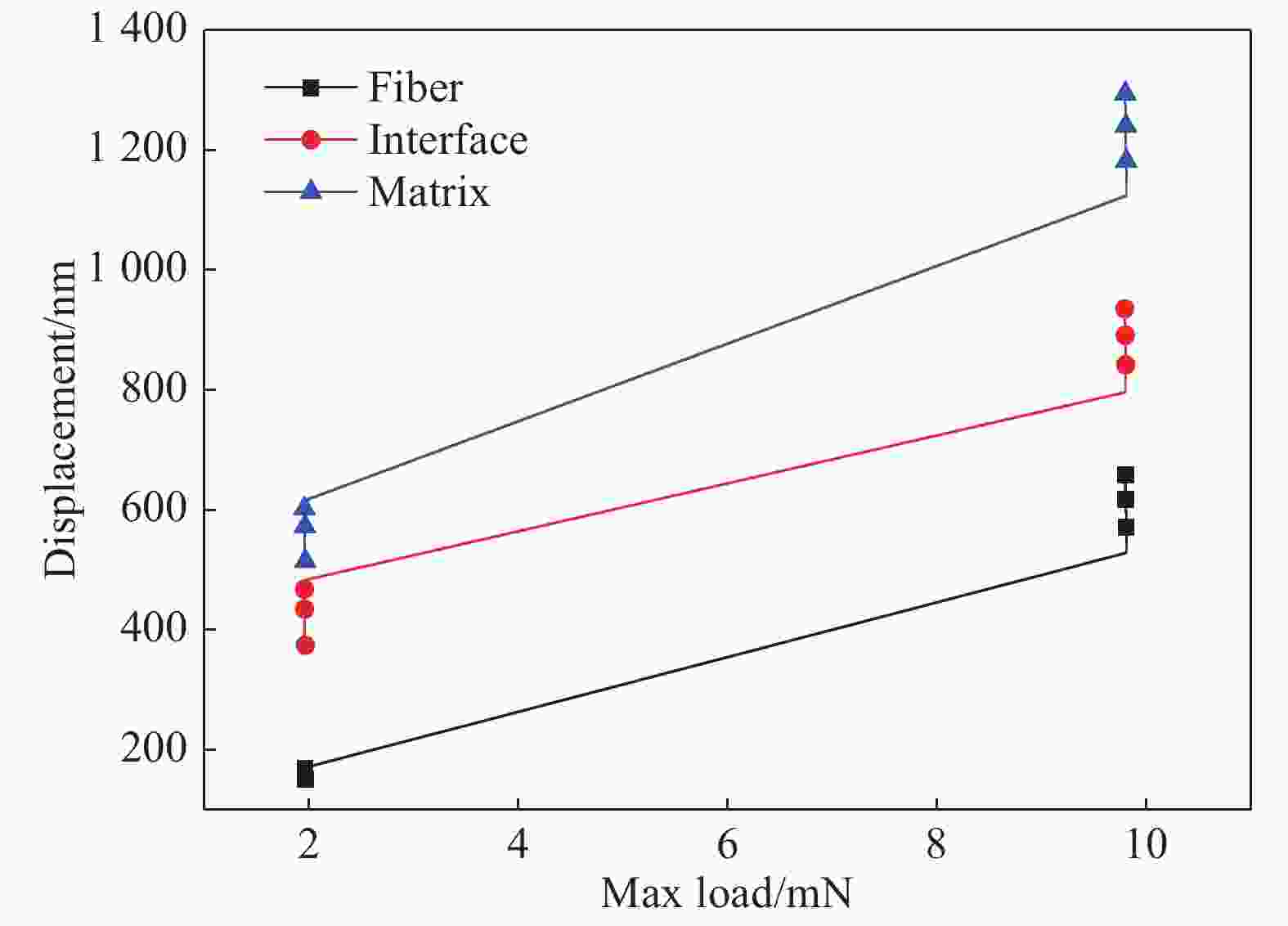

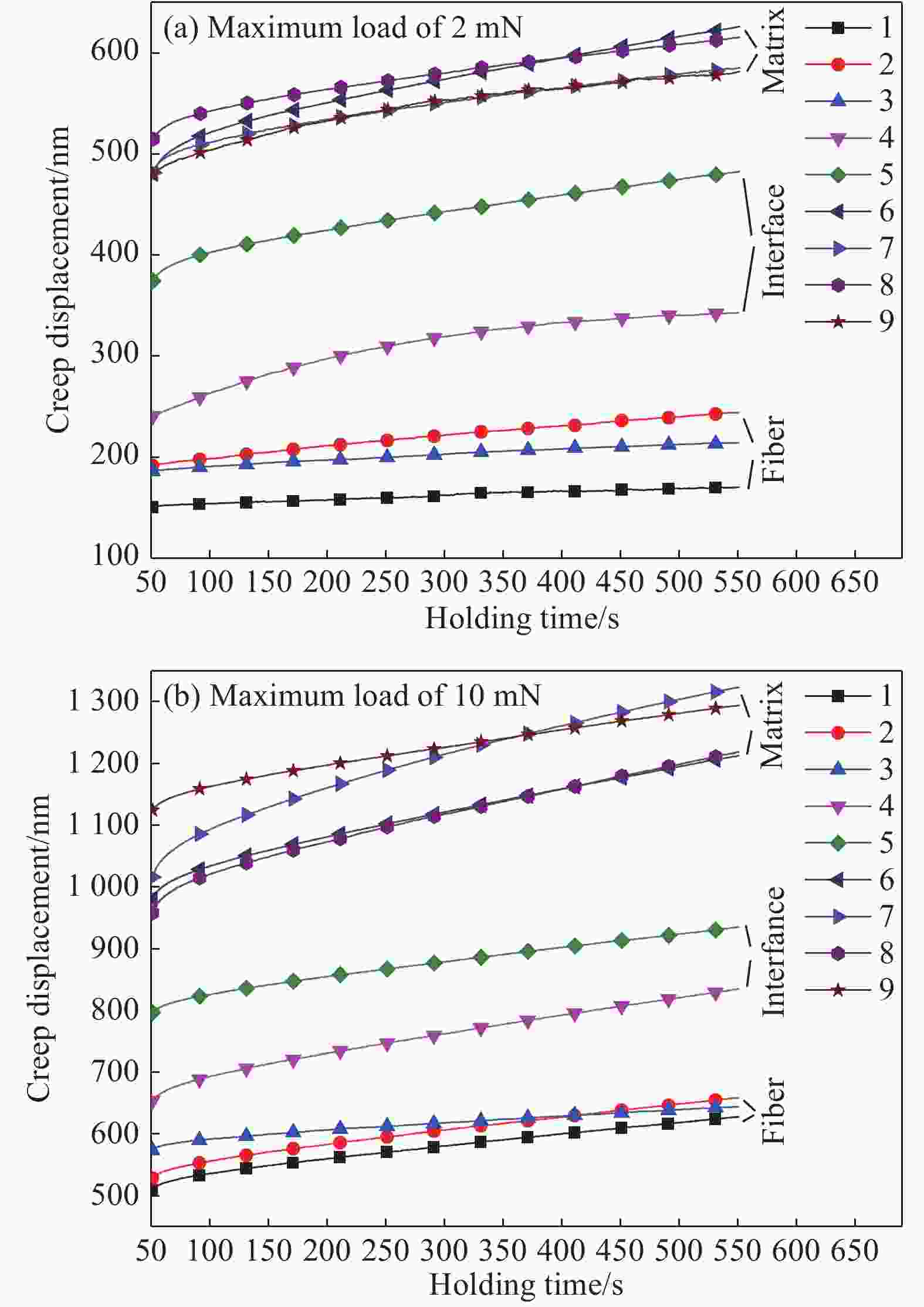

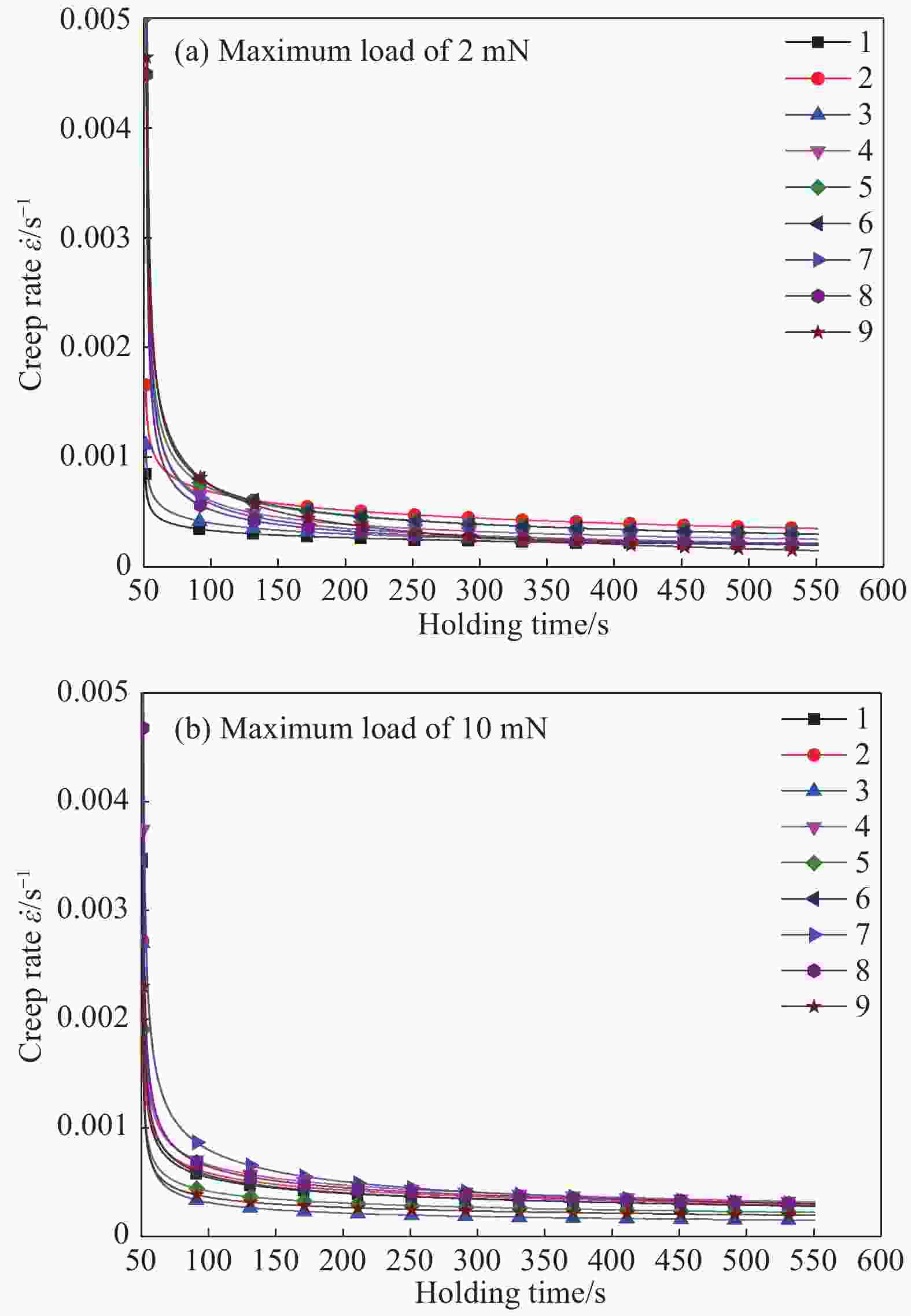

Abstract: Carbon fiber reinforced resin composites are widely used in various fields because of their excellent performance. Since the resin matrix has viscoelastic properties, the composite material synthesized by resin also exhibits viscoelastic behavior. Creep is the most typical type of phenomenon in the viscoelastic deformation, so it is of great significance to study the microcreep properties for carbon fiber reinforced resin composites. Under different peak loads, the microcreep behavior of the resin matrix, interface and fiber for carbon fiber reinforced resin composites were analyzed by nanoindentation technique at room temperature. At the same creep time, the results show that the creep displacements of the fibers which are about 1/3 and 1/2 of the matrix under 2 mN and 10 mN. And the values of interfacial creep displacements are between the fiber and the matrix. The creep rate of steady state creep stage is less than 0.1%. The creep stress indexes of the matrix, interface and fiber are 3.6, 2.9 and 2.1. The first and second complex modulus and the viscosity of the dashpot and creep complicement for the matrix, interface and fiber were obtained using the Kelvin-Voigt model at different peak loads. -

表 1 最大载荷为2 mN的碳纤维增强树脂复合材料的Kelvin-Voigt模型拟合参数

Table 1. Kelvin-Voigt model fitting parameters of carbon fiber reinforced resin composite with maximum load of 2 mN

Fiber Interface Matrix E1/GPa 122.38 40-80 33.39 Ek/GPa 15.47 4-9 3.37 η/(GPa·s) 1 144.25 340-900 319.08 R2 0.96296 0.95341 0.95462 Notes: E1—Complex modulus of the first spring element; Ek—Complex modulus of the second spring; η—Viscosity of the dashpot; R2—Reliability value. 表 2 最大载荷为10 mN的碳纤维增强树脂复合材料的Kelvin-Voigt模型拟合参数

Table 2. Kelvin-Voigt model fitting parameters of carbon fiber reinforced resin composite with maximum load of 10 mN

Fiber Interface Matrix E1/GPa 154.54 35-100 22.34 Ek/GPa 12.70 5-8.5 3.43 η/(GPa·s) 1 042.00 300-1 000 362.50 R2 0.95781 0.96357 0.95493 -

[1] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316.CHEN Y, GE E D, FU Y C, et al. Research status and prospect of hole making technology of carbon fiber reinforced resin matrix composites[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese). [2] 穆霞英. 蠕变力学[M]. 西安: 西安交通大学出版社, 1990: 67.MU X Y. Creep mechanics[M]. Xi'an: Xi'an Jiaotong University Press, 1990: 67. [3] NABARRO F R N, DE VILLIERS H L. The physics of creep[M]. London: Taylor and Francis, 1995: 113. [4] LI W B, HENSHALL J L, HOOPER R M, et al. The mechanisms of indentation creep[J]. Acta Metallurgica et Materialia,1991,39:3099-3110. doi: 10.1016/0956-7151(91)90043-Z [5] 孟龙晖, 杨吟飞, 何宁. 纳米压痕法测量Ti6Al4V钛合金室温蠕变应力指数[J]. 稀有金属材料与工程, 2016, 45(3):617-622.MENG L H, YANG Y F, HE N. Creep stress index of Ti6Al4V titanium alloy at room temperature was measured by nano-indentation[J]. Rare Metal Materials and Engineering,2016,45(3):617-622(in Chinese). [6] RANAIVOMANANA N, STÉPHANE M, TURATSINZE A. Basic creep of concrete under compression, tension and bending[J]. Construction and Building Materials,2013,38(9):173-180. [7] MAHMUDI R, ROUMINA R, RAEISINIA B. Investigation of stress exponent in the power-law creep of Pb-Sb alloys[J]. Materials Science <italic>&</italic> Engineering A (Structural Materials: Properties, Microstructure and Processing),2004,382(1-2):15-22. [8] GAO Y, WEN S P, WANG X H, et al. Investigation on indentation creep by depth sensing indentation[J]. Journal of Aeronautical Materials,2006,26(3):148. [9] MA X, YOSHIDA F. Rate-dependent indentation hardness of a power-law creep solder alloy[J]. Applied Physics Letters,2003,82(2):188-190. doi: 10.1063/1.1537513 [10] 易楠, 顾轶卓, 李敏, 等. 碳纤维复合材料界面结构的形貌与尺寸的表征[J]. 复合材料学报, 2010, 27(5):36-40.YI N, GU Y Z, LI M, et al. Morphology and size characterization of interface structure of carbon fiber composites[J]. Acta Materiae Compositae Sinica,2010,27(5):36-40(in Chinese). [11] 高雪玉, 杨庆生, 刘志远, 等. 基于纳米压痕技术的碳纤维/环氧树脂复合材料各组分原位力学性能测试[J]. 复合材料学报, 2012(5):209-214.GAO X Y, YANG Q S, LIU Z Y, et al. In-situ mechanical properties test of carbon fiber/epoxy composites based on nanoindentation technology[J]. Acta Materiae Compositae Sinica,2012(5):209-214(in Chinese). [12] 徐宏扬, 柯海波, 黄火根, 等. U<sub>65</sub>Fe<sub>30</sub>Al<sub>5</sub>非晶合金的纳米压痕蠕变行为研究[J]. 金属学报, 2017, 53(7):817-823.XU H Y, KE H B, HANG H G, et al. Creep behavior of U<sub>65</sub>Fe<sub>30</sub>Al<sub>5</sub> amorphous alloy in nanometer indentation[J]. Acta Metallurgica Sinica,2017,53(7):817-823(in Chinese). [13] MUZTAHID M, MOHAMMAD M, BRIAN T, et al. Depth-sensing time-dependent response of additively manufactured Ti-6Al-4V alloy[J]. Additive Manufacturing,2018(24):37-46. [14] ZHANG J. Characterization and analysis of delamination fracture and nanocreep, properties in carbon epoxy composites manufactured by different processes[J]. Journal of Composite Materials,2005,40(14):1287-1299. [15] FU K K, SHEPPARD L R, CHANG L, et al. Length-scale-dependent nanoindentation creep behaviour of Ti/Al multilayers by magnetron sputtering[J]. Materials Characterization,2018,139:165-175. doi: 10.1016/j.matchar.2018.02.041 [16] RAMAN V, BERRICHE R. An investigation of the creep processes in tin and aluminum using a depth-sensing indentation technique[J]. Journal of Materials Research,1992,7(3):12. [17] LI H, NGAN A H W. Size effects of nanoindentation creep[J]. Journal of Materials Research,2004,19(2):513-522. doi: 10.1557/jmr.2004.19.2.513 [18] SHEN B L, ITOI T, YAMASAKI T, et al. Indentation creep of nanocrystalline Cu-TiC alloys prepared by mechanical alloying[J]. Scripta Materialia,2000,42(9):893-898. doi: 10.1016/S1359-6462(00)00309-2 [19] FISCHER-CRIPPS A C. A simple phenomenological approach to nanoindentation creep[J]. Materials Science <italic>&</italic> Engineering A (Structural Materials: Properties, Microstructure and Processing),2004,385(1-2):74-82. [20] PENG G, ZHANG T, FENG Y, et al. Determination of shear creep compliance of linear viscoelastic solids by instrumented indentation when the contact area has a single maximum[J]. Journal of Materials Research,2012,27(12):1565-1572. doi: 10.1557/jmr.2012.120 -

下载:

下载: