Preparation of surface functionalized nano SiO2 and its application in solution polymerized styrene butadiene rubber-polybutadiene rubber

-

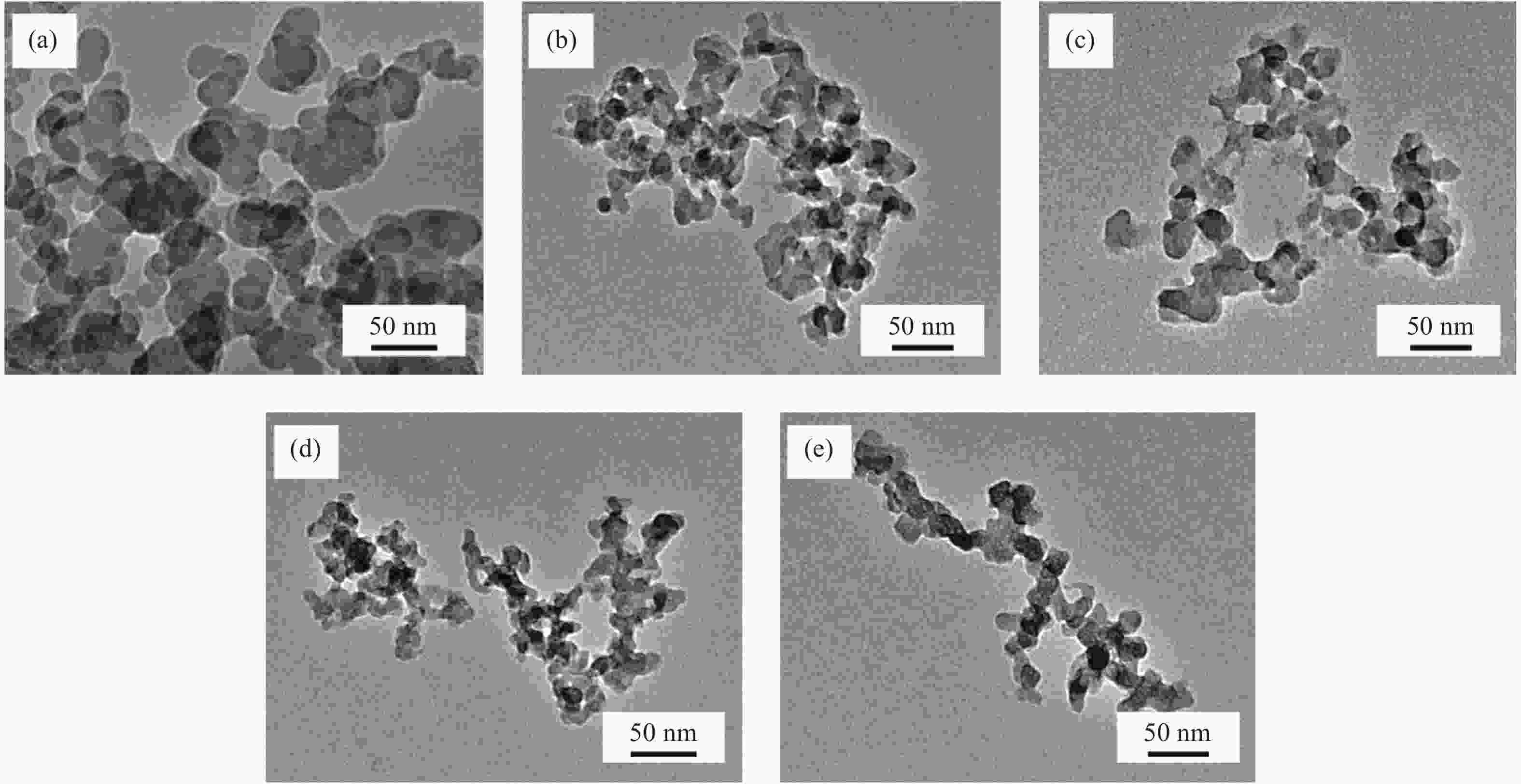

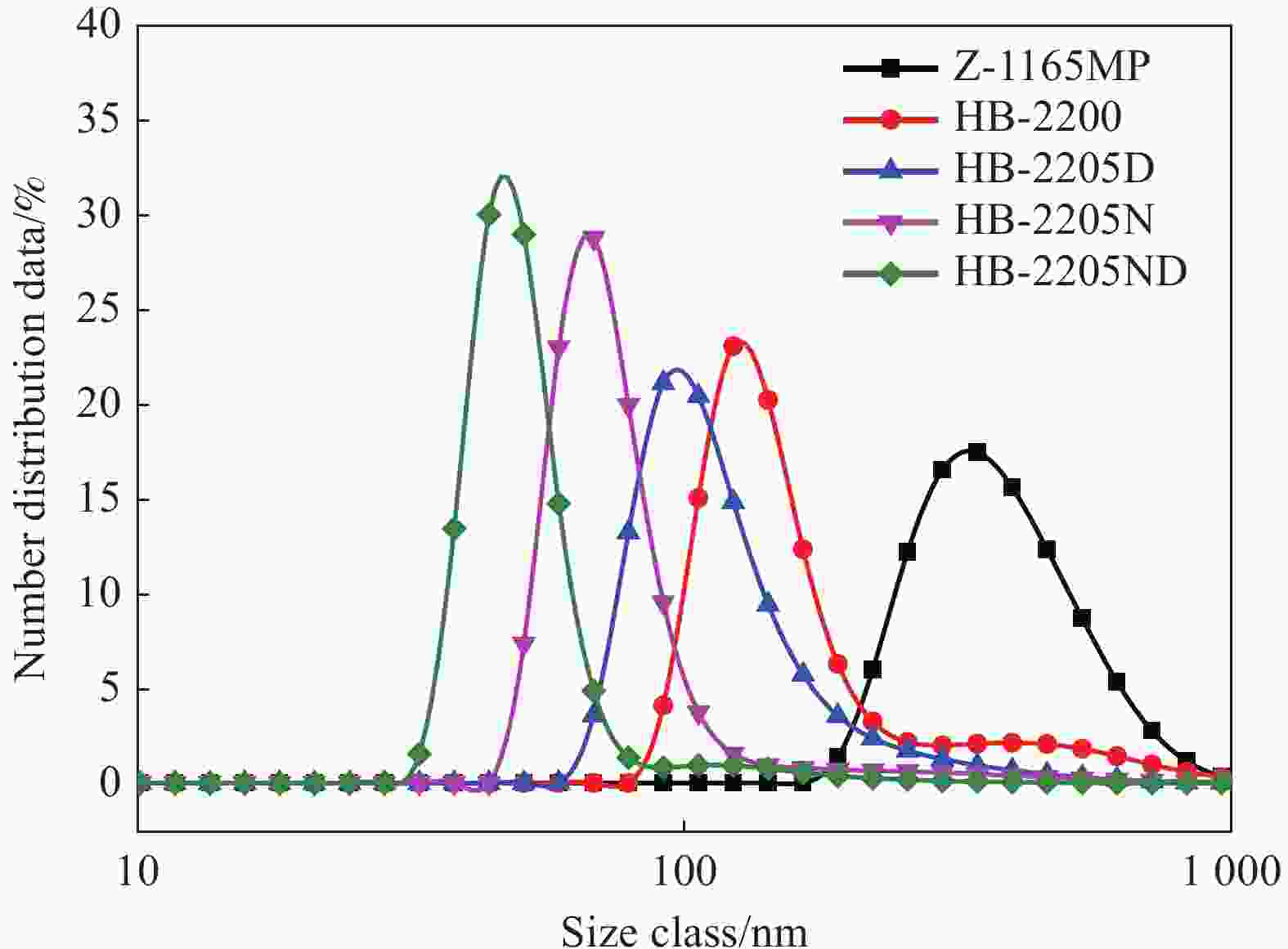

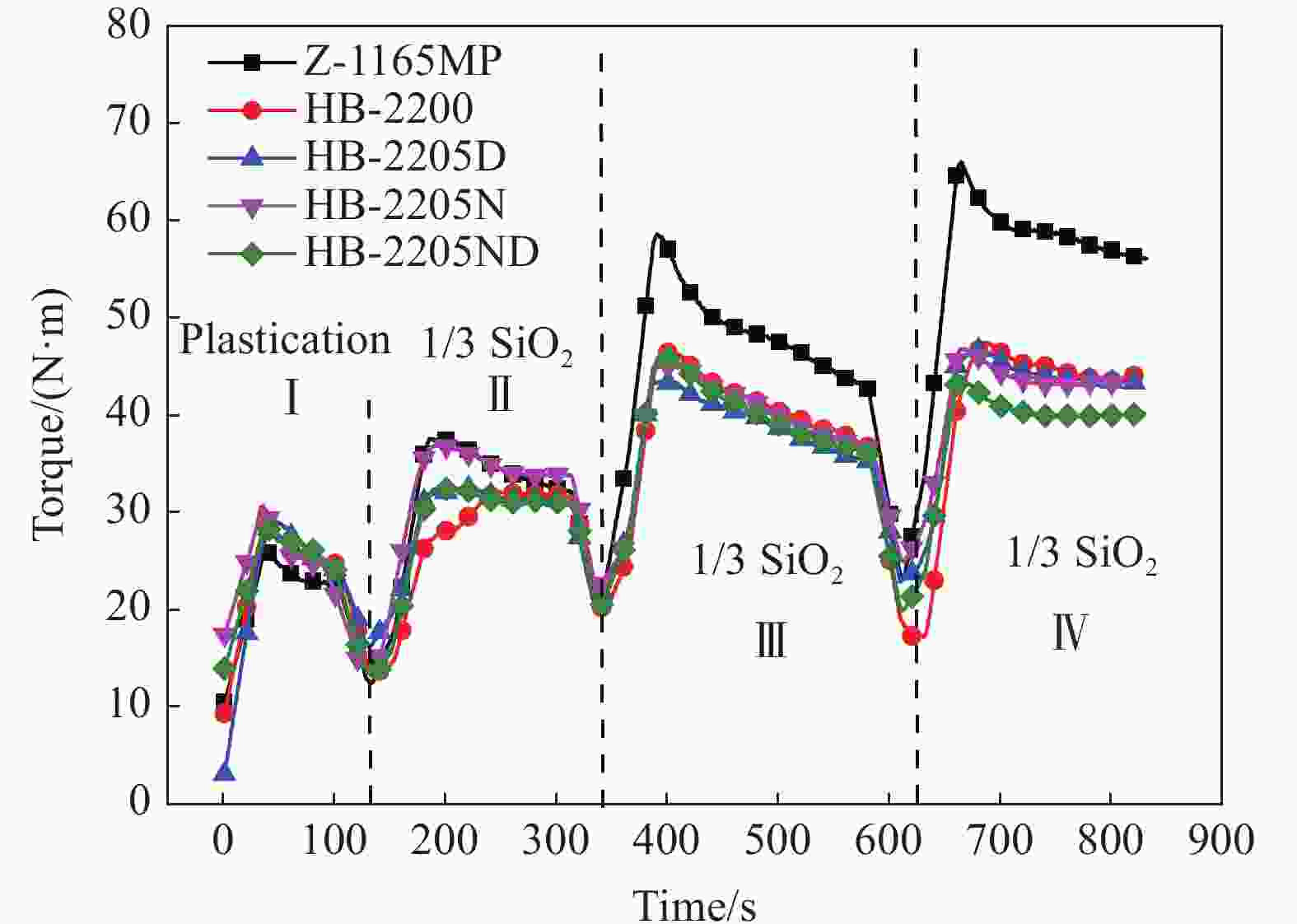

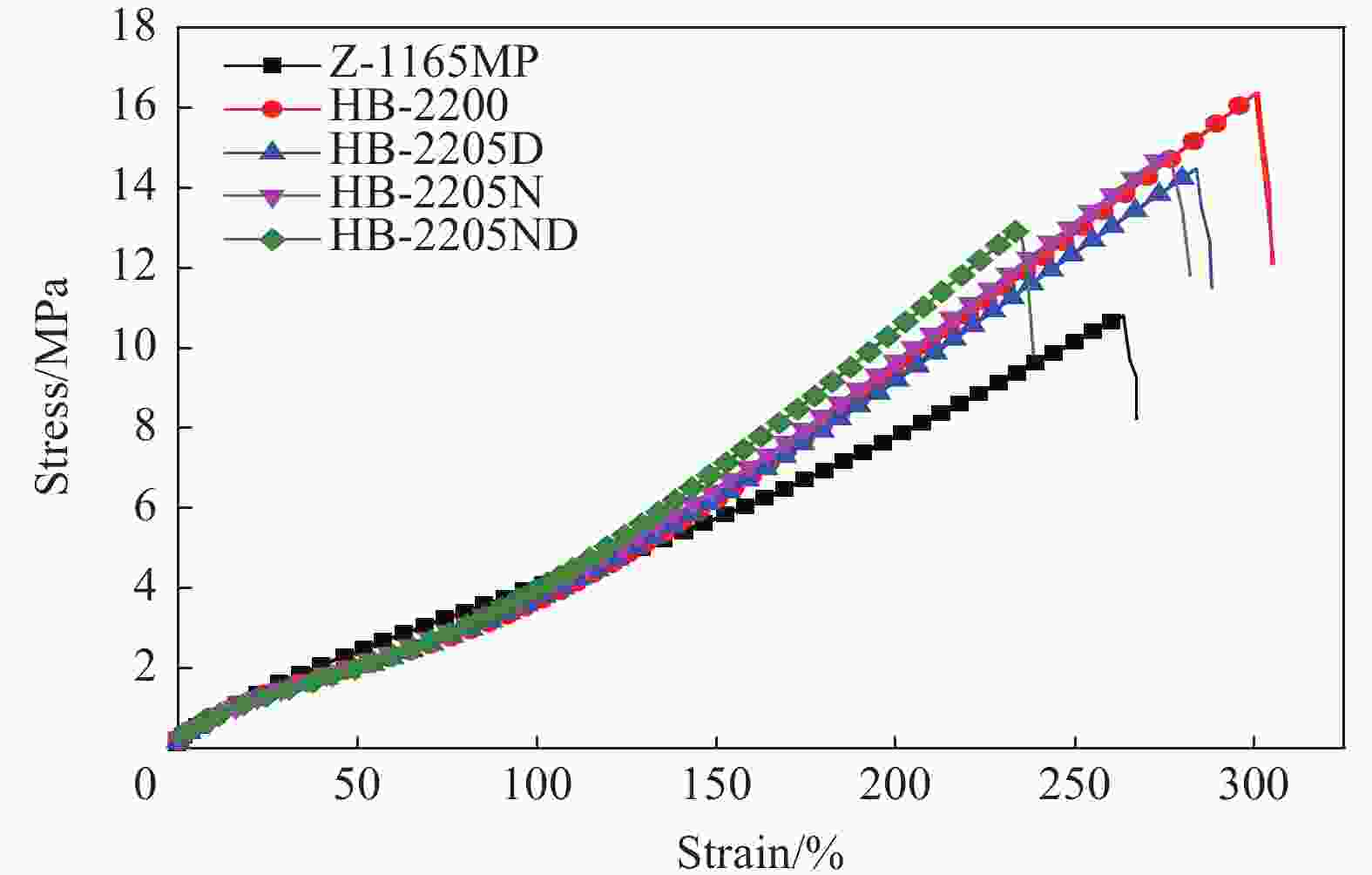

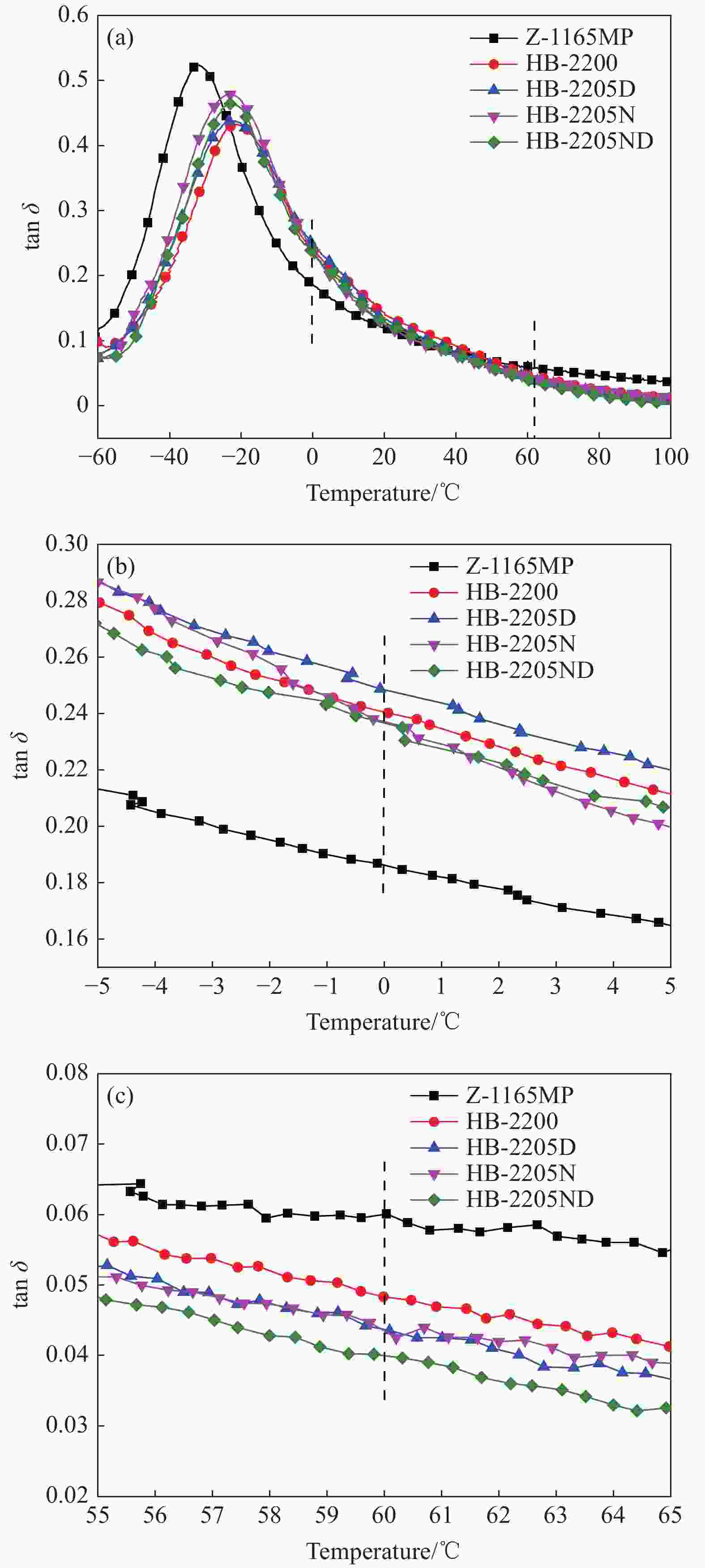

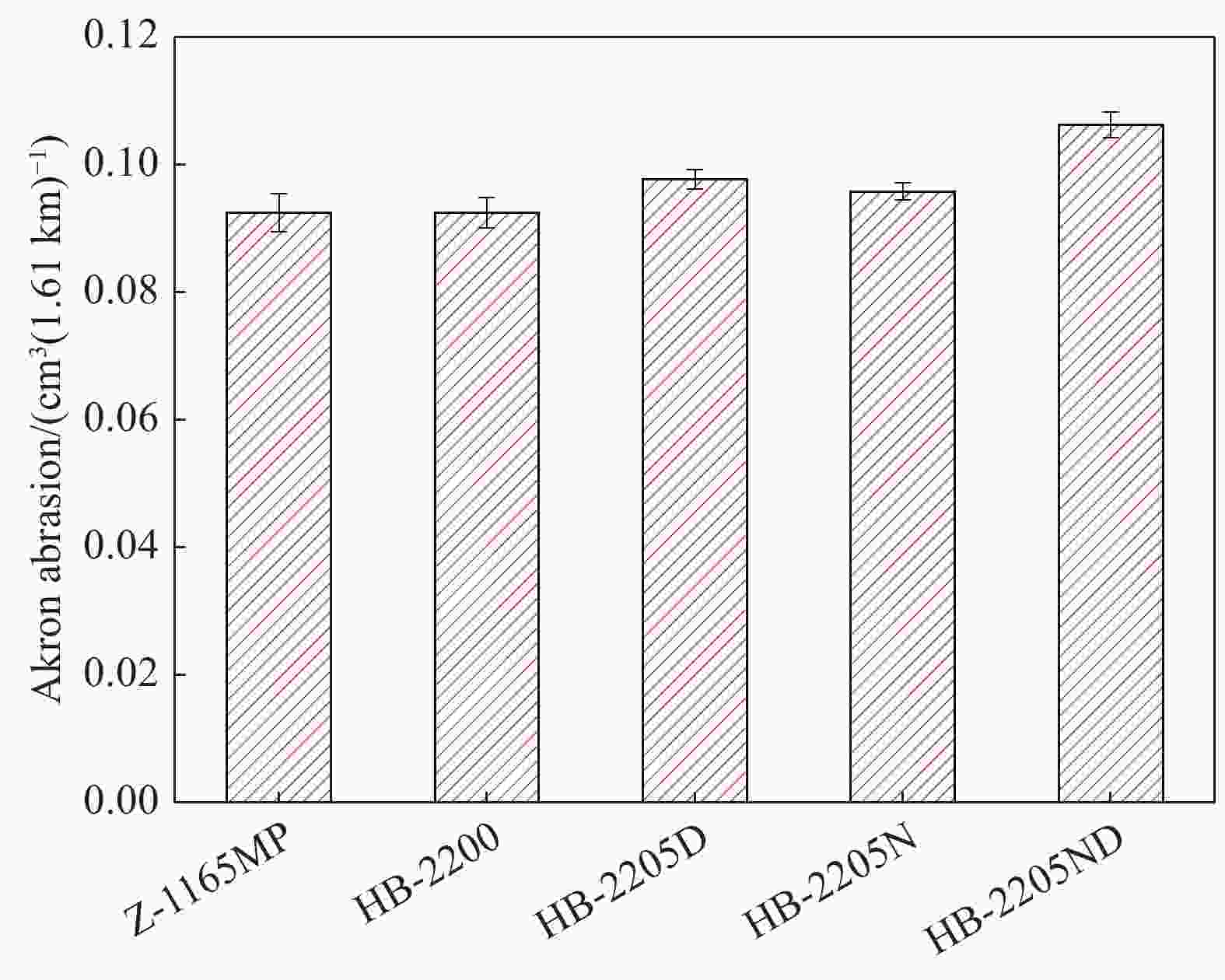

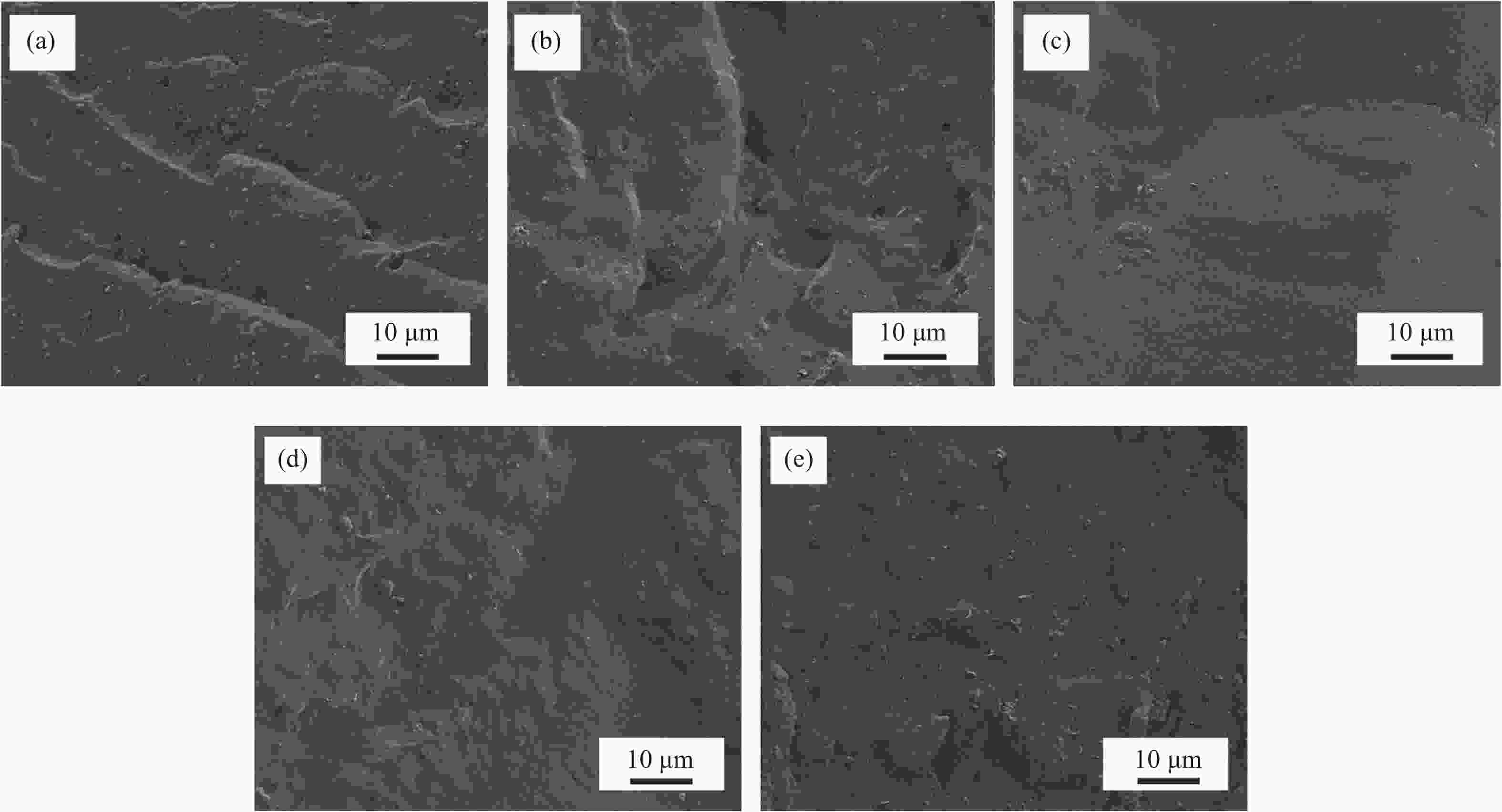

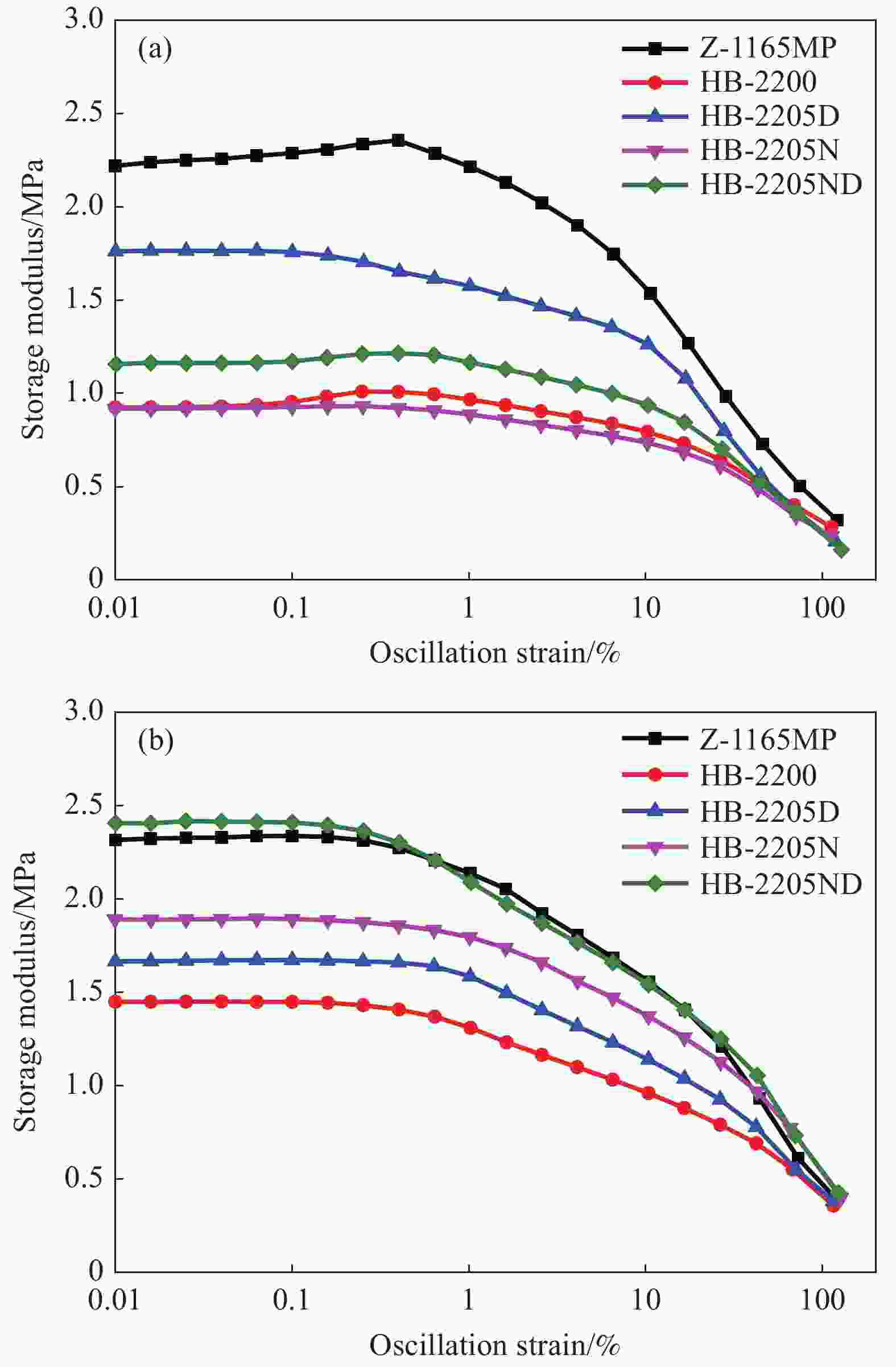

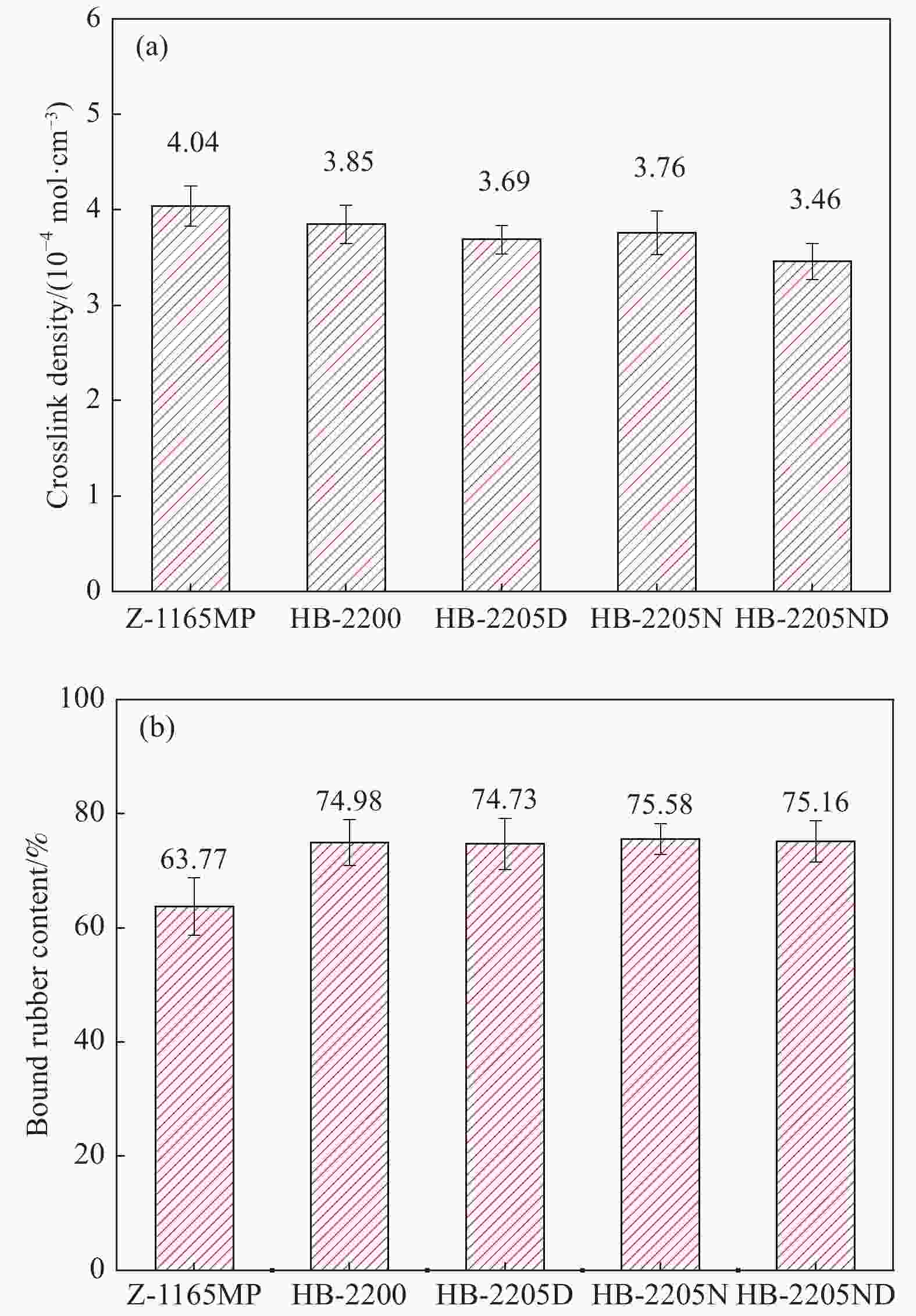

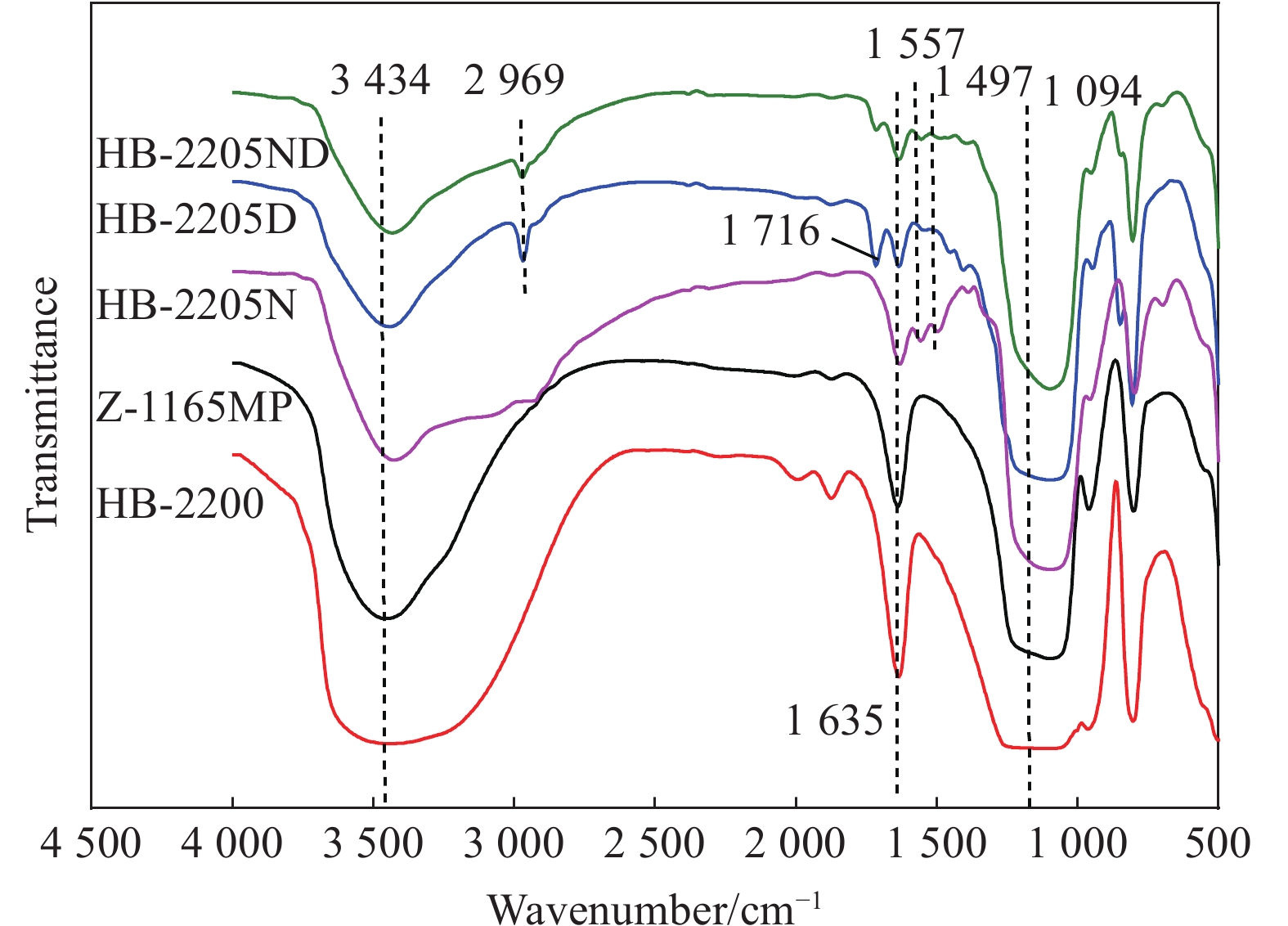

摘要: 采用液相原位修饰技术,制备了表面接枝有机硅烷的纳米SiO2(HB-2200)、表面接枝氨基的纳米SiO2(HB-2205N)、表面接枝不饱和双键的纳米SiO2(HB-2205D)、表面接枝氨基和双键的纳米SiO2(HB-2205ND)。利用TEM、SEM、流变仪对纳米SiO2/溶液聚合丁苯橡胶-顺丁橡胶(SSBR-BR)复合材料的结构和性能进行表征。结果表明:与未改性的纳米SiO2相比,表面功能化纳米SiO2与橡胶基体相容性改善,Payne效应降低,纳米SiO2之间的相互作用减弱,其在SSBR-BR复合材料中的分散性提高。HB-2200/SSBR-BR复合材料的混炼扭矩降低了35.7%,混炼能耗降低了15%,结合胶含量增加,填料/橡胶之间的界面结合作用增强,拉伸强度提高了60%。动态热力学和磨耗性能分析表明:纳米SiO2表面引入可反应性双键(HB-2205D),使HB-2205D/SSBR-BR复合材料的抗湿滑性能提高了40%,滚动阻力降低了43%。纳米SiO2表面接枝可反应性双键,可在不牺牲HB-2205D/SSBR-BR复合材料耐磨性能的基础上,降低其滚动阻力,提高其抗湿滑性能,为高性能轮胎的制备提供基础原材料。Abstract: A series of nano SiO2 grafted with organosilane (HB-2200), nano SiO2 grafted with amino (HB-2205N), nano SiO2 grafted with double bond (HB-2205D) and nano SiO2 grafted with amino-double bond (HB-2205ND) groups were prepared through liquid phase in-situ surface modification method. The structure and properties of nano SiO2/solution polymerized styrene butadiene rubber-polybutadiene rubber (SSBR-BR) composites were characterized by TEM, SEM and rheometer. The results show that compared with the unmodified nano SiO2, the compatibility between surface functionalized nano SiO2 and rubber matrix is improved, Payne effect is reduced, the interaction between nano SiO2 is weakened, and the dispersion of nano SiO2 in SSBR-BR is improved. Compared with nano SiO2/SSBR-BR composite, the mixing torque of HB-2200/SSBR-BR composite is reduced by 35.7%, the mixing energy consumption is saved by 15%, the interfacial bond between the filler and the rubber is strengthened due to the increase in the content of bound rubber, and its tensile strength is increased by 60%. The dynamic mechanical and abrasion performance analyses show that the reactive double bond group grafted on the surface of SiO2 could improve the wet slip resistance of HB-2205D/SSBR-BR composite by 40% and reduce the rolling resistance by 43%. Nano SiO2 surface grafted with reactive double bond could reduce its rolling resistance and improve its resistance to wet slip, without sacrificing the wear resistance of HB-2205D/SSBR-BR composite. It provides the basic raw materials for the preparation of high-performance tires.

-

Key words:

- in-situ modification /

- SiO2 /

- interfacial interaction /

- rubber /

- Payne effect

-

表 1 纳米SiO2/溶液聚合丁苯橡胶-顺丁橡胶(SSBR-BR)复合材料混炼配方

Table 1. Mixing formula of nano SiO2/solution polymerized styrene butadiene rubber-polybutadiene rubber(SSBR-BR) composite

Material Amount/g SSBR 96.25 BR 30 SiO2 70 Si69 7 ZnO 3 Stearic acid 1.5 6PPD(4020) 1.5 Paraffin wax 1.5 CBS 1.5 DPG 2 Sulfur 1.4 Notes:6PPD(4020)—N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine;CBS—N-cyclohexylbenzothiazole-2-sulphenamide;DPG—1,3-diphenyl guanidine. 表 2 纳米SiO2表面官能团种类和含量

Table 2. Contents of functional groups on surface of nano SiO2

Sample Nano SiO2/wt% Methyl/wt% Double bond /wt% Amino /wt% Z-1165MP 100 0 0 0 HB-2200 80 20 0 0 HB-2205D 80 15 5 0 HB-2205N 80 15 0 5 HB-2205ND 80 15 2.5 2.5 Notes: HB-2200—SiO2 surface grafted with methyl functional groups; HB-2205D—SiO2 surface grafted with methyl functional groups and polymers containing double bonds groups; HB-2205N—SiO2 surface grafted with methyl functional groups and polymers containing amino groups; HB-2205ND—SiO2 surface grafted with methyl functional groups and polymers containing double bonds and amino groups. 表 3 5种纳米SiO2物性参数

Table 3. Physical parameters of 5 types of nano SiO2

Structure parameter Z-1165MP HB-2200 HB-2205D HB-2205N HB-2205ND Apparent density /(g·mL−1) 0.28 0.15 0.16 0.16 0.13 Thermal mass loss at 400℃/% 3.13 4.82 4.27 6.31 5.84 Thermal mass loss at 950℃/% 5.54 6.50 5.97 9.58 8.24 Specific surface area/(m2·g−1) 159 124 142 108 119 Adsorption aperture/nm 18.4 21.2 25.4 19.6 20.9 Particle size D50/μm 11.2 10.3 10.0 10.7 10.0 表 4 纳米SiO2/SSBR-BR复合材料的最大混炼扭矩和能耗

Table 4. Max mixing torque and energy consumption of nano SiO2/SSBR-BR composites

Sample Max mixing

torque/(N·m)Energy consumption/kJ Z-1165MP/SSBR-BR 78.9 336 HB 2200/SSBR-BR 50.7 288 HB 2205D/SSBR-BR 50.8 301 HB 2205N/SSBR-BR 51.8 303 HB 2205ND/SSBR-BR 51.6 301 -

[1] 冯文江, 贾德民, 郭宝春. 橡胶纳米复合材料的一些新进展[J]. 高分子通报, 2014(5):22-32.FENG W J, JIA D M, GUO B C. Some new advances in rubber nanocomposites[J]. Polymer Bulletin,2014(5):22-32(in Chinese). [2] 马建华, 张立群, 吴友平. 轮胎胎面胶料性能及其机理研究进展[J]. 高分子通报, 2014(5):1-9.MA J H, ZHANG L Q, WU Y P. Properties of tire tread composite and their mechanism[J]. Polymer Bulletin,2014(5):1-9(in Chinese). [3] 唐源, 张春华, 田庆丰, 等. 高性能轮胎胎面胶“魔三角”性能平衡研究进展[J]. 橡胶工业, 2019, 66(5):388-394.TANG Y, ZHANG C H, TIAN Q F, et al. Research progress of “magic triangle” properties balance of high performance tire tread compound[J]. China Rubber Industry,2019,66(5):388-394(in Chinese). [4] 周彤辉, 阮文红, 王跃林, 等. 原位接枝改性纳米二氧化硅/聚丙烯复合材料Ⅱ:性能测试[J]. 复合材料学报, 2007, 24(3):45-51. doi: 10.3321/j.issn:1000-3851.2007.03.009ZHOU T H, RUAN W H, WANG Y L, et al. Polypropylene composites with nano-silica modified by in-situ grafting polymerization Ⅱ: Performance[J]. Acta Materiae Compositae Sinica,2007,24(3):45-51(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.03.009 [5] ZHU A, DIAO H, RONG Q, et al. Preparation and properties of polylactide-silica nanocomposites[J]. Journal of Applied Polymer Science,2010,116(5):2866-2873. [6] MA X K, LEE N H, OH H J, et al. Surface modification and characterization of highly dispersed silica nanoparticles by a cationic surfactant[J]. Colloids & Surfaces A: Physicochemical & Engineering Aspects,2010,358(1-3):172-176. [7] MALLAKPOUR S, NAGHDI M. Fabrication and characterization of novel polyvinylpyrrolidone nanocomposites having SiO2 nanoparticles modified with citric acid and L(+)-ascorbic acid[J]. Polymer,2016,90:295-301. doi: 10.1016/j.polymer.2016.03.029 [8] ZHANG C H, TANG Y, TIAN Q, et al. Preparation of dispersible nanosilica surface-capped by hexamethyl disilazane via an in situ surface-modification method and investigation of its effects on the mechanical properties of styrene-butadiene/butadiene rubber[J]. Journal of Applied Polymer Science,2019,136(30):47763. [9] JESIONOWSKI T, KRYSZTAFKIEWICZ A. Influence of silane coupling agents on surface properties of precipitated silicas[J]. Applied Surface Science,2001,172(1):18-32. [10] PONNAMMA D, RAMACHANDRAN R, HUSSAIN S, et al. Free-volume correlation with mechanical and dielectric properties of natural rubber/multi walled carbon nanotubes composites[J]. Composites Part A: Applied Science and Manufacturing,2015,77:164-171. doi: 10.1016/j.compositesa.2015.06.023 [11] TIAN Q F, TANG Y, DING T, et al. Effect of nano-silica surface-capped by bis[3-(triethoxysilyl)propyl] tetrasulfide on the mechanical properties of styrene-butadiene rubber/butadiene rubber nanocomposites[J]. Composites Communications,2018,10:190-193. doi: 10.1016/j.coco.2018.10.005 [12] HUANG Q, LIU M, MAO L, et al. Surface functionalized SiO2 nanoparticles with cationic polymers via the combination of mussel inspired chemistry and surface initiated atom transfer radical polymerization: Characterization and enhanced removal of organic dye[J]. Journal of Colloid & Interface Science,2017,499:170-179. [13] KHANI M M, WOO D, MUMPOWER E L, et al. Poly(alkyl methacrylate)-grafted silica nanoparticles in polyethylene nanocomposites[J]. Polymer,2017,109:339-348. doi: 10.1016/j.polymer.2016.12.046 [14] 李小红, 曹智, 刘丰, 等. 反应性二氧化硅纳米微粒: 中国专利, ZL200410010125.9[P]. 2008-06-04.LI X H, CAO Z, LIU F, et al. Reactive silica nanoparticles: Chinese Patent, ZL200410010125.9[P]. 2008-06-04(in Chinese). [15] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic: Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [16] 中国国家标准化管理委员会. 硫化橡胶耐磨性能的测定(用阿克隆磨耗机): GB/T 1689—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People’s Republic of China. Rubber vulcanized: Determination of abrasion resistance (Akron machine): GB/T 1689—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [17] MAO Y, TIAN Q F, ZHANG C H, et al. Vulcanization accelerator functionalized nanosilica: Effect on the reinforcement behavior of SSBR/BR[J]. Polymer Engineering & Science,2019,59(6):1270-1278. [18] BRINKE J W, DEBNATH S C, REUVEKAMP L A E M, et al. Mechanistic aspects of the role of coupling agents in silica-rubber composites[J]. Composites Science and Technology,2003,63(8):1165-1174. doi: 10.1016/S0266-3538(03)00077-0 [19] WANG Y X, WU Y P, LI W J, et al. Influence of filler type on wet skid resistance of SSBR/BR composites: Effects from roughness and micro-hardness of rubber surface[J]. Applied Surface Science,2011,257(6):2058-2065. doi: 10.1016/j.apsusc.2010.08.129 [20] RIMDUSIT S, THAMPRASOM N, SUPPAKARN N, et al. Effect of triphenyl phosphate flame retardant on properties of arylamine-based polybenzoxazines[J]. Journal of Applied Polymer Science,2013,130(2):1074-1083. doi: 10.1002/app.39248 [21] PAYNE A R. The dynamic properties of carbon black-loaded natural rubber vulcanizates Part Ⅰ[J]. Journal of Applied Polymer Science,1962,6(19):57-63. doi: 10.1002/app.1962.070061906 [22] ZHONG B C, JIA Z X, LUO Y L, et al. A method to improve the mechanical performance of styrene-butadiene rubber via vulcanization accelerator modified silica[J]. Composites Science and Technology,2015,117:46-53. doi: 10.1016/j.compscitech.2015.05.012 [23] LEI Y D. Synthesis of novel functional liquid and its application as a modifier in SBR/silica composites[J]. Express Polymer Letters,2010,4(11):692-703. doi: 10.3144/expresspolymlett.2010.84 [24] LIU J, CHENG Y, XU K, et al. Effect of nano-silica filler on microstructure and mechanical properties of poly dimethyl siloxane-based nanocomposites prepared by “inhibition-grafting” method[J]. Composites Science and Technology,2018,167:355-363. doi: 10.1016/j.compscitech.2018.08.014 -

下载:

下载: