Preparation and abrasion resistance properties of EP-PDMS-PVDF-SiO2 superhydrophobic composite coating

-

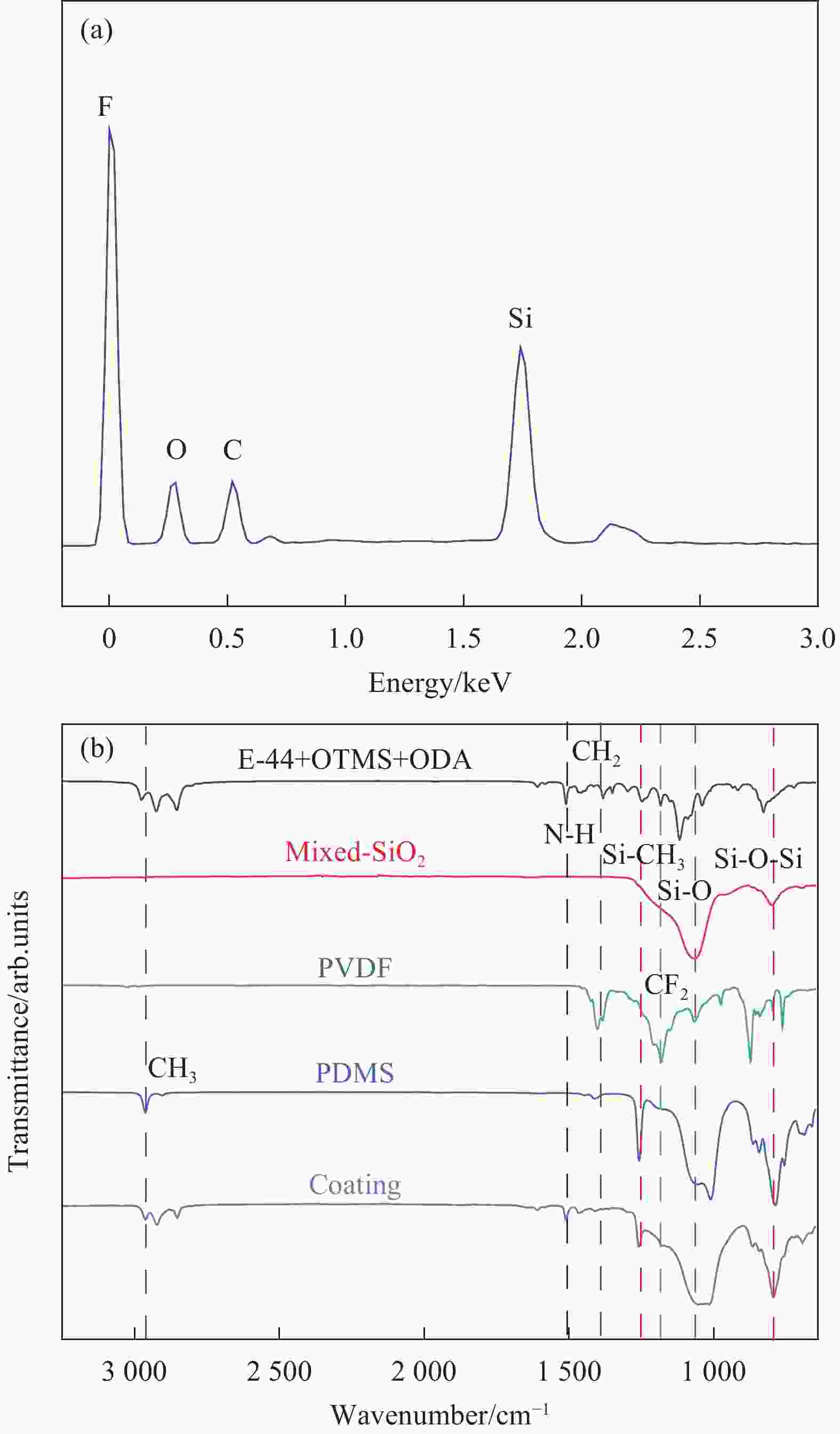

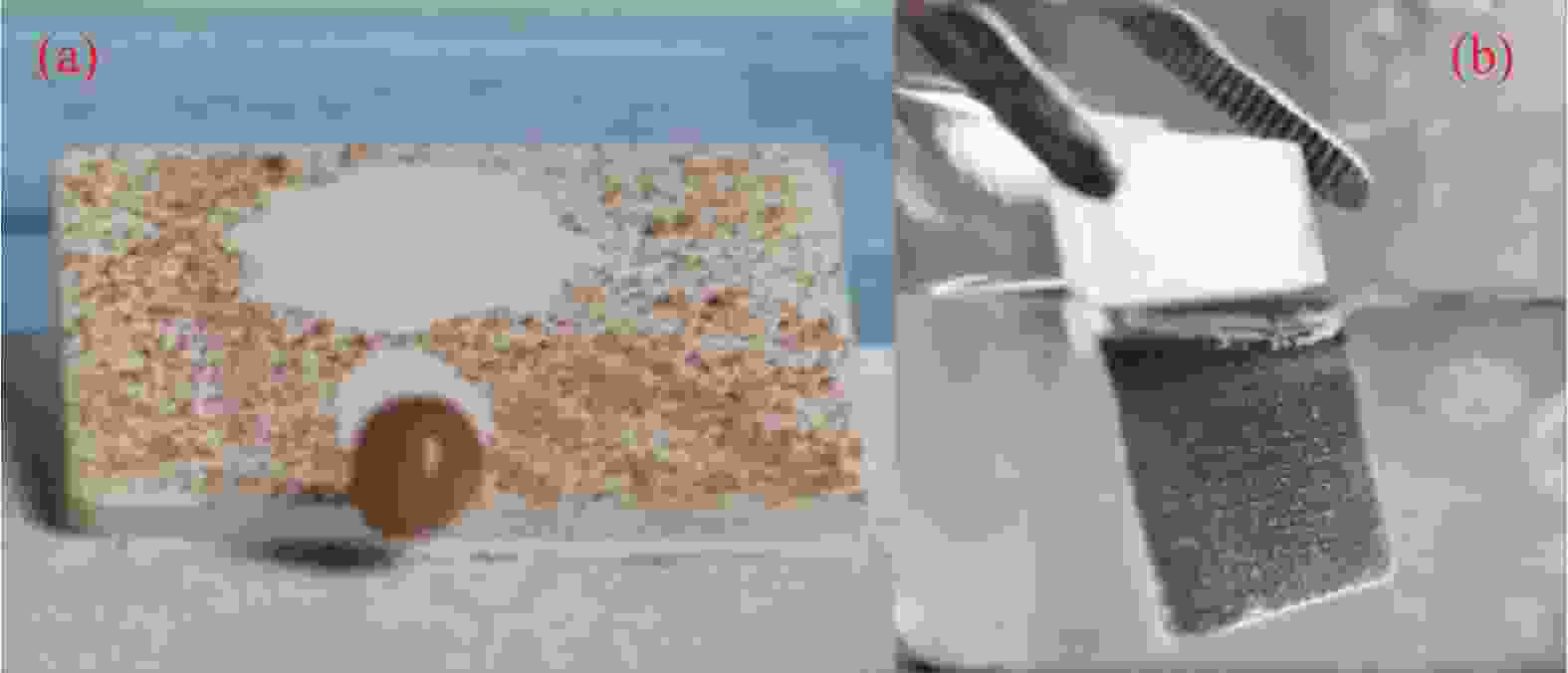

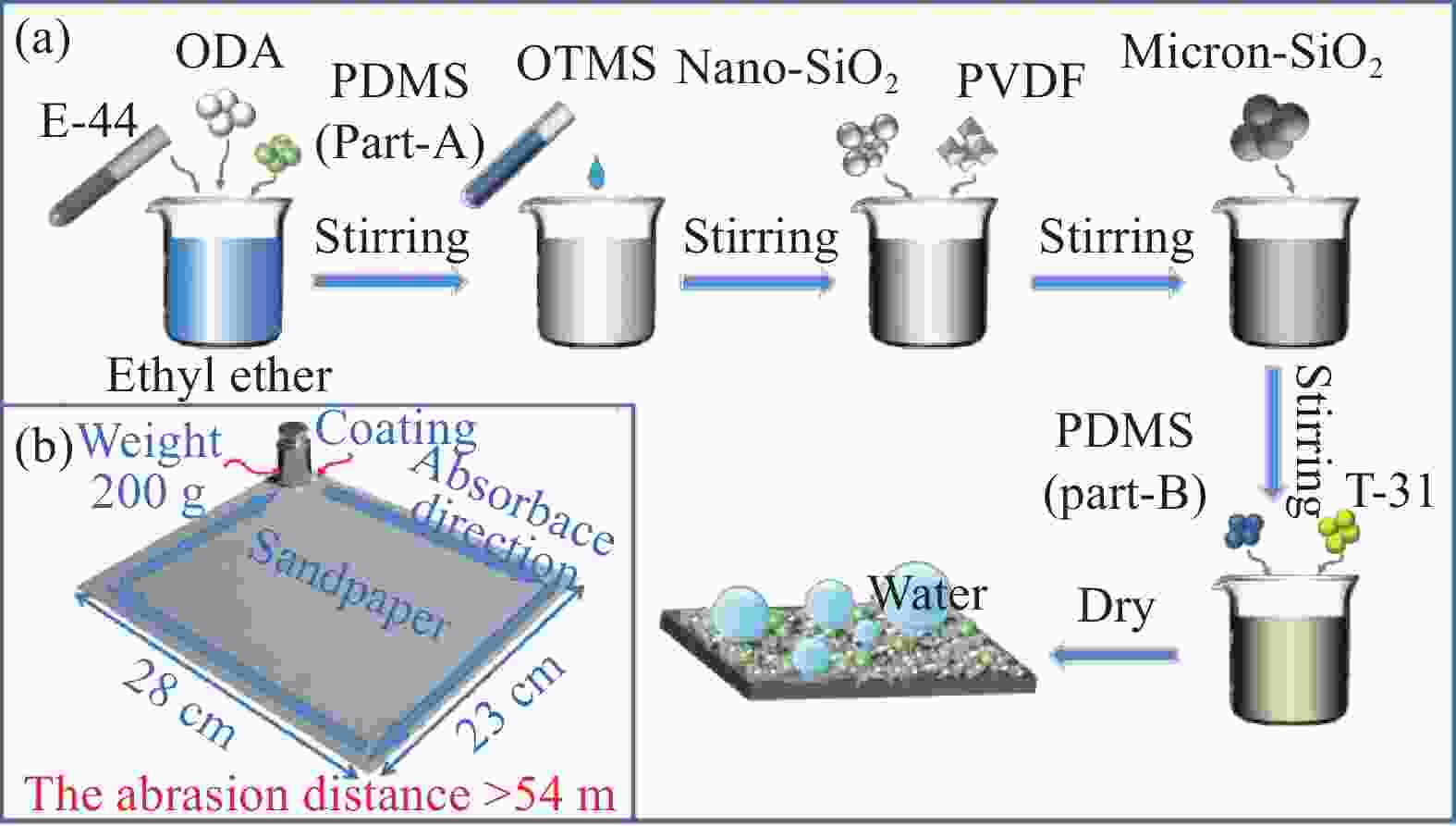

摘要: 提高超疏水涂层砂纸耐摩擦性能对其应用具有重要意义。因此,以环氧树脂(EP)、聚二甲基硅氧烷(PDMS)和聚偏氟乙烯(PVDF)为粘结剂,以四种纳米级二氧化硅(SiO2)粒子为主要填料和一种微米级SiO2粒子作为增强涂层耐摩擦性能的辅助填料制备了一种耐摩擦性能优异的超疏水涂层,并对其砂纸耐摩擦性能进行系统地测试和分析。接触角测试结果表明涂层水滴接触角和滚动角分别保持在156°~165°和2°~4°之间。砂纸摩擦测试表明添加2或5 μm的SiO2粒子能使涂层耐摩擦周期提高2-3倍。同时,涂层耐摩擦性能还与砂纸粒度相关。涂层被9 或6.5 μm粒度砂纸摩擦失去超疏水性能后,能通过19或11 μm粒度砂纸的摩擦而恢复其超疏水特性。然而,涂层被38、19或11 μm粒度砂纸摩擦后其超疏水性能无法恢复。分析表明,低粒度砂纸更易破坏涂层表面多级微纳粗糙结构,但该结构可通过高粒度砂纸摩擦而被恢复,高粒度砂纸则倾向于使涂层从基材表面剥离。Abstract: Improving the sandpaper abrasion resistance of superhydrophobic coating is of great significance for its application. Therefore, a superhydrophobic coating with exceptional abrasion resistance was prepared by utilizing epoxy resin (EP), polydimethylsiloxane (PDMS) and polyvinylidene fluoride (PVDF) as binders in combination with four types of nano-sized silicon dioxide (SiO2) particles as primary fillers. Moreover, micron-sized SiO2 particles are incorporated as auxiliary fillers to enhance the abrasion resistance of the coating. In this work, the sandpper abrasion resistance of the coating is systematically tested and analyzed.The results of the contact angle test demonstrate that the contact angle and rolling angle of water droplets on the coating surface remain within the range of 156°-165° and 2°-4°, respectively. Sandpaper abrasion tests reveal that 2 or 5 μm SiO2 particles can enhance the sandpaper abrasion-resistance cycles of the coating by 2-3 times. Additionally, it is observed that the grit of sandpaper also affects the abrasion resistance of the coating. If the coating loses its superhydrophobic properties due to abrasion with 9 or 6.5 μm grit sandpaper, these properties can be restored by the abrasion of 19 or 11 μm grit sandpaper. However, if the coating was abraded by 38, 19 or 11 μm grit sandpaper, the superhydrophobic properties cannot be restored with abrasion of any grit sandpaper. The result analysis shows that samll grit sandpapers are more likely to damage the hierarchical micro-nano structure on the surface of the coating. However, this structure can be recovered through the abrasion of large grit sandpapers. Meanwhile, the sandpaper with large grit tends to induce the coating to peel off from the substrate surface.

-

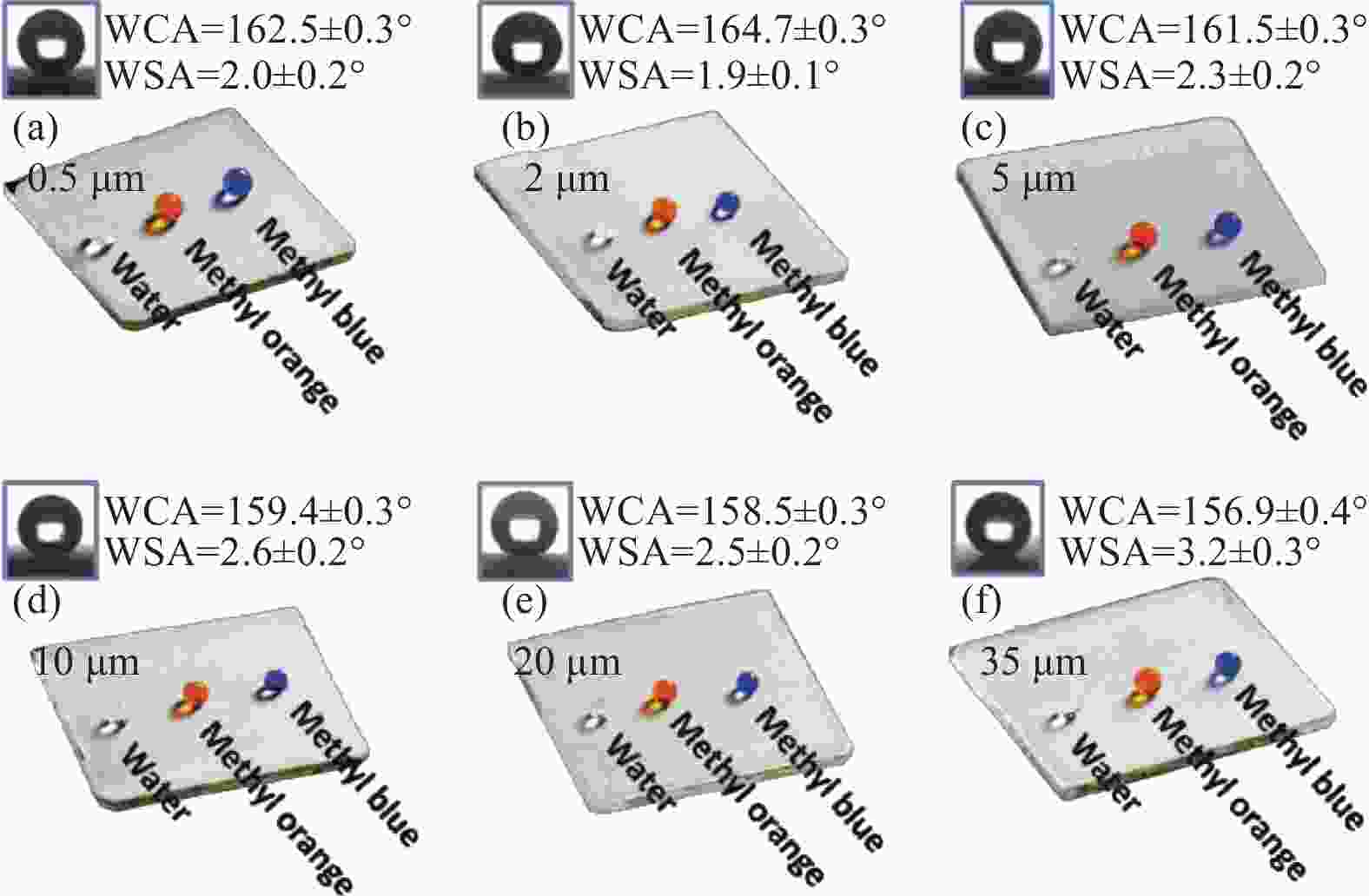

图 3 含有不同微米级SiO2颗粒的EP-PDMS-PVDF-SiO2涂层表面不同液滴光学图像及其接触角(WCA)和滚动角(WSA):(a) 0.5 μm,(b) 2 μm,(c) 5 μm, (d) 10 μm,(e) 20 μm,(f) 35 μm

Figure 3. The optical images, water contact angle (WCA) and water sliding angle (WSA) of different droplets on the surface of the EP-PDMS-PVDF-SiO2 coatings with different micron-sized SiO2 particles: (a) 0.5 μm,(b) 2 μm, (c) 5 μm, (d) 10 μm, (e) 20 μm, (f) 35 μm

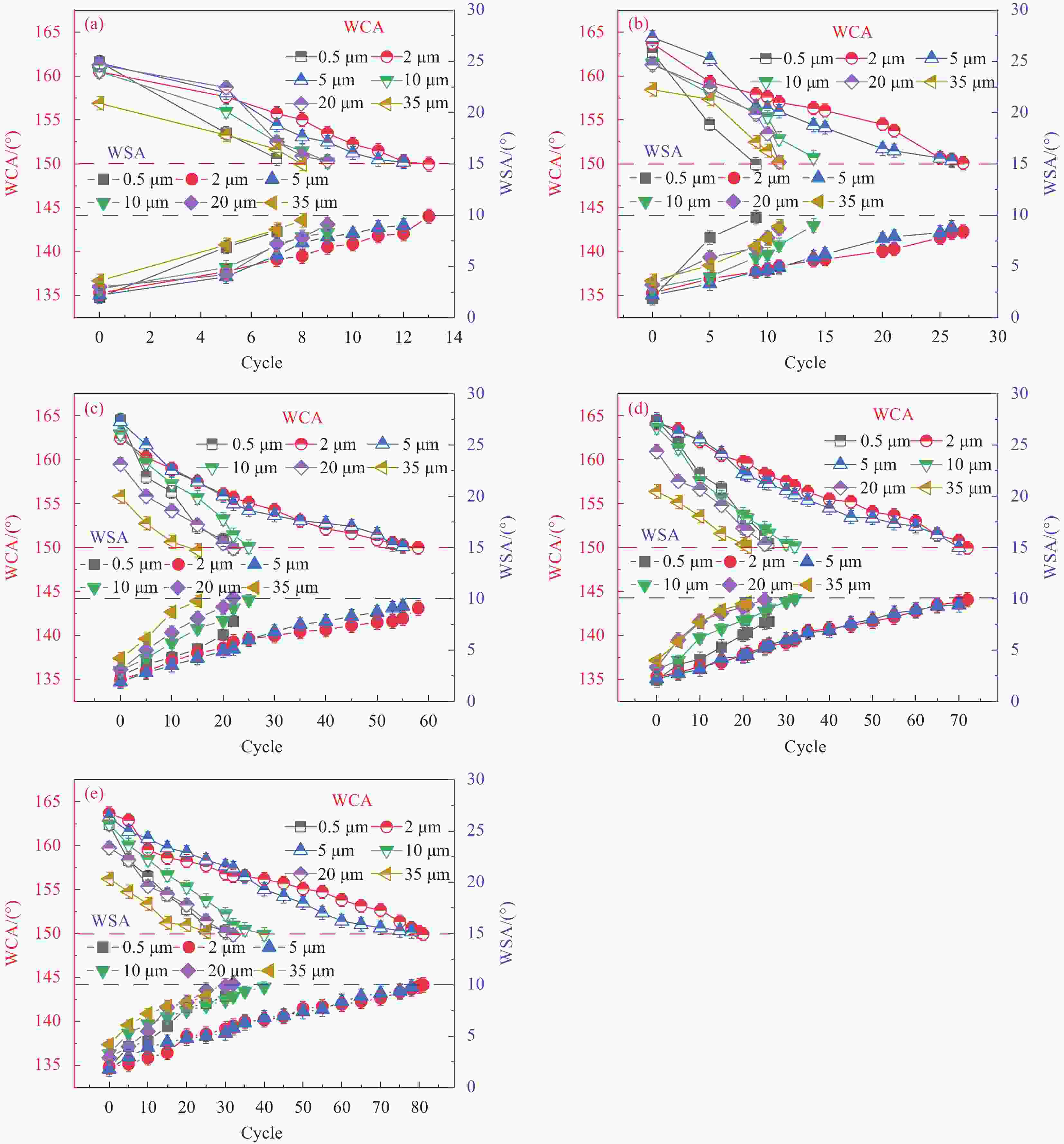

图 6 (a)-(e) EP-PDMS-PVDF-SiO2涂层WCA和WSA随摩擦周期次数的变化曲线图。所有含有不同尺寸微米级SiO2颗粒的EP-PDMS-PVDF-SiO2涂层均被相同粒度的砂纸摩擦: (a) 38 μm,(b) 19 μm,(c) 11 μm,(d) 9 μm,(e) 6.5 μm

Figure 6. (a)-(e) The changes of the WCAs and WSAs with the abrasion cycles. All the EP-PDMS-PVDF-SiO2 coatings with adding different size SiO2 particles were abraded by the same grit sandpaper: (a) 38 μm, (b) 19 μm, (c) 11 μm, (d) 9 μm, (e) 6.5 μm

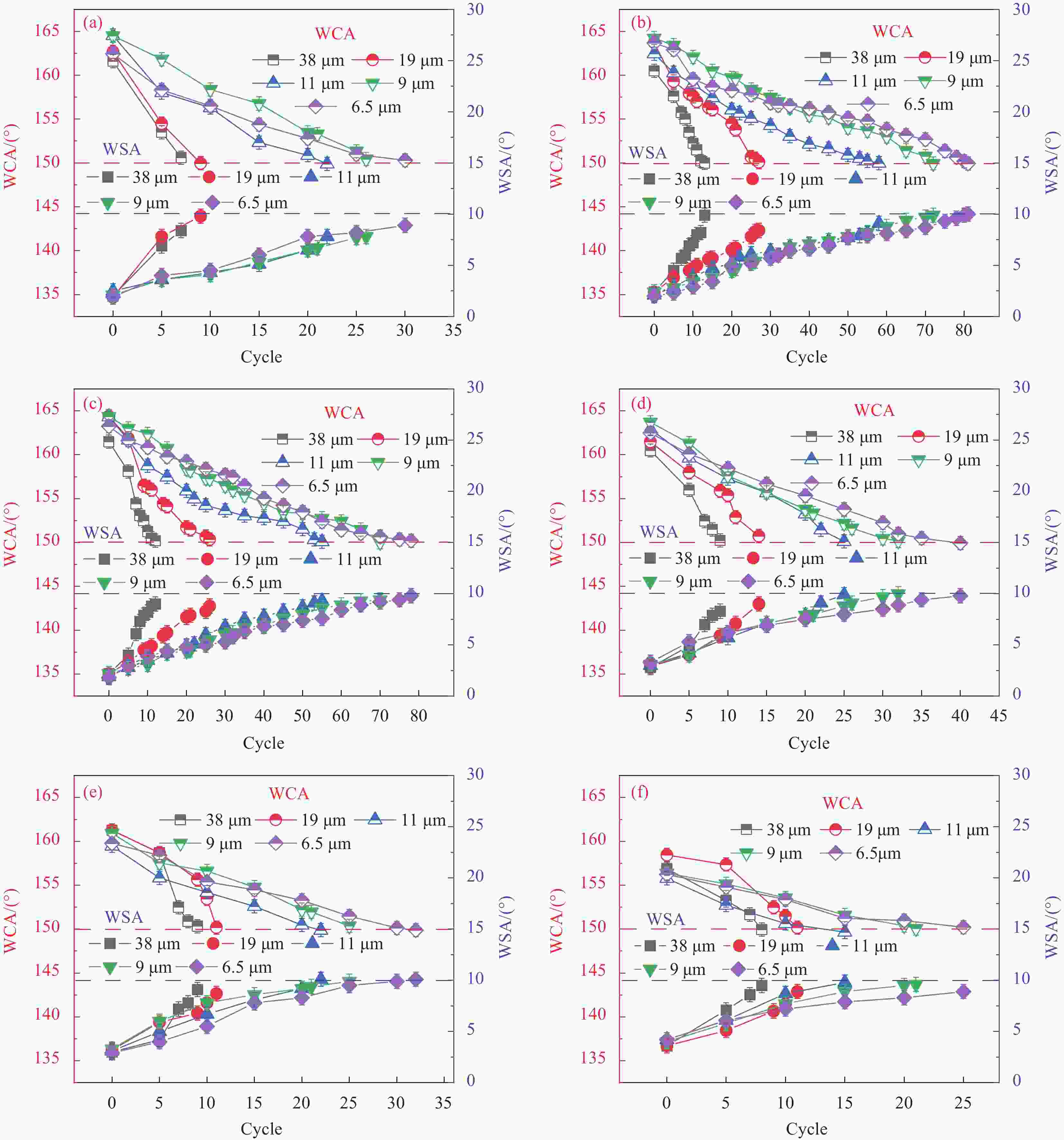

图 7 含有相同尺寸微米级SiO2颗粒的EP-PDMS-PVDF-SiO2涂层被不同粒度砂纸摩擦后WCA和WSA随摩擦周期数的变化曲线: (a) 0.5 μm,(b) 2 μm,(c) 5 μm,(d)10 μm,(e) 20 μm,(f) 35 μm

Figure 7. The changes of the WCA and WSA after that the EP-PDMS-PVDF-SiO2 coatings with the same micron-sized SiO2 particles were abraded by the different grit sandpaper, (a) 0.5 μm, (b) 2 μm, (c) 5 μm, (d) 10 μm, (e) 20 μm, (f) 35 μm

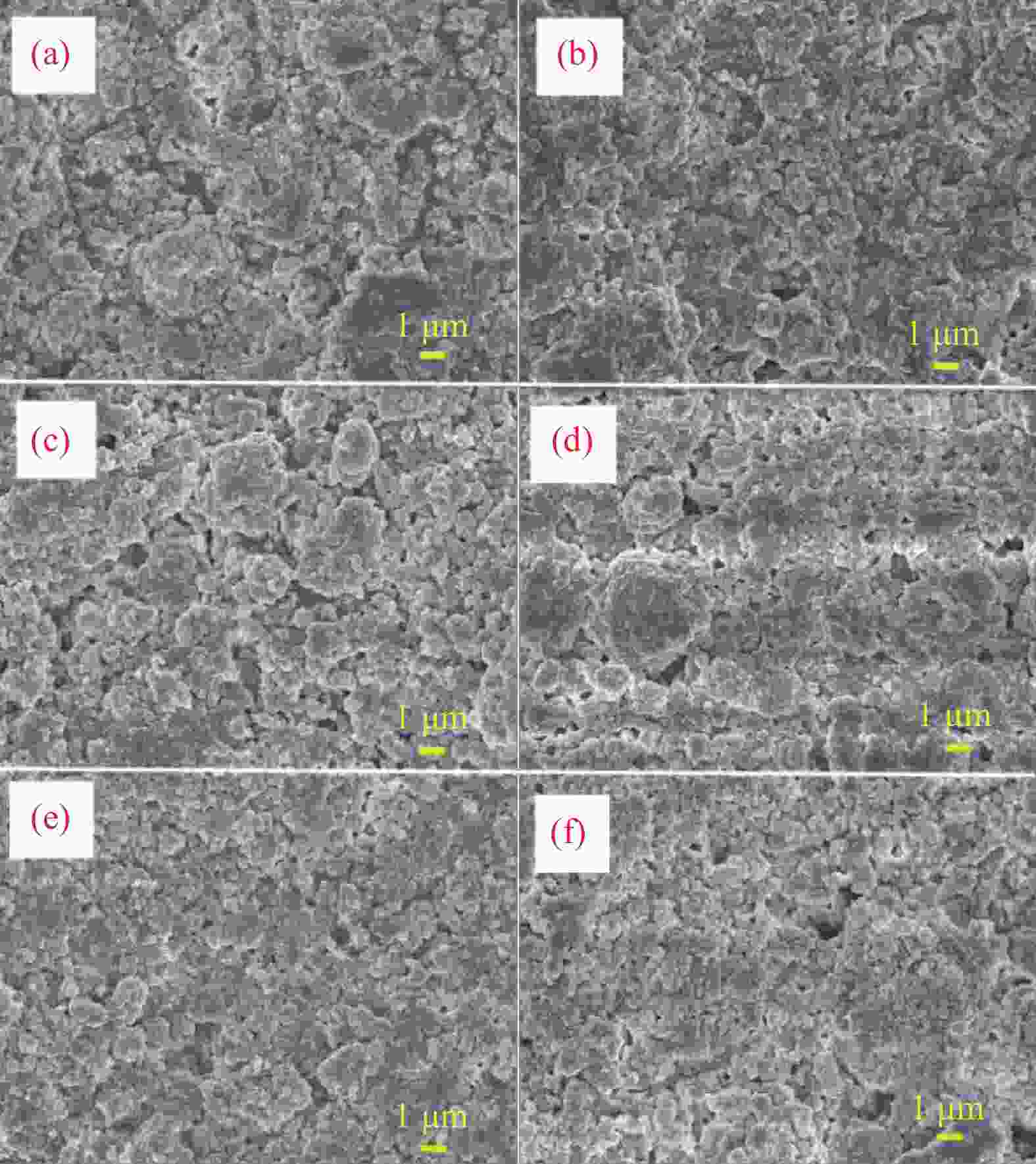

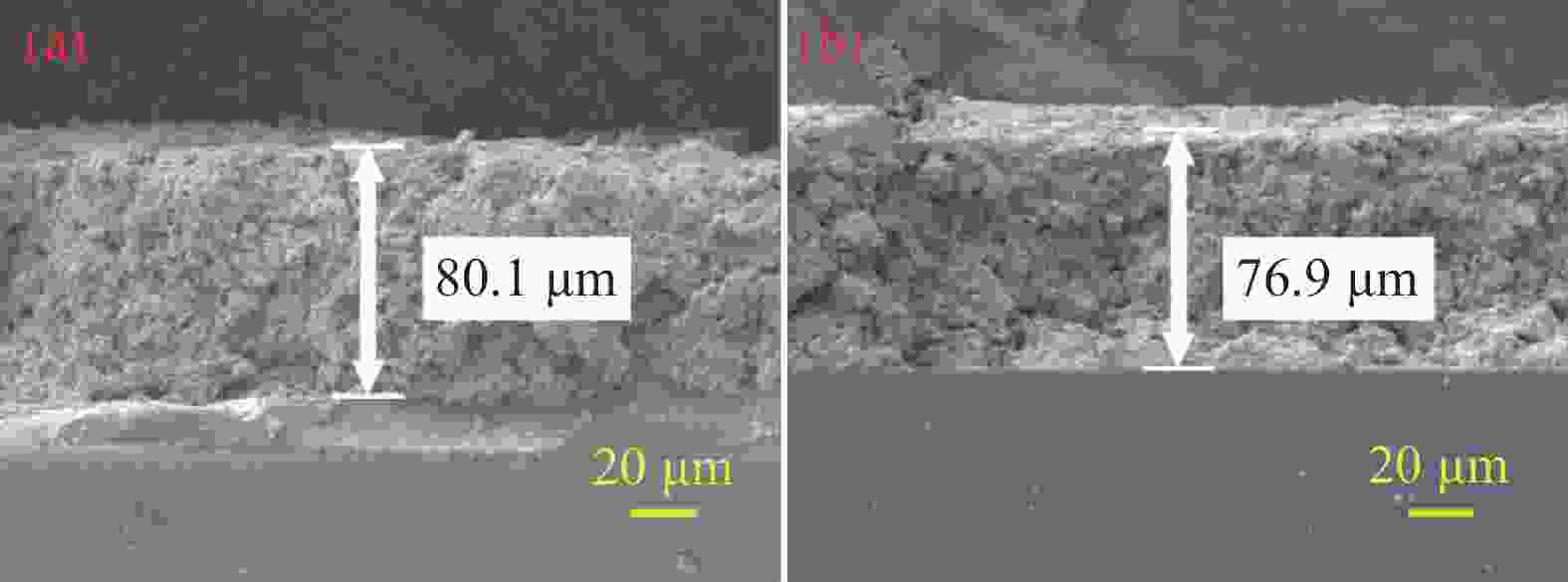

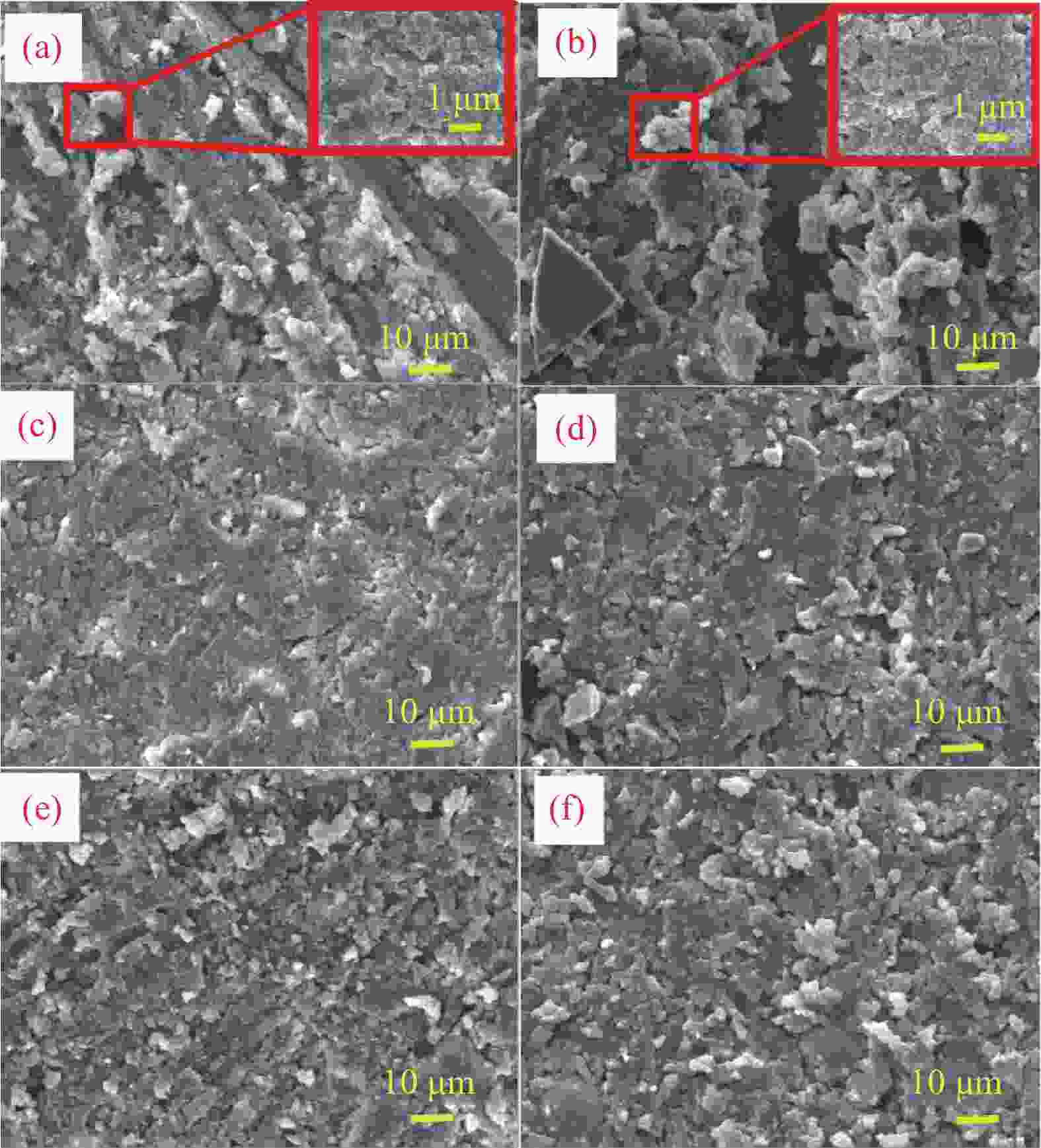

图 10 含有2 μm (a) 和 20 μm (b) SiO2颗粒的EP-PDMS-PVDF-SiO2涂层被38 μm粒度砂纸摩擦3-5个周期后的表面形貌;含有2 μm (c) 和20 μm (d) SiO2颗粒的EP-PDMS-PVDF-SiO2涂层被6.5 μm粒度砂纸摩擦3-5个周期丧失超疏水性能后的表面形貌;含有2 μm (e) 和 20 μm (f) SiO2颗粒的EP-PDMS-PVDF-SiO2涂层被6.5 μm粒度砂纸摩擦3-5个循环丧失超疏水性能后再通过11 μm粒度砂纸摩擦使其超疏水性能被恢复后相应表面形貌

Figure 10. The surface morphologies of the EP-PDMS-PVDF-SiO2 coatings with adding 2 μm (a) and 20 μm (b) SiO2 particles which were abraded for 3-5 cycles by 38 μm grit sandpaper; the surface morphologies of the EP-PDMS-PVDF-SiO2 coatings with adding 2 μm (c) and 20 μm (d) SiO2 particles which were abraded for 3-5 cycles by 6.5 μm grit sandpaper; after abrasion of 3-5 cycles with 6.5 μm grit sandpaper, for the EP-PDMS-PVDF-SiO2 coatings with adding 2 μm (e) and 20 μm (f) SiO2 particles, the corresponding EP-PDMS-PVDF-SiO2 coating surface morphologies with the simple re-abrasion of 11 μm grit sandpaper

图 11 含有2 μm (a) 和 20 μm (b) SiO2颗粒的EP-PDMS-PVDF-SiO2涂层被38 μm粒度砂纸摩擦失去超疏水性能后的表面形貌;含有2 μm (c) 和 20 μm (d) SiO2颗粒的EP-PDMS-PVDF-SiO2涂层丧失超疏水性能后再次被11 μm粒度砂纸摩擦1-2个周期后的表面形貌

Figure 11. The surface morphologies of the EP-PDMS-PVDF-SiO2 coatings with the addition of 2 μm (a) and 20 μm (b) SiO2 particles which lose their superhydrophobic performance by the abrasion of 38 μm grit sandpaper; after being re-abraded by 11 μm grit sandpaper, the surface morphologies of the two EP-PDMS-PVDF-SiO2 coatings which have been abraded by the 400 grit sandpaper with the addition of (c) 2 and (d) 20 μm SiO2 particles

图 12 含有不同尺寸微米级SiO2颗粒的EP-PDMS-PVDF-SiO2涂层被不同粒度数砂纸摩擦后单位基底面积损失的涂层质量R随摩擦周期数的变化曲线: (a) 0.5 μm, (b) 2 μm, (c) 5 μm, (d) 10 μm, (e) 20 μm, (f) 35 μm

Figure 12. The changes of the R of the EP-PDMS-PVDF-SiO2 coatings with different micron-sized SiO2 particles which were abraded by the different grit sandpaper: (a) 0.5 μm, (b) 2 μm, (c) 5 μm, (d) 10 μm, (e) 20 μm, (f) 35 μm

图 13 含有不同尺寸(a) 0.5 μm、(b) 2 μm 和 (c) 20 μm SiO2颗粒的EP-PDMS-PVDF-SiO2涂层黏附力测试结果;(d) EP-PDMS-PVDF-SiO2涂层耐酸/碱/盐性能;(e) EP-PDMS-PVDF-SiO2涂层耐紫外线性能;(f) EP-PDMS-PVDF-SiO2涂层耐高低温性能

Figure 13. The adhesion test results of the EP-PDMS-PVDF-SiO2 coatings with the addition of (a) 0.5 , (b) 2 and (c) 20 μm SiO2 particles; the changes of the WCAs and WSAs of the EP-PDMS-PVDF-SiO2 coating after (d) the immersion in acid/alkali/salt solution, (e) the ultraviolet radiation and (f) the treatments at 180 / -20℃ ambient environment, respectively

-

[1] SU C Z, ZHOU L, YUAN C Y, et al. Robust superhydrophobic composite fabricated by a dual-sized particle design[J]. Composites Science and Technology, 2023, 231: 109785. doi: 10.1016/j.compscitech.2022.109785 [2] JIANG L H, HAN M M, SUN J J, et al. Strong mechanical and durable superhydrophobic photothermal MWCNTs/SiO2/PDMS/PVDF composite coating for anti-icing and de-icing[J]. Progress in Organic Coatings, 2023, 174: 107282. doi: 10.1016/j.porgcoat.2022.107282 [3] JIANG L H, HOU P P, HE S, et al. The robust superhydrophobic SiO2/Diatomite/PDMS/KH-570/Me-MQ composite coating for self-cleaning application of building surface[J]. Colloids and Surfaces, 2022, A 634: 127936. [4] LI G Q, MAI Z H, SHU X, et al. Superhydrophobic/superoleophilic cotton fabrics treated with hybridcoatings for oil/water separation[J]. Advanced Composites and Hybrid Materials, 2019, 2: 254-265. doi: 10.1007/s42114-019-00092-w [5] MAI Z H, XIONG Z W, SHU X, et al. Multifunctionalization of cotton fabricswith polyvinylsilsesquioxane/ZnO composite coatings[J]. Carbohydrate Polymers, 2018, 199: 516-525. doi: 10.1016/j.carbpol.2018.07.052 [6] WU J X, LI J Y, DENG B, et al. Self-healing of the superhydrophobicity by ironing for the abrasion durable superhydrophobic cotton fabrics[J]. Scientific Reports, 2013, 3.2951. [7] DAN Z, ZHENG G L, CHUANG Z, et al. Preparation and characterization of wear-resistant superhydrophobic cotton Fabrics[J]. Progress in Organic Coatings, 2019, 134: 226-233. doi: 10.1016/j.porgcoat.2019.04.070 [8] GUO W W, WANG X, HUANG J L, et al. Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water-oil separation application[J]. Chemical Engineering Journal, 2020, 398.125661. [9] WANG Y, ZHANG Q, LI P P, et al. A durable and sustainable superhydrophobic surface with intertwined cellulose/SiO2 blends for anti-icing and self-cleaning applications[J]. Materials & Design, 2022, 217: 110628. [10] WANG Z H, YUAN L, LIANG G Z, et al. Mechanically durable and self-healing superhydrophobic coating with hierarchically structured KH-570 modified SiO2-decorated aligned carbon nanotube bundles[J]. chemical engineering journal, 2021, 408: 127623. [11] FAN X Q, SONG S J, SHI Y T, et al. Mechanochemical stable superhydrophobic coating toward lasting corrosion protection[J]. Progress in Organic Coatings, 2023, 178: 107478. doi: 10.1016/j.porgcoat.2023.107478 [12] ZHANG C J, LIANG F H, ZHANG W, et al. Constructing mechanochemical durable and self-healing superhydrophobic surfaces[J]. ACS Omega, 2020, 5: 986-994. doi: 10.1021/acsomega.9b03912 [13] ZHANG Y F, ZHANG L Q, XIAO Z, et al. Fabrication of robust and repairable superhydrophobic coatings by an immersion method[J]. Chemical Engineering Journal, 2019, 369: 1-7. doi: 10.1016/j.cej.2019.03.021 [14] 赵亚梅, 霍梦丹, 曹婷婷, 等. 提升超疏水材料力学耐久性的研究进展[J]. 复合材料学报, 2023, 40(4): 2004-2014.ZHAO Yamei, HUO Mengdan, CAO Tingting, et al. Progress in improving the mechanical durability of superhydrophobic materials[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2004-2014 (in Chinese). [15] WANG N, TANG L L, TONG W, et al. Fabrication of robust and scalable superhydrophobic surfaces and investigation of their anti-icing properties[J]. Materials & Design, 2018, 156: 320-328. [16] CAO Y, CHENG H D, GU N, et al. Excellent mechanical durability of superhydrophobic coating by electrostatic spraying[J]. Materials Chemistry and Physics, 2023, 301: 127658. doi: 10.1016/j.matchemphys.2023.127658 [17] LI R Q, LI M Q, WU X, et al. A pine needle-like superhydrophobic Zn/ZnO coating with excellent mechanochemical robustness and corrosion resistance[J]. Materials & Design, 2023, 225: 111583. [18] WU T, XU W H, GUO K, et al. Efficient fabrication of lightweight polyethylene foam with robust and durable superhydrophobicity for self-cleaning and anti-icing applications[J]. Chemical Engineering Journal, 2021, 407: 127100. doi: 10.1016/j.cej.2020.127100 [19] HOU K, ZENG Y C, ZHOU C L, et al. Facile generation of robust POSS-based superhydrophobic fabrics via thiolene click chemistry[J]. Chemical Engineering Journal, 2018, 332: 150-159. doi: 10.1016/j.cej.2017.09.074 [20] 常州涂料化工研究院. 色漆和清漆漆膜的划格试验: GB/T 9286—1998[S]. 北京: 国家质量技术监督局, 1998.Changzhou Coatings Chemical Research Institute. Test method for resistance of paint films to cracking (grid method): GB/T 9286—1998[S]. Beijing: State Bureau of Quality and Technical Supervision, 1998(in Chinese). [21] LI Y W, SHI X T, BAI W X , et al. Robust superhydrophobic materials with outstanding durability fabricated by epoxy adhesive-assisted facile spray method[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 664: 131109. [22] 汪雨微, 欧宝立, 鲁忆, 等. 功能化纳米TiO2/环氧树脂超疏水防腐复合涂层的制备与性能[J]. 复合材料学报, 2021, 38(12): 3971-3985. WANG Yuwei, OU Baoli, LU Yi, et al. Preparation and properties of functionalized nano-TiO2/epoxy resin superhydrophobic anticorrosive composite coating[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 3971- 3985 (in Chinese). [23] JIANG L H, GONG M T, SUN J J, et al. The design and performance research of PTFE/PVDF/PDMS superhydrophobic radiative cooling composite coating with high infrared emissivity[J]. Materials Today Communications, 2024, 38: 108406. doi: 10.1016/j.mtcomm.2024.108406 [24] ZHANG Z B, ZHAO J W, LEI Y Q, et al. Preparation of intricate nanostructures on 304 stainless steel surface by SiO2-assisted HF etching for high superhydrophobicity[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2020, 586: 124287. doi: 10.1016/j.colsurfa.2019.124287 [25] LI K Q, XIANG J M, ZHOU J L, et al. Self-healing and wear resistance stable superhydrophobic composite coating with electrothermal and photothermal effects for anti-icing[J]. Progress in Organic Coatings, 2023, 177: 107415. doi: 10.1016/j.porgcoat.2023.107415 -

点击查看大图

点击查看大图

计量

- 文章访问数: 67

- HTML全文浏览量: 34

- 被引次数: 0

下载:

下载: