Advances in flexible wearable bismuth telluride-based Materials thermoelectric devices

-

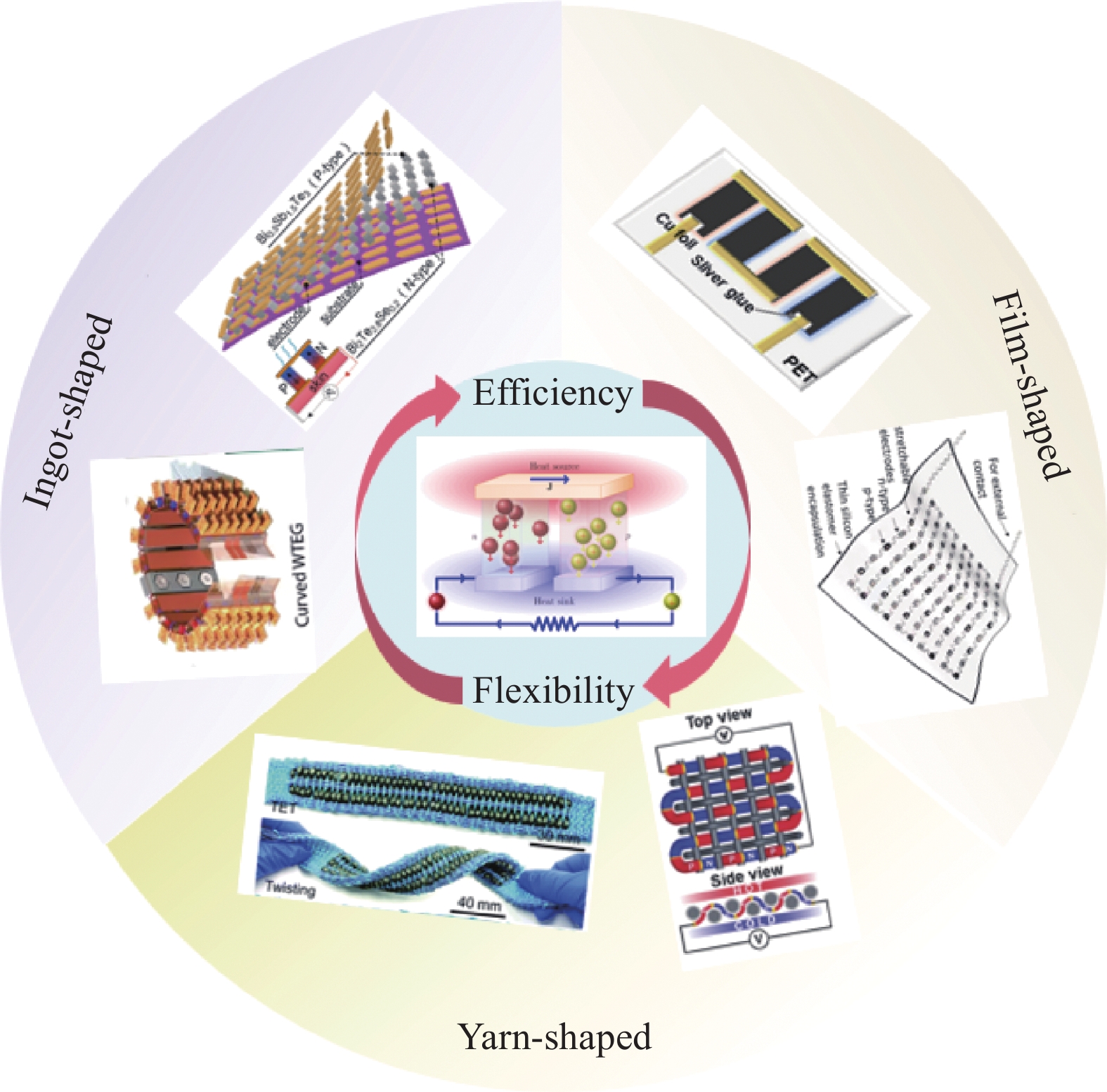

摘要: 随着全球能源的消耗加剧,热电器件的开发应用成为解决能源消耗问题的有效途径之一,其中,碲化铋(Bi2Te3)基柔性热电器件因在可穿戴领域逐步实现应用,得到了学界和业界的广泛关注。然而,受其材料成本较高、刚性结构等多方面因素的限制,Bi2Te3基柔性热电器件难以在保持高效热电性能的同时,实现柔性可穿戴化应用。本文系统地阐述了当前Bi2Te3基柔性热电器件在材料复合与柔性结构设计上的研究进展,特别是在柔性结构设计上,涵盖了块状、膜类以及纱线型三种结构。最后,总结分析了Bi2Te3柔性热电器件未来可能面临的挑战与发展趋势,以期促进热电器件在可穿戴领域实现广泛应用。Abstract: As the global energy consumption increasing rapidly, development and application of thermoelectric devices have become one of the effective ways to solve the problem. Among them, bismuth telluride-based flexible devices attract widespread attention because they have been applied in the wearable sector gradually. However, due to the limitations of high material cost, rigid structure, and other factors, it is difficult for bismuth telluride-based flexible thermoelectric devices to achieve flexible wearable applications while maintaining efficient thermoelectric properties. This paper systematically reviews the current research progress of bismuth telluride-based flexible thermoelectric devices in terms of material composites and flexible structure design, especially in terms of flexible structure design, which covers three types of structures: ingot-, film- and yarn- shaped. Finally, it summarizes and analyzes the possible future challenges and development trends of bismuth telluride-based flexible thermoelectric devices, to facilitate the realization of a wide range of applications for thermoelectric devices in the wearable field.

-

图 3 (a) f-TEG的制造工艺[20]; (b) TEG实样图[46]; (c)热电器件结构图[44];(d)中空结构器件结构图[45] ; (e)中空结构器件在手指表面的弯曲图[45]

Figure 3. (a) Manufacturing process of f-TEG[20]; (b) TEG sample drawing[46]; (c) Structure of the TEG[44]; (d) Structure of the Hollow Structure Device[45]; (e) Bending diagram of a hollow structure device on the surface of a finger[45]

表 1 Bi2Te3基热电器件应用总结

Table 1. Summary of Bismuth Telluride-based Thermoelectric Device Applications

Device type TE Materials Substance* input

voltage/mVPower Factor/

μW/mK2Power density/

µW/cm2Seebeck

coefficient/

μV/KRef. Flexible ingot-shaped thermoelectric devices Single-Walled

Carbon Nanotubes (SWCNT)

Bi2Te3/ 23

(135 K)891.6

(340 K)/ / [16] Bi0.5Te1.5Te3

(P-Type)

Bi2Te2.8Se0.2

(N-Type)Polyimide film

(PIF)2800-3300

(body temperature)/ 3.5 / [20] Bi0.5Sb1.5Te3

(P-Type)

Bi2Se0.3Te2.7

(N-Type)Flexible Printed Circuit Board

(FPCB)63 / 8.68 / [44] Bi0.5Sb1.5Te3

(P-Type)

Bi2Se0.5Te2.5

(N-Type)Flexible Printed Circuit Board

(FPCB)5.35 / 4.75 / [45] Carbon Nanotubes

(CNTs)

P,N Bi2Te3Polydimethylsiloxane

(PDMS)920 / 570 / [46] Flexible film-shaped thermoelectric devices Bi2Te3

Polyvinylidene Fluoride

(PVDF)Polyethylene terephthalate

(PET)2.3

(natural exhalation)133(P)

124 (N)/ / [6] N bismuth telluride(Graphene)

P bismuth telluride

(SWCNT)Polyimide

(PI)23

(135 K)55

(P)

108

(N)/ / [30] Bi2Te3

PEDOT:PSS

Dimethyl sulfoxide

(DMSO)/ / / / 45 ± 2.1 [40] Bi2Te3 AIN / 1130 / / [48] Bi2Te3 MASnI3 / / / / [49] Bi2Te3 Polyimide film

(PIF)155.1

(46℃)/ 2530 / [55] Bi0.4Sb1.6Te3

(P-Type)

Bi2Se0.3Te2

(N-Type)Polyimide film

(PIF)55.15

(AM 1.5 G)/ / 166.37

(P)

−116.38

(N)[56] Bi2Te3 Ecoflex / / 150 / [57] Flexible yarn-shaped thermoelectric devices Bi2Te3

Polyvinyl pyrrolidone(PVP)/ / / / 3062 [32] Bi2Te3-

Sb2Te3-PAN/ 15.8

14.8.

11.9/ 62

11

9/ [60] Bi0.4Sb1.3Te3

(P-Type)

Bi2Te3.3Se0.2

(N-Type)Polyimide Filament

Polydimethylsiloxane

(PDMS)/ / 58 / [61] Bi2Te3 Extreme filaments

Poly (3,4-ethylenedioxythiophene)-poly(PEDOT)/ / 613

(25 K)/ [62] Notes:Input voltage is the voltage produced by a device at a certain temperature;Power factor is the ratio of the power dissipated to the product of the input volts times amps;Power density is the power generated per square centimeter of the TEG;Seebeck coefficient is defined as follows: S=−ΔV/ΔT with S being the Seebeck coefficient, ΔT the temperature difference between the ends of the material, and ΔV the potential difference. -

[1] CHEN X, LI C, GRäTZEL M, et al. Nanomaterials for renewable energy production and storage[J]. Chemistry Society Reviews, 2012, 41(23): 7909-7937. doi: 10.1039/c2cs35230c [2] CONTI J, HOLTBERG P, DIEFENDERFER J, et al. International energy outlook 2016 with projections to 2040 [R]. USDOE Energy Information Administration (EIA), Washington, DC (United States)…, 2016. [3] ARISTOV Y I. Adsorptive conversion of ultralow-temperature heat: Thermodynamic issues[J]. Energy, 2021, 236: 121892. doi: 10.1016/j.energy.2021.121892 [4] UCHIDA K, TAKAHASHI S, HARII K, et al. Observation of the spin Seebeck effect[J]. Nature, 2008, 455(7214): 778-781. doi: 10.1038/nature07321 [5] DREBUSHCHAK V. The peltier effect[J]. Journal of Thermal Analysis and Calorimetry, 2008, 91: 311-315. doi: 10.1007/s10973-007-8336-9 [6] NA Y, KIM S, MALLEM S P R, et al. Energy harvesting from human body heat using highly flexible thermoelectric generator based on Bi2Te3 particles and polymer composite[J]. Journal of Alloys and Compounds, 2022, 924: 166575. doi: 10.1016/j.jallcom.2022.166575 [7] HOU W, NIE X, ZHAO W, et al. Fabrication and excellent performances of Bi0. 5Sb1. 5Te3/epoxy flexible thermoelectric cooling devices[J]. Nano Energy, 2018, 50: 766-776. [8] DAI X, WANG Y, LI K, et al. Joint-free single-piece flexible thermoelectric devices with ultrahigh resolution p–n patterns toward energy harvesting and solid-state cooling[J]. ACS Energy Letters, 2021, 6(12): 4355-4364. doi: 10.1021/acsenergylett.1c02005 [9] GAO F-L, MIN P, GAO X-Z, et al. Integrated temperature and pressure dual-mode sensors based on elastic PDMS foams decorated with thermoelectric PEDOT: PSS and carbon nanotubes for human energy harvesting and electronic-skin[J]. Journal of Materials Chemistry A, 2022, 10(35): 18256-18266. doi: 10.1039/D2TA04862K [10] LIU Y, YIN L, ZHANG W, et al. A wearable real-time power supply with a Mg3Bi2-based thermoelectric module[J]. Cell Reports Physical Science, 2021, 2(6): 100445 doi: 10.1016/j.xcrp.2021.100445 [11] KONG D, ZHU W, GUO Z, et al. High-performance flexible Bi2Te3 films based wearable thermoelectric generator for energy harvesting[J]. Energy, 2019, 175: 292-299. doi: 10.1016/j.energy.2019.03.060 [12] KIM S J, LEE H E, CHOI H, et al. High-performance flexible thermoelectric power generator using laser multiscanning lift-off process[J]. ACS Nano, 2016, 10(12): 10851-10857. doi: 10.1021/acsnano.6b05004 [13] LIU Z, TIAN B, LI Y, et al. Evolution of Thermoelectric Generators: From Application to Hybridization[J]. Nano Micro Small, 2023: 2304599. [14] HUANG L, LIN S, XU Z, et al. Fiber-Based Energy Conversion Devices for Human-Body Energy Harvesting[J]. Advanced in Materials, 2019, 32(5): 1902034 [15] 李佳. 石墨烯/碲化铋/PEDOT: PSS纳米复合热电材料的制备与性能探究 [D]; 上海应用技术大学, 2020.LI J. Preparation and Thermoelectric Properties of Graphene/Bi2Te3/ PEDOT: PSS Nanocomposite Thermoelectric Materials [D]. Shanghai Institute of Technology, 2020(in Chinese). [16] LIU Y, DU Y, MENG Q, et al. Effects of preparation methods on the thermoelectric performance of SWCNT/Bi2Te3 bulk composites[J]. Materials, 2020, 13(11): 2636. doi: 10.3390/ma13112636 [17] KIM J, BAE E J, KANG Y H, et al. Elastic thermoelectric sponge for pressure-induced enhancement of power generation[J]. Nano Energy, 2020, 74: 104824. doi: 10.1016/j.nanoen.2020.104824 [18] JUNG K K, JUNG Y, CHOI C J, et al. Flexible thermoelectric generator with polydimethyl siloxane in thermoelectric material and substrate[J]. Current Applied Physics, 2016, 16(10): 1442-1448. doi: 10.1016/j.cap.2016.08.010 [19] ZHANG Z, WANG B, QIU J, et al. Roll-to-roll printing of spatial wearable thermoelectrics[J]. Manufacturing Letters, 2019, 21: 28-34. doi: 10.1016/j.mfglet.2019.07.002 [20] YUAN J, ZHU R. A fully self-powered wearable monitoring system with systematically optimized flexible thermoelectric generator[J]. Applied energy, 2020, 271: 115250. doi: 10.1016/j.apenergy.2020.115250 [21] BUBNOVA O, KHAN Z U, MALTI A, et al. Optimization of the thermoelectric figure of merit in the conducting polymer poly (3, 4-ethylenedioxythiophene)[J]. Nature materials, 2011, 10(6): 429-433. doi: 10.1038/nmat3012 [22] 张洪银, 莫政宇. 热电材料ZT值的测量研究[J]. 内燃机与配件, 2023, (4): 94-6. doi: 10.3969/j.issn.1674-957X.2023.04.030ZHANG H, MO Z. Measurement of ZT values of thermoelectric materials[J]. Internal Combustion Engine & Parts, 2023, (4): 94-6(in Chinese). doi: 10.3969/j.issn.1674-957X.2023.04.030 [23] SINGH D, KUTBEE A T, GHONEIM M T, et al. Strain-Induced Rolled Thin Films for Lightweight Tubular Thermoelectric Generators[J]. Advanced Materials Technologies, 2018, 3(1): 1700192. doi: 10.1002/admt.201700192 [24] PEI J, CAI B, ZHUANG H-L, et al. Bi2Te3-based applied thermoelectric materials: research advances and new challenges[J]. National science review, 2020, 7(12): 1856-1858. doi: 10.1093/nsr/nwaa259 [25] TANG X, LI Z, LIU W, et al. A comprehensive review on Bi2Te3-based thin films: thermoelectrics and beyond[J]. Interdisciplinary Materials, 2022, 1(1): 88-115. doi: 10.1002/idm2.12009 [26] CHEN Y, HOU X, MA C, et al. Review of development status of Bi2Te3-based semiconductor thermoelectric power generation[J]. Advances in Materials Science and Engineering, 2018, 2018: 1-9. [27] HONG S, GU Y, SEO J K, et al. Wearable thermoelectrics for personalized thermoregulation[J]. Science advances, 2019, 5(5): 0536. [28] WU B, GUO Y, HOU C, et al. From carbon nanotubes to highly adaptive and flexible high-performance thermoelectric generators[J]. Nano Energy, 2021, 89: 106487. doi: 10.1016/j.nanoen.2021.106487 [29] GUO Z, YU Y, ZHU W, et al. Kirigami-based stretchable, deformable, ultralight thin-film thermoelectric generator for BodyNET application[J]. Advanced Energy Materials, 2022, 12(5): 2102993. doi: 10.1002/aenm.202102993 [30] WU B, GUO Y, HOU C, et al. High-performance flexible thermoelectric devices based on all-inorganic hybrid films for harvesting low-grade heat[J]. Advanced Functional Materials, 2019, 29(25): 1900304. doi: 10.1002/adfm.201900304 [31] AWASTHI R, MANCHANDA S, DAS P, et al. Poly(vinylpyrrolidone) [M]. Engineering of Biomaterials for Drug Delivery Systems. 2018: 255-272. [32] AKRAM R, KHAN J S, QAMAR Z, et al. Ultra-low thermal conductivity and thermoelectric properties of polymer-mixed Bi 2 Te 3 nanofibers by electrospinning[J]. Journal of Materials Science, 2022: 1-13. [33] WANG X, MENG F, WANG T, et al. High performance of PEDOT: PSS/SiC-NWs hybrid thermoelectric thin film for energy harvesting[J]. Journal of Alloys and Compounds, 2018, 734: 121-129. doi: 10.1016/j.jallcom.2017.11.013 [34] FAN X, NIE W, TSAI H, et al. PEDOT: PSS for Flexible and Stretchable Electronics: Modifications, Strategies, and Applications[J]. Advanced Science, 2019, 6(19): 1900813. doi: 10.1002/advs.201900813 [35] DU Y, SHEN S Z, CAI K, et al. Research progress on polymer–inorganic thermoelectric nanocomposite materials[J]. Progress in Polymer Science, 2012, 37(6): 820-841. doi: 10.1016/j.progpolymsci.2011.11.003 [36] CHEN Y, ZHAO Y, LIANG Z J E, et al. Solution processed organic thermoelectrics: towards flexible thermoelectric modules[J]. Physics Energy and Environmental Science, 2015, 8(2): 401-422. doi: 10.1039/C4EE03297G [37] FAN Z, LI P, DU D, et al. Significantly enhanced thermoelectric properties of PEDOT: PSS films through sequential post-treatments with common acids and bases[J]. Advanced Energy Materials, 2017, 7(8): 1602116. doi: 10.1002/aenm.201602116 [38] KIM G-H, SHAO L, ZHANG K, et al. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency[J]. Nature Materials, 2013, 12(8): 719-723. doi: 10.1038/nmat3635 [39] DU Y, CAI K, SHEN S Z, et al. Multifold enhancement of the output power of flexible thermoelectric generators made from cotton fabrics coated with conducting polymer[J]. RSC advances, 2017, 7(69): 43737-43742. doi: 10.1039/C7RA08663F [40] KIM W S, ANOOP G, JEONG I S, et al. Feasible tuning of barrier energy in PEDOT: PSS/Bi2Te3 nanowires-based thermoelectric nanocomposite thin films through polar solvent vapor annealing[J]. Nano Energy, 2020, 67: 104207. doi: 10.1016/j.nanoen.2019.104207 [41] ZHOU C, DUN C, GE B, et al. Highly robust and flexible n-type thermoelectric film based on Ag2Te nanoshuttle/polyvinylidene fluoride hybrids[J]. Nanoscale, 2018, 10 31: 14830-14834. [42] DUN C, HEWITT C A, HUANG H, et al. Layered Bi2Se3 nanoplate/polyvinylidene fluoride composite based n-type thermoelectric fabrics[J]. ACS applied materials & interfaces, 2015, 7 13: 7054-7059. [43] ZHAO Y, FU X, LIU B, et al. Ultra-stretchable hydrogel thermocouples for intelligent wearables[J]. Science China Materials, 2023: 1-7. [44] KIM J, KHAN S, WU P, et al. Self-charging wearables for continuous health monitoring[J]. Nano Energy, 2021, 79: 105419. doi: 10.1016/j.nanoen.2020.105419 [45] SHI Y, WANG Y, MEI D, et al. Design and fabrication of wearable thermoelectric generator device for heat harvesting[J]. IEEE Robotics and Automation Letters, 2017, 3(1): 373-378. [46] JUNG K K, JUNG Y, CHOI C J, et al. Flexible thermoelectric generator with polydimethyl siloxane in thermoelectric material and substrate[J]. Current Applied Physics, 2016, 16(10): 1442-1448. doi: 10.1016/j.cap.2016.08.010 [47] YU Y, ZHU W, KONG X, et al. Recent development and application of thin-film thermoelectric cooler[J]. Frontiers of Chemical Science and Engineering, 2020, 14: 492-503. [48] AHMED A, HAN S J S R. Fabrication, micro-structure characteristics and transport properties of co-evaporated thin films of Bi2Te3 on AlN coated stainless steel foils[J]. Scientific Reports, 2021, 11(1): 4041. doi: 10.1038/s41598-021-83476-7 [49] MORIMOTO M, KAWANO S, MIYAMOTO S, et al. Electronic structure and thermal conductance of the MASnI3/Bi2Te3 interface: a first-principles study[J]. Scientific Reports, 2022, 12(1): 217. doi: 10.1038/s41598-021-04234-3 [50] GHASEMI A, KEPAPTSOGLOU D, GALINDO P L, et al. Van der Waals epitaxy between the highly lattice mismatched Cu-doped FeSe and Bi2Te3[J]. NPG Asia Materials, 2017, 9(7): e402-e402. doi: 10.1038/am.2017.111 [51] HE Q L, LIU H, HE M, et al. Two-dimensional superconductivity at the interface of a Bi2Te3/FeTe heterostructure[J]. Nature communications, 2014, 5(1): 4247. doi: 10.1038/ncomms5247 [52] NI Y, SUN B, LI J, et al. Thermal transport in Bi2Te3-PbTe segmented thermoelectric nanofilms[J]. Chinese Journal of Physics, 2022, 75: 199-205. doi: 10.1016/j.cjph.2021.11.032 [53] HUANG C, LIU J, ZHAO L, et al. Advances in atomic oxygen resistant polyimide composite films[J]. Composites Part A: Applied Science and Manufacturing, 2023: 107459. [54] CAO Z, KOUKHARENKO E, TUDOR M, et al. Flexible screen printed thermoelectric generator with enhanced processes and materials[J]. Sensors and Actuators A:Physical, 2016, 238: 196-206. doi: 10.1016/j.sna.2015.12.016 [55] 杨龙, 尤汉, 唐可琛, et al. Bi2Te3柔性热电器件的制备与发电性能研究[J]. 传感器与微系统, 2021, 40(10): 14-16,20.YANG L, YOU H, TANG K, et al. Research on preparation and power generation performance of Bi2Te3 flexible thermoelectric device[J]. Transducer and Microsystem Technologies, 2021, 40(10): 14-16,20(in Chinese). [56] JUNG Y S, JEONG D H, KANG S B, et al. Wearable solar thermoelectric generator driven by unprecedentedly high temperature difference[J]. Nano energy, 2017, 40: 663-672. doi: 10.1016/j.nanoen.2017.08.061 [57] YANG Y, HU H, CHEN Z, et al. Stretchable nanolayered thermoelectric energy harvester on complex and dynamic surfaces[J]. Nano letters, 2020, 20(6): 4445-4453. doi: 10.1021/acs.nanolett.0c01225 [58] JUNG Y S, JEONG D H, KANG S B, et al. Wearable solar thermoelectric generator driven by unprecedentedly high temperature difference[J]. Nano Energy, 2017, 40: 663-672. doi: 10.1016/j.nanoen.2017.08.061 [59] YANG Y, HU H, CHEN Z, et al. Stretchable Nanolayered Thermoelectric Energy Harvester on Complex and Dynamic Surfaces[J]. Nano letters, 2020, 20: 6,4445-4453 [60] LEE J A, ALIEV A E, BYKOVA J S, et al. Woven-yarn thermoelectric textiles[J]. Advanced Materials, 2016, 28(25): 5038-5044. doi: 10.1002/adma.201600709 [61] ZHENG Y, HAN X, YANG J, et al. Durable, stretchable and washable inorganic-based woven thermoelectric textiles for power generation and solid-state cooling[J]. Energy & Environmental Science, 2022, 15(6): 2374-2385. [62] JING Y, LUO J, HAN X, et al. Scalable manufacturing durable, tailorable and recyclable multifunctional woven thermoelectric textile system[J]. Energy & Environmental Science, 2023, 16(10): 4334-4344 -

下载:

下载: