Recycled carbon fiber layering orientation optimization and its performance of composites

-

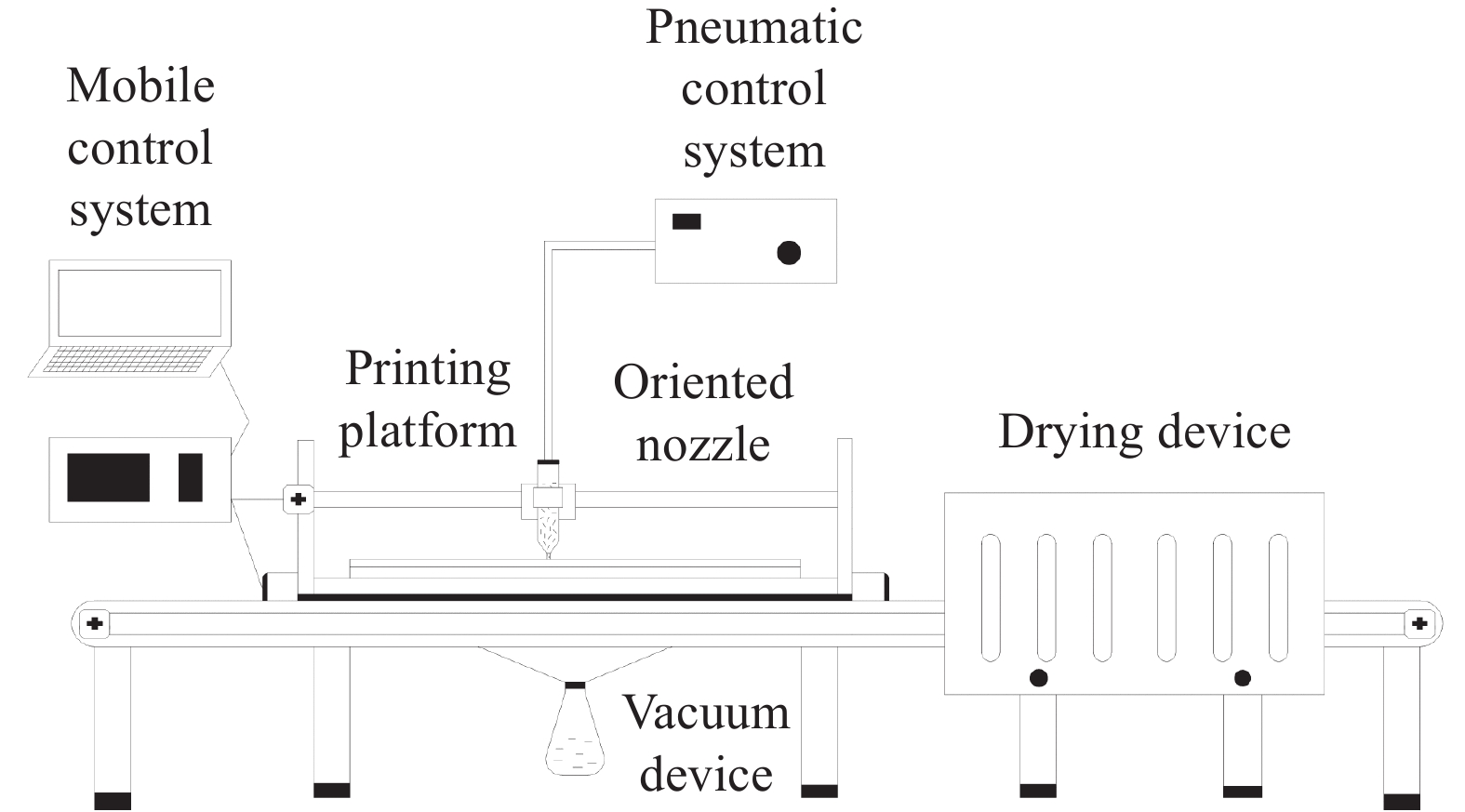

摘要: 回收得到的再生碳纤维(RCF)多为蓬松杂乱的短纤维束,基于湿法纤维取向技术可对其重新取向。传统纤维增强复合材料通常将纤维沿单向铺层,对开孔制件难以完全发挥纤维的增益效果,通过纤维曲线铺层可以提高复合材料的结构性能。本文通过设计纤维分散实验,研究了一定RCF含量与不同浓度羟乙基纤维素(HEC)的最佳配置参数。利用自行搭建的纤维取向路径可调控装置,将制备的分散液铺放得到不同轨迹和形状的纤维毡,基于二维快速傅里叶变换(2D FFT)评价RCF的取向效果。通过模压成型制备再生碳纤维/环氧树脂(RCF/EP)复合材料开孔试样,分析了不同铺层路径对开孔试样承载能力的影响。结果表明:当6 mm RCF含量为6 g/L时,最佳HEC浓度为14 g/L;按曲线路径制备的开孔试样有效减少开孔处的应力集中,较无序路径和水平路径开孔试样,极限载荷分别提高了69.5%、35.9%。研究拓宽了RCF/EP复合材料结构的设计自由度,为实现RCF材料的高性能再利用提供了参考。Abstract: Recycled carbon fibers (RCF) are mostly fluffy and disorganized short fiber bundles, which can be reoriented based on wet fiber orientation technology. Conventional fiber-reinforced composites are usually layered with fibers in a unidirectional direction, which makes it difficult to fully utilize the gain effect of the fibers on open-hole parts, but the structural properties of the composites can be improved by curved layups of the fibers. The optimal configuration parameters of certain RCF content with different concentrations of hydroxyethyl cellulose (HEC) were investigated by designing fiber dispersion experiments. Using the self-constructed fiber orientation path control device, the prepared dispersion was spread to obtain fiber mats with different trajectories and shapes, and the orientation effect of RCF was evaluated based on a two-dimensional fast Fourier transform (2D FFT). The open-hole specimens of Recycled carbon fiber/Epoxy resin (RCF/EP) composites were prepared by molding, and the effects of different layup paths on the load-bearing capacity of the open-hole specimens were analyzed. The results show that the optimal HEC concentration is 14 g/L when the 6 mm RCF content is 6 g/L. The open-hole specimens prepared according to the curved path effectively reduce the stress concentration at the open hole, and the ultimate load is increased by 69.5% and 35.9% compared with the open-hole specimens prepared according to the unordered path and the horizontal path, respectively. The study broadens the design freedom of RCF/EP composite structures and provides a reference for realizing high-performance reuse of RCF.

-

Key words:

- recycled carbon fiber /

- fiber orientation /

- path programming /

- reuse /

- mechanical property

-

表 1 不同纤维角归一化取向值

Table 1. Normalized orientation values of different angles

Fiber angle/(°) Summed pixel intensity Minimum pixel intensity Normalized pixel intensity 2 D FFT alignment value 0 87841.75 1.320618 0.320618 1 85998.94 1.292913 0.292913 2 82924.78 1.246696 0.246696 3 81181.90 1.220494 0.220494 … … 66515.63 … … 178 88437.30 1.329572 0.329572 179 88464.48 1.329980 0.329980 180 88385.25 1.328789 0.328789 181 86827.31 1.305367 0.305367 … … … … … 表 2 RCF/EP复合材料三点弯曲试验的测试结果和标准差

Table 2. Test results and standard deviation of the three-point bending test of RCF/EP composites

Specimen 1 Specimen 2 Specimen 3 σ F1/N 331.466 317.465 351.385 13.918 F2/N 238.113 254.242 243.695 6.688 F3/N 134.331 126.611 123.841 4.439 F4/N 182.621 209.595 197.895 11.044 Notes:F1, F2, F3 and F4 represent the ultimate loads for the curved path, horizontal path, vertical path and unordered path specimens, respectively. -

[1] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review[J]. Advanced Composites and Hybrid Materials, 2019, 2: 214-233. doi: 10.1007/s42114-018-0072-z [2] PEI Chun, CHEN Piyu, KONG Sicheng, et al. Recyclable separation and recovery of carbon fibers from CFRP composites: Optimization and mechanism[J]. Separation and Purification Technology, 2021, 278: 119591. doi: 10.1016/j.seppur.2021.119591 [3] ABDOU T R, JUNIOR A B, ESPINOSA D C R, et al. Recycling of polymeric composites from industrial waste by pyrolysis: Deep evaluation for carbon fibers reuse[J]. Waste Management, 2021, 120: 1-9. doi: 10.1016/j.wasman.2020.11.010 [4] PAKDEL E, KASHI S, VARLEY R, et al. Recent progress in recycling carbon fibre reinforced composites and dry carbon fiber wastes[J]. Resources, Conservation and Recycling, 2021, 166: 105340. doi: 10.1016/j.resconrec.2020.105340 [5] RANI M, CHOUDHARY P, KRISHNAN V, et al. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades[J]. Composites part B:engineering, 2021, 215: 108768. doi: 10.1016/j.compositesb.2021.108768 [6] DENG Zongyi, YUE Jianglai, HUANG Zhixiong. Solvothermal degradation and reuse of carbon fiber reinforced boron phenolic resin composites[J]. Composites Part B:Engineering, 2021, 221: 109011. doi: 10.1016/j.compositesb.2021.109011 [7] 刘腾飞, 田小永, 朱伟军, 等. 连续碳纤维增强聚乳酸复合材料3D打印及回收再利用机理与性能[J]. 机械工程学报, 2019, 55(7): 128-134. doi: 10.3901/JME.2019.07.128LIU Tengfei, TIAN Xiaoyong, ZHU Weijun, et al. Research on 3D Printing of Continuous Fiber Self-reinforced Composites and Its Recyclability[J]. Journal of Mechanical Engineering, 2019, 55(7): 128-134(in Chinese). doi: 10.3901/JME.2019.07.128 [8] MANTELLI A, ROMANI A, SURIANO R, et al. UV-assisted 3D printing of polymer composites from thermally and mechanically recycled carbon fibers[J]. Polymers, 2021, 13(5): 726. doi: 10.3390/polym13050726 [9] WANG Kaifeng, CHEN Chi, ZHENG Qitan, et al. Multifunctional recycled carbon fiber-Ti3C2Tx MXene paper with superior electromagnetic interference shielding and photo/electro-thermal conversion performances[J]. Carbon, 2022, 197: 87-97. doi: 10.1016/j.carbon.2022.06.026 [10] ZHANG Jin, CHEVALI V S, WANG Hao, et al. Current status of carbon fiber and carbon fiber composites recycling[J]. Composites Part B:Engineering, 2020, 193: 108053. doi: 10.1016/j.compositesb.2020.108053 [11] 成焕波, 黄海鸿, 刘志峰, 等. 碳纤维复合材料在超临界正丁醇中降解的反应动力学[J]. 复合材料学报, 2016, 33(9): 1922-1930. doi: 10.13801/j.cnki.fhclxb.20151112.003CHENG Huanbo, HUANG Haihong, LIU Zhifeng, et al. Reaction kinetics of degradation of carbon fiber-reinforced plastic in supercritical n-butanol[J]. Chinese Journal of Composites, 2016, 33(9): 1922-1930(in Chinese). doi: 10.13801/j.cnki.fhclxb.20151112.003 [12] WANG P H, STERKENBURG R, KIM G, et al. Investigating the void content, fiber content, and fiber orientation of 3d printed recycled carbon fiber[J]. Key Engineering Materials, 2019, 801: 276-281. doi: 10.4028/www.scientific.net/KEM.801.276 [13] FLEMMING T, KRESS G, FLEMMING M. A new aligned short-carbon-fiber-reinforced thermoplastic prepreg[J]. Advanced Composite Materials, 1996, 5(2): 151-159. doi: 10.1163/156855196X00068 [14] LONGANA M L, YU H, LEE J, et al. Quasi-isotropic and pseudo-ductile highly aligned discontinuous fiber composites manufactured with the HiPerDiF (High Performance Discontinuous Fiber) technology[J]. Materials, 2019, 12(11): 1794. doi: 10.3390/ma12111794 [15] LONGANA M L, ONDRA V, YU H N, et al. Reclaimed Carbon and Flax Fibre Composites: Manufacturing and Mechanical Properties[J]. Recycling, 2018, 3.4: 52. [16] LONGANA M L, ONG N, YU H, et al. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) method[J]. Composite Structures, 2016, 153: 271-277. doi: 10.1016/j.compstruct.2016.06.018 [17] NEKODA V D W, REESE M S, Reda Taha M M, et al. Investigating the Effects of Fiber Surface Treatment and Alignment on Mechanical Properties of Recycled Carbon Fiber Composites[J]. Composites Part A:Applied Science and Manufacturing, 2019, 119: 38-47. doi: 10.1016/j.compositesa.2019.01.012 [18] 李森, 黄海鸿, 刘威豪, 等. 再生短碳纤维湿法取向技术及其增强性能分析[J]. 复合材料学报, 2021, 39(3): 1068-1078. doi: 10.13801/j.cnki.fhclxb.20210603.001LI Sen, HUANG Haihong, LIU Weihao, et al. Wet orientation technology of recycled short carbon fiber and analysis of its reinforcement performance[J]. Journal of Composite Materials, 2021, 39(3): 1068-1078(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210603.001 [19] MCLOUTH D T, SEVERINO V J, ADAMS M P, et al. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS[J]. Additive Manufacturing, 2017, 18: 103-109. doi: 10.1016/j.addma.2017.09.003 [20] HYER M W, CHARETTE R F. Use of curvilinear fiber format in composite structure design[J]. AIAA journal, 1991, 29(6): 1011-1015. doi: 10.2514/3.10697 [21] HYER M W, LEE H H. The use of curvilinear fiber format to improve buckling resistance of composite plates with central circular holes[J]. Composite structures, 1991, 18(3): 239-261. doi: 10.1016/0263-8223(91)90035-W [22] JEGLEY D, TATTING B, GURDAL Z. Tow-steered panels with holes subjected to compression or shear loading[J]. In: 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. 2005: 2081. [23] 杜宇, 杨涛, 戴维蓉, 等. 纤维曲线铺放的变刚度复合材料损伤失效试验研究[J]. 固体火箭技术, 2013, 36(6): 826-830.DU Yu, YANG Tao, DAI Weirong, et al. Experimental research of damaging failure of variable-stiffness composite[J]. Solid Rocket Technology, 2013, 36(6): 826-830(in Chinese). [24] 杜宇, 杨涛, 李志猛, 等. 纤维曲线铺放的变刚度复合材料层合板的失效分析[J]. 宇航材料工艺, 2013, 43(5): 22-25. doi: 10.3969/j.issn.1007-2330.2013.05.004DU Yu, YANG Tao, LI Zhimeng, et al. Failure Analysis of Variable-Stiffness Composite Laminates With Curvilinear Fiber Placement[J]. Aerospace Materials Technology, 2013, 43(5): 22-25(in Chinese). doi: 10.3969/j.issn.1007-2330.2013.05.004 [25] 吴尘瑾, 祖磊, 李书欣, 等. 变刚度复合材料层合板的纤维铺放路径设计及屈曲分析[J]. 玻璃钢/复合材料, 2018, (04): 5-10.WU Chenjin, ZU Lei, LI Shuxin, et al. Design of fiber placement path and buckling analysis of variable-stiffness composite laminates[J]. Glass Fiber Reinforced Plastic/Composite, 2018, (04): 5-10(in Chinese). [26] SHAFIGHFARD T, CENDER T A, DEMIR E. Additive manufacturing of compliance optimized variable stiffness composites through short fiber alignment along curvilinear paths[J]. Additive Manufacturing, 2021, 37: 101718. [27] 邓媛, 刘东, 祝颖丹, 等. 纤维变角度牵引铺缝技术的研究进展[J]. 玻璃钢/复合材料, 2015, (06): 97-100.DENG Yuan, LIU Dong, ZHU Yingdan, et al. Progress in fibre variable angle tow placement technology[J]. Glass Fiber Reinforced Plastic/Composite Materials, 2015, (06): 97-100(in Chinese). [28] 黄海鸿, 张保玉, 赵志培. 超临界正丁醇对回收碳纤维复合材料的降解及表征[J]. 高等学校化学学报, 2017, 38(09): 1687-1694.HUANG Haihong, ZHANG Baoyu, ZHAO Zhipei. Degradation and Characterization of Recycling Carbon Fiber/Epoxy Resin Composites in Supercritical n-Butanol[J]. CHEMICAL JOURNAL OF CHINESE UNIVERSITIES, 2017, 38(09): 1687-1694(in Chinese). [29] LI N, LINK G, WANG T, et al. Path-designed 3D printing for topological optimized continuous carbon fiber reinforced composite structures[J]. Composites Part B:Engineering, 2020, 182: 107612. doi: 10.1016/j.compositesb.2019.107612 [30] AYRES C E, JHA B S, MEREDITH H, et al. Measuring fiber alignment in electrospun scaffolds: a user's guide to the 2D fast Fourier transform approach[J]. Journal of Biomaterials Science, Polymer Edition, 2008, 19(5): 603-621 doi: 10.1163/156856208784089643 [31] CHENG Huanbo, ZHOU Jinhu, GUO Lijun, et al. Dispersibility optimization of short carbon fiber suspension for the preparation of carbon fiber aligned mat reinforced composites[J]. Journal of Cleaner Production, 2023, 389: 136075. doi: 10.1016/j.jclepro.2023.136075 [32] WRIGHT W J, KOERNER H, RAPKING D, et al. Rapid fiber alignment quantification in direct write printing of short fiber reinforced composites[J]. Composites Part B, 2022, 236: 109814. doi: 10.1016/j.compositesb.2022.109814 [33] WANG Huaqiao, CHEN Jihong, FAN Zhichao, et al. Experimental Investigation on the Influence of Fiber Path Curvature on the Mechanical Properties of Composites[J]. Materials, 2021, 14.10: 2602. [34] FU S Y, MAI Y W, LAUKE B, et al. Synergistic effect on the fracture toughness of hybrid short glass fiber and short carbon fiber reinforced polypropylene composites[J]. Materials Science & Engineering A, 2002, 323(1-2): 326-335. [35] ZHANG Wenqing, DENG Xi, SUI Gang, et al. Improving interfacial and mechanical properties of carbon nanotube-sized carbon fiber/epoxy composites[J]. Carbon, 2019, 145: 629-639. doi: 10.1016/j.carbon.2019.01.063 [36] MEI Hui, ZHANG Siming, CHEN Hao, et al. Interfacial modification and enhancement of toughening mechanisms in epoxy composites with CNTs grafted on carbon fibers[J]. Composites Science and Technology, 2016, 134: 89-95. doi: 10.1016/j.compscitech.2016.08.010 -

下载:

下载: