Development of light-weight composite pavement slab in suspension bridge and its mechanical properties

-

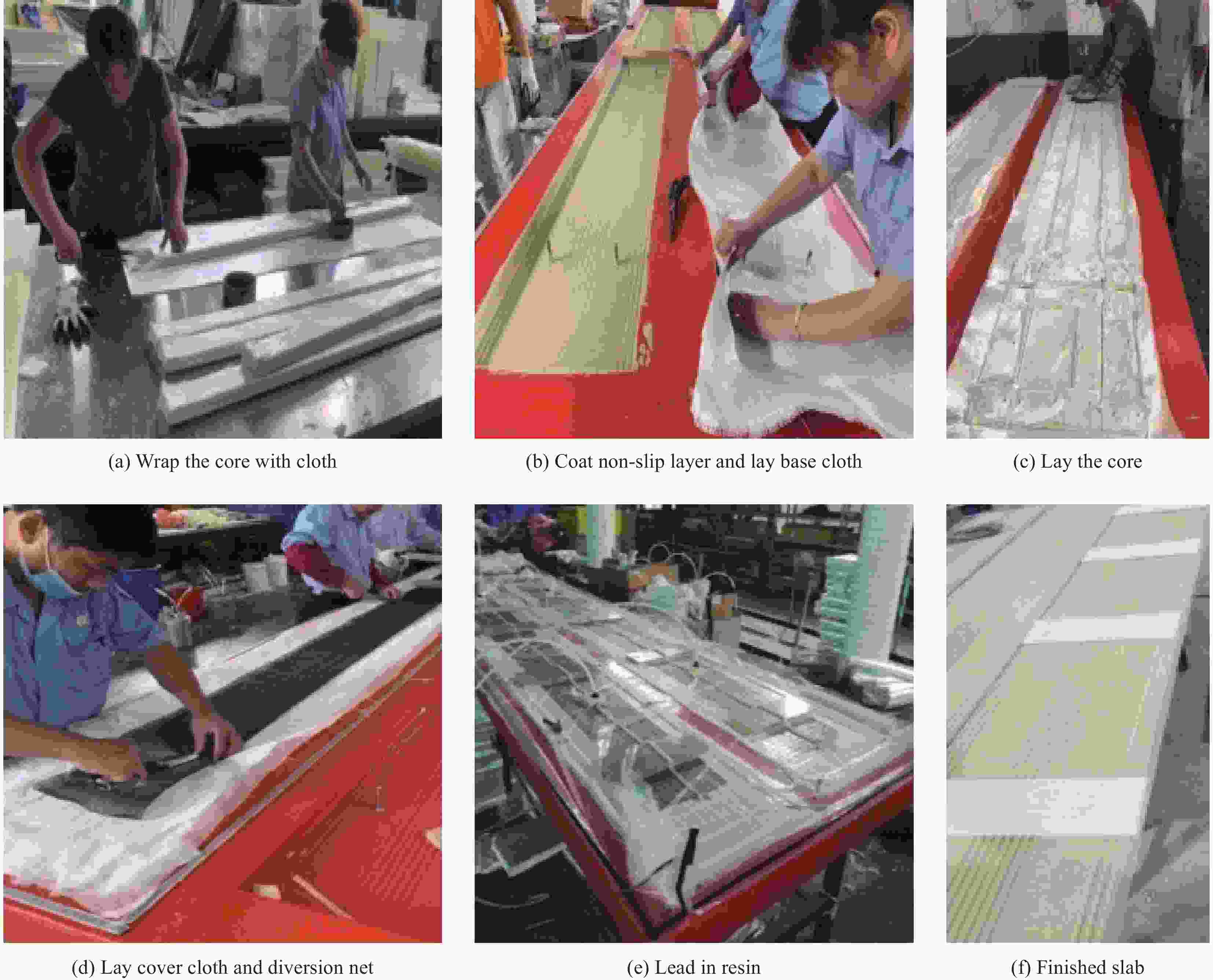

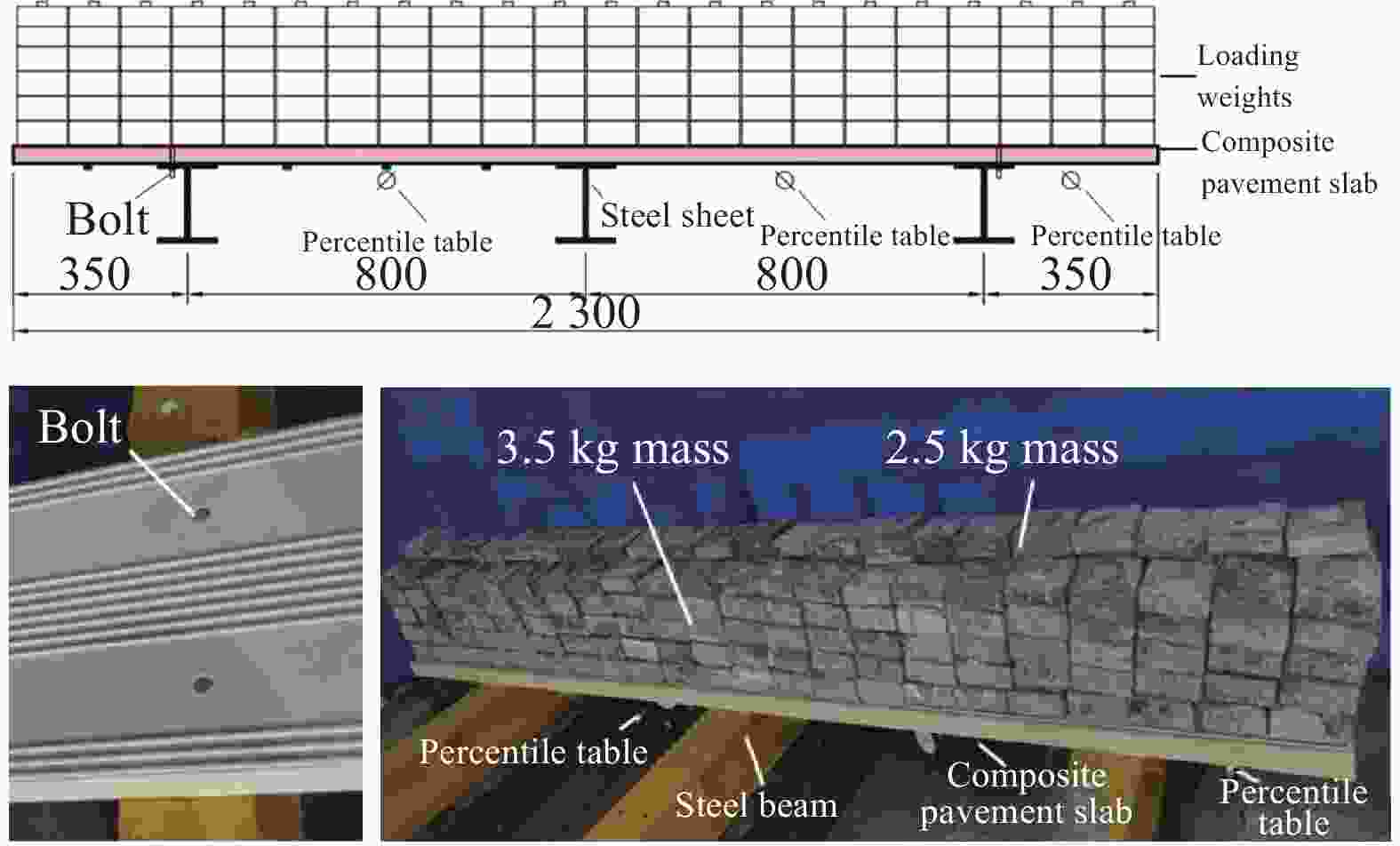

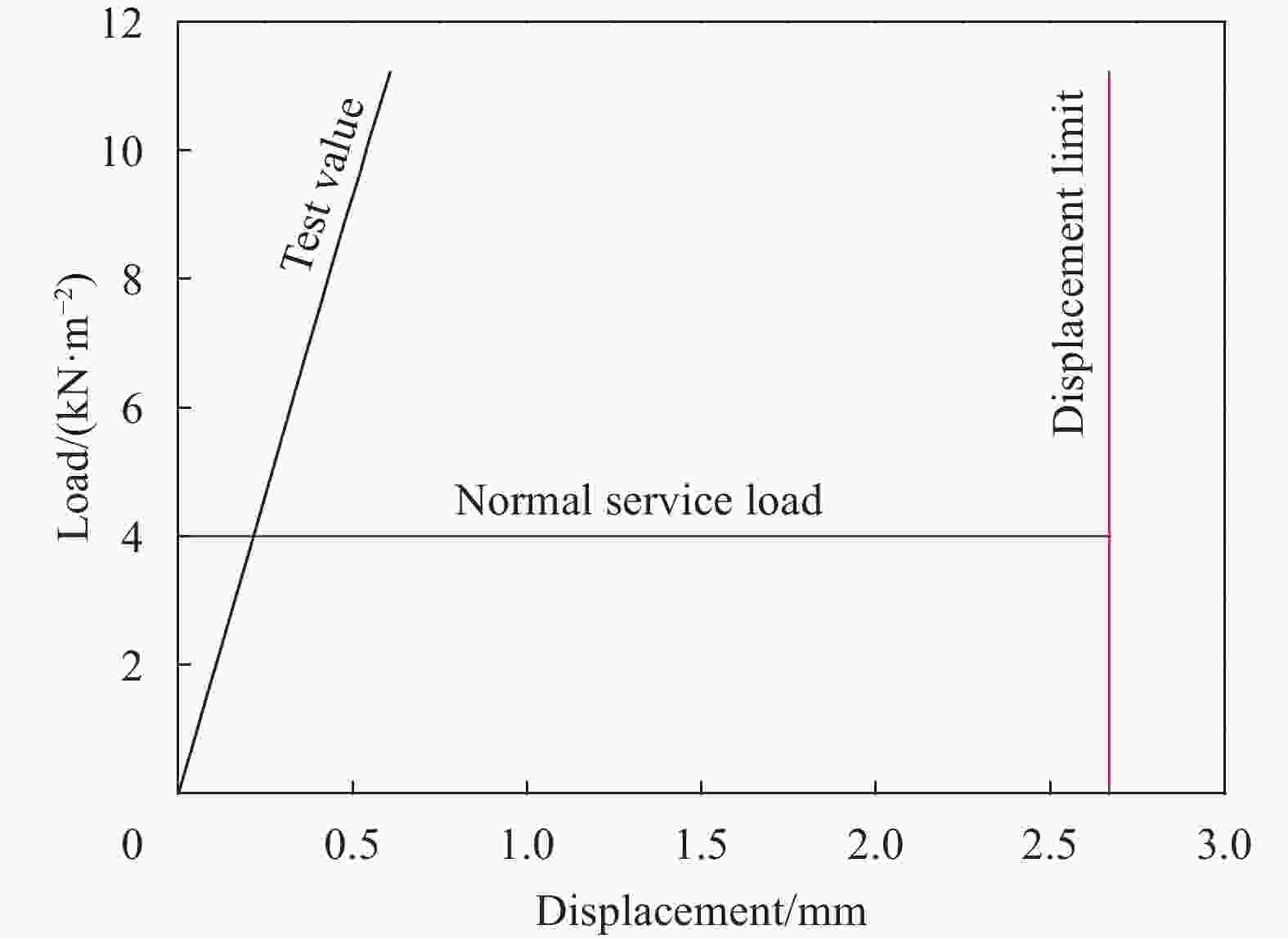

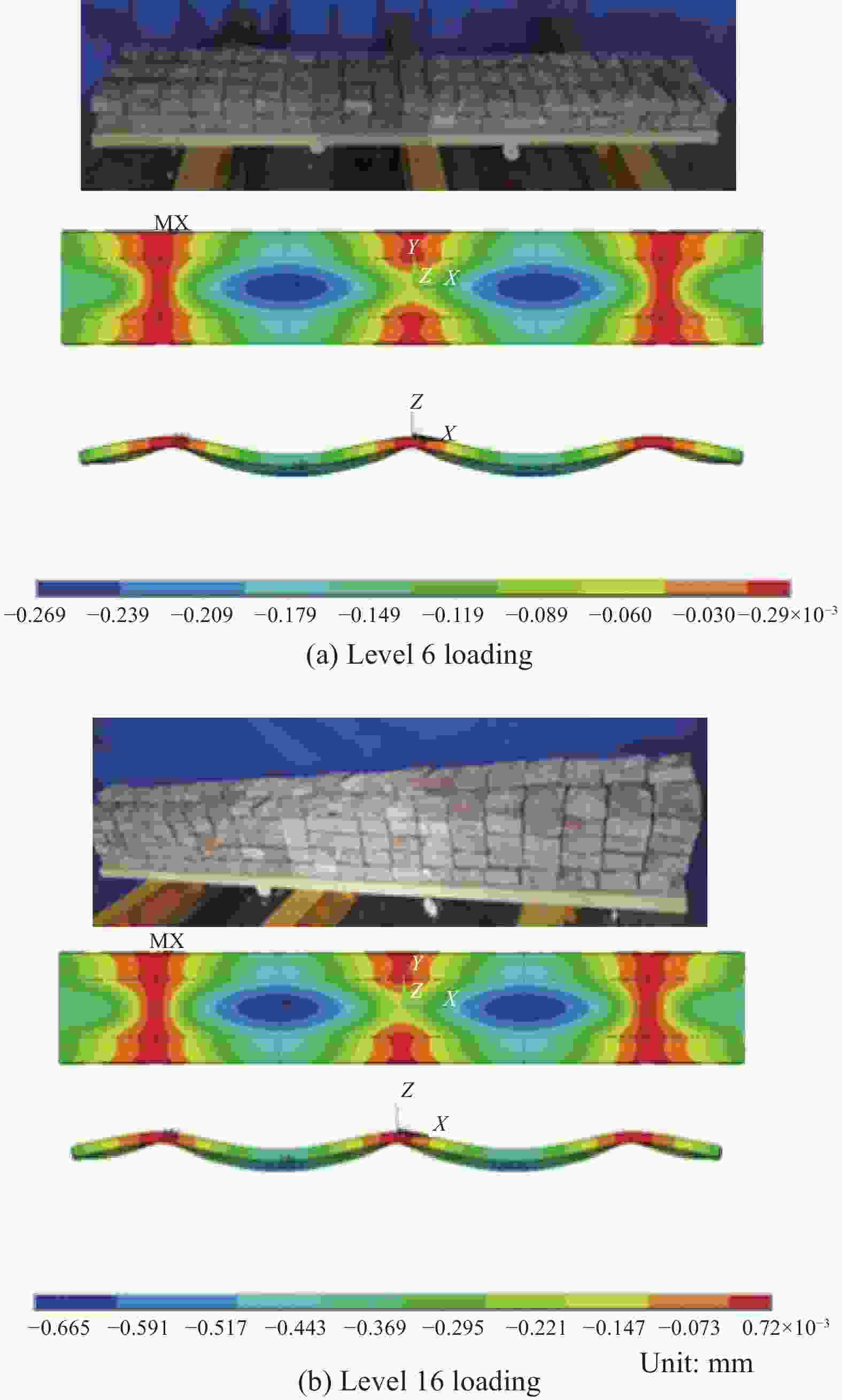

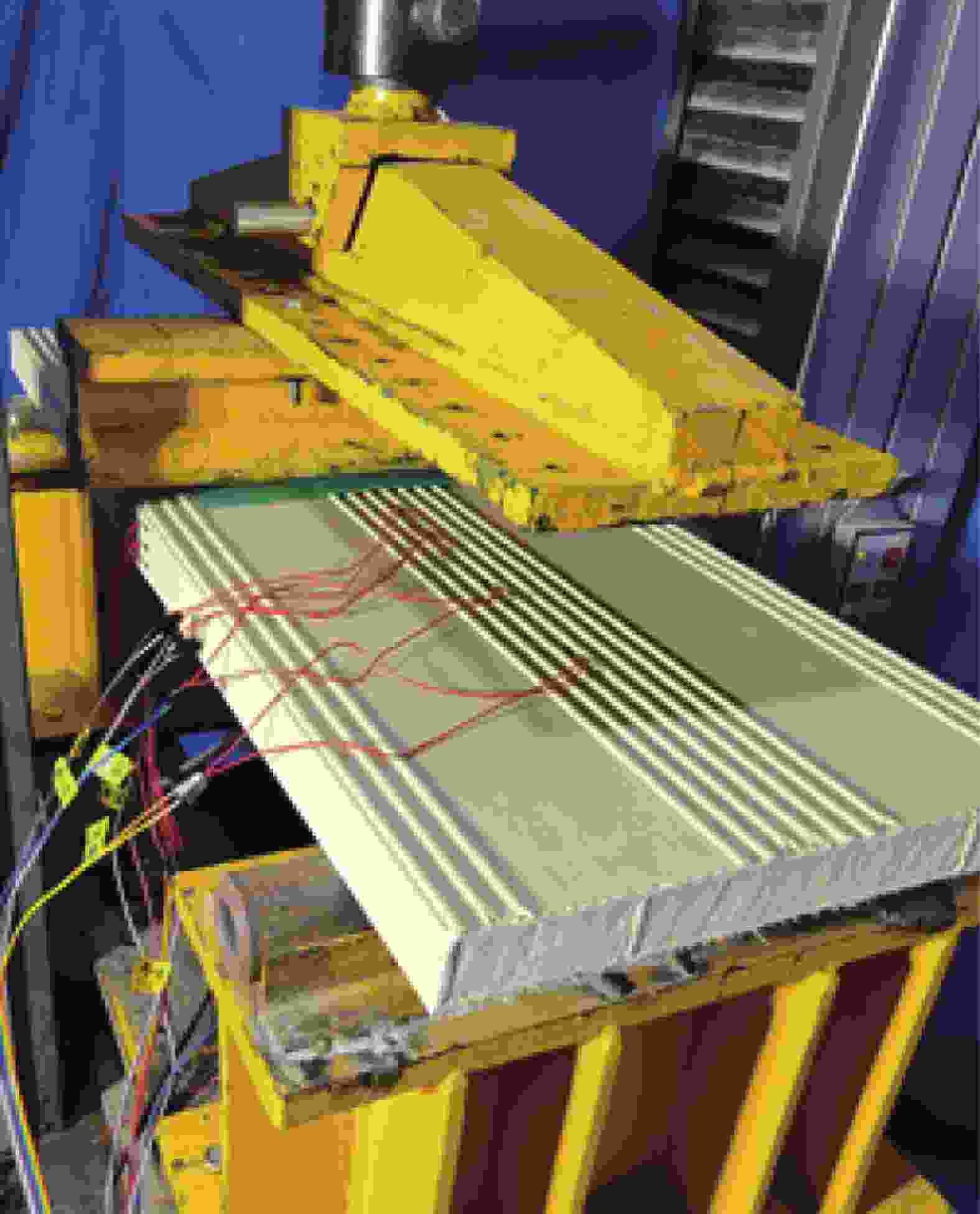

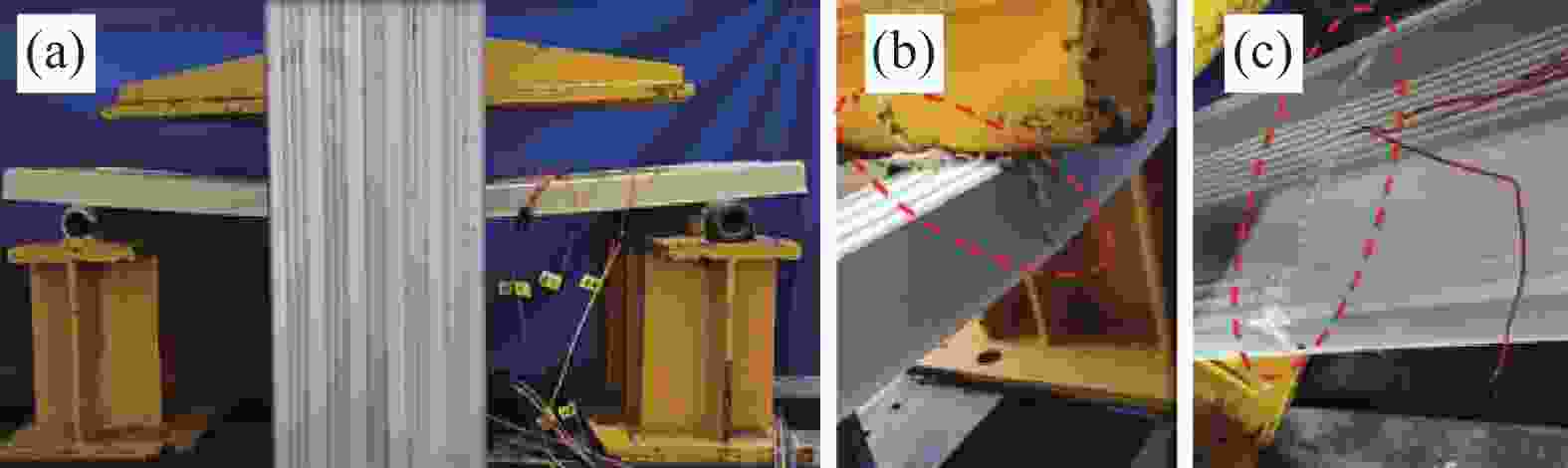

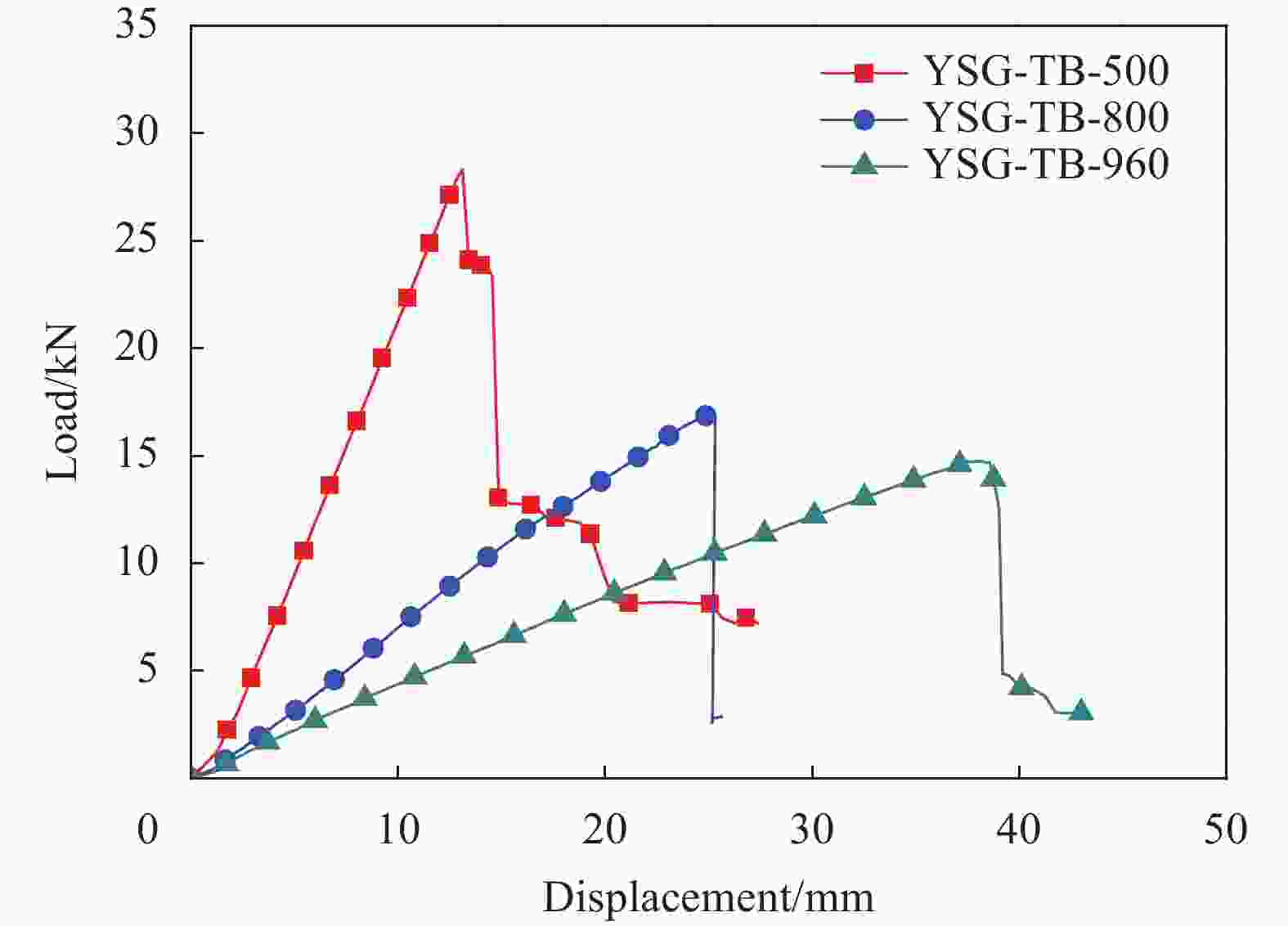

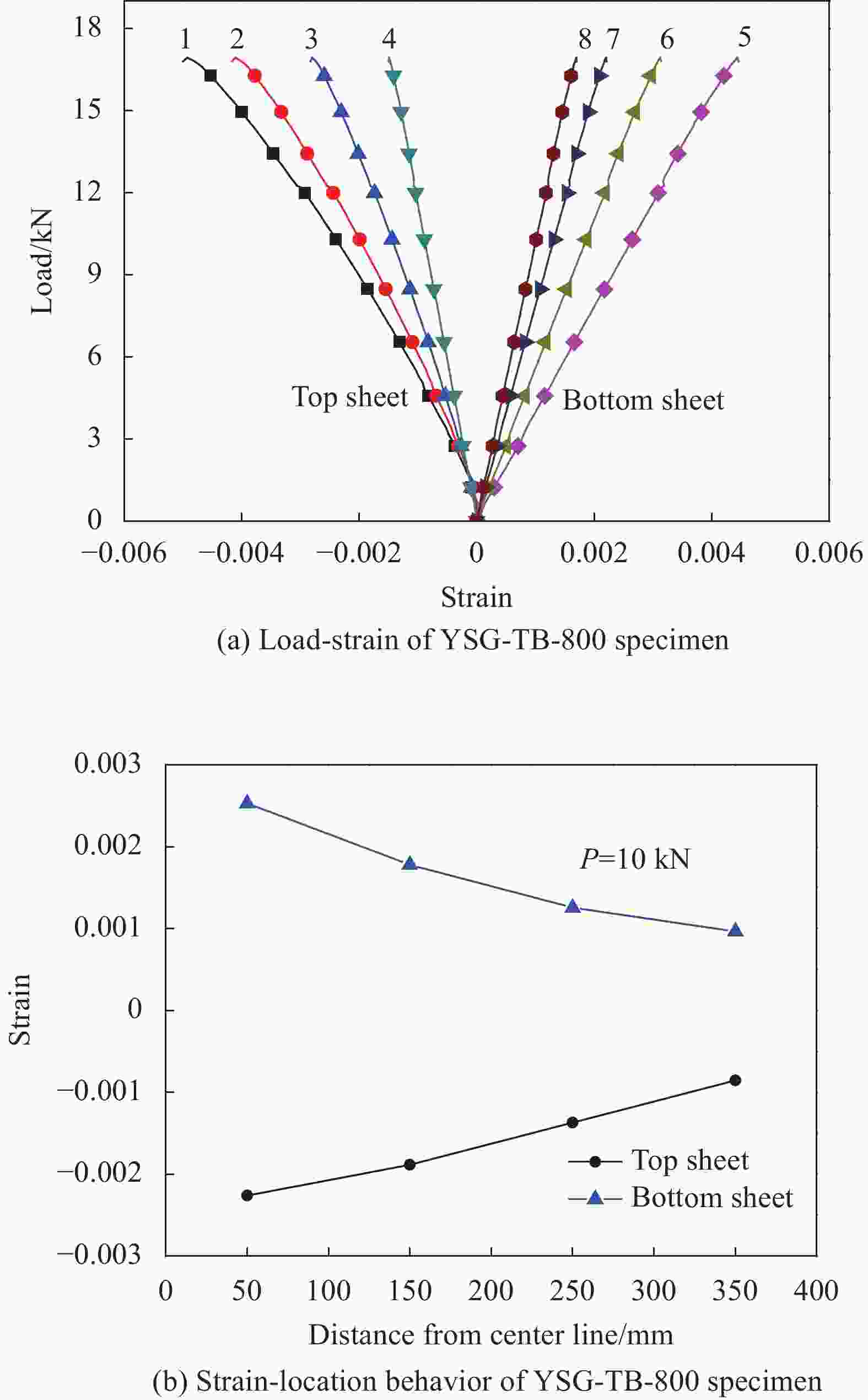

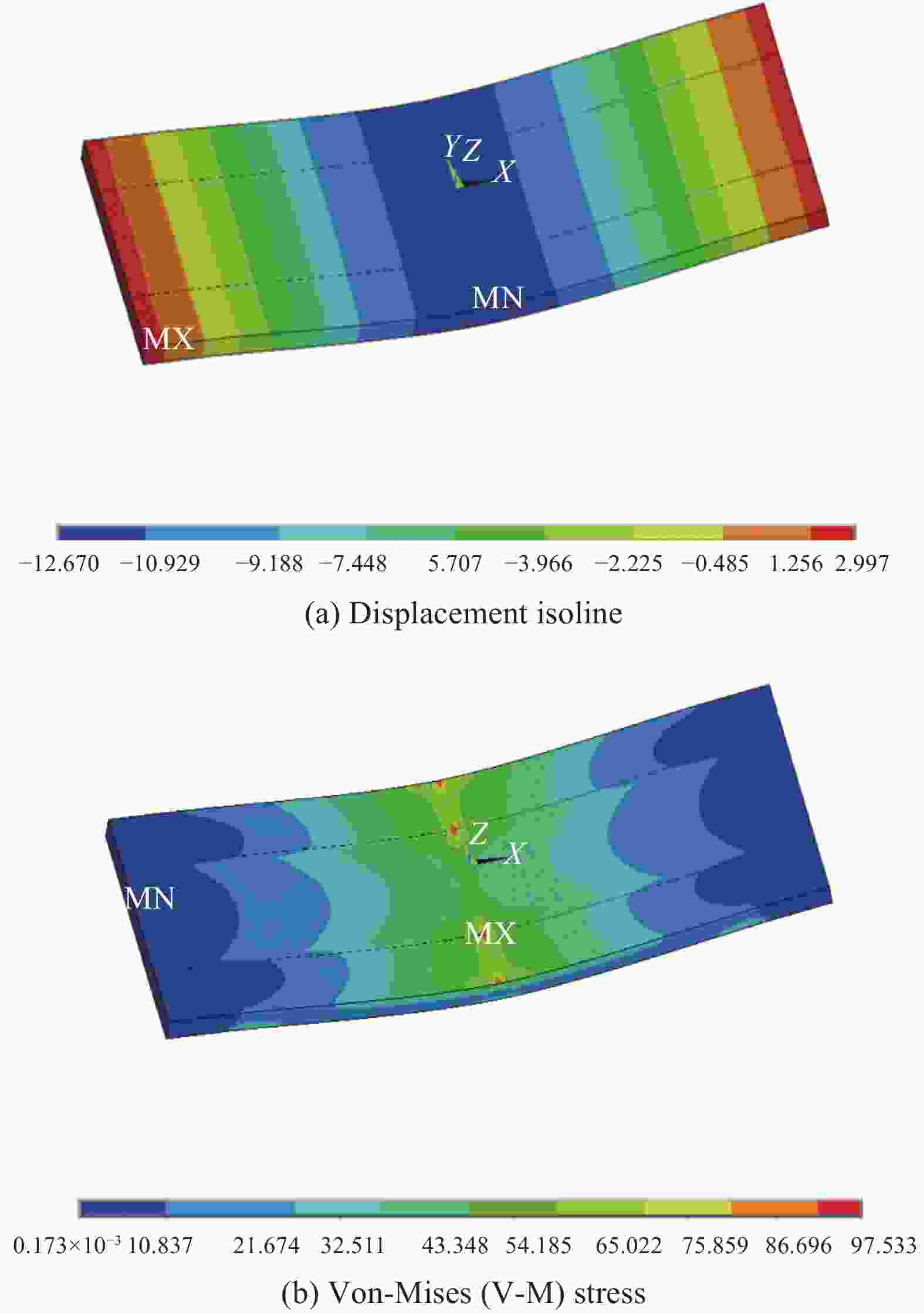

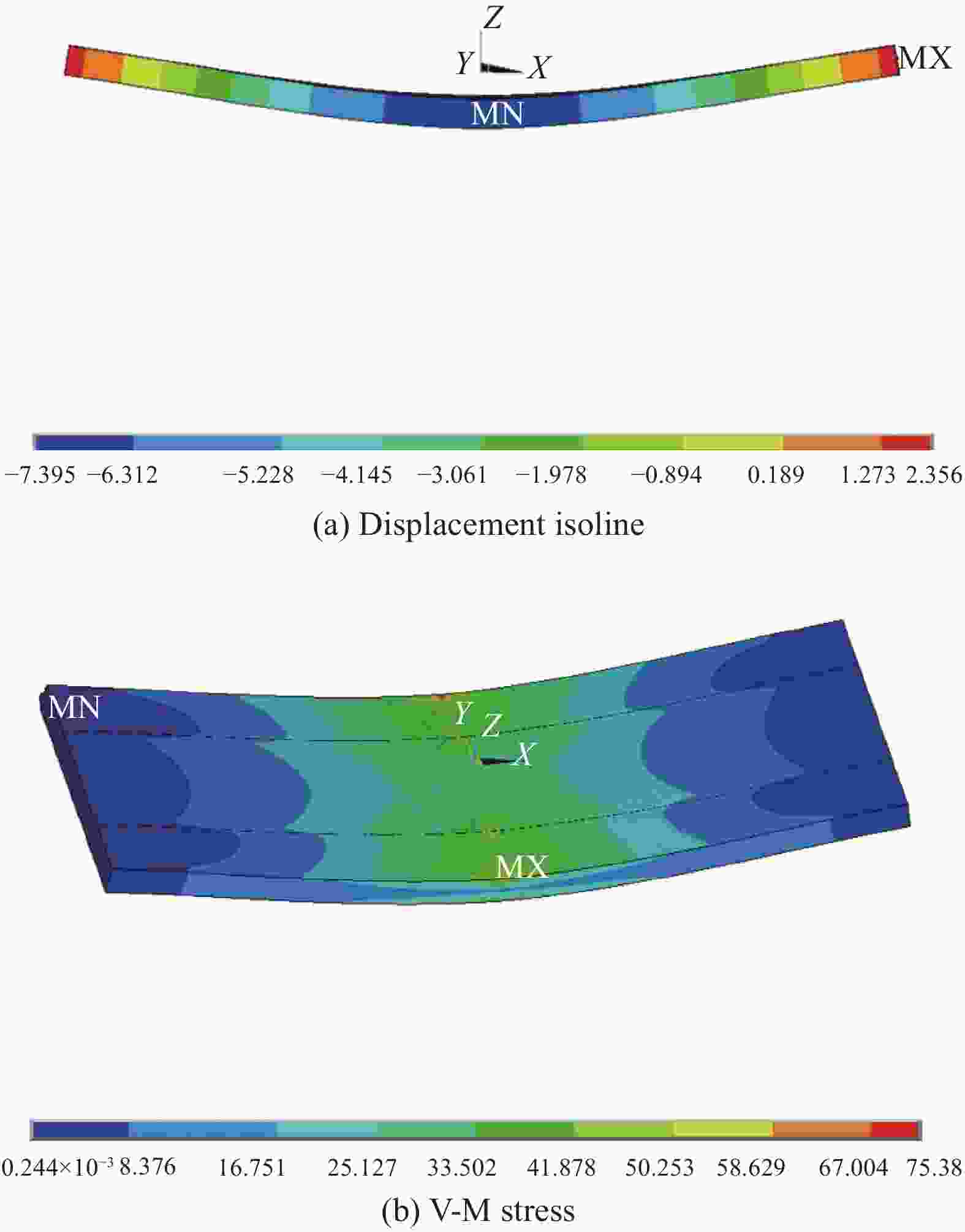

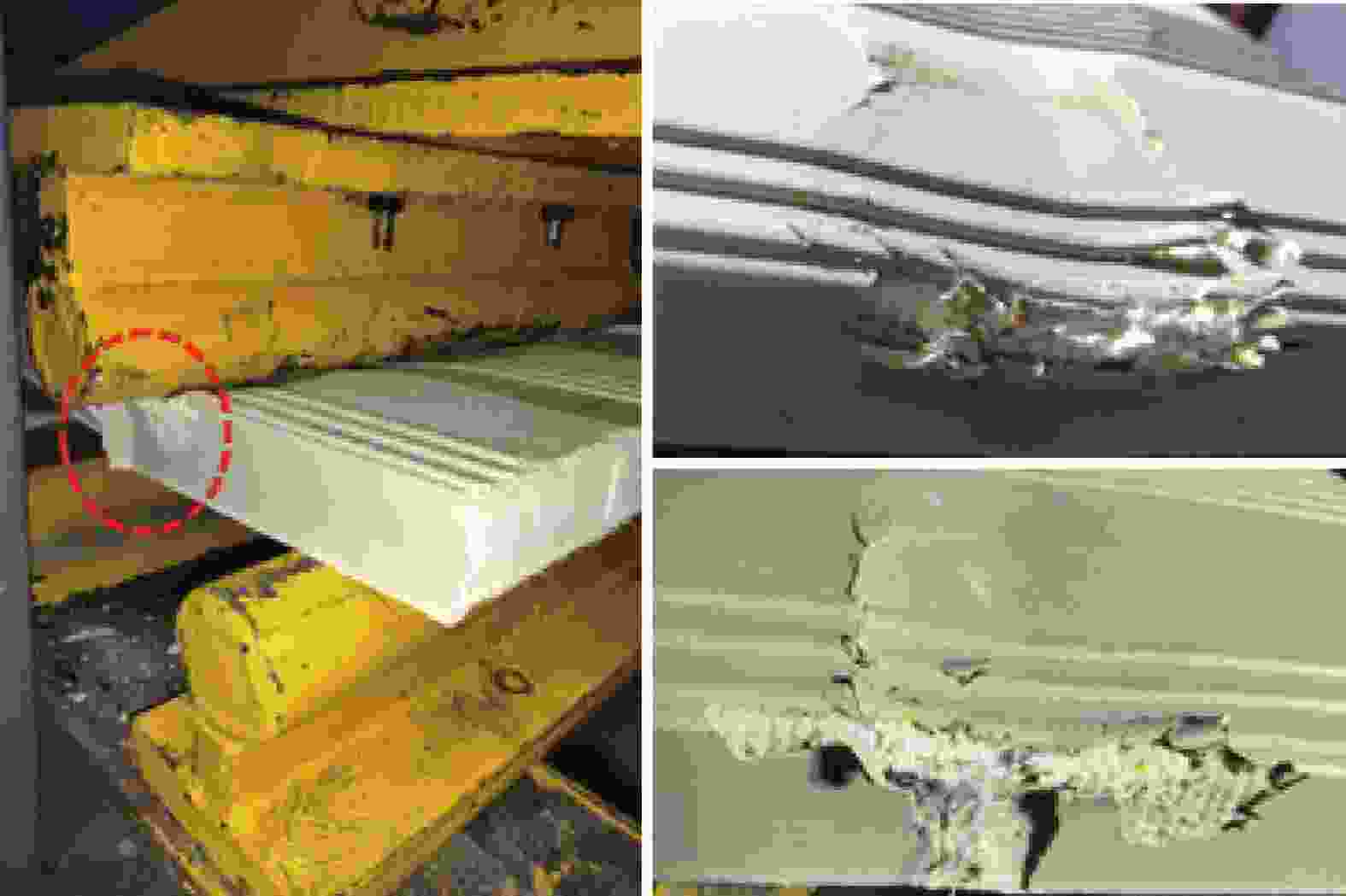

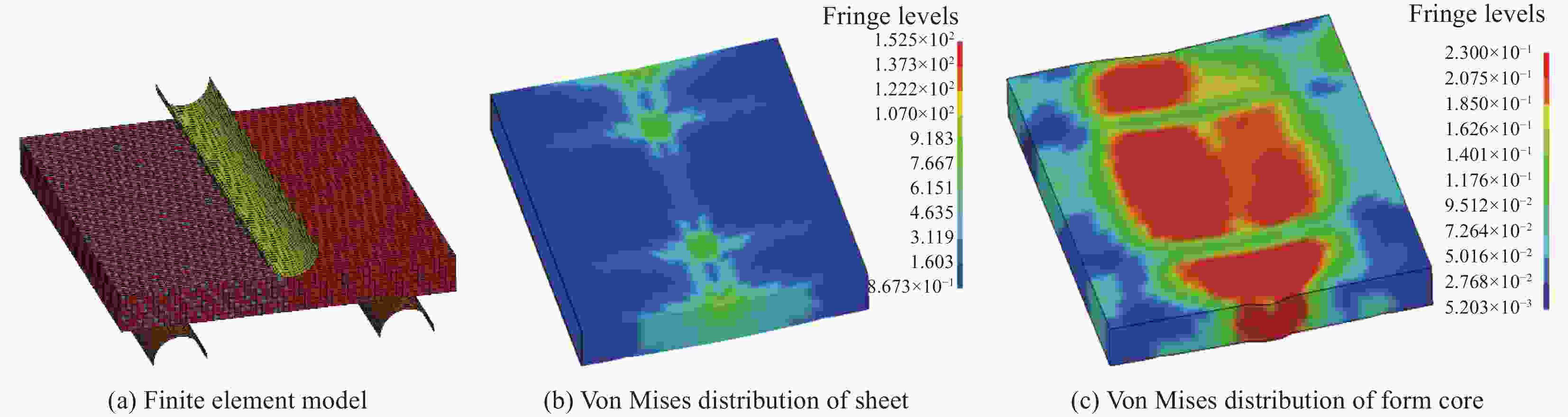

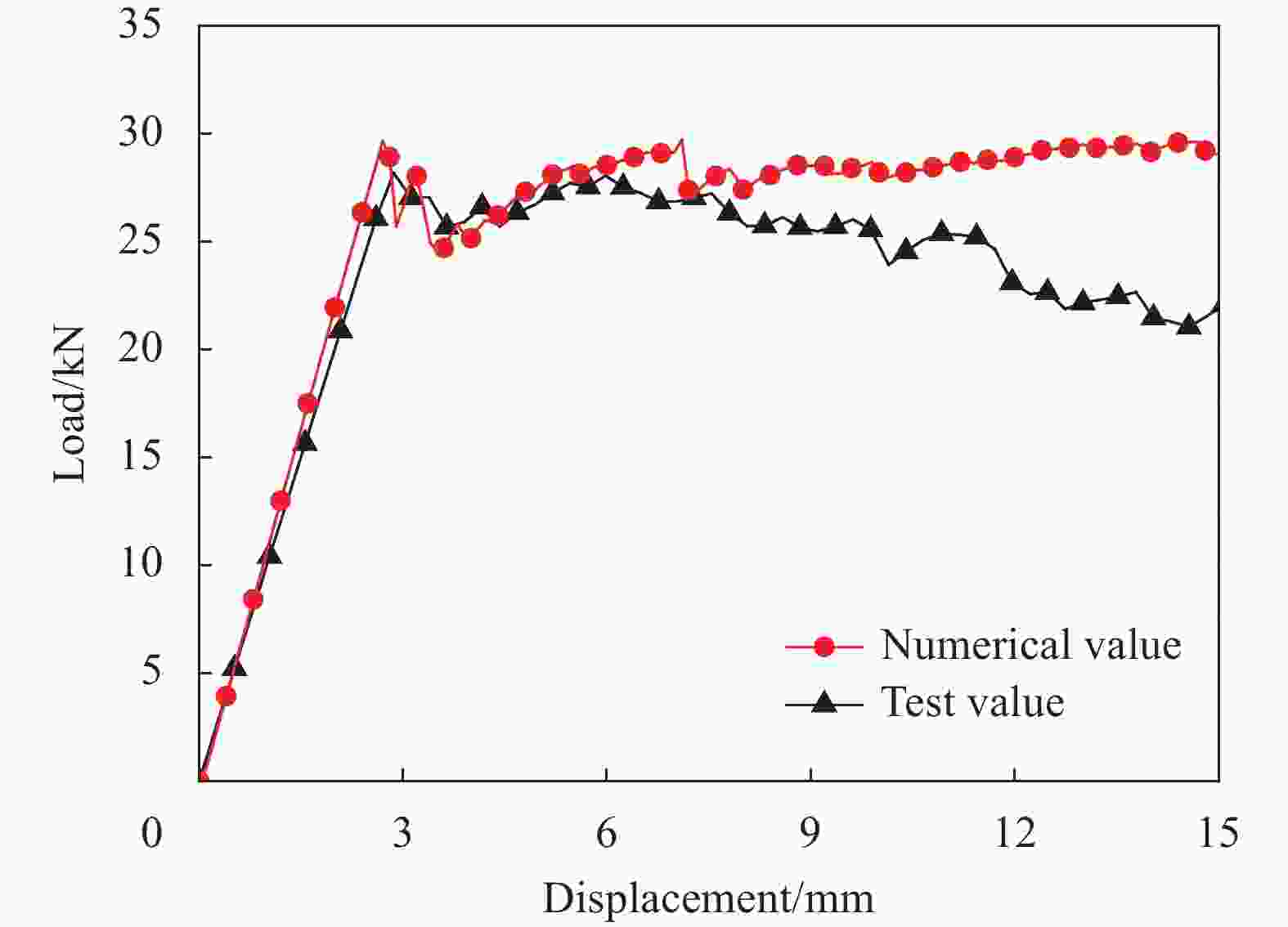

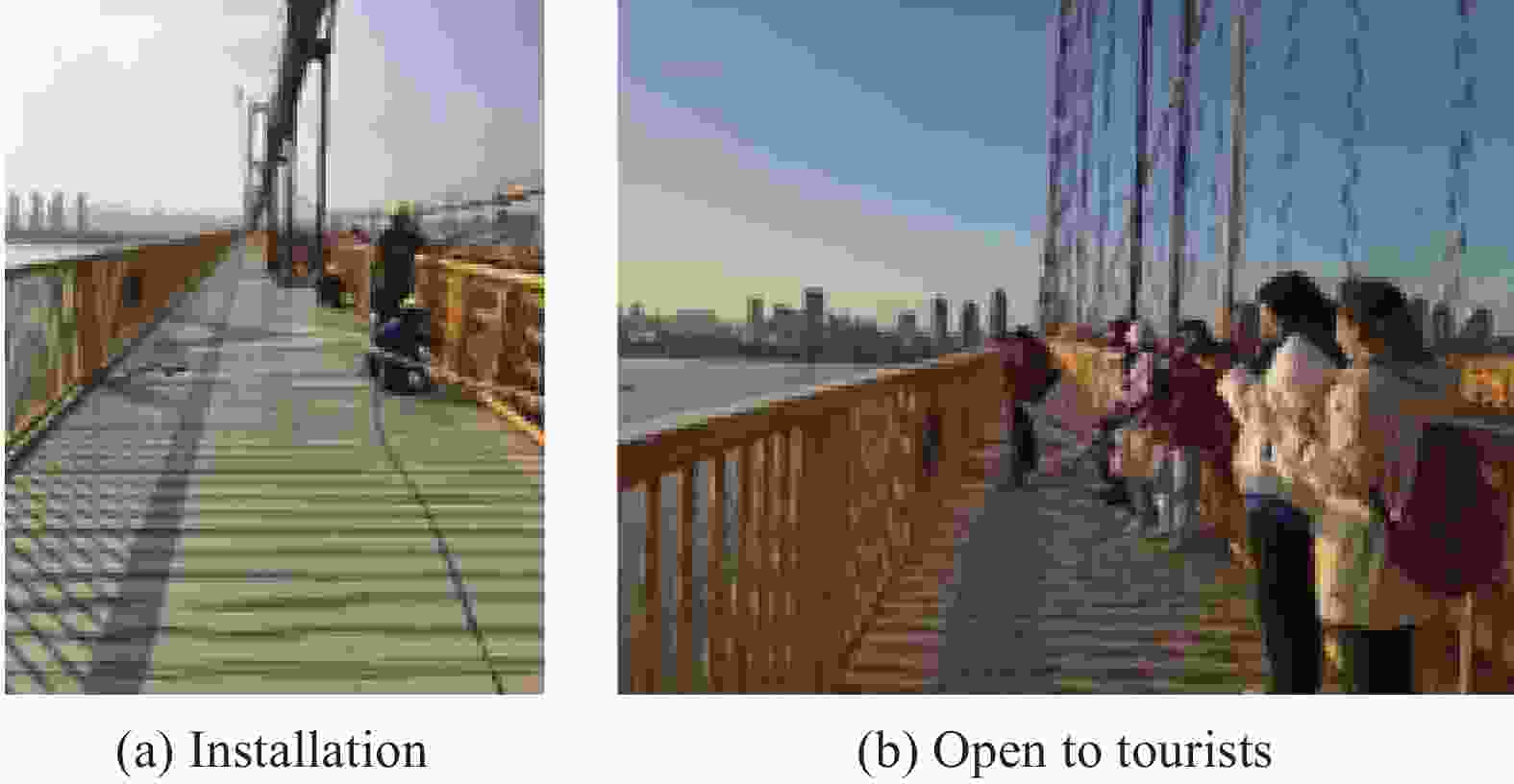

摘要: 为满足大跨悬索桥主梁减重的需求,研制了新型轻质复材人行道板,并将其成功应用于武汉杨泗港长江大桥。采用试验、理论和有限元的方法研究了轻质复材人行道板的受力性能并设计了快速拼装工艺。采用配重砝码块进行重力分级均布加载模拟人群荷载下复材人行道板的受力响应,在规范人群荷载下,复材板跨中挠度仅为挠度限值的 9.14%;对3种跨度的复材人行道板进行三点弯曲试验研究,3 种试件的破坏形式均为面板屈曲破坏,跨度最大的试件YSG-TB-960的极限承载力最小为14.79 kN;复材人行道板剪切试验的极限承载力为28.68 kN。采用ANSYS/Multiphysics软件建立了复材人行道板的三维模型并进行有限元分析,模拟复材人行道板在人群荷载和跨中集中荷载下的响应,有限元计算结果与试验值吻合较好。采用一阶剪切变形理论计算受弯复材人行道板在极限承载力时下面板跨中挠度,理论结果和试验结果最小误差仅为–7.73%,总体吻合良好。对研制的复材人行道板进行了性能评估,轻质复材人行道板的最小安全系数为10.42,均满足设计要求。Abstract: A new type of lightweight composite pavement slab was developed to meet the weight reduction requirement of the main girder of the long span suspension bridge, and was successfully applied to the Yangsigang Yangtze River Bridge in Wuhan. Experimental, theoretical and finite element methods were used to study the mechanical behavior of the lightweight composite pavement slab, and the rapid assembly process was designed. The counterweight was used to simulate the response of the composite pavement slab under the crowd load, and the mid-span deflection of the compo-site slab was only 9.14% of the limit value of deflection. Three-point bending tests were carried out on three lightweight composite pavement slabs with different spans. The results show that the failure mode of the three specimens is basically panel yield failure, the ultimate bearing capacity of the largest span member YSG-TB-960 is the smallest (14.79 kN) , and the ultimate bearing capacity in shearing test is 28.68 kN. The 3D model of composite pavement slab was established by ANSYS/Multiphysics software and the finite element analysis was carried out to simulate the response of composite pavement slab under crowd load and concentrated load. The results of finite element analysis are in good agreement with the experimental data. The minimum error between the theoretical results and the experimental results is –7.73% when the ultimate bearing capacity is calculated by theory. The performance of the composite pavement slab was evaluated, and the minimum safety factor of the lightweight composite pavement slab is 10.42. All the components meet the design requirements.

-

表 1 复合材料面板片材基本力学性能参数

Table 1. Basic mechanical performance of composite specimens

表 2 聚氨酯泡沫基本力学性能参数

Table 2. Basic mechanical performance of polyurethane foam

表 3 复材人行道板均布荷载加载制度及有限元与试验跨中挠度对比

Table 3. Uniform load system and span deflection comparison between numerical method and test for composite pavement slab

Cumulative loading/

(kN·m−2)Quantity of

mass at one time/

blockSingle

loading/

(kN·m−2)Mass specifications/

(kg/block)Total number of loading Δex/mm Δfem/mm Error (Δfem−Δex)/

Δex/%0.755 22 0.755 3.5 1 0.041 0.045 9.27 1.509 22 0.755 3.5 2 0.081 0.090 10.62 2.264 22 0.755 3.5 3 0.122 0.134 10.16 3.018 22 0.755 3.5 4 0.163 0.179 9.88 3.773 22 0.755 3.5 5 0.203 0.224 10.30 4.528 22 0.755 3.5 6 0.244 0.269 10.12 5.282 22 0.755 3.5 7 0.283 0.313 10.78 6.037 22 0.755 3.5 8 0.323 0.358 10.93 6.791 22 0.755 3.5 9 0.364 0.403 10.74 7.546 22 0.755 3.5 10 0.404 0.448 10.87 8.301 22 0.755 3.5 11 0.445 0.493 10.72 9.055 22 0.755 3.5 12 0.486 0.537 10.58 9.594 22 0.539 2.5 13 0.518 0.569 9.92 10.133 22 0.539 2.5 14 0.545 0.601 10.35 10.672 22 0.539 2.5 15 0.576 0.633 9.97 11.211 22 0.539 2.5 16 0.607 0.665 9.62 Notes: Δfem—Span deflection of composite pavement slab with numerical method; Δex—Span deflection of composite pavement slab with test method. 表 4 复材人行道板受弯试件参数统计

Table 4. Details of tested composite pavement slab bending specimens

Specimen Dimension parameter of specimen Width/

mmHeight/

mmSpan/

mmTotal length/

mmYSG-TB-500 370 35 500 700 YSG-TB-800 800 1000 YSG-TB-960 960 1160 表 5 复材人行道板三点弯曲试验结果

Table 5. Three point flexual test results of composite pavement slab

Specimen Ultimate bearing

capacity/kNUltimate deflection/

mmFailure

modeYSG-TB-500 28.34 13.09 YSG-TB-800 16.94 25.10 Buckling of

upper sheetYSG-TB-960 14.79 37.86 表 6 复材人行道板跨中挠度结果对比

Table 6. Comparison of results on mid-span deflection of composite pacememt slab

Specimen Theoretical

value/mmTest value

/

mmError/% YSG-TB-500 11.12 13.09 −15.05 YSG-TB-800 23.16 25.10 −7.73 YSG-TB-960 33.75 37.86 −10.86 Note: Error=(Theoretical value − Test value)/Test value. 表 7 复材人行道板跨中挠度结果对比(荷载P=10 kN)

Table 7. Comparison of mid-span deflection of composite pavement slab (Load P=10 kN)

Specimen Numerical value/mm Test value/mm Error/% YSG-TB-500 4.87 5.25 −7.24 YSG-TB-800 12.67 13.71 −7.59 YSG-TB-960 23.75 24.08 −1.37 Note: Error = (Numerical value – Test value)/Test value. 表 8 人行道板试件性能评估结果

Table 8. Results of performance evaluation of composite pavement slab

Specimen Ftest Fshear/kN Safety factor Performance evaluation YSG-TB-210 14.34 0.16 89.63 Meet YSG-TB-500 14.17 0.37 38.30 Meet YSG-TB-800 8.47 0.59 14.36 Meet YSG-TB-960 7.40 0.71 10.42 Meet Notes: Ftest—Ultimate shear force of test; Fshear—Equivalent maximum shear value. -

[1] 曾志斌. 铁路混凝土梁人行道步行板的技术要求和结构选型[J]. 铁道建设, 2019, 59(8):42-44.ZENG Zhibin. Technical requirements and structural selection of sidewalk walking board of railway concrete girder[J]. Railway Engineering,2019,59(8):42-44(in Chinese). [2] 王伟. 浸锌钢结构人行道板优化设计[J]. 科技创新与应用, 2018, 20:87-88. doi: 10.3969/j.issn.2095-2945.2018.29.039WANG Wei. Optimum design of galvanized steel structure pavement slab[J]. Technology Innovation and Application,2018,20:87-88(in Chinese). doi: 10.3969/j.issn.2095-2945.2018.29.039 [3] 杨易琳, 牛潮. 铝合金踏板加工设备的设计探讨[J]. 有色冶金设计与研究, 2010, 5:34-36. doi: 10.3969/j.issn.1004-4345.2010.02.013YANG Yilin, NIU Chao. A study on engineering of alumi-num alloy floor sheet machining equipment[J]. Nonferrous Metals Engineering & Research,2010,5:34-36(in Chinese). doi: 10.3969/j.issn.1004-4345.2010.02.013 [4] 冯鹏, 田野, 覃兆平. 纤维增强复合材料拉挤型材桁架桥静动力性能研究[J]. 工业建筑, 2013, 43(6):36-41.FENG Peng, TIAN Ye, QIN Zhaoping. Static and dynamic behavior of a truss bridge made of FRP pultruded profiles[J]. Industrial Construction,2013,43(6):36-41(in Chinese). [5] 韩娟, 刘伟庆, 方海. 纤维增强树脂基复合材料在土木基础设施领域中的应用[J]. 南京工业大学学报(自然科学版), 2020, 42(5):543-554.HAN Juan, LIU Weiqing, FANG Hai. Application of fiber-reinforced resin matrix composites in the civil infrastructure field[J]. Journal of Nanjing Tech University (Natural Science Edition),2020,42(5):543-554(in Chinese). [6] FANG H, BAI Y, LIU W Q, et al. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments[J]. Composites Part B: Engineering,2019,164:129-143. doi: 10.1016/j.compositesb.2018.11.047 [7] 冯鹏, 叶列平. 外部纤维缠绕增强FRP桥面板受力性能试验研究[J]. 土木工程学报, 2009, 42(9):61-67. doi: 10.3321/j.issn:1000-131X.2009.09.009FENG Peng, YE Lieping. Experimental study on exterior filament-wound strengthening fiber-reinforced polymer bridge decks[J]. China Civil Engineering Journal,2009,42(9):61-67(in Chinese). doi: 10.3321/j.issn:1000-131X.2009.09.009 [8] 史慧媛, 刘伟庆, 方海, 等. GFRP复合材料-轻木夹芯梁弯曲疲劳性能试验[J]. 复合材料学报, 2018, 35(5):1114-1122. doi: 10.13801/j.cnki.fhclxb.20170707.001SHI Huiyuan, LIU Weiqing, FANG Hai, et al. Experimental research on flexural fatigue behavior of GFRP-balsa sandwich beams[J]. Acta Materiae Compositae Sinica,2018,35(5):1114-1122(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170707.001 [9] KELLER T, ROTHE J, DE CASTRO J, et al. GFRP-balsa sandwich bridge deck-concept, design and experimental validation[J]. Journal of Composites for Construction,2014,18(2):1-10. [10] 柴生波, 王秀兰, 肖汝诚. 悬索桥主缆纵桥向约束刚度研究[J]. 中国公路学报, 2015, 28(8):59-66. doi: 10.3969/j.issn.1001-7372.2015.08.008CHAI Shengbo, WANG Xiulan, XIAO Rucheng. Study on longitudinal restraint stiffness of main cable in suspension bridge[J]. China Journal of Highway Transport,2015,28(8):59-66(in Chinese). doi: 10.3969/j.issn.1001-7372.2015.08.008 [11] CLEMENTE P, NICOLOSI G, RAITHEL A. Preliminary design of very long-span suspension cable bridge[J]. Engineering Structures,2000,22(12):1699-1706. doi: 10.1016/S0141-0296(99)00112-1 [12] 刘伟庆, 方海, 万里. 格构增强型复合材料夹层结构: 中国专利, ZL 200710021396.8[P]. 2007-04-10.LIU Weiqing, FANG Hai, WAN Li. Lattice reinforced composite sandwich structure: Chinese patent, ZL 200710021396.8[P]. 2007-04-10(in Chinese). [13] 邓晓光, 刘沐宇, 史晶, 等. 大跨径双层悬索桥钢桁梁整体焊接节点疲劳分析与试验[J]. 中国公路学报, 2017, 30(3):96-103. doi: 10.3969/j.issn.1001-7372.2017.03.010DENG Xiaoguang, LIU Muyu, SHI Jing, et al. Fatigue analysis and test on integral welded joint at steel truss girder of long-span double deck suspension bridge[J]. China Jour-nal of Highway Transport,2017,30(3):96-103(in Chinese). doi: 10.3969/j.issn.1001-7372.2017.03.010 [14] 中华人民共和国行业标准. 公路桥涵设计通用规范: JTG D60—2015[S]. 北京: 人民交通出版社股份有限公司, 2015.Industry Standard of the People’s Republic of China. General specifications for design of highway bridges and culverts: JTG D60—2015[S]. Beijing: China Communications Press CO., LTD., 2015(in Chinese). [15] ASTM. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039[S]. West Conshohocken: ASTM International, 2017. [16] ASTM. Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° laminate: ASTM D3518[S]. West Conshohocken: ASTM International, 2018. [17] ASTM. Standard test method for compressive properties of polymer matrix composite materials with unsupported gage section by shear loading: ASTM D3410[S]. West Conshohocken: ASTM International, 2016. [18] ASTM. Standard test method for flatwise tensile strength of sandwich constructions: ASTM C297[S]. West Conshohocken: ASTM International, 2015. [19] ASTM. Standard test method for shear properties of sandwich core materials: ASTM C273[S]. West Conshohocken: ASTM International, 2020. [20] ASTM. Standard test method for flatwise compressive properties of sandwich cores: ASTM C365[S]. West Conshohocken: ASTM International, 2022. [21] 中华人民共和国行业标准. 公路钢筋混凝土及预应力混凝土桥涵设计规范: JTG 3362—2018[S]. 北京: 人民交通出版社股份有限公司, 2018.Industry Standard of the People’s Republic of China. Specifications for design of highway reinforced concrete and prestressed concrete bridges and culverts: JTG 3362—2018[S]. Beijing: China Communications Press CO., LTD., 2018(in Chinese). [22] ASTM. Standard test method for flexural properties of sandwich constructions: ASTM C393[S]. West Conshohocken: ASTM International, 2020. [23] WANG L, LIU W Q, WAN L, et al. Mechanical performance of foam-filled lattice composite panels in four-point bending: Experimental investigation and analytical modeling[J]. Composites Part B: Engineering,2014,67:270-279. doi: 10.1016/j.compositesb.2014.07.003 -

下载:

下载: