Preparation and dielectric properties of silanized multi-walled carbon nanotubes/silicone rubber composites

-

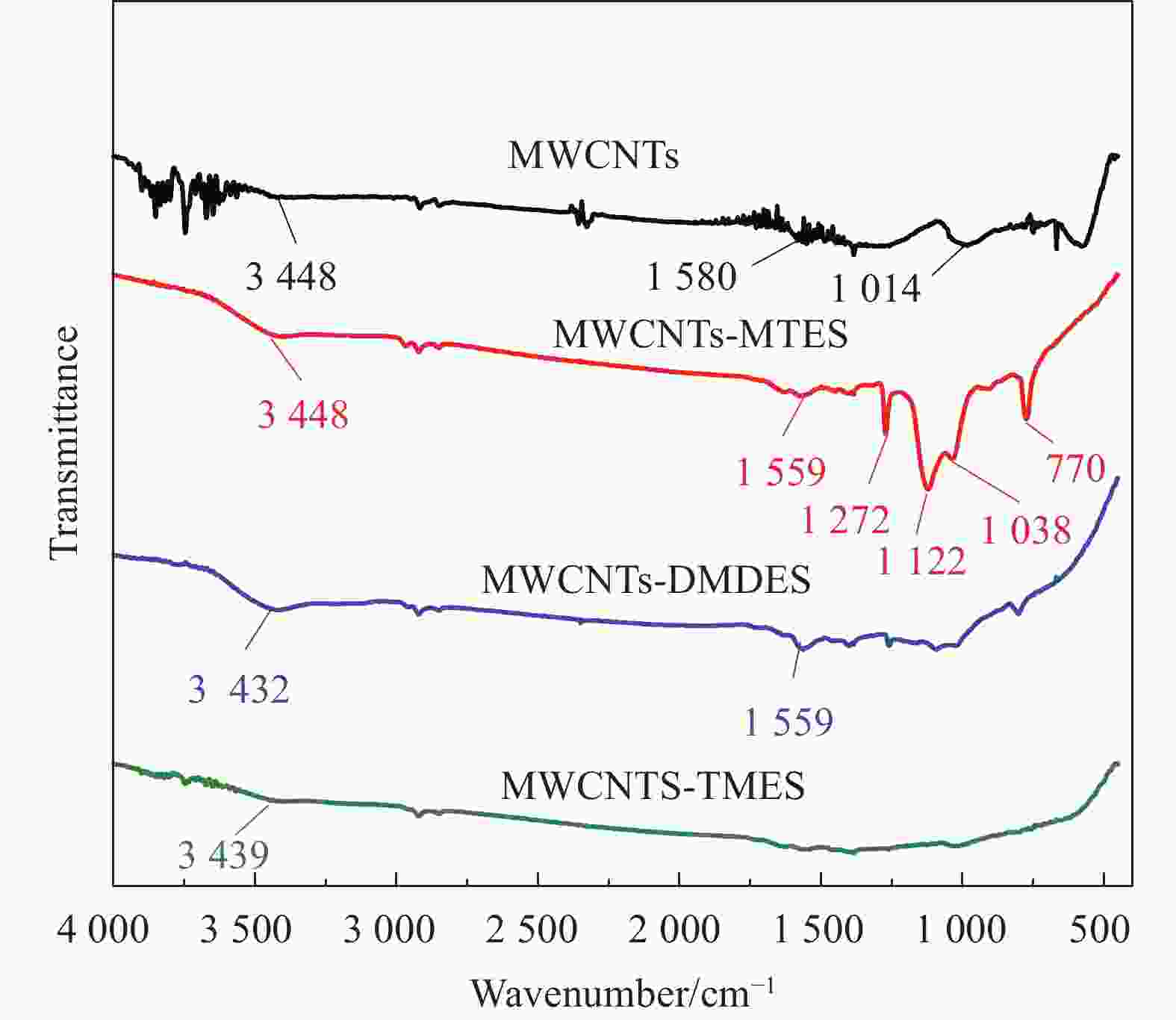

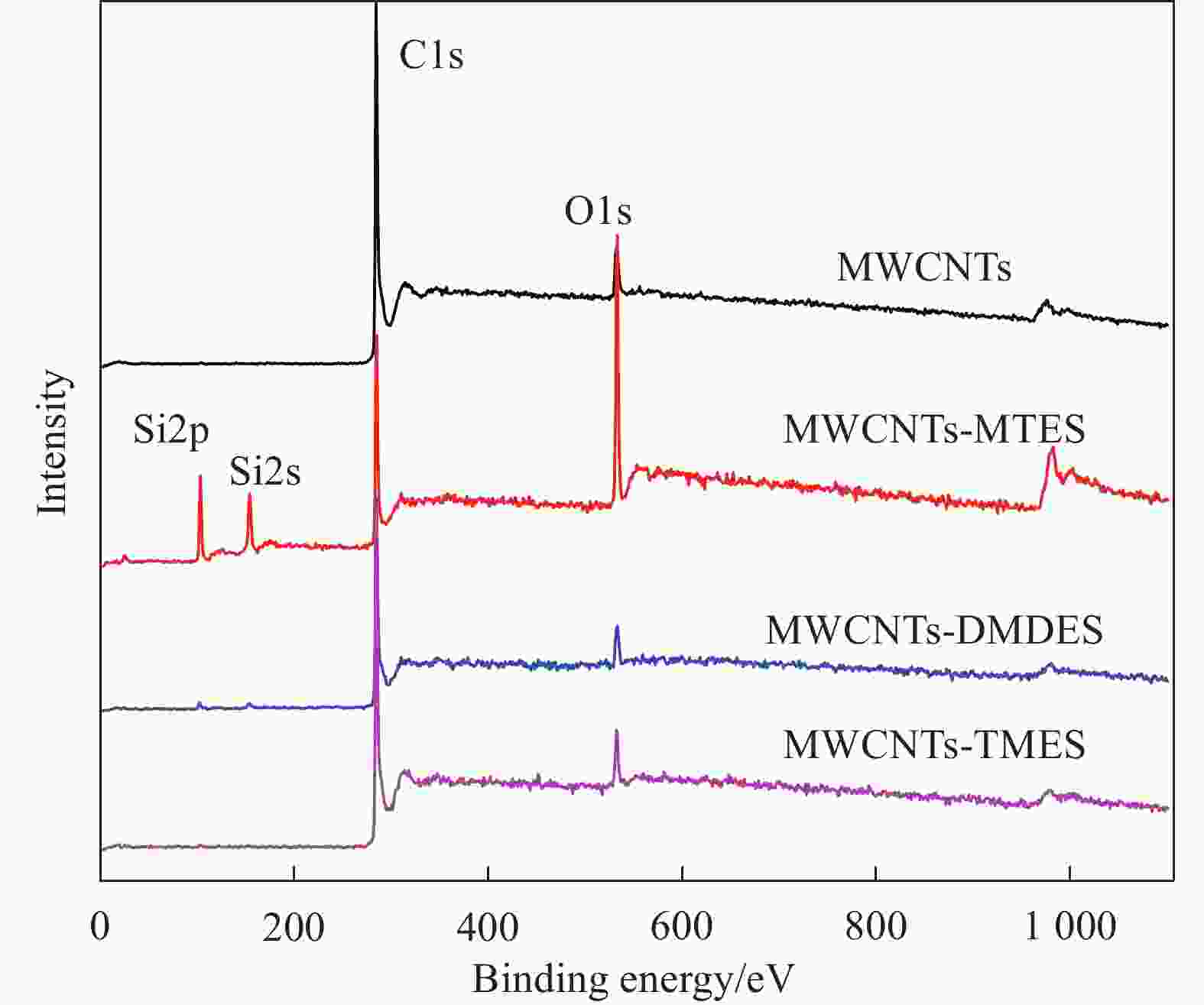

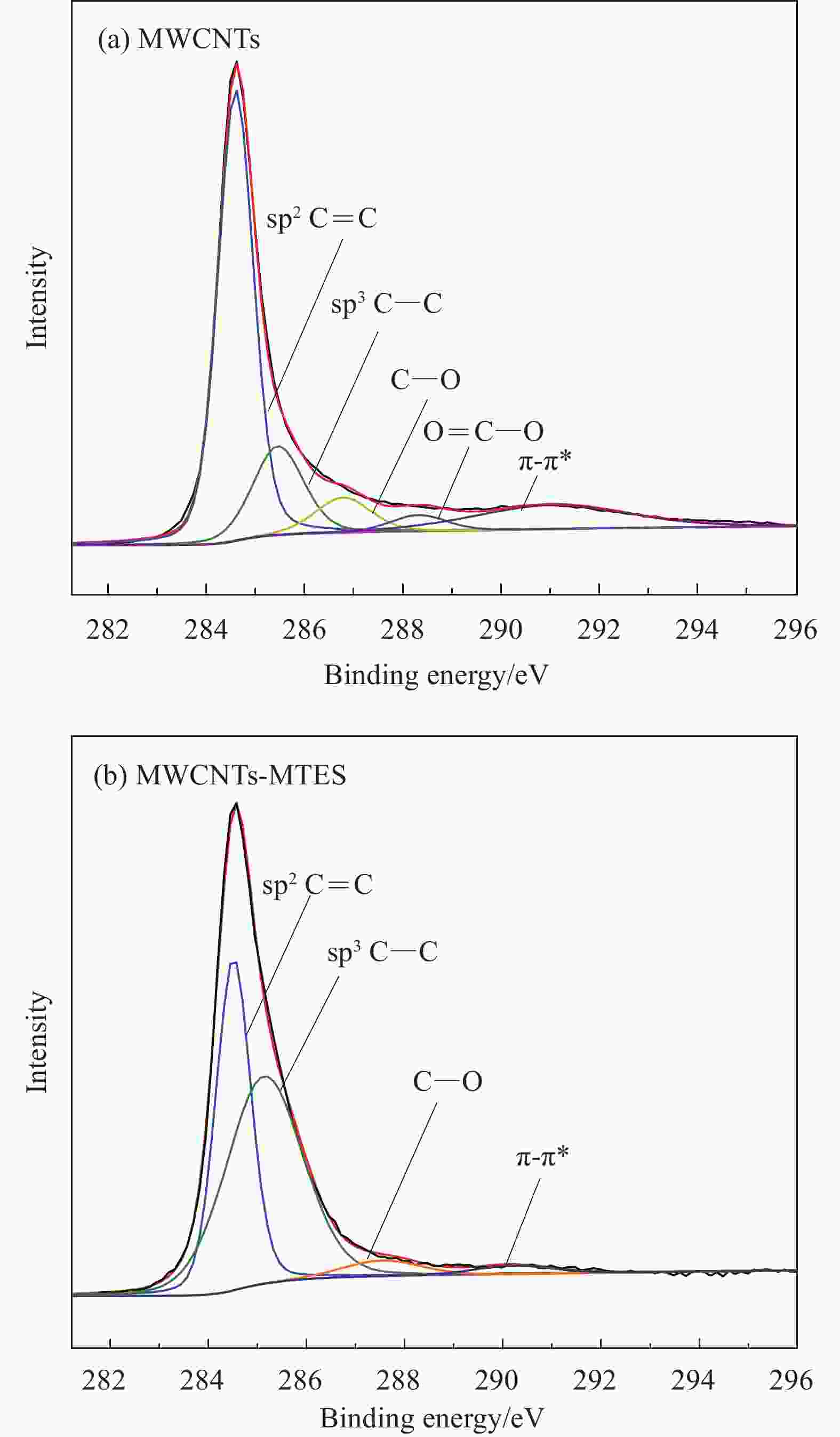

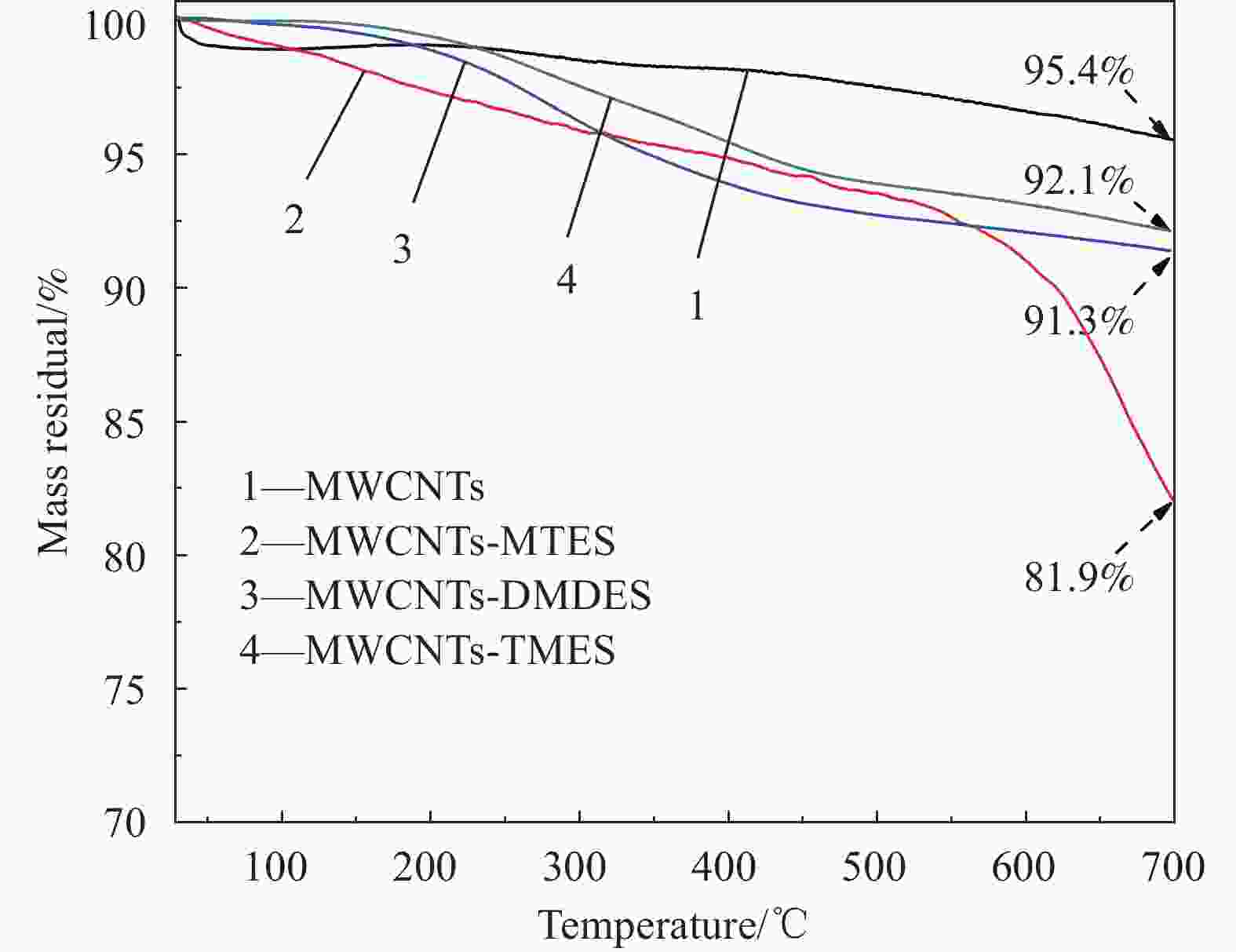

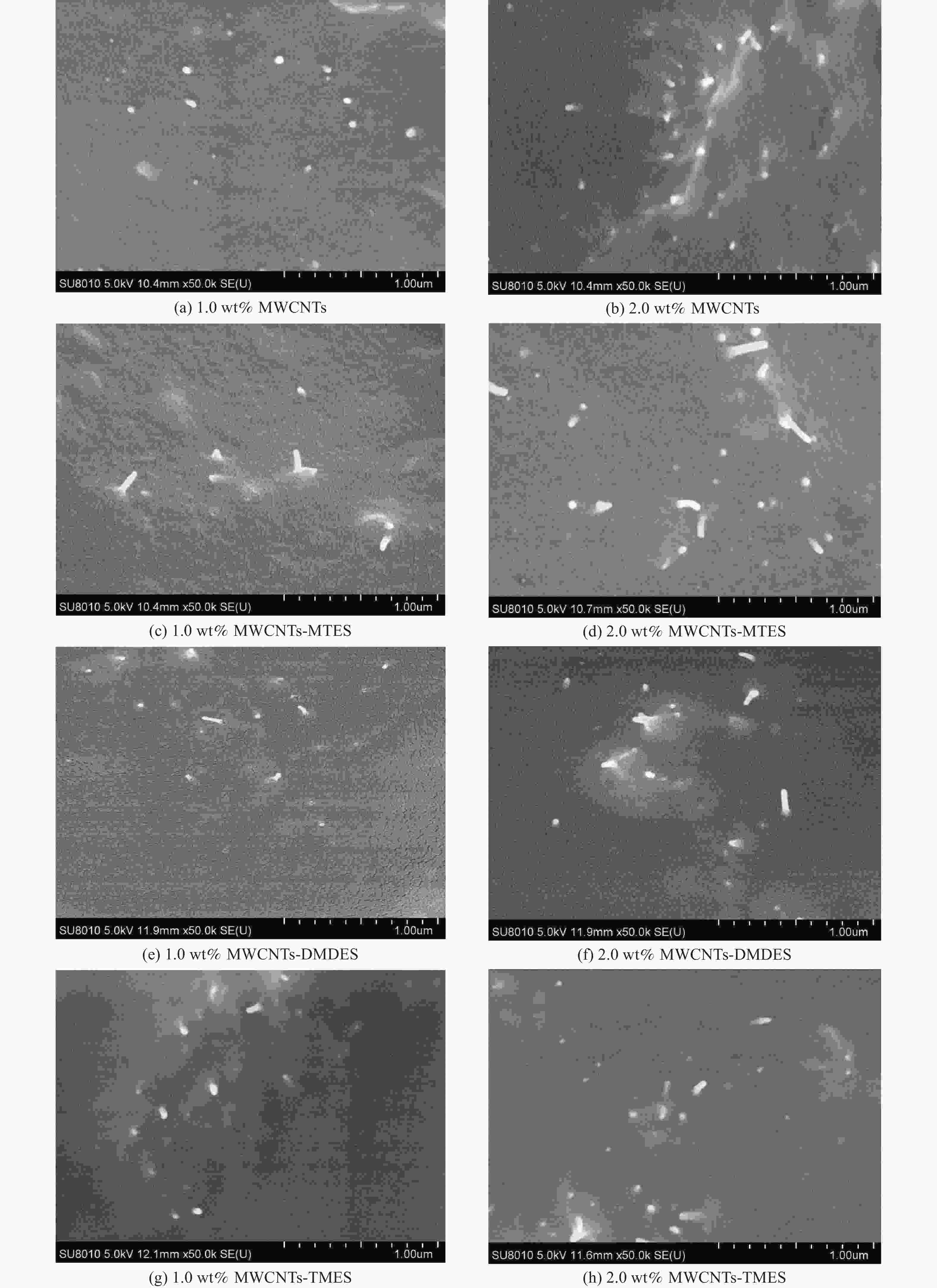

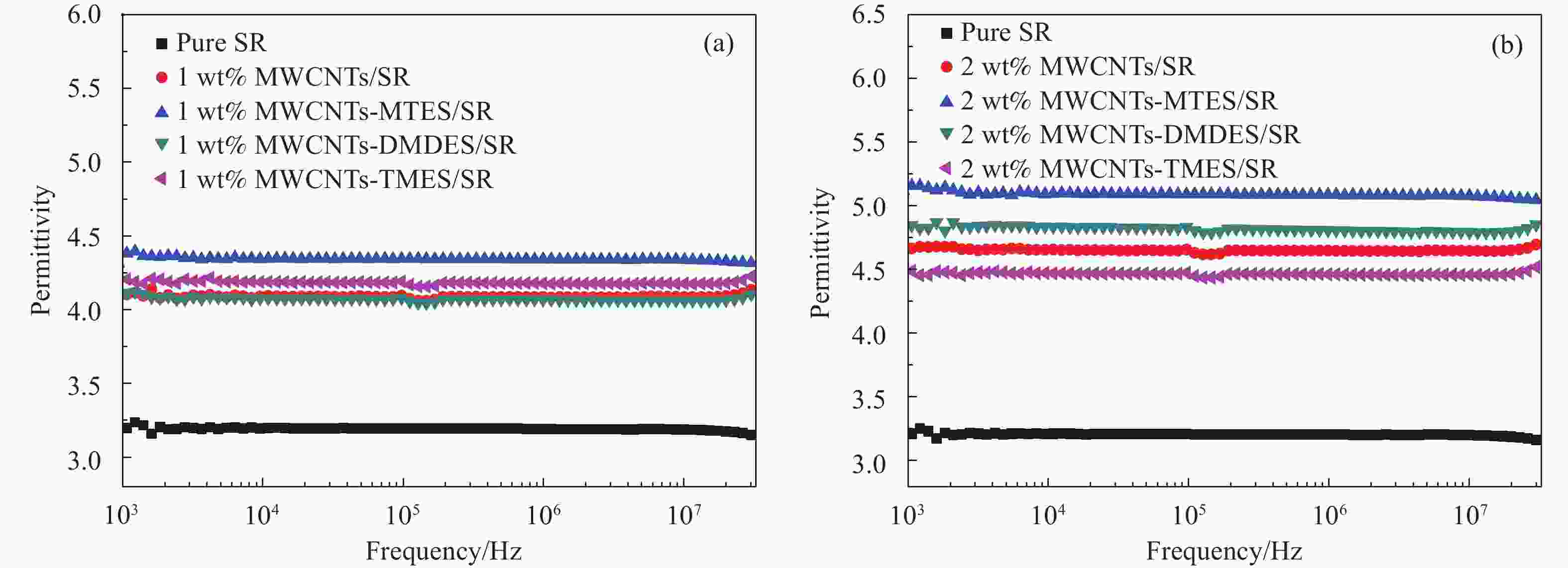

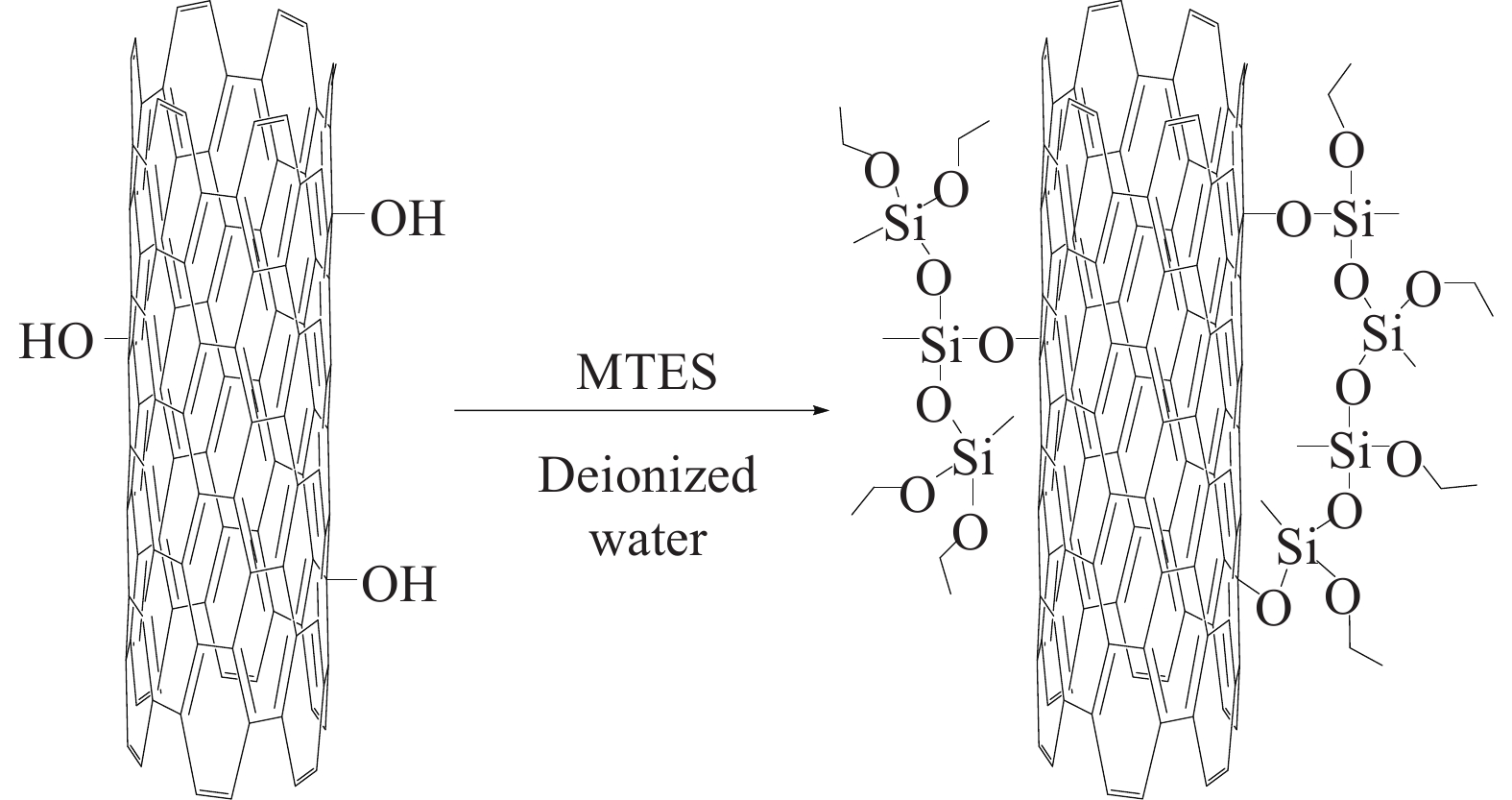

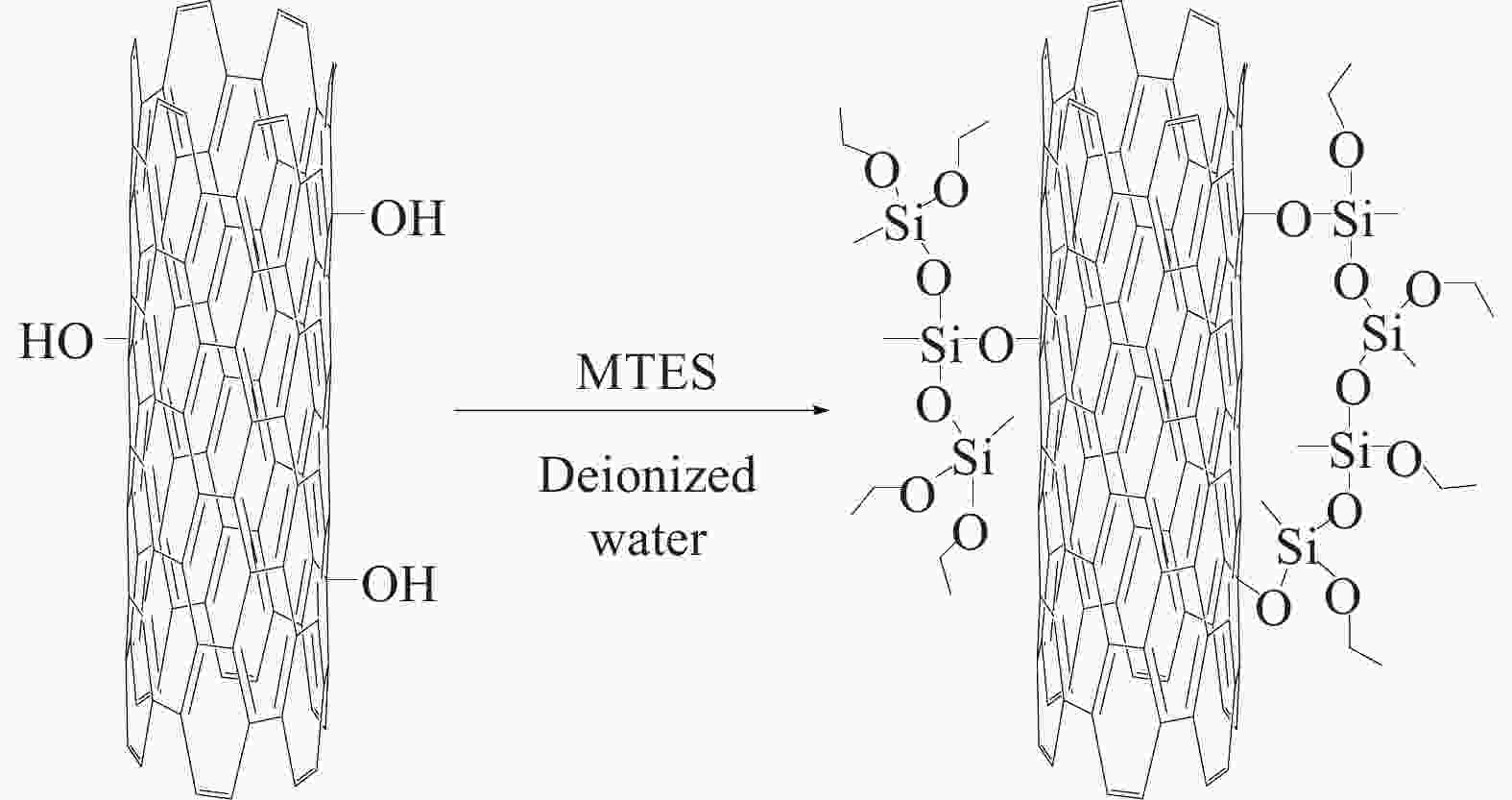

摘要: 采用三种不同官能度的硅烷偶联剂(甲基三乙氧基硅烷(MTES)、二甲基二乙氧基硅烷(DMDES)及三甲基乙氧基硅烷(TMES))在有水条件下对多壁碳纳米管(MWCNTs)进行表面改性,通过FTIR、XPS、TG及SEM表征了MWCNTs改性前和改性后的化学结构。采用机械共混法制备了MWCNTs/硅橡胶(SR)复合材料。SEM结果表明,将不同质量分数的MWCNTs、MWCNTs-MTES、MWCNTs-DMDES和MWCNTs-TMES填充到SR中,硅烷改性可以降低MWCNTs间的相互作用,改善其在SR中的分散性。拉伸试验结果表明,改性MWCNTs与SR之间的相互作用增强,二者的相容性得到改善。当改性MWCNTs含量≤2wt%时,MWCNTs/SR复合材料的弹性模量无明显变化。介电性能测试结果表明,当MWCNTs-MTES质量分数为2wt% 时,MWCNTs-MTES/SR复合材料在104 Hz时介电常数达到5.02,较纯硅橡胶提高了57%,而介电损耗仍低于0.01,保持在极低水平。Abstract: The three different silane coupling agents (methyltriethoxysilane (MTES), dimethyldiethoxysilane (DMDES) and trimethylethoxysilane (TMES)) were used to modify the surface of multi-walled carbon nanotubes (MWCNTs) under the hydrous conditions. The chemical structures of MWCNTs before and after modification were characterized by FTIR, XPS, TG and SEM. The different mass fractions of MWCNTs, MWCNTs-MTES, MWCNTs-DMDES and MWCNTs-TMES were filled in silicone rubber (SR). The MWCNTs/SR composites were prepared by mechanical blending. SEM images show that the silane modification can reduce the interaction between MWCNTs and improve their dispersion in SR. The tensile tests show that the interaction between MWCNTs and SR is enhanced and the compatibility between them is improved. The elastic modulus of the MWCNTs/SR composites shows no obvious change when the contents of modified MWCNTs are within 2wt%. The dielectric constant of MWCNTs/SR composite reaches 5.02 (at 104 Hz) when filled with 2wt% modified MWCNTs-MTES, which is 57% higher than that of the pure SR, while the dielectric loss is still less than 0.01 (at 104 Hz).

-

表 1 甲基三乙氧基硅烷(MTES)、二甲基二乙氧基硅烷(DMDES)及三甲基乙氧基硅烷(TMES)硅烷偶联剂的官能度

Table 1. Functionality of methyltriethoxysilane(MTES), dimethyldiethoxysilane(DMDES) and trimethylethoxysilane(TMES) sliane coupling agents

Sliane coupling agent Functionality MTES 3 DMDES 2 TMES 1 表 2 MWCNTs和MWCNTs-MTES的主要元素及含量

Table 2. Summary of element compositions of MWCNTs and MWCNTs-MTES

Core level MWCNTs MWCNTs-MTES Peak/eV Content/at% Peak/eV Content/at% C 1s 254.05 96.25 284.94 53.64 O1s 532.94 3.75 532.94 30.95 Si 2p − − 102.98 15.41 表 3 MWCNTs和MWCNTs-MTES的C 1s结合方式及含量

Table 3. C 1s peak affiliations and contents of MWCNTs and MWCNTs-MTES

Core level MWCNTs MWCNTs‒MTES Peak/eV Atm/at% Peak/eV Atm/at% sp2 C=C 284.62 58.90 284.59 40.01 sp3 C—C 285.48 16.67 285.21 53.59 C—O 286.79 7.62 287.60 4.09 O=C—O 288.32 3.37 − − π-π* C 291.02 13.44 290.25 2.31 表 4 MWCNTs/SR、MWCNTs-MTES/SR、MWCNTs-DMDES/SR及MWCNTs-TMES/SR复合材料的拉伸性能

Table 4. Tensile properties of MWCNTs/SR, MWCNTs-MTES/SR, MWCNTs-DMDES/SR and MWCNTs-TMES/SR composites

Sample Mass fraction of MWCNTs/wt% Tensile strength/MPa Elongation at break/% Young’s modulus/MPa Pure SR − 0.26 408 0.12 MWCNTs/SR 0.5 0.23 348 0.15 1.0 0.19 288 0.12 1.5 0.17 248 0.14 2.0 0.19 361 0.12 MWCNTs-MTES/SR 0.5 0.20 204 0.15 1.0 0.25 308 0.15 1.5 0.23 304 0.14 2.0 0.27 354 0.14 MWCNTs-DMDES/SR 0.5 0.23 294 0.16 1.0 0.21 251 0.15 1.5 0.20 228 0.16 2.0 0.19 301 0.13 MWCNTs-TMES/SR 0.5 0.17 208 0.14 1.0 0.18 218 0.14 1.5 0.17 244 0.13 2.0 0.16 291 0.11 表 5 MWCNTs/SR、MWCNTs-MTES/SR、MWCNTs-DMDES/SR和MWCNTs-TMES/SR复合材料在104 Hz的介电常数及介电损耗

Table 5. Permittivities and dielectric losses of MWCNTs/SR, MWCNTs-MTES/SR, MWCNTs-DMDES/SR and MWCNTs-TMES/SR composites at 104 Hz

Sample Mass fraction of MWCNTs/wt% Permittivity Dielectric loss/10−3 Pure SR − 3.19 0.87 MWCNTs/SR 1.0 4.01 0.99 2.0 4.60 1.75 MWCNTs-MTES/SR 1.0 4.35 0.98 2.0 5.02 1.02 MWCNTs-DMDES/SR 1.0 4.07 1.21 2.0 4.77 1.92 MWCNTs-TMES/SR 1.0 4.18 0.83 2.0 4.42 1.42 -

[1] BROCHU P, PEI Q B. Advances in dielectric elastomers for actuators and artificial muscles[J]. Macromolecular Rapid Communications,2010,31(1):10-36. doi: 10.1002/marc.200900425 [2] PELRINE R, KORNBLUH R, PEI Q B, et al. High-speed electrically actuated elastomers with strain greater than 100%[J]. Science,2000,287(5454):836-839. doi: 10.1126/science.287.5454.836 [3] JORDI C, MICHEL S, KOVACS G, et al. Scaling of planar dielectric elastomer actuators in an agonist-antagonist configuration[J]. Sensors and Actuators A: Physical,2010,161(1-2):182-190. [4] LÖWE C, ZHANG X Q, KOVACS G, et al. Dielectric elastomers in actuator technology[J]. Advanced Engineering Materials,2005,7(5):361-367. doi: 10.1002/adem.200500066 [5] MADSEN F B, DAUGAARD A E, HVILSTED S, et al. The current state of silicone-based dielectric elastomer transducers[J]. Macromolecular Rapid Communications,2016,37(5):378-413. doi: 10.1002/marc.201500576 [6] ŞTIUBIANU G, SOROCEANU A, VARGANICI C D, et al. Dielectric elastomers based on silicones filled with transitional metal complexes[J]. Composites Part B: Engineering,2016,93:236-243. doi: 10.1016/j.compositesb.2016.03.005 [7] RACLES C, ALEXANDRU M, BELE A, et al. Chemical modification of polysiloxanes with polar pendant groups by co-hydrosilylation[J]. RSC Advances,2014,4(71):37620-37628. doi: 10.1039/C4RA06955B [8] GUO J, WANG X, JIA Z, et al. Nonlinear electrical properties and field dependency of BST and nano-ZnO-doped silicone rubber composites[J]. Molecules,2018,23(12):3153. doi: 10.3390/molecules23123153 [9] SHI Z, WANG J, MAO F, et al. Significantly improved dielectric performances of sandwich-structured polymer composites induced by alternating positive-k and negative-k layers[J]. Journal of Materials Chemistry A,2017,5(28):14575-14582. doi: 10.1039/C7TA03403B [10] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature,1991,354(6348):56-58. doi: 10.1038/354056a0 [11] 王劭妤, 石坚, 郑来云. 碳纳米管/PLA 复合材料制备及性能[J]. 复合材料学报, 2012, 29(6):50-54.WANG S Y, SHI J, ZHENG L Y. Preparation and properties of CNTs/PLA composites[J]. Acta Materiae Compositae Sinica,2012,29(6):50-54(in Chinese). [12] 胡松青, 吕强, 王志坤, 等. 碳纳米管/聚合物复合材料界面结合性能的研究进展[J]. 复合材料学报, 2017, 34(1):12-22.HU S Q, LV Q, WANG Z K, et al. Advances in the interfacial bonding characteristics of carbon nanotube/polymer composites[J]. Acta Materiae Compositae Sinica,2017,34(1):12-22(in Chinese). [13] 李洪峰, 曲春艳, 王德志, 等. 酸化处理多壁碳纳米管/氰酸酯树脂复合材料性能[J]. 复合材料学报, 2018, 35(11):2973-2978.LI H F, QU C Y, WANG D Z, et al. Properties of acid treated multi-walled carbon nanotubes/cyanate ester resin composites[J]. Acta Materiae Compositae Sinica,2018,35(11):2973-2978(in Chinese). [14] AGRAWAL S, OJHA K S, SAHU D. Structural and dielectric studies of MWCNT reinforced microcellular silicone elastomer nanocomposite[J]. Materials Today: Proceedings,2015,2(9):4516-4520. doi: 10.1016/j.matpr.2015.10.065 [15] 李海, 观姗姗, 赵树高, 等. 多壁碳纳米管协同改性及高介电纳米复合材料的制备[J]. 绝缘材料, 2017, 50(2):18-23.LI H, GUAN S S, ZHAO S G, et al. Synergistic modification of multi-walled carbon nanotubes and preparation of nanocomposites with high dielectric constant[J]. Insulating Materials,2017,50(2):18-23(in Chinese). [16] PONNAMMA D, RAMACHANDRAN R, HUSSAIN S, et al. Free-volume correlation with mechanical and dielectric properties of natural rubber/multi walled carbon nanotubes composites[J]. Composites Part A: Applied Science and Manufacturing,2015,77:164-171. doi: 10.1016/j.compositesa.2015.06.023 [17] WILDER J W G, VENEMA L C, RINZLER A G, et al. Electronic structure of atomically resolved carbon nanotubes[J]. Nature,1998,391:59-62. doi: 10.1038/34139 [18] LU W, CHOU T W. Analysis of the entanglements in carbon nanotube fibers using a self-folded nanotube model[J]. Journal of the Mechanics and Physics of Solids,2011,59(3):511-524. doi: 10.1016/j.jmps.2011.01.004 [19] KONG J, TONG Y, SUN J, et al. Electrically conductive PDMS-grafted CNTs-reinforced silicone elastomer[J]. Composites Science and Technology,2018,159:208-215. doi: 10.1016/j.compscitech.2018.02.018 [20] AVILÉS F, CAUICH-RODRÍGUEZ J V, TORO-ESTAY P, et al. Improving carbon nanotube/polymer interactions in nanocomposites[M]. Amsterdam: Elsevier, 2018. [21] JIANG M J, DANG Z M, YAO S H, et al. Effects of surface modification of carbon nanotubes on the microstructure and electrical properties of carbon nanotubes/rubber nanocomposites[J]. Chemical Physics Letters,2008,457(4-6):352-356. doi: 10.1016/j.cplett.2008.04.022 [22] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic: Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [23] VENNERBERG D, RUEGER Z, KESSLER M R. Effect of silane structure on the properties of silanized multiwalled carbon nanotube-epoxy nanocomposites[J]. Polymer,2014,55(7):1854-1865. doi: 10.1016/j.polymer.2014.02.018 [24] 董晓娜, 杨一兵, 陈衍华, 等. 多壁碳纳米管/有机硅改性环氧树脂复合材料的研制[J]. 中国胶粘剂, 2015, 24(7):31-34.DONG X N, YANG Y B, CHEN Y H, et al. Study on preparing MWCNTs/organic silicon modified epoxy resin composite[J]. China Adhesives,2015,24(7):31-34(in Chinese). [25] FAN X, PENG W, LI Y, et al. Deoxygenation of exfoliated graphite oxide under alkaline conditions: A green route to graphene preparation[J]. Advanced Materials,2008,20(23):4490-4493. doi: 10.1002/adma.200801306 [26] YANÁMA X. Hyperbranched polysiloxane grafted graphene for improved tribological performance of bismaleimide composites[J]. RSC Advances,2015,5(17):12578-12582. doi: 10.1039/C4RA13134G [27] 吴小利, 岳涛, 陆荣荣, 等. 碳纳米管的表面修饰及FTIR、Raman和XPS光谱表征[J]. 光谱学与光谱分析, 2005, 25(10):1595-1598. doi: 10.3321/j.issn:1000-0593.2005.10.016WU X L, YUE T, LU R R, et al. Hydrothermo-assisted functionalization, FTIR, Raman and XPS spectra characterization of carbon nanotubes[J]. Spectroscopy and Spectral Analysis,2005,25(10):1595-1598(in Chinese). doi: 10.3321/j.issn:1000-0593.2005.10.016 [28] YAGHOUBI A, NIKJE M M A. Silanization of multi-walled carbon nanotubes and the study of its effects on the properties of polyurethane rigid foam nanocomposites[J]. Composites Part A: Applied Science and Manufacturing,2018,109:338-344. doi: 10.1016/j.compositesa.2018.03.028 [29] KONG J, SUN J, TONG Y, et al. Carbon nanotubes-bridged-fumed silica as an effective binary nanofillers for reinforcement of silicone elastomers[J]. Composites Science and Technology,2019,169:232-241. doi: 10.1016/j.compscitech.2018.11.006 [30] GALLONE G, GALANTINI F, CARPI F. Perspectives for new dielectric elastomers with improved electromechanical actuation performance: Composites versus blends[J]. Polymer International,2010,59(3):400-406. doi: 10.1002/pi.2765 [31] YANG D, ZHANG L, LIU H, et al. Lead magnesium niobate-filled silicone dielectric elastomer with large actuated strain[J]. Journal of Applied Polymer Science,2012,125(3):2196-2201. doi: 10.1002/app.36428 -

下载:

下载: