Effect of ceramic-nylon composite fiber content on properties and micromorphologies of gypsum mold

-

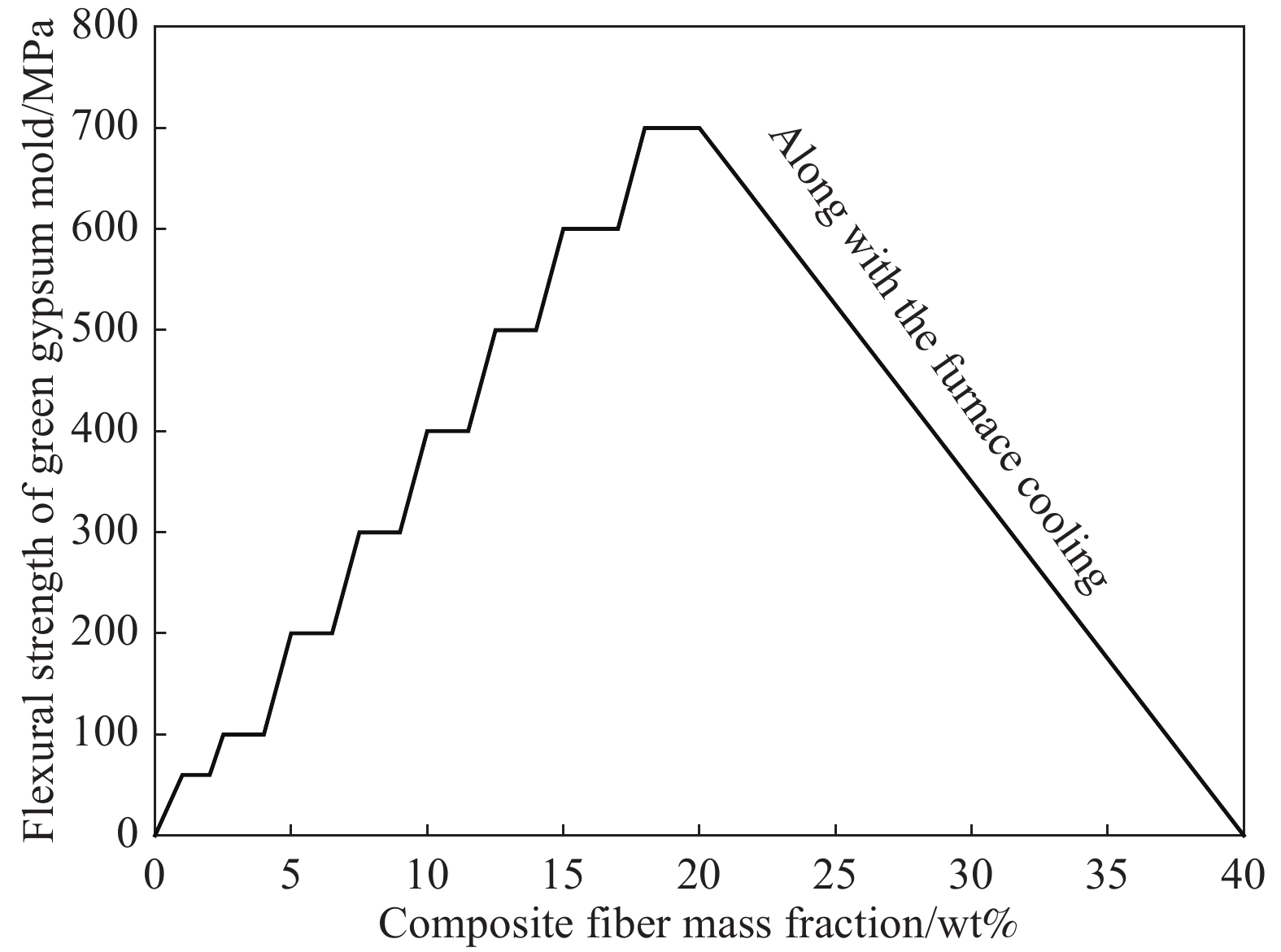

摘要: 向石膏粉料中添加不同含量陶瓷-尼龙复合纤维制备石膏铸型试样,测试分析陶瓷-尼龙复合纤维交织强化石膏试样的性能并观察其断口,研究陶瓷-尼龙复合纤维含量对石膏铸型性能和微观形貌的影响。结果表明,陶瓷-尼龙复合纤维含量对石膏铸型性能影响显著,随着陶瓷-尼龙复合纤维含量增加,石膏试样生胚抗弯强度呈倒V字形变化趋势,焙烧后的抗弯强度变化不大;石膏试样透气率随陶瓷-尼龙复合纤维含量的增加而增大,当石膏混合料中陶瓷-尼龙复合纤维质量分数为1.25wt%时达到最大值32.3,与传统石膏铸型相比,增大近21倍,尼龙纤维焙烧后形成的孔洞提高了石膏铸型透气率,陶瓷纤维保留在基体中提高强度,当陶瓷-尼龙复合纤维质量分数大于0.75wt%时,纤维会团聚并割裂基体;导热性和抗热震性随陶瓷-尼龙复合纤维含量的增加而先增大后减小,当陶瓷-尼龙复合纤维含量为0.75wt%~1wt%时,导热性和抗热震性相对最佳。Abstract: Gypsum mold samples were prepared by put different contents of ceramic-nylon composite fibers into gypsum slurry. The properties and fractures of the ceramic-nylon composite fibers reinforced gypsum mold samples were tested and analyzed. The effect of the composite fiber content on the properties and microscopic appearance of gypsum mold was studied. The results show that the composite fiber content has a significant effect on the properties of gypsum mold. With the increase of the composite fiber content, the flexural strength of gypsum samples has an inverted V-shape, and the flexural strength after calcination does not change much. The gas permeability of gypsum samples increases with the increase of the composite fiber content. When the mass fraction of the composite fiber in the gypsum mixture is 1.25wt%, the gas permeability reaches maximum of 32.3, which is nearly 21 times higher than that of traditional gypsum molds. The pores formed after the roasting of the nylon fiber increase the gas permeability of the gypsum mold, and the ceramic fiber remains in the matrix to increase the strength. When the fiber content exceeds 0.75wt%, the fiber agglomerates and splits the matrix. The thermal conductivity and thermal shock resistance increase first and then decrease with the increase of the composite fiber content. When the fiber content is 0.75wt%-1wt%, the thermal conductivity and thermal shock resistance are relatively optimal.

-

Key words:

- gypsum mold /

- composite fiber /

- flexural strength /

- gas permeability /

- thermal conductivity /

- microscopic appearance

-

表 1 纤维的主要性能指标

Table 1. Main performance indicators of fiber

Fiber type Length/mm Diameter/μm Tensile strength/GPa Elastic coefficient/GPa Density/(g·cm−3) Melting point/℃ Ceramic fiber 4-7 4-8 4 290 1.85 1 800 Nylon fiber 4 9-13 0.9 5.17 1.16 224 表 2 石膏铸型浆料成分质量分数

Table 2. Mass fraction of gypsum mold slurry compositions

Slurry composition Gypsum(70 μm) Quartz(44 μm) Alumina(80 μm) Talcum(41 μm) K2SO4 N-octanol Water-solid ratio Mass fraction/wt% 40 20 30 8 2 0.05 53 表 3 700~1 100 ℃不同陶瓷-尼龙复合纤维含量石膏铸型抗热震性能评级

Table 3. Thermal shock resistance rating of gypsum molds with different ceramic-nylon composite fiber contents from 700℃ to 1 100℃

Temperature/℃ Ceramic-nylon composite fiber mass fraction/wt% 0 0.25 0.5 0.75 1 1.25 700 Ⅱ Ⅰ Ⅱ Ⅰ Ⅰ Ⅰ 800 Ⅱ Ⅱ Ⅱ Ⅰ Ⅰ Ⅰ 900 Ⅲ Ⅱ Ⅱ Ⅱ Ⅱ Ⅱ 1 000 Ⅲ Ⅱ Ⅲ Ⅱ Ⅱ Ⅱ 1 100 Ⅳ Ⅱ Ⅲ Ⅱ Ⅱ Ⅱ -

[1] 芦刚, 毛蒲, 严青松, 等. 复合纤维含量对精铸硅溶胶型壳强度及透气性的影响[J]. 中国有色金属学报, 2015, 25(11):3164-3170.LU Gang, MAO Pu, YAN Qingsong, et al. Effect of composite fiber content on strength and gas permeability of precision cast silica sol shells[J]. The Chinese Journal of Nonferrouss Metals,2015,25(11):3164-3170(in Chinese). [2] ELIADES P, BHATTACHARYA S N, CHRYSS A, et al. The influence of hermitic clay on the time dependent properties of formulated gypsum plaster pastes[J]. Journal of Materials Science,2003,38:3871-3875. doi: 10.1023/A:1025961022923 [3] EDMÉA L, MEIRA J B C, FILHO L E R, et al. Expansion of high flow mixtures of gypsum-bonded investments in contact with absorbent liners[J]. Dental Materials,2005,21(6):573-579. doi: 10.1016/j.dental.2004.12.001 [4] 叶久新, 陈永泰. 石膏铸型熔模铸造工艺研究[J]. 湖南大学学报: 自然科学版, 2000, 27(3):49-53.YE Jiuxin, CHEN Yongtai. Research on investment casting process of gypsum casting[J]. Journal of Hunan University: Natural Science,2000,27(3):49-53(in Chinese). [5] 赵忠兴, 石颖科, 叶锦华. 石膏型快速烘干工艺的研究[J]. 特种铸造及有色合金, 2008, 28(6):460-461, 408. doi: 10.3870/j.issn.1001-2249.2008.06.017ZHAO Zhongxing, SHI Yingke, YE Jinhua. Research on rapid drying process of gypsum casting[J]. Special Casting & Nonferrous Alloys,2008,28(6):460-461, 408(in Chinese). doi: 10.3870/j.issn.1001-2249.2008.06.017 [6] 程鲁, 董选普, 马戎, 等. 熔模铸造复杂薄壁镁合金易溃散性石膏型研究[J]. 特种铸造及有色合金, 2011, 31(8):736-739. doi: 10.3870/tzzz.2011.08.015CHENG Lu, DONG Xuanpu, MA Rong, et al. Research on casting of complex thin-walled magnesium alloy with investment casting[J]. Special Casting & Nonferrous Alloys,2011,31(8):736-739(in Chinese). doi: 10.3870/tzzz.2011.08.015 [7] 张永红, 蒋玉明, 杨屹. 石膏型熔模特种铸造工艺[J]. 铸造技术, 2002, 23(6):347-349. doi: 10.3969/j.issn.1000-8365.2002.06.011ZHANG Yonghong, JIANG Yuming, YANG Yi. Casting process of gypsum casting melting model[J]. Foundry Technology,2002,23(6):347-349(in Chinese). doi: 10.3969/j.issn.1000-8365.2002.06.011 [8] 吴先哲, 唐华, 肖乐. 石膏铸型抗热震性研究[J]. 铸造技术, 2010, 31(4):471-473.WU Xianzhe, TANG Hua, XIAO Le. Study on thermal shock resistance of gypsum casting[J]. Foundry Technology,2010,31(4):471-473(in Chinese). [9] 韩昌仁, 周铁涛, 王薇薇, 等. 石膏型简易制模工艺的研究[J]. 特种铸造及有色合金, 2000(4):27-29, 2. doi: 10.3321/j.issn:1001-2249.2000.04.010HAN Changren, ZHOU Tietao, WANG Weiwei, et al. Research on simple molding process of gypsum casting[J]. Special Casting & Nonferrous Alloys,2000(4):27-29, 2(in Chinese). doi: 10.3321/j.issn:1001-2249.2000.04.010 [10] ASAOKA K, BAE J Y, LEE H H. Porosity of dental gypsum-bonded investments in setting and heating process[J]. Dental Materials Journal,2013,31(1):120-124. [11] BOBBY S, SINGAMNENI S. Influence of moisture in the gypsum moulds made by 3D printing[J]. Procedia Engineering,2014,97:1618-1625. doi: 10.1016/j.proeng.2014.12.312 [12] 芦刚, 郭振华, 严青松, 等. 复合纤维配比对精铸硅溶胶型壳性能的影响[J]. 复合材料学报, 2018, 35(6):1535-1541.LU Gang, GUO Zhenhua, YAN Qingsong, et al. Influence of composite fiber ratio on properties of cast silica sol shells[J]. Acta Materiae Compositae Sinica,2018,35(6):1535-1541(in Chinese). [13] JONES S, YUAN C. Advances in shell moulding for investment casting[J]. Journal of Materials Processing Technology,2003,135(2-3):258-265. doi: 10.1016/S0924-0136(02)00907-X [14] 罗洪林, 杨鼎宜, 周兴宇, 等. 不同长径比聚丙烯纤维增强混凝土的力学特性[J]. 复合材料学报, 2019, 36(8):1935-1948.LUO Honglin, YANG Dingyi, ZHOU Xingyu, et al. Mechanical properties of polypropylene fiber reinforced concrete with different aspect ratios[J]. Acta Materiae Compositae Sinica,2019,36(8):1935-1948(in Chinese). [15] 高丹盈, 李晗, 杨帆. 聚丙烯-钢纤维增强高强混凝土高温性能[J]. 复合材料学报, 2013, 30(1):187-193.GAO Danying, LI Han, YANG Fan. High temperature performance of polypropylene-steel fiber reinforced high strength concrete[J]. Acta Materiae Compositae Sinica,2013,30(1):187-193(in Chinese). [16] 王裕银, 李国忠, 柏玉婷. 玉米秸秆纤维/脱硫石膏复合材料的性能[J]. 复合材料学报, 2010, 27(6):94-99.WANG Yuyin, LI Guozhong, BAI Yuting. Performance of corn straw fiber/desulfurization gypsum composites[J]. Acta Materiae Compositae Sinica,2010,27(6):94-99(in Chinese). [17] 王兰馨, 赵忠兴, 耿德军. 添加剂对石膏铸型强度的影响[J]. 沈阳理工大学学报, 2009, 6:24-27. doi: 10.3969/j.issn.1003-1251.2009.06.007WANG Lanxin, ZHAO Zhongxing, GENG Dejun. Influence of additives on the strength of gypsum casting[J]. Journal of Shenyang Ligong University,2009,6:24-27(in Chinese). doi: 10.3969/j.issn.1003-1251.2009.06.007 [18] 黄韡, 姜会钰, 杨海浪. 碳纤维增强石膏的力学性能及其制备方法[J]. 武汉纺织大学学报, 2014, 27(3):74-77. doi: 10.3969/j.issn.2095-414X.2014.03.018HUANG Wei, JIANG Huiyu, YANG Hailang. Mechanical properties and preparation methods of carbon fiber reinforced gypsum[J]. Journal of Wuhan Textile University,2014,27(3):74-77(in Chinese). doi: 10.3969/j.issn.2095-414X.2014.03.018 [19] 芦刚, 纪超众, 严青松, 等. 陶瓷纤维长度对复合精铸型壳抗弯强度与透气性的影响及增强行为[J]. 复合材料学报, 2017, 34(4):637-644.LU Gang, JI Chaozhong, YAN Qingsong, et al. Effect of ceramic fiber length on flexural strength and gas permeability of composite casting shell and its enhanced behavior[J]. Acta Materiae Compositae Sinica,2017,34(4):637-644(in Chinese). [20] 吕凯, 刘向东, 王浩, 等. 短切硅酸铝纤维增强硅溶胶型壳的抗弯强度及高温自重变形[J]. 材料工程, 2015, 43(7):56-61. doi: 10.11868/j.issn.1001-4381.2015.07.010LV Kai, LIU Xiangdong, WANG Hao, et al. Bending strength and high temperature self-weight deformation of short-cut aluminum silicate fiber reinforced silica sol shell[J]. Journal of Materials Engineering,2015,43(7):56-61(in Chinese). doi: 10.11868/j.issn.1001-4381.2015.07.010 [21] 郭振华. 复合纤维含量对其在石膏浆料中的分散性及石膏铸型性能的影响[D]. 南昌: 南昌航空大学, 2017.GUO Zhenhua. Effect of composite fiber content on its dispersibility in gypsum slurry and gypsum mold properties[D]. Nanchang: Nanchang Hangkong University, 2017(in Chinese). -

下载:

下载: