Structure and properties of cellulose-krill protein composite fibers in situ crosslinked with ethylene glycol diglycidyl ether

-

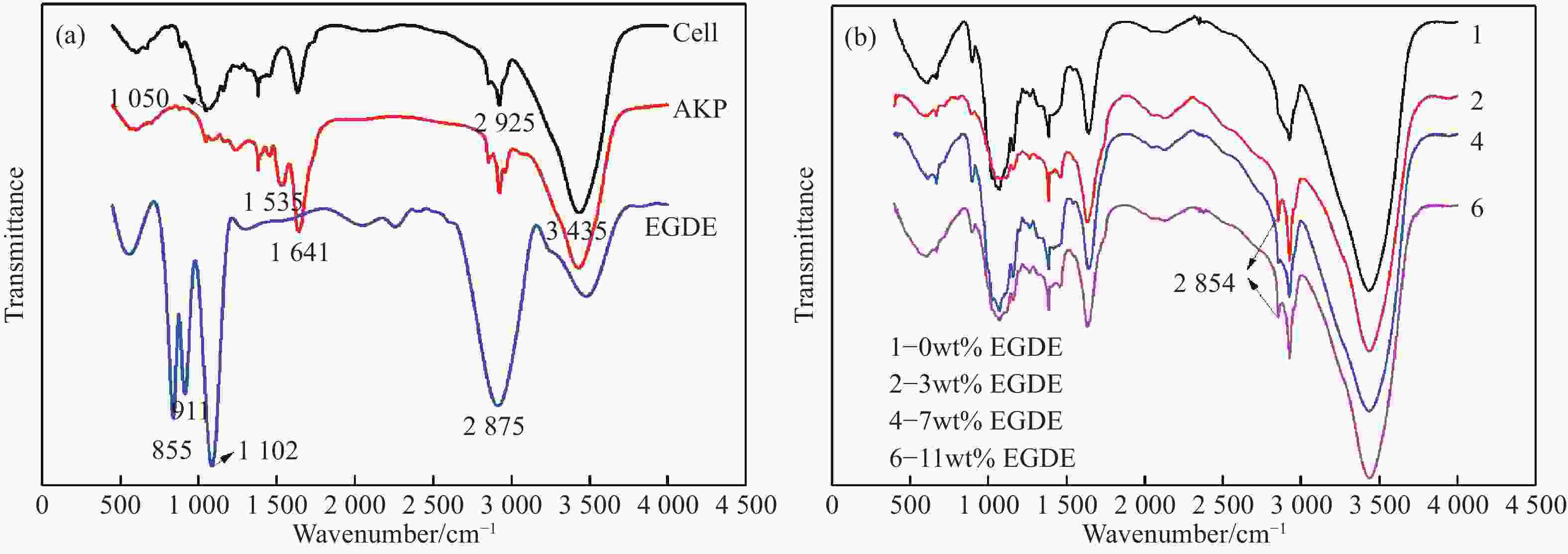

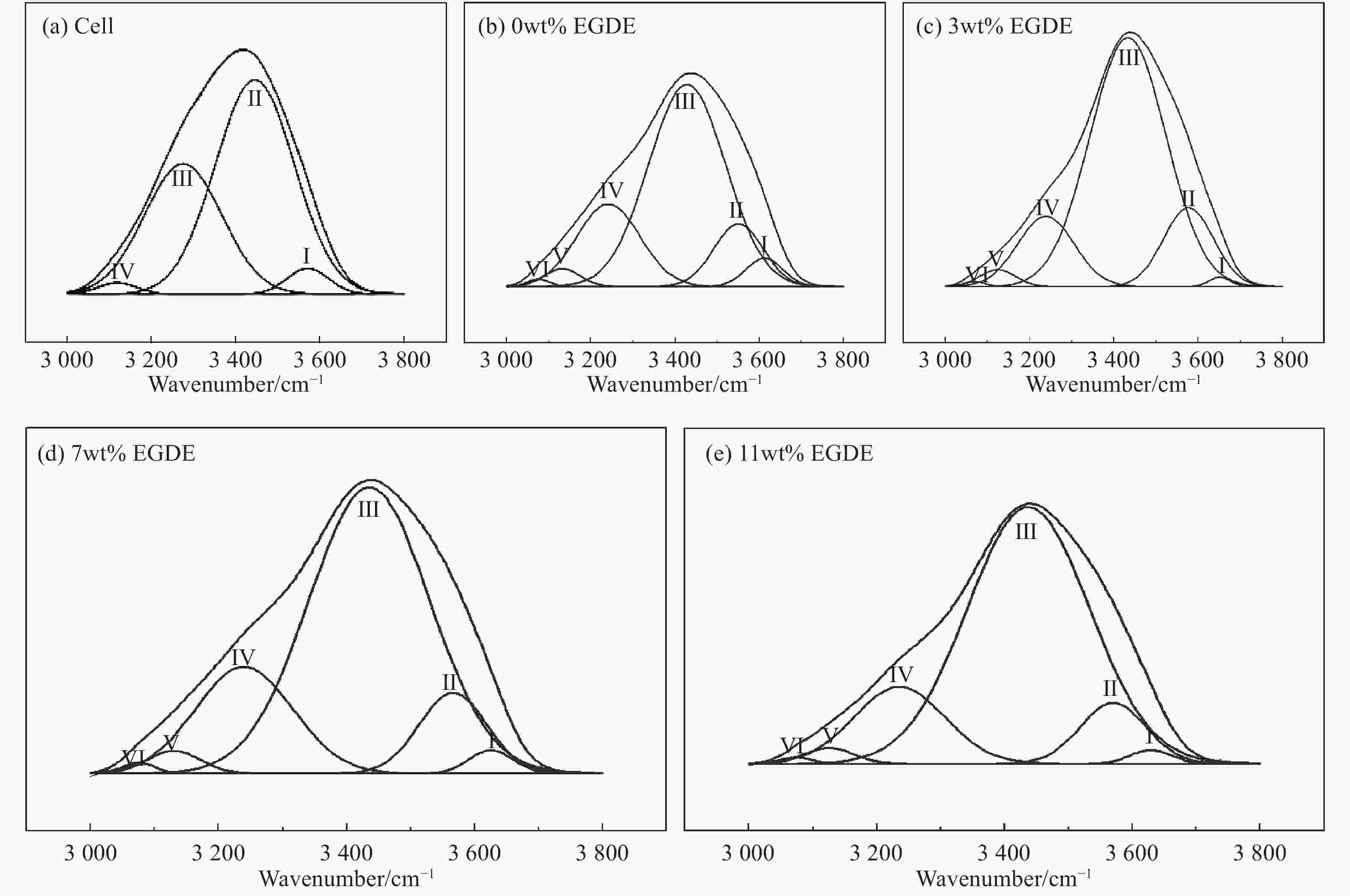

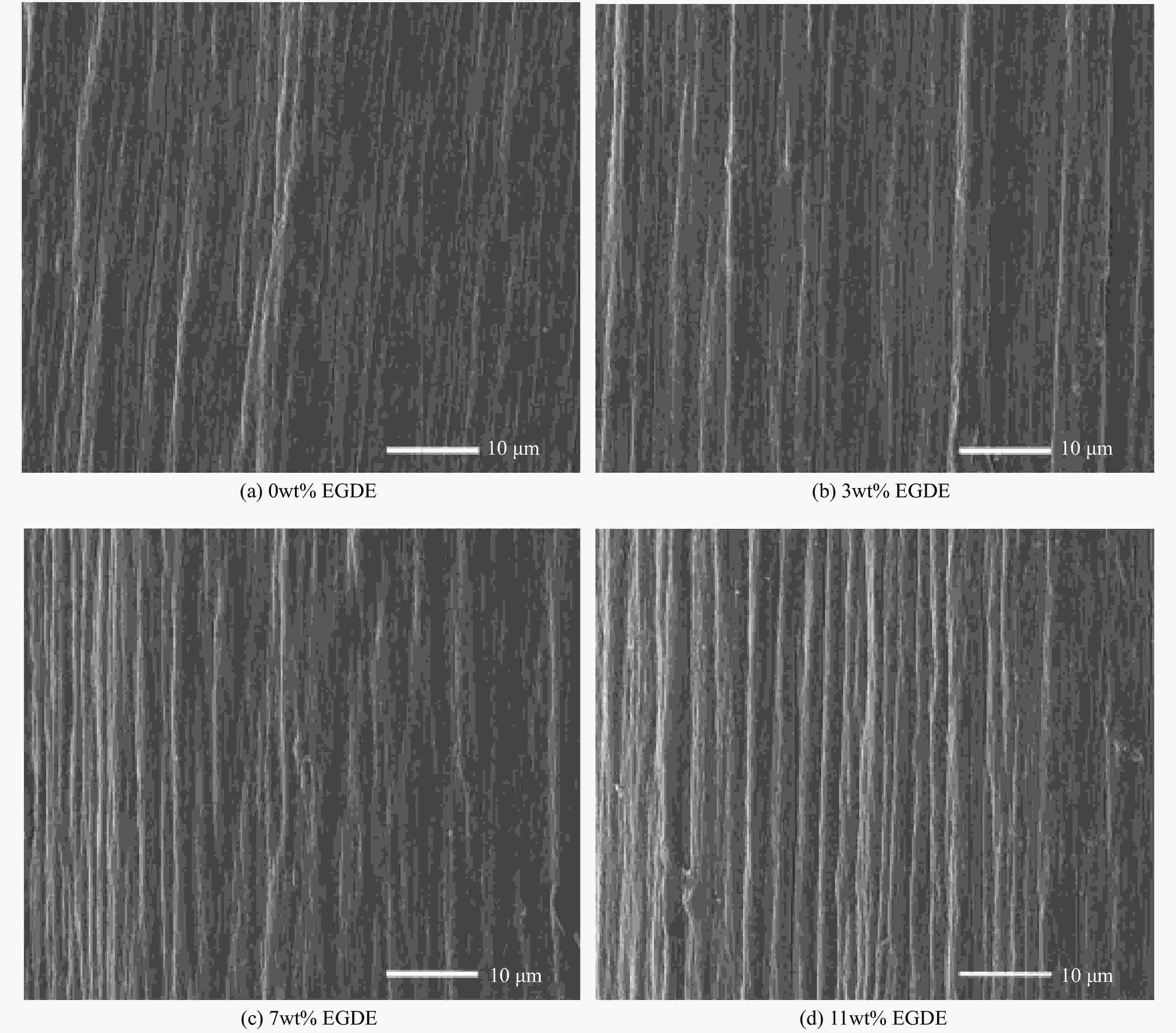

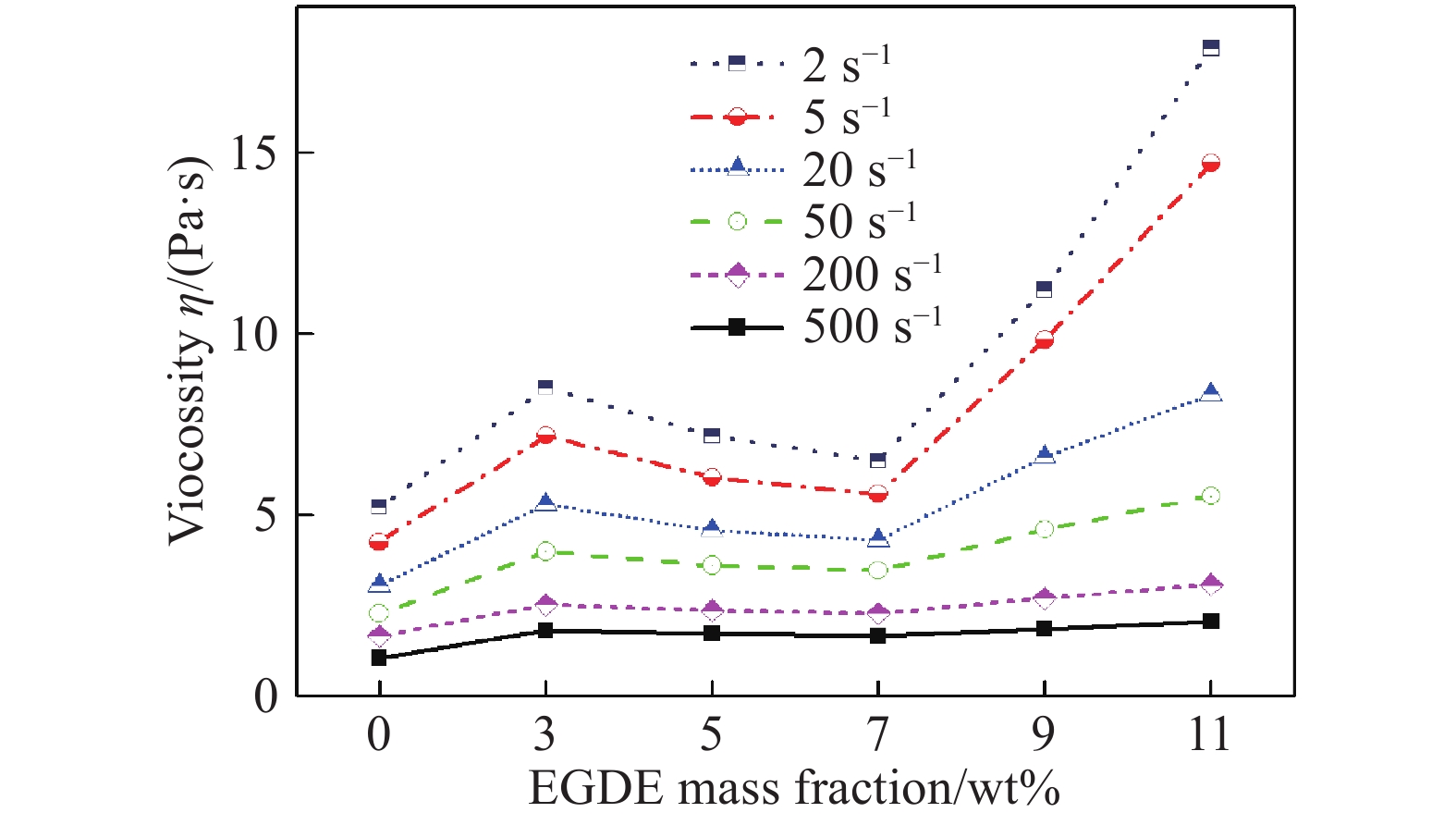

摘要: 以纤维素(Cell)和南极磷虾蛋白(AKP)为原料,以乙二醇二缩水甘油醚(EGDE)为潜在交联剂,NaOH和尿素水溶液作溶剂,在低温下溶解Cell和AKP后,加入EGDE制备Cell-AKP-EGDE复合纺丝原液,将纺丝原液挤入H2SO4-Na2SO4-H2O构成的凝固浴中,经热拉伸定型获得EGDE原位交联的Cell-AKP复合纤维。利用FTIR研究了交联剂EGDE的含量对Cell-AKP复合体系分子间相互作用的影响,采用SEM、XRD、TG等考察了交联剂EGDE的含量与Cell-AKP复合体系的表面形态、结晶性、热稳定性和力学性能的相关性。结果表明:交联剂EGDE含量的不同对Cell-AKP复合纤维的表观黏度、力学性能、结晶性及表面形态等均有影响,且交联剂EGDE含量为3wt%时,Cell-AKP复合纤维的综合性能较好。Abstract: Taking cellulose (Cell) and antarctic krill protein (AKP) as the raw materials, ethylene glycol diglycidyl ether (EGDE) as the latent crosslinker, NaOH and urea aqueous solution as the solvents, Cell-AKP-EGDE composite spinning solution was prepared after dissolving Cell and AKP at low temperature. Then the spinning solution was squeezed into a coagulation bath composed of H2SO4-Na2SO4-H2O, and the Cell-AKP composite fibers crosslinked in situ by EGDE were obtained by hot stretching. The effect of the content of EGDE on the intermolecular interaction of Cell-AKP composite system was studied by FTIR. The correlation between cross-linking agent content and the surface morphology, crystallinity, thermal stability and mechanical properties of Cell-AKP composites was investigated by SEM, XRD and TG. The results show that the apparent viscosity, mechanical properties, crystallinity and surface morphology of the Cell-AKP composite fibers are affected by the content of EGDE crosslinking agent, and the comprehensive properties of the Cell-AKP composite fibers are the best when the content of EGDE crosslinking agent is 3wt%.

-

Key words:

- cellulose /

- antarctic krill protein /

- cross-linking agent content /

- composite fibers /

- in situ crosslink

-

表 1 不同乙二醇二缩水甘油醚(EGDE)含量的纤维素-磷虾蛋白-EGDE (Cell-AKP-EGDE)复合纤维编号

Table 1. Number of cellulose-antarctic krill protein-ethylene glycol diglycidyl ether (Cell-AKP-EGDE) composite fibers with different contents of EGDE

No. 1 2 3 4 5 6 EGDE mass fraction/wt% 0 3 5 7 9 11 表 2 不同剪切速率下AKP、Cell、AKP-EGDE、Cell-EGDE、Cell-EGDE-AKP、Cell-AKP-EGDE复合溶液的黏度η

Table 2. Viscosity η of AKP, Cell, AKP-EGDE, Cell-EGDE, Cell-EGDE-AKP and Cell-AKP-EGDE composite solutions with different shear rates

Speed/s–1 Viscosity η/(Pa·S) AKP AKP-EGDE Cell Cell-EGDE Cell-EGDE-AKP Cell-AKP Cell-AKP-EGDE 2 0.0380 0.0540 4.061 4.567 5.876 4.785 6.214 20 0.0115 0.0164 2.918 3.259 3.663 3.338 3.981 50 0.0810 0.0115 2.434 2.634 2.831 2.682 3.106 表 3 Cell和Cell-AKP-EGDE复合纤维的氢键拟合结果

Table 3. Hydrogen bond fitting results of Cell and Cell-AKP-EGDE composite fibers

Sample Hydrogen bond type Fitting curve Abbreviations Wavenumber/cm–1 Average peak area Relative strength/% Cell Free hydroxyl Ⅰ —OH 3 571 6.60 3.76 3.76 Intramolecular Ⅱ OH...OH 3 445 103.48 59.32 60.88 Hydrogen bond Ⅳ Annular polymer 3 118 2.73 1.56 – Hydrogen bond Ⅲ OH...ether O 3 274 61.70 35.36 35.36 1 Free hydroxyl Ⅰ —OH 3 611 2.73 4.05 4.05 Intramolecular Ⅲ OH. . .OH 3 428 40.70 60.45 62.94 Hydrogen bond Ⅴ Annular polymer 3 131 1.68 2.49 – Intermolecular Ⅱ OH. . .π 3 241 13.69 20.32 33.01 Hydrogen bond Ⅳ OH. . .ether O 3 550 8.12 12.05 – – Ⅵ OH. . .N 3 075 0.43 0.63 – 2 Free hydroxyl Ⅰ —OH 3 650 0.51 0.70 0.70 Intramolecular Ⅲ OH...OH 3 433 49.64 68.21 70.36 Hydrogen bond V Annular polymer 3 124 1.56 2.15 – Intermolecular Ⅱ OH...π 3 238 10.40 14.30 28.94 Hydrogen bond Ⅳ OH...ether O 3 577 10.36 14.25 – – Ⅵ OH...N 3 069 0.28 0.39 – 4 Free hydroxyl I —OH 3 625 1.72 1.91 1.91 Intramolecular Ⅲ OH...OH 3 435 58.61 65.31 67.57 Hydrogen bond Ⅴ Annular polymer 3 130 2.03 2.26 – Intermolecular Ⅱ OH...π 3 240 17.56 19.57 30.52 Hydrogen bond Ⅳ OH...ether O 3 565 9.24 10.30 – – Ⅵ OH...N 3 075 0.58 0.65 – 6 Free hydroxyl Ⅰ —OH 3 629 0.81 1.27 1.27 Intramolecular Ⅲ OH...OH 3 437 45.77 71.53 73.27 Hydrogen bond Ⅴ Annular polymer 3 125 1.11 1.74 – Intermolecular Ⅱ OH...π 3 570 5.83 9.11 25.46 Hydrogen bond Ⅳ OH...ether O 3 235 10.19 15.92 – – Ⅵ OH...N 3 074 0.28 0.43 – 表 4 Cell-AKP-EGDE复合纤维的结晶度

Table 4. Crystallinity of Cell-AKP-EGDE composite fibers

EGDE mass fraction/wt% 0 3 5 7 9 11 Crystallinity/% 65.86 61.13 62.58 64.57 60.39 56.43 -

[1] SIRVIÖ J. Fabrication of regenerated cellulose nanoparticles by mechanical disintegration of cellulose after dissolution and regeneration from a deep eutectic solvent[J]. Journal of Materials Chemistry A,2019,7(2):755-763. doi: 10.1039/C8TA09959F [2] PUSPASARI T, AKHTAR F H, OGIEGLO W, et al. High dehumidification performance of amorphous cellulose composite membranes prepared from trimethylsilyl cellulose[J]. Journal of Materials Chemistry A,2018,6(19):9271-9279. doi: 10.1039/C8TA00350E [3] 陈港, 胡稳, 朱朋辉, 等. 高透明羧甲基纤维素/纤维素纤维复合薄膜的制备及其力学性能[J]. 复合材料学报, 2018, 35(6):1574-1581.CHEN G, HU W, ZHU P H, et al. Preparation and mechanical properties of highly transparent CMC/cellulose composite films[J]. Acta Materiae Compositae Sinica,2018,35(6):1574-1581(in Chinese). [4] BABAEE M, JONOOBI M, HAMZEH Y, et al. Biodegradability and mechanical properties of reinforced starch nanocomposites using cellulose nanofibers[J]. Carbohydrate Polymers,2015,132:1-8. doi: 10.1016/j.carbpol.2015.06.043 [5] KANNAM S K, OEHME D, DOBLIN M, et al. Hydrogen bonds and twist in cellulose microfibrils[J]. Carbohydrate Polymers,2017,175:433-439. doi: 10.1016/j.carbpol.2017.07.083 [6] UTO T, YAMAMOTO K, KADOKAWA J I. Cellulose crystal dissolution in imidazolium-based ionic liquids: A theoretical study[J]. Journal of Physical Chemistry B,2017,122(1):258-266. [7] PIRAS C C, FERNÁNDEZ-PRIETO S, BORGGRAEVE W M D. Ball milling: A green technology for the preparation and functionalisation of nanocellulose derivatives[J]. Nanoscale Advances,2019,1(3):937-947. doi: 10.1039/C8NA00238J [8] LING Z, WANG T, MAKAREM M, et al. Effects of ball milling on the structure of cotton cellulose[J]. Cellulose,2019,26(1):305-328. doi: 10.1007/s10570-018-02230-x [9] GHANBARI A, TABARSA T, ASHORI A, et al. Preparation and characterization of thermoplastic starch and cellulose nanofibers as green nanocomposites: Extrusion processing[J]. International Journal of Biological Macromolecules,2018,112:442-447. doi: 10.1016/j.ijbiomac.2018.02.007 [10] 罗康佳, 郭建生, 李静怡, 等. 纤维素的溶解技术与研究现状[J]. 合成纤维, 2018, 47(1):1-5.LUO K J, GUO J S, LI J Y, et al. Dissolution technology and research status of cellulose[J]. Synthetic Fibers,2018,47(1):1-5(in Chinese). [11] KRYSZTOF M, OLEJNIK K, KULPINSKI P, et al. Regenerated cellulose from N-methylmorpholine N-oxide solutions as a coating agent for paper materials[J]. Cellulose,2018,25(6):3595-3607. doi: 10.1007/s10570-018-1799-y [12] LI W J, ZHANG F Y, WANG W K, et al. Rheological transitions and in-situ IR characterizations of cellulose/LiCl•DMAc solution as a function of temperature[J]. Cellulose,2018,25(9):4955-4968. doi: 10.1007/s10570-018-1923-z [13] DISSANAYAKE N, THALANGAMAARACHCHIGE V D, TROXELL S, et al. Substituent effects on cellulose dissolution in imidazolium-based ionic liquids[J]. Cellulose,2018,25(12):6887-6900. doi: 10.1007/s10570-018-2055-1 [14] CAO J, WEI W, GOU G Y, et al. Cellulose films from the aqueous DMSO/TBAH-system[J]. Cellulose,2018,25(12):1-12. [15] 王文聪, 杜淑宁, 王鸿博, 等. 低取代羟乙基纤维素在碱溶剂中的溶解行为及其机制[J]. 纺织学报, 2018, 39(10):18-23.WANG W C, DU S N, WANG H B, et al. Dissolution behavior and mechanisms of low substituted hydroxyethyl cellulose in alkali solvents[J]. Journal of Textiles,2018,39(10):18-23(in Chinese). [16] WANG S, LYU K J, SUN P, et al. Influence of cation on the cellulose dissolution investigated by MD simulation and experiments[J]. Cellulose,2017,24(11):1-11. [17] CHENG G, ZHU P X, LI J L, et al. All-cellulose films with excellent strength and toughness via a facile approach of dissolution-regeneration[J]. Journal of Applied Polymer Science,2019,136(2):46925-46936. doi: 10.1002/app.46925 [18] CAI J, ZHANG L N, LIU S L, et al. Dynamic self-assembly induced rapid dissolution of cellulose at low temperatures[J]. Macromolecules,2008,41(23):9345-9351. doi: 10.1021/ma801110g [19] HUANG J C, ZHONG Y, ZHANG L N, et al. Extremely strong and transparent chitin films: A high-efficiency, energy-saving, and “Green” route using an aqueous KOH/Urea solution[J]. Advanced Functional Materials,2017,27(26):1701100-1701110. doi: 10.1002/adfm.201701100 [20] CHENG D, WEI P D, ZHANG L N, et al. Surface-initiated atom transfer radical polymerization grafting from nanoporous cellulose gels to create hydrophobic nanocomposites[J]. RSC Advances,2018,8(48):27045-27053. doi: 10.1039/C8RA04163F [21] KAMMIOVIRTA K, JÄÄSKELÄINEN A S, KUUTTI L, et al. Keratin-reinforced cellulose filaments from ionic liquid solutions[J]. RSC Advances,2016,6(91):88797-88806. doi: 10.1039/C6RA20204G [22] HE M, CHEN H, ZHANG X J, et al. Construction of novel cellulose/chitosan composite hydrogels and films and their applications[J]. Cellulose,2018,25(3):1-10. [23] KIM J R, NETRAVALI A N. Self-healing green composites based on soy protein and microfibrillated cellulose[J]. Composites Science & Technology,2017,143:22-30. [24] ZHAO Y T, HE M, JIN H F, et al. Construction of highly biocompatible hydroxyethyl cellulose/soy protein isolate composite sponges for tissue engineering[J]. Chemical Engineering Journal,2018,341:402-413. doi: 10.1016/j.cej.2018.02.046 [25] 全沁果, 段伟文, 曾雪鸽, 等. 南极磷虾粉成分分析及营养学评价[J]. 食品与机械, 2018, 34(9):68-76.QUAN Q G, DUAN W W, ZENG X G, et al. Composition analysis and nutritional evaluation of antarctic krill powder[J]. Food and Machinery,2018,34(9):68-76(in Chinese). [26] HUANG J W, CUI C, ZHENG X J, et al. Study on defluorination technology of antarctic krill protein hydrolysate[J]. China Condiment,2018,43(1):1-8. [27] GUO F, WANG Z H, SHI W Z, et al. Distribution characteristics and speciation of fluorine in different parts of antarctic krill[J]. Food Science,2018,39(8):237-242. [28] BAX M L, AUBRY L, FERREIRA C, et al. Cooking temperature is a key determinant of in vitro meat protein digestion rate: investigation of underlying mechanisms[J]. Journal of Agricultural & Food Chemistry,2012,60(10):2569-76. [29] ZHANG R, GUO J, LIU Y, et al. Effects of sodium salt types on the intermolecular interaction of sodium alginate/antarctic krill protein composite fibers[J]. Carbohydrate Polymers,2018,189:72-78. doi: 10.1016/j.carbpol.2018.02.013 [30] SONG J X, GUO J, ZHANG S, et al. Properties of cellulose/antarctic krill protein composite fibers prepared in different coagulation baths[J]. International Journal of Biological Macromolecules,2018,114:334-340. doi: 10.1016/j.ijbiomac.2018.03.118 [31] 杨利军, 郭静, 李圣林, 等. 高强度南极磷虾蛋白/海藻复合纤维的制备与表征[J]. 复合材料学报, 2016, 33(7):1524-1530.YANG L J, GUO J, LI S L, et al. Preparation and characterization of high strength antarctic krill protein/algae composite fibers[J]. Journal of Composite Materials,2016,33(7):1524-1530(in Chinese). [32] WU J, GUO J, YANG L J, et al. Molecular interaction and characterization of sodium alginate/antarctic krill protein/polyvinyl alcohol composite fiber[J]. Journal of Textile Research,2017,38(2):7-13. [33] XU S, LI R Q, ZHANG J F, et al. Ethylene glycol diglycidyl ether cross-linked with sodium alginate-carboxymethyl cellulose to immobilize lipase[J]. China Biotechnology,2017,37(12):77-83. [34] 郭静, 李学才, 于春芳, 等. 南极磷虾蛋白的提取及其复合纤维的性能[J]. 大连工业大学学报, 2014, 33(4):270-273.GUO J, LI X C, YU C F, et al. Extraction of antarctic krill protein and properties of its composite fibers[J]. Journal of Dalian University of Technology,2014,33(4):270-273(in Chinese). [35] 李亮, 刘淑萍, 刘让同, 等. NaOH/尿素溶液中纤维素稳态流变性的浓度依赖性[J]. 纺织科技进展, 2017(9):30-33. doi: 10.3969/j.issn.1673-0356.2017.09.008LI L, LIU S P, LIU R T, et al. Concentration-dependent steady-state rheological properties of cellulose in NaOH/urea solution[J]. Advances in Textile Science and Technology,2017(9):30-33(in Chinese). doi: 10.3969/j.issn.1673-0356.2017.09.008 [36] CAI J, ZHANG L N. Unique gelation behavior of cellulose in NaOH/urea aqueous solution[J]. Biomacromolecules,2006,7(1):183-189. doi: 10.1021/bm0505585 [37] LIU J, WANG H F, ZHANG L, et al. Preparation, structure and performances of cross-linked regenerated cellulose fibers[J]. Wuhan University Journal of Natural Sciences,2019,24(1):1-7. doi: 10.1007/s11859-019-1361-2 [38] ZHONG Z L, ZHANG X, ZHU M, et al. Effect of different pretreatments on solubility of hemp fibers in ionic liquids[J]. Journal of Donghua University (English Edition),2018,35(1):52-57. -

下载:

下载: