Reliability and global sensitivity analysis for static strength of quartz/epoxy composite

-

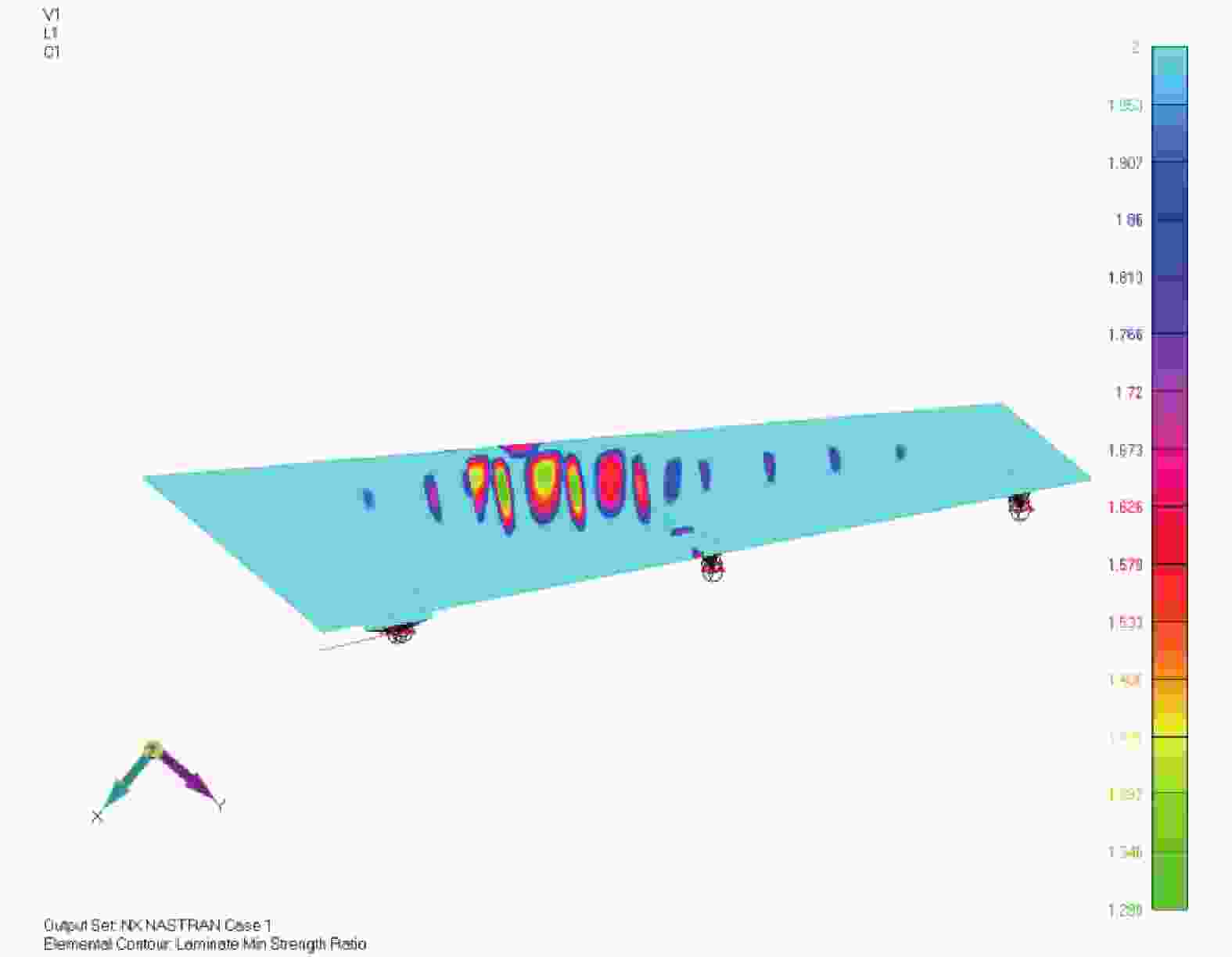

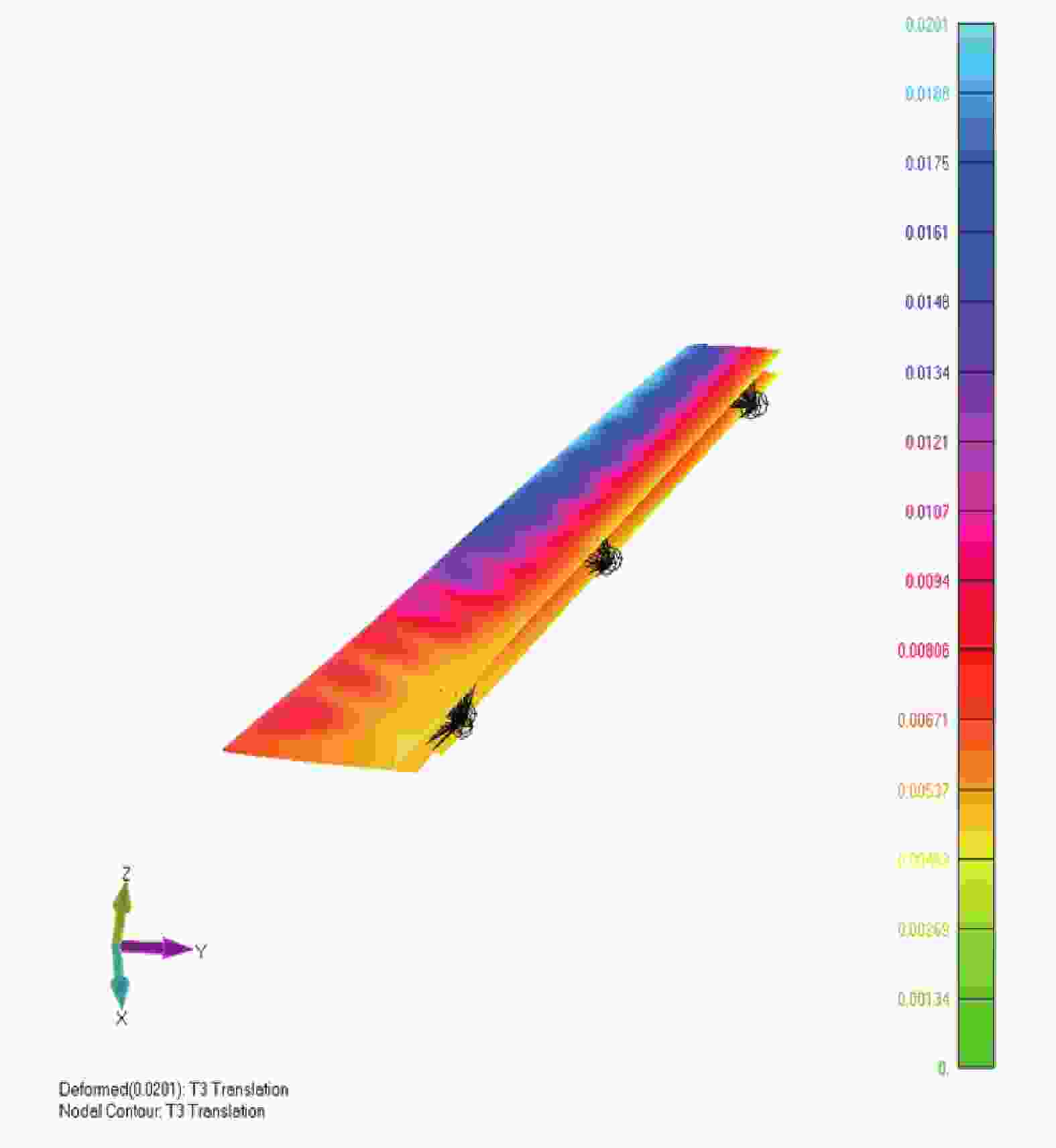

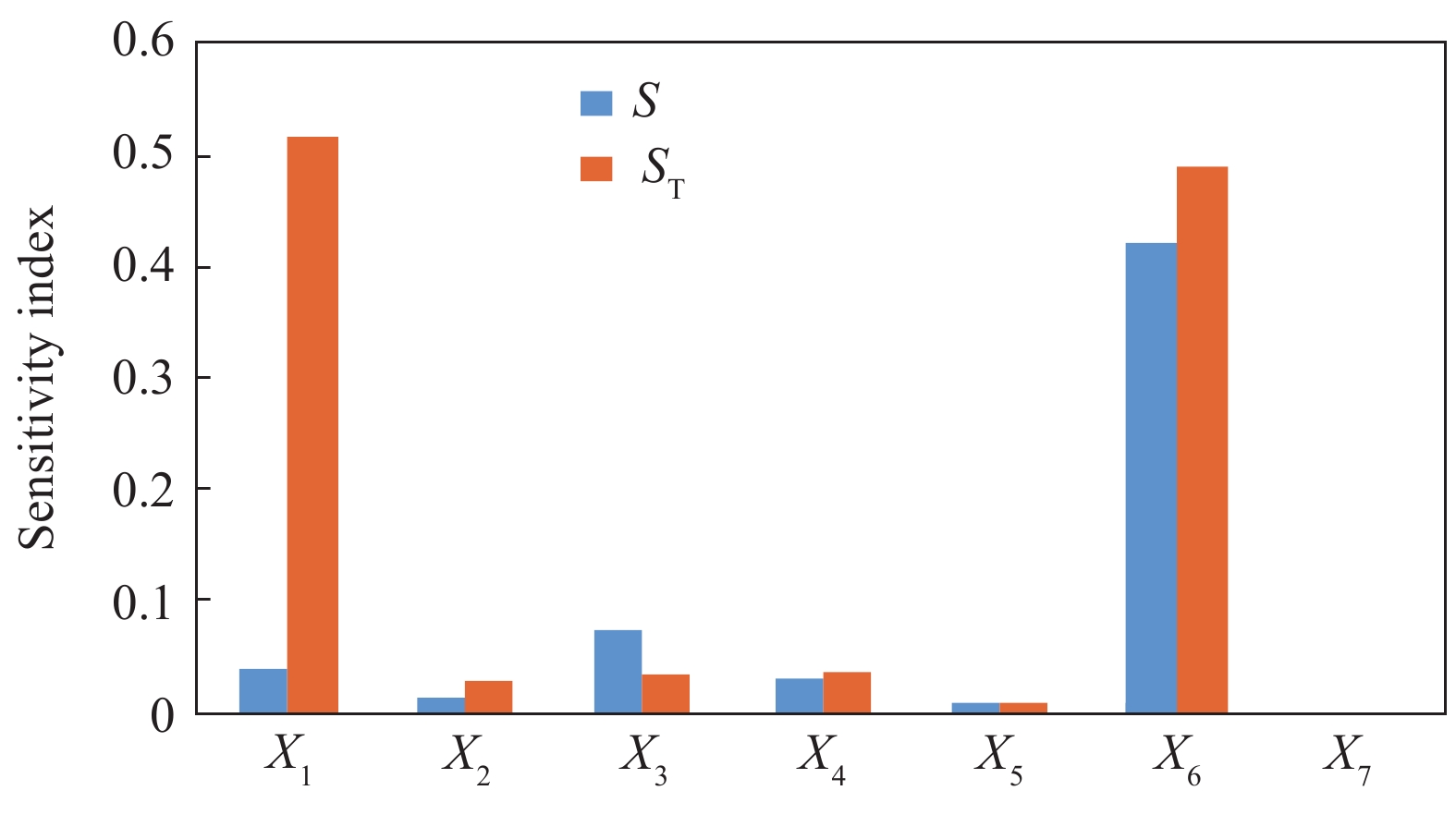

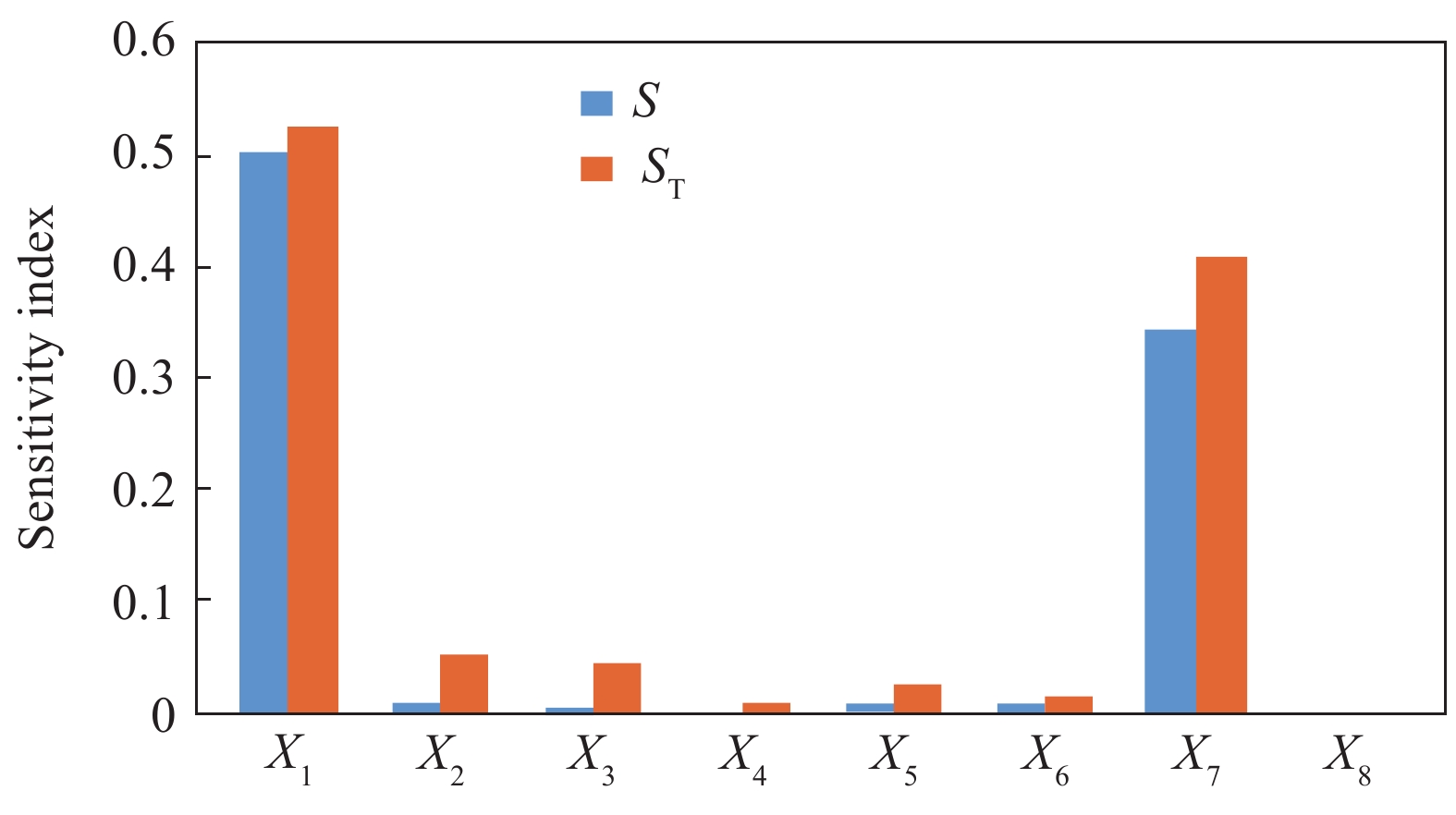

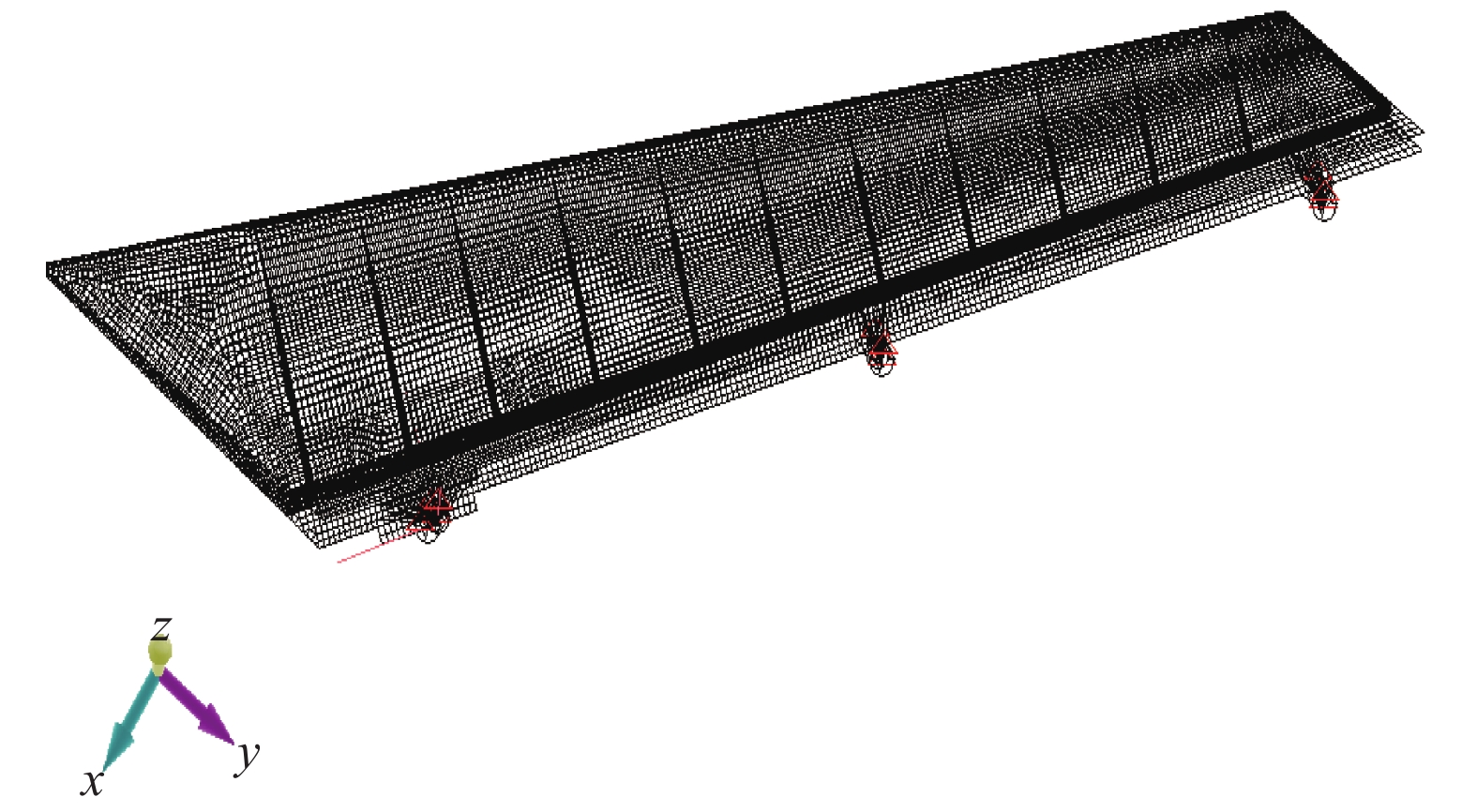

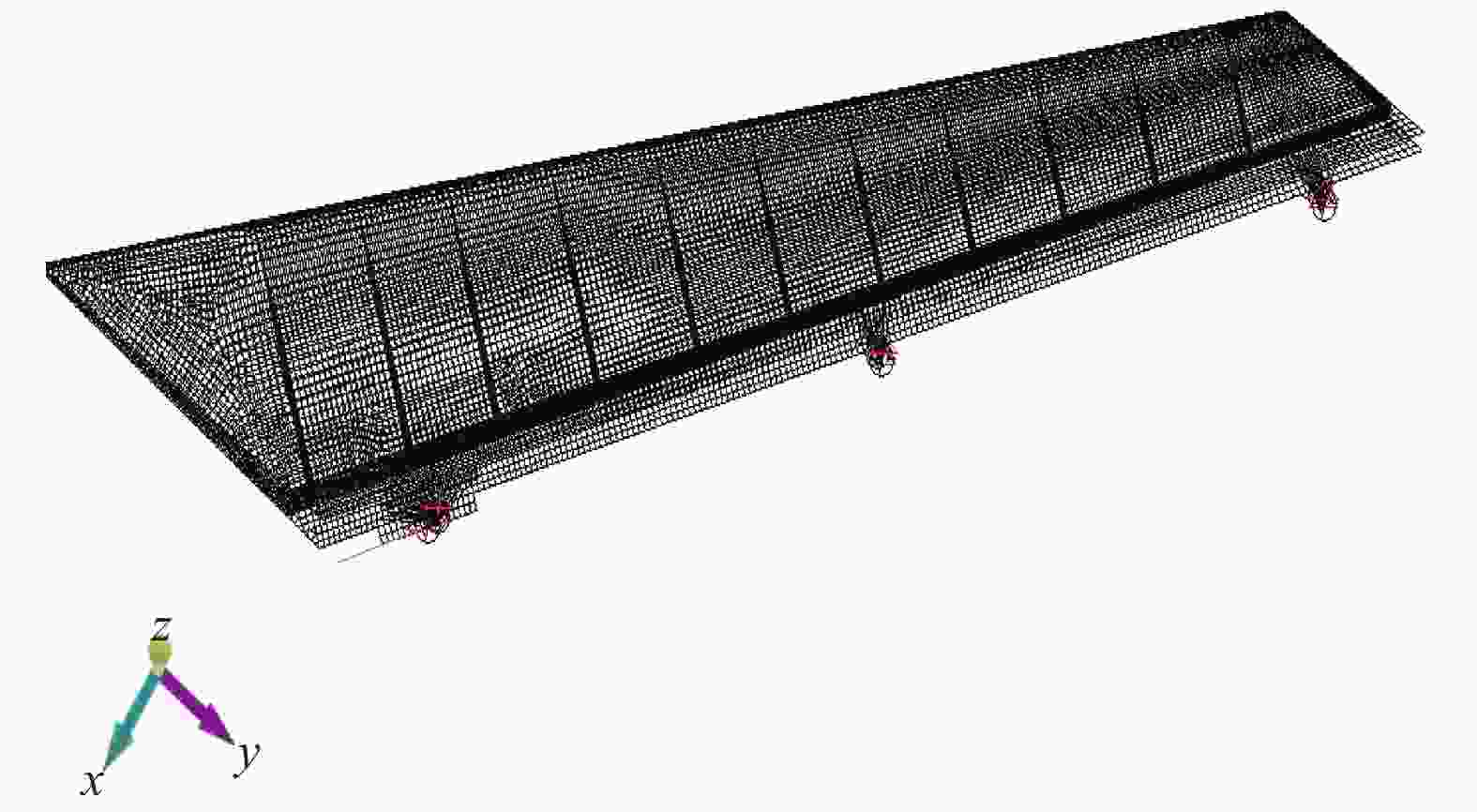

摘要: 以石英纤维/环氧树脂复合材料结构为研究对象,考虑设计参数的随机性,采用全局灵敏度分析理论,研究了各输入随机因素对石英纤维/环氧树脂复合材料结构静强度响应的影响。首先利用MATLAB和NASTRAN的联合仿真得到各输入变量样本值对应的输出响应值,结合自适应Kriging模型构建极限状态函数的代理模型,在此基础上实现石英纤维/环氧树脂复合材料结构静强度可靠度及各输入变量的不确定性对输出响应及失效概率全局灵敏度的计算,得到输入变量的全局灵敏度排序结果,为工程实际中复合材料结构的优化设计提供一定指导。Abstract: Taking the quartz/epoxy composite structure as the object, the global sensitivity theory was adopted to analyze the influences of the input parameters on the strength response of quartz/epoxy composite structure by considering the random characteristics of the input parameters. MATLAB and NASTRAN were combined to obtain the output response after considering all the input parameter randomness, then the adaptive Kriging model was introduced to construct the ultimate surrogate model. On basis of this surrogate model, the reliability of overall strength of the quartz/epoxy composite structure was computed, and the global sensitivity indices reflecting the influences of the input parameters on the output response were also obtained. The importance of the input parameters can be ranked according to the sensitivity results, which can provide guidance information for the design of composite structure.

-

Key words:

- composite structure /

- global sensitivity analysis /

- Kriging model /

- MATLAB /

- reliability

-

表 1 石英纤维/环氧树脂复合材料结构参数化建模输入随机因素设置

Table 1. Settings of input randomness for parametric modeling of quartz/epoxy composite structure

Mark Mean Standard deviation Distribution type ${E_{11}}/{\rm{GPa}}$ 37 3.7 Normal ${E_{22}}/{\rm{GPa}}$ 10 1.0 Normal ${G_{12}}/{\rm{GPa}}$ 4.1 0.41 Normal ${G_{13}}/{\rm{GPa}}$ 3.3 0.33 Normal ${G_{23}}/{\rm{GPa}}$ 3.3 0.33 Normal A0/(°) 0 4.5 Normal A90/(°) 90 4.5 Normal A45/(°) 45 4.5 Normal A−45/(°) −45 4.5 Normal t/mm 0.13 0.013 Normal $\rho$/(kg·m−3) 1 700 170 Normal ${T_{11}}/{\rm{MPa}}$ 1 500 150 Normal ${C_{11}}/{\rm{MPa}}$ 750 75.0 Normal ${T_{22}}/{\rm{MPa}}$ 390 39.0 Normal ${C_{22}}/{\rm{MPa}}$ 180 18.0 Normal ${S_{12}}/{\rm{MPa}}$ 100 10.0 Normal ${S_{\rm{S}}}/{\rm{MPa}}$ 85.0 8.5 Normal Notes: ${E_{11}}$—Modulus in 11 direction; ${E_{22}}$—Modulus in 22 direction; ${G_{12}}$—Modulus in 12 direction; ${G_{13}}$—Modulus in 13 direction; ${G_{23}}$—Modulus in 23 direction; A0—0° ply angle; A90—90° ply angle; A45—45° ply angle; A−45—–45° ply angle; $t$—Monolayer thickness; $\rho $—Material density; ${T_{11}}$—Tensile strength in 11 direction; ${C_{11}}$—Compression strength in 11 direction; ${T_{22}}$—Tensile strength in 22 direction; ${C_{22}}$—Compression strength in 22 direction; ${S_{12}}$—Shear strength in plane; ${S_{\rm{S}}}$—Shear strength in interlayer. 表 2 计算石英纤维/环氧树脂复合材料结构强度裕度用变量

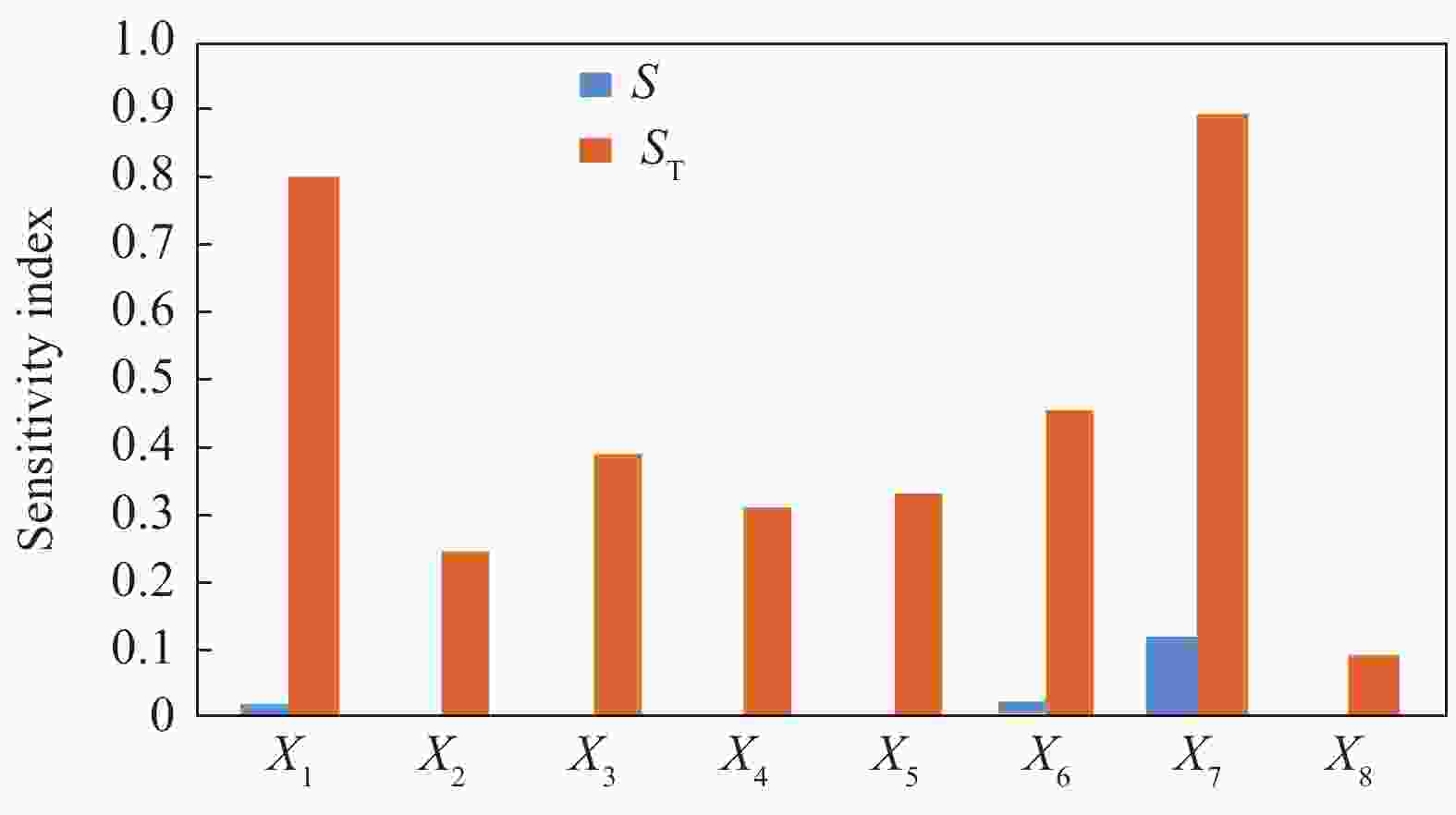

Table 2. Variables used in strength analysis of quartz/epoxy composite structure

Variable Mark ${X_1}$ ${E_{11}}$; ${E_{22}}$; ${G_{12}}$; ${G_{13}}$; ${G_{23}}$ ${X_2}$ ${T_{11}}$; ${C_{11}}$; ${T_{22}}$; $C{}_{22}$; ${S_{12}}$; ${S_{\rm{S}}}$ ${X_3}$ ${A_0}$ ${X_4}$ ${A_{90}}$ ${X_5}$ ${A_{45}}$ ${X_6}$ ${A_{{\rm{ - }}45}}$ ${X_7}$ $t$ ${X_8}$ $\rho $ 表 3 计算石英纤维/环氧树脂复合材料结构变形用变量

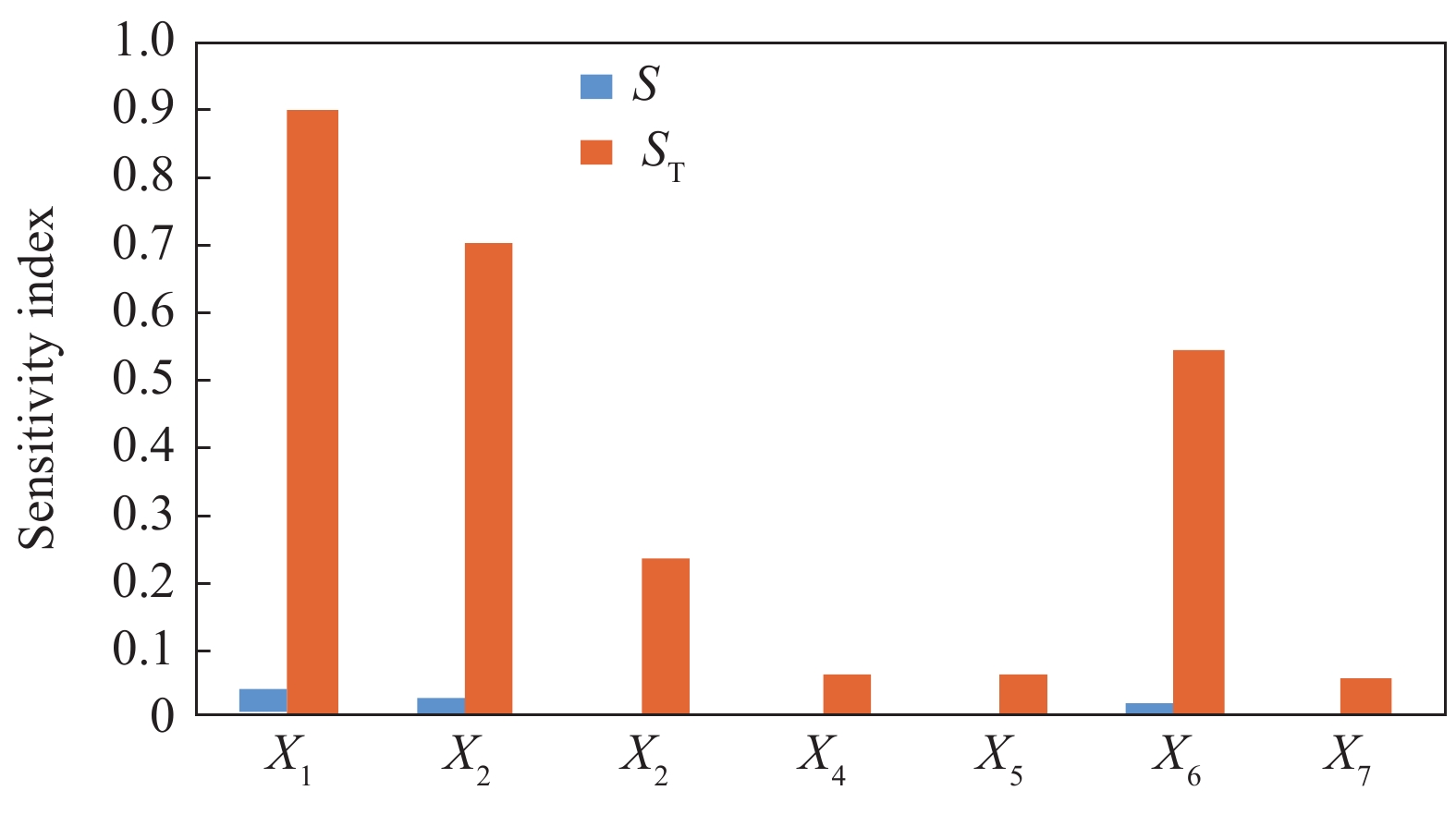

Table 3. Variables used in deformation analysis of quartz/epoxy composite structure

Variable Mark ${X_1}$ ${E_{11}}$; ${E_{22}}$; ${G_{12}}$; ${G_{13}}$; ${G_{23}}$ ${X_2}$ ${A_0}$ ${X_3}$ ${A_{90}}$ ${X_4}$ ${A_{45}}$ ${X_5}$ ${A_{{\rm{ - }}45}}$ ${X_6}$ $t$ ${X_7}$ $\rho $ -

[1] OMAIREY S L, DUNNING P D, SRIRAMULA S. Influence of micro-scale uncertainties on the reliability of fibre-matrix composites[J]. Composite Structures,2018,203:204-216. doi: 10.1016/j.compstruct.2018.07.026 [2] LIU Q, PAAVOLA J. General analytical sensitivity analysis of composite laminated plates and shells for classical and first-order shear deformation theories[J]. Composite Structures,2018,183:21-34. doi: 10.1016/j.compstruct.2016.11.052 [3] LI D, LIU Y, ZHANG X. Linear statics and free vibration sensitivity analysis of the composite sandwich plates based on a layerwise/solid-element method[J]. Composite Structures,2013,106:175-200. doi: 10.1016/j.compstruct.2013.05.056 [4] FENG X, LU Z X, YANG Z Y, et al. Analysis on the variances of material and structural properties based on random field theory[J]. Probabilistic Engineering Mechanics,2011,26(2):222-230. doi: 10.1016/j.probengmech.2010.07.006 [5] 阮文斌, 吕震宙, 安军, 等. 不确定条件下复合材料结构的全局灵敏度分析[J]. 复合材料学报, 2014, 31(3):699-706.RUAN Wenbin, LV Zhenzhou, AN Jun, et al. Global sensitivity analysis for composite structures with uncertainties[J]. Acta Materiae Compositae Sinica,2014,31(3):699-706(in Chinese). [6] TIAN L F, LU Z Z, HAO W R. Investigation of the uncertainty of the in-plane mechanical properties of composite laminates[J]. Journal of Mechanical Science,2012,226(7):1739-1750. doi: 10.1177/0954406211426638 [7] ECHARD B, GAYTON N, LEMAIRE M. AK-MCS: An active learning reliability method combining Kriging and Monte Garlo simulation[J]. Structural Safety,2001,33(2):145-154. [8] 张琦.基于Kriging方法的结构可靠性分析及优化设计[D]. 大连: 大连理工大学, 2005.ZHANG Qi. Structural reliability analysis and optimization based on Kriging technique[D]. Dalian: Dalian University of Technology, 2005(in Chinese). [9] 尤凤翔, 郝庆东. 基于灵敏度分析的复合材料层合板优化设计[J]. 噪声与振动控制, 2005, 25(4):67-70. doi: 10.3969/j.issn.1006-1355.2005.04.020YOU Fengxiang, HAO Qingdong. Design optimization of composite laminated plates based on sensitivity analysis[J]. Noise and Vibration Control,2005,25(4):67-70(in Chinese). doi: 10.3969/j.issn.1006-1355.2005.04.020 [10] 吴浩, 燕瑛. 基于可靠性的复合材料结构稳定性约束优化设计[J]. 复合材料学报, 2007, 24(3):149-153.WU Hao, YAN Ying. Reliability-based optimization of composite structures subject to buckling constraint[J]. Acta Materiae Compositae Sinica,2007,24(3):149-153(in Chinese). [11] ZHOU C, ZHANG Z, LIU F, et al. Sensitivity analysis for probabilistic anti-resonance design of aeronautical hydraulic pipelines[J]. Chinese Journal of Aeronautics,2019,32(4):948-953. doi: 10.1016/j.cja.2019.01.001 [12] 吕震宙, 李璐祎, 宋述芳, 等. 不确定性结构系统的重要性分析与求解方法[M]. 北京: 科学出版社, 2015.LV Zhenzhou, LI Luyi, SONG Shufang, et al. Importance analysis and computational methods for uncertain structural systems[M]. Beijing: Science Press, 2015(in Chinese). [13] CUI L J, LU Z Z, ZHAO X P. Moment-independent importance measure of basic random variable and its probability density evolution solution[J]. Science China Technological Sciences,2010,53:1138-1145. doi: 10.1007/s11431-009-0386-8 [14] 航空航天工业部科学技术研究院. 复合材料设计手册[M]. 北京: 航空工业出版社, 1990.Institute of Science and Technology, Ministry of Aeronautics and Astronautics Industry. Composite design manual[M]. Beijing: Aviation Industry Press, 1990(in Chinese). [15] 沈观林, 胡更开. 复合材料力学[M]. 北京: 清华大学出版社, 2006.SHEN Guanlin, HU Gengkai. Mechanics of composite materrials[M]. Beijing: Tsinghua University Press, 2006(in Chinese). [16] 刘卓峰. GFRP层合板厚板VIMP制备工艺与力学性能尺寸效应研究[D]. 长沙: 国防科学技术大学, 2010.LIU Zhuofeng. Study on vacuum infusion moulding process and mechanical properties size effects of glass fibre reinforce polymer composites thick laminates[D]. Changsha: National University of Defense Technology, 2010(in Chinese). -

下载:

下载: