Prediction of thermal conductivity of CuO-ZnO/(ethylene glycol-water) hybrid nanofluids based on radial basis neural network model

-

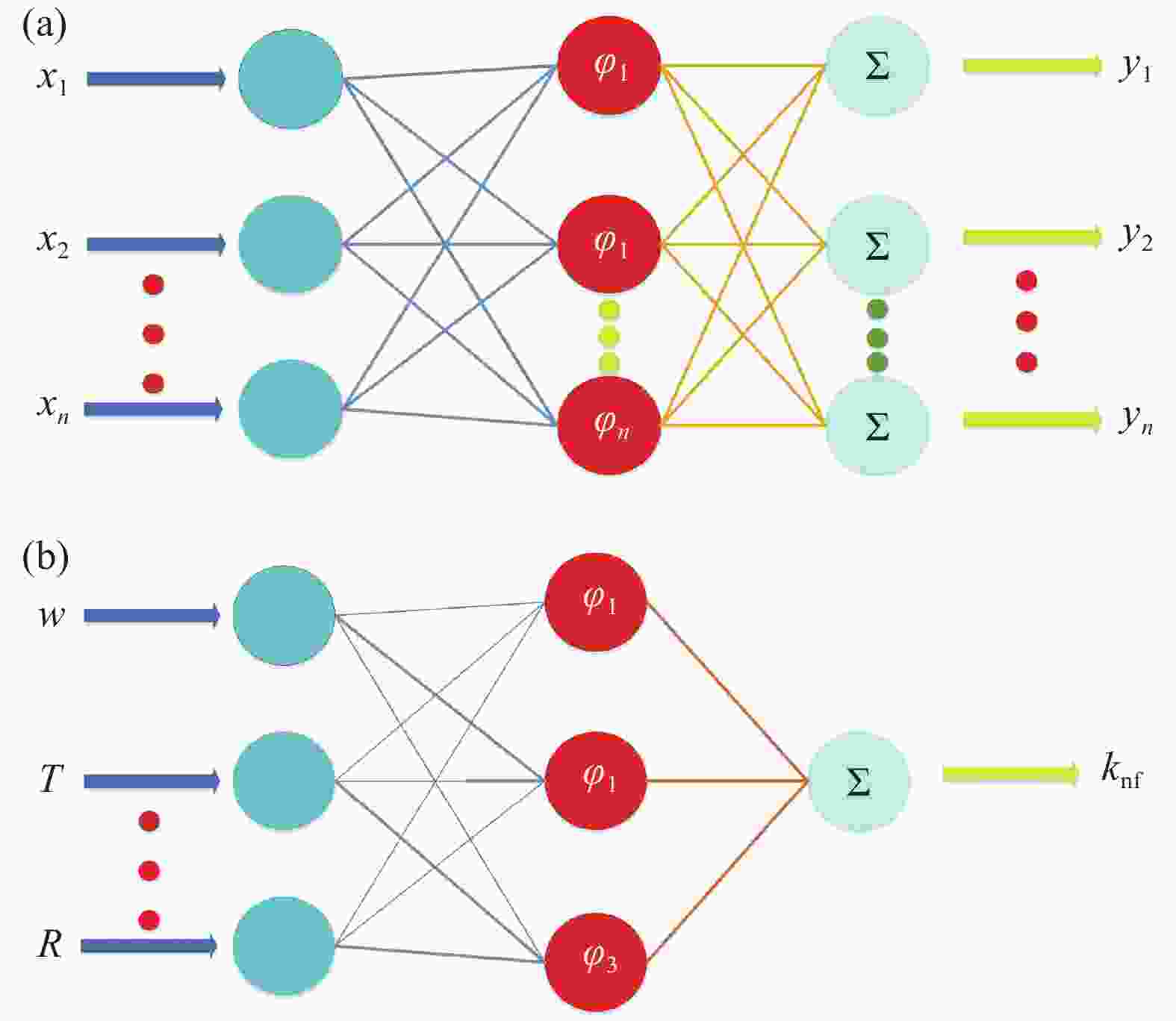

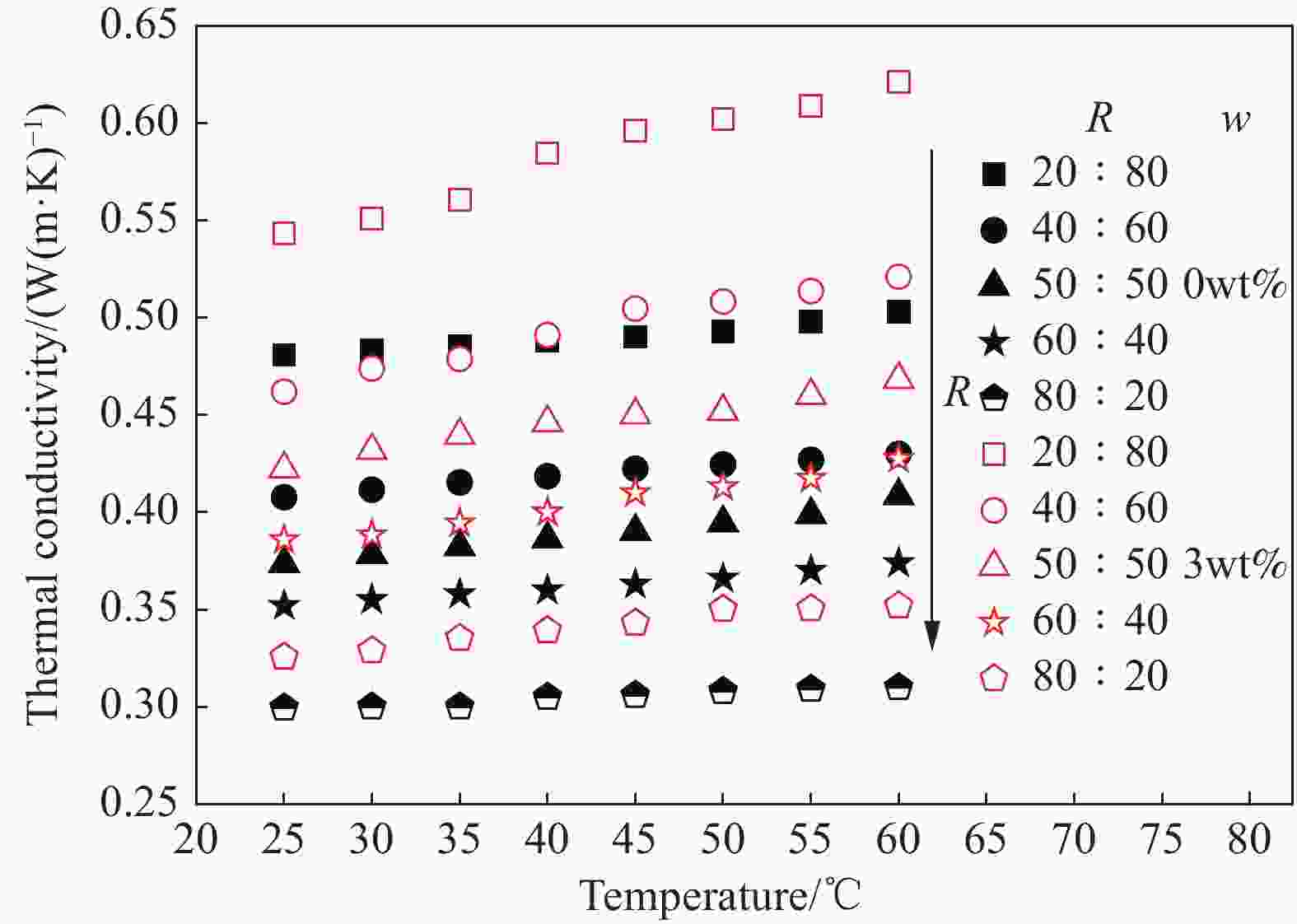

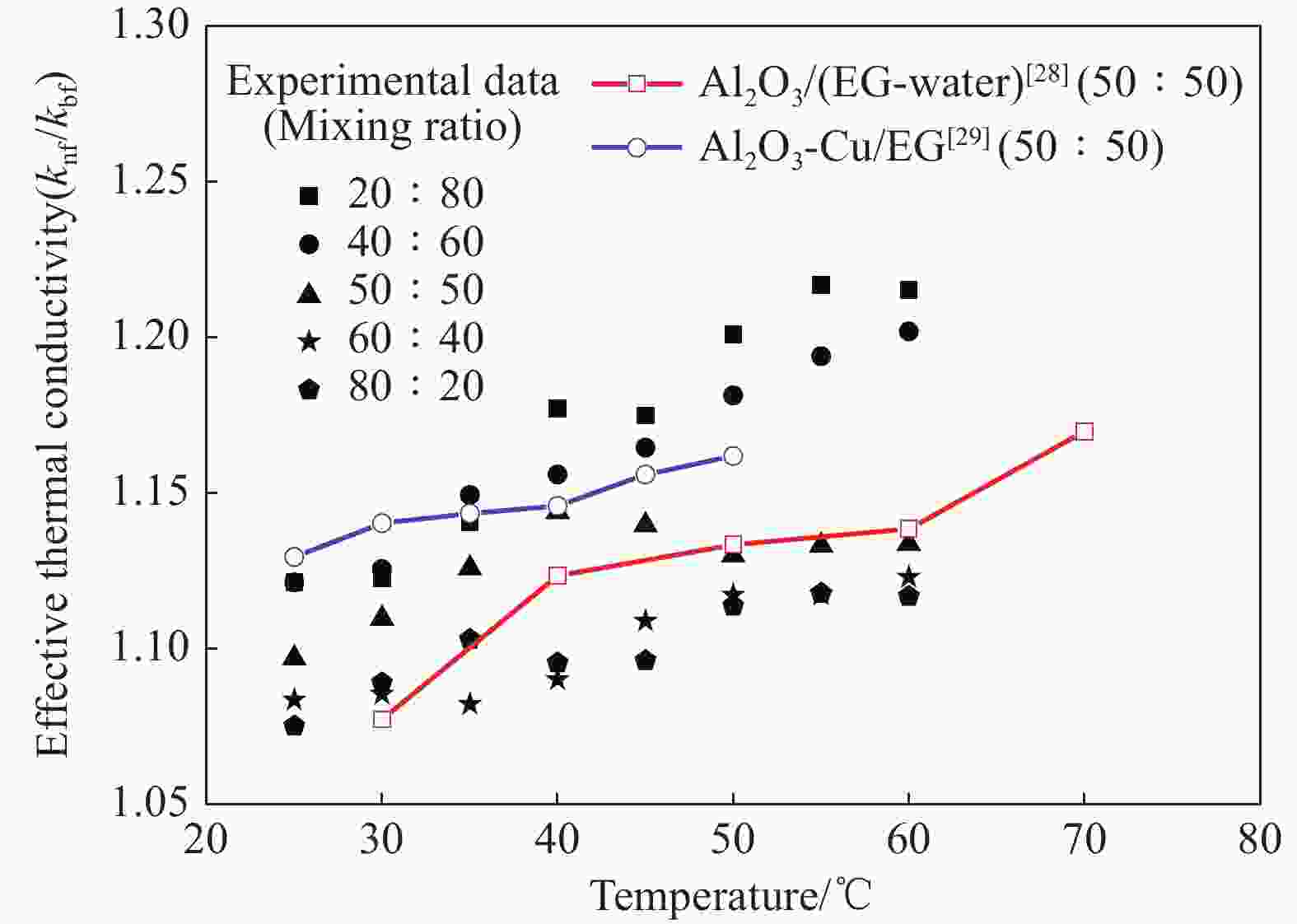

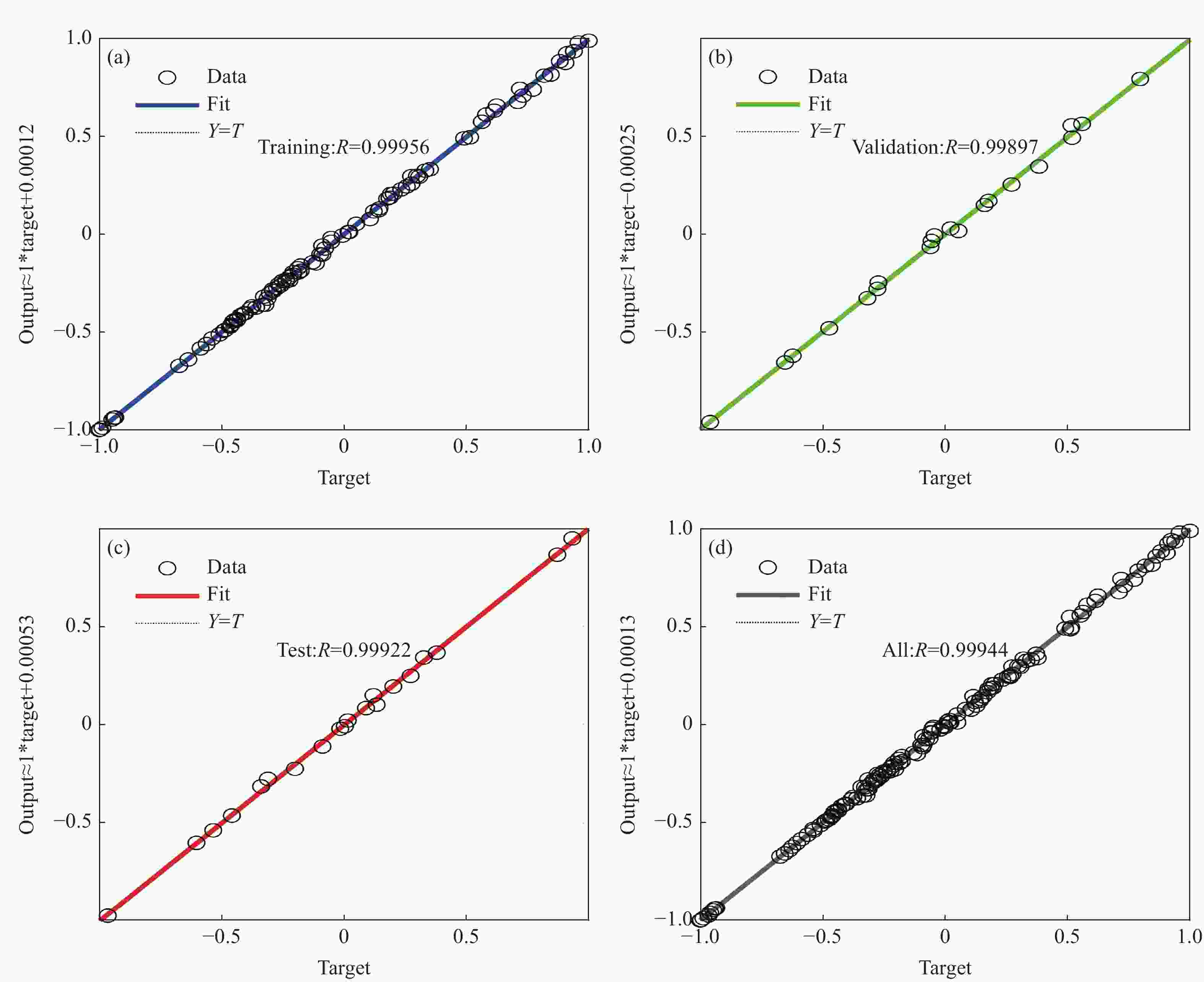

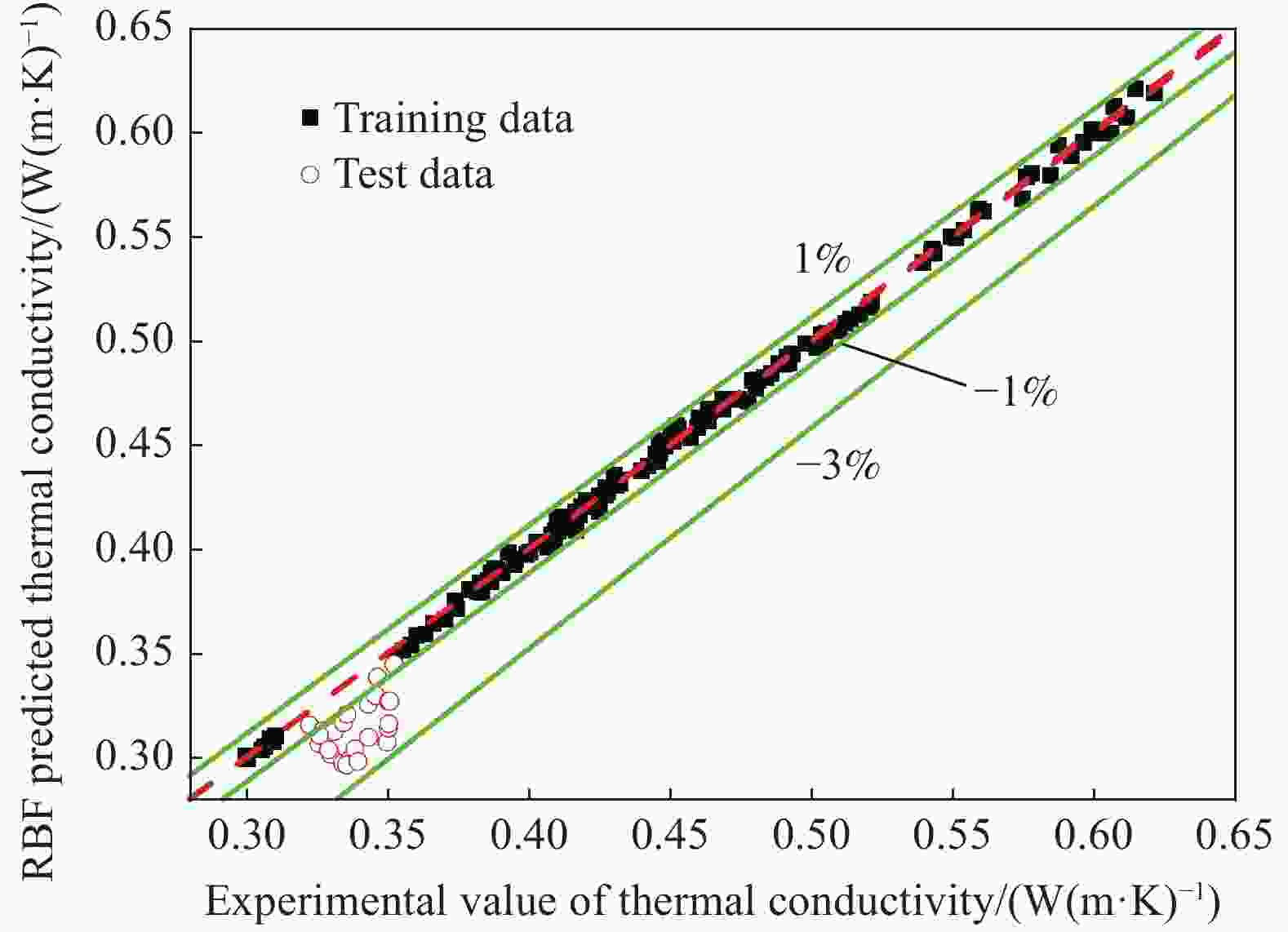

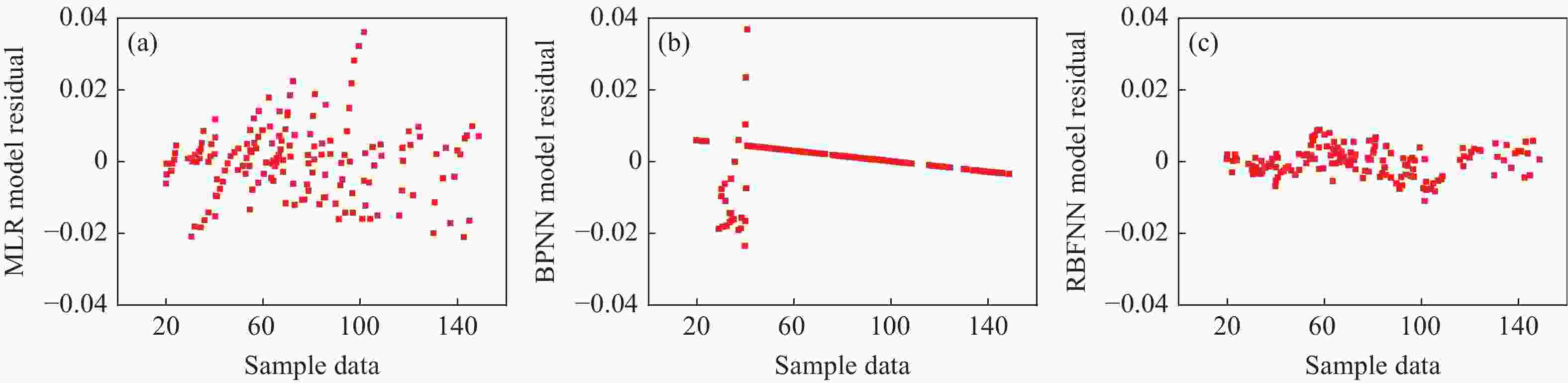

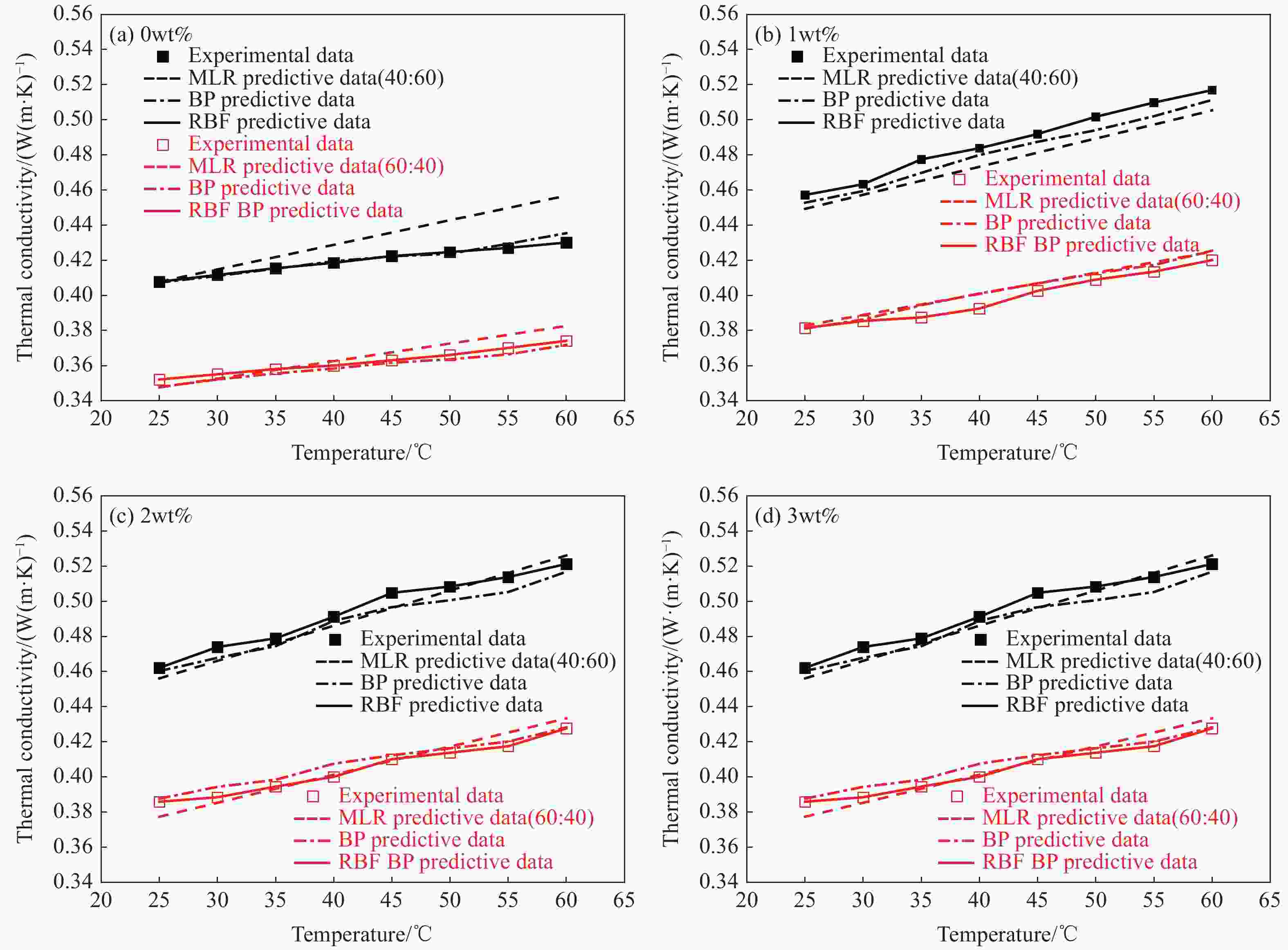

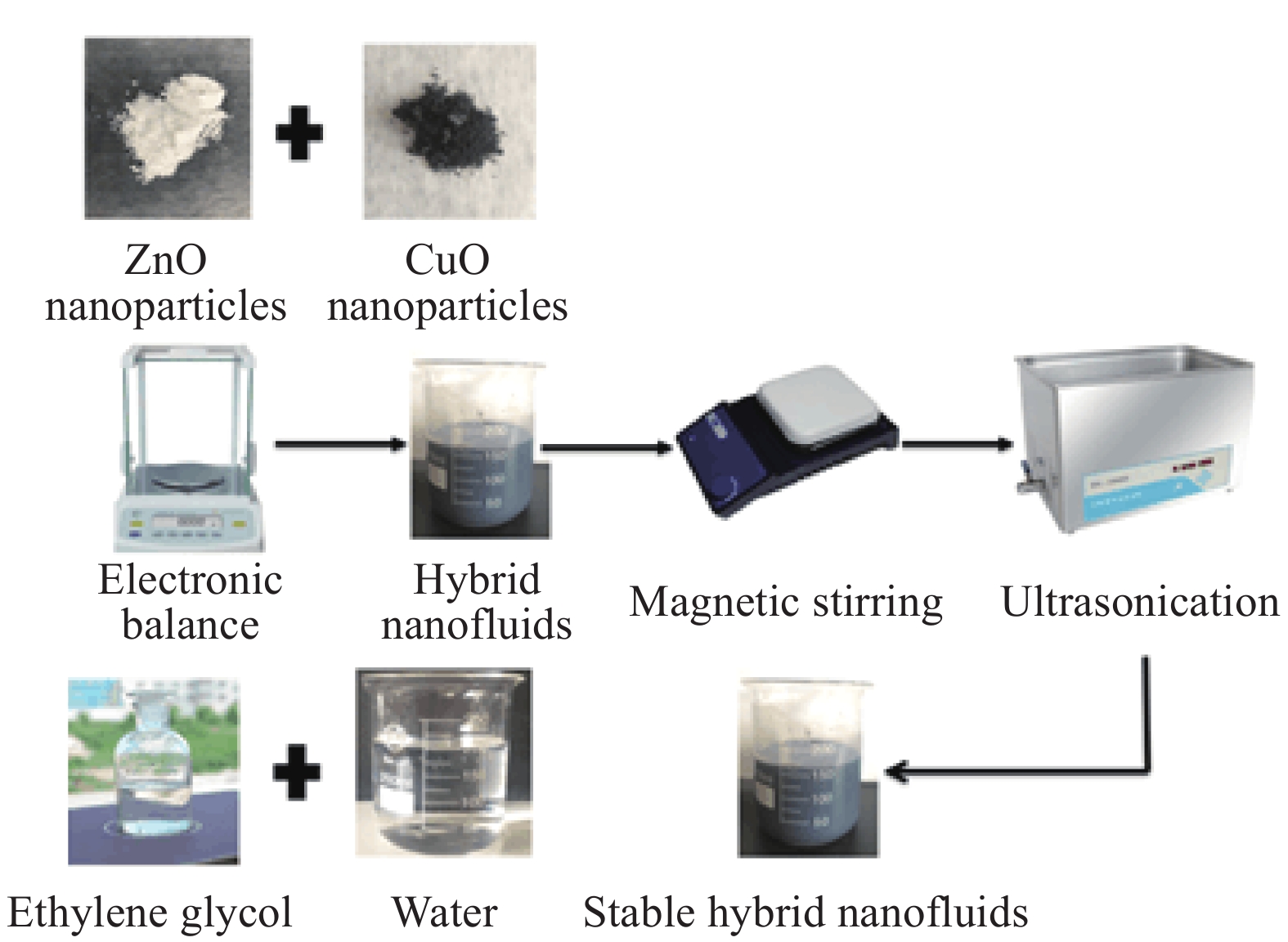

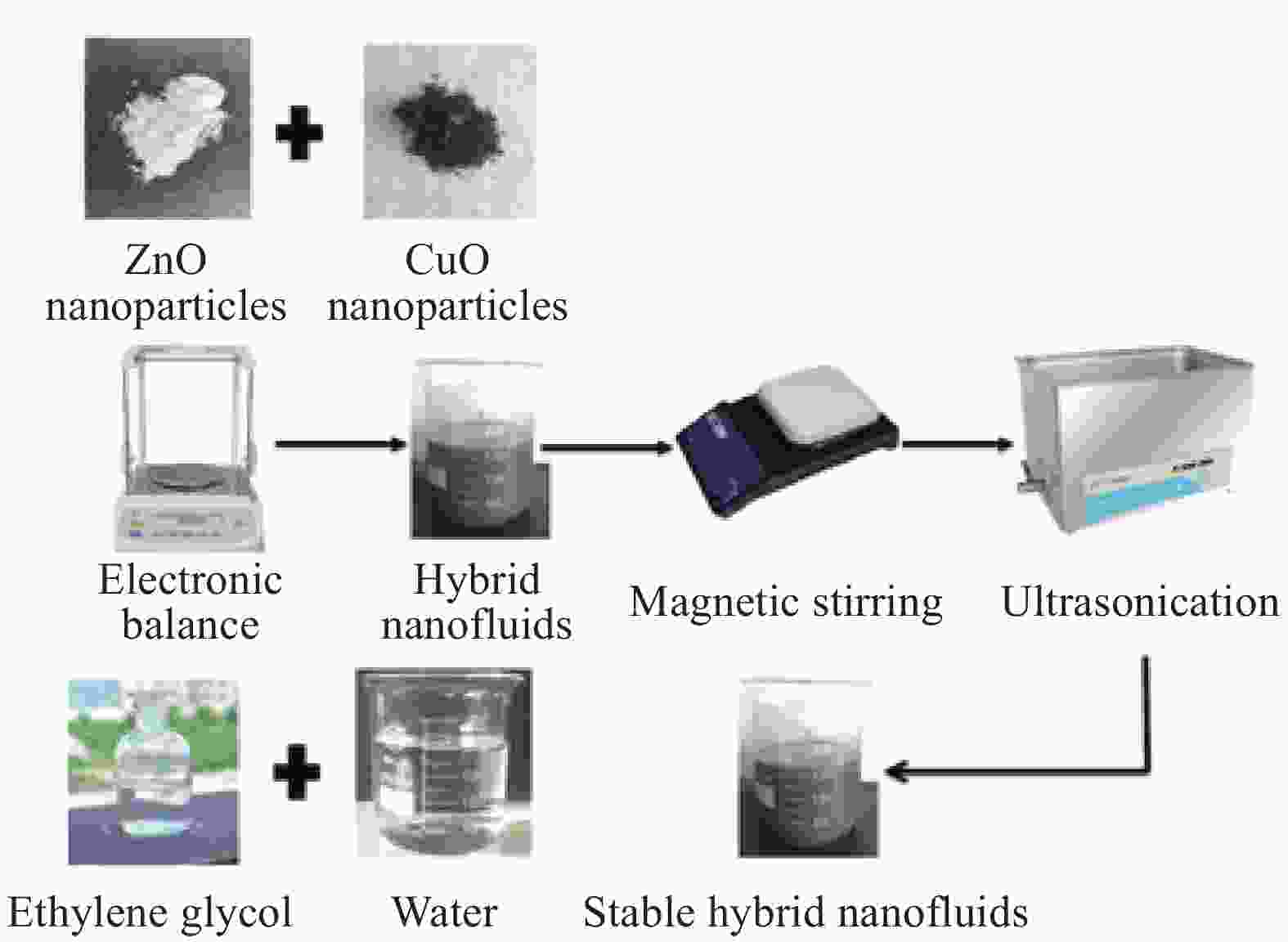

摘要: 采用两步法制备CuO-ZnO质量分数为0~3 wt%的CuO-ZnO/(乙二醇(EG)-水)混合纳米流体。其中,纳米颗粒CuO和ZnO质量比为50∶50不变,基液混合比(EG与去离子水的质量比)变化范围为20∶80~80∶20,分析其导热系数随温度(25~60℃)及基液比的变化规律。然后,以质量分数、温度及基液混合比为自变量,导热系数为因变量,采用径向基神经网络(RBFNN)模型预测导热系数,并与反向传播神经网络(BPNN)模型和多元线性回归(MLR)模型的预测值对比。结果表明,CuO-ZnO/(EG-水)纳米流体导热系数随温度的升高呈非线性增大,当CuO-ZnO质量分数为3 wt%及基液混合比为20∶80时,其导热系数与纯基液相比增大了14.03%~23.47%;但随着基液中的EG含量增大,导热系数非线性下降。总之,CuO-ZnO/(EG-水)纳米流体的导热系数受粒子随机运动和温度变化呈非线性变化。采用RBFNN模型预测CuO-ZnO/(EG-水)纳米流体的导热系数,其结果与BPNN模型和MLR模型对比,RBFNN模型性能评价指标均方根误差(RMSE)、平均相对百分比误差(MRPE)及误差平方和(SSE)更接近于0,多元统计系数R2更接近于1,说明RBFNN模型预测导热系数的精度更高,能够较好地表征不同参数对导热系数的影响,为CuO-ZnO/(EG-水)纳米流体的热物理性能参数的预测提供了一种有效的数据驱动建模方法。Abstract: The CuO-ZnO/(ethylene glycol(EG)-water) nanofluid with CuO-ZnO mass fractions of 0–3 wt% were prepared by two-step method. First, the mixing mass ratio of nanoparticles CuO to ZnO was fixed at 50∶50, and the mass ratios of EG to deionized water varied from 20∶80 to 80∶20. Variations of thermal conductivity with temperature (25–60℃) and mixing mass ratios of base liquids were studied. Second, the radial basis function neural network (RBFNN) model was used to predict the thermal conductivity. In the model, the mass fraction, temperature and mixing mass ratios of base liquids were considered as independent variables while the thermal conductivity is the dependent variable. The predicted values were compared with the values predicted by back propagation neural network (BPNN) and multiple linear regression (MLR). The results show that the thermal conductivities of CuO-ZnO/(EG-water) nanofluid increase nonlinearly with the increase of temperature, while decrease with the increase of mixing mass ratios of base liquids. Compared with the thermal conductivity of the base fluid, it increases from 14.03% to 23.47% at the mass fraction of 3 wt% and the mixing mass ratio of base fluid of 20∶80. The thermal conductity of CuO-ZnO/(EG-water) changes nonlinear with random motion of nanoparticles and temperature. The results obtained by RBF model are more precise than that predited by BPNN model and MLR model. The model evaluated indexes of root mean square error (RMSE), mean relative percentage error (MRPE) and sum of squared error (SSE) are closer to 0 and duostatistical coefficient of multiple determination R2 is closer to 1 indicating that the RBFNN model can accurately predict the thermal conductivity. It can also be used to characterize the effect of various parameters on the thermal conductivity. The results offer an effective method to establish the data-driven model to accurately predict the thermal conductivity of CuO-ZnO/(EG-water) nanofluid.

-

图 5 质量分数为1 wt%的CuO-ZnO/(EG-水)纳米流体有效导热系数与文献相关数据及经验公式对比

Figure 5. Comparison of effective thermal conductivity of CuO-ZnO/ (EG-water) nanofluids between present data and data in literature and empirical correlations at 1 wt% mass fraction of CuO-ZnO

kbf—Thermal conductivity of base liquids; knf—Thermal conductivity of hybrid nanofluids

表 1 隐含层节点数目选取结果评价指标对比

Table 1. Comparison of evaluation results of the number of hidden layer nodes

Number of neurons Transfer function Mean squared error/10–4 R2 [3] [logsig] 1.3662 0.99887 [4] [logsig] 2.1945 0.99863 [5] [logsig] 3.8805 0.99875 [6] [logsig] 3.7558 0.99881 [7] [logsig] 3.9099 0.99820 [8] [logsig] 0.4723 0.99944 [9] [logsig] 1.1441 0.99901 [10] [logsig] 3.6291 0.99926 [11] [logsig] 12.3670 0.99614 [12] [logsig] 2.3768 0.99836 Note: R2—Duostatistical coefficient of multiple determination. 表 2 RBFNN、BPNN及多元线性回归(MLR)预测模型CuO-ZnO/(EG-水)纳米流体导热系数性能评估

Table 2. Performance evaluation for CuO-ZnO/(EG-water) nanofluids by predictionmodel of RBFNN, BPNN and multiple linear regression (MLR)

Prediction model Root mean squared error $E_{\rm{RMSE}}$ Mean relative percentage error $E_{\rm{MRPE}}$/% Sum of squared error $S_{\rm{SE}}$ R2 RBFNN 0.0038 0.70 0.0003 0.9999 BPNN 0.0069 1.66 0.0011 0.9994 MLR 0.0109 2.03 0.0199 0.9876 -

[1] CHOI S U S, EASTMAN J A. Enhancing thermal conductivity of fluids with nanoparticles[C]//1995 International Mechanical Engineering Congress and Exhibition. San Francisco: Argonne National Laboratory, 1995. [2] SARKAR J, GHOSH P, ADIL A. A review on hybrid nanofluids: Recent research, development and applications [J]. Renewable & Sustainable Energy Reviews, 2015, 43: 164-177. [3] SURESH S, VENKITARAJ K P, SELVAKUMAR P, et al. Synthesis of Al2O3-Cu/water hybrid nanofluids using two step method and its thermo physical properties[J]. Colloids & Surfaces A: Physicochemical & Engineering Aspects,2011,388(1-3):41-48. [4] BAGHBANZADEH M, RASHIDI A, RASHTCHIAN D, et al. Synthesis of spherical silica/multiwall carbon nanotubes hybrid nanostructures and investigation of thermal conductivity of related nanofluids[J]. Thermochimica Acta,2012,549:87-94. [5] ESFE M H, SAEDODIN S, YAN W M, et al. Study on thermal conductivity of water-based nanofluids with hybrid suspensions of CNTs/Al2O3, nanoparticles[J]. Journal of Thermal Analysis and Calorimetry,2016,124(1):455-460. doi: 10.1007/s10973-015-5104-0 [6] HWANG Y J, AHN Y C, SHIN H S, et al. Investigation on characteristics of thermal conductivity enhancement of nanofluids[J]. Current Applied Physics,2006,6(6):1068-1071. doi: 10.1016/j.cap.2005.07.021 [7] TIMOFEEVA E V, GAVRILOV A N, MCCLOSKEY J M, et al. Thermal conductivity and particle agglomeration in alumina nanofluids: Experiment and theory[J]. Physical Review E,2007,76(6):061203. doi: 10.1103/PhysRevE.76.061203 [8] LEE D, KIM J W, KIM B G. A new parameter to control heat transport in nanofluids: Surface charge state of the particle in suspension[J]. The Journal of Physical Chemistry B,2006,110(9):4323-4328. doi: 10.1021/jp057225m [9] JIA T, ZHANG Y, MA H B, et al. Investigation of the characteristics of heat current in a nanofluids based on molecular dynamics simulation[J]. Applied Physics A,2012,108(3):537-544. doi: 10.1007/s00339-012-7019-y [10] WEI X, ZHU H, KONG T, et al. Synthesis and thermal conductivity of Cu2O nanofluids[J]. International Journal of Heat and Mass Transfer,2009,52(19-20):4371-4374. doi: 10.1016/j.ijheatmasstransfer.2009.03.073 [11] XIE H, WANG J, XI T, et al. Thermal conductivity enhancement of suspensions containing nanosized alumina particles[J]. Journal of Applied Physics,2002,91(7):4568-4572. doi: 10.1063/1.1454184 [12] 曾广胜, 孙刚. 工艺参数对淀粉/EVA生物质材料挤出发泡的影响及BP神经网络的预[J]. 复合材料学报, 2014, 31(2):512-517.ZENG Guangsheng, SUN Gang. Effect of process parameters on extrusion foaming of starch/EVA biomass materials and prediction of BP neural network[J]. Acta Materiae Compositae Sinica,2014,31(2):512-517(in Chinese). [13] HOJJAT M, ETEMAD S G, BAGHERI R, et al. Thermal conductivity of non-Newtonian nanofluids: Experimental data and modeling using neural network[J]. International Journal of Heat and Mass Transfer,2011,54(5-6):1017-1023. doi: 10.1016/j.ijheatmasstransfer.2010.11.039 [14] ESFE M H, SAEDODIN S, BAHIRAEI M, et al. Thermal conductivity modeling of MgO/EG nanofluids using experimental data and artificial neural network[J]. Journal of Thermal Analysis and Calorimetry,2014,118(1):287-294. doi: 10.1007/s10973-014-4002-1 [15] ESFE M H, SAEDODIN S, NADERI A, et al. Modeling of thermal conductivity of ZnO-EG using experimental data and ANN methods[J]. International Communications in Heat and Mass Transfer,2015,63:35-40. doi: 10.1016/j.icheatmasstransfer.2015.01.001 [16] ESFE M H, WONGWISES S, NADERI A, et al. Thermal conductivity of Cu/TiO2-water/EG hybrid nanofluid: Experimental data and modeling using artificial neural network and correlation[J]. International Communications in Heat and Mass Transfer,2015,66:100-104. doi: 10.1016/j.icheatmasstransfer.2015.05.014 [17] ESFE M H, AFRAND M, WONGWISES S, et al. Applications of feedforward multilayer perceptron artificial neural networks and empirical correlation for prediction of thermal conductivity of Mg(OH)2/EG using experimental data[J]. International Communications in Heat and Mass Transfer,2015,67:46-50. doi: 10.1016/j.icheatmasstransfer.2015.06.015 [18] ESFE M H, SAEDODIN S, SINA N, et al. Designing an artificial neural network to predict thermal conductivity and dynamic viscosity of ferromagnetic nanofluid[J]. International Communications in Heat and Mass Transfer,2015,68:50-57. doi: 10.1016/j.icheatmasstransfer.2015.06.013 [19] ESFE M H, ROSTAMIAN H, AFRAND M, et al. Modeling and estimation of thermal conductivity of MgO-water/EG (60∶40) by artificial neural network and correlation[J]. International Communications in Heat and Mass Transfer,2015,68:98-103. doi: 10.1016/j.icheatmasstransfer.2015.08.015 [20] ESFE M H, TATAR A, AHANGAR M R H, et al. A comparison of performance of several artificial intelligence methods for predicting the dynamic viscosity of TiO2/SAE 50 nano-lubricant[J]. Physica E: Low-dimensional Systems and Nanostructures,2018,96:85-93. doi: 10.1016/j.physe.2017.08.019 [21] ESFE M H, NADERI A, AKBARI M, et al. Evaluation of thermal conductivity of COOH-functionalized MWCNTs/water via temperature and solid volume fraction by using experimental data and ANN methods[J]. Journal of Thermal Analysis and Calorimetry,2015,121(3):1273-1278. doi: 10.1007/s10973-015-4565-5 [22] ESFE M H, AHANGAR M R H, TOGHRAIE D, et al. Designing artificial neural network on thermal conductivity of Al2O3/water-EG (60–40%) nanofluid using experimental data[J]. Journal of Thermal Analysis and Calorimetry,2016,126(2):837-843. [23] MOODY J, DARKEN C J. Fast learning in networks of locally-tuned processing units[J]. Neural Computation,1989,1(2):281-294. doi: 10.1162/neco.1989.1.2.281 [24] 傅惠民, 岳晓蕊. 多元混合数据回归分析方法[J]. 航空动力学报, 2011, 26(1):173-177.FU Huimin, YUE Xiaorui. Multivariate mixed data regression analysis[J]. Journal of Aerospace Power,2011,26(1):173-177(in Chinese). [25] HUANG G B, SARATCH P, MEMBER S, et al. An efficient sequential learning algorithm for growing and pruning RBF (GAP-RBF) networks[J]. IEEE Transactions on Systems, Man, and Cybernetics,2004,34(6):2284-2292. doi: 10.1109/TSMCB.2004.834428 [26] 张德贤. 前向神经网络合理隐含层结点个数估计[J]. 计算机工程与应用, 2003, 39(5):21-23. doi: 10.3321/j.issn:1002-8331.2003.05.007ZHANG Dexian. Estimation of reasonable implicit layer nodes in feedforward neural networks[J]. Computer Engineering and Applications,2003,39(5):21-23(in Chinese). doi: 10.3321/j.issn:1002-8331.2003.05.007 [27] DAI H, YANG Z, GUO S. Real-time traffic volume estimation with fuzzy linear regression[C]//2006 6th World Congress on Intelligent Control and Automation. Dalian: IEEE, 2006. [28] CHIAM H W, AZMI W H, USRI N A, et al. Thermal conductivity and viscosity of Al2O3 nanofluids for different based ratio of water and ethylene glycol mixture[J]. Experimental Thermal and Fluid Science,2016,81:420-429. [29] PARSIAN A, AKBARI M. New experimental correlation for the thermal conductivity of ethylene glycol containing Al2O3-Cu hybrid nanoparticles[J]. Journal of Thermal Analysis and Calorimetry,2017,131(3):1-9. -

下载:

下载: