Compressive constitutive model of polyvinyl alcohol fiber/cement composite material in frozen state

-

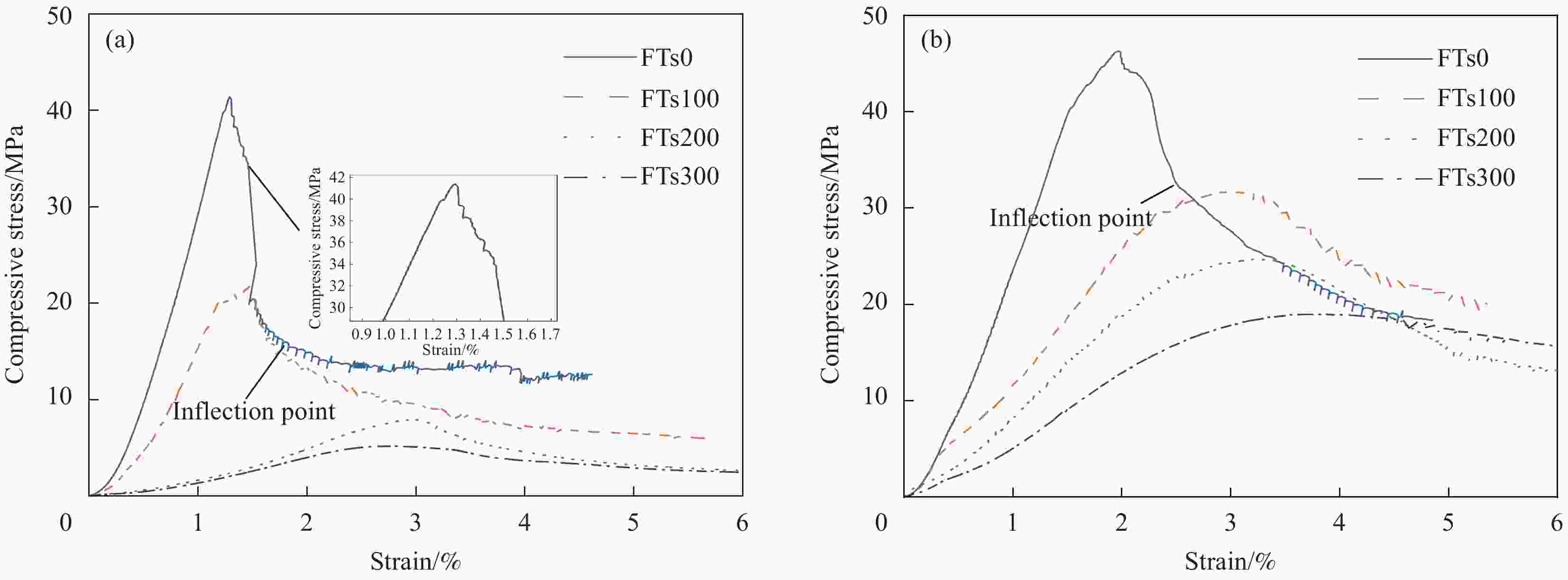

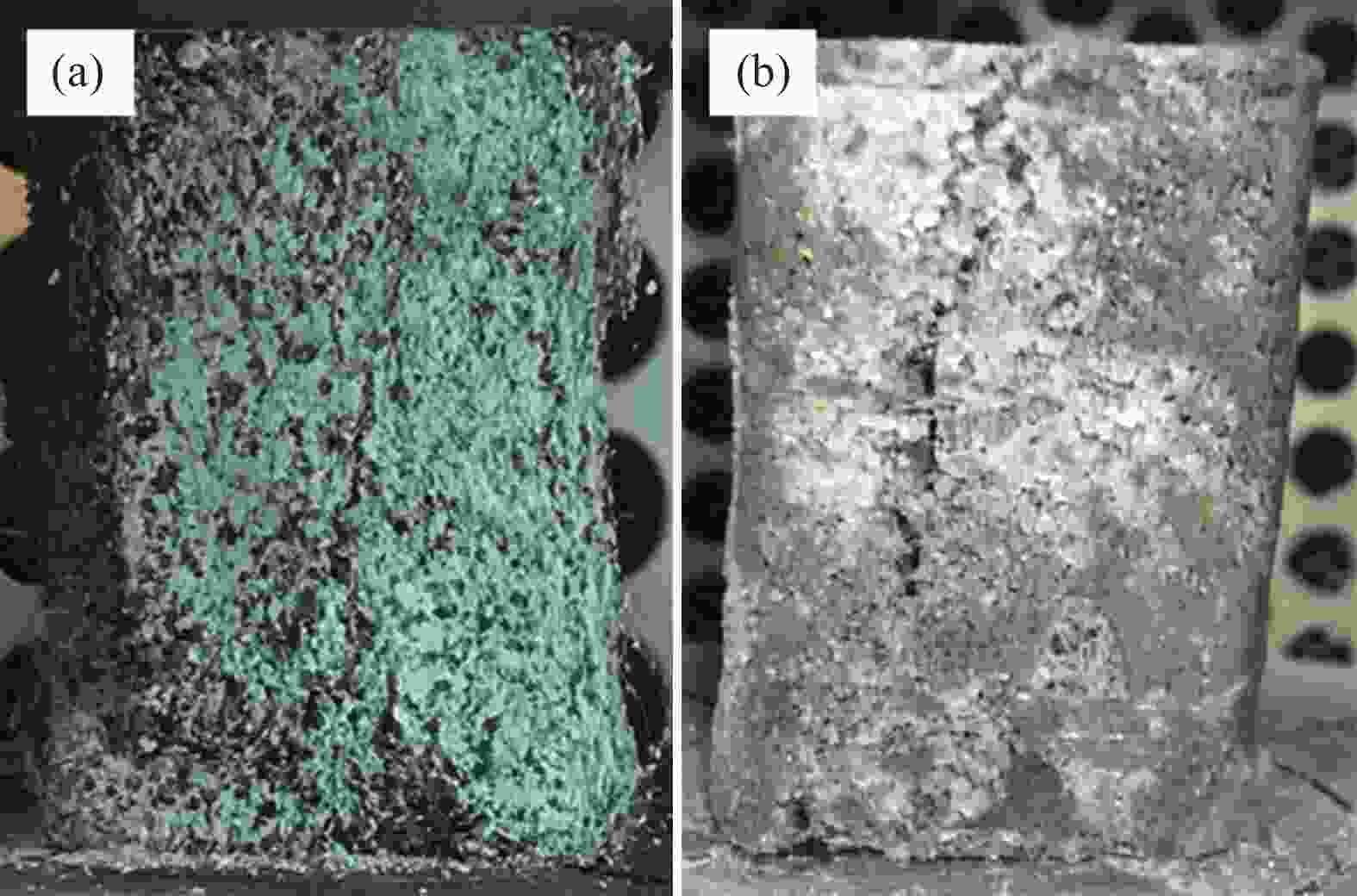

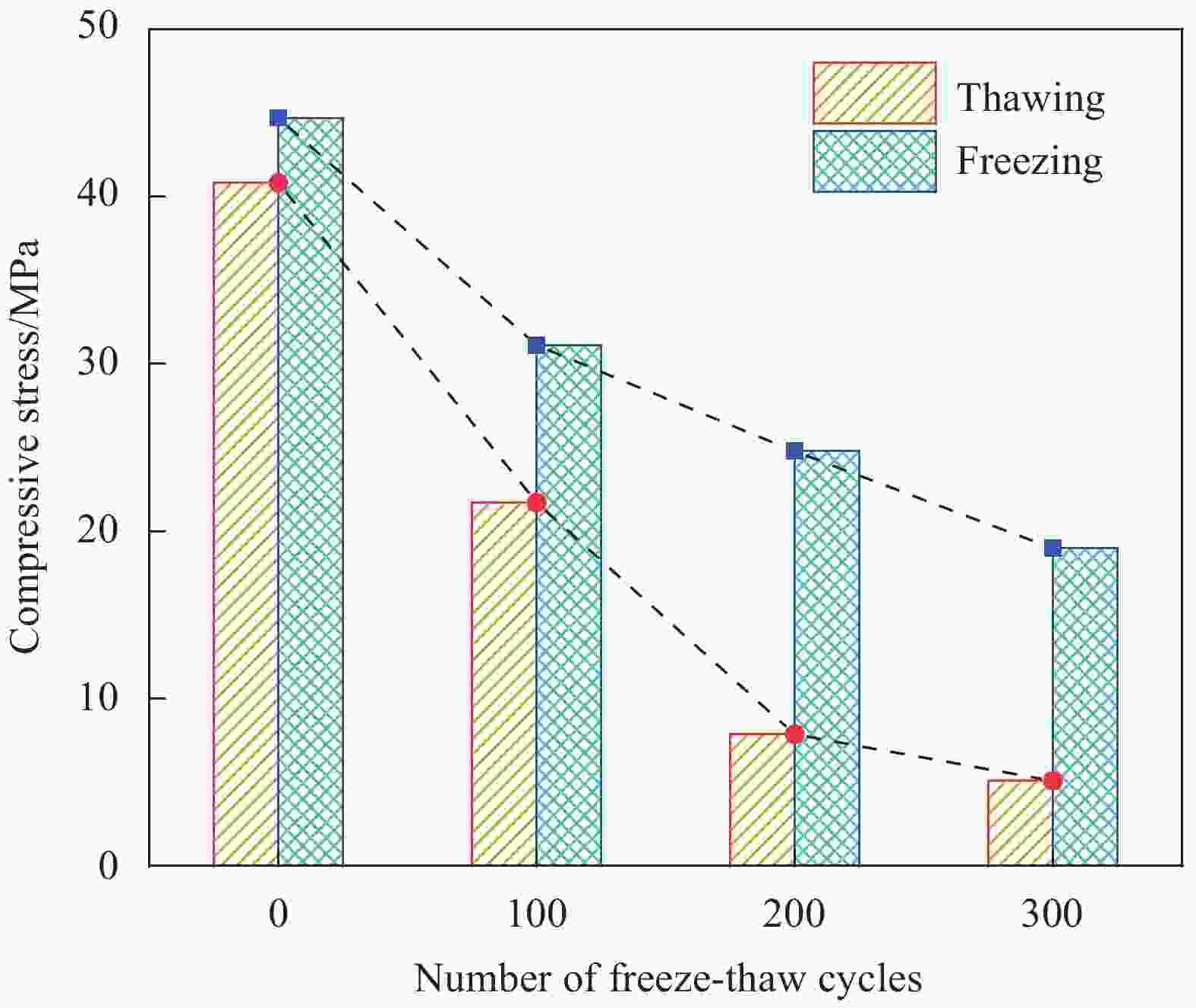

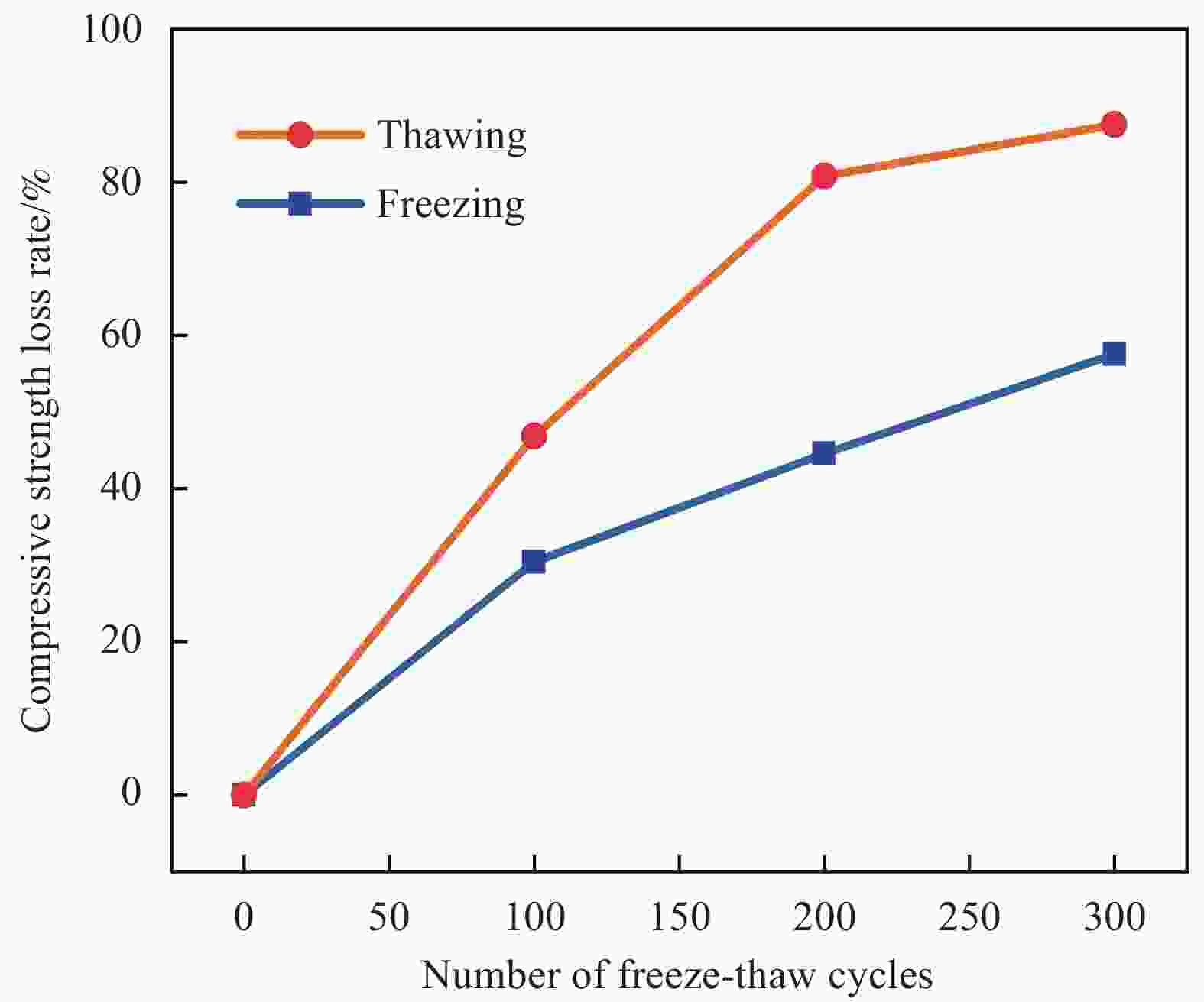

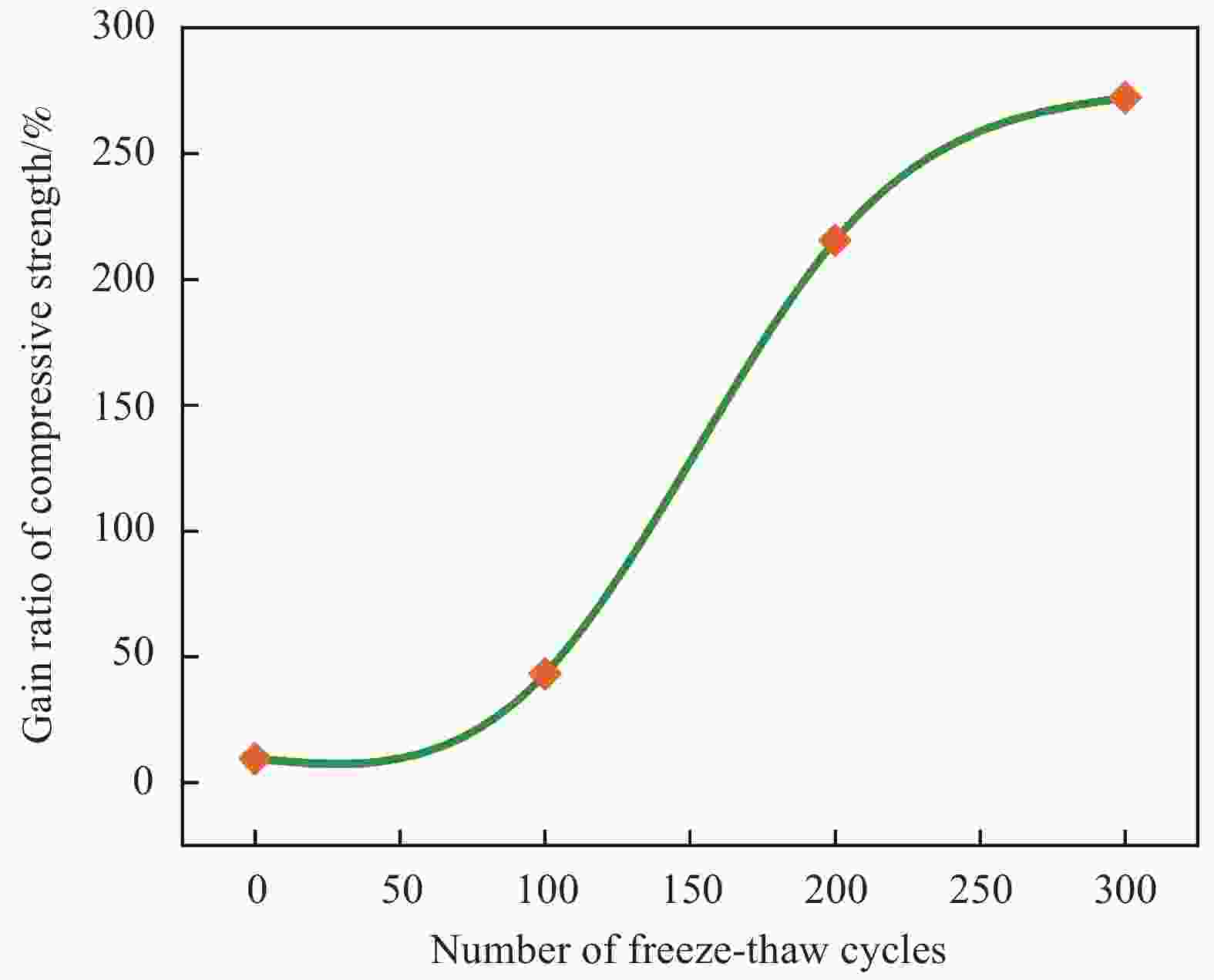

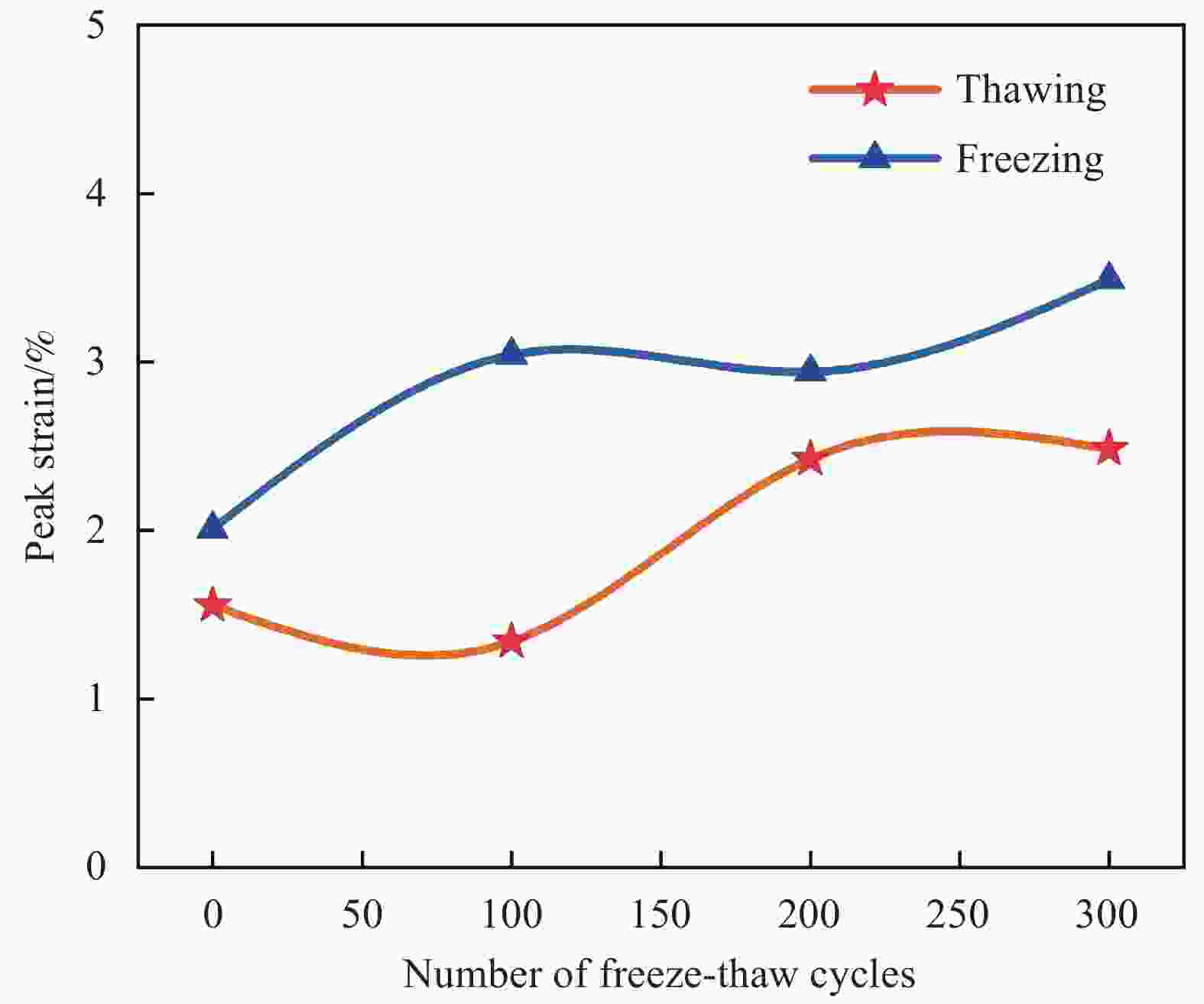

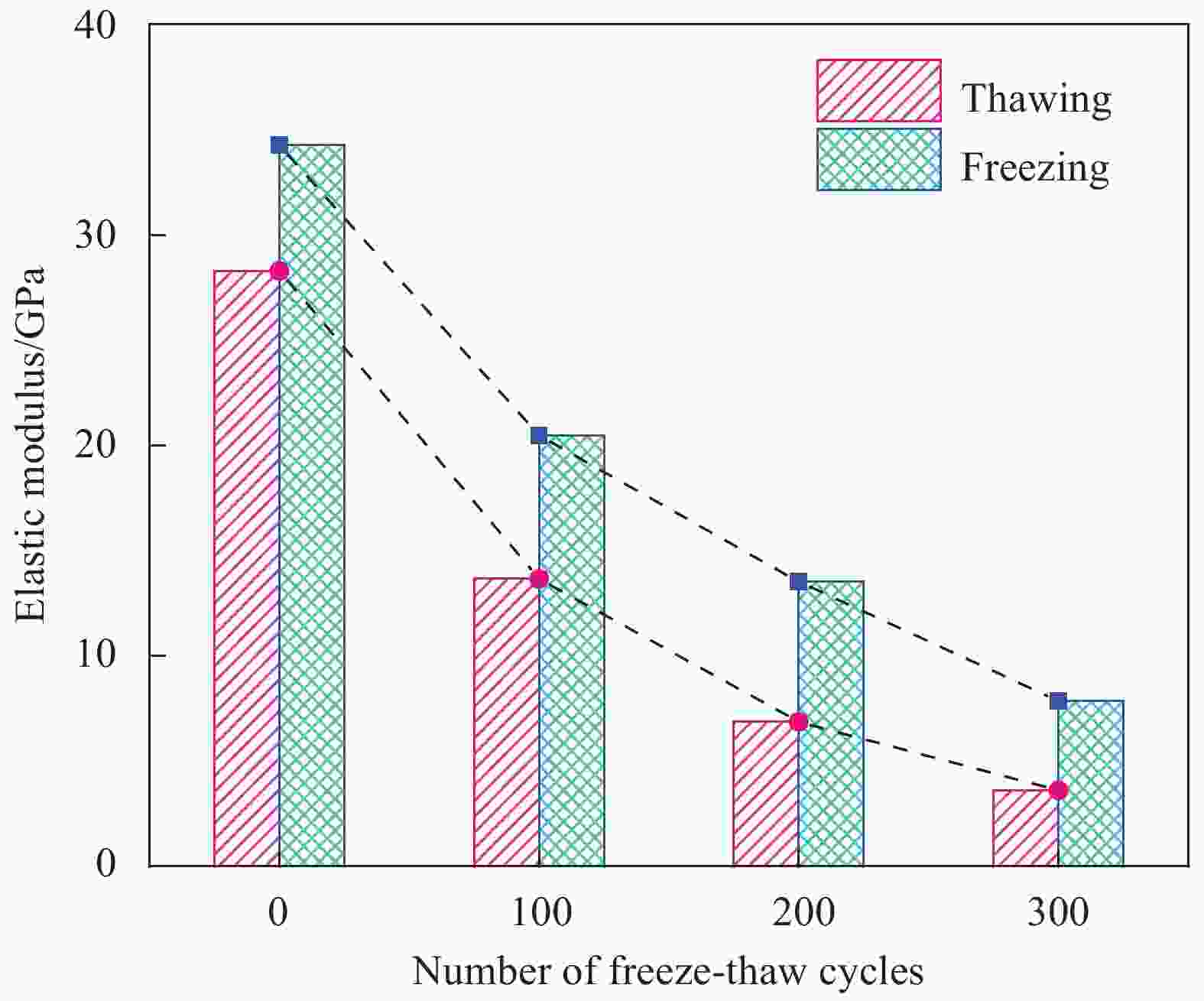

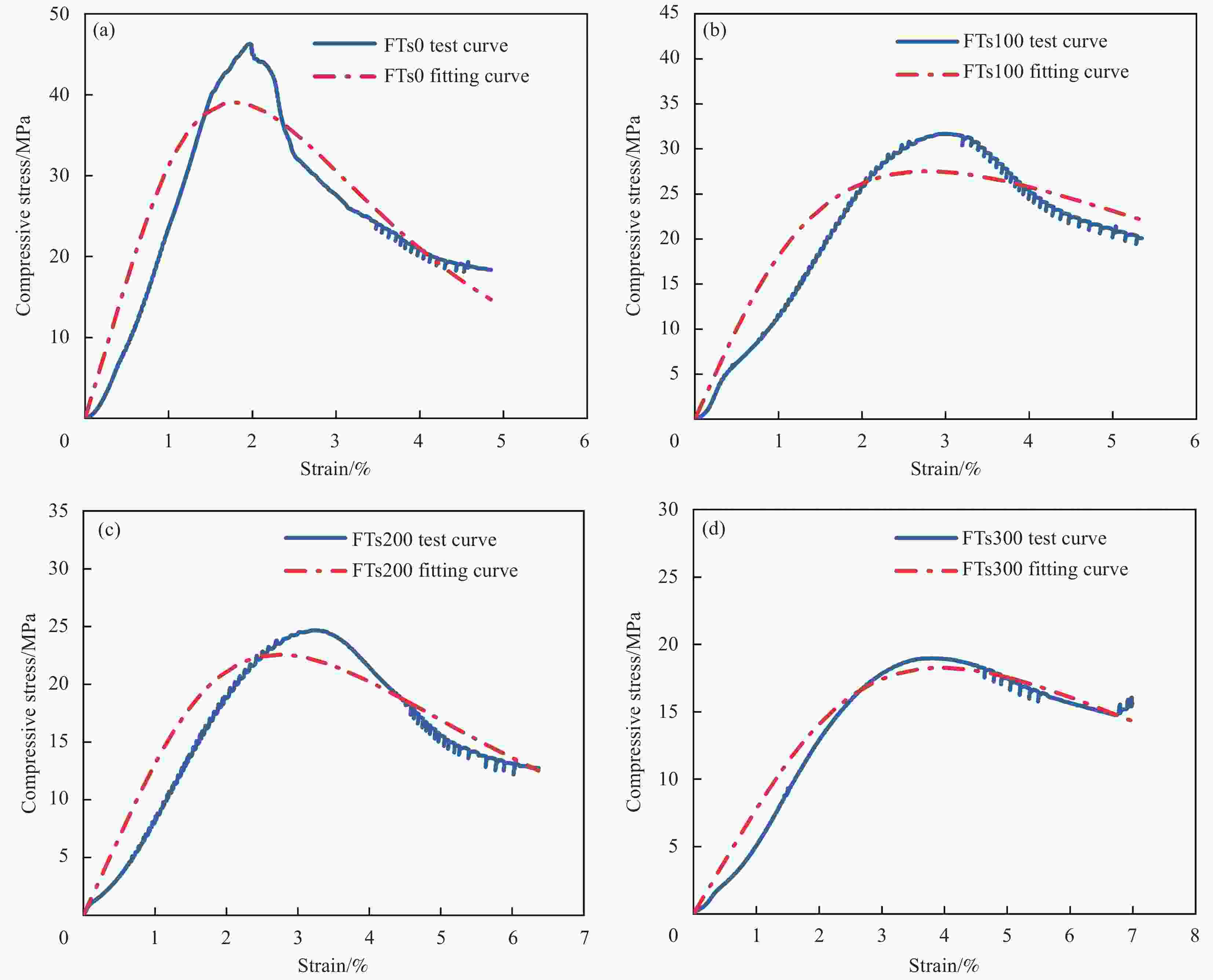

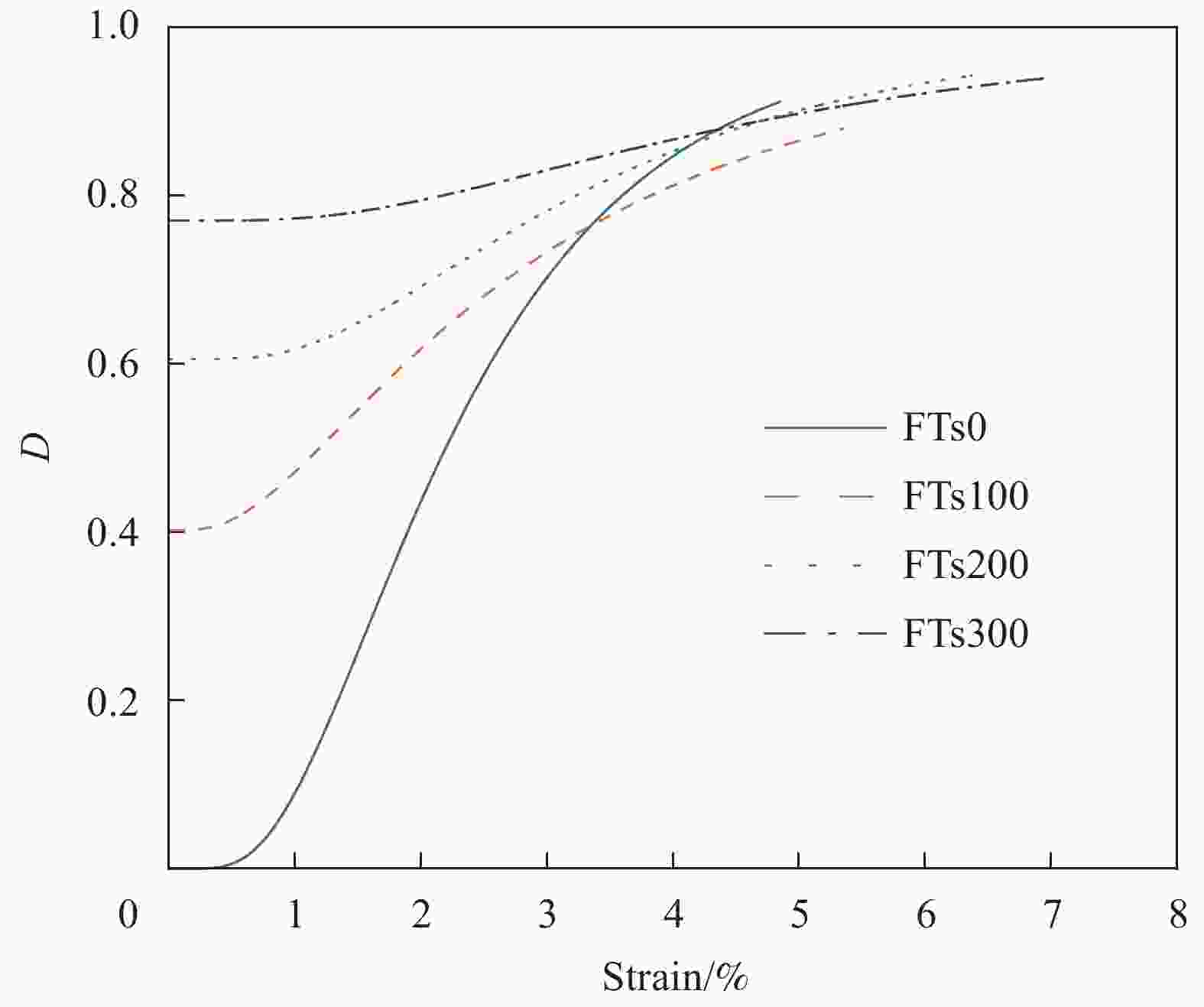

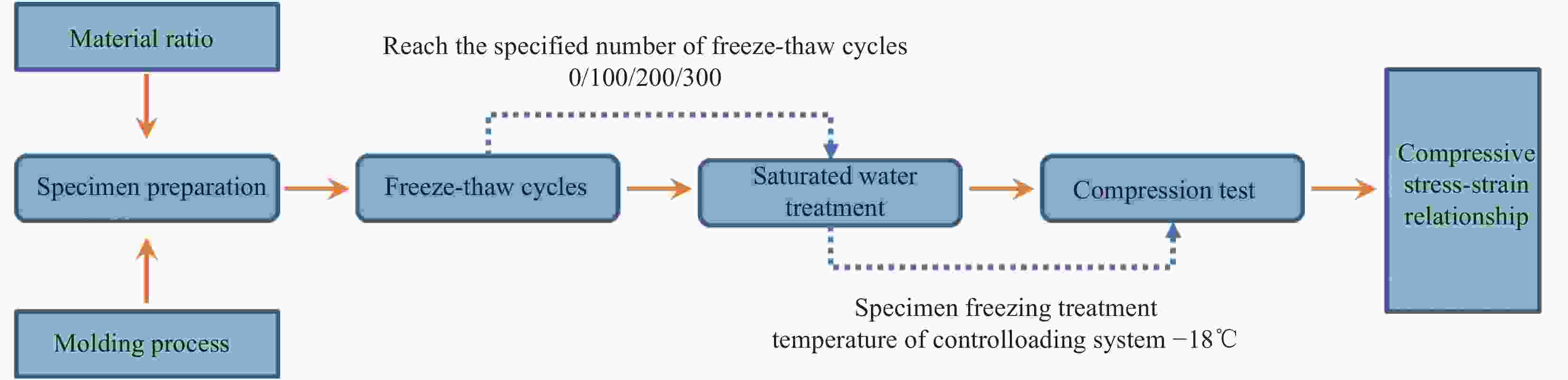

摘要: 为了研究冻融循环后的聚乙烯醇纤维/水泥基复合材料在冻结状态下的抗压服役情况,设计了冻结聚乙烯醇纤维/水泥基复合材料抗压试验,先对试样进行0~300次的冻融循环,冻融循环试验后在−18℃的持续低温环境下对试样进行抗压试验,分析试样的抗压应力-应变关系及影响机制。在此基础上,结合等效应力原理和统计损伤理论,建立了冻结状态聚乙烯醇纤维/水泥基复合材料抗压本构模型,讨论了损伤变量随冻融循环次数的演化特征。结果表明:随着冻融循环次数的增加,冻结状态下聚乙烯醇纤维/水泥基复合材料的抗压峰值强度降低,峰值应变增加,极限破坏时脆性特征显著,高冻融循环次数下试样的弹性模量主要由试样中的孔隙冰来提供。建立的模型可以较好地预测实际经受冻融循环作用后的聚乙烯醇纤维/水泥基复合材料在冻结状态下的抗压应力-应变关系,冻融损伤变量和总损伤变量与冻融次数有显著相关性。

-

关键词:

- 纤维增强水泥基复合材料 /

- 冻融循环 /

- 低温冻结 /

- 单轴压缩 /

- 本构模型

Abstract: In order to study the compressive service of polyvinyl alcohol fiber/cement composites under freezing condition after freeze-thaw cycle, the compressive test of polyvinyl alcohol fiber/cement composites under freezing condition was designed. Firstly, the samples were subjected to 0-300 freeze-thaw cycles, and then the samples were subjected to compressive test at −18℃ under continuous low temperature. The relationship between compressive stress and strain and its influence mechanism were analyzed. On this basis, combined with the principle of equiva-lent stress and statistical damage theory, the compressive constitutive model of polyvinyl alcohol fiber reinforced cement composites in frozen state was established, and the evolution characteristics of damage variable with the number of freeze-thaw cycles were discussed. The results show that: with the increase of freeze-thaw cycles, the peak compressive strength of polyvinyl alcohol fiber/cement composite decreases, the peak strain increases, and the brittleness is obvious at ultimate destruction. The elastic modulus of the sample under high freeze-thaw cycles is mainly provided by the pore ice in the sample. The established model can predict the compressive stress-strain relationship of polyvinyl alcohol fiber reinforced cement composites under freeze-thaw cycles. The freeze-thaw damage variate and total damage variate have significant correlation with freeze-thaw times. -

表 1 聚乙烯醇(PVA)纤维性能指标

Table 1. Performance index of polyvinyl alcohol fiber (PVA) fiber

Tensile strength

/MPaYoung's modulus

/GPaDiameter

/μmLength

/mmElongation

/%1600 40 40 12 6 表 2 PVA/水泥基复合材料(ECC)原材料配合比

Table 2. Mix proportion of raw materials of PVA/engineered cementitious composite (ECC)

Cement/

(kg·m−3)Fly ash/

(kg·m−3)Silica sand/

(kg·m−3)Water/

(kg·m−3)Superplasticizer/

(kg·m−3)mw/mb PVA fiber/

vol%252.64 1010.57 454.76 303.17 17.68 0.24 2.00 Notes: mw—Water consumption; mb—Cementitious material consumption; mw/mb—Water binder ratio. 表 3 PVA/ECC抗压理论模型相关参数

Table 3. Related parameters of PVA/ECC compression theoretical model

Freeze thaw cycles Parameter a Parameter b Related coefficient R2 0 0.58632 0.78675 0.85045 100 0.82549 0.98783 0.84895 200 0.63271 1.18297 0.87027 300 0.66074 1.52024 0.95792 -

[1] TANG S W, YAO Y, ANDRADE C, et al. Recent durability studies on concrete structure[J]. Cement and Concrete Research,2015,78:143-154. doi: 10.1016/j.cemconres.2015.05.021 [2] AÏTCIN P C. The durability characteristics of high perfor-mance concrete: A review[J]. Cement and Concrete Composites,2003,25(45):409-420. [3] ALEXANDER M, BENTUR A, MINDESS S. Durability of concrete: Design and construction[M]. Boca Raton: CRC Press, 2017. [4] LI V C, MISHRA D K, WU H C. Matrix design for pseudo-strain-hardening fibre reinforced cementitious compo-sites[J]. Materials and Structures,1995,28(10):586-595. doi: 10.1007/BF02473191 [5] LI V C. Engineered cementitious composites (ECC): Bendable concrete for sustainable and resilient infrastructure[M]. Berlin: Springer, 2019. [6] ZHANG Z, ZHANG Q. Matrix tailoring of engineered cementitious composites (ECC) with non-oil-coated, low tensile strength PVA fiber[J]. Construction and Building Materials,2018,161:420-431. doi: 10.1016/j.conbuildmat.2017.11.072 [7] PAN Z, WU C, LIU J, et al. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC)[J]. Construction and Building Materials,2015,78:397-404. doi: 10.1016/j.conbuildmat.2014.12.071 [8] MUKTADIR M G, ALAM M I F, RAHMAN A, et al. Compari-son of compressive strength and flexural capacity between engineered cementitious composites (bendable concrete) and conventional concrete used in Bangladesh[J]. Journal of Materials and Engineering Structures,2020,7(1):73-82. [9] PAUL S C, BABAFEMI A J. A review of the mechanical and durability properties of strain hardening cement-based composite (SHCC)[J]. Journal of Sustainable Cement-Based Materials,2018,7(1):57-78. doi: 10.1080/21650373.2017.1394236 [10] GENCTURK B, HOSSEINI F. Evaluation of reinforced concrete and reinforced engineered cementitious composite (ECC) members and structures using small-scale testing[J]. Canadian Journal of Civil Engineering,2015,42(3):164-177. doi: 10.1139/cjce-2013-0445 [11] LEPECH M D, LI V C. Application of ECC for bridge deck link slabs[J]. Materials and Structures,2009,42(9):1185. doi: 10.1617/s11527-009-9544-5 [12] ROKUGO K, KANDA T, YOKOTA H, et al. Applications and recommendations of high performance fiber reinforced cement composites with multiple fine cracking (HPFRCC) in Japan[J]. Materials and Structures,2009,42(9):1197. doi: 10.1617/s11527-009-9541-8 [13] 徐世烺. 浙江大学研发出能弯曲的混凝土[J]. 商品混凝土, 2018(11):14.XU Shilang. Zhejiang University develops bending concrete[J]. Ready-Mixed Concrete,2018(11):14(in Chinese). [14] 国家技术监督局, 中华人民共和国建设部. 建筑气候区划标准: GB 50178—1993[S]. 北京: 计划出版社, 1993.State Bureau of Quality and Technical Supervision, Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for building climate zonin: GB 50178—1993[S]. Beijing: Planning Press, 1993(in Chinese). [15] SMITH P F. Architecture in a climate of change: A guide to sustainable design[M]. Woburn: Architectural Press, 2001. [16] 曾强. 水泥基材料低温结晶过程孔隙力学研究[D]. 北京: 清华大学, 2012.ZENG Qiang. Study on pore mechanics of cementitious materials during low temperature crystallization[D]. Beijing: Tsinghua University, 2012(in Chinese). [17] LUO Q, LIU D X, QIAO P, et al. Microstructural damage characterization of concrete under freeze-thaw action[J]. International Journal of Damage Mechanics,2018,27(10):1551-1568. doi: 10.1177/1056789517736573 [18] ŞAHMARAN M, LACHEMI M, LI V C. Assessing the durabi-lity of engineered cementitious composites under freezing and thawing cycles[J]. Journal of ASTM International,2009,6(7):1-13. [19] YUN H D, ROKUGO K. Freeze-thaw influence on the flexural properties of ductile fiber-reinforced cementitious composites (DFRCCs) for durable infrastructures[J]. Cold Regions Science and Technology,2012,78:82-88. doi: 10.1016/j.coldregions.2012.02.002 [20] XU S, CAI X. Mechanics behavior of ultra high toughness cementitious composites after freezing and thawing[J]. Journal of Wuhan University of Technology-Materials Science Edition,2010,25(3):509-514. doi: 10.1007/s11595-010-0033-z [21] 龙广成, 杨振雄, 白朝能, 等. 荷载-冻融耦合作用下充填层自密实混凝土的耐久性及损伤模型[J]. 硅酸盐学报, 2019, 47(7):855-864.LONG G C, YANG Zhenxiong, BAI Chaoneng, et al. Durability and damage constitutive model of filling layer self-compacting concrete subjected to coupling action of freeze-thaw cycles and load[J]. Journal of the Chinese Ceramic Society,2019,47(7):855-864(in Chinese). [22] 龙广成, 刘赫, 马昆林, 等. 考虑冻融作用的混凝土单轴压缩损伤本构模型[J]. 中南大学学报(自然科学版), 2018, 49(8):1884-1892.LONG Guangcheng, LIU He, MA Kunlin, et al. Uniaxial compression damage constitutive model of concrete subjected to freezing and thawing[J]. Journal of Central South University (Science and Technology),2018,49(8):1884-1892(in Chinese). [23] 苏骏, 钱维民, 郭锋, 等. 超低温对高韧性水泥基复合材料抗压韧性影响试验研究[J]. 复合材料学报, 2021, 38(12):4325-4336.SU Jun, QIAN Weimin, GUO Feng, et al. Experimental study on the influence of ultra-low temperature on compressive toughness of high toughness ultra high toughness cementitious composites[J]. Acta Materiae Compositae Sinica,2021,38(12):4325-4336(in Chinese). [24] 过震文, 刘小方, 段昕智, 等. 超高性能混凝土在环境温度变化下的力学性能试验研究[J]. 复合材料学报, 2021, 38(10):3495-3503.GUO Zhenwen, LIU Xiaofang, DUAN Xinzhi, et al. Experiment study on mechanical properties of ultra high perfor-mance concrete under ambient temperature change[J]. Acta Materiae Compositae Sinica,2021,38(10):3495-3503(in Chinese). [25] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of long-term performance and durability of ordinary concrete: GB/T 50082—2009[S]. Beijing: China Architecture Publishing & Media Co., Ltd., 2009(in Chinese). [26] 中华人民共和国工业和信息化部. 高延性纤维增强水泥基复合材料力学性能试验方法: JC/T 2461—2018[S]. 北京: 中国建材工业出版社, 2018.Ministry of Industry and Information Technology of the People's Republic of China. Test method for mechanical properties of high ductility fiber reinforced cement based composites: JC/T 2461—2018[S]. Beijing: China Building Materials Press, 2018(in Chinese). [27] ROKUGO K, KANDA T, YOKOTA H, et al. Applications and recommendations of high performance fiber reinforced cement composites with multiple fine cracking (HPFRCC) in Japan[J]. Materials and Structures, 2009, 42(9): 1197. [28] LEMAITRE J. How to use damage mechanics[J]. Nuclear Engineering and Design,1984,80(2):233-245. doi: 10.1016/0029-5493(84)90169-9 [29] 余寿文. 损伤力学[M]. 北京: 清华大学出版社, 1997: 26-32.YU Shouwen. Damage mechanics[M]. Beijing: Tsinghua University Press, 1997: 26-32(in Chinese). [30] 段安. 受冻融混凝土本构关系研究和冻融过程数值模拟[D]. 北京: 清华大学, 2009.DUAN An. Research on constitutive relationship of frozen-thawed concrete and mathematical modeling of freeze-thaw process[D]. Beijing: Tsinghua University, 2009(in Chinese). [31] 袁小清, 刘红岩, 刘京平. 冻融荷载耦合作用下节理岩体损伤本构模型[J]. 岩石力学与工程学报, 2015, 34(8):1602-1611.YUAN Xiaoqing, LIU Hongyan, LIU Jingping. A damage model of jointed rock under coupled action of freezing and thawing[J]. Chinese Journal of Rock Mechanics,2015,34(8):1602-1611(in Chinese). -

下载:

下载: