Process modification and properties analysis of bismaleimide

-

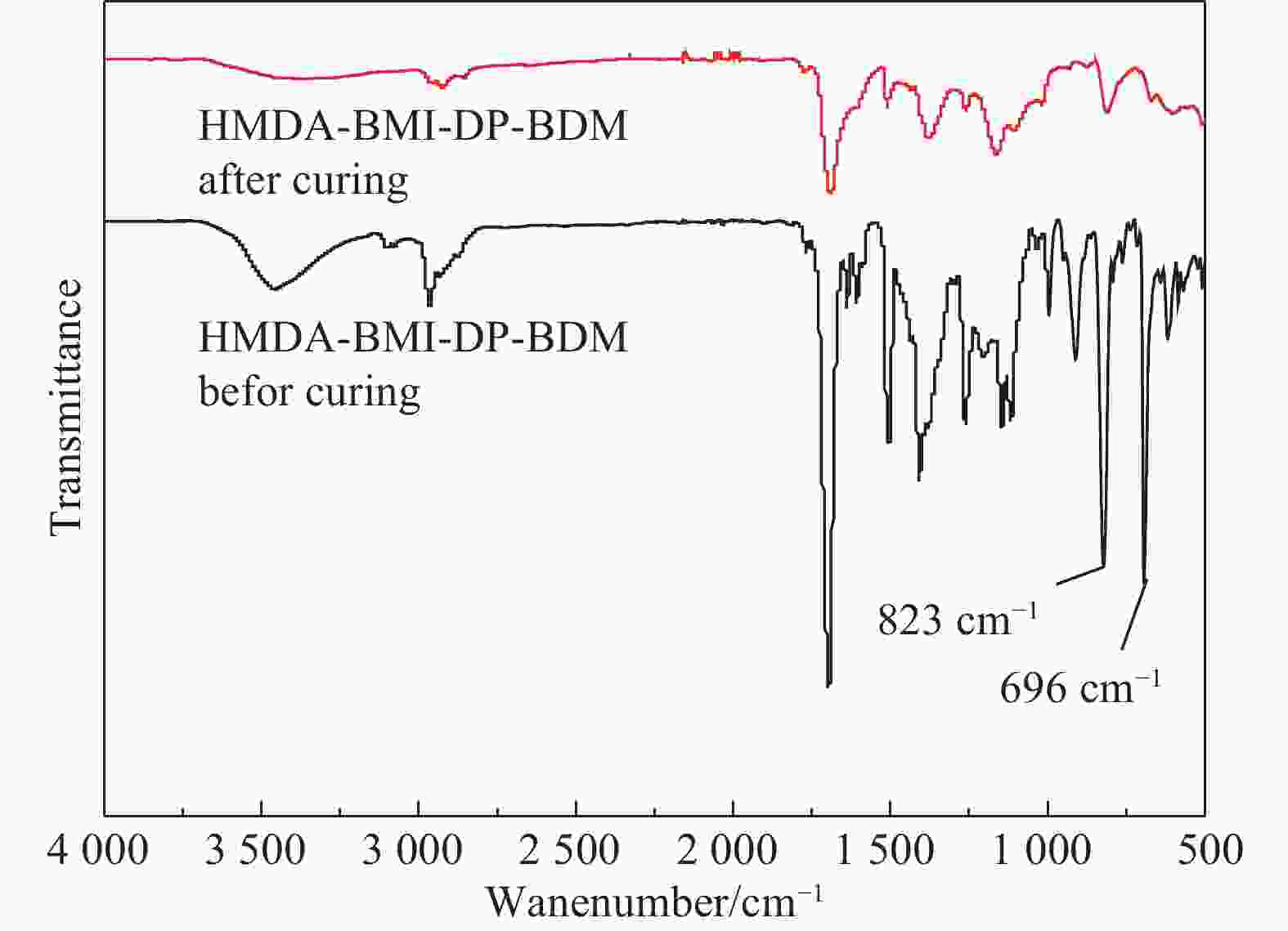

摘要: 采用脂肪族双马来酰亚胺(HMDA-BMI)对4,4’-二苯甲烷型双马来酰亚胺(BDM)进行工艺改性,得到了一种低黏度、流动性好的基体树脂。当HMDA-BMI与BDM的摩尔比为1: 1时,黏度-温度曲线表明改性体系黏度可降低至0.50 Pa·s左右,低黏度平台的温度区间为85~175℃之间;黏度-时间曲线表明改性体系合适的充模温度为130~145℃,获得的改性基体树脂适合RTM成型工艺;通过DSC曲线确定了改性基体树脂固化工艺为160℃×2 h+180℃×2 h+200℃×2 h+230℃×4 h;FTIR表明改性体系按照此工艺可以固化完全;DMA曲线和TG曲线分析结果表明改性体系的耐热性基本保持不变;共聚改性体系的拉伸强度和弯曲强度分别为80.1 MPa和116 MPa。Abstract: Aliphatic bismaleimide(HMDA-BMI) was used to copolymerize with 4,4’-bismaleimide diphenylmethyene (BDM) for preparing a matrix resin with low viscosity and good processing. When the molar ratio of HMDA-BMI to BDM is 1: 1, the viscosity-temperature test result shows that the viscosity of the HMDA-BMI-BDM system can be reduced to about 0.5 Pa·s, and the temperature range of the low viscosity platform is between 85-175℃. The viscosity-time result shows that the suitable mold filling temperature of the modified system is 130-145℃, and the obtained modified matrix HMDA-BMI-BDM resin is suitable for RTM. The curing process determined by the DSC method is 160℃×2 h+180℃×2 h+200℃×2 h+230℃×4 h. FTIR result shows that the modified system can be completely cured according to this process.The results of DMA and TG analysis show that the heat resistance of the modified system remains basically unchanged. The tensile strength and flexural strength of the modified system reaches 80.1 MPa and 116 MPa, respectively.

-

Key words:

- aliphatic bismaleimide /

- copolymerization /

- processability /

- rheological property /

- modification

-

表 1 不同共聚体系摩尔比

Table 1. Mole ratios of different copolymerization systems

Cololymerization

systemBDM/mol HMDA-BMI/mol DP/mol DP-BDM 1 0 0.87 HMDA-BMI-DP-BDM 0.5 0.5 0.87 DP-HMDA-BMI 0 1 0.87 表 2 HMDA-BMI-DP-BDM 体系不同升温速率下特征峰温度

Table 2. Characteristic peak temperatures at different heating rates of HMDA-BMI-DP-BDM system

β/(℃·min−1) Ti/℃ Tp/℃ Tf/℃ 5 214 248 286 10 226 262 300 15 235 274 311 20 247 284 328 Notes: β—Temperature rate; Ti—Onset temperature; Tp—Peak temperature; Tf—End temperature. -

[1] 梁国正, 顾媛娟. 双马来酰亚胺树脂[M]. 北京: 化学工业出版社, 1997: 3.LIANG G Z, GU Y J. Bismaleimide resin[M]. Beijing: Chemistry Industry Press, 1997: 3(in Chinese). [2] GUO Ying, CHEN Fenghua, HAN Yue, et al. High performance fluorinated bismaleimide-triazine resin with excellent dielectric properties[J]. Journal of Polymer Research,2018,25(2):27-31. doi: 10.1007/s10965-017-1407-0 [3] GUO Ying, HAN Yue, LIU Feng, et al. Fluorinated bismaleimide resin with good processability, high toughness, and outstanding dielectric properties[J]. Journal of Applied Polymer Science,2015,132(46):42791. [4] 陈宇飞, 郭红缘, 李志超, 等. 聚醚砜/双马来酰亚胺-环氧树脂复合材料的微观结构与性能[J]. 复合材料学报, 2017, 34(5):939-944.CHEN Yufei, GUO Hongyuan, LI Zhichao, et al. Micro-structure and properties of polyether sulfone/bismaleimide-epoxy composite[J]. Acta Materiae Compositae Sinica,2017,34(5):939-944(in Chinese). [5] HABBI D, MARVI O. Montmorillonite KSF and momtmorillonite K-10 clays as efficien catalysts for the solventless synthesis of bismaleimides and bisphthalimides using microwave irradiation[J]. Arkivoc,2006,8:8-15. [6] SAVA M. Bismaleimides and biscitraconimides: Synthesis and properties[J]. Journal of Applied Polymer Science,2004,91:3806-3812. doi: 10.1002/app.13548 [7] HAN Yue, ZHANG Xiaohua, YU Xueping, et al. Bio-inspired aggregationcontrol of carbon nanotubes for ultra-strong composites[J]. Scientific Reports,2015,5:11533. doi: 10.1038/srep11533 [8] OZAWA Y. Thermosetting resins composed of l-lysine methyl ester and bismaleimide[J]. Journal of Applied Polymer Science,2014,131(12):40379. [9] TAKEICHI T, SAITO Y. High-performance polymer alloys of polybenaoxazine and bismaleimide[J]. Polymer,2008,49(5):1173-1179. doi: 10.1016/j.polymer.2008.01.041 [10] WU G L, KOU K C, ZHOU L H, et al. Preparation and characterization of novel dicyanate/benzoxazine/bismaleimide copolymer[J]. Thermochimica Acta,2013,559:86-91. doi: 10.1016/j.tca.2013.02.030 [11] WANG Y Q, KOU K C, WU G L, et al. Study on synthesis of novel benzoxazine resin and its modification of CE/BMI[J]. Engineering Plastics Application,2013,41(10):22-25. [12] 王德志, 王鑫, 刘立柱, 等. 双马来酰亚胺共聚改性及性能[J]. 复合材料学报, 2017, 34(5):1088-1094.WANG Dezhi, WANG Xin, LIU Lizhu, et al. Study on the copolymerization and properties of bismaleimide systems[J]. Acta Materiae Compositae Sinica,2017,34(5):1088-1094(in Chinese). [13] BOEY F Y C, SONG X L, YUE C Y, et al. Modeling the curing kinetics for a modified bismaleimide resin[J]. Journal of Polymer Science Part A: Polytmer Chemistry,2000,38(5):907-913. doi: 10.1002/(SICI)1099-0518(20000301)38:5<907::AID-POLA15>3.0.CO;2-F [14] LIU X Y, ZHAN G Z, HAN Z W, et al. Phase moephology and mechanical properties of a poly(ether sulfone)-modified bismaleimide resin[J]. Journal of Applied Polymer Science,2007,106(1):77-83. doi: 10.1002/app.26493 [15] HSIAO S H, CHEN C F. Syntheses and thermal properties of ether-containing bismaleimide and their cured resins[J]. Journal of Polymer Research,1996,3(1):31-37. doi: 10.1007/BF01493378 [16] ZHOU J T, YAO Z J, ZHEN W J, et al. Dielectric and thermal performances of the graphene/bismaleimide/2,2’-diallylbisphenol a composite[J]. Materials Letters,2014,124:155-157. doi: 10.1016/j.matlet.2014.03.074 [17] WANG X, JIANG Q, XU W Z, et al. Effect of carbon nanotube length on thermal, electrical and mechanical properties of CNT/bismaleimide composites[J]. Carbon,2013,53:145-152. doi: 10.1016/j.carbon.2012.10.041 [18] 徐佩弦. 高聚物流变学及应用[M]. 北京: 化学工业出版社, 2003: 13-30.XU P X. Rheology of polymer and application[M]. Beijing: Chemical Industry Press, 2003: 13-30(in Chinese). [19] 石凤, 段跃新, 梁志勇, 等. RTM专用双马来酰亚胺树脂体系化学流变特性[J]. 复合材料学报, 2006(1):56-62. doi: 10.3321/j.issn:1000-3851.2006.01.009SHI Feng, DUAN Yuexin, LIANG Zhiyong, et al. Rheological behavior of a bismaleimide resin system for RTM process[J]. Acta Materiae Compositae Sinica,2006(1):56-62(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.01.009 [20] 王永贵, 梁宪珠, 薛向晨, 等. 热压罐工艺的传热分析和框架式模具温度场分布[J]. 航空制造技术, 2008(22):80-83, 87. doi: 10.3969/j.issn.1671-833X.2008.22.016WANG Yonggui, LIANG Xianzhu, XUE Xiangchen, et al. Analysis of heat transfer and temperature field distribution on frame tooling in autoclave process[J]. Aeronautical Manufacturing Technology,2008(22):80-83, 87(in Chinese). doi: 10.3969/j.issn.1671-833X.2008.22.016 [21] CHAUDHARI M, GALVIN T, KING J, et al. Characterzation of bismaleimide system, xu292[J]. SAMPE Journal,1985,11(5):17-21. [22] 金保宏, 王柏臣, 陈平, 等. RTM用BMI树脂的活性稀释剂研究[J]. 玻璃钢/复合材料, 2011(1):36-39. doi: 10.3969/j.issn.1003-0999.2011.01.009JIN Baohong, WANG Bochen, CHEN Ping, et al. Study on reactive diluent of bmi resin for resin trensfermolding[J]. Fiber Reinforced Plastics/Composites,2011(1):36-39(in Chinese). doi: 10.3969/j.issn.1003-0999.2011.01.009 [23] 赵卫生, 孙超明, 王文晶, 等. RTM用乙烯基酯树脂化学流变性研究[J]. 玻璃钢/复合材料, 2014(8):97-100. doi: 10.3969/j.issn.1003-0999.2014.08.019ZHAO Weisheng, SUN Chaoming, WANG Wenjing, et al. Study on chemical rheological properties of rtm with vinyl ester resin[J]. Fiber Reinforced Plastics/Composites,2014(8):97-100(in Chinese). doi: 10.3969/j.issn.1003-0999.2014.08.019 [24] 许亚洪, 陈萍. RTM复合材料结构件用BMI树脂基体6421体系的研究[J]. 航空制造工程, 1998(6):6-7.XU Yahong, CHEN Ping. Study on bmi resin matrix 6421 system for rtm composite structural parts[J]. Aeronautical Manufacturing Engineering,1998(6):6-7(in Chinese). [25] 许亚洪, 秦明, 李小刚, 等. 6421双马来酰亚胺树脂的反应流变性及树脂传递模塑成型工艺研究[J]. 材料工程, 2002(12):35, 39-40. doi: 10.3969/j.issn.1001-4381.2002.12.021XU Yahong, QIN Ming, LI Xiaogang, et al. Study on reaction rheological and resin transfer molding process of 6421 bismaleimide resin[J]. Journal of Materials Engineering,2002(12):35, 39-40(in Chinese). doi: 10.3969/j.issn.1001-4381.2002.12.021 [26] 柴红梅, 王雷, 吕金燕, 等. RTM用高性能环氧树脂体系研究[J]. 玻璃钢/复合材料, 2009(1):28-30. doi: 10.3969/j.issn.1003-0999.2009.01.007CHAI Hongmei, WANG Lei, LV Jinyan, et al. Research on high performance epoxy resin system for RTM[J]. Fiber Reinforced Plastics/Composites,2009(1):28-30(in Chinese). doi: 10.3969/j.issn.1003-0999.2009.01.007 [27] 中国国家标准化管理委员会. 树脂浇注体性能试验方法: GB/2567—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of China. Test methods for properties of resin casting body: GB/2567—2008[S]. Beijing: Standard Press of China, 2008(in Chinese). [28] YAN H X, NING R C, LIANG G Z, et al. The effect of silane coupling agent on the sliding wear behavior of nanoment ZrO2/bismalemide composites[J]. Journal of Materials Science,2007,42(3):958-965. doi: 10.1007/s10853-006-0008-9 -

下载:

下载: