Application of continuum damage mechanics model for composites in progressive failure prediction of bolted joints

-

摘要: 提出考虑层合板面内(纤维和基体失效)和层间失效的复合材料连续损伤力学模型,对螺栓接头的渐进失效行为进行预测。基于Tsai-Wu强度准则,发展可以判定复合材料面内和层间失效的强度准则。采用幂指数衰减材料退化模型模拟复合材料的损伤扩展过程。建立连续损伤力学模型用以研究0°铺层比例和螺栓直径对复合材料螺栓接头挤压性能的影响,预测结果与实验结果吻合。结果表明:0°铺层比例过高,接头发生剪切破坏,降低连接结构承载能力;增大螺栓直径,层合板损伤受到抑制,可提高复合材料螺栓接头的挤压强度。Abstract: A continuum damage mechanics model for composites, considering the intralaminar (fibre and matrix failure) and interlaminar failure, was proposed to predict the progressive damage behavior of bolted joints. Based on Tsai-Wu strength criterion, a new failure-judgement formula was developed to distinguish the intralaminar and interlaminar failure. An exponent material degradation model was introduced to simulate the damage evolution of the composite. A continuum damage mechanics model was established to analyze the effect of 0° ply ratio and bolt diameter on the bearing characteristic of the composite bolted joints. The predicted results exhibit good agreement with the experimental results. These results show that high 0° ply ratio induces the shear-out failure of the composite bolted joints, decreasing the structural bearing capability. Increasing the bolt diameter can restrain the damage of the composite laminate and improve the bearing strength of the composite bolted joints.

-

Key words:

- composite /

- bolted joint /

- continuum damage mechanics model /

- progressive damage /

- strength criterion

-

表 1 T800级碳纤维增强聚合物复合材料层合板铺层比例和顺序

Table 1. Ply ratios and sequences of T800 carbon fiber reinforced polymer composite laminate

Code Ply ratio/

%[0°/±45°/90°]Ply sequence A (30/60/10) [45°/0°/−45°/0°/45°/90°/−45°/0°/45°/−45°]3s B (50/40/10) [45°/0°/−45°/0°/90°/0°/45°/0°/−45°/0°]3s C (70/20/10) [45°/0°/0°/−45°/0°/0°/0°/90°/0°/0°]3s 表 2 T800级碳纤维增强聚合物复合材料力学性能[23]

Table 2. Mechanical properties of T800 carbon fiber reinforced polymer composite[23]

Elastic constant Value Strength Value E1/GPa 195 XT/MPa 3 071 E2=E3/GPa 8.58 XC/MPa 1 747 G12=G13/GPa 4.57 YT=ZT/MPa 88 G23/GPa 2.9 YC=ZC/MPa 271 ν12=ν13 0.33 S12=S13/MPa 143 v23 0.48 S23/MPa 143 Notes: Ei(i=1,2,3)—Elastic modulus in material principle directions; Gij(1≤i<j≤3)—Shear elastic modulus in material principle directions; νij(1≤i<j≤3)—Poison’s ratio in material principal directions; XT and XC—Tensile and compressive strength in fiber directions; YT and YC—Tensile and compressive strength normal to fiber directions; ZT and ZC—Tensile and compressive strength in interlaminar directions; S12 and S13—In-plane shear strength in material directions; S23—Interlaminar shear strength in material directions. 表 3 T800级碳纤维增强聚合物复合材料的断裂韧性[24]

Table 3. Fracture toughness of T800 carbon fiber reinforced polymer composite[24]

Gf/(N·mm−1) Gn/(N·mm−1) Gs/(N·mm−1) 106.3 0.28 0.79 Notes: Gf—Fracture toughness in fiber direction; Gn—Transverse normal fracture toughness; Gs—Shear fracture toughness. Property Value E/GPa 110 — — ν 0.29 — — σy/MPa 950 1 034 1 103 εp 0 0.002 0.1 Notes: E—Young’s modulus; ν—Poison’s ratio; σy—Yield stress; εp—Yield strain. 表 5 T800级碳纤维增强聚合物复合材料螺栓接头的拉伸试验矩阵

Table 5. Tensile test matrix of T800 carbon fiber reinforced polymer composite bolted joints

Specimen Ply ratio/%[0°/±45°/90°] Bolt diameter D/mm A-12.8 (30/60/10) 12.8 B-12.8 (50/40/10) 12.8 C-12.8 (70/20/10) 12.8 A-9.53 (30/60/10) 9.5 A-14.3 (30/60/10) 14.3 表 6 试验与数值结果比较(接头C-12.8)

Table 6. Comparison between experimental and numerical results (Joint configuration C-12.8)

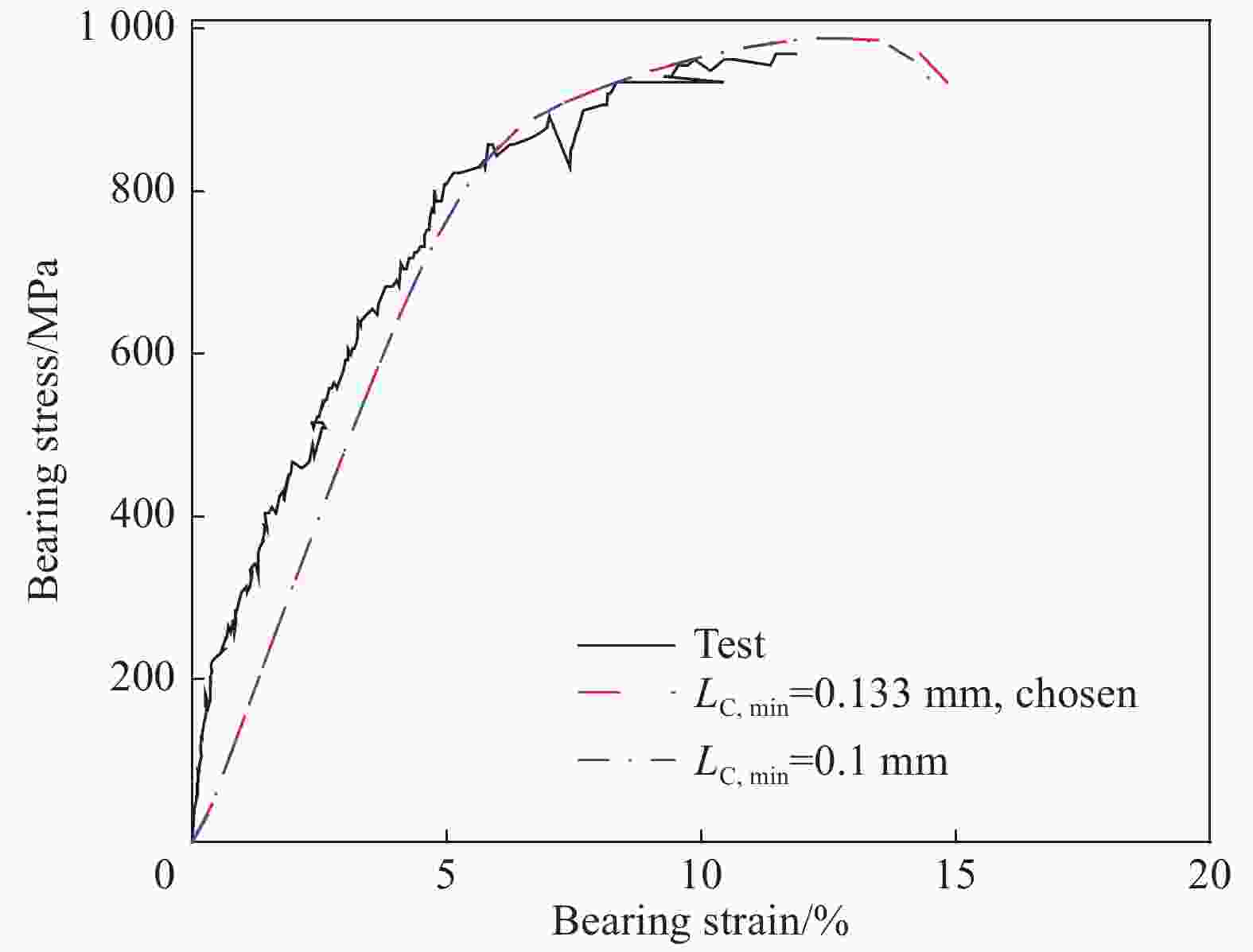

Model Ultimate bearing strength/MPa Prediction Test Error/% This paper 967.3 935.3 3.4 Linde model 1 007 935.3 7.7 Hashin model 1 001 935.3 7.1 -

[1] 赵丽滨, 山美娟, 彭雷, 等. 制造公差对复合材料螺栓连接结构强度分散性的影响研究[J]. 复合材料学报, 2015, 32(4):1092-1098.ZHAO L B, SHAN M J, PEI L, et al. Effect of manufacturing tolerance on the strength scatter of composite bolted joints[J]. Acta Materiae Compositae Sinica,2015,32(4):1092-1098(in Chinese). [2] LIU P, CHENG X Q, WANG S W, et al. Numerical analysis of bearing failure in countersunk composite joints using 3D explicit simulation method[J]. Composite Structures,2016,138:30-39. doi: 10.1016/j.compstruct.2015.11.058 [3] XIAO Y, ISHIKAWA T. Bearing strength and failure behavior of bolted composite joints(Part I: Experimental investigation)[J]. Composite Science Technology,2005,65:1022-1031. doi: 10.1016/j.compscitech.2005.02.011 [4] XIAO Y, ISHIKAWA T. Bearing strength and failure behavior of bolted composite joints(Part II: modeling and simulation)[J]. Composite Science Technology,2005,65:1032-1043. doi: 10.1016/j.compscitech.2004.12.049 [5] HILL R. A theory of the yielding and plastic flow of anisotropic metals[J]. Proceedings of the Royal Society of London. Series A,1948,193(1033):281-297. [6] HOFFMAN O. The brittle strength of orthotropic materials[J]. Journal of Composite Materials,1967,1(2):200-206. doi: 10.1177/002199836700100210 [7] TSAI S W, WU E. A general theory of strength for anistropic materials[J]. Journal of Composite Materials,1971,5(1):58-80. doi: 10.1177/002199837100500106 [8] HASHIN Z. Failure criteria for unidirectional fibre compo-sites[J]. Journal of Applied Mechanics,1980,47:329-334. doi: 10.1115/1.3153664 [9] HASHIN Z, ROTEM A. A fatigue failure criterion for fiber reinforced materials[J]. Journal of Composite Materials,1973,7:448-464. doi: 10.1177/002199837300700404 [10] PUCK A, SCHURMANN H. Failure analysis of FRP laminates by means of physically based phenomenological models[J]. Composites Science and Technology,2002,62(12-13):1633-1662. doi: 10.1016/S0266-3538(01)00208-1 [11] 吴义韬, 姚卫星, 吴富强, 等. 基于应变能耗散的复合材料层合板面内缺口强度分析CDM模型[J]. 复合材料学报, 2014, 31(4):1013-1021.WU Y T, YAO W X, WU F Q, et al. CDM model for analyzing intralaminar strength of notched composite laminates based on the dissipation of strain energy[J]. Acta Materiae Compositae Sinica,2014,31(4):1013-1021(in Chinese). [12] ZHOU Y H, YAZDANI-NEZHAD H, MCCARTHY M A, et al. A study of intra-laminar damage in double-lap, multi-bolt, composite joints with variable clearance suing continuum damage mechanics[J]. Composite Structures,2014,116:441-452. doi: 10.1016/j.compstruct.2014.05.051 [13] 黄河源, 赵美英, 万小鹏, 等. 复合材料中厚板沉头连接结构强度与损伤失效[J]. 复合材料学报, 2017, 34(3):557-563.HUANG H Y, ZHAO M Y, WAN X P, et al. Strength and damage evolution of mid-thick composite laminates with countersunk bolt joints[J]. Acta Materiae Compositae Sinica,2017,34(3):557-563(in Chinese). [14] EGAN B, MCCARTHY M A, FRIZZELL R M, et al. Modelling bearing failure in countersunk composite joints under quasi-static loading using 3D explicit finite element analysis[J]. Composite Structures,2014,108:963-977. doi: 10.1016/j.compstruct.2013.10.033 [15] TANG Y L, ZHOU Z G, PAN S D, et al. Mechanical property and failure mechanism of 3D carbon-carbon braided composites bolted joints under unidirectional tensile loading[J]. Materials and Design,2015,65:243-253. doi: 10.1016/j.matdes.2014.08.073 [16] ZHAO L B, QIN T L, ZHANG J Y, et al. 3D gradual material degradation model for progressive damage analyses of unidirectional composite materials[J]. Mathematical Problems in Engineering,2015,145629:1-11. [17] RICCIO A, MARCIANO L. Effects of geometrical and material features on damage onset and propagation in single-lap bolted composite joints under tensile load: Part I-experimental studies[J]. Journal of Composite Materials,2005,39:2071-2090. doi: 10.1177/0021998305052026 [18] CHANG F K, LESSARD L B. Damage tolerance of laminated composites containing an open hole and subject to compressive loadings: Part I-analysis[J]. Journal of Composite Materials,1991,25(1):2-43. doi: 10.1177/002199839102500101 [19] DAVILA C G, CAMANHO P P, ROSE C A. Failure criteria for FRP laminates[J]. Journal of Composite Materials,2005,39(4):323-345. doi: 10.1177/0021998305046452 [20] ZOU Z, REID S R, LI S, et al. Application of a delamination model to laminated composite structures[J]. Composite Structures,2002,56:375-389. doi: 10.1016/S0263-8223(02)00021-1 [21] LINDE P, DE BOER H. Modelling of inter-rivet buckling of hybrid composites[J]. Composite Structures,2006,73:221-228. doi: 10.1016/j.compstruct.2005.11.062 [22] BENZEGAGH M L, KENANE M. Measurement of mix-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J]. Composite Science and Technology,1996,56(4):439-449. doi: 10.1016/0266-3538(96)00005-X [23] 何柏灵, 葛东云, 莫与明, 等. T800碳纤维增强复合材料双剪单钉连接的拉伸试验及强度估算[J]. 复合材料学报, 2016, 33(7):1540-1552.HE B L, GE D Y, MO Y M, et al. Tensile tests and strength estimation for double-lap single bolt joints in T800 carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica,2016,33(7):1540-1552(in Chinese). [24] WANG L, ZHENG C X, LUO H Y. Continuum damage modeling and progressive failure analysis of carbon fiber/epoxy composite pressure vessel[J]. Composite Structures,2015,134:475-482. doi: 10.1016/j.compstruct.2015.08.107 [25] MIL-HDBK-5H. Metallic materials and elements for aerospace vehicle structures[M]. USA: Department of Defense, 1998. [26] OLMEDO A, SANTIUSTE C. On the prediction of bolted single-lap composite joints[J]. Composite Structures,2012,94:2110-2117. doi: 10.1016/j.compstruct.2012.01.016 [27] American Society for Testing and Materials International. Standard test method for bearing response of polymer matrix composite laminates: ASTM D5961/D5961M—13[S]. West Conshohocken: ASTM International, 2013. -

下载:

下载: