In-plane deformation behavior of unidirectional carbon fiber/epoxy prepreg layups

-

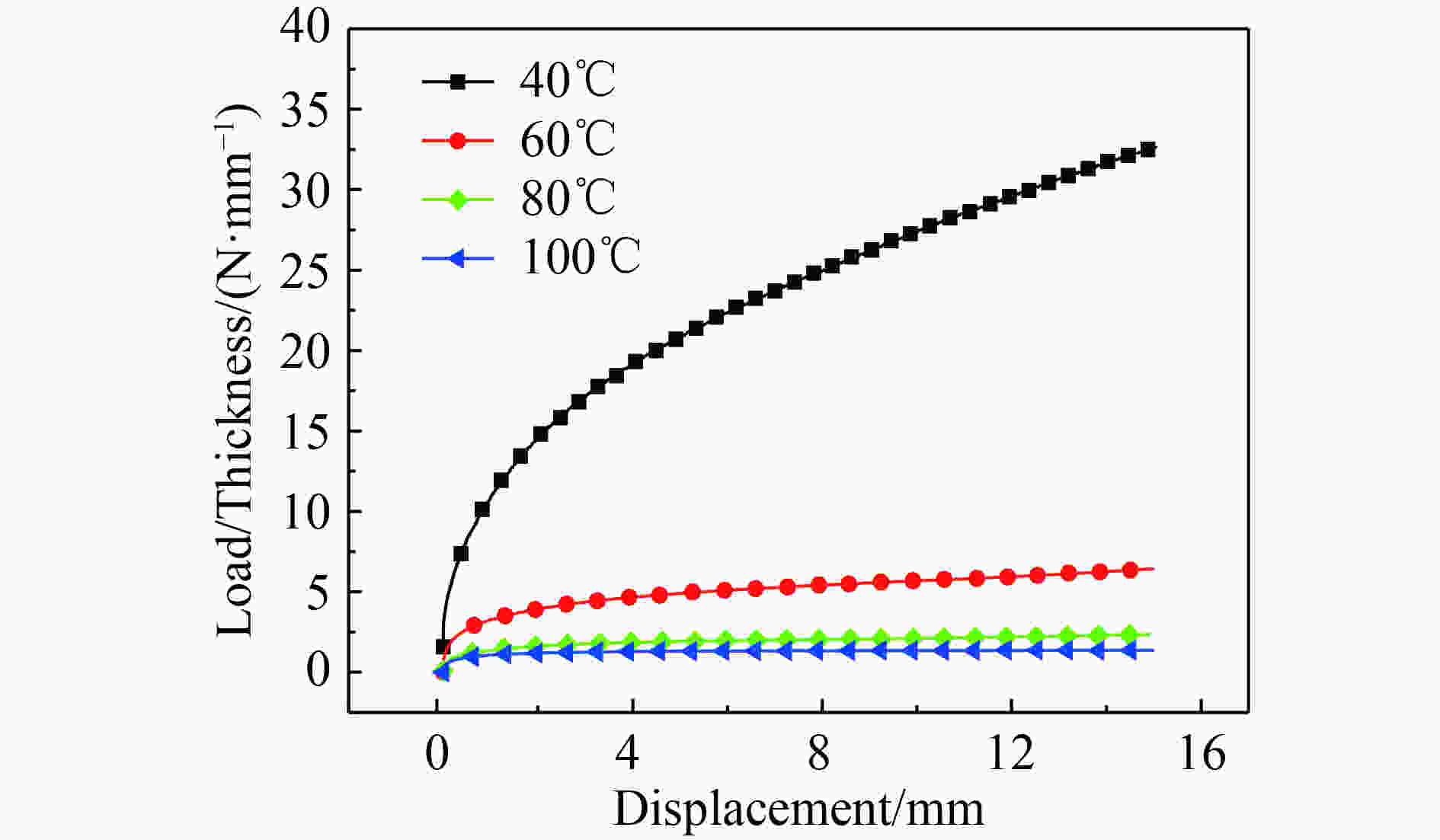

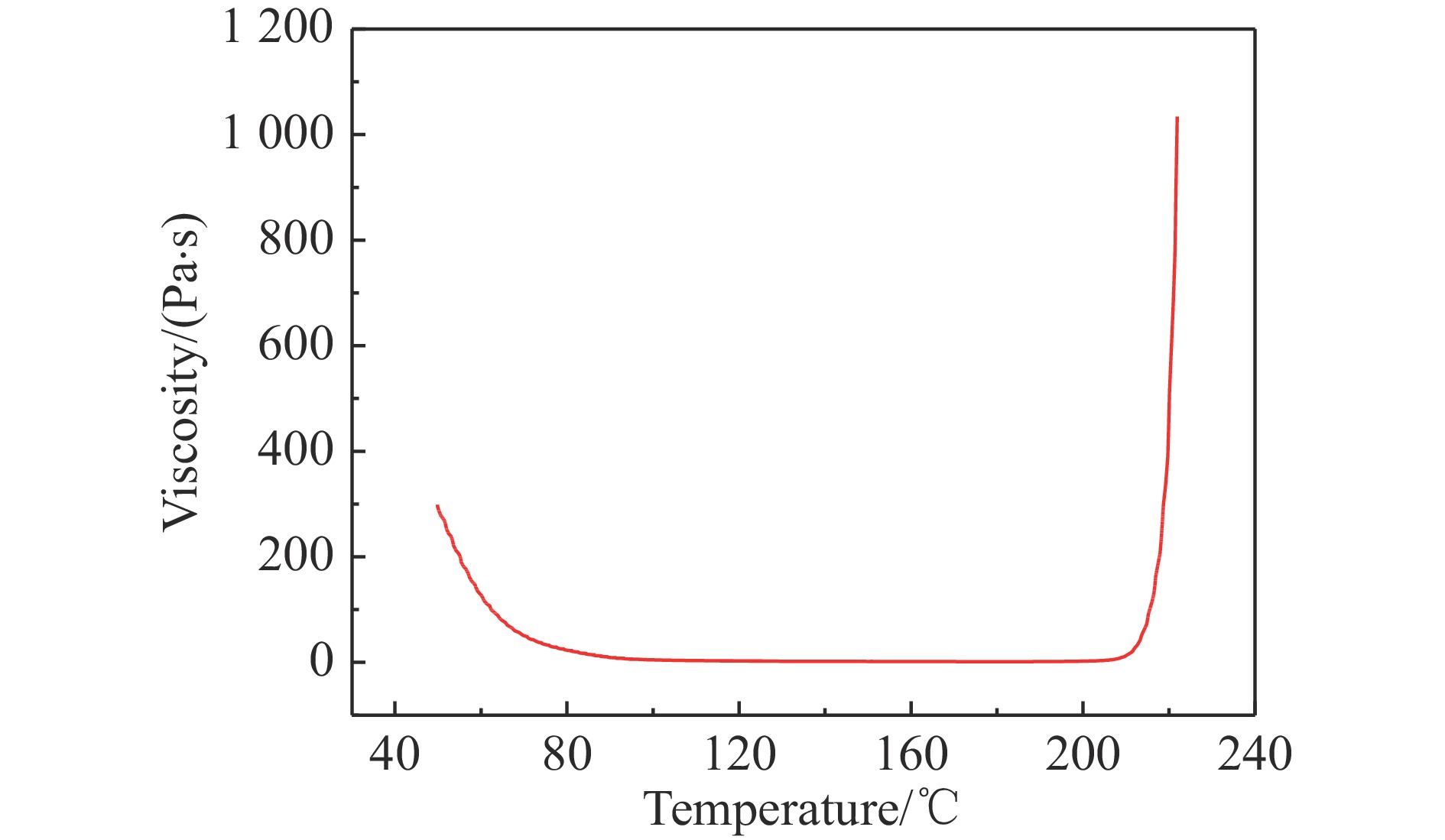

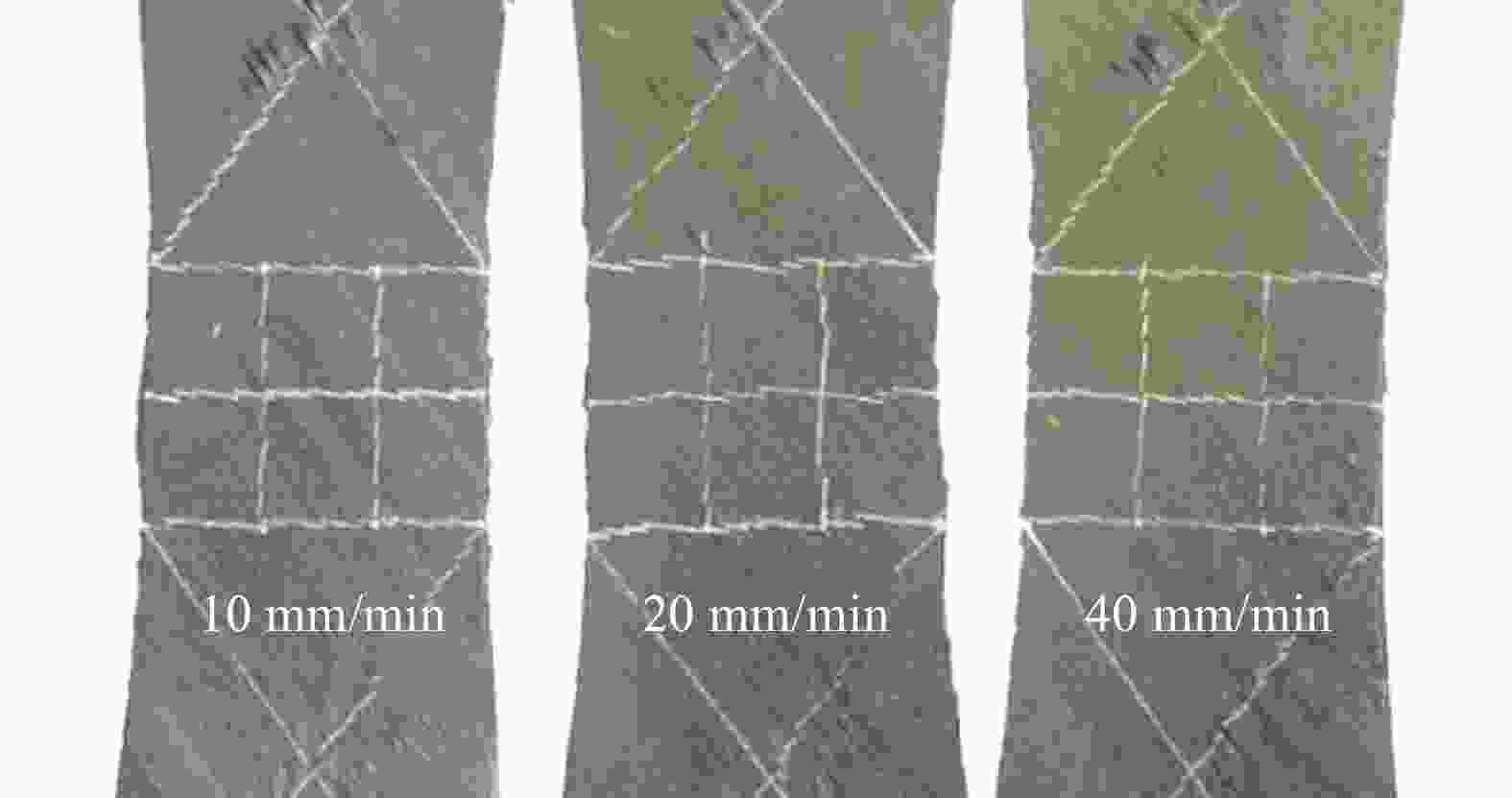

摘要: 为了充分了解热隔膜成型过程中预浸料的变形行为,通过偏轴拉伸测试探索了热固性单向碳纤维/环氧树脂预浸料在高温条件下的面内变形机制。研究参数包括试验温度、拉伸速率、预热时间和铺层顺序等。利用数字图像相关技术,在测试过程中监测单向碳纤维/环氧树脂预浸料的变形和纤维的旋转情况。结果表明,提高试验温度或降低拉伸速率均有利于促进单向碳纤维/环氧树脂预浸料的变形。铺层顺序对单向碳纤维/环氧树脂预浸料铺层的变形行为有很大影响,[45/–45/90]S铺层方式比 [45/90/–45]S铺层方式更有利于纤维旋转,且[45/–45/90]S铺层方式变形阻力更小。采用铰链连接网(Pin-joined net, PJN) 理论对单向碳纤维/环氧树脂预浸料铺层变形过程中纤维角度变化进行预测并与实验结果进行对比,结果表明,用PJN理论预测的纤维旋转角度值与测试值存在较大偏差,说明其并不适用于预测热固性单向碳纤维/环氧树脂预浸料变形过程中纤维角的变化。同时,80℃预加热可以提高单向碳纤维/环氧树脂预浸料的变形阻力。

-

关键词:

- 偏轴拉伸 /

- 热固性预浸料 /

- 变形机制 /

- 铰链连接网(PJN)理论 /

- 热隔膜成型

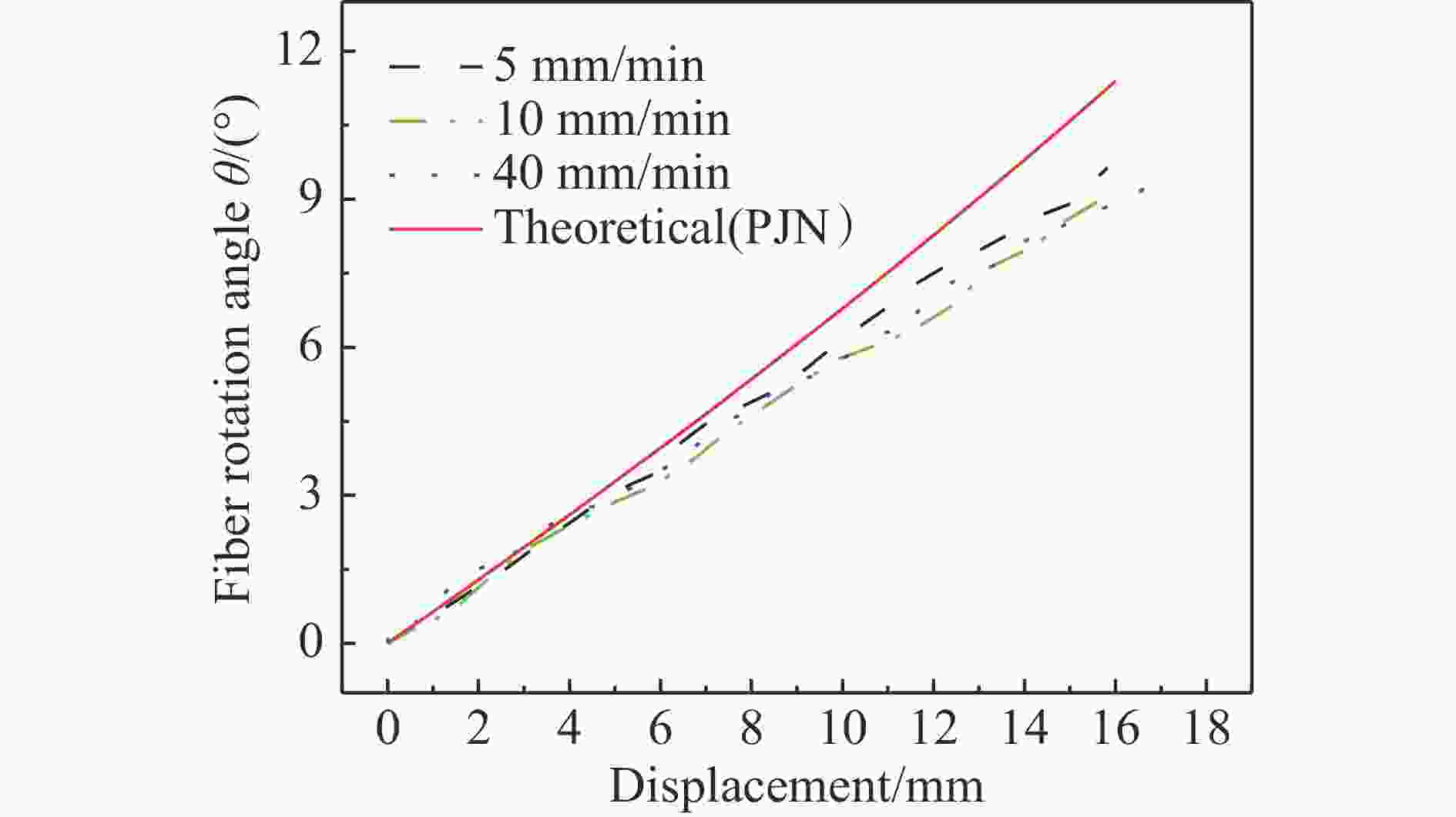

Abstract: In order to fully understand the deformation behavior of prepreg in the process of hot diaphragm forming, the in-plane deformation mechanism of unidirectional carbon fiber/epoxy thermoset prepreg at high temperature was studied using the bias extension method. The effects of testing temperature, tensile rate, preheating time and stacking sequence on the in-plane deformation were investigated. Using digital image correlation technology, the specimen deformation and fiber rotation were captured during testing process. The results show that increasing temperature or decreasing tensile rate can promote the deformation of unidirectional carbon fiber/epoxy thermoset prepreg. Stacking sequence has a great influence on the deformation behavior of the unidirectional carbon fiber/epoxy thermoset prepreg stacks. The fiber rotation of [45/–45/90]S layup is easier than that of [45/90/–45]S layup, and the former has lower deformation resistance. The Pin-joined net (PJN) theory was used to predict the fiber rotation angle during the deformation process of the unidirectional carbon fiber/epoxy thermoset prepreg stacks, and the prediction value was compared with the experiment value. The results show that the prediction values deviate greatly from the experiment values, indicating that the PJN theory is not suitable for the prediction of the fiber rotation angle during the deformation of unidirectional carbon fiber/epoxy thermoset prepreg. Being preheated at 80℃ can increase the deformation resistance of the prepreg. -

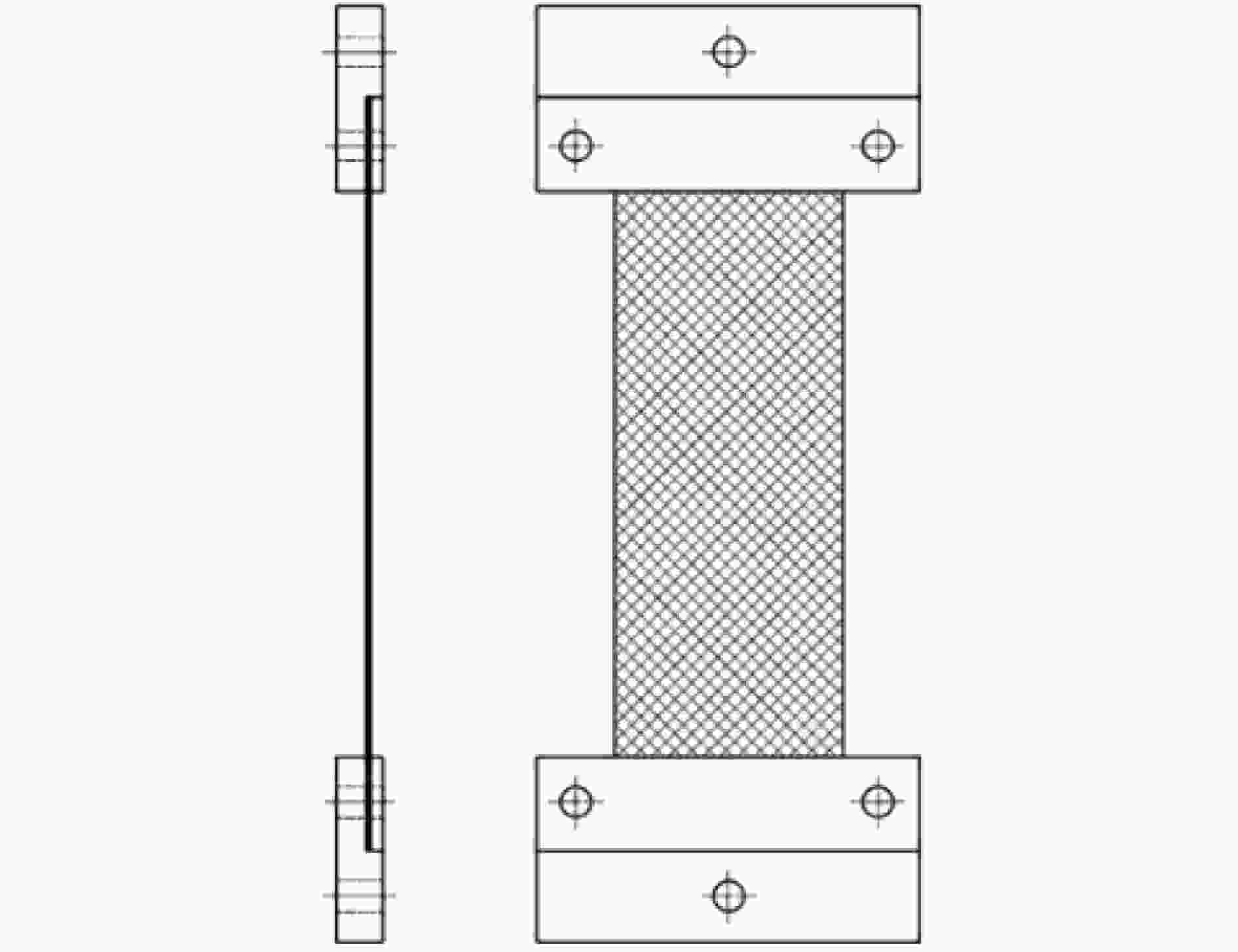

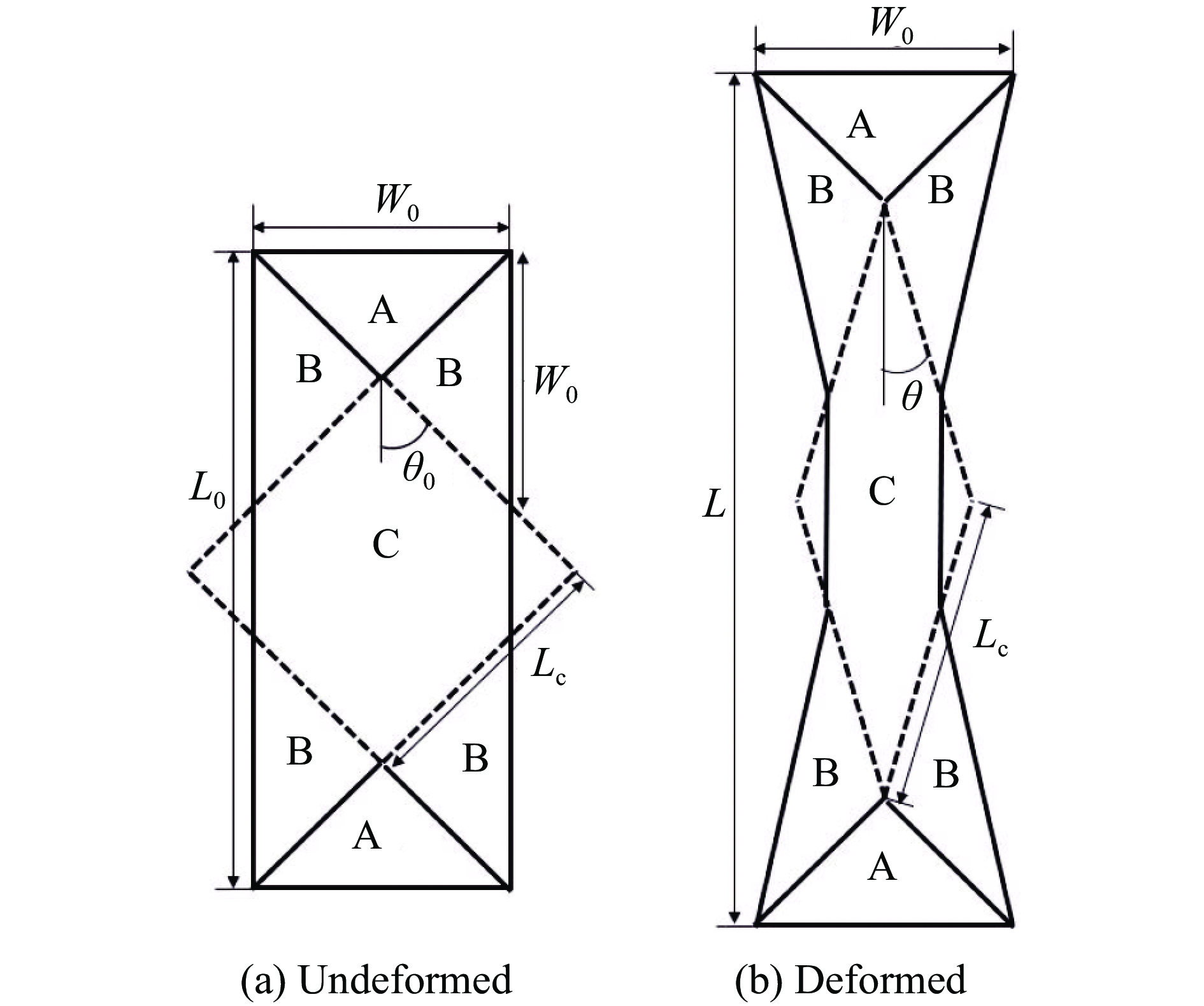

图 1 未变形和变形后偏轴拉伸测试试样

Figure 1. Schematics of undeformed and deformed shapes of specimens in bias-extension test (θ0—Initial fiber angle; θ—Instantaneous fiber angle during deformation; W0—Initial sample width; L0—Initial sample length; L—Instantaneous sample length during deformation; Lc—Side length of square in zone C)

-

[1] 黄莹. 复合材料热隔膜预成型工艺分析[J]. 机械设计与制造工程, 2015, 44(9):20-22.HUANG Ying. The analysis on the hot diaphragm preforming process for composite material[J]. Mechanical Design and Manufacturing Engineering,2015,44(9):20-22(in Chinese). [2] 杨博, 王菲, 陈永清. 大尺寸复合材料翼梁的制造技术发展[J]. 航空制造技术, 2013(22):74-77. doi: 10.3969/j.issn.1671-833X.2013.22.013YANG Bo, WANG Fei, CHEN Yongqing. Development of manufacturing technology in large composites wing spar[J]. Aeronautical Manufacturing Technology,2013(22):74-77(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.22.013 [3] SJÖLANDER J, HALLANDER P, ÅKERMO M. Forming induced wrinkling of composite laminates: A numerical study on wrinkling mechanisms[J]. Composites Part A: Applied Science and Manufacturing,2016,81:41-51. doi: 10.1016/j.compositesa.2015.10.012 [4] 吴志恩. 复合材料热隔膜成型[J]. 航空制造技术, 2009(s2):113-116.WU Zhien. Hot drape forming of composite[J]. Aeronautical Manufacturing Technology,2009(s2):113-116(in Chinese). [5] 陈亚莉. 复合材料成型工艺在A400M军用运输机上的应用[J]. 航天制造技术, 2008(10):32-35.CHEN Yali. Application of composite forming technique in military freighter A400M[J]. Aerospace Manufacturing Technology,2008(10):32-35(in Chinese). [6] 王永军, 杨凯, 陈森林, 等. 热固性碳纤维编织复合材料C形结构隔膜成型工艺[J]. 玻璃钢/复合材料, 2015(3):59-65.WANG Yongjun, YANG Kai, CHEN Senlin, et al. Hot-diaphragm for thermosetting carbon woven fabric composite with C-shape structure[J]. Fiber Reinforced Plastics/Composites,2015(3):59-65(in Chinese). [7] SMILEY A J, PIPES R B. Analysis of the diaphragm forming of continuous fiber reinforced thermoplastics[J]. Journal of Thermoplastic Composite Materials,1988,1(4):298-321. doi: 10.1177/089270578800100401 [8] YU X, CARTWRIGHT B, MCGUCKIN D, et al. Intra-ply shear locking in finite element analyses of woven fabric forming processes[J]. Composites Part A: Applied Science and Manufacturing,2006,37(5):790-803. doi: 10.1016/j.compositesa.2005.04.024 [9] BOISSE P, HAMILA N, VIDAL-SALLE E, et al. Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses[J]. Composites Science and Technology,2011,71(5):683-692. doi: 10.1016/j.compscitech.2011.01.011 [10] THIJE R H W T, AKKERMAN R. Solutions to intra-ply shear locking in finite element analyses of fibre reinforced materials[J]. Composites Part A: Applied Science and Manufacturing,2008,39(7):1167-1176. doi: 10.1016/j.compositesa.2008.03.014 [11] LEBRUN G, BUREAU M N, DENAULT J. Evaluation of bias-extension and picture-frame test methods for the measurement of intraply shear properties of PP/glass commingled fabrics[J]. Composite Structures,2003,61(4):341-352. doi: 10.1016/S0263-8223(03)00057-6 [12] POTTER K. Beyond the pin-jointed net: Maximising the deformability of aligned continuous fibre reinforcements[J]. Composites Part A: Applied Science and Manufacturing,2002,33(5):677-686. doi: 10.1016/S1359-835X(02)00014-3 [13] HARRISON P, CLIFFORD M J, LONG A C. Shear characterization of viscous woven textile composites: A comparison between picture frame and bias extension experiments[J]. Composites Science and Technology,2004,64(10-11):1453-1465. doi: 10.1016/j.compscitech.2003.10.015 [14] LARBERY Y, ÅKERMO M. In-plane deformation of multi-layered unidirectional thermoset prepreg: Modelling and experimental verification[J]. Composites Part A: Applied Science and Manufacturing,2014,56:203-212. [15] POTTER K. In-plane and out-of-plane deformation properties of unidirectional preimpregnated reinforcement[J]. Composites Part A: Applied Science and Manufacturing,2002,33(11):1469-1477. doi: 10.1016/S1359-835X(02)00138-0 [16] LARBERY Y R, AKERMO M, NORRBY M. On the in-plane deformability of cross-plied unidirectional prepreg[J]. Journal of Composite Materials,2009,46(8):929-939. [17] 陈洁, 顾轶卓, 李敏, 等. 碳纤维/环氧预浸料摩擦滑移特性测试及其变化规律[J]. 复合材料学报, 2014, 31(1):101-106.CHEN Jie, GU Yizhuo, LI Min, et al. Measurement and evolution of frictional slipping behavior of carbon fiber/epoxy prepreg[J]. Acta Materiae Compositae Sinica,2014,31(1):101-106(in Chinese). [18] 边旭霞, 顾轶卓, 孙晶, 等. 热隔膜工艺温度与成型速率对C形复合材料成型质量的影响[J]. 玻璃钢/复合材料, 2013(5):45-50.BIAN Xuxia, GU Yizhuo, SUN Jing, et al. Effect of temperature and molding rate in hot diaphragm forming process n the forming quality of C-shaped composite[J]. Fiber Reinforced Plastics/Composites,2013(5):45-50(in Chinese). [19] KIM D, CENTEA T, NUTT S R. Out-time effects on cure kinetics and viscosity for an out-of-autoclave (OOA) prepreg: Modelling and monitoring[J]. Composites Science and Technology,2014,100:63-69. -

下载:

下载: