Preparation and lightning strike protection properties of lightweight high conductive metallized carbon nanotube film

-

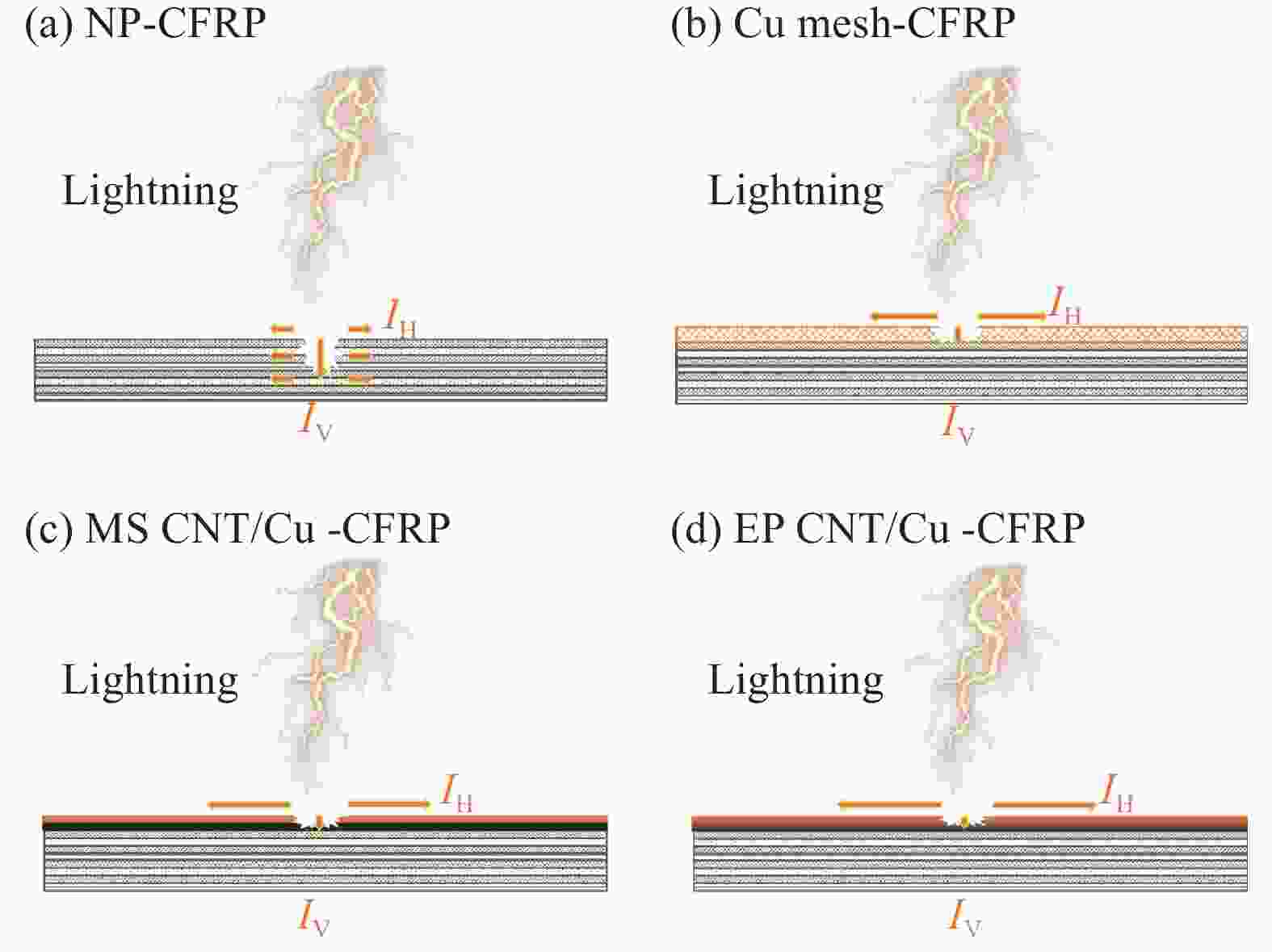

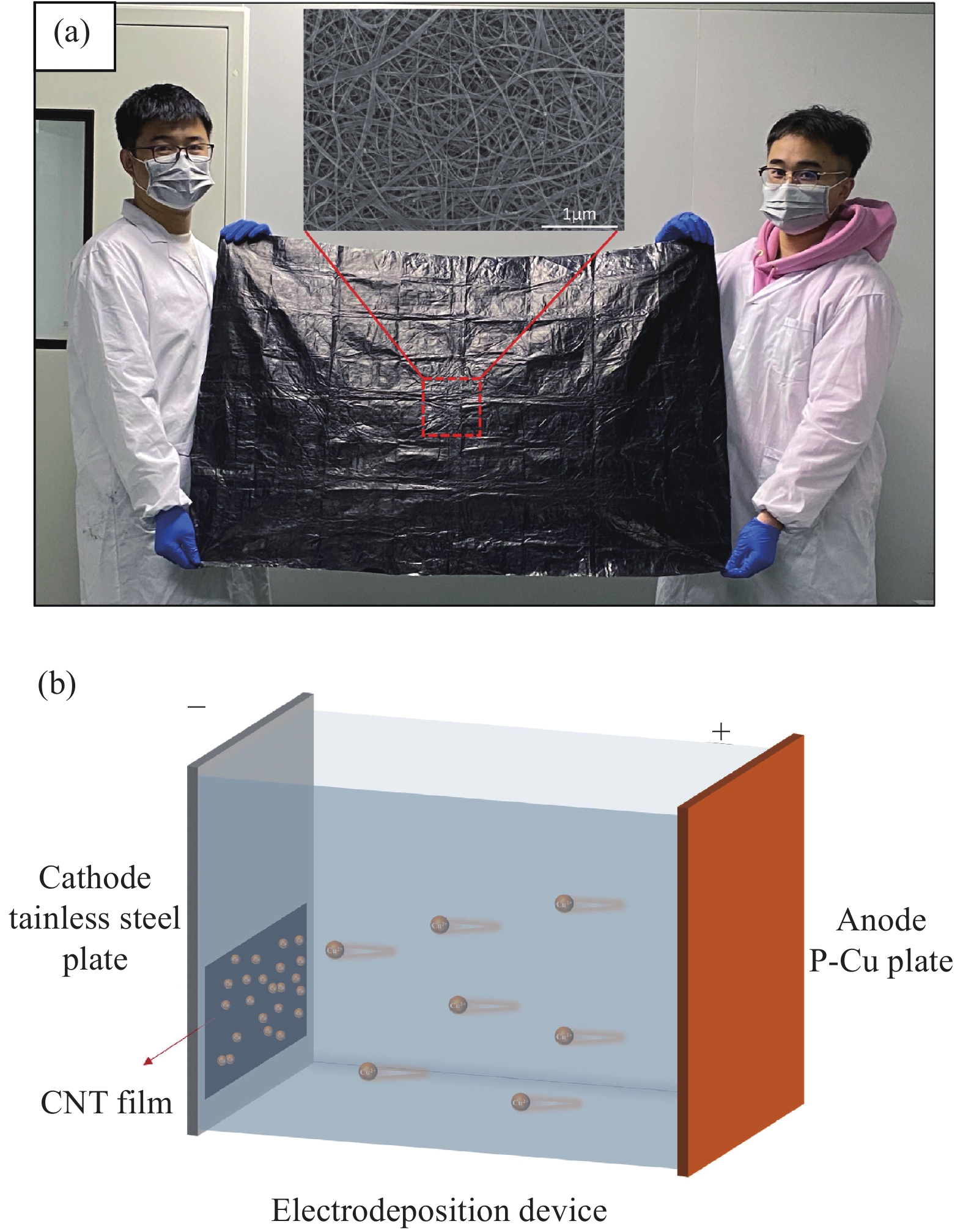

摘要: 碳纤维增强树脂基复合材料(CFRP)导电性差,无法满足飞机航行过程中的雷击防护需求。金属化碳纳米管薄膜具备轻质、高导电、高载流的特点,可应用于复合材料雷击防护。采用电化学沉积工艺成功制备了一种碳纳米管(CNT)/Cu复合薄膜,并对其微观结构、电学性能及载流失效行为进行了表征分析。结果表明,CNT/Cu复合薄膜柔性较好,具有明显的梯度结构,铜的含量在薄膜厚度方向上逐渐递减。复合薄膜电导率与Cu同一量级,比电导率为Cu的2倍,载流量及比载流量分别为商用铜网的1.4倍和7倍。复合薄膜中的CNT抑制了Cu在大载流作用下电迁移的发生,进而延长其载流失效时间。基于CNT/Cu复合薄膜制备了CFRP雷击防护试样,进行人工模拟雷击试验及高精度损伤分析,评估雷击防护效果。与商用铜网雷击防护材料相比,CNT/Cu复合薄膜质量减轻61%,且表现出更为优异的雷击防护性能。Abstract: Due to the poor conductivity, carbon fiber reinforced resin matrix composites (CFRP) cannot meet the lightning strike protection requirement of aircrafts. The metallization of carbon nanotube (CNT) films are lightweight, and possess high conductivity and high current-carrying capacity, making them promising for lightning strike protection of composite materials. CNT/Cu composite films were successfully prepared by electrochemical deposition process, and its microstructure, electrical properties and current-carrying failure behavior were characterized and analyzed. The results show that CNT/Cu composite films are flexible and have gradient microstructures, where the content of Cu gradually decreases from one side to another. The electrical conductivity of the composite films is 2.16×107 S/m, and their specific conductivity is 2 times of pure Cu, and the current carrying capacity and specific current carrying capacity are 1.4 times and 7 times of copper mesh, respectively. CNTs in the composite film can inhibit the electromigration of Cu, thus prolonging its current-carrying failure time. CFRPs for lightning strike protection testing were prepared by using CNT/Cu composite films, and the lightning strike protection performance was evaluated by artificial simulation lightning test and damage analysis. Compared with copper mesh, CNT/Cu composite films are 61% lighter and showed more excellent lightning protection performance.

-

Key words:

- CNT/Cu /

- composite materials /

- electrical properties /

- metallized /

- lightning strike protection /

- non-destructive examination /

- CFRP

-

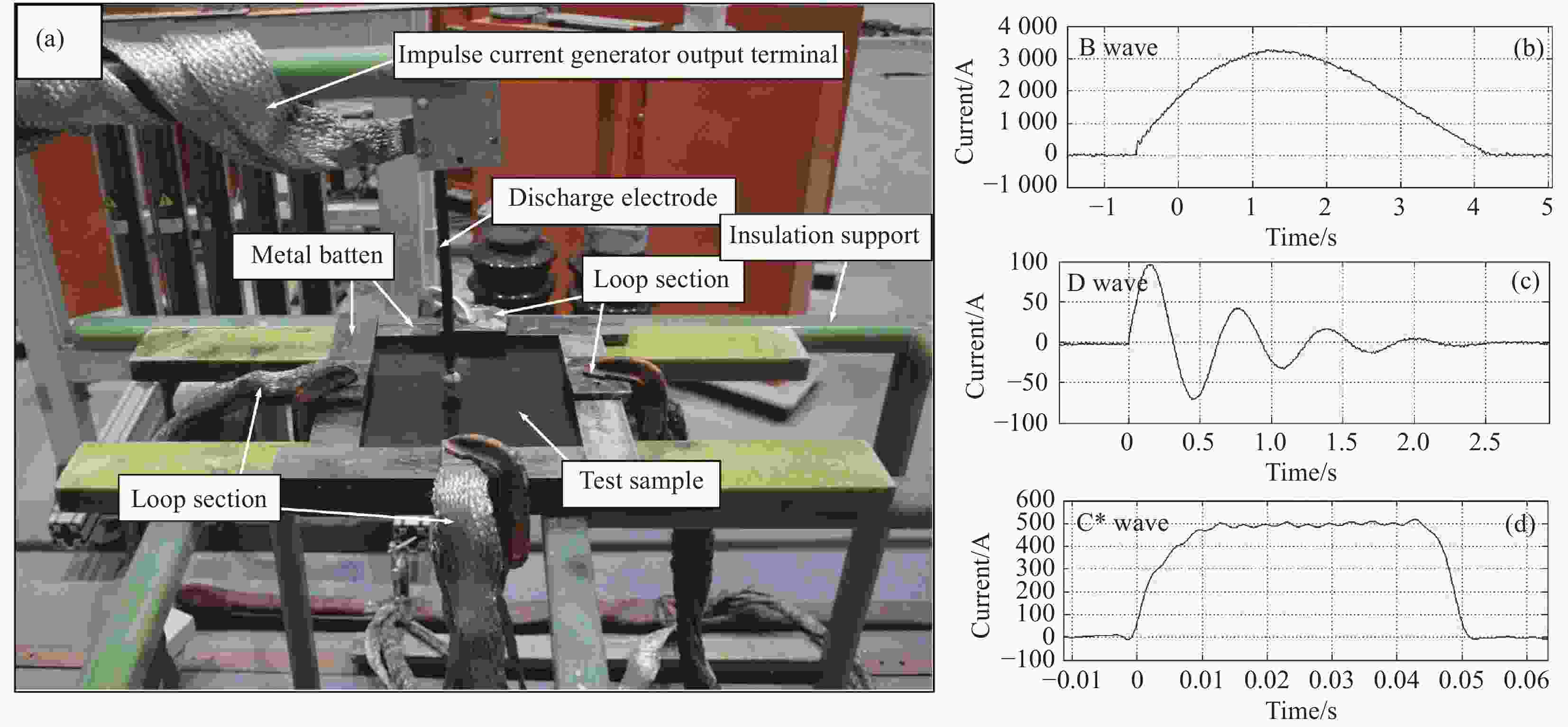

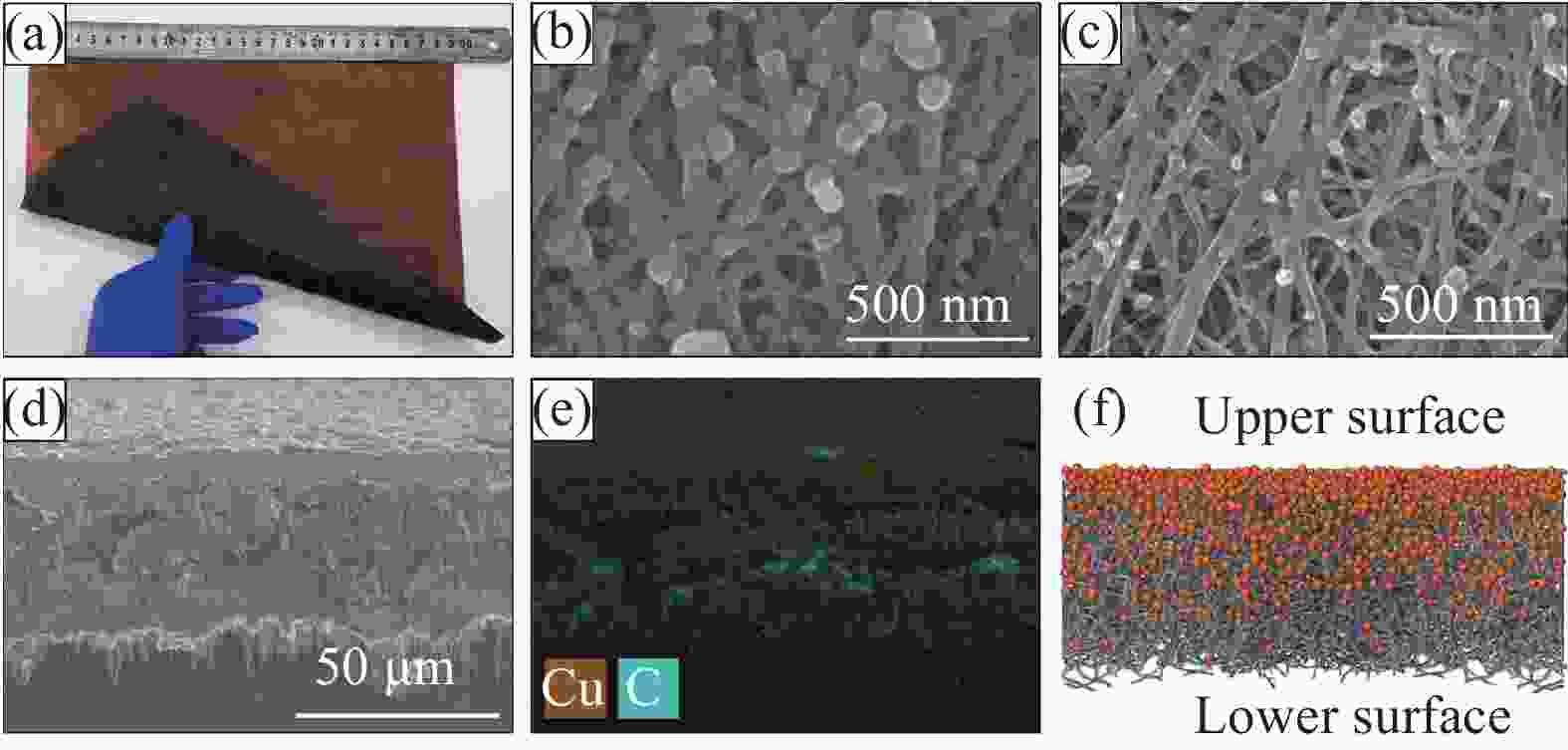

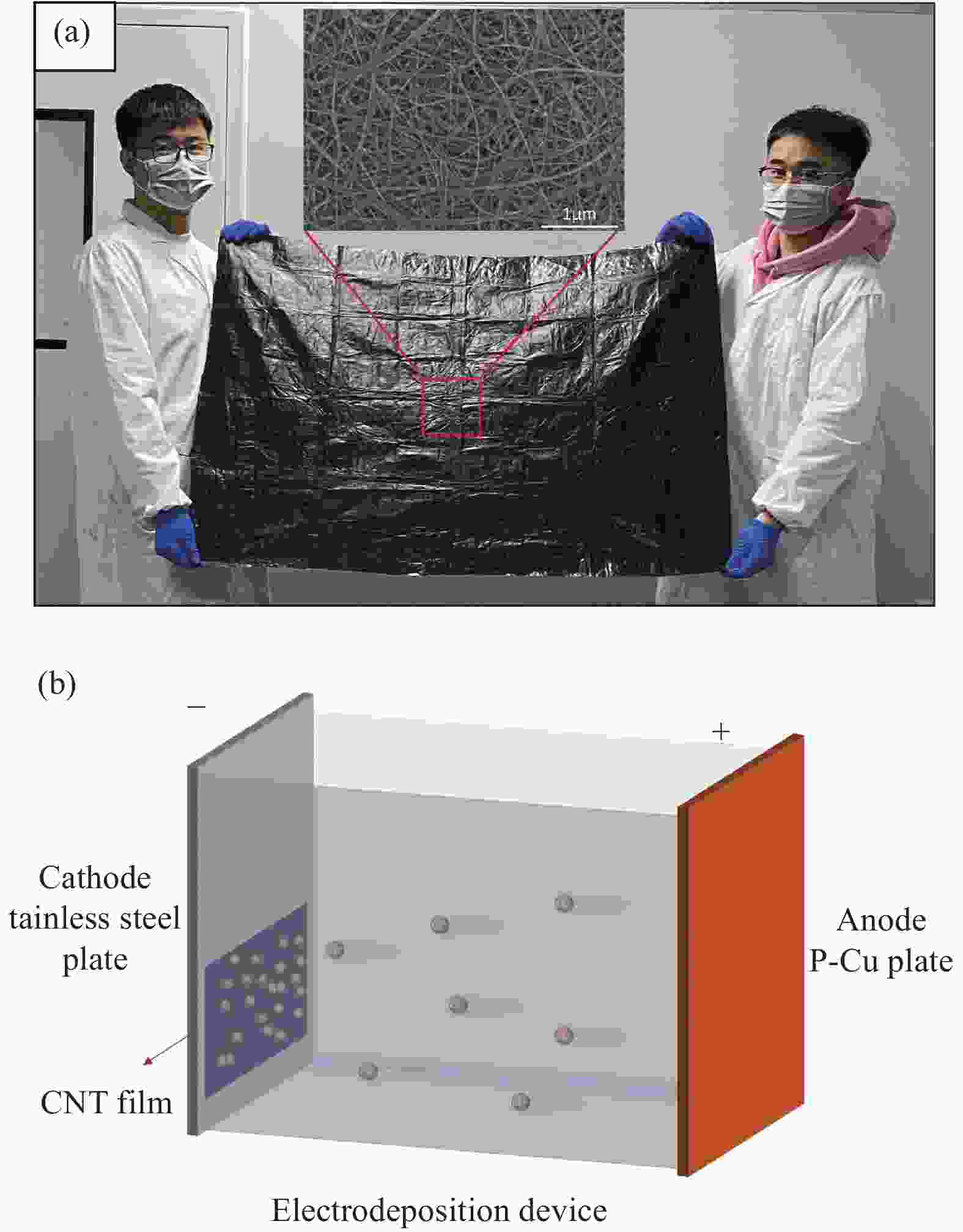

图 3 (a) 电化学沉积法制备的CNT/Cu复合薄膜试样;CNT/Cu复合薄膜上表面 (b) 及下表面 (c) 的SEM图像;复合薄膜截面微观形貌 (d) 及对应EDS元素表征 (e);(f) 复合薄膜截面Cu元素分布示意图

Figure 3. (a) CNT/Cu composite film sample prepared by electrochemical deposition; SEM images of upper (b) and lower surfaces (c) of CNT/Cu composite film; Micromorphology of CNT/Cu composite film section (d) and its elemental analysis by EDS (e); (f) Schematic diagram of Cu element distribution of composite film section

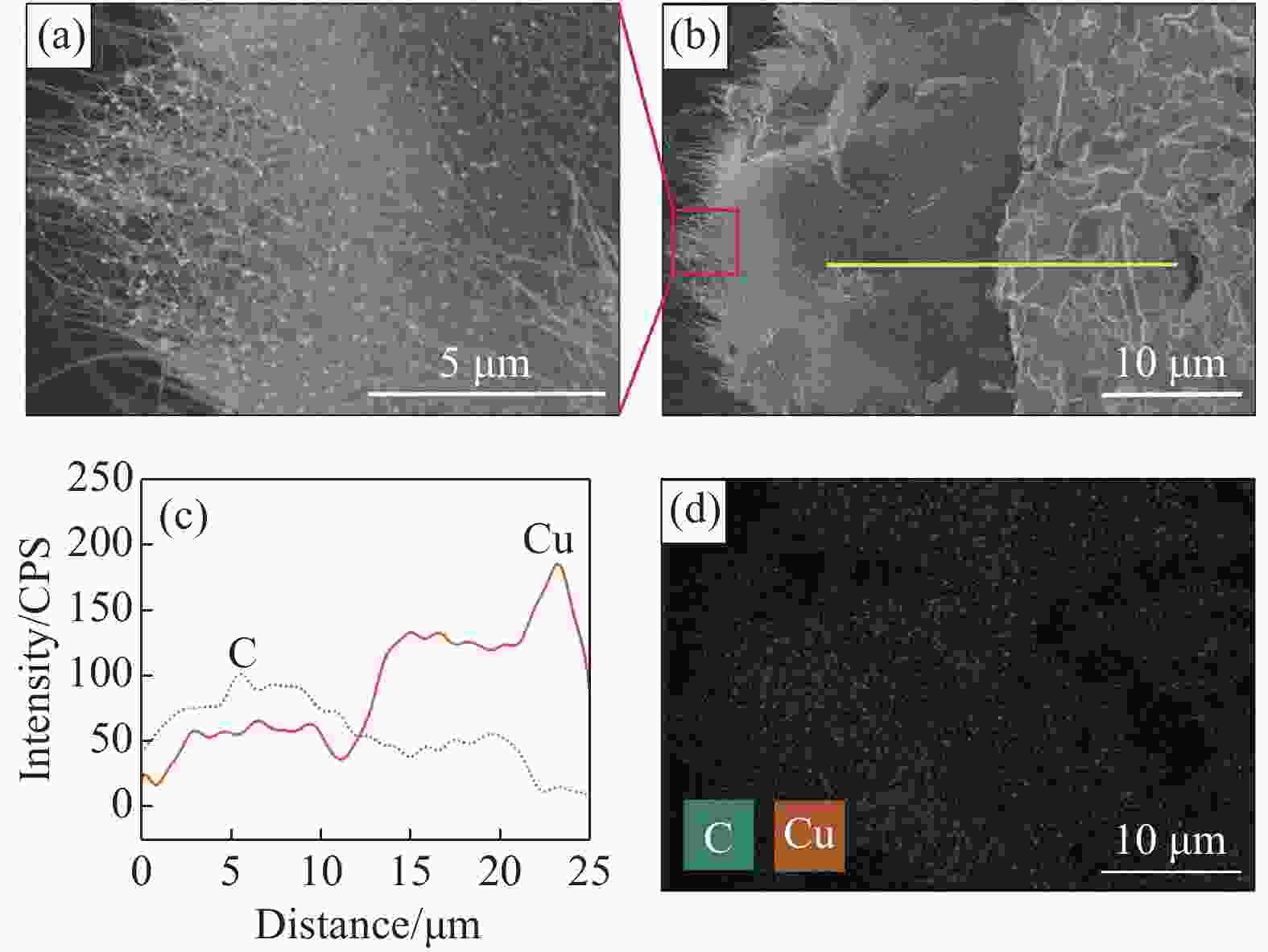

图 7 CNT/Cu复合薄膜载流失效断口形貌及元素分析:((a), (b)) 复合薄膜断口处SEM图像;((c), (d)) 图7(b)中对应位置元素线扫描及面扫描结果

Figure 7. Fracture morphology and elemental analysis of current carrying failure of CNT/Cu composite films: ((a), (b)) SEM images of composite film fracture; ((c), (d)) Line scan and map scan results of corresponding position elements in Fig. 7(b)

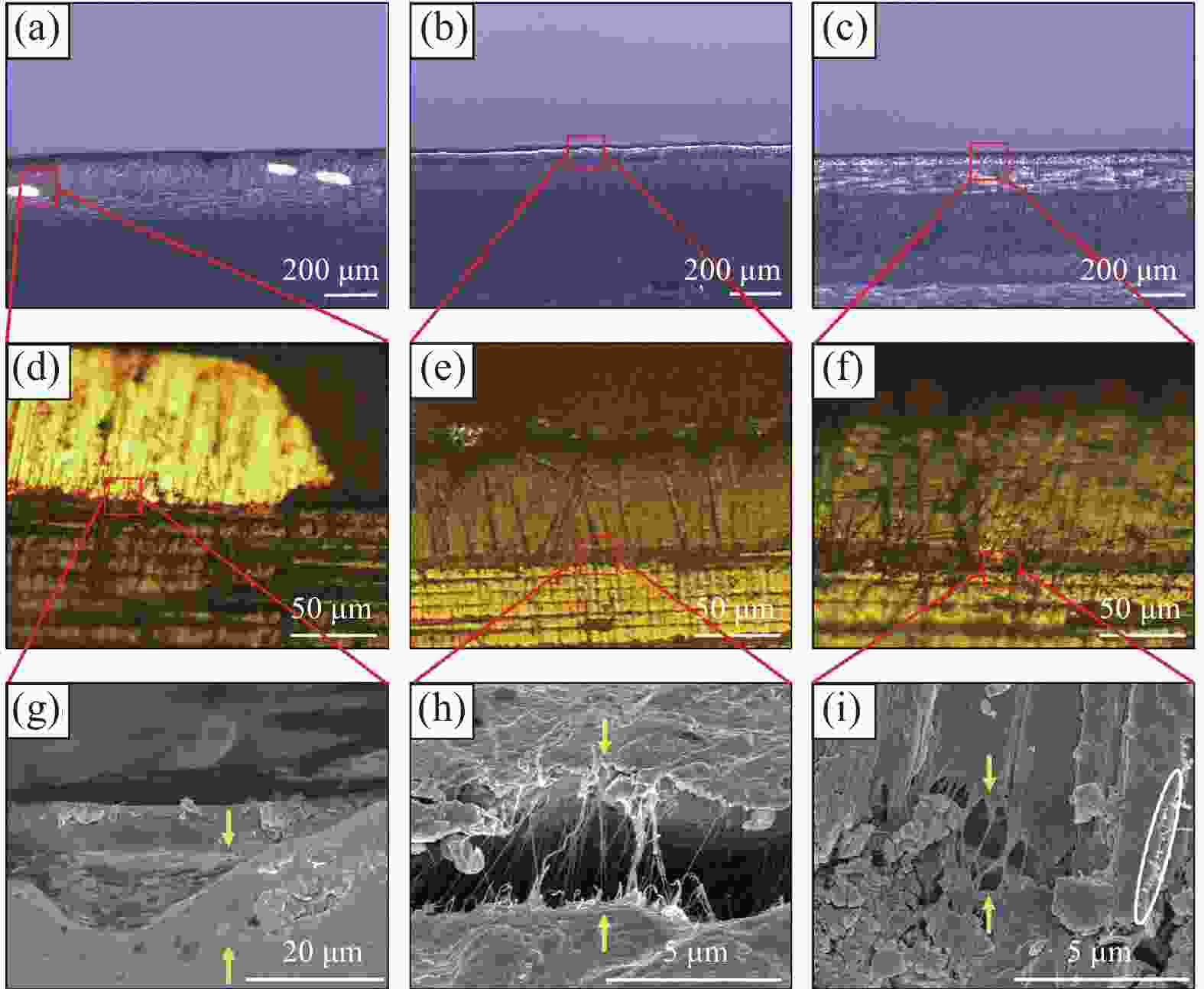

图 8 CFRP试样截面形貌及界面形态:((a), (d), (g)) 商用铜网防护(Cu mesh-CFRP);((b), (e), (h)) 磁控溅射CNT/Cu复合薄膜防护(MS CNT/Cu-CFRP);((c), (f), (i)) 电沉积 CNT/Cu 复合薄膜防护(EP CNT/Cu-CFRP) (由上至下分别为3D共聚焦显微图、金相图、SEM图像)

Figure 8. Section morphology and interface morphology of CFRP samples: ((a), (d), (g)) Commercial copper mesh (Cu mesh-CFRP); ((b), (e), (h)) CNT/Cu composite films produced by magnetron sputtering (MS CNT/Cu-CFRP); ((c), (f), (i)) CNT/Cu composite films produced by electrodeposition (EP CNT/Cu-CFRP ) (From top to bottom are 3D confocal micrograph, metallographic diagram, SEM images)

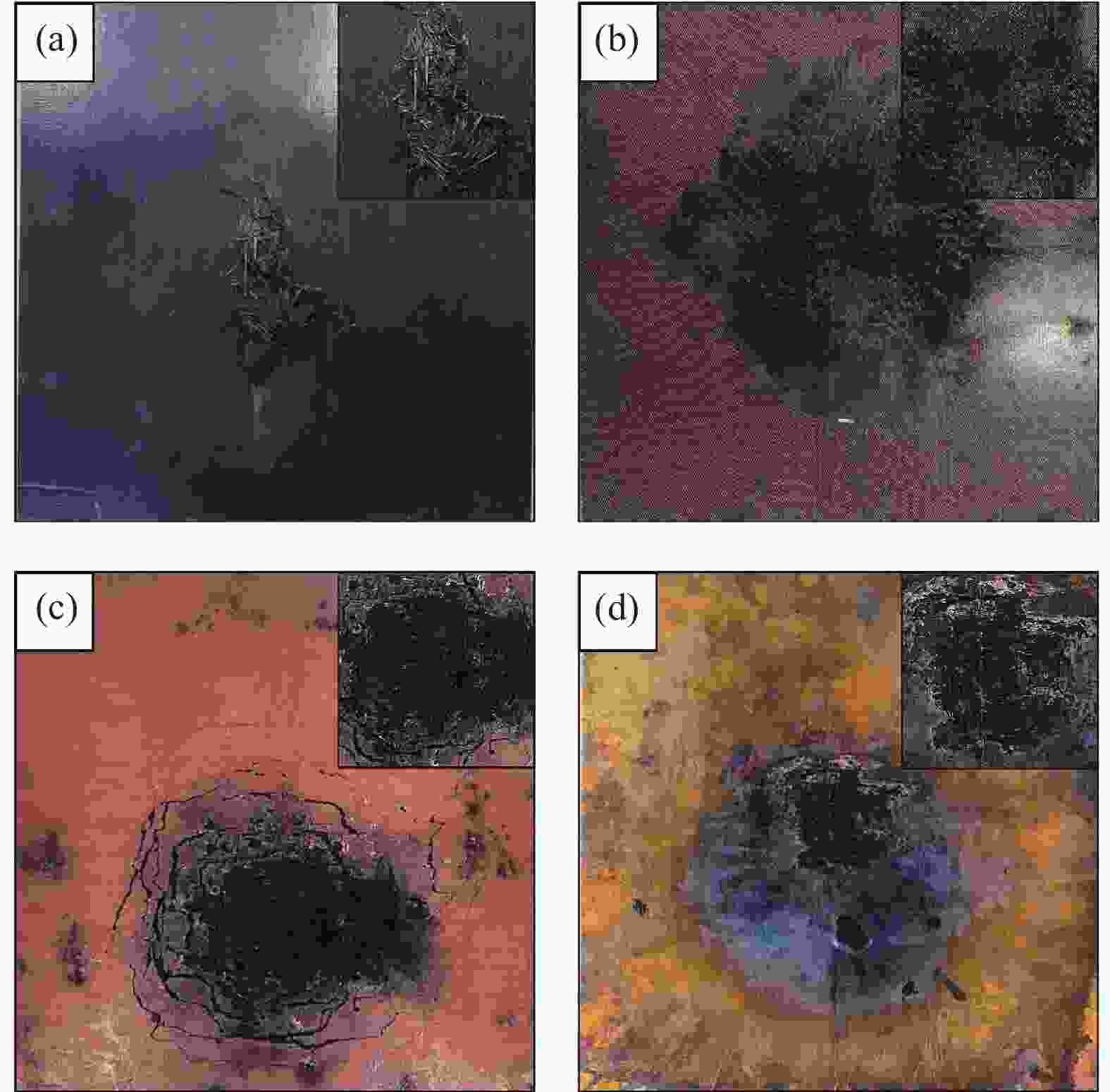

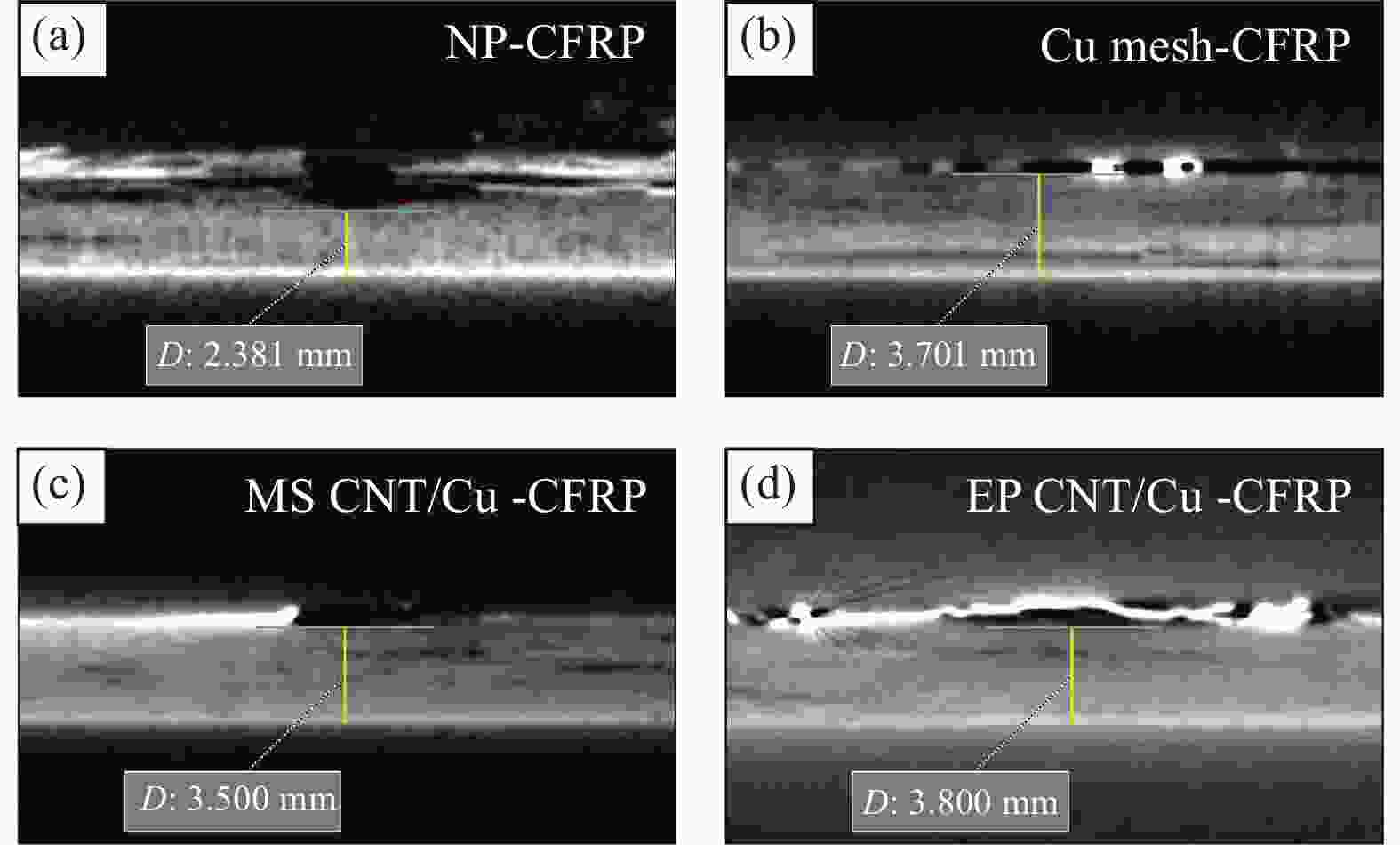

图 11 试样雷击试验后计算机断层(CT)扫描整体形貌:(a) NP-CFRP;(b) Cu mesh-CFRP;(c) MS CNT/Cu-CFRP;(d) EP CNT/Cu-CFRP;随深度变化10%、20%、40%的剖面损伤形貌: ((a1)~(a3)) NP-CFRP;((b1)~(b3)) Cu mesh-CFRP;((c1)~(c3)) MS CNT/Cu-CFRP;((d1)~(d3)) EP CNT/Cu-CFRP

Figure 11. Computed tomography (CT) scanning of samples overall damage morphology after lightning strike test: (a) NP-CFRP; (b) Cu mesh-CFRP; (c) MS CNT/Cu-CFRP; (d) EP CNT/Cu-CFRP; Profile damage morphology varies by 10%, 20% and 40% with depth: ((a1)-(a3)) NP-CFRP; ((b1)-(b3)) Cu mesh-CFRP; ((c1)-(c3)) MS CNT/Cu-CFRP; ((d1)-(d2)) EP CNT/Cu-CFRP

表 1 商用铜网参数

Table 1. Commercial copper mesh parameters

Project Parameter Long intercept 2.54 mm±5% Short intercept 1.40 mm±6% Areal density (245±20) g/m2 Long intercept direction resistance ≤2.10 mΩ Short intercept direction resistance ≤6.30 mΩ 表 2 雷击防护CFRP试样电导率测试结果

Table 2. Conductivity test results of CFRP samples for lightning strike protection

Direction Sample Conductivity/(S·m−1) X NP-CFRP 23.14±3.47 Cu mesh-CFRP 31.02±2.88 MS CNT/Cu-CFRP 55.82±6.55 EP CNT/Cu-CFRP 99.81±7.13 Y NP-CFRP 8.57±0.61 Cu mesh-CFRP 19.62±2.36 MS CNT/Cu-CFRP 32.19±2.66 EP CNT/Cu-CFRP 62.87±9.47 Z NP-CFRP 0.79±0.06 Cu mesh-CFRP 1.30±0.07 MS CNT/Cu-CFRP 1.65±0.25 EP CNT/Cu-CFRP 2.38±0.35 Notes: NP-CFRP—Completely unprotected carbon fiber reinforced composite;MS—Magnetron sputtering; EP—Electrodeposition. 表 3 4组CFRP试样雷击测试后损伤深度分析

Table 3. Analysis of damage depth of four groups of CFRP samples after lightning strike test

Sample Total thickness/mm Protective layer thickness/mm Total damage thickness/mm Total damage rate/% Damage rate of carbon

fiber structural layer/%NP-CFRP 3.837 0 1.456 37.95 37.95 Cu mesh-CFRP 4.372 0.218 0.671 15.35 10.91 MS CNT/Cu-CFRP 3.870 0.055 0.370 9.56 8.26 EP CNT/Cu-CFRP 3.850 0.050 0.050 1.30 0 -

[1] SOULAS F, ESPINOSA C, LACHAUD F, et al. A method to replace lightning strike tests by ball impacts in the design process of lightweight composite aircraft panels[J]. International Journal of Impact Engineering,2018,111:165-176. doi: 10.1016/j.ijimpeng.2017.09.007 [2] VICTOR G. Structural health monitoring of aerospace composites[M]. New York: Academic Press, 2016: 1-23. [3] GUO Y L, XU Y, WANG Q, et al. Eliminating lightning strike damage to carbon fiber composite structures in Zone 2 of aircraft by Ni-coated carbon fiber nonwoven veils[J]. Composites Science and Technology,2019,169:95-102. doi: 10.1016/j.compscitech.2018.11.011 [4] UMAN M A, RAKOV V A. The interaction of lightning with airborne vehicles[J]. Progress in Aerospace Sciences,2003,39(1):61-81. doi: 10.1016/S0376-0421(02)00051-9 [5] GAGNE M, THERRIAULT D. Lightning strike protection of composites[J]. Progress in Aerospace Sciences,2014,64:1-16. doi: 10.1016/j.paerosci.2013.07.002 [6] WANG F S, DING N, LIU Z Q, et al. Ablation damage characteristic and residual strength prediction of carbon fiber/epoxy composite suffered from lightning strike[J]. Composite Structures,2014,117:222-233. doi: 10.1016/j.compstruct.2014.06.029 [7] DONG Q, GUO Y, SUN X, et al. Coupled electrical-thermal-pyrolytic analysis of carbon fiber/epoxy composites subjected to lightning strike[J]. Polymer,2015,56:385-394. doi: 10.1016/j.polymer.2014.11.029 [8] CHEN H, WANG F S, MA X T, et al. The coupling mechanism and damage prediction of carbon fiber/epoxy composites exposed to lightning current[J]. Composite Structures,2018,203:436-445. doi: 10.1016/j.compstruct.2018.07.017 [9] WANG B, ZHU Y, MING Y, et al. Understanding lightning strike induced damage mechanism of carbon fiber reinforced polymer composites: An experimental study[J]. Materials & Design,2020,192:108724. [10] ZHAO Z J, XIAN G J, YU J G, et al. Development of electrically conductive structural BMI based CFRPs for lightning strike protection[J]. Composites Science and Technology,2018,167:555-562. doi: 10.1016/j.compscitech.2018.08.026 [11] KUMAR V, YOKOZEKI T, KARCH C, et al. Factors affecting direct lightning strike damage to fiber reinforced composites: A review[J]. Composites Part B: Engineering,2020,183:107688. doi: 10.1016/j.compositesb.2019.107688 [12] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature,1991,354(6348):56-58. doi: 10.1038/354056a0 [13] ZHANG S, NGUYEN N, LEONHARDT B, et al. Carbon-nanotube-based electrical conductors: Fabrication, optimization, and applications[J]. Advanced Electronic Materials,2019,5(6):1800811. doi: 10.1002/aelm.201800811 [14] DYDEK K, BOCZKOWSKA A, KOZERA R, et al. Effect of SWCNT-tuball paper on the lightning strike protection of CFRPs and their selected mechanical properties[J]. Materials,2021,14(11):3140. doi: 10.3390/ma14113140 [15] ZHANG J, ZHANG X, CHENG X, et al. Lightning strike damage on the composite laminates with carbon nanotube films: Protection effect and damage mechanism[J]. Composites Part B: Engineering,2019,168:342-352. doi: 10.1016/j.compositesb.2019.03.054 [16] ARAI S. Fabrication of metal/carbon nanotube composites by electrochemical deposition[J]. Electrochem,2021,2(4):563-589. doi: 10.3390/electrochem2040036 [17] SUBRAMANIAM C, YAMADA T, KOBASHI K, et al. One hundred fold increase in current carrying capacity in a carbon nanotube-copper composite[J]. Nature Communications,2013,4:2202. doi: 10.1038/ncomms3202 [18] LEGGIERO A P, TRETTNER K J, URSINO H L, et al. High conductivity copper-carbon nanotube hybrids via site-specific chemical vapor deposition[J]. ACS Applied Nano Materials,2018,2(1):118-126. [19] BAZBOUZ M B, AZIZ A, COPIC D, et al. Fabrication of high specific electrical conductivity and high ampacity carbon nanotube/copper composite wires[J]. Advanced Electronic Materials,2021,7(4):2001213. doi: 10.1002/aelm.202001213 [20] SUNDARAM R M, YAMADA T, HATA K, et al. The influence of Cu electrodeposition parameters on fabricating structurally uniform CNT-Cu composite wires[J]. Materials Today Communications,2017,13:119-125. doi: 10.1016/j.mtcomm.2017.09.003 [21] SUNDARAM R M, YAMADA T, HATA K, et al. Electrical performance of lightweight CNT-Cu composite wires impacted by surface and internal Cu spatial distribution[J]. Scientific Reports,2017,7(1):9267. doi: 10.1038/s41598-017-09279-x [22] SUNDARAM R, SEKIGUCHI A, SEKIYA M, et al. Copper/carbon nanotube composites: Research trends and outlook[J]. Royal Society Open Science,2018,5(11):180814. doi: 10.1098/rsos.180814 [23] 郭妙才, 黑艳伟, 李斌太, 等. 石墨烯/碳纳米管共改性碳纤维复合材料的结构、力学、导电和雷击性能[J]. 复合材料学报, 2022, 39(9):4354-4365.GUO Miaocai, HEI Yanwei, LI Bintai, et al. Structure, mechanical property, electrical conductivity and lightning strike damage behavior of graphene/carbon nanotube co-modified CFRPs[J]. Acta Materiae Compositae Sinica,2022,39(9):4354-4365(in Chinese). [24] Society of Automotive Engineers. Aircraft lightning test methods: SAE ARP 5416A—2013[S]. Washington D.C.: Society of Automotive Engineers International, 2013. [25] Society of Automotive Engineers. Aircraft lightning environment and related test waveforms: SAE ARP 5412B—2013[S]. Washington D.C.: Society of Automotive Engineers International, 2013. [26] HWANG H J, JOO S J, KIM H S. Copper nanoparticle/multiwalled carbon nanotube composite films with high electrical conductivity and fatigue resistance fabricated via flash light sintering[J]. ACS Applied Materials & Interfaces,2015,7(45):25413-25423. doi: 10.1021/acsami.5b08112 [27] HUANG Y Y, TERENTJEV E M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization, and composite properties[J]. Polymers,2012,4(1):275-295. doi: 10.3390/polym4010275 -

下载:

下载: