Effect of steel fiber-polypropylene fiber hybrid additon on impact resistance of recycled aggregate concrete

-

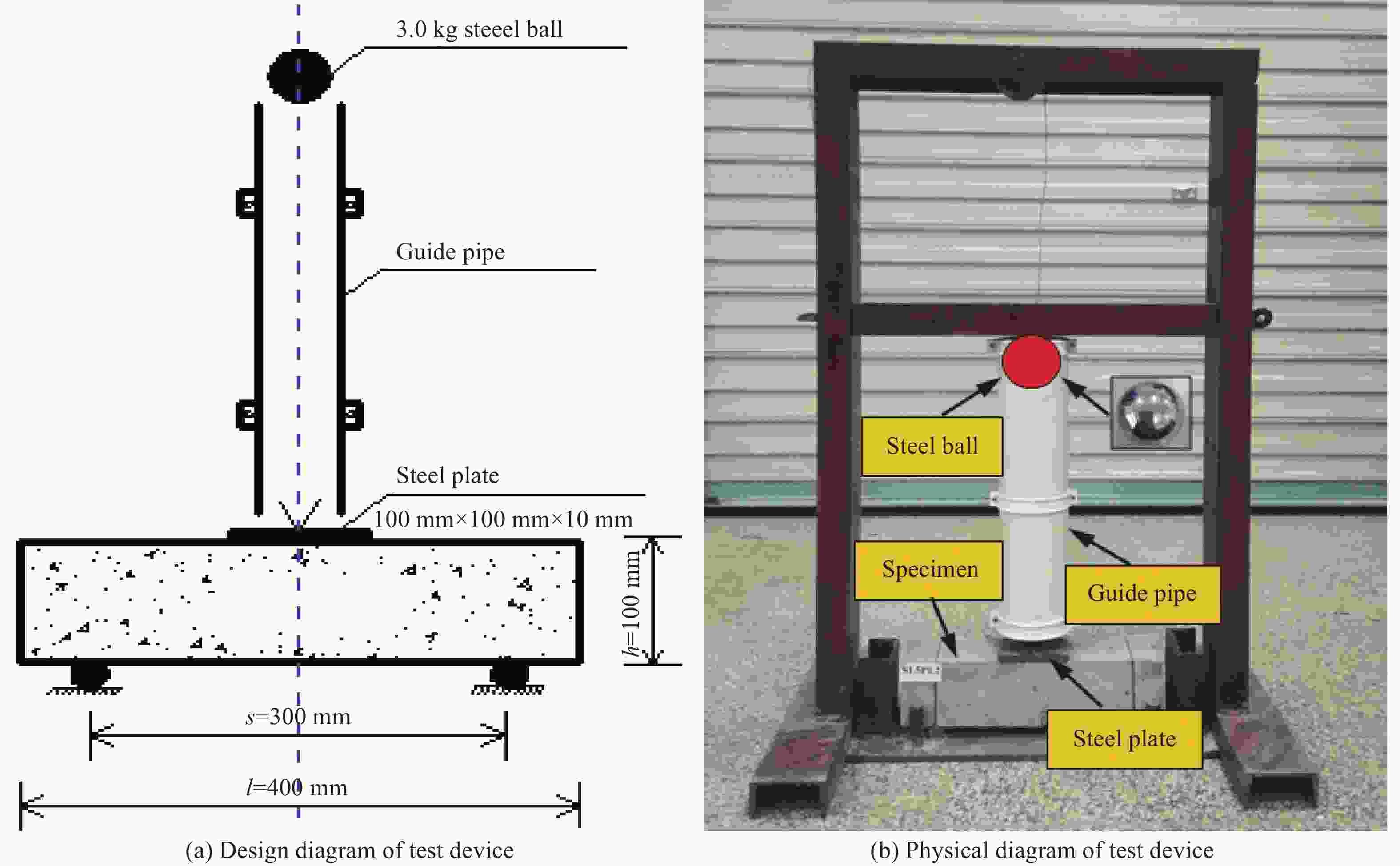

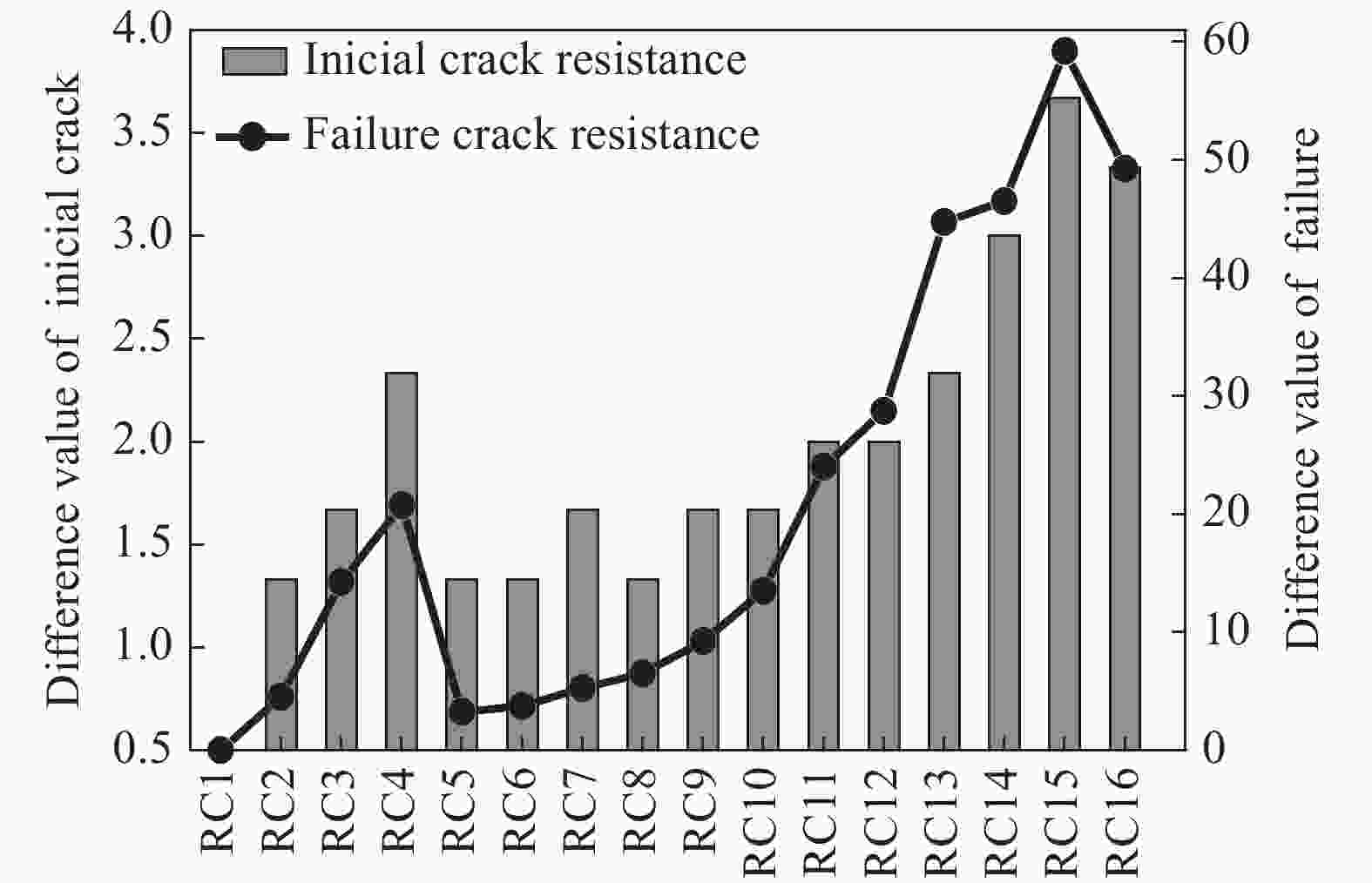

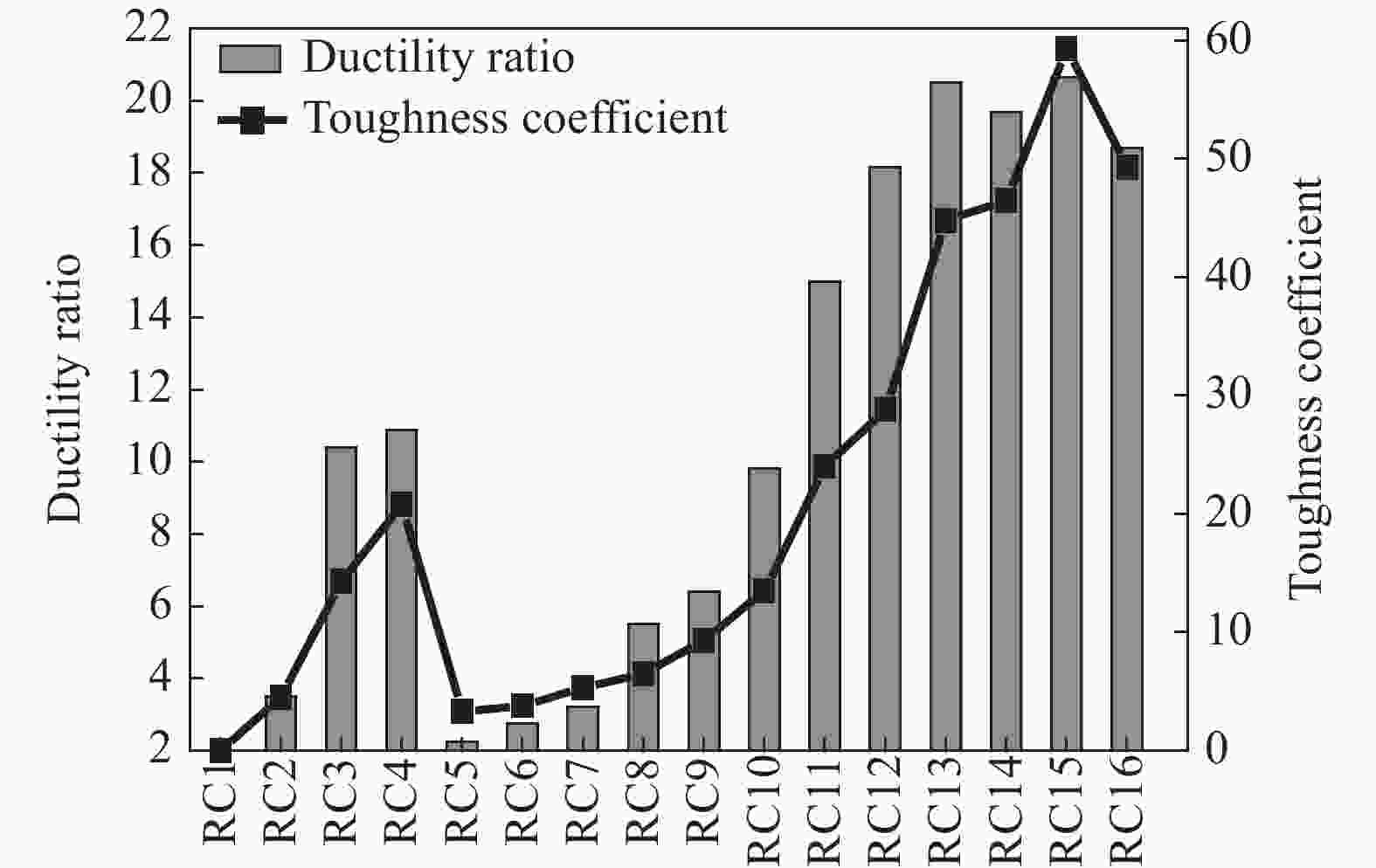

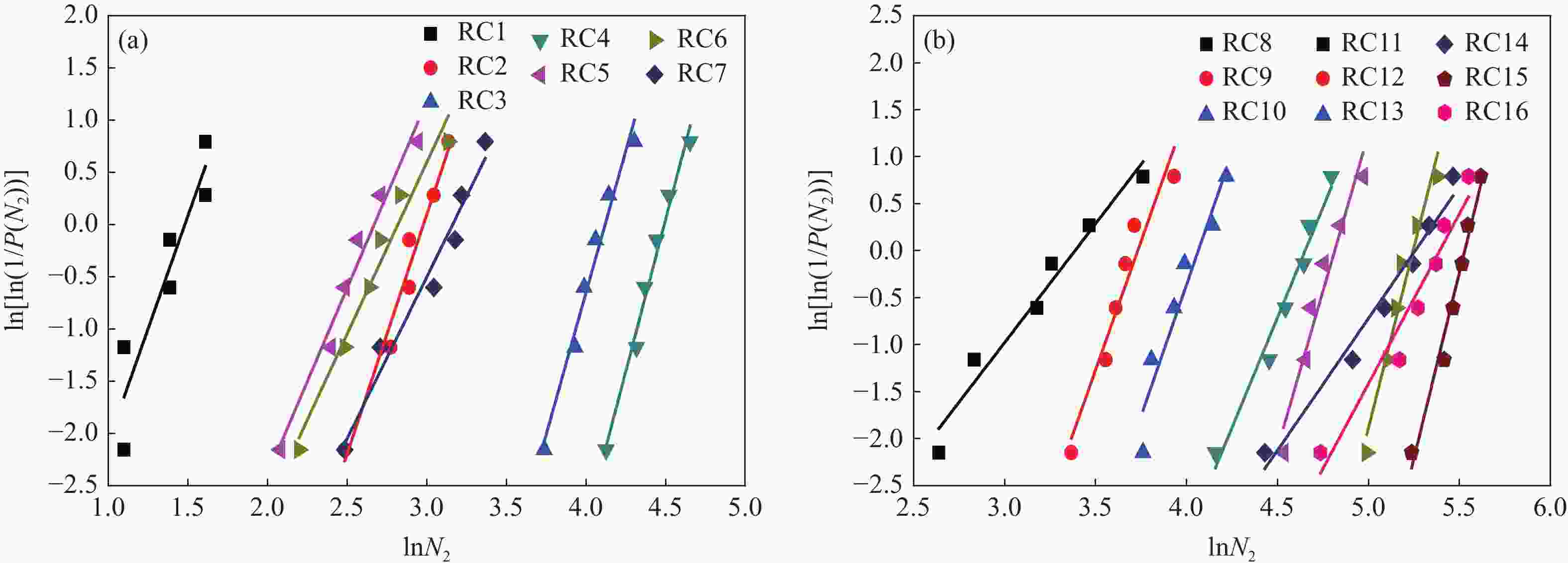

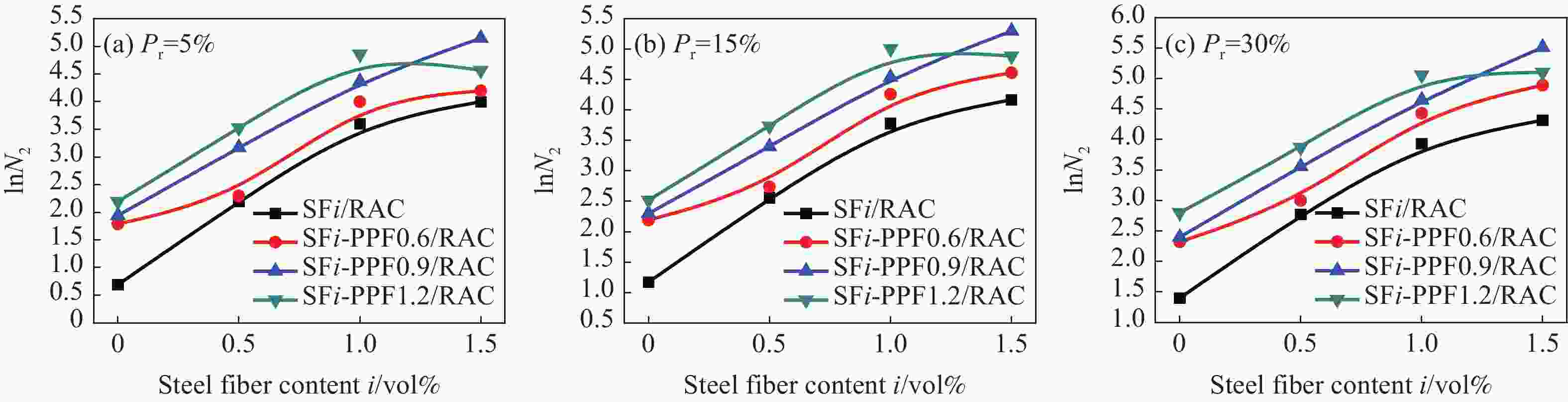

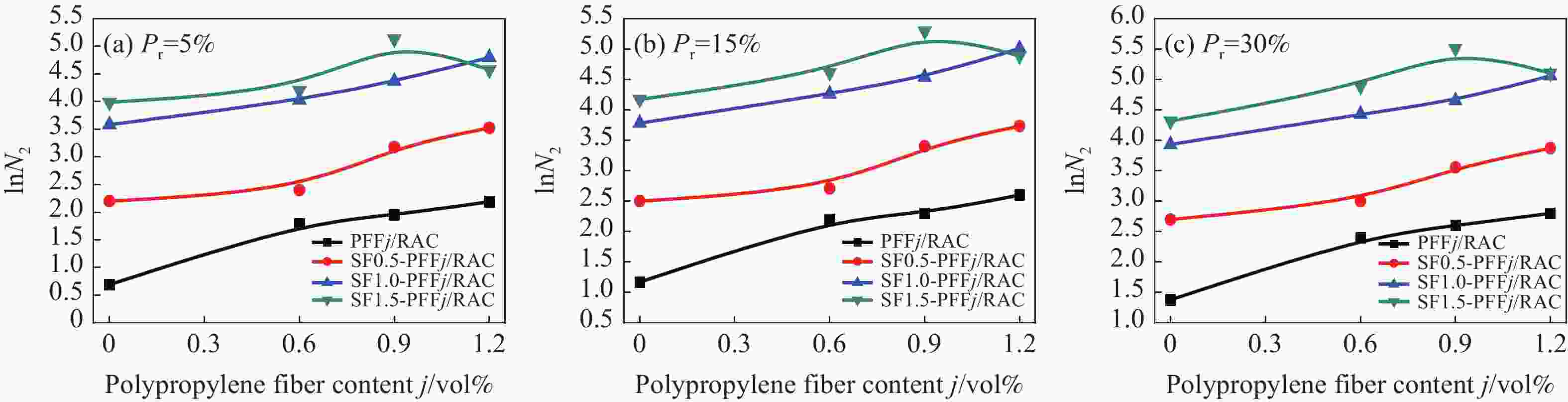

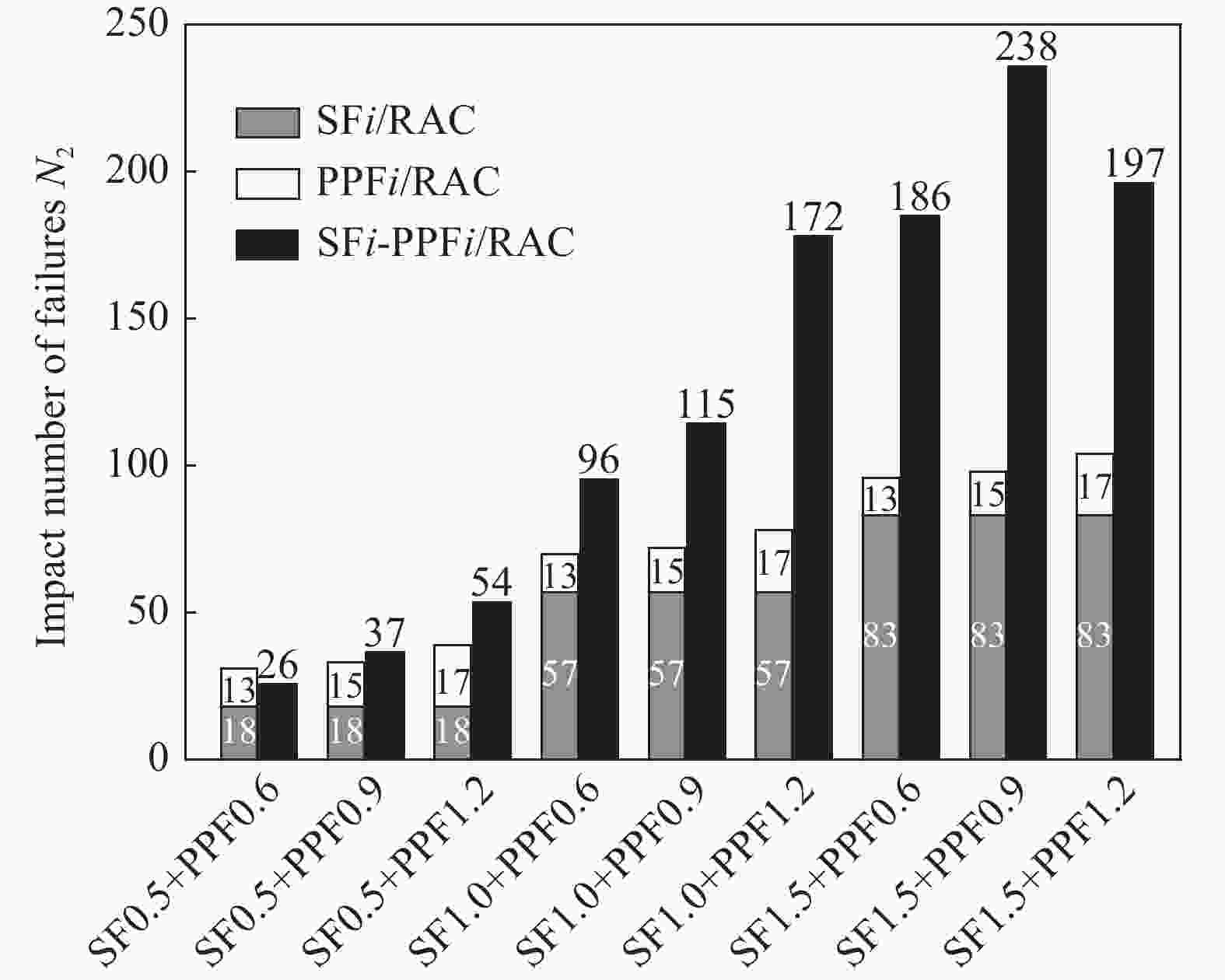

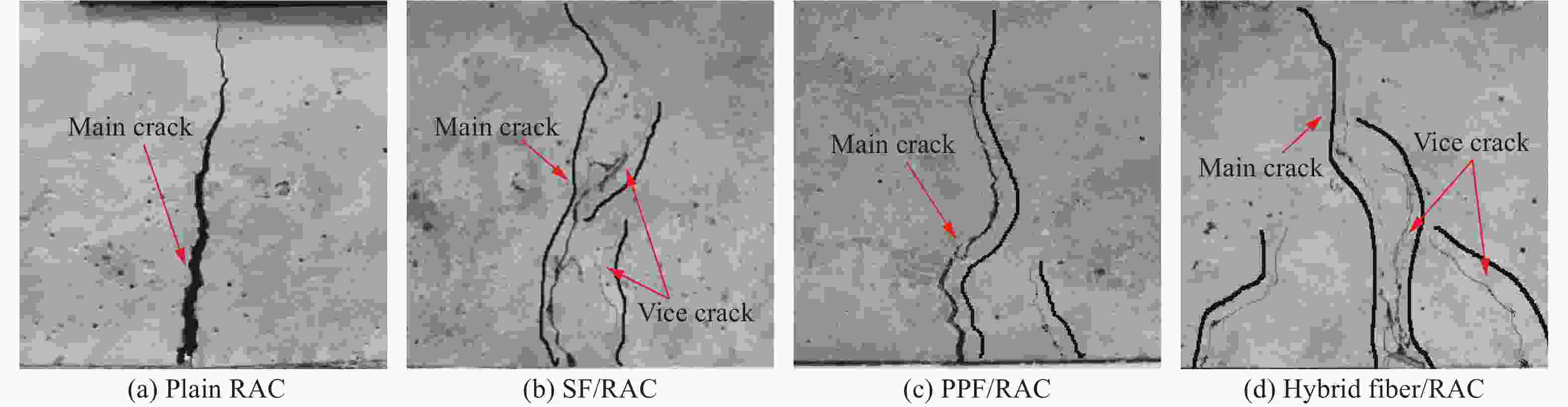

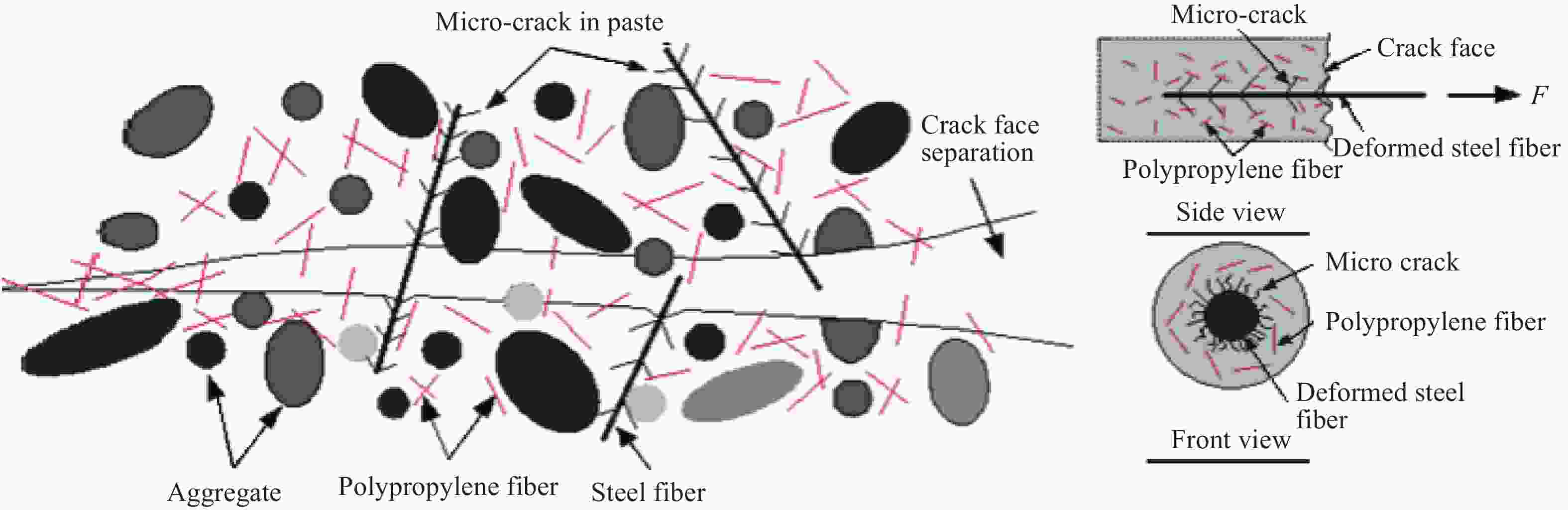

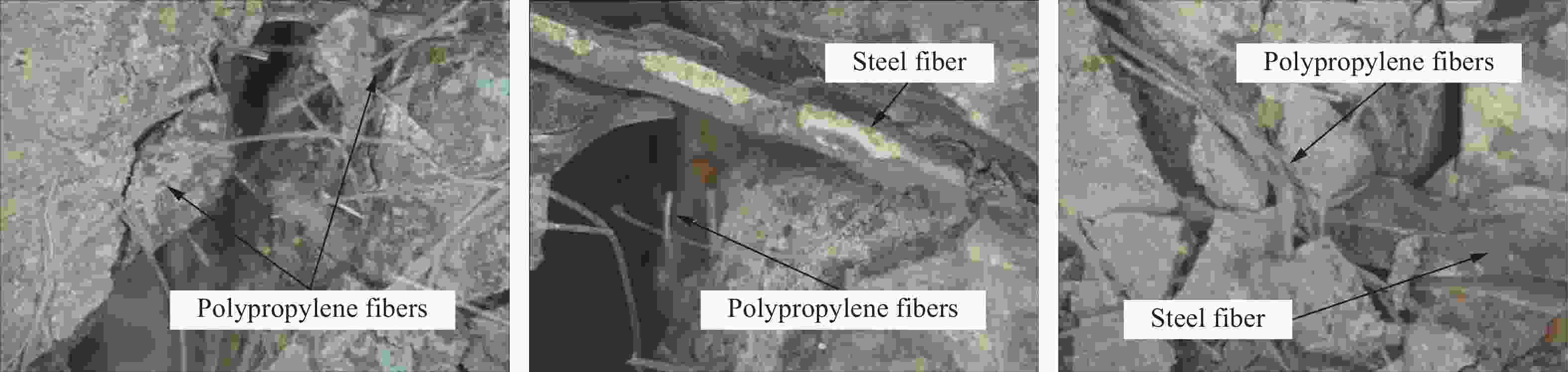

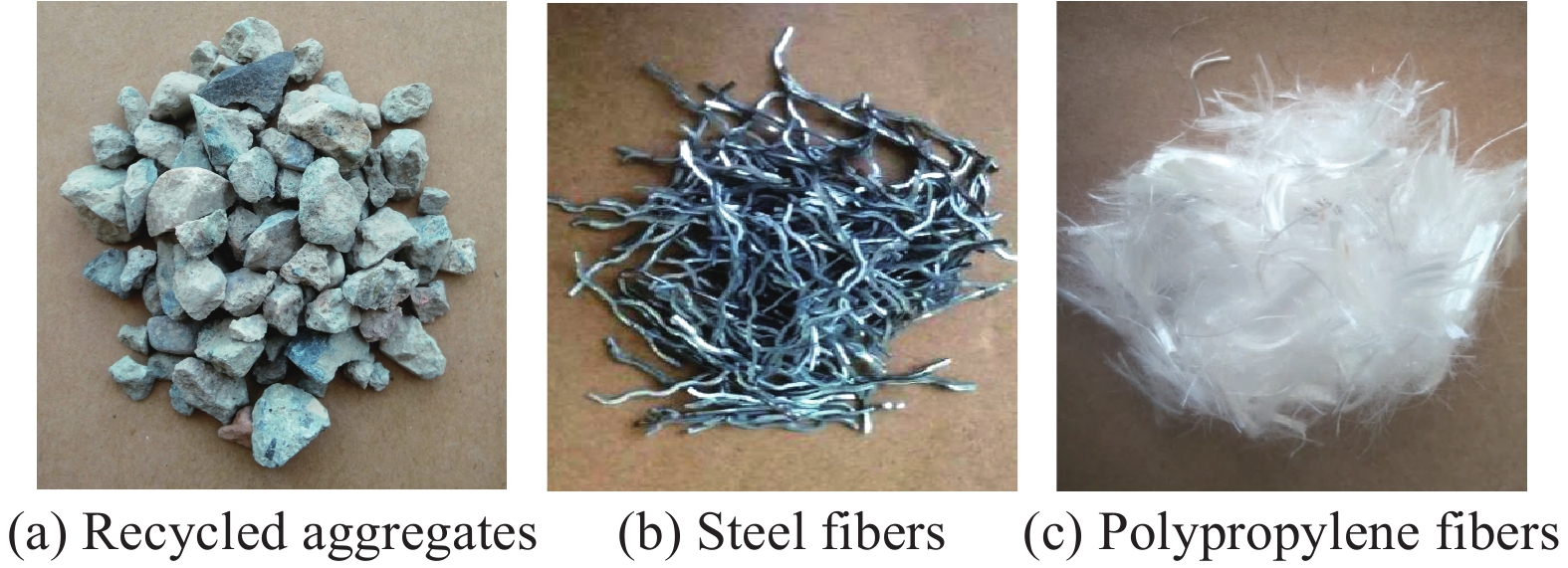

摘要: 为研究钢纤维(SF)与聚丙烯纤维(PPF)混杂后对再生混凝土(RAC)抗冲击性能的影响,采用落锤弯曲冲击试验装置对素RAC、SF/RAC、PPF/RAC和SF-PPF/RAC进行抗冲击试验;分析了不同纤维掺量和掺入方式对RAC抗冲击性能的影响;采用数理统计模型对冲击试验结果进行拟合和失效概率预测,并对SF-PPF/RAC抗冲击性能的阻裂增强机制进行深入分析。结果表明:单掺或混杂纤维均可提高RAC的抗冲击性能;其中混合掺入体积分数为1.5vol%的SF和体积分数为0.9vol%的PPF时,RAC抗冲击耗能的提高幅度最大,RAC基体的延性和韧性最佳。SF-PPF/RAC的抗冲击次数很好地服从两参数Weibull分布。SF与PPF混杂对改善RAC的抗冲击性能呈现出优异的混杂增强效应。Abstract: In order to investigate the effect of hybrid steel fibe (SF) and polypropylene fiber (PPF) on the impact resistance of the recycled aggregate concrete (RAC), the flexural impact resistances of plain RAC, SF/RAC, PPF/RAC and SF-PPF/RAC were studied by drop weight impact test. The effects of fiber content and the way of incorporation on the impact resistance of RAC were analyzed. The mathematical statistical model was used to fit the impact experimental results and predict the failure probability. The crack resistance enhancement mechanism of SF-PPF/RAC was further analyzed. The results indicate that both single fibers and hybrid fibers can improve the impact performance of RAC. The specimen with the hybrid volume fraction of 1.5vol% SF and volume fraction of 0.9vol% PPF is found to have the maximum increase in impact energy consumption and the best ductility and toughness in concrete matrix. The impact resistance numbers of SF-PPF/RAC are well subordinated to the two-parameter Weibull distribution. The SF-PPF exhibit significant hybrid effect on improving the impact resistance of RAC.

-

表 1 再生粗骨料的物理性能

Table 1. Physical properties of recycle coarse aggregate

Size/mm Apparent density/(kg·m–3) Bulk density/(kg·m–3) Crushing index/% Water absorption/% Mud content/% 5–20 2 640 1 460 17.1 3.4 0.2 表 2 钢纤维(SF)和聚丙烯纤维(PPF)的物理性能

Table 2. Physical properties of steel fiber(SF) and polypropylene fiber(PPF)

Fiber type Length/mm Aspect ration Density/(g·cm−3) Tensile strength/MPa Elastic modulus/GPa SF 30 60 7.8 ≥800 210 PPF 12 343 0.91 ≥350 3.5 表 3 SF-PPF/再生混凝土(RAC)试件编号和配合比设计

Table 3. Specimen codes and mix design of SF-PPF/recycled aggregate concrete(RAC)

No. Notation Cement/

(kg·m−3)Sand/

(kg·m−3)Water/

(kg·m−3)Aggregate/

(kg·m−3)Water reducer/

(kg·m−3)SF/vol% PPF/vol% RC1 RAC 540 618 190 1 052 2.16 − − RC2 SF0.5/RAC 540 618 190 1 052 2.16 0.5 − RC3 SF1.0/RAC 540 618 190 1 052 2.16 1.0 − RC4 SF1.5/RAC 540 618 190 1 052 2.16 1.5 − RC5 PPF0.6/RAC 540 618 190 1 052 2.16 − 0.6 RC6 PPF0.9/RAC 540 618 190 1 052 2.16 − 0.9 RC7 PPF1.2/RAC 540 618 190 1 052 2.16 − 1.2 RC8 SF0.5-PPF0.6/RAC 540 618 190 1 052 2.16 0.5 0.6 RC9 SF0.5-PPF0.9/RAC 540 618 190 1 052 2.16 0.5 0.9 RC10 SF0.5-PPF1.2/RAC 540 618 190 1 052 2.16 0.5 1.2 RC11 SF1.0-PPF0.6/RAC 540 618 190 1 052 2.16 1.0 0.6 RC12 SF1.0-PPF0.9/RAC 540 618 190 1 052 2.16 1.0 0.9 RC13 SF1.0-PPF1.2/RAC 540 618 190 1 052 2.16 1.0 1.2 RC14 SF1.5-PPF0.6/RAC 540 618 190 1 052 2.16 1.5 0.6 RC15 SF1.5-PPF0.9/RAC 540 618 190 1 052 2.16 1.5 0.9 RC16 SF1.5-PPF1.2/RAC 540 618 190 1 052 2.16 1.5 1.2 表 4 SF-PPF/RAC的抗压强度和抗冲击试验结果

Table 4. Test results of compressive strength and impact resistance of SF-PPF/RAC

No. Notation fcu/MPa Specimen number Average value Impact energy/J C μ 1 2 3 4 5 6 N1/N2 N1/ N2 N1/ N2 N1/ N2 N1/ N2 N1/ N2 N1/ N2 N1/ N2 RC1 RAC 49.2 2/3 2/3 3/4 3/4 4/5 4/6 3/4 26.5/35.3 – – RC2 SF0.5/RAC 55.2 3/12 3/16 4/18 4/21 5/18 6/23 4/18 35.3/158.8 4.5 3.5 RC3 SF1.0RAC 58.4 4/42 4/54 5/51 5/58 6/63 6/74 5/57 44.1/502.7 14.3 10.4 RC4 SF1.5/RAC 60.6 5/62 6/75 7/79 7/92 8/85 8/105 7/83 61.7/723.1 20.8 10.9 RC5 PPF0.6/RAC 48.1 2/8 3/11 3/12 4/13 4/19 5/15 4/13 35.3/114.7 3.3 2.3 RC6 PPF0.9/RAC 47.2 3/9 3/12 4/14 5/15 5/17 6/23 4/15 35.3/132.3 3.8 2.8 RC7 PPF1.2/RAC 46.9 3/14 4/15 5/21 5/25 6/24 6/29 5/21 44.1/185.2 5.3 3.2 RC8 SF0.5-PPF0.6/RAC 54.1 3/16 3/24 4/17 4/32 5/26 5/41 4/26 35.3/229.3 6.5 5.5 RC9 SF0.5-PPF0.9/RAC 52.7 3/29 3/35 4/39 5/37 7/41 7/51 5/37 44.1/326.3 9.3 6.4 RC10 SF0.5-PPF1.2/RAC 50.8 3/43 4/45 4/51 5/54 6/63 8/68 5/54 44.1/476.3 13.5 9.8 RC11 SF1.0-PPF0.6/RAC 56.2 4/64 6/86 6/104 7/94 7/107 8/121 6/96 52.9/846.7 24.0 15.0 RC12 SF1.0-PPF0.9/RAC 50.4 4/93 5/105 6/108 7/116 7/127 9/144 6/115 52.9/1 014.3 28.8 18.2 RC13 SF1.0-PPF1.2/RAC 47.8 5/137 6/167 7/156 7/185 8/174 12/215 8/172 70.6/1 517.0 43.0 20.5 RC14 SF1.5-PPF0.6/RAC 57.4 5/184 8/136 8/162 9/189 11/207 13/236 9/186 79.4/1 640.5 46.5 19.7 RC15 SF1.5-PPF0.9/RAC 45.2 6/188 8/225 10/248 11/236 13/256 15/275 11/238 97.0/2 099.2 59.5 20.6 RC16 SF1.5-PPF1.2/RAC 44.2 5/114 7/176 8/195 9/215 13/257 15/225 10/197 88.2/1 737.5 49.3 18.7 Notes: fcu—Cube compressive strength at age of 28d; C—Toughness coefficient; μ—Ductility ratio. N1, N2—Impact number. 表 5 SF-PPF/RAC抗冲击次数的Weibull分布线性回归分析结果

Table 5. Results of linear regression in Weibull distribution for impact resistance numbers of SF-PPF/RAC

Number Notation Regression coefficient α Regression coefficient β Correlation coefficient R2 N1 N2 N1 N2 N1 N2 RC1 RAC 3.179 3.612 3.869 5.540 0.841 0.851 RC2 SF0.5/RAC 3.612 4.579 5.540 13.641 0.852 0.961 RC3 SF1.0RAC 5.447 5.434 9.194 22.385 0.839 0.969 RC4 SF1.5/RAC 5.710 5.820 11.399 26.138 0.942 0.979 RC5 PPF0.6/RAC 3.230 3.576 4.416 9.548 0.943 0.966 RC6 PPF0.9/RAC 3.476 3.286 5.479 9.262 0.870 0.961 RC7 PPF1.2/RAC 3.878 3.504 6.504 11.104 0.976 0.919 RC8 SF0.5-PPF0.6/RAC 4.322 2.823 6.399 9.546 0.840 0.913 RC9 SF0.5-PPF0.9/RAC 2.571 5.505 4.393 20.541 0.843 0.920 RC10 SF0.5-PPF1.2/RAC 2.954 5.634 5.104 22.898 0.913 0.909 RC11 SF1.0-PPF0.6/RAC 4.222 4.708 8.201 21.900 0.895 0.965 RC12 SF1.0-PPF0.9/RAC 3.672 6.726 7.157 32.376 0.971 0.934 RC13 SF1.0-PPF1.2/RAC 3.777 6.879 7.910 35.866 0.885 0.949 RC14 SF1.5-PPF0.6/RAC 3.156 2.822 7.301 14.833 0.942 0.967 RC15 SF1.5-PPF0.9/RAC 3.182 7.957 7.845 43.985 0.996 0.967 RC16 SF1.5-PPF1.2/RAC 2.573 3.632 6.119 19.469 0.954 0.931 表 6 不同失效概率下SF-PPF/RAC的抗冲击次数

Table 6. Impact resistance numbers of SF-PPF/RAC under different failure probabilities

Number Notation Failure probability Pr 5% 15% 30% N1 N2 N1 N2 N1 N2 RC1 RAC 1 2 2 3 2 4 RC2 SF0.5/RAC 2 10 3 13 4 16 RC3 SF1.0RAC 3 36 4 44 5 51 RC4 SF1.5/RAC 4 54 5 65 6 75 RC5 PPF0.6/RAC 2 6 2 9 3 11 RC6 PPF0.9/RAC 2 7 3 10 4 12 RC7 PPF1.2/RAC 3 10 3 14 4 18 RC8 SF0.5-PPF0.6/RAC 2 10 3 16 4 20 RC9 SF0.5-PPF0.9/RAC 2 24 3 30 4 35 RC10 SF0.5-PPF1.2/RAC 2 34 3 42 4 49 RC11 SF1.0-PPF0.6/RAC 4 56 5 71 6 84 RC12 SF1.0-PPF0.9/RAC 3 79 4 94 5 106 RC13 SF1.0-PPF1.2/RAC 4 119 5 141 6 158 RC14 SF1.5-PPF0.6/RAC 4 67 6 101 7 133 RC15 SF1.5-PPF0.9/RAC 5 173 7 200 9 221 RC16 SF1.5-PPF1.2/RAC 3 94 5 129 7 160 -

[1] BEHERA M, BHATTACHARYYA S K, MINOCHA A K, et al. Recycled aggregate from C&D waste & its use in concrete-A breakthrough towards sustainability in construction sector: A review[J]. Construction and Building Materials,2014,68:501-516. doi: 10.1016/j.conbuildmat.2014.07.003 [2] KHOURY E, CAZACLIU B, REMOND S. Impact of the initial moisture level and pre-wetting history of recycled concrete aggregates on their water absorption[J]. Materials and Structures,2017,50(5):229. doi: 10.1617/s11527-017-1093-8 [3] 史才军, 曹芷杰, 谢昭彬. 再生混凝土力学性能的研究进展[J]. 材料导报, 2016, 30(23):96-103.SHI Caijun, CAO Zhijie, XIE Zhaobin. Research progress in the mechanical properties of recycled aggregate concrete[J]. Materials Review,2016,30(23):96-103(in Chinese). [4] XIE J H, HUANG L, GUO Y C, et al. Experimental study on the compressive and flexural behaviour of recycled aggregate concrete modified with silica fume and fibres[J]. Construction and Building Materials,2018,178:612-623. [5] 章文姣, 鲍成成, 孔祥清, 等. 混杂纤维掺量对再生混凝土力学性能的影响研究[J]. 科学技术与工程, 2016, 16(13):106-112. doi: 10.3969/j.issn.1671-1815.2016.13.019ZHANG Wenjiao, BAO Chengcheng, KONG Xiangqing, et al. Experimental study on mechanical properties of hybrid fiber basic of recycled concrete[J]. Science Technology and Engineering,2016,16(13):106-112(in Chinese). doi: 10.3969/j.issn.1671-1815.2016.13.019 [6] NILI M, AFROUGHSABET V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete[J]. Construction & Building Materials,2010,24(6):927-933. [7] 王璞, 黄真, 周岱, 等. 碳纤维混杂纤维混凝土抗冲击性能研究[J]. 振动与冲击, 2012, 31(12):14-18.WANG Pu, HUANG Zhen, ZHOU Dai, et al. Impact mechanical properties of concrete reinforced with hybrid carbon fibers[J]. Journal of Vibration and Shock,2012,31(12):14-18(in Chinese). [8] HSIE M, TU C, SONG P S. Mechanical properties of polypropylene hybrid fiber-reinforced concrete[J]. Materials Science & Engineering A,2008,494(1-2):153-157. [9] OUYANG D, KONG L J, FU H, et al. Experimental investigations on mechanical properties and fire resistance of steel-polypropylene hybrid fiber reinforced concrete[J]. Advanced Materials Research,2013,772:182-187. doi: 10.4028/www.scientific.net/AMR.772.182 [10] CHEN B, LIU J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability[J]. Cement and Concrete Research,2005,35(5):913-917. doi: 10.1016/j.cemconres.2004.07.035 [11] TABATABAEIAN M, KHALOO A, JOSHAGHANI A, et al. Experimental investigation on effects of hybrid fibers on rheological, mechanical, and durability properties of high-strength SCC[J]. Construction and Building Materials,2017,147:497-509. doi: 10.1016/j.conbuildmat.2017.04.181 [12] 景嘉骅. 混杂纤维再生砖骨料混凝土试验及性能计算方法[D]. 郑州: 郑州大学, 2018.JING Jiahua. The experiment and performance calculation method of hybrid fibers reinforced recycled bricks aggregate concrete[D]. Zhengzhou: Zhengzhou University, 2018(in Chinese). [13] MESBAH H A, BUYLE-BODIN F. Efficiency of polypropylene and metallic fibres on control of shrinkage and cracking of recycled aggregate mortars[J]. Construction & Building Materials,1999,13(8):439-447. [14] 陈图真. 钢纤维和聚丙烯粗纤维改性再生混凝土力学性能试验研究[D]. 广州: 广东工业大学, 2015.CHEN Tuzhen. Experimental study on mechanical properties of steel fiber and macro polypropylene fiber reinforced recycled concrete[D]. Guangzhou: Guangdong University of Technology, 2015(in Chinese). [15] Amerian Concrete Institute. Measurement of properties of fiber reinforced concrete: ACI 544.2R—89[S]. Detroit: Amerian Concrete Institute, 1999. [16] 中国国家标准化管理委员会. 水泥混凝土和砂浆用合成纤维: GB/T 21120—2007[S]. 北京: 中国标准出版社, 2007.Standardization Administration of the People’s Republic of China. Synthetic fibres for cement concrete and mortar: GB/T 21120—2007[S]. Beijing: China Standards Press, 2007(in Chinese). [17] 潘慧敏, 马云朝. 钢纤维混凝土抗冲击性能及其阻裂增韧机理[J]. 建筑材料学报, 2017, 20(6):956-961. doi: 10.3969/j.issn.1007-9629.2017.06.021PAN Huimin, MA Yunzhao. Impact resistance of steel fiber reinforced concrete and its mechanism crack resistance and toughening[J]. Journal of Building Structures,2017,20(6):956-961(in Chinese). doi: 10.3969/j.issn.1007-9629.2017.06.021 [18] 邓宗才, 薛会青, 刘爱军. 纤维素纤维及混杂纤维混凝土的抗弯冲击性能[J]. 北京工业大学学报, 2008, 34(11):1149-1153.DENG Zongcai, XUE Huiqing, LIU Aijun. Flexural impact behavior of cellulose and hybrid fiber reinforced concrete beams[J]. Journal of Beijing University of Technology,2008,34(11):1149-1153(in Chinese). [19] 陈相宇. 纤维混凝土抗冲击性能的试验研究[D]. 大连: 大连理工大学, 2010.CHEN Xiangyu. Experimental research on impact resistance of fibre reinforced concrete[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [20] 李冬, 丁一宁. 钢筋与结构型合成纤维对混凝土抗冲击性能混杂效应的分析[J]. 振动与冲击, 2017, 36(2):123-128.LI Dong, DING Yining. Hybrid effect of steel rebar and polypropylene fiber on the impact resistance of concrete[J]. Journal of Vibration and Shock,2017,36(2):123-128(in Chinese). [21] ALI M A E M, SOLIMAN A M, NEHDI M L. Hybrid-fiber reinforced engineered cementitious composite under tensile and impact loading[J]. Materials & Design,2017,117:139-149. [22] GUPTA T, SHARMA R K, CHAUDHARY S. Impact resistance of concrete containing waste rubber fiber and silica fume[J]. International Journal of Impact Engineering,2015,83:76-87. doi: 10.1016/j.ijimpeng.2015.05.002 [23] LI J J, NIU J G, WAN C J, et al. Investigation on mechanical properties and microstructure of high performance polypropylene fiber reinforced lightweight aggregate concrete[J]. Construction and Building Materials,2016,118:27-35. doi: 10.1016/j.conbuildmat.2016.04.116 [24] 欧祖敏, 孙璐. 冻融损伤混凝土的弯曲疲劳寿命可靠性分析[J]. 浙江大学学报(工学版), 2017, 51(6):1074-1081, 1103. doi: 10.3785/j.issn.1008-973X.2017.06.003OU Zumin, SUN Lu. Flxural fatigue-life reliability of frost-damaged concrete[J]. Journal of Zhejiang University (Engineering Science),2017,51(6):1074-1081, 1103(in Chinese). doi: 10.3785/j.issn.1008-973X.2017.06.003 [25] 石小平, 姚祖康, 李华, 等. 水泥混凝土的弯曲疲劳特性[J]. 土木工程学报, 1990, 23(3):11-22.SHI Xiaoping, YAO Zukang, LI Hua, et al. Study on flexural fatigue behavior of cement concrete[J]. China Civil Engineering Journal,1990,23(3):11-22(in Chinese). [26] WEIBULL W. A statistical distribution function of wide applicability[J]. Journal of Applied Microelectron,1951,28(4):613-617. [27] SAGHAFI A, MIRHABILI A R, YARI G H. Improved linear regression method for estimating Weibull parameters[J]. Theoretical & Applied Fracture Mechanics,2009,52(3):180-182. [28] RAHMANI T, KIANI B, SHEKARCHI M, et al. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test[J]. Construction & Building Materials,2012,37:360-369. [29] 赵庆新, 董进秋, 潘慧敏, 等. 玄武岩纤维增韧混凝土冲击性能[J]. 复合材料学报, 2010, 27(6):120-125.ZHAO Qingxin, DONG Jinqiu, PAN Huimin, et al. Impact behavior of basalt fiber reinforced concrete[J]. Acta Materiae Compositae Sinica,2010,27(6):120-125(in Chinese). [30] LI B, XU L H, SHI Y C, et al. Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete[J]. Construction and Building Materials,2018,181:474-486. doi: 10.1016/j.conbuildmat.2018.06.065 -

下载:

下载: