Research on thermal conductivity and insulation of oriented silicon carbide whisker silicone rubber composites

-

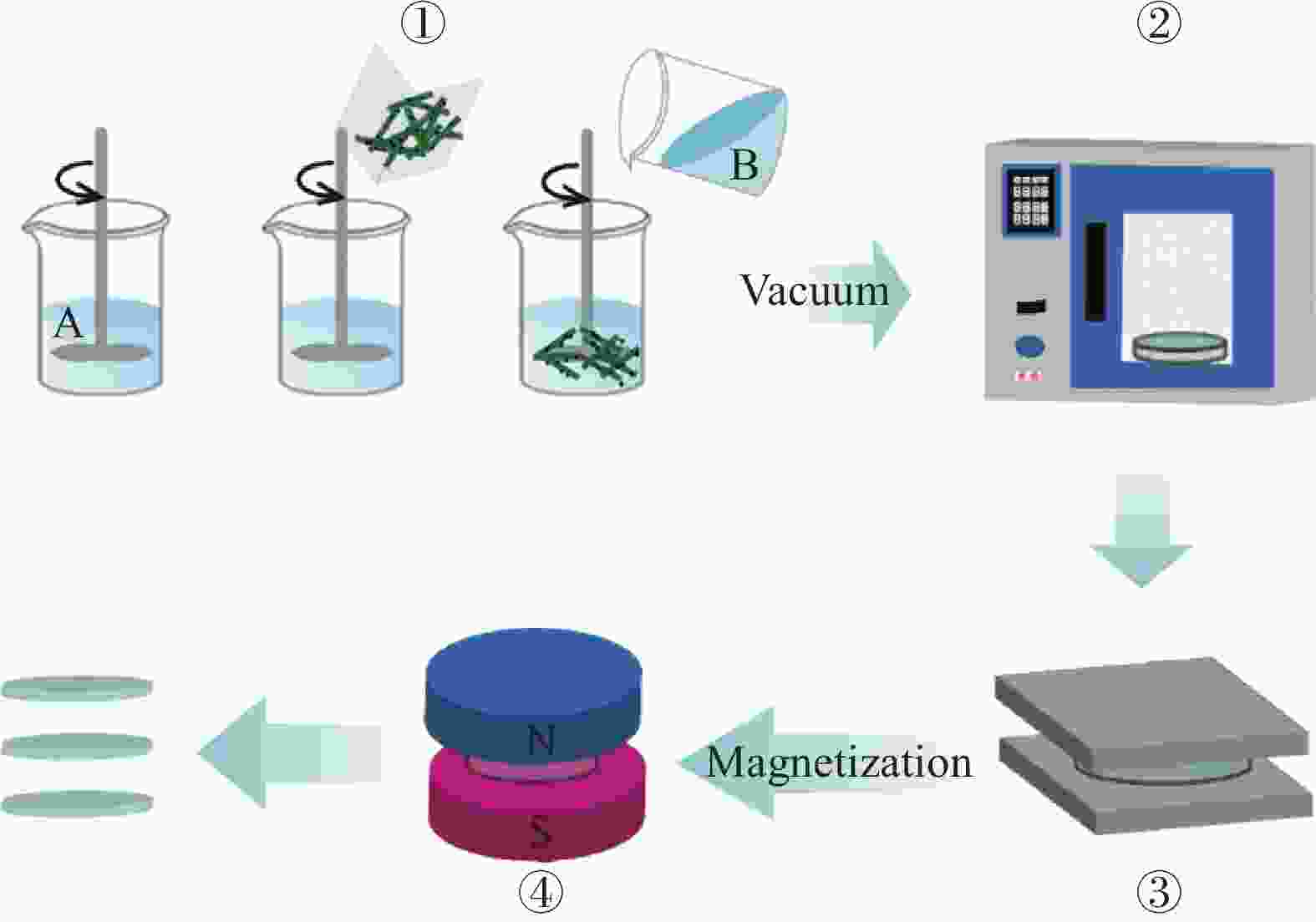

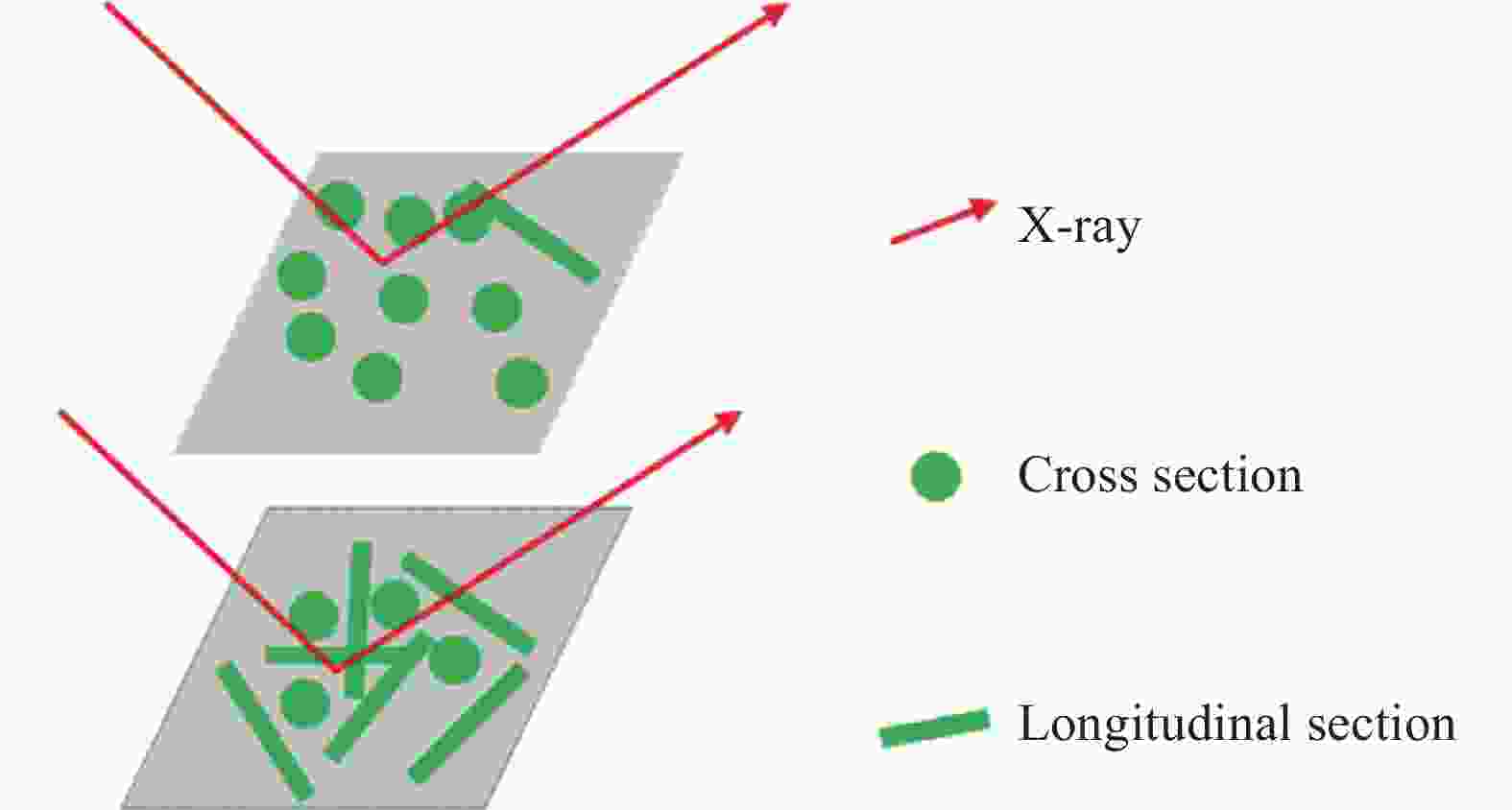

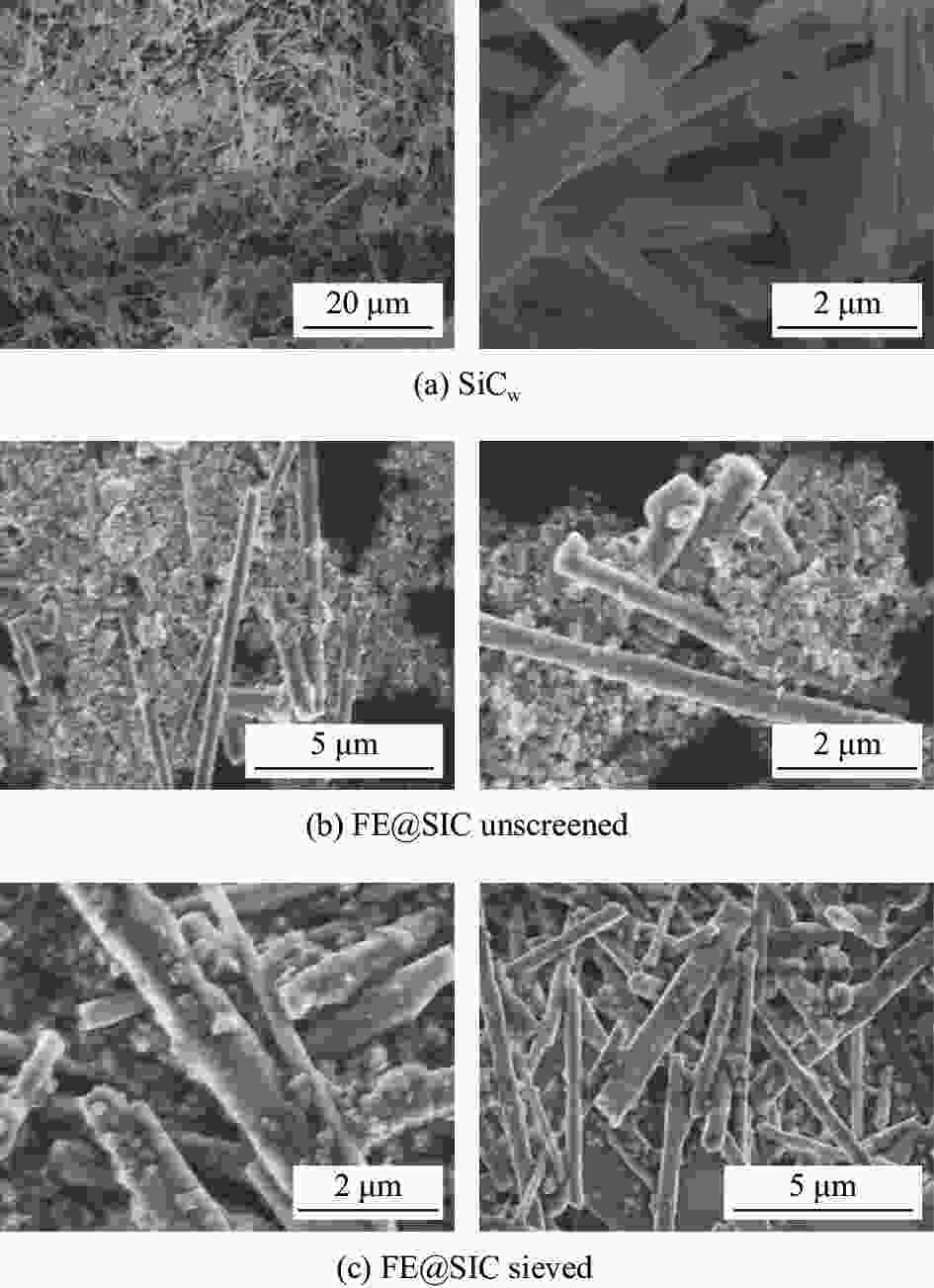

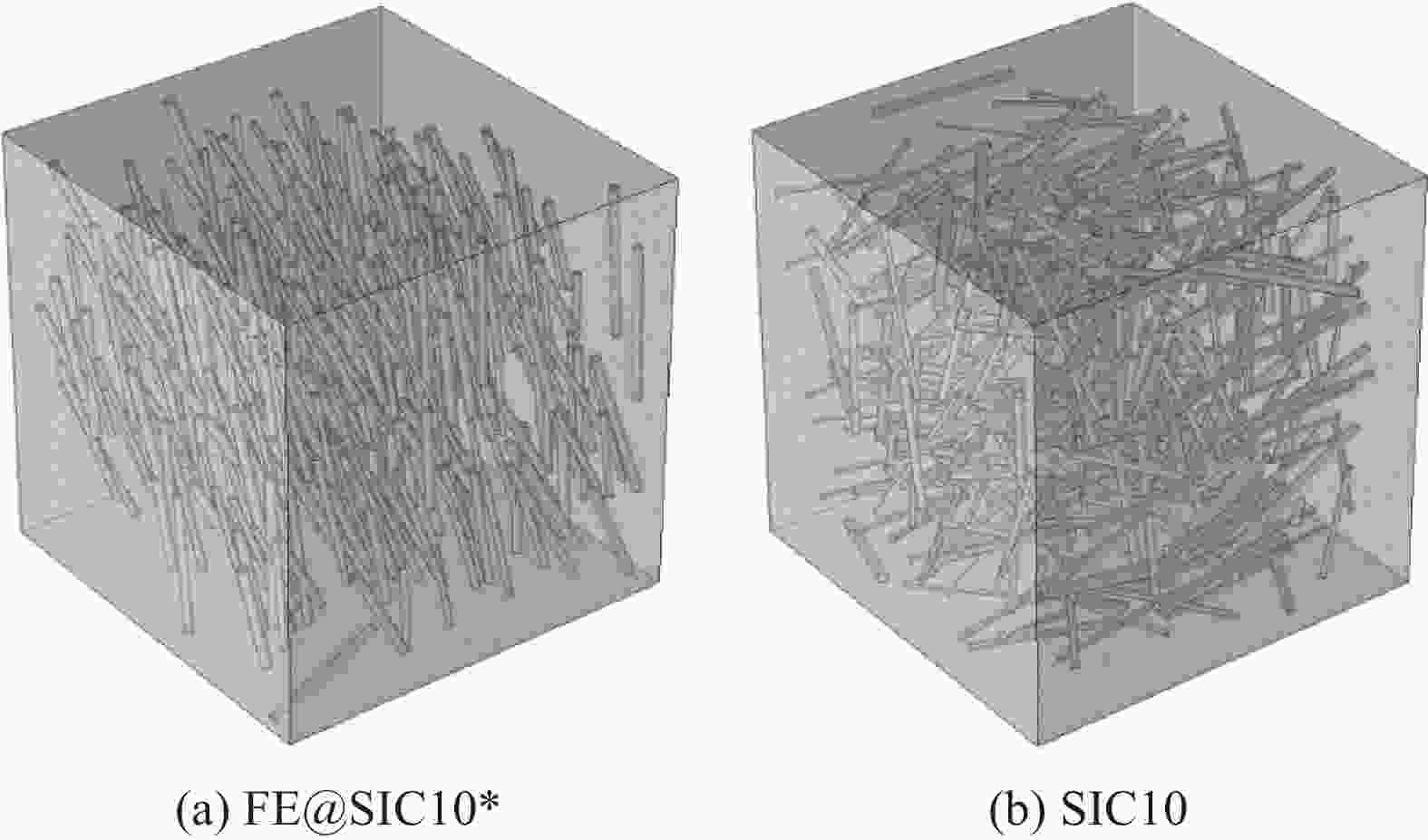

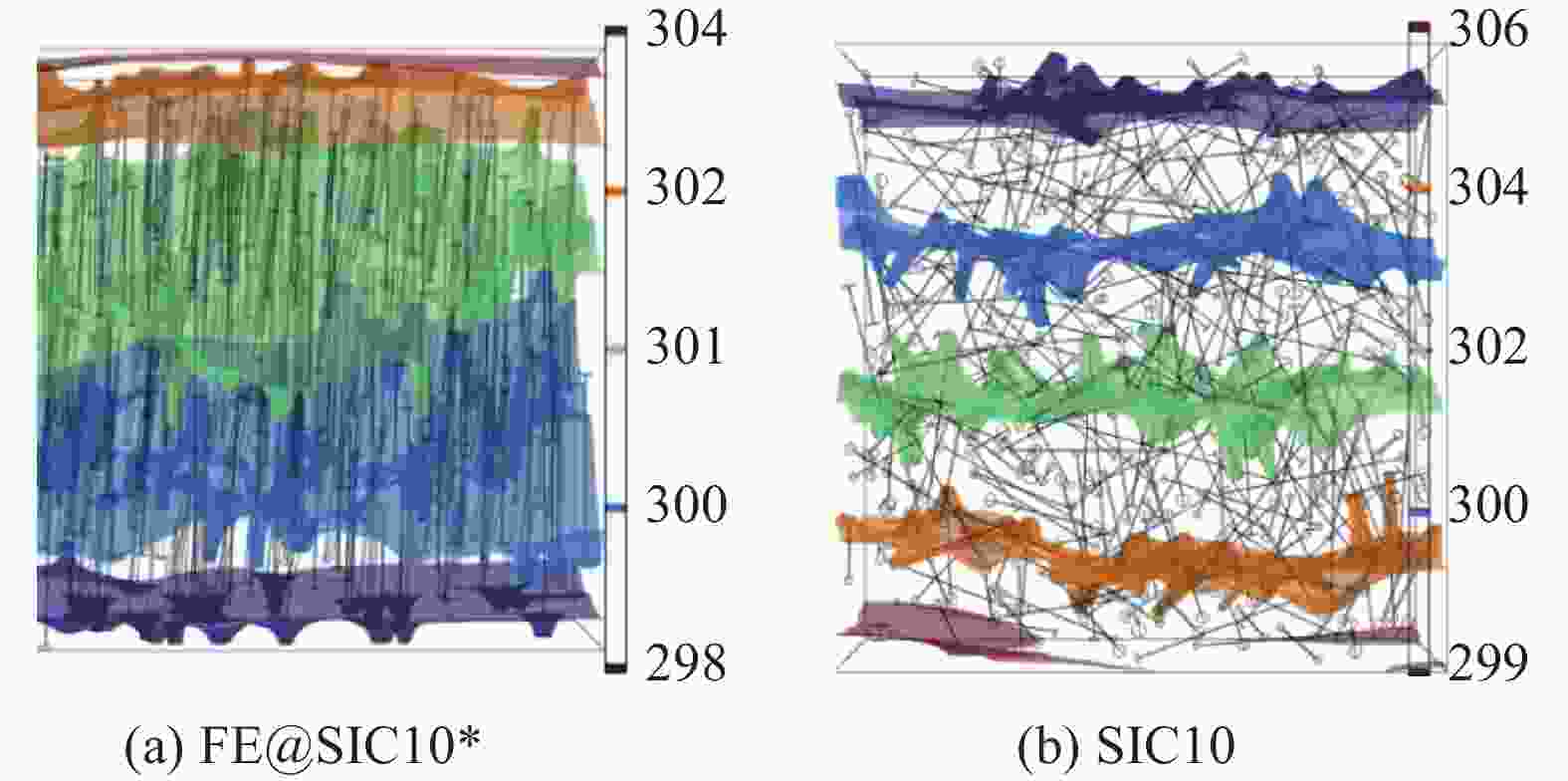

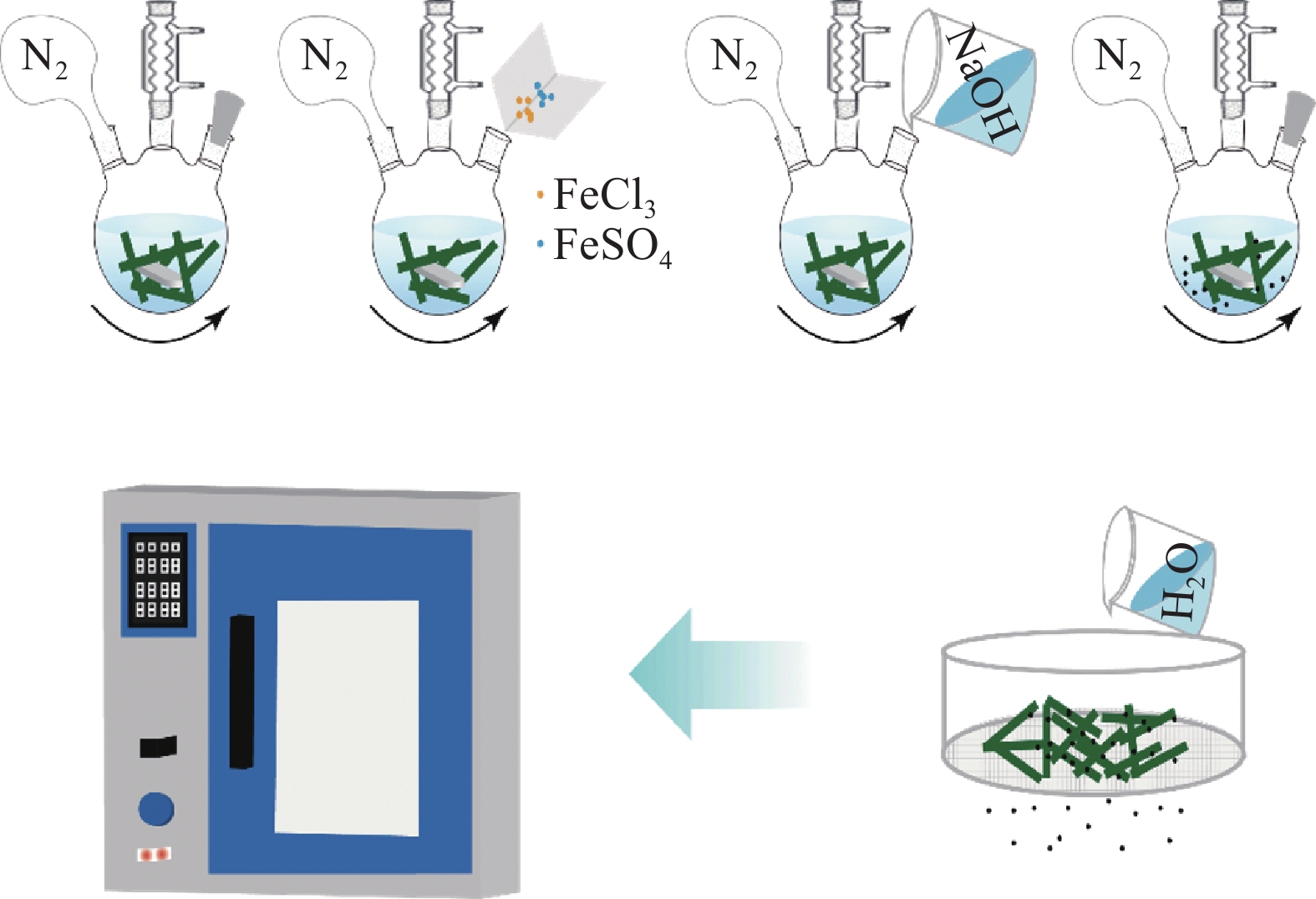

摘要: 随着电子产品的集成密度和功率密度不断增加,优化热界面材料变的尤为重要。本文以一维碳化硅晶须(SiCw)为填料,硅橡胶为基体制备出导热硅橡胶复合材料,综合分析了复合材料的微观形貌、物相结构、导热性及绝缘性。首先通过共沉淀法制备出Fe3O4对SiCw包覆的改性材料,其次将包覆Fe3O4的SiCw在液体硅橡胶基体中分散均匀,最后将其置于恒稳磁场中完成晶须取向及基体固化。结果表明:SiCw晶须表面包覆一层Fe3O4纳米颗粒且在硅橡胶基体中呈现取向排列,制备出SiCw取向结构的硅橡胶复合材料。当取向SiCw含量达到10wt%时,相比于纯硅橡胶导热系数可提升72%,比未取向10wt%SiCw填充的高40%。相比于纯硅橡胶体积电阻率下降两个数量级,但仍然具有良好的绝缘性。通过COMSOL对SiCw随机分散与取向排列的硅橡胶复合材料进行模拟仿真,仿真结果表明,含量10wt%的SiCw可使硅橡胶导热系数提升60%,体积电阻率在1015 Ω∙cm以上,而10wt%取向SiCw可使硅橡胶导热系数提升170%,体积电阻率在1014 Ω∙cm以上,与实验结果的趋势相一致。Abstract: With the increasing integration density and power density of electronic products. It is particularly important to optimize the research of thermal interface materials. In this paper, one-dimensional silicon carbide whisker (SiCw) was used as filler and silicone rubber was used as matrix to prepare thermal conductive silicone rubber composites. The microstructure, phase structure, thermal conductivity and insulation of the composites were comprehensively analyzed. Firstly, the modified material of SiCw coated by Fe3O4 was prepared by coprecipitation method. Secondly, SiCw coated with Fe3O4 was evenly dispersed in the liquid silicone rubber matrix. Finally, it is placed in a constant magnetic field to complete whisker orientation and matrix curing. The results show that the surface of SiCw whiskers is coated with Fe3O4 nanoparticles, and they are oriented in the silicone rubber matrix. Silicone rubber composites with SiCw oriented structure were prepared. When the oriented SiCw reaches 10wt%, the thermal conductivity can be increased by 72% compared with pure silicone rubber, and it is 40% higher than that filled with non-oriented 10wt%SiCw. Compared with pure silicone rubber, the volume resistivity decreases by two orders of magnitude. But it still has good insulation. The silicone rubber composites with randomly dispersed and oriented SiCw were simulated by COMSOL. The simulation results show that the thermal conductivity of silicone rubber can be improved by 60% with 10wt%SiCw. The volume resistivity is above 1015 Ω∙cm. However, 10wt% oriented SiCw can improve the thermal conductivity of silicone rubber by 170% and the volume resistivity is above 1014 Ω∙cm. It is consistent with the trend of experimental results.

-

Key words:

- silicone rubber /

- silicon carbide whisker /

- orientation /

- thermal conductivity /

- insulation

-

表 1 仿真与实验数据对比表

Table 1. The comparison table of simulation results and experimental data

Experimental data Simulation results Name of sample SIC10 SIC10@FE10* SIC10 SIC10@FE10* Thermal conductivity/(W/(m·K)) 0.167 0.235 0.221 0.374 Volume resistivity/Ω·cm 3.71×1015 8.11×1014 4×1015 1×1014 表 1 试样编号明细表

Table 1. Specimen details

Name of sample Detailed description FE@SIC Fe3O4 coated SiCw SR Pure silicone rubber sample SiCw/SR SiCw filled silicone rubber series samples SIC10 10wt% SiCw filled silicone rubber sample FE@SIC10* Magnetized sample of 10wt%FE@SIC

silicone rubberFE@SIC10 10wt%FE@SIC silicone rubber sample SICFE10* Magnetized sample of 10wt%SiCw+Fe3O4

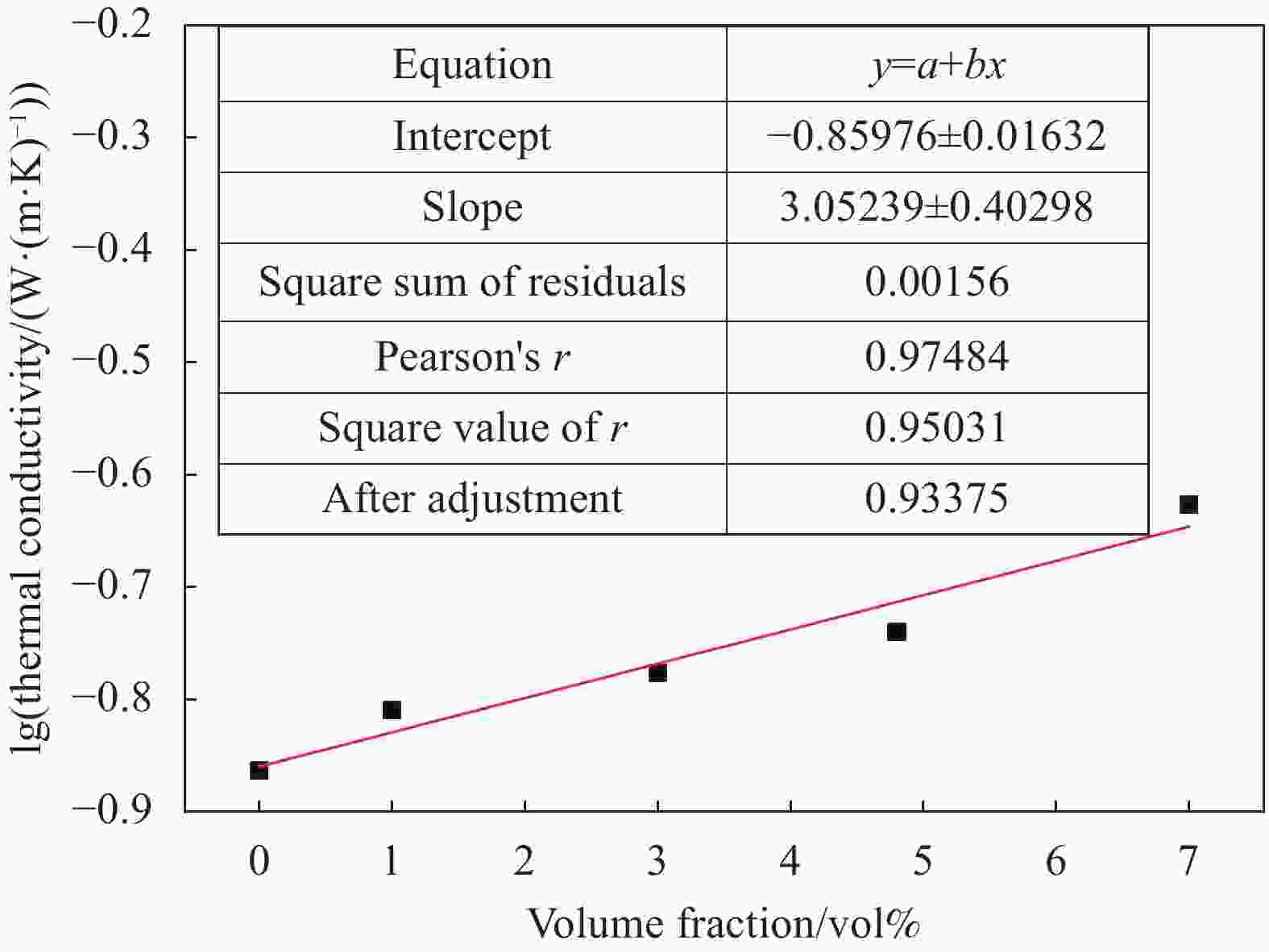

silicone rubber表 2 SiCw/SR的导热系数

Table 2. Thermal conductivity of SiCw/SR

SiCw/SR/wt% Thermal conductivity/(W·(m·K)−1) 0 0.137 5 0.148 10 0.167 15 0.181 20 0.236 表 3 FE@SIC10*导热系数对比表

Table 3. Comparison table of thermal conductivity of FE@SIC10*

Name of sample Thermal conductivity/(W·(m·K)−1) SR 0.137 SIC10 0.167 SICFE10* 0.172 FE@SIC10 0.168 FE@SIC10* 0.235 表 4 SiCw/SR体积电阻率

Table 4. Volume resistivity of SiCw/SR

SiCw/SR/wt% Volume resistivity/(Ω·cm) 0 4.00×1016 5 7.84×1015 10 3.70×1015 15 5.60×1014 20 3.90×1014 表 5 FE@SIC10*体积电阻率对比

Table 5. Comparison of volume resistivity of FE@SIC10*

Name of sample Volume resistivity/(Ω·cm) SR 4.0×1016 SIC10 3.7×1015 FE@SIC10* 8.1×1014 表 6 试样性能的仿真与实验数据对比

Table 6. Comparison of simulation results and experimental data of sample properties

Sample Thermal conductivity/(W·(m·K)−1) Volume resistivity/(Ω·cm) Experimental

dataSimulation

resultsExperimental

dataSimulation

resultsSIC10 0.167 0.221 3.70×1015 4.00×1015 SIC10@

FE10*0.235 0.374 8.11×1014 1.00×1014 -

[1] FENG C P, YANG L Y, YANG J, et al. Recent advances in polymer-based thermal interface materials for thermal management: A mini-review[J]. Composites Communications,2020,22:100528. doi: 10.1016/j.coco.2020.100528 [2] XUE Y, WANG H S, LI X F, et al. Exceptionally thermally conductive and electrical insulating multilaminar aligned silicone rubber flexible composites with highly oriented and dispersed filler network by mechanical shearing[J]. Composites Part A: Applied Science and Manufacturing,2021,144:106336. doi: 10.1016/j.compositesa.2021.106336 [3] ZHANG L, DENG H, FU Q. Recent progress on thermal conductive and electrical insulating polymer composites[J]. Composites Communications,2018,8:74-82. doi: 10.1016/j.coco.2017.11.004 [4] 周文英, 王蕴, 曹国政, 等. 本征导热高分子材料研究进展[J]. 复合材料学报, 2021, 38(7):2038-2055. doi: 10.13801/j.cnki.fhclxb.20210312.001ZHOU Wenying, WANG Yun, CAO Guozheng, et al. Research progress of polymer materials with intrinsic heat conduction[J]. Acta Materiae Compositae Sinica,2021,38(7):2038-2055(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210312.001 [5] NIU H Y, REN Y J, GUO H C, et al. Recent progress on thermally conductive and electrical insulating rubber composites: Design, processing and applications[J]. Composites Communications,2020,22:100430. doi: 10.1016/j.coco.2020.100430 [6] ZHANG H, ZHANG X W, FANG Z, et al. Recent advances in preparation, mechanisms, and applications of thermally conductive polymer composites: A review[J]. Journal of Composites Science,2020,4(4):180-226. doi: 10.3390/jcs4040180 [7] VYSOTSKY V V, ROLDUGHIN V I. Aggregate structure and percolation properties of metal-filled polymer films[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,1999,160(2):171-180. doi: 10.1016/S0927-7757(99)00355-6 [8] 李宾, 刘妍, 孙斌, 等. 聚合物基导热复合材料的性能及导热机理[J]. 化工学报, 2009, 60(10):2650-2655.LI Bin, LIU Yan, SUN Bin, et al. Properties and thermal conductivity mechanism of polymer-based thermal conductivity composites[J]. Journal of Chemical Technology,2009,60(10):2650-2655(in Chinese). [9] YANG X, LI X F, WANG H S, et al. Improvement in thermal conductivity of through-plane aligned boron nitride/silicone rubber composites[J]. Materials & Design,2019,165:107580-107588. [10] XU S, LIU H, LI Q M, et al. Influence of magnetic alignment and layered structure of BN&Fe/EP on thermal conducting performance[J]. Journal of Materials Chemistry C,2016,4(4):872-878. doi: 10.1039/C5TC03791C [11] SONG S Q, WANG J Y, LIU C, et al. A facile route to fabricate thermally conductive and electrically insulating polymer composites with 3D interconnected graphene at an ultralow filler loading[J]. Nanoscale,2019,11(32):15234-15244. doi: 10.1039/C9NR05153H [12] 伍垚屹, 陈松, 张雪娇, 等. 冰模板法制备取向氮化硼@聚多巴胺/纳米银导热网络及其硅橡胶复合导热垫片[J]. 复合材料学报, 2022, 39(7):3131-3143. doi: 10.13801/j.cnki.fhclxb.20210906.001WU Yaoyi, CHEN Song, ZHANG Xuejiao, et al. Preparation of oriented boron nitride@polydopamine/nano silver thermal conductive network and its silicone rubber composite thermal conductive gasket by ice template method[J]. Acta Materiae Compositae Sinica,2022,39(7):3131-3143(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210906.001 [13] MA H Q, GAO B, WANG M, et al. Vertical alignment of carbon fibers under magnetic field driving to enhance the thermal conductivity of silicone composites[J]. Polymers for Advanced Technologies, 2021, 32(11): 4318-4325. [14] 中国石油和化学工业联合会. 硫化橡胶或热塑性橡胶体积和/或表面电阻率的测定: GB/T 40719—2021[S]. 北京: 中国标准出版社, 2019.China Petroleum and Chemical Industry Federation. Rubber, vulcanized or thermoplastic—Determination of volume and/or surface resistivity: GB/T 40719—2021[S]. Beijing: Standards Press of China, 2019(in Chinese). [15] 贾园, 马欢, 杨菊香, 等. 磁性四氧化三铁纳米粒子的制备及其应用研究进展[J]. 化学工业与工程, 2023, 40(5): 8-18.JIA Yuan, MA Huan, YANG Juxiang, et al. Progress in preparation and application of magnetic Fe3O4 nanoparticles[J]. Chemical Industry and Engineering, 2023, 40(5): 8-18(in Chinese). [16] 侯涛, 徐仁扣. 胶体颗粒表面双电层之间的相互作用研究进展[J]. 土壤, 2008, 40(3):377-381. doi: 10.3321/j.issn:0253-9829.2008.03.008HOU Tao, XU Renkou. Research progress on the interaction between electric double layers on the surface of colloidal particles[J]. Soil,2008,40(3):377-381(in Chinese). doi: 10.3321/j.issn:0253-9829.2008.03.008 [17] MERLE MÉJEAN T, ABDELMOUNM E, QUINTARD P. Oxide layer on silicon carbide powder: A Ft-Ir investigation[J]. Journal of Molecular Structure, 1995, 349: 105-108. [18] WANG H Y, BERTAAND Y, FISCHMAN G S. Microstructure of silicon carbide whiskers synthesized by carbothermal reduction of silicon nitride[J]. Journal of the American Ceramic Society,1992,75(5):1080-1084. doi: 10.1111/j.1151-2916.1992.tb05541.x [19] SHEN M X, CUI Y X, HE J, et al. Thermal conductivity model of filled polymer composites[J]. International Journal of Minerals, Metallurgy, and Materials,2011,18(5):623-631. doi: 10.1007/s12613-011-0487-9 [20] ACARI Y, UEDA A, NACAI S. Thermal conductivity of a polyethylene filled with disoriented short-cut carbon fibers[J]. Journal of Applied Polymer Science,1991,43(6):1117-1124. doi: 10.1002/app.1991.070430612 [21] 周文英, 丁小卫. 导热高分子材料[M]. 北京: 国防工业出版社, 2014: 29.ZHOU Wenying, DING Xiaowei. Thermal conductive polymer materials[M]. Beijing: National Defense Industry Press, 2014: 29(in Chinese). [22] ACARI Y, UEDA A, NACAI S. Thermal conductivities of composites in several types of dispersion systems[J]. Journal of Applied Polymer Science,1991,42(6):1665-1669. doi: 10.1002/app.1991.070420621 [23] WONG C P, BOLLAMPALLY R S. Thermal conductivity, elastic modulus, and coefficient of thermal expansion of polymer composites filled with ceramic particles for electronic packaging[J]. Journal of Applied Polymer Science,1999,74(14):3396-3403. [24] GU J W, RUAN K. Breaking through bottlenecks for thermally conductive polymer composites: A perspective for intrinsic thermal conductivity, interfacial thermal resistance and theoretics[J]. Nano-Micro Letters,2021,13:110. [25] 任佳, 蔡静. 导热系数测量方法及应用综述[J]. 计测技术, 2018, 38(S1):46-49.REN Jia, CAI Jing. Summary of thermal conductivity measurement methods and applications[J]. Measurement Technology,2018,38(S1):46-49(in Chinese). [26] 张正荣. 传热学[M]. 北京: 高等教育出版社, 1982: 11-17.ZHANG Zhengrong. Heat transfer[M]. Beijing: Higher Education Press, 1982: 11-17(in Chinese). -

下载:

下载: