Simulation and experiment on thermal deformation influence parameters of high accuracy carbon fiber reinforced plastic sandwiched antenna panels

-

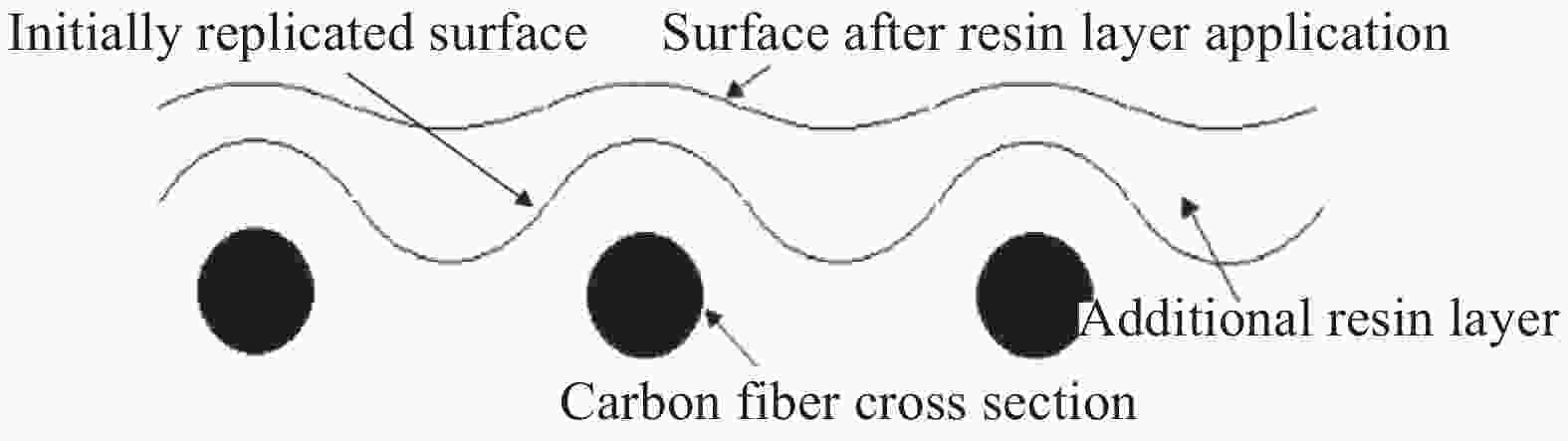

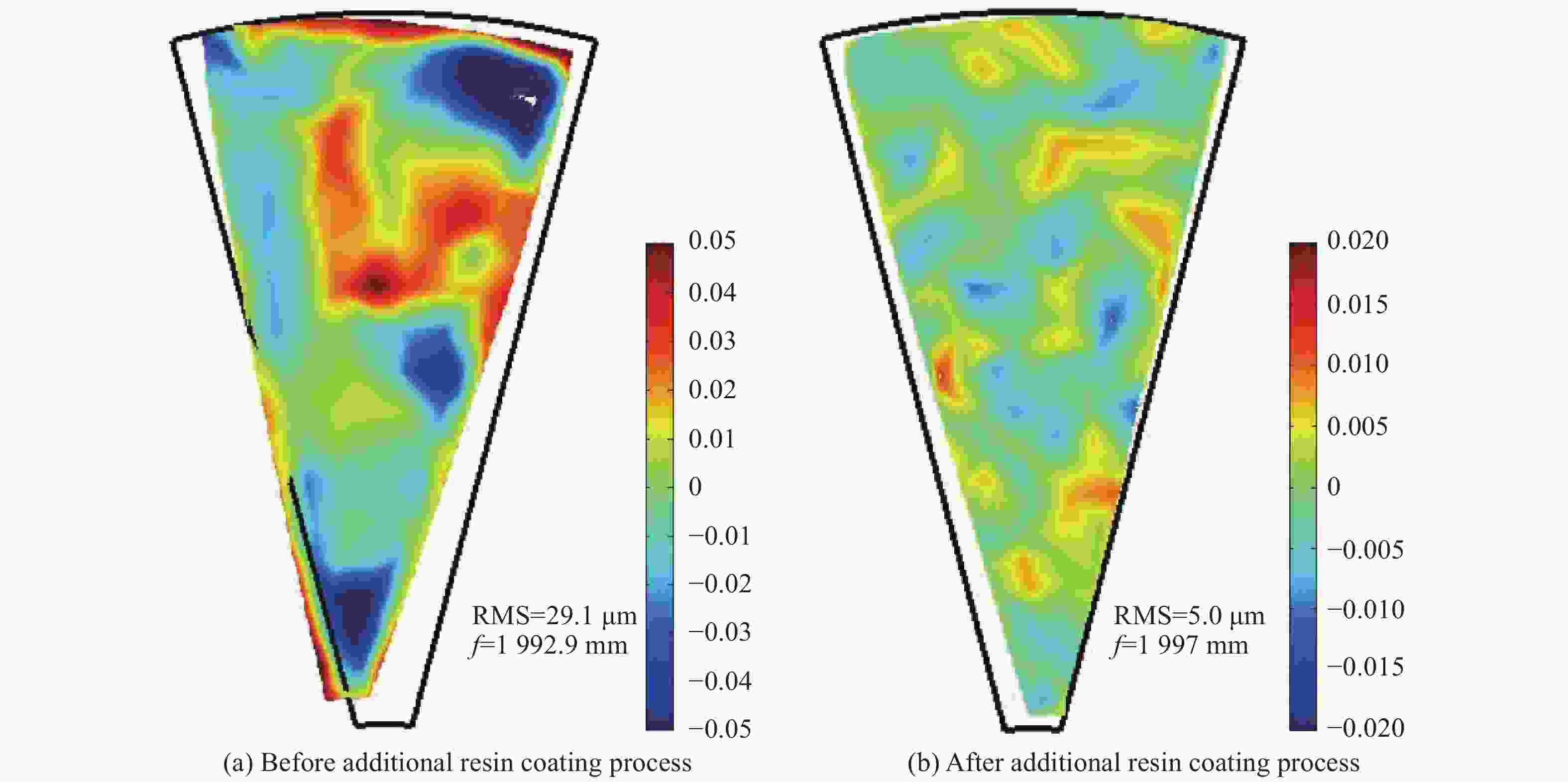

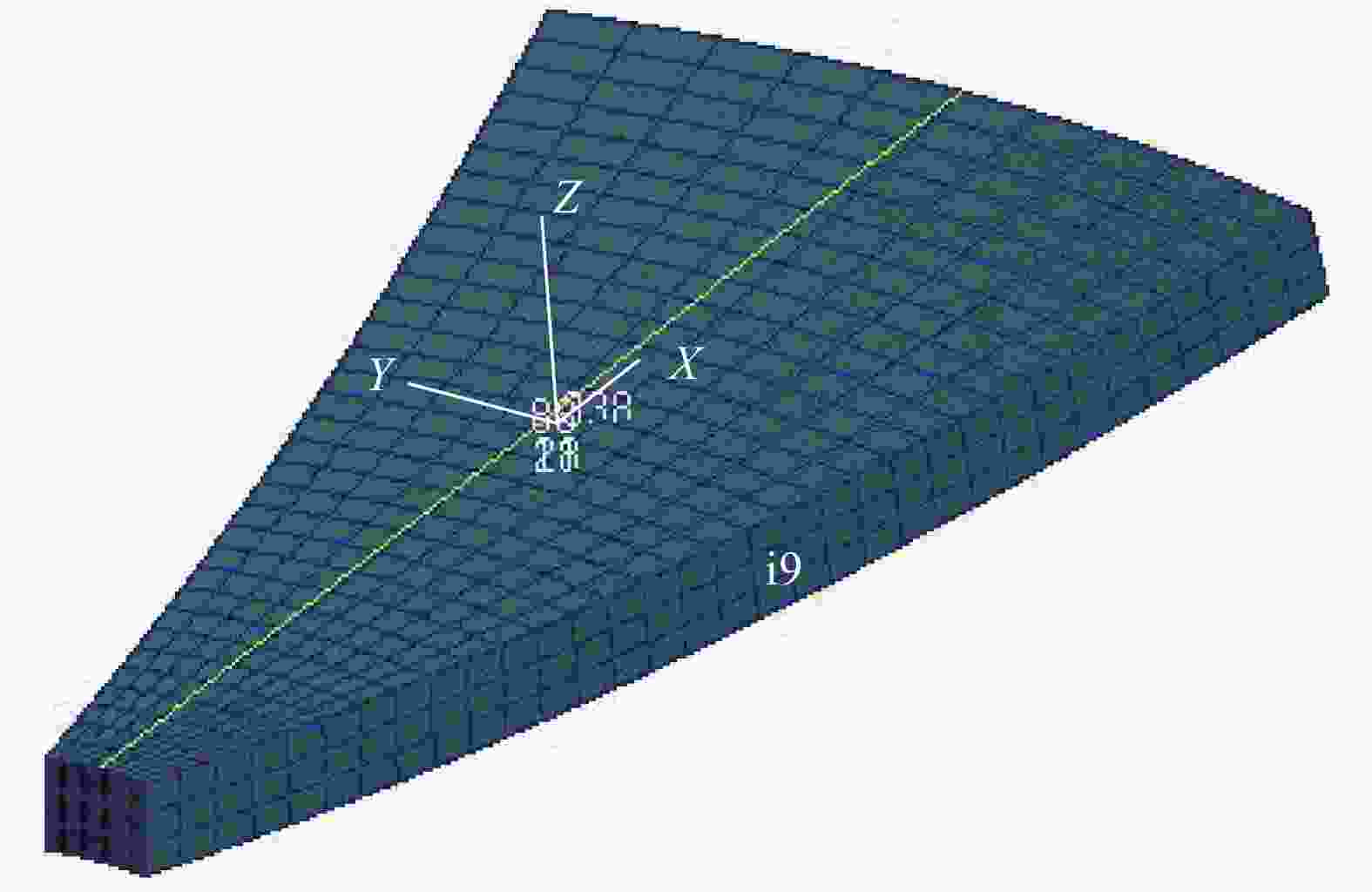

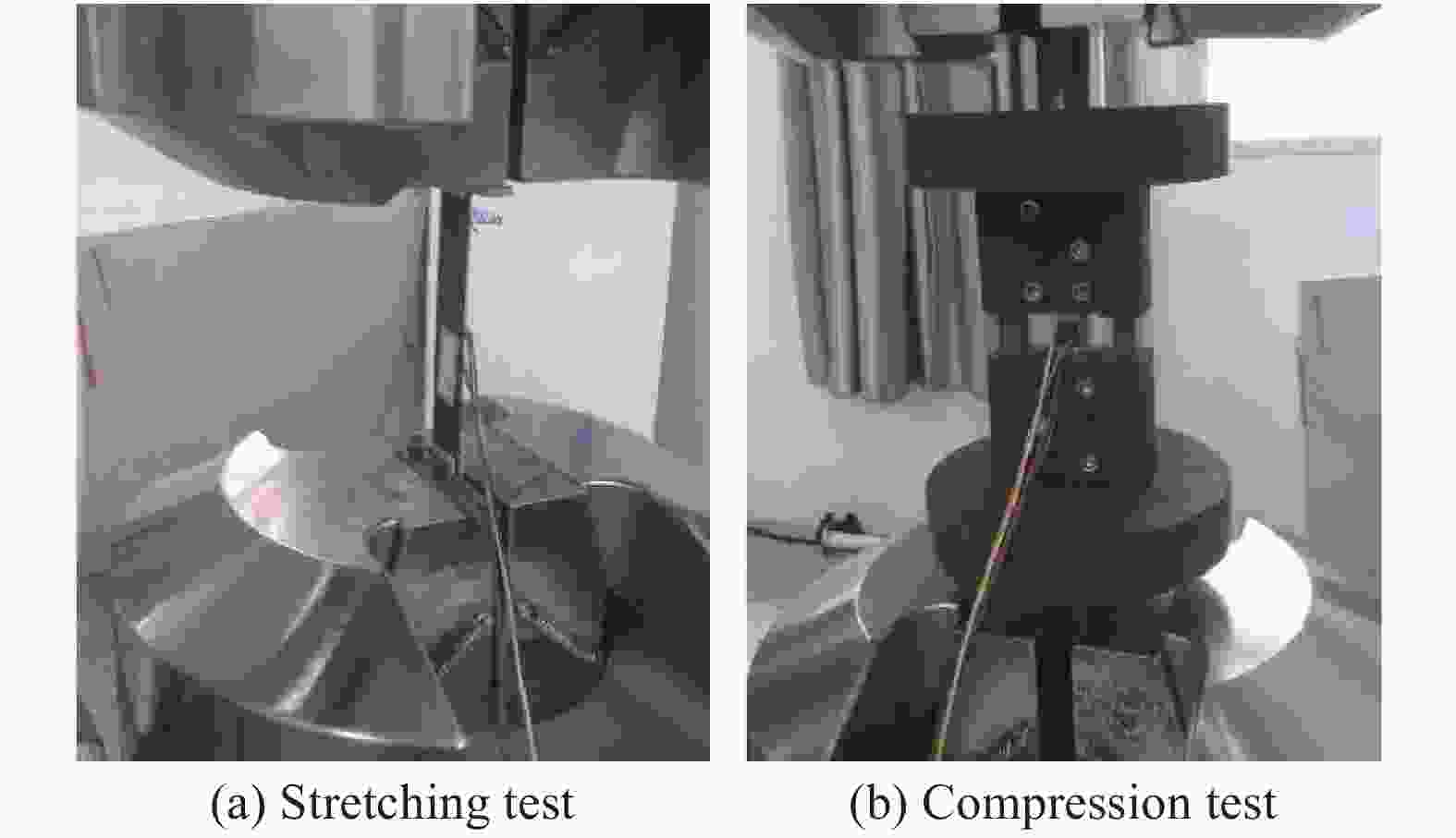

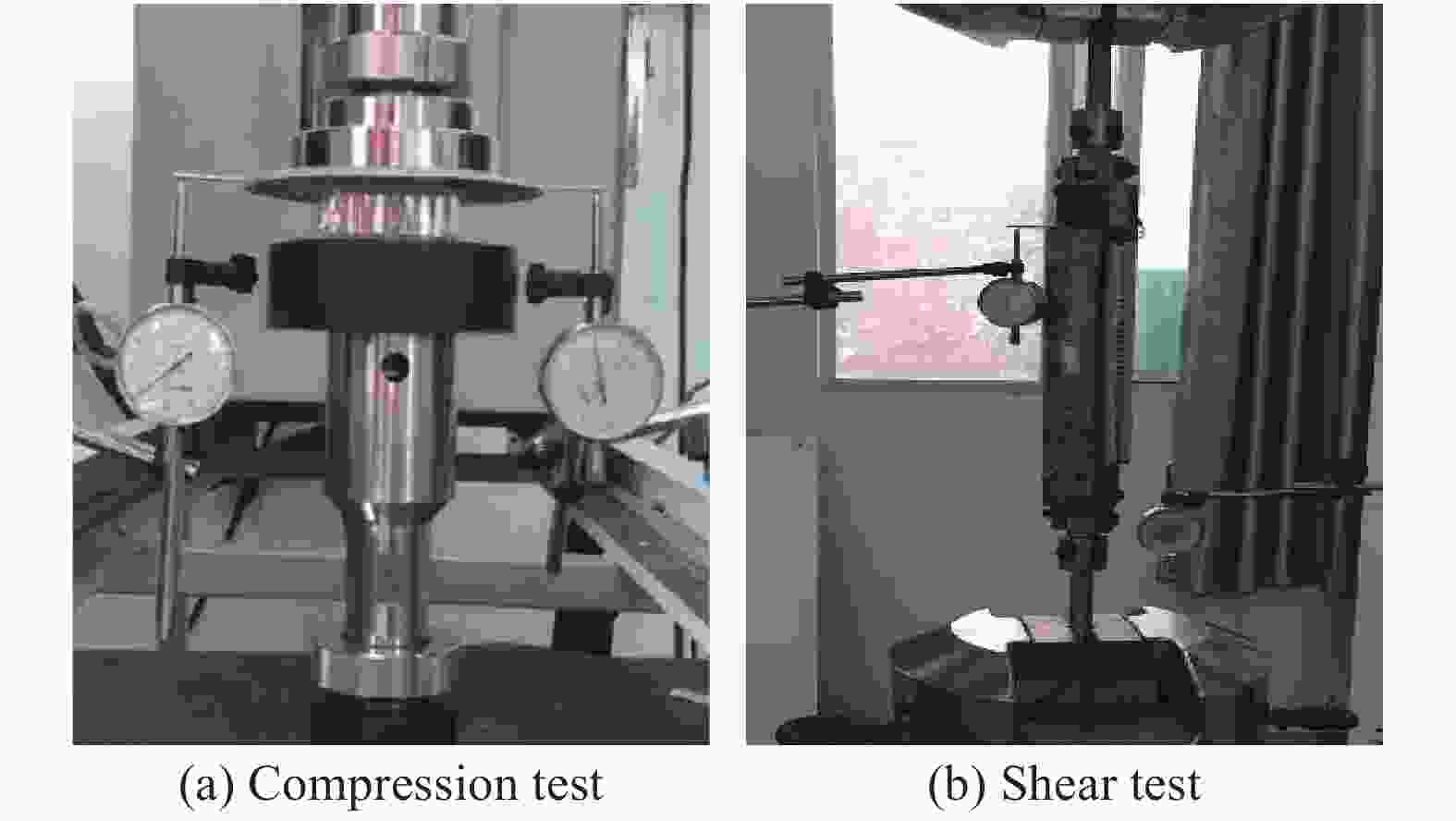

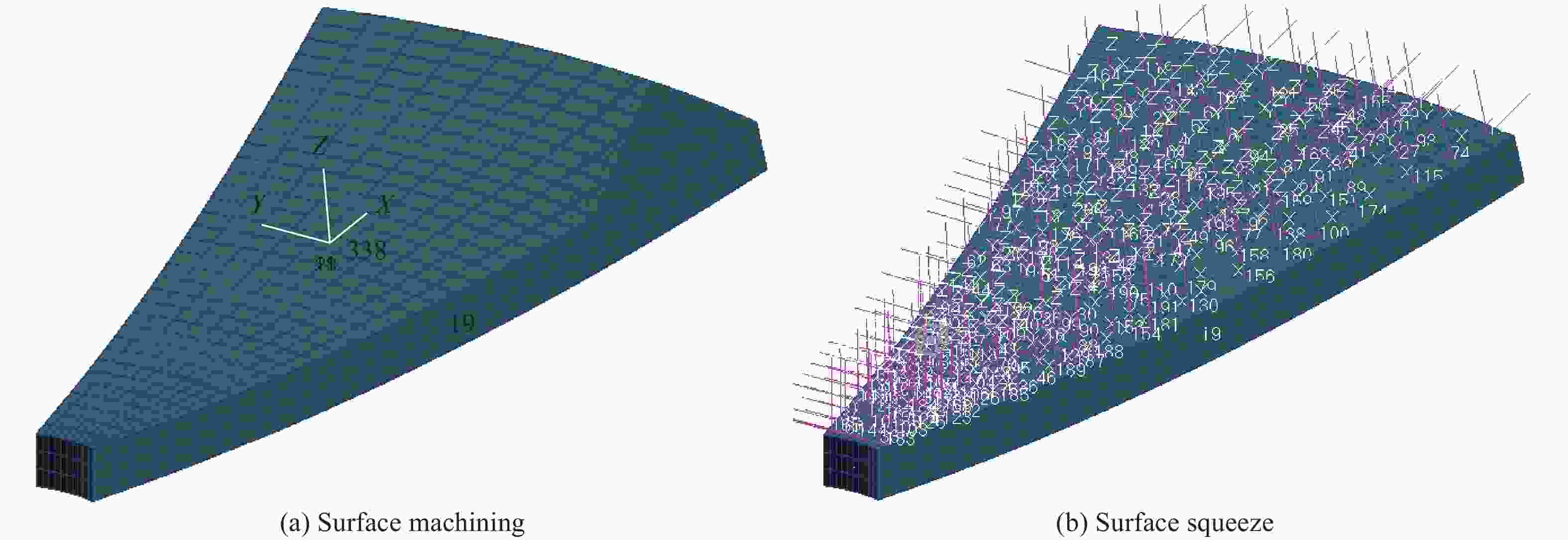

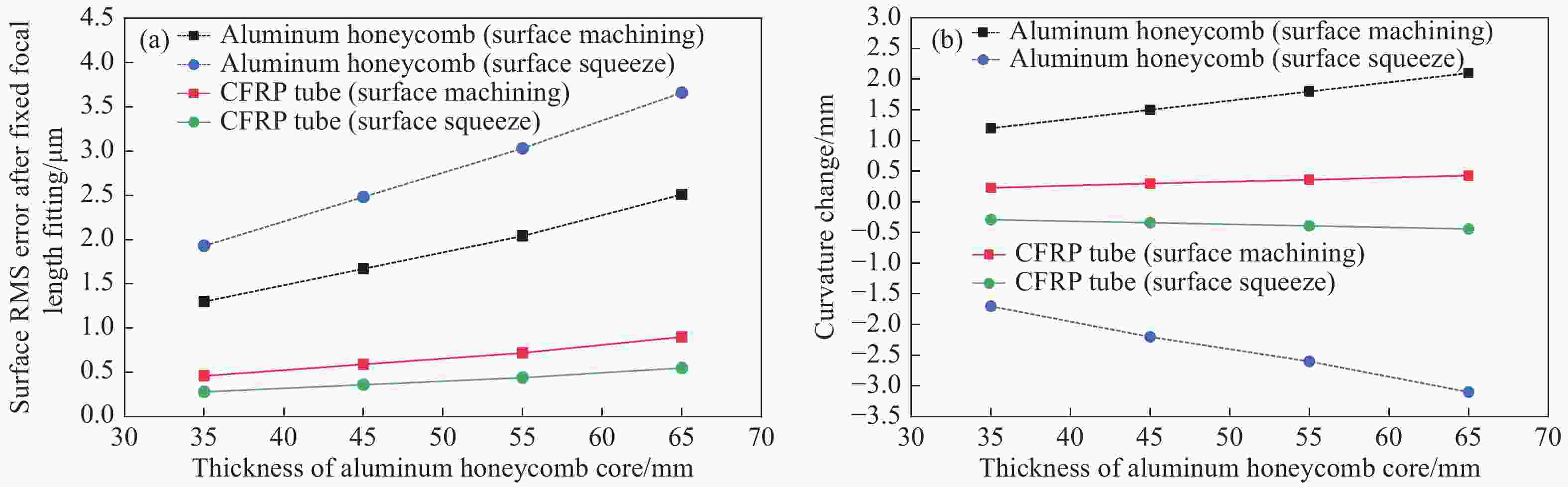

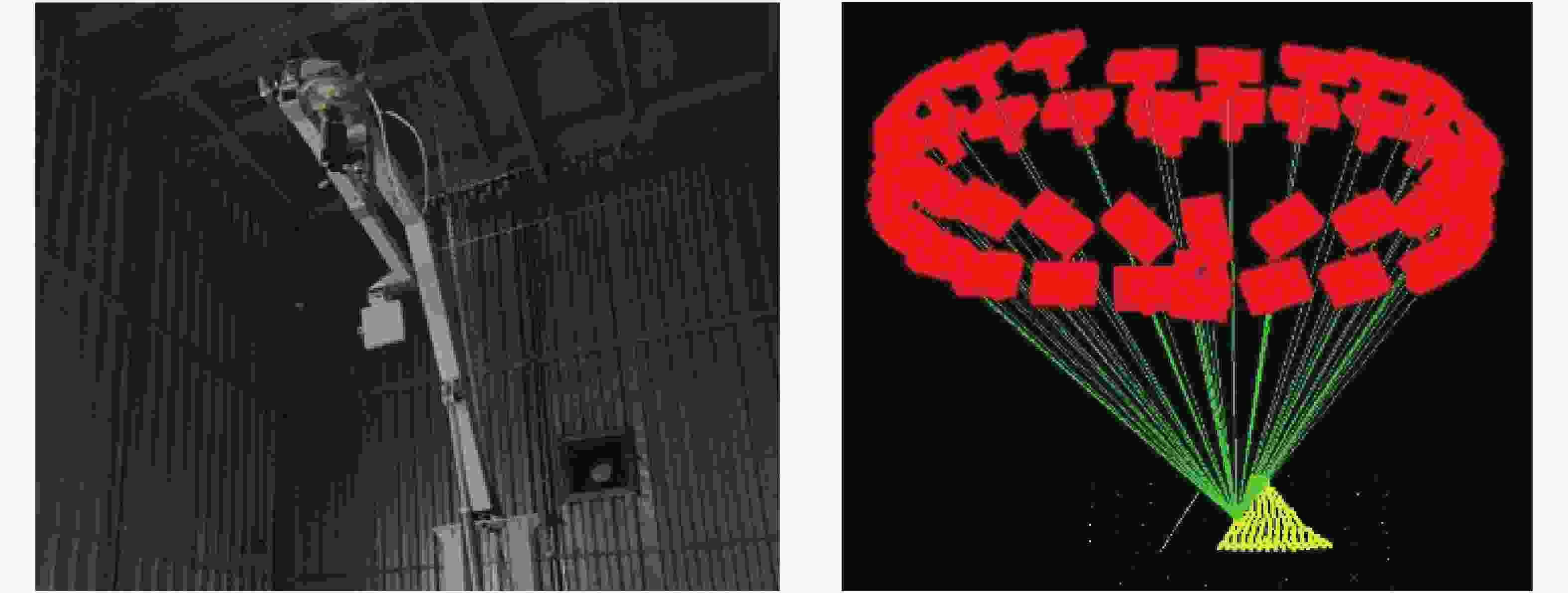

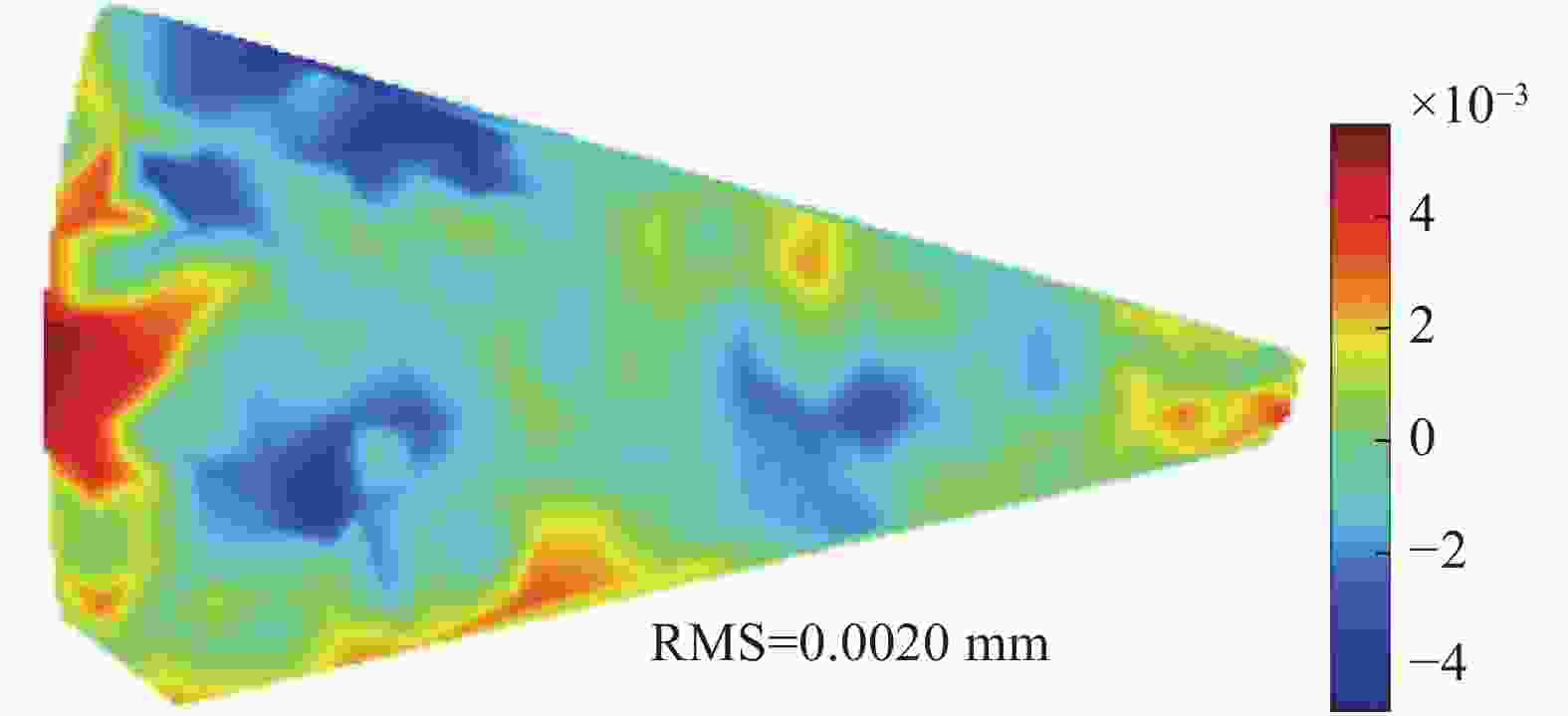

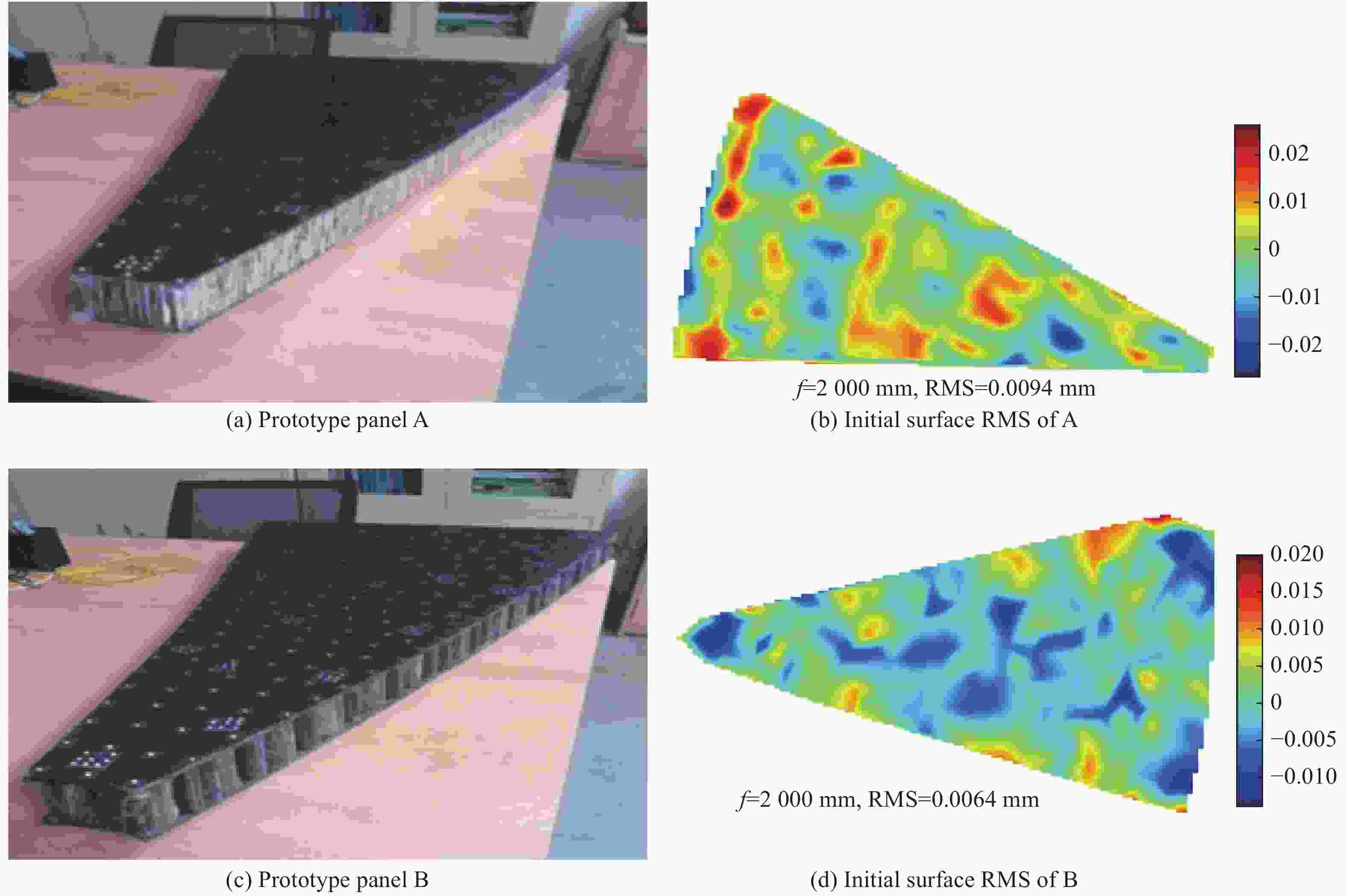

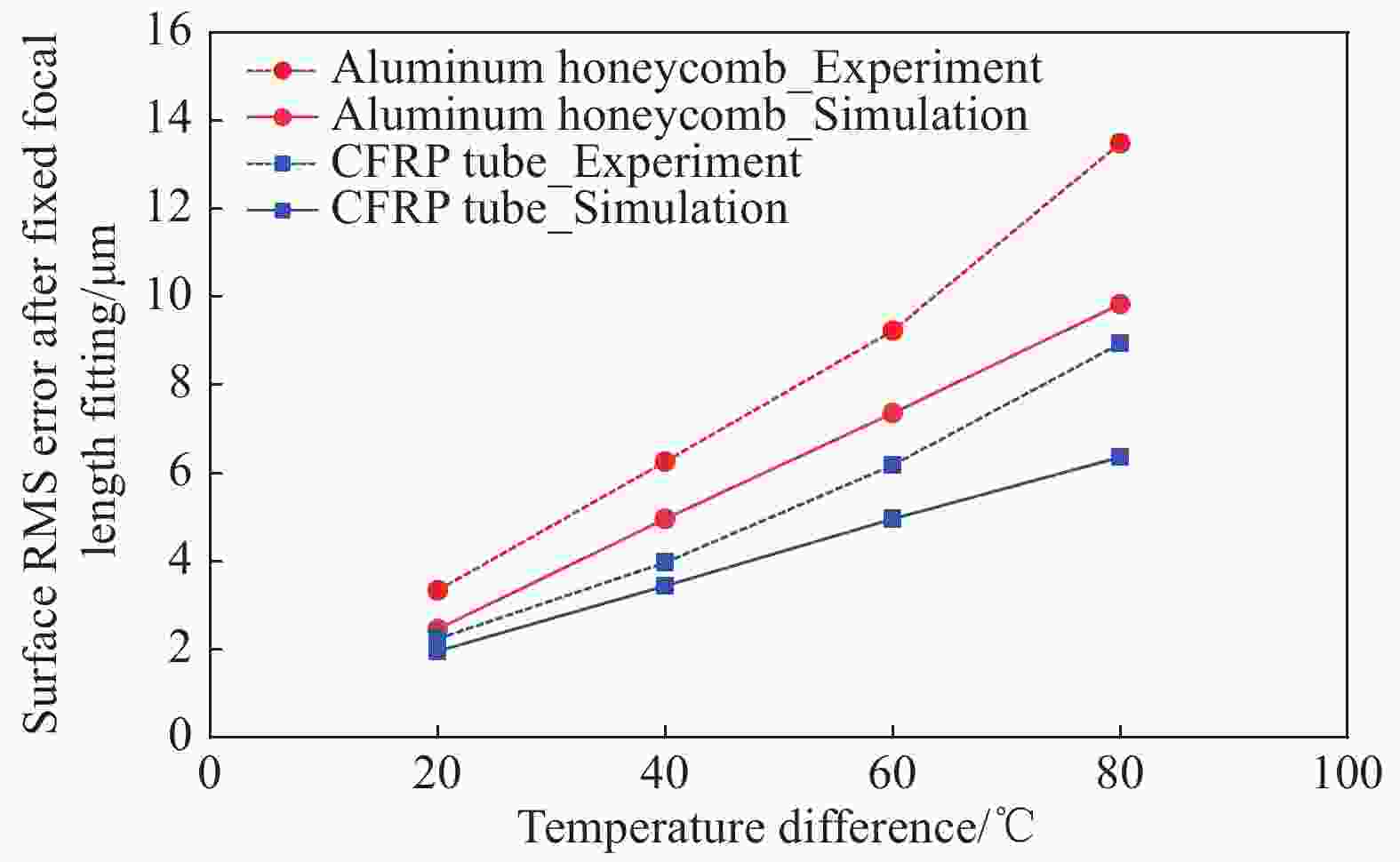

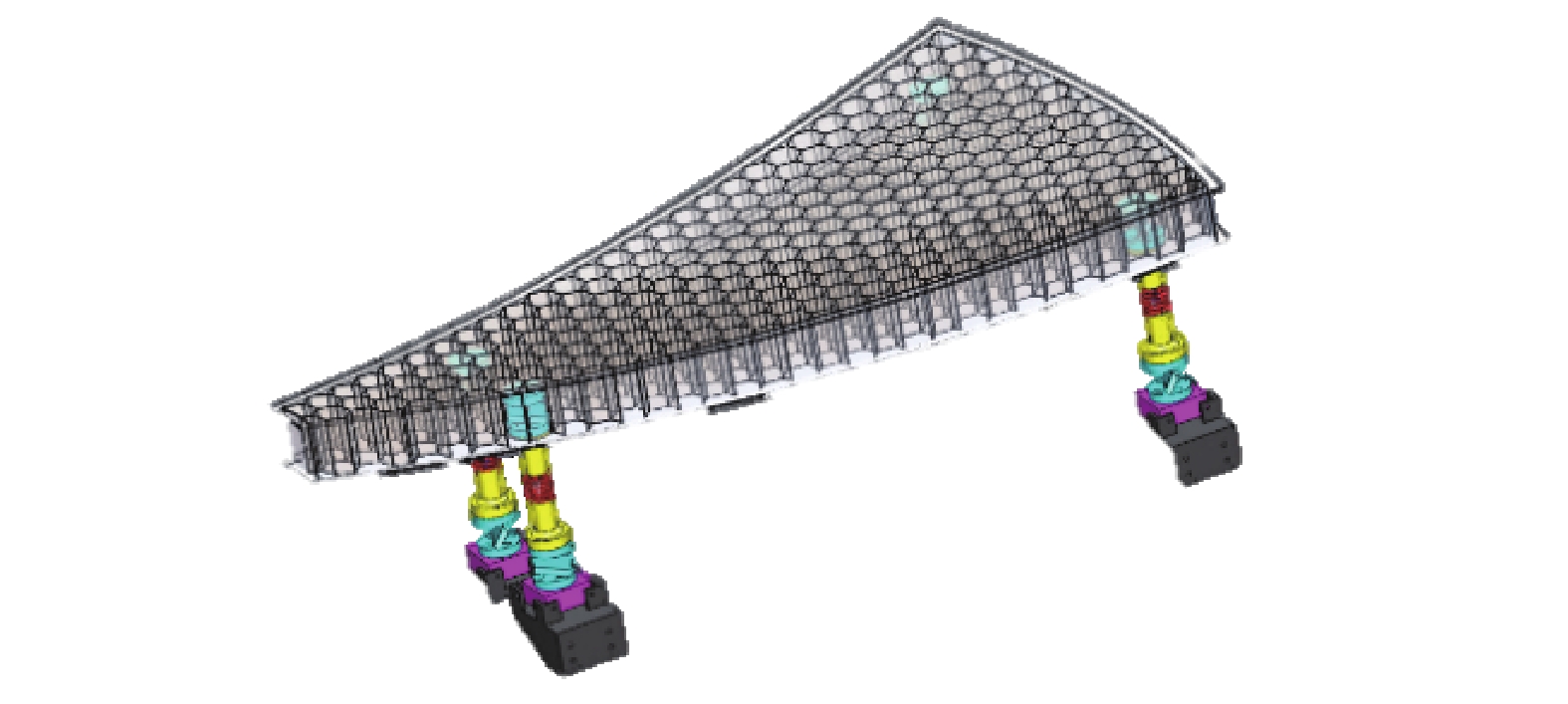

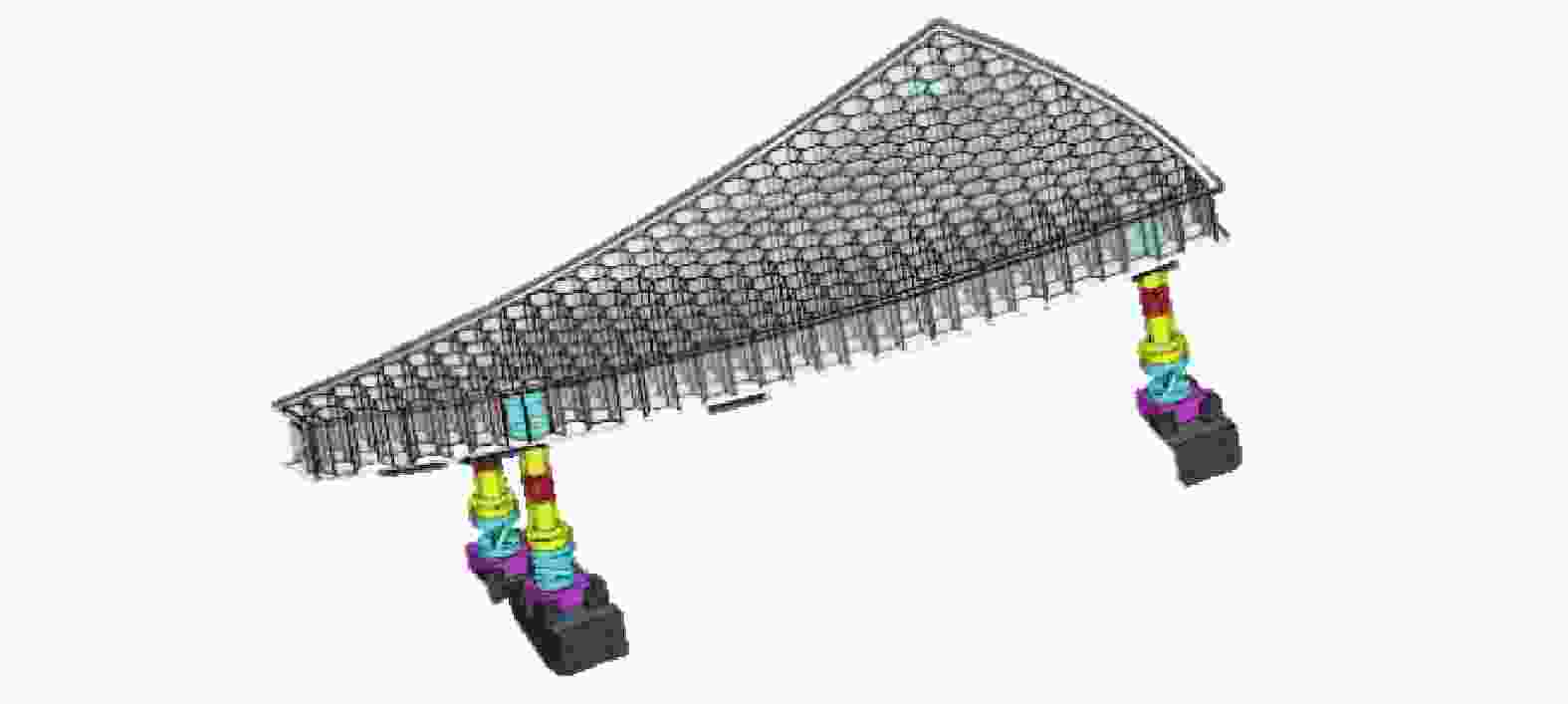

摘要: 为满足亚毫米波、太赫兹波段等高频天线反射面的应用需求,采用附加树脂修型技术制得1米级、面形精度优于10 μm均方差(RMS)的碳纤维增强树脂(CFRP)复合材料天线面板。主要开展了针对高精度CFRP复合材料面板在极端低温环境下的热变形机制研究。根据基础材料性能测试数据,建立面板的有限元仿真模型,预测大温差工况下多结构参数面板的热变形残差,分析了影响面板热变形特性的主要因素。比较了铝蜂窝和碳管阵列夹芯两种面板结构热变形特性的差异。结果表明,碳管夹芯结构面板具备更高的比刚度和热稳定性。通过仿真结构优化给出了面板的结构设计参数,并重新试制了原型面板。采用基于高精度数字摄影测量的实验方法,对铝蜂窝和碳管阵列两种夹芯结构原型面板在低温环境下的热变形误差进行了测量,通过分析实验与仿真结果的误差来源,讨论了有限元预测方法的可行性,给出了针对高精度CFRP复合材料面板设计及工艺方法的指导意见。Abstract: A one-meter-level carbon fiber reinforced plastic(CFRP) composite antenna panel with the surface error less than 10 μm root-mean-square(RMS) has been trial-produced by using additional resin modification technology to satisfy the requirements of high frequency antenna reflector in submillimeter and terahertz wave band. The thermal deformation mechanisms of the high accuracy CFRP composite panel under extreme low temperature were studied. Based on the test data of the basic material, a finite element model was established to predict the thermal deformation residual error of the the panels considering different parameters under the condition of large temperature difference. The main factors affecting the thermal deformation characteristics of the panel were analyzed. The thermal deformation characteristics of the panels with aluminum honeycomb and CFRP composite tube array cores were compared, respectively, which shows that the higher specific stiffness and thermal stability are provided by the panel structure with CFRP composite tube array core. The structural design parameters of the prototype panel were given after the structural optimization, and the prototype panels were remanufactured. The thermal deformation residual errors of prototype panels with aluminum honeycomb and CFRP composite tube array cores were measured by the experimental method of high precision photogrammetry. The guidance for the design and process of high accuracy CFRP composite sandwiched panels was provided.

-

表 1 蒙皮及芯材的性能参数

Table 1. Property parameters of sheet and core

Property Sheet Aluminum honeycomb(l=4 mm/t1=0.03 mm) CFRP tube (r=20 mm/t2=0.2 mm) Elastic modulus E11/GPa 125.4 0.01 0.01 E22/GPa 10.6 0.01 0.01 E33/GPa − 0.67 0.34 Shear modulus G12/GPa 4 0.01 0.01 G23/GPa − 0.25 0.3 G13/GPa − 0.15 0.3 Poisson’s ratio μ12 0.27 0.3 0.9 μ23 − 0.01 0.01 μ13 − 0.01 0.01 CTE α1/10−6℃−1 1.8 23 2.5 α2/10−6℃−1 − 23 2.5 α3/10−6℃−1 − 23 2.5 Notes:CTE—Coefficient of thermal expansion; l—Length of aluminum honeycomb; t1—Thickness of aluminum honeycomb; r—Radius of composite tube; t2—Thickness of CFRP composite tube. 表 2 CFRP复合材料夹层天线面板多种仿真工况的参数

Table 2. Parameters of multiple simulated conditions for CFRP composite sandwiched antenna panel

Condition Thickness of sheets/mm Thickness of core/mm Lay-out of sheets Angle error of lay-out/(°) Ⅰ 2.4 65 Orthogonal/quasi-isotropy − Ⅱ 0.8–3.6 65 Orthogonal/quasi-isotropy − Ⅲ 2.4 35–65 Quasi-isotropy − Ⅳ 2.4 65 Quasi-isotropy 0–10 表 3 芯材的仿真参数

Table 3. Parameters of core

Condition Types of core Thickness of core/mm Core processing process Ⅴ Aluminum honeycomb/CFRP tube array 35–65 Surface machining /Surface squeeze 表 4 原型面板的参数

Table 4. Parameters of prototype panel

Number Thickness of sheets/mm Types of

coreFiber volume fraction/vol% Thickness of core/mm Lay-out

of sheetssCore processing

processDesign value 2.2 − 60/60 65 Orthogonal Surface squeeze A 2.5/2.2 Aluminum honeycomb 52.4/60.5 65 Orthogonal Surface squeeze B 2.5/2.2 CFRP tube array 51.5/62.3 65 Orthogonal Surface squeeze -

[1] RUZE J. Antenna tolerance theory: A review[C]//Proceedings of the IEEE. IEEE, 1966, 54(4): 633-640. [2] HAMIDOUCHE M, YOUNG E, MARCUM P, et al. Stratospheric observatory for infrared astronomy[C]//Proceedings of the Annual Meeting of the French Society of Astronomy and Astrophysics. Marseille: [s. n.], 2010. [3] RUHL J, ADE P A R, CARLSTROM J E, et al. The south pole telescope[C]//Proceedings Volume 5498, Millimeter and Submillimeter Detectors for Astronomy II. Glasgow: SPIE, 2004. [4] YANG J, ZUO Y X, LOU Z, et al. Conceptual design studies of the 5 m terahertz antenna for Dome A, Antarctica[J]. Research in Astronomy and Astrophysics,2013,13(12):1493-1508. doi: 10.1088/1674-4527/13/12/010 [5] UKITA N, SAITO M, EZAWA H, et al. Design and performance of the ALMA-J prototype antenna[C]//Proceedings Volume 5489, Ground-based Telescopes. Glasgow:SPIE, 2004. [6] MARCHIORI G, RAMPINI F. The European ALMA project: Design, manufacturing and performances[C]//Proceedings of the Fourth European Conference on Antennas and Propagation. IEEE, 2010. [7] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [8] BAARS J W M, MARTIN R N, MANGUM J G, et al. The Heinrich Hertz telescope and the submillimeter telescope observatory[J]. Publications of the Astronomical Society of the Pacific,1999,111(759):627-646. doi: 10.1086/316365 [9] BAARS J W M, MARTIN R N. The Heinrich Hertz telescope: A new instrument for submillimeter-wavelength astronomy[J]. Reviews in Modern Astronomy,1996,9:111-126. [10] BAARS J W M, HOOGHOUDT B G, MEZGER P G, et al. The IRAM 30-m millimeter radio telescope on Pico Veleta, Spain[J]. Astronomy and Astrophysics,1987,175(1-2):319-326. [11] 郝长岭, 周贤宾, 李志光, 等. 紧缩场蜂窝夹层反射面板材料参数优化反求[J]. 复合材料学报, 2008, 25(3):190-196. doi: 10.3321/j.issn:1000-3851.2008.03.032HAO C L, ZHOU X B, LI Z G, et al. Material parameter identification of sandwich reflector panels of compact antenna test range by genetic algorithm-based inverse method[J]. Acta Materiae Compositae Sinica,2008,25(3):190-196(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.03.032 [12] HOFFMANN W F, HELWIG G, SCHEULEN D. Thermal stability tests of CFRP sandwich panels for far infrared astronomy[C]//29th Annual Technical Symposium. San Diego: SPTE, 1985. [13] WILLIS P B, DYER J E, DUMMER S. Fabrication and thermo-optical properties of the MLS composite primary reflector[C]//SPIE’s International Symposium on Optical Science, Engineering, and Instrumentation. Denver:SPIE, 1999. [14] MARTIN R N, ROMEO R C. Lightweight optical telescope structures fabricated from CFRP composites[C]//Optical Engineering and Applications. California: SPIE, 2007. [15] STUTE T, WULZ G, SCHEULEN D. Recent developments of advanced structures for space optics at Astrium, Germany[C]//Optical Science and Technology, SPIE’s 48th Annual Meeting. California: SPIE, 2003. [16] MARTIN R N, ROMEO R C, BARBER G, et al. Lightweight CFRP spherical mirrors for the LHCb RICH-1 detector[C]//Optical Engineering and Applications. California: SPIE, 2007. [17] 周星驰, 唐振刚, 周徐斌, 等. CFRP圆形胞元蜂窝芯层面外剪切模量[J]. 复合材料学报, 2018, 35(10):2777-2785.ZHOU X C, TANG Z G, ZHOU X B, et al. The external shear modulus of CFRP circular cell honeycomb[J]. Acta Materiae Compositae Sinica,2018,35(10):2777-2785(in Chinese). [18] 江万松, 王欣, 高红成, 等. 碳纤维天线反射体制造技术[J]. 玻璃钢/复合材料, 2004(5):38-40. doi: 10.3969/j.issn.1003-0999.2004.05.013JIANG W S, WANG X, GAO H C, et al. Manufacturing technique of CFRP antenna reflector[J]. Fiber Reinforced Plastics/Composites,2004(5):38-40(in Chinese). doi: 10.3969/j.issn.1003-0999.2004.05.013 [19] MASSARELLO J J, WELSH J S, HOCHHALTER J D, et al. Fiber print-through mitigation technique for composite mirror replication[J]. Optical Engineering,2006,45(12):123401. doi: 10.1117/1.2402497 [20] LEENDERTZ J A. Interferometric displacement measurement on scattering surfaces utilizing speckle effect[J]. Journal of Physics E: Scientific Instruments,1970,3(3):214-218. doi: 10.1088/0022-3735/3/3/312 [21] BENNETT J, ANDERSON A, MCINNES P, et al. Microwave holographic metrology of large reflector antenna[J]. IEEE Transactions on Antennas & Propagation,1976,24(3):295-303. [22] 王保丰, 李广云, 李宗春, 等. 高精度数字摄影测量技术在50 m大型天线中的应用[J]. 测绘工程, 2007, 16(1):42-46. doi: 10.3969/j.issn.1006-7949.2007.01.011WANG B F, LI G Y, LI Z C, et al. Application of high accuracy digital photogrammetry technology in a 50 meter large antenna[J]. Engineering of Surveying and Mapping,2007,16(1):42-46(in Chinese). doi: 10.3969/j.issn.1006-7949.2007.01.011 [23] 范钦红, 范生宏, 左营喜, 等. 基于数字摄影测量技术的13.7 m毫米波天线面形检测[J]. 天文学报, 2010, 51(2):210-216.FAN Q H, FAN S H, ZUO Y X, et al. Application of digital industrial photogrammetric technology to measure the surface accuracy of 13.7 m millimeter-wave radio telescope antenna[J]. Acta Astronomica Sinica,2010,51(2):210-216(in Chinese). [24] 娄铮, 钱元, 范生宏, 等. 基于数字摄影测量技术的高精度低温面形测量[J]. 天文学报, 2016, 57(1):115-124.LOU Z, QIAN Y, FAN S H, et al. High-precision photogrammetric surface figure measurements under cryogenic environment[J]. Acta Astronomica Sinica,2016,57(1):115-124(in Chinese). -

下载:

下载: