Fatigue deformation characteristics and life prediction of ECC under uniaxial tension

-

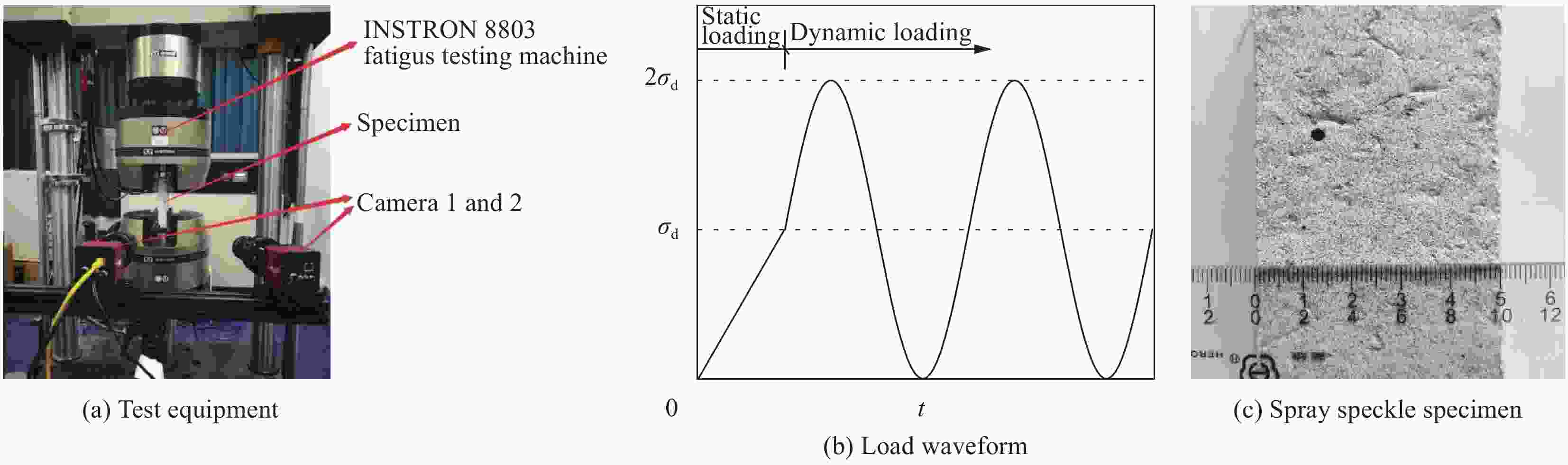

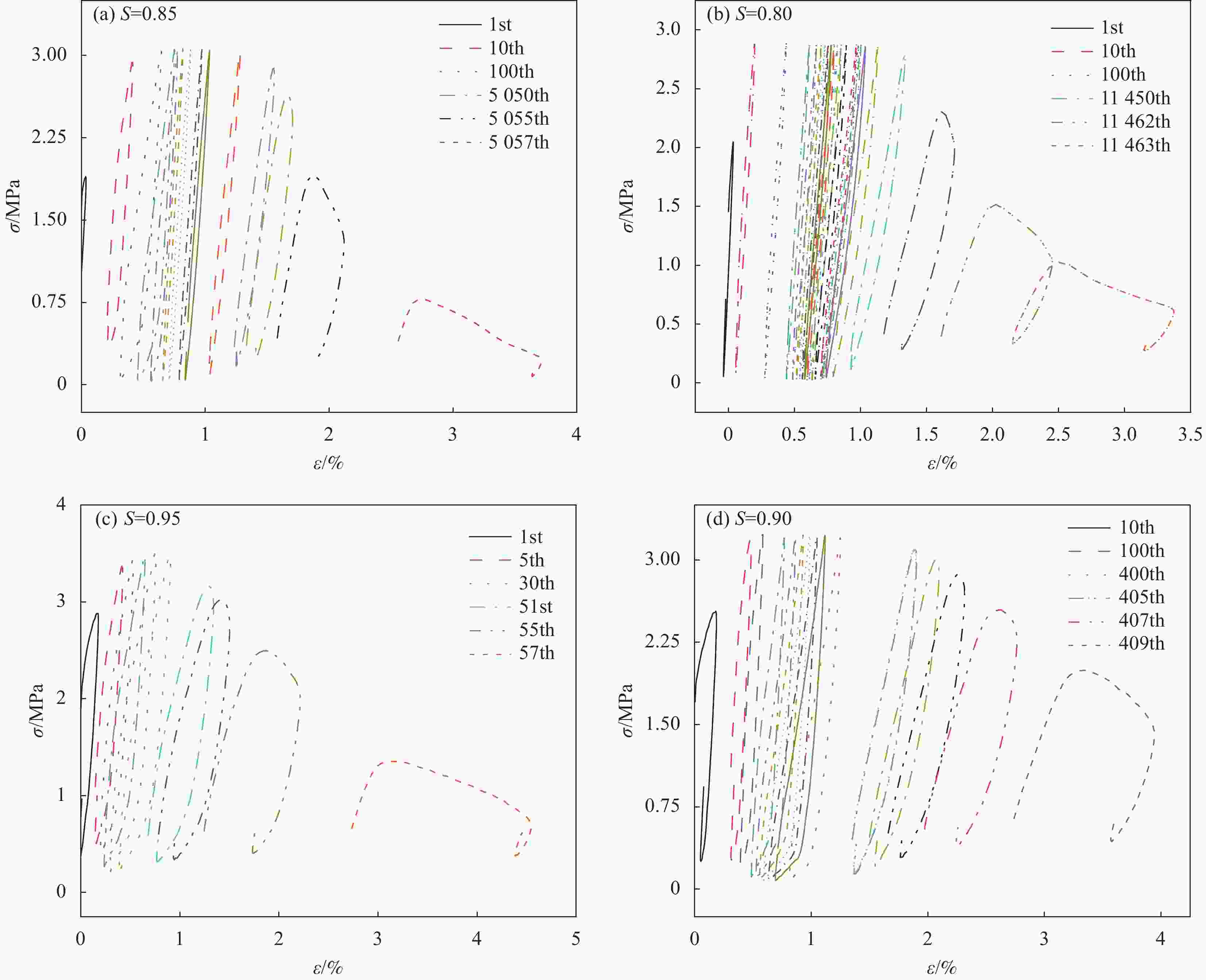

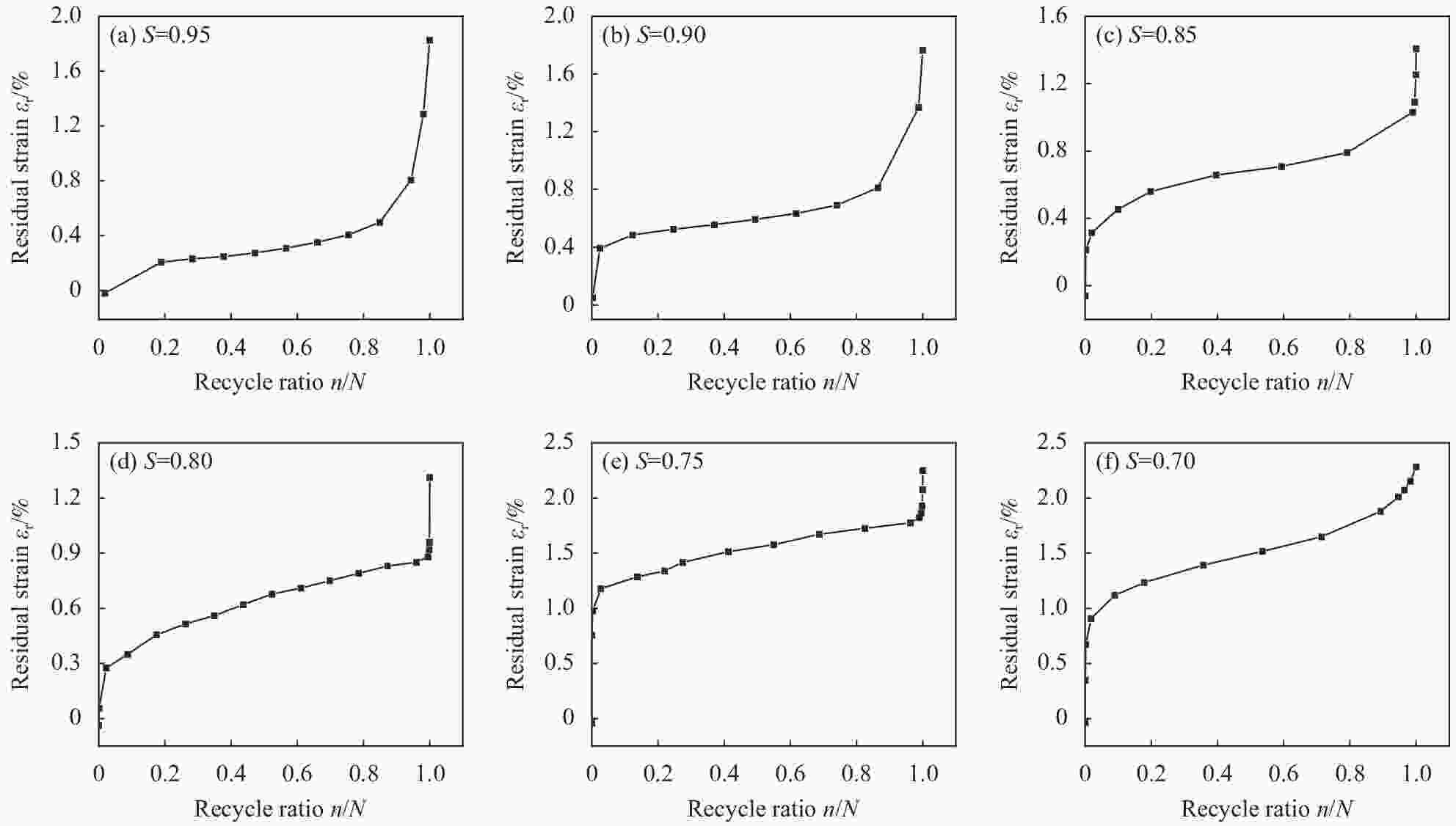

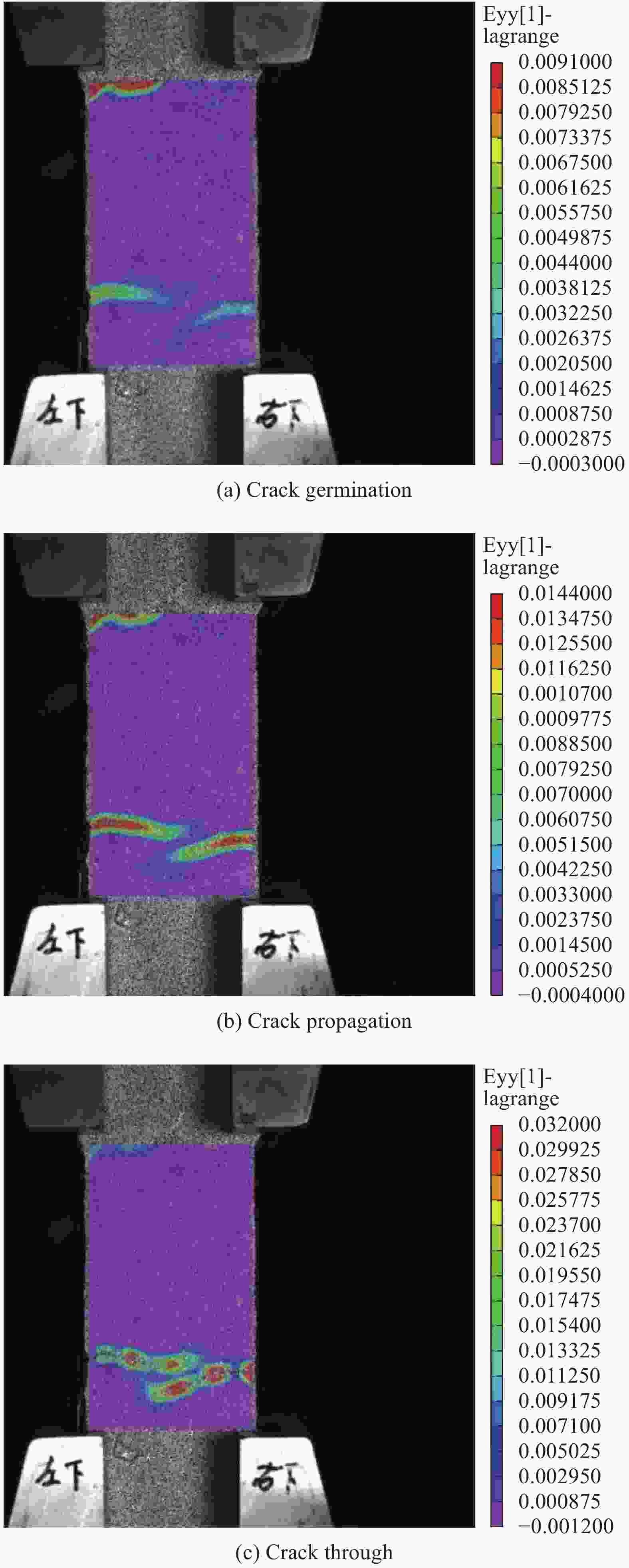

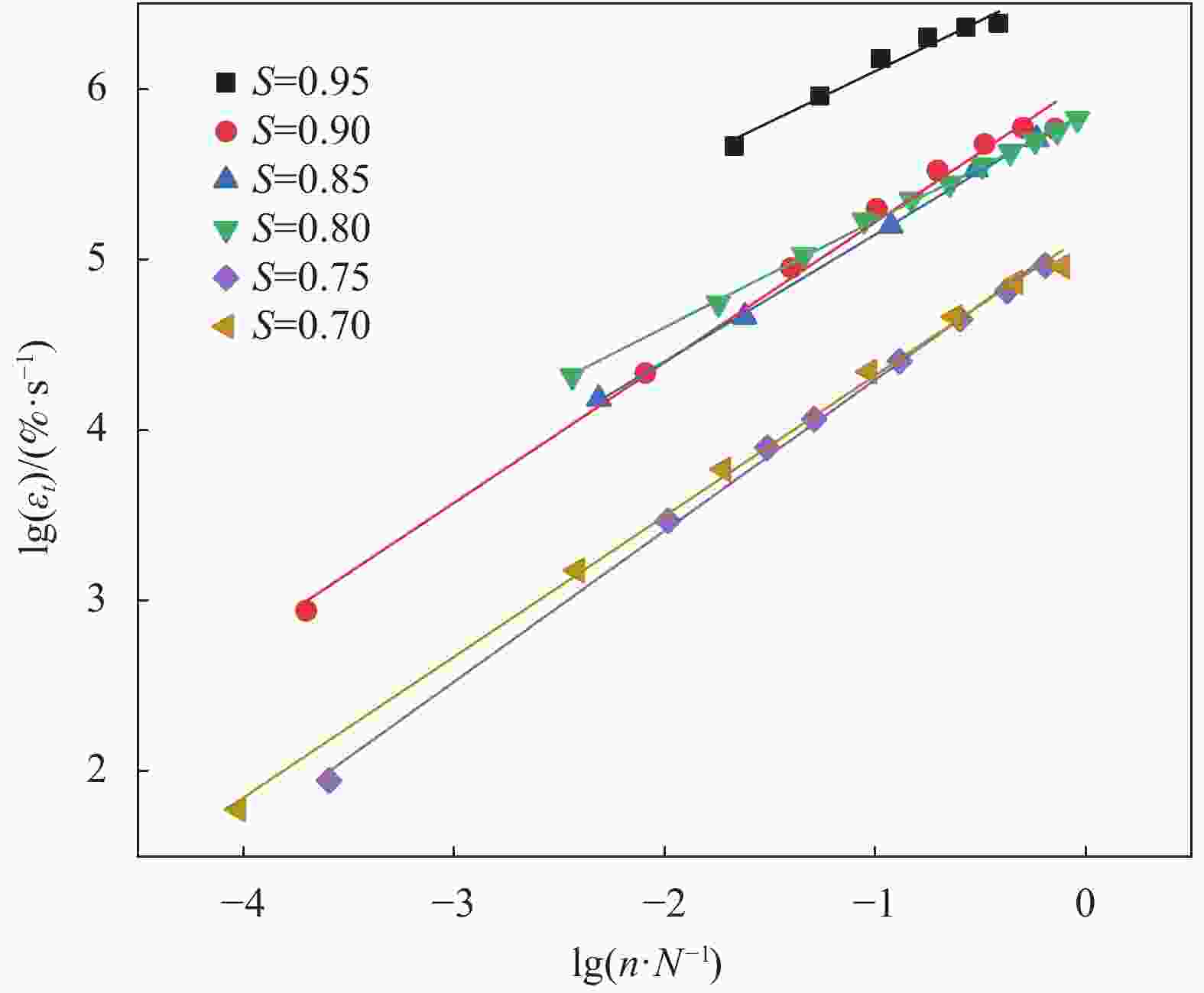

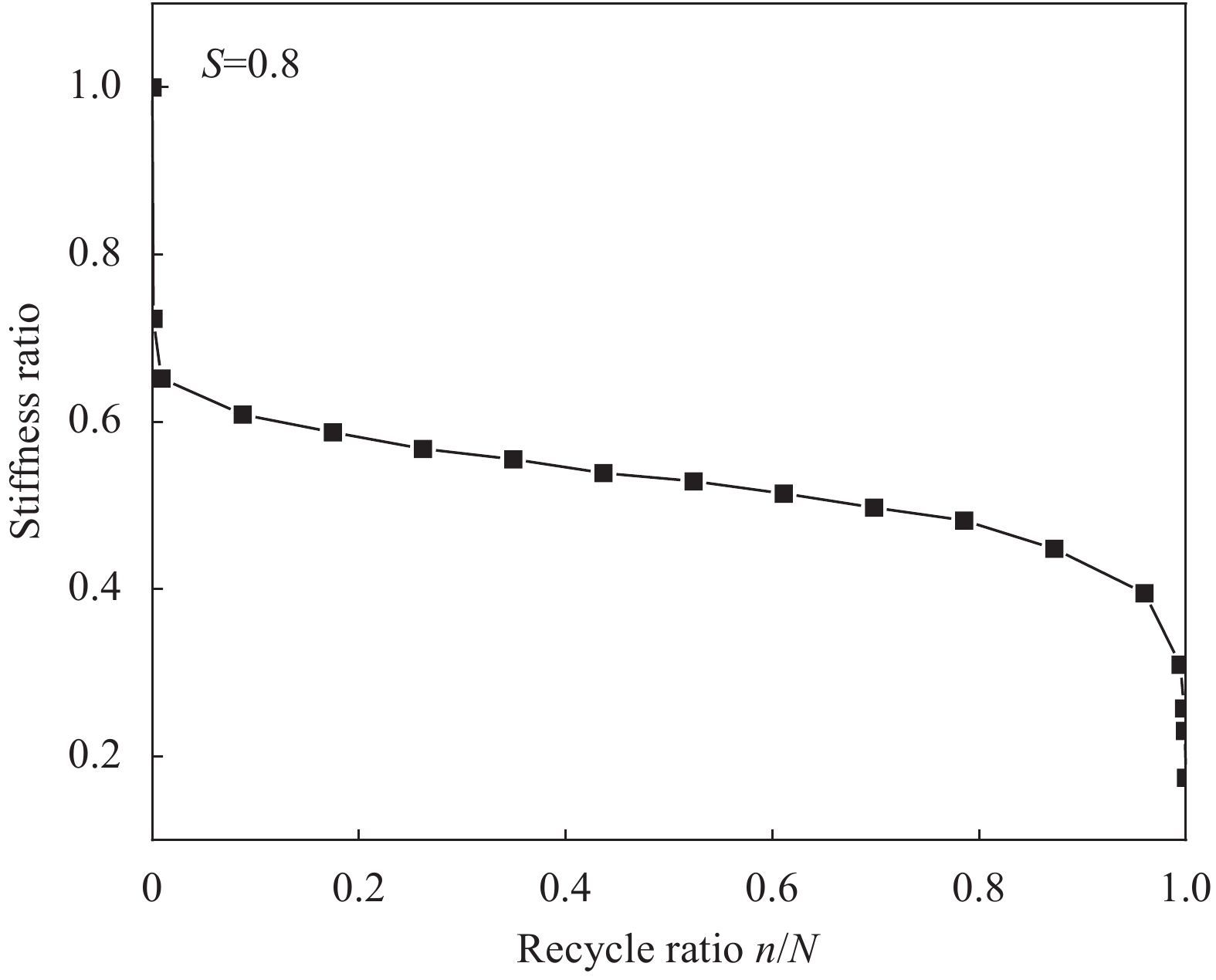

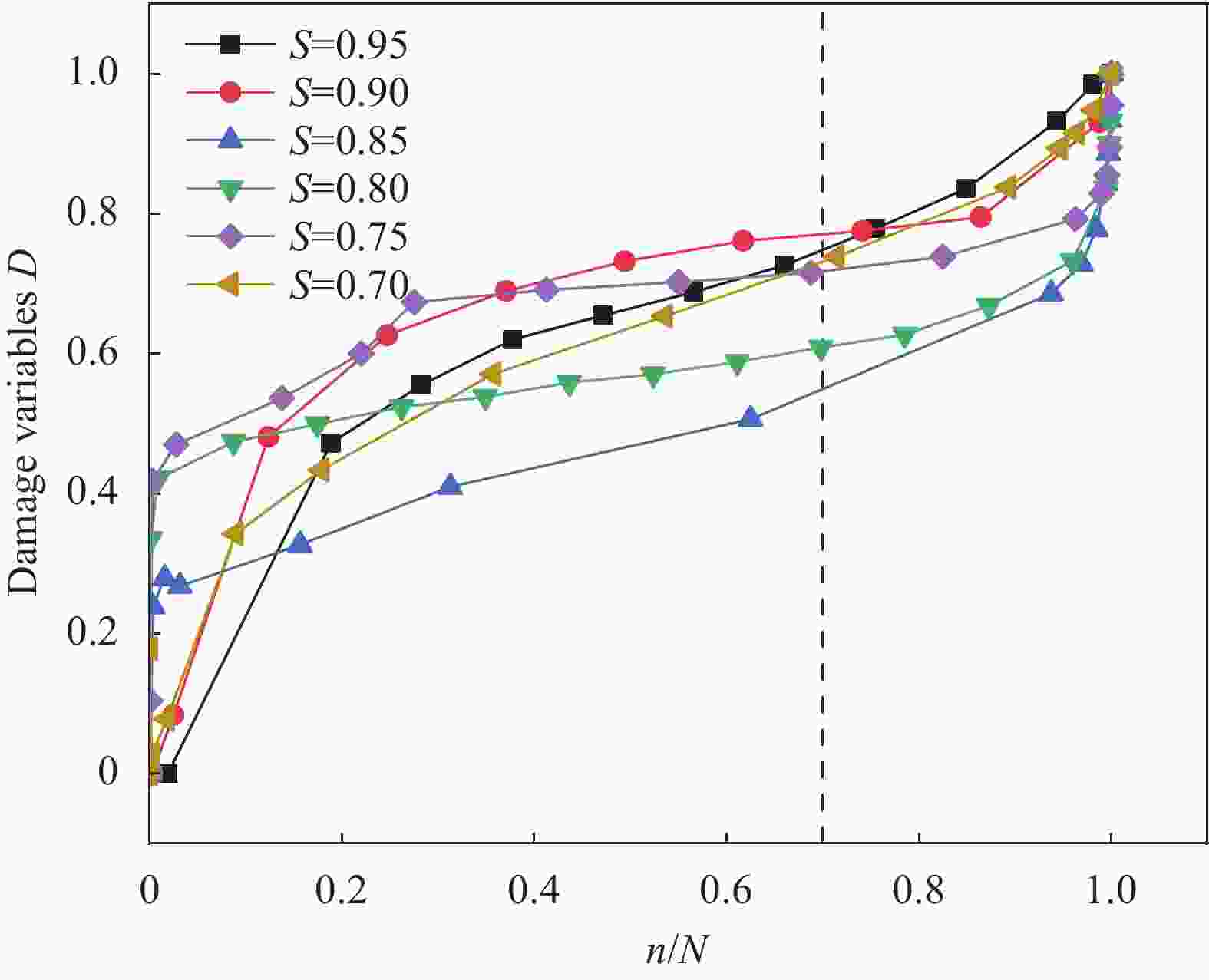

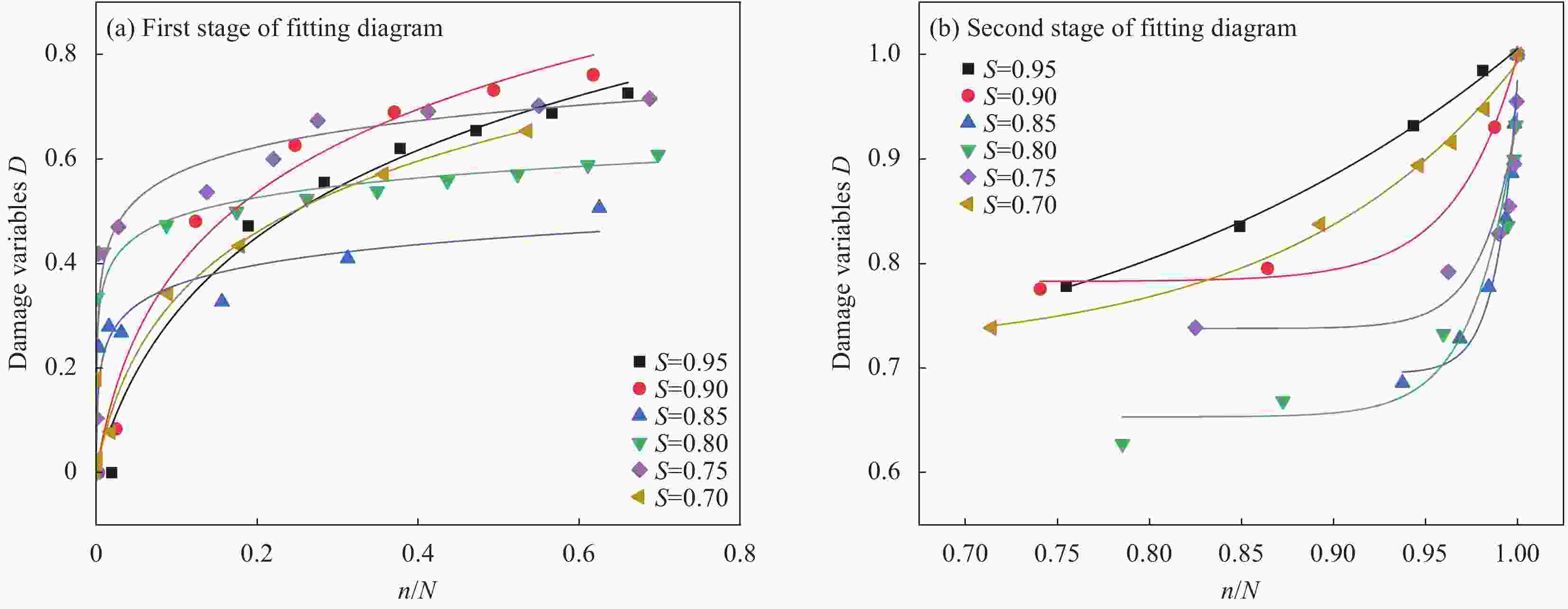

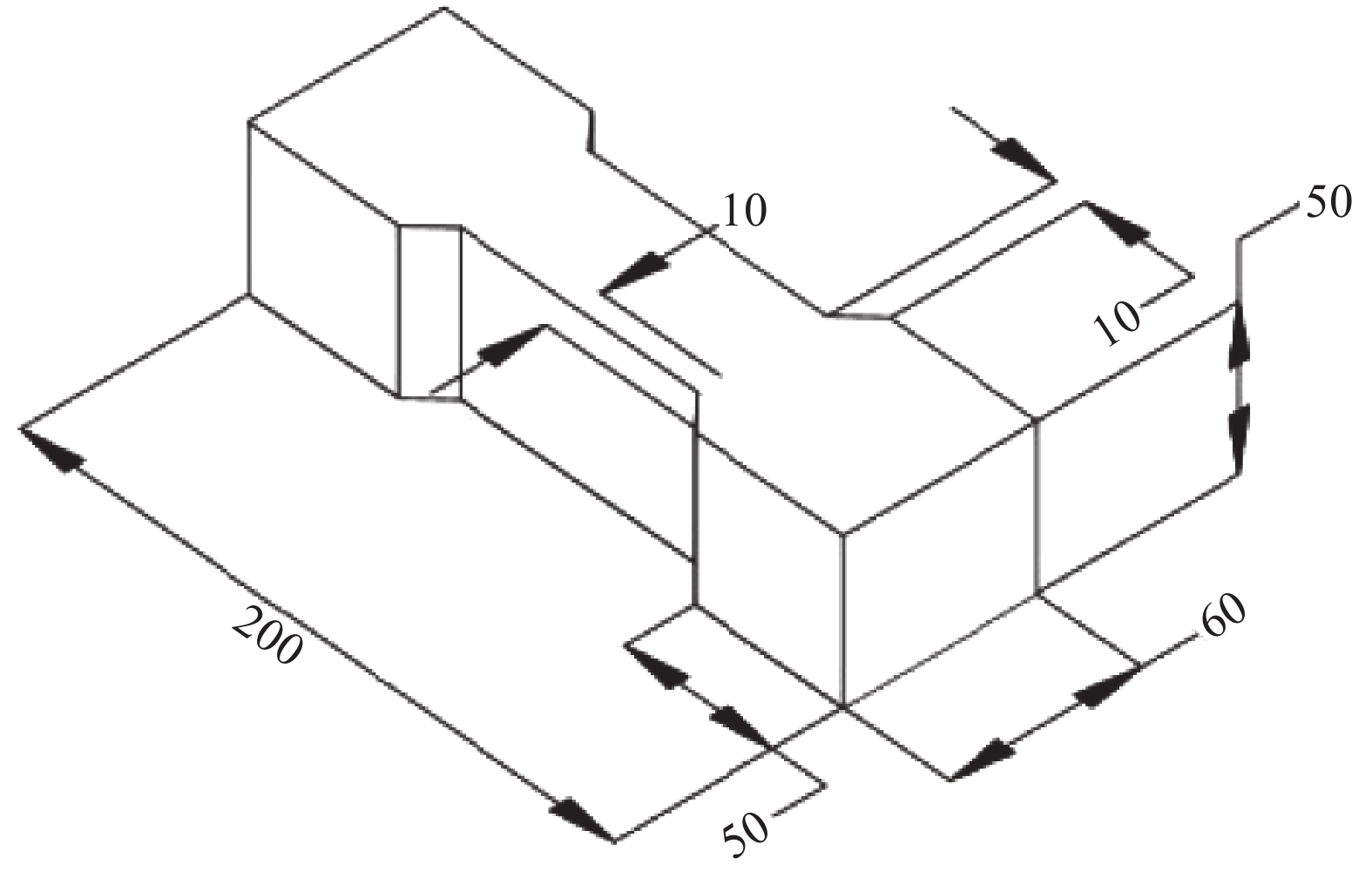

摘要: 工程水泥基复合材料(ECC)多用于结构的抗震补强,其疲劳性能是工程中关注的重点。利用疲劳试验机对ECC试件进行单轴拉伸循环加载试验,分析了动力变形、损伤模型和疲劳寿命的发展规律。结果表明:单向拉伸疲劳荷载下,ECC应力-应变曲线呈疏-密-疏特点;残余应变呈三阶段发展,采用六次多项式进行拟合描述,相关系数基本大于0.9;针对第二阶段定义应变率及应变增长率两个物理量,发现拉应力比越高,应变率越大,第二阶段循环比越短;应变增长率在0.0028~0.0098之间变化,其随着拉应力比的增加而减小。用疲劳变形模量定义损伤变量,建立以循环寿命比n/N=0.7为分界点的两阶段疲劳损伤演变方程。针对应力比S=0.85进行验证,评估疲劳损伤程度并预估剩余寿命,其与试验结果对比相关性较高。Abstract: Engineering cementitious composite (ECC) is widely used in structural seismic strengthening, and its fatigue performance is the focus of engineering. The uniaxial tensile cyclic loading test of ECC specimens was carried out by fatigue testing machine, and the development law of dynamic deformation, damage model and fatigue life was analyzed. The results show that under uniaxial tensile fatigue load, the stress-strain curve of ECC is sparse-dense-sparse. Residual strain develops in three stages and is described by six polynomial fitting. The correlation coefficient is basically greater than 0.9. Two physical quantities, strain rate and strain growth rate, are defined for the second stage. It is found that the higher the tensile stress ratio is, the larger the strain rate is and the shorter the cycle ratio is in the second stage. Strain growth rate varies from 0.0028 to 0.0098 and decreases with the increase of tensile stress ratio. The damage variable is defined by fatigue deformation modulus, and the two-stage fatigue damage evolution equation is established with the cycle life ratio n/N=0.7. The stress ratio

S=0.85 was verified, and the fatigue damage degree of the specimen was evaluated and the remaining life was predicted, which was highly correlated with the test results. -

Key words:

- ECC /

- tensile fatigue /

- fatigue deformation /

- fatigue damage /

- fatigue life predict

-

表 1 聚乙烯醇(PVA)纤维的各项性能指标

Table 1. Various performance indexes of polyvinyl alcohol (PVA) fiber

Length/mm Diameter/μm Length-diameter ratio/103 Tensile strength/MPa Elastic modulus/GPa Elongation/% Density/(g·cm−3) 12 39 0.31 1600 39 17 0.91 表 2 工程水泥基复合材料(ECC)试件配合比(kg/m3)

Table 2. Mix ratio of engineered cementitious composite (ECC) specimens (kg/m3)

Cement Water Sand PVA fiber Fly ash Water-reducing admixture 380 190 190 26 253 10.1 表 3 ECC残余应变拟合六次方程相关参数

Table 3. ECC residual strain fitting six-order equation related parameters

a b c d e f g R2 S=0.95 2.18 −6.15 6.57 −3.27 0.74 −0.05 0 0.993 S=0.90 0.02 0.48 −1.22 1.1 −0.43 0.07 0 0.973 S=0.85 0.91 −2.16 1.67 −0.37 −0.09 0.05 0 0.95 S=0.80 −0.035 0.4 −0.874 0.7654 −0.307 0.05969 0.00043 0.9268 S=0.75 −0.934 3.57 −5.129 3.47 −1.12 0.161 0.0059 0.8468 S=0.70 −1.54 5.23 −6.78 4.20 −1.27 0.18 0 0.950 Notes: S—Stress ratio; a-g—Equation coefficients; R2—Correlation coefficient. 表 4 ECC残余应变拟合双对数方程相关参数

Table 4. Related parameters of ECC residual strain fitting double logarithmic equation

a b R2 S=0.95 0.59 6.7 0.984 S=0.90 0.82 6.04 0.994 S=0.85 0.74 5.89 0.999 S=0.80 0.627 5.892 0.999 S=0.75 0.885 5.18 0.998 S=0.70 0.83 5.15 0.997 表 5 不同应力比下的ECC第二阶段应变增长率

Table 5. The second-stage strain growth rate of ECC under different stress ratios

$ S $ Strain growth rate $ \varepsilon $ 0.95 0.0028 0.90 0.0042 0.85 0.0045 0.80 0.0055 0.75 0.0068 0.70 0.0098 表 6 ECC试验方程拟合参数与相关系数

Table 6. Fitting parameters and correlation coefficients of test equations for ECC

$S$ $ {a}_{1} $ $ {b}_{1} $ $ {c}_{1} $ $ {R}^{2} $ $ {D}_{0.7} $ $ {a}_{2} $ $ {b}_{2} $ $ {R}^{2} $ 0.95 0.28 19.41 −0.11 0.971 0.642 0.01 4.04 0.997 0.90 0.25 37.04 −0.04 0.978 0.783 3.26×10-14 29.52 0.996 0.85 0.06 6145.94 0.19 0.999 0.695 3.64×10-39 87.25 0.977 0.80 0.05 84328.71 0.10 0.903 0.653 4.26×10-20 43.37 0.935 0.75 0.07 25819.68 0.05 0.964 0.738 1.51×10-24 53.26 0.842 0.70 0.21 37.81 0.02 0.925 0.713 8.57×10-5 8.08 0.995 Notes: S—Stress ratio; a1, a2, b1, b2, c1—Equation coefficients; R2—Correlation coefficient. 表 7 ECC残余应变计算与疲劳寿命预测

Table 7. Residual strain calculation and fatigue life prediction of ECC

Cycle index n Residual strain Life prediction 1000 0.005580 4615.5 2 000 0.006567 4614.5 3000 0.007074 6264.4 4000 0.007896 5048.0 表 8 ECC疲劳损伤变量计算与预测

Table 8. Calculation and prediction of fatigue damage variables of ECC

Model calculation n/N D* Test result n/N D n=1 000 0.21667 0.62169 n=1 000 0.1979 0.61626 n=2 000 0.43343 0.66322 n=2 000 0.3958 0.65783 n=3 000 0.47890 0.66926 n=3 000 0.5937 0.68214 n=4 000 0.79239 0.69500 n=4 000 0.7916 0.69500 Notes: D—Damage variables; D*—Prediction of damage variables. 表 9 ECC模型预测结果与试验结果对比

Table 9. Comparison of model prediction results and test results of ECC

Stress level S=0.85 Life prediction/

Test lifeDamage prediction/

Test damagen=1000 0.9133 1.0088 n=2000 0.9132 1.0082 n=3000 1.2396 0.9812 n=4000 0.9990 1.0000 -

[1] LI V C. Steady-state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics,1992,188(11):2246-2264. [2] LI V C. Engineered cementitious composites (ECC)-tailored composites through micromechanical modeling[M]. Montreal: Canadian Society for Civil Engineering, 1998. [3] LI H Y. Experimental study on the fatigue damage of high strength concrete under uniaxial compression[J]. Key Engineering Materials,2014(619):109-115. [4] KIM J, YI C, LEE S J, et al . Flexural fatigue behaviour of concrete under uniaxial and biaxial stress[J]. Magazine of Concrete Research,2013,65(12):757-764. doi: 10.1680/macr.12.00215 [5] KOLASE P K, DESAI A K. Experimental study on monotonic and fatigue behavior of polypropylene fiber-reinforced roller-compacted concrete with fly ash[J]. Road Materials and Pavement Design,2019,20(5):1096-1113. [6] CACHIM P B, FIGUEIRAS J A, PEREIRA P A A. Fatigue behavior of fiber-reinforced concrete in compression[J]. Cement and Concrete Composites,2002,24(2):211-217. doi: 10.1016/S0958-9465(01)00019-1 [7] CHEN X D, BU J W, FAN X Q, et al. Effect of loading frequency and stress level on low cycle fatigue behavior of plain concrete in direct tension[J]. Construction and Building Materials,2017,133(2):367-375. [8] 邓明科, 杨铄, 梁兴文. 高延性混凝土单面加固构造柱约束砖砌体墙抗震性能试验研究[J]. 土木工程学报, 2018, 51(4):10-19.DENG Mingke, YANG Shuo, LIANG Xingwen. Experimental studies on seismic behavior of confined masonry walls strengthened with single HDC layer[J]. China Civil Engineering Journal,2018,51(4):10-19(in Chinese). [9] 邓明科, 张阳玺, 胡红波. 高延性混凝土加固钢筋混凝土柱抗剪承载力计算[J]. 工程力学, 2018, 35(3):159-166. doi: 10.6052/j.issn.1000-4750.2016.11.0888DENG Mingke, ZHANG Yangxi, HU Hongbo. Experimental study and calculation of the shear capacity of RC columns strengthened with high ductile concrete[J]. Engineering Mechanics,2018,35(3):159-166(in Chinese). doi: 10.6052/j.issn.1000-4750.2016.11.0888 [10] 邓明科, 张阳玺, 胡红波. 高延性混凝土加固钢筋混凝土柱抗震性能试验研究[J]. 建筑结构学报, 2017, 38(06):86-94.DENG Mingke, ZHANG Yangxi, HU Hongbo. Experimental study on seismic behavior of reinforced concrete column strengthened with high ductile concrete[J]. Journal of Building Structures,2017,38(06):86-94(in Chinese). [11] 邓明科, 刘华政, 马福栋, 等. 聚乙烯醇纤维改性高延性混凝土双面剪切试验及剪切韧性评价方法[J]. 复合材料学报, 2020, 37(02):461-471.DENG Mingke, LIU Huazheng, MA Fudong, et al. Double shear experiment of highly ductile concrete modified by polyvingl alcohol and shear toughness evaluation method[J]. Acta Materiae Compositae Sinica,2020,37(02):461-471(in Chinese). [12] 邓明科, 成媛, 翁世强, 等. 高温后高延性混凝土的抗压性能及微观结构[J]. 复合材料学报, 2020, 37(4):985-996.DENG Mingke, CHENG Yuan, WENG Shiqiang, et al. Compressive properties and micro-structure of high ductility concrete exposed to elevated temperature[J]. Acta Materiae Compositae Sinica,2020,37(4):985-996(in Chinese). [13] 邓明科, 潘姣姣, 梁兴文. 高延性混凝土与钢筋黏结性能的试验研究[J]. 土木工程学报, 2018, 51(3):19-26+35.DENG Mingke, PAN Jiaojiao, LIANG Xingwen. Experimental study on bond behavior between steel bar and high ductility concrete[J]. China Civil Engineering Journal,2018,51(3):19-26+35(in Chinese). [14] 宋玉普, 吕培印. 混凝土轴心拉-压疲劳性能研究[J]. 建筑结构学报, 2002, 23(4):36-41. doi: 10.3321/j.issn:1000-6869.2002.04.007SONG Yupu, LV Peiyin. Study on the behavior of concrete under axial tension-compression fatigue loading[J]. Journal of Building Structures,2002,23(4):36-41(in Chinese). doi: 10.3321/j.issn:1000-6869.2002.04.007 [15] 余江滔, 许万里, 张远淼. ECC-混凝土黏结界面断裂试验研究[J]. 建筑材料学报, 2015, 18(6):958-963+970. doi: 10.3969/j.issn.1007-9629.2015.06.008YU Jiangtao, XU Wanli, ZHANG Yuanmiao. Experiment study on fracture property of ECC-concrete interface[J]. Journal of Building Materials,2015,18(6):958-963+970(in Chinese). doi: 10.3969/j.issn.1007-9629.2015.06.008 [16] 林建辉, 余江滔, LI Victor C. PVA纤维增强水泥基复合材料热处理后的力学性能[J]. 复合材料学报, 2016, 33(01):116-122.LIN Jianhui, YU Jiangtao, LI Victor C. Mechanical properties of PVA fiber reinforced engineered cementitious composite after thermal treatment[J]. Acta Materiae Compositae Sinica,2016,33(01):116-122(in Chinese). [17] 王玉清, 刘潇, 高元明, 等. 不同纤维掺量下聚乙烯醇纤维增强工程水泥复合材料梁剪切韧性试验[J]. 复合材料学报, 2019, 36(8):1968-1976.WANG Yuqing, LIU Xiao, GAO Yuanming, et al. Experimental study on shear toughness of polyvinyl alcohol fiber reinforced engineered cementitious composite beams with different fiber contents[J]. Acta Materiae Compositae Sinica,2019,36(8):1968-1976(in Chinese). [18] 王玉清, 孙亮, 刘曙光, 等. 不同纤维掺量下聚乙烯醇纤维/水泥复合材料徐变性能试验[J]. 复合材料学报, 2020, 37(01):205-213.WANG Yuqing, SUN Liang, LIU Shuguang, et al. Experimental study on creep performance of polyvinyl alcohol fiber/engineered cementitious composite with different fiber contents[J]. Acta Materiae Compositae Sinica,2020,37(01):205-213(in Chinese). [19] 江佳斐, 隋凯. 纤维网格增强超高韧性水泥复合材料加固混凝土圆柱受压性能试验[J]. 复合材料学报, 2019, 36(08):1957-1967.JIANG Jiafei, SUI Kai. Experimental study of compression performance of concrete cylinder strengthened by textile reinforced engineering cement composites[J]. Acta Materiae Compositae Sinica,2019,36(08):1957-1967(in Chinese). [20] 韦选纯, 汤盛文, 何真, 等. 聚乙烯醇纤维增强钢渣粉-水泥复合材料基本力学性能及微观结构[J]. 复合材料学报, 2019, 36(8):1918-1925.WEI Xuanchun, TANG Shengwen, HE Zhen, et al. Mechanical and microstructural characteristics of polyvinyl alcohol fiber reinforced cementitious composites containing steel slag powder[J]. Acta Materiae Compositae Sinica,2019,36(8):1918-1925(in Chinese). [21] 王振波, 韩硕, 孙鹏, 等. 混杂纤维ECC高温后力学特性与微观结构变化[J]. 华中科技大学学报(自然科学版), 2021, 49(5):74-79.WANG Zhengbo, HAN Shuo, SUN Peng, et al. Mechanical properties of hybrid fiber reinforced engineered cementitious composites under uniaxial compression[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition),2021,49(5):74-79(in Chinese). [22] 崔涛, 何浩祥, 闫维明, 等. ECC与既有混凝土结合面的抗剪性能[J]. 建筑材料学报, 2020, 23(5):1030-1037. doi: 10.3969/j.issn.1007-9629.2020.05.006CUI Tao, HE Haoxiang, YAN Weiming, et al. Shear resistance property of ECC-existing concrete interface[J]. Journal of Building Materials,2020,23(5):1030-1037(in Chinese). doi: 10.3969/j.issn.1007-9629.2020.05.006 [23] 潘金龙, 何佶轩, 王路平, 等. ECC双轴压力学性能及破坏准则试验研究[J]. 工程力学, 2016, 33(6):186-193.PAN Jinlong, HE Jixuan, WANG Luping, et al. Experimental study on mechanical behaviors and failure criterion of engineered cementitious composites under biaxial compression[J]. Engineering Mechanics,2016,33(6):186-193(in Chinese). [24] 朱劲松. 混凝土双轴疲劳试验与破坏预测理论研究[D]. 大连: 大连理工大学, 2003.ZHU Jinsong. Expermental study on fatigue properties of plain concrete under biaxial stress states and theories on failure prediction[D]. Dalian: Dalian University of Technology, 2003 (in Chinese). [25] 刘问, 徐世烺, 李庆华. 等幅疲劳荷载作用下超高韧性水泥基复合材料弯曲疲劳寿命试验研究[J]. 建筑结构学报, 2012, 33(1):119-127.LIU Wen, XU Shilang, LI Qinghua. Study on flexural fatigue life of ultra-high toughness cementitious composites under constant amplitude cyclic loading[J]. Journal of Building Structures,2012,33(1):119-127(in Chinese). [26] 中国建筑材料联合会. 高延性纤维增强水泥基复合材料力学性能试验方法: JC/T 2461—2018[S]. 北京: 中国建材工业出版社, 2018.China Building Material Council. Standard test method for the mechanical properties of the ductile fiber reinforced cementitious composites: JC/T 2461—2018[S]. Beijing: China Building Material Industry Publishing House, 2018(in Chinese). [27] 中国建筑科学研究院. 普通混凝土拌合物性能试验方法标准: GB/T 50081—2016[S]. 北京: 中国建筑工业出版社, 2016.China Academy of Building Research. Standard for test method of performance on ordinary fresh concrete: GB/T 50081—2016[S]. Beijing: China Architecture & Building Press, 2016(in Chinese). [28] 张滨生, 吴科如. 水泥混凝土疲劳破坏的损伤力学分析[J]. 同济大学学报, 1989, 17(1): 59-69.ZHNAG Bingsheng, WU Keru. Damage mechanics analysis of fatigue failure of cement concrete[J]. Journal of Tongji University, 1989, 17(1):59-69(in Chinese). [29] 勒迈特 J. 损伤力学教程[M]. 倪金刚, 陶春虎, 译. 北京: 科学出版社, 1996.LEMAITRE J. Damage mechanics[M]. Translated by NI Jingang, TAO Chunhu. Beijing: Science Press, 1996 (in Chinese). [30] 杨健辉. 侧压下混凝土静态受拉与受拉疲劳性能研究[D]. 大连: 大连理工大学, 2003.YANG Jianhui. Study on static and fatigue behaviors in tension for concrete under lateral pressures[D]. Dalian: Dalian University of Technology, 2003(in Chinese). [31] 林燕清. 混凝土疲劳累积损伤与力学性能劣化研究[D]. 哈尔滨: 哈尔滨工业大学, 1998.LIN Yanqing. Research on accumulative fatigue damage and deterioration of mechanical properties of concrete[D]. Harbin: Harbin Institute of Technology, 1998(in Chinese). -

下载:

下载: