Progressive failure analysis of composite materials based on rate-dependent three-dimensional elastoplastic damage model

-

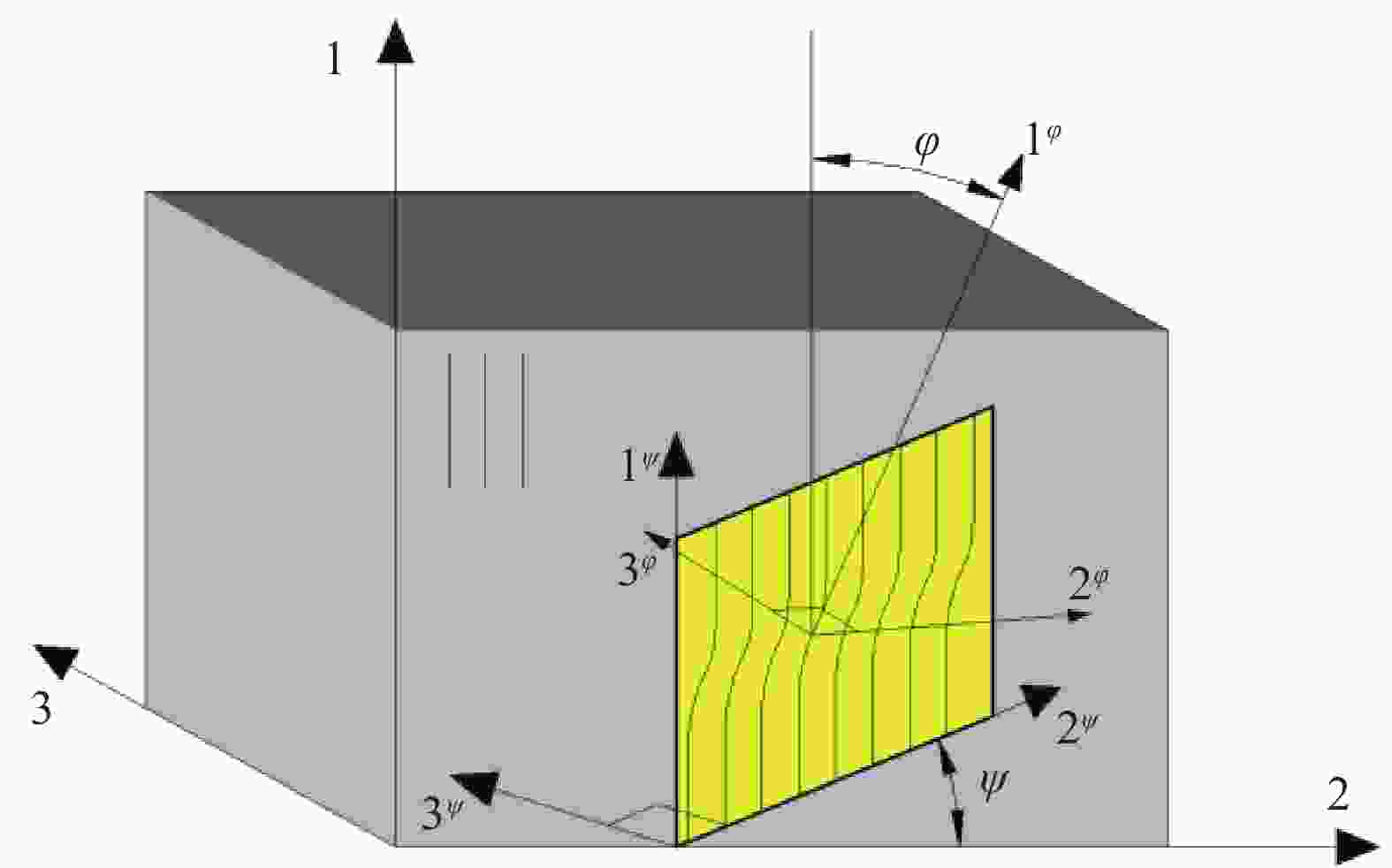

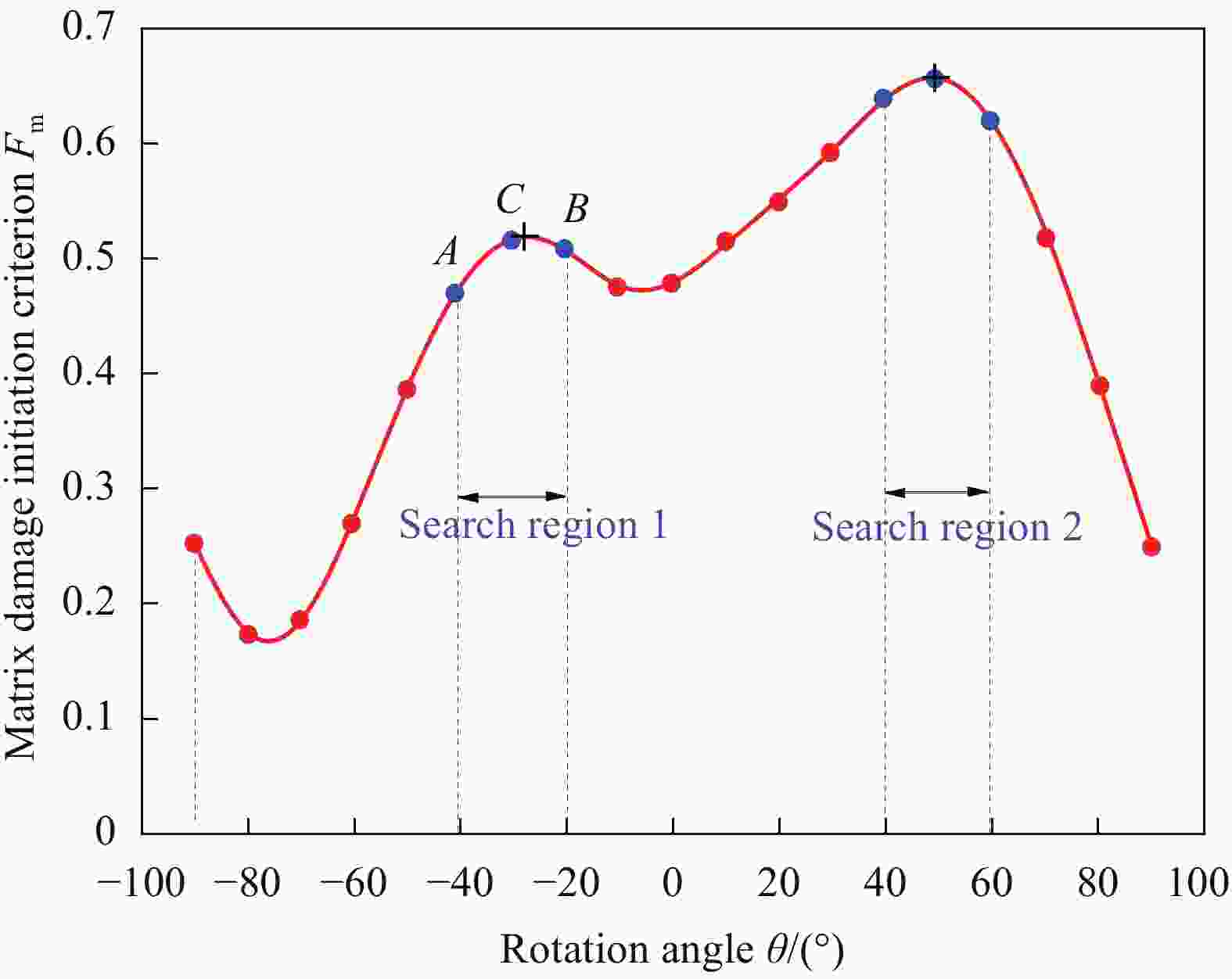

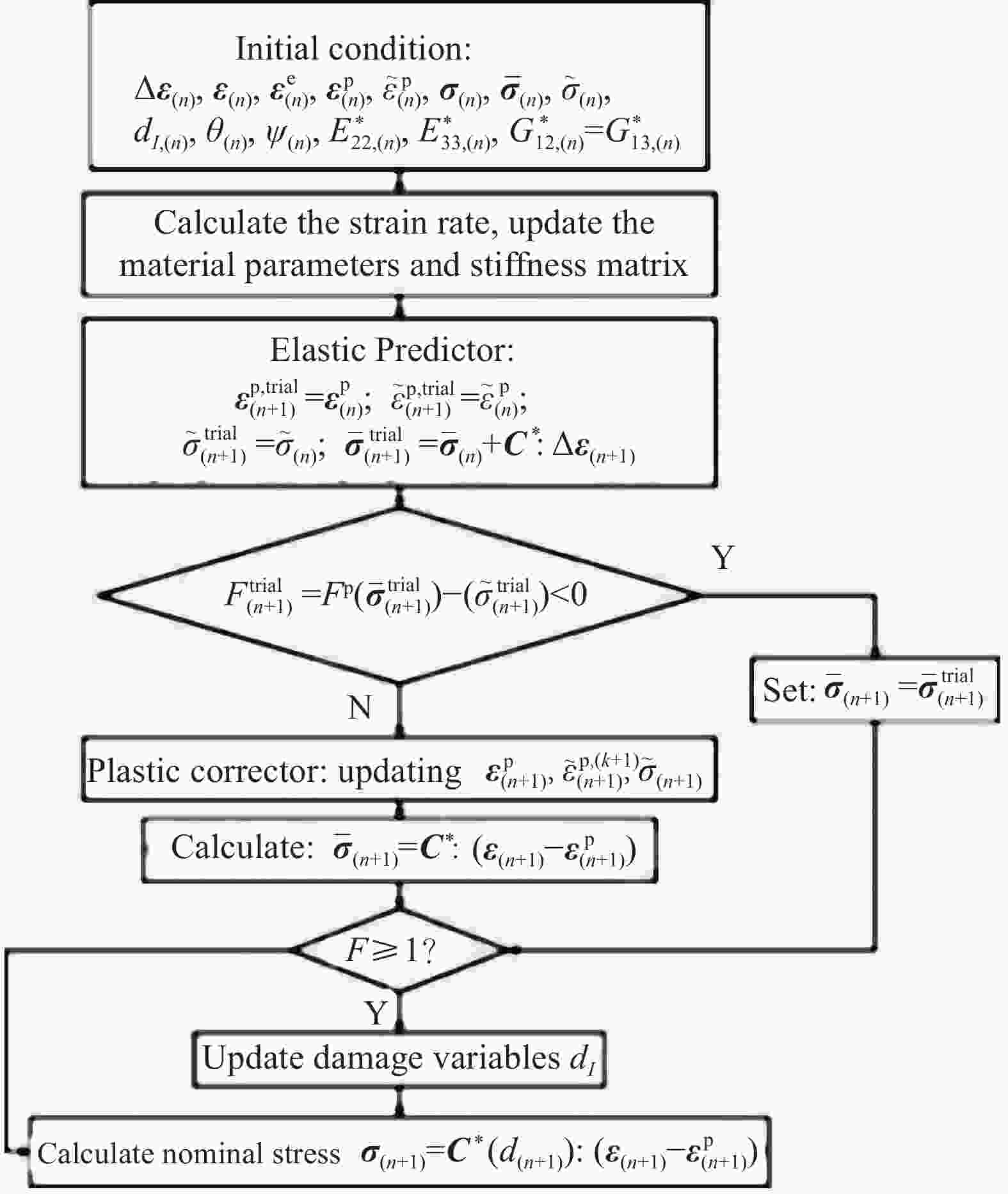

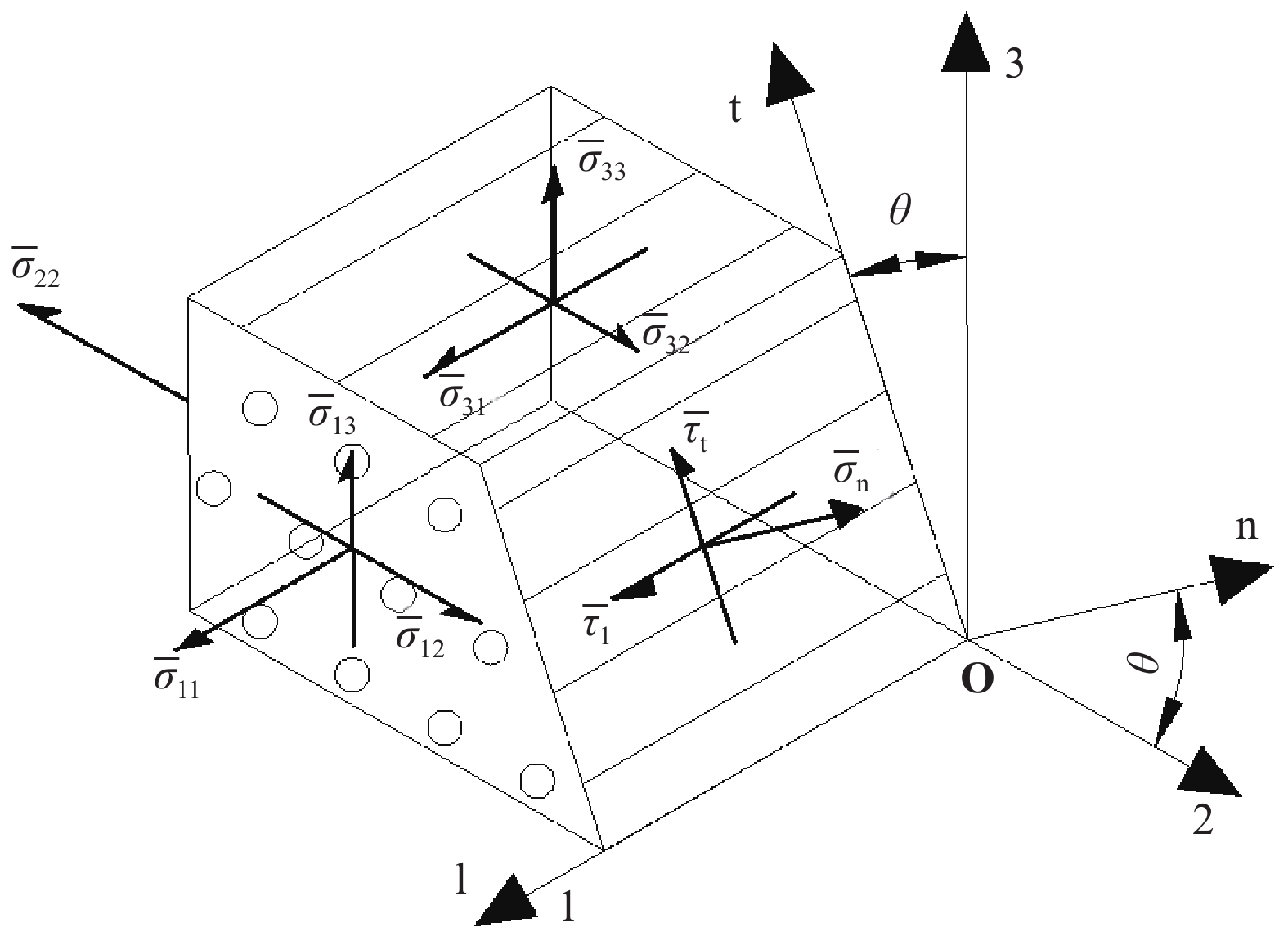

摘要: 建立了一个同时考虑复合材料非线性力学响应、应变率效应和损伤累积导致材料属性退化的弹塑性三维损伤本构模型。采用改进的塑性力学模型表征材料在动态荷载下的非线性力学行为。为准确预测复合材料在动态荷载下的弹塑性力学响应,引入了率相关放大系数对准静态下的塑性强化函数进行修正。采用“断裂带模型”对已开发的本构模型软化段进行规则化,以减轻有限元分析结果的网格敏感性。采用分区反抛物线插值法对基体损伤初始断裂面角度及纤维扭结/劈裂平面角度进行求解。开发包含数值积分算法的用户材料自定义子程序VUMAT,并嵌于有限元程序ABAQUS V6.14中,对力学行为展现显著非线性力学效应和应变率效应的IM7/8552碳纤维/环氧树脂复合材料层合板进行了渐进失效分析,验证本文提出的材料本构模型的有效性。结果显示,预测结果与已报道的试验结果吻合良好,表明已建立的率相关三维弹塑性损伤本构模型能准确预测此类复合材料层合板的在动态荷载下的力学行为,为复合材料构件及其结构设计提供了一种有效的分析方法。Abstract: A three-dimensional elastoplastic damage constitutive model which takes into account the nonlinear mechanical response, strain rate effects of composites, material properties degradation due to damage evolution was proposed. A modified plastic model was used to characterize the nonlinear mechanical response under dynamic load. To accurately describe the elastoplastic mechanical response of composite materials under dynamic load, the rate-dependent amplification factor was introduced to modify the plastic hardening law under static condition. In order to alleviate mesh sensitivity of finite element analysis results, the“Crack Band Theory”was applied to regularize the softening branch of the material constitutive model. The Selective Range Inverse Parabolic Interpolation algorithm was used to calculate the angle of the initial fracture plane of matrix damage and the angle of the fiber kinking/splitting plane. User-defined material subroutine VUMAT containing the numerical integration algorithm was coded and implemented in finite element procedure ABAQUS V6.14. The efficiency of the material constitutive model was demonstrated through progressive failure analysis of IM7/8552 carbon fiber/epoxy composite laminates, the mechanical behavior of which demonstrates significant nonlinear mechanical response. The numerical results agree well with the experimental data reported in the literature. It is shown that the rate-dependent three-dimensional elastoplastic damage constitutive model can predict the mechanical behavior of composites under dynamic loads with sufficient accuracy. The proposed approach provides an efficient method for the design of composite components and structures.

-

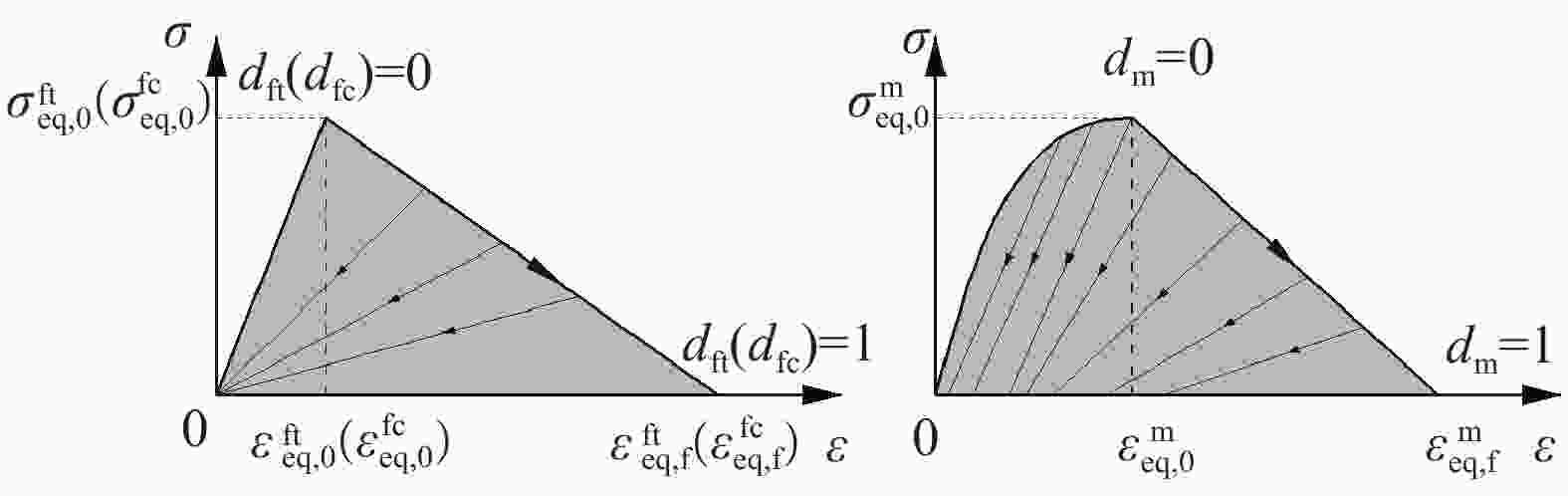

图 3 横向和剪切方向材料损伤本构关系

Figure 3. Material damage constitutive relationships in the transverse and shear directions

dI (I=ft,fc,m)—Damage variables corresponding to tensile and compressive failure in the fiber direction and matrix cracking, respectively; ${\sigma }^I_{{\rm{e}}{\rm{q}},0}$ and ${\varepsilon }^I_{{\rm{e}}{\rm{q}},0}$(I=ft,fc,m)—Equivalent stresses and equivalent strains when damage initiation criteria corresponding to tensile and compressive failure in the fiber direction and matrix cracking (see Eq. (17)) are met; ${\varepsilon }^I_{{\rm{e}}{\rm{q}},{\rm{f}}}$(I=ft,fc,m)—Equivalent strains at complete tensile and compressive failure in the fiber direction and complete matrix failure

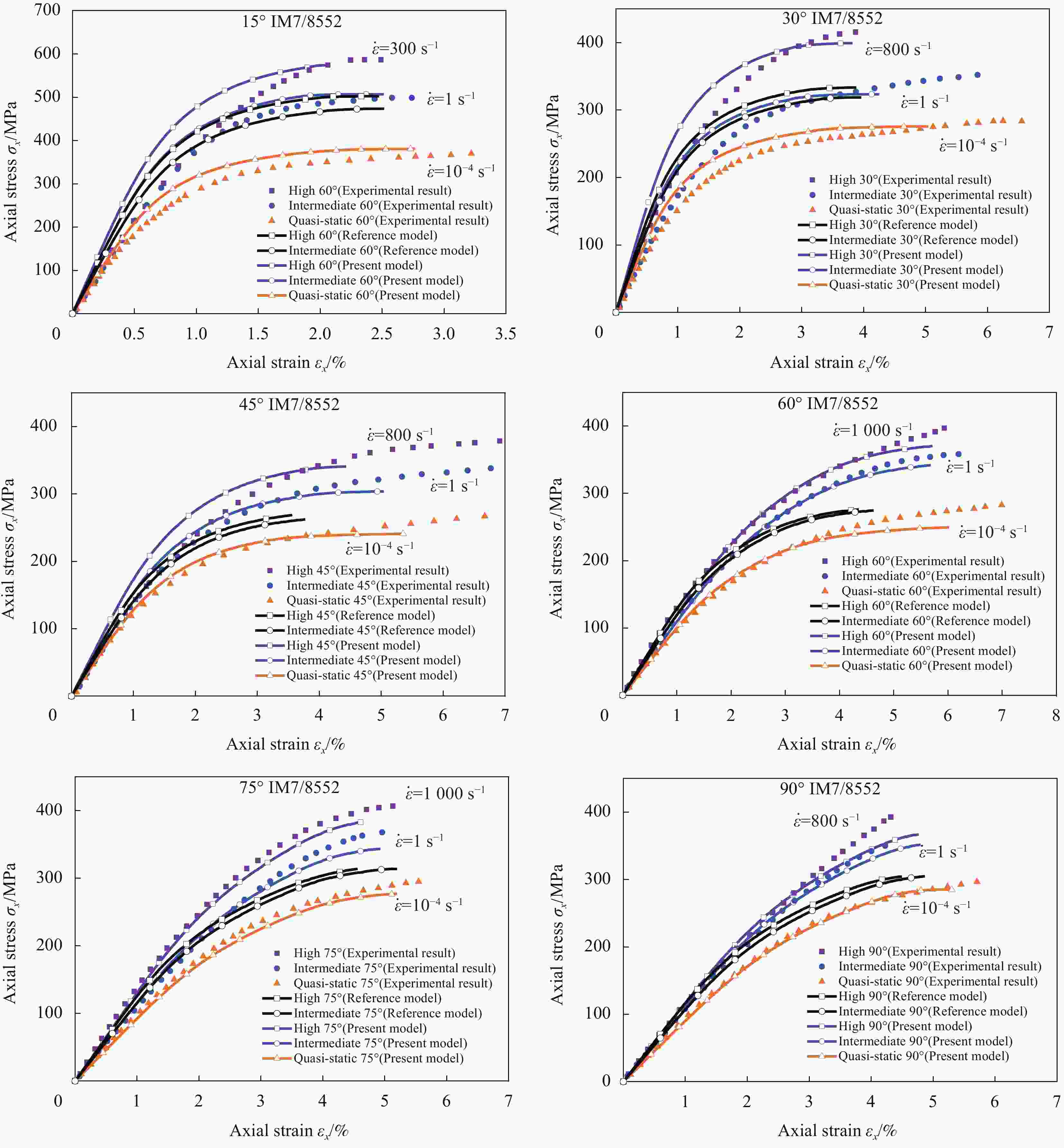

图 8 不同偏轴角度IM7/8552碳纤维/环氧树脂复合材料单向层合板在应变率分别为10−4 s−1(准静态)、1 s−1(中应变率)和高应变率压缩荷载下的试验与预测应力-应变曲线

Figure 8. Experimental and predicted stress-strain curves of off-axis IM7/8552 carbon fiber/epoxy unidirectional laminated specimens subjected to compressive loadings at strain rates of 10−4 s−1 (quasi-static), 1 s−1 (intermediate) and high strain rates

表 1 IM7/8552碳纤维/环氧树脂复合材料单向板属性

Table 1. Material properties of IM7/8552 carbon fiber/epoxy unidirectional composite laminate

$ {E}_{11} ^0$/GPa $ {E}_{22}^0={E}_{33} ^0$/GPa $ {X}_{\rm{T}} $/MPa $ {X}_{\rm{C}} $/MPa $ {Y}_{\rm{T}} $/MPa $ {Y}_{\rm{C}} $/MPa $ {S}_{12} $/MPa 154 9 1725 2650 76.4 288 89 $ {\nu }_{12}={\nu }_{13} $ $ {\nu }_{23} $ $ {G}_{12}^0={G}_{13} ^0$/GPa $ {G}_{23} ^0$/GPa $ {G}_{{\rm{I}}{\rm{C}}} $/(N·mm−1) $ {G}_{{\rm{I}}{\rm{I}}{\rm{C}}}={G}_{{\rm{I}}{\rm{I}}{\rm{I}}{\rm{C}}} $/(N·mm−1) 0.33 0.43 5.6 3.98 0.26 1.002 $ {G}_{{\rm{f}}{\rm{t}},{\rm{c}}} $/(N·mm−1) $ {G}_{{\rm{f}}{\rm{c}},{\rm{c}}} $/(N·mm−1) $ {m}_{\rm{e}} $ $ {m}_{\rm{s}} $ $ {a}_{66} $ β $ {n}_{\rm{p}} $ 80 80 0.035 0.055 2 794.233 0.1973 Notes: $ {E}_{11} ^0$, $ {E}_{22} ^0$, $ {E}_{33} ^0$—Quasi static elastic moduli in the fiber, transverse and through-thickness directions; $ {X}_{\rm{T}} $,$ {X}_{\rm{C}} $—Tensile and compressive strengths in the fiber direction; $ {Y}_{\rm{T}} $, $ {Y}_{\rm{C}} $—Tensile and compressive strengths in the transverse direction; $ {S}_{12} $—Shear strength in 1-2 plane; $ {\nu }_{ij} $,$ {G}_{ij} ^0$ (ij=12,13,23)—Poisson’s ratios and shear moduli in the 1-2,1-3, 2-3 planes; $ {G}_{{\rm{I}}{\rm{C}}} $, $ {G}_{{\rm{I}}{\rm{I}}{\rm{C}}} $, $ {G}_{{\rm{I}}{\rm{I}}{\rm{I}}{\rm{C}}} $—Fracture toughnesses for Mode I, II and III failure in the through-thickness direction, respectively; $ {G}_{{\rm{f}}{\rm{t}},{\rm{c}}} $, $ {G}_{{\rm{f}}{\rm{c}},{\rm{c}}} $—Tensile and compressive fracture toughnesses in the fiber direction; $ {m}_{\rm{e}} $, $ {m}_{\rm{s}} $—Strain-rate parameters related to elastic moduli and failure strengths; $ {a}_{66} $—Material parameter of the plastic model; β, $ {n}_{\rm{p}} $—Coefficients that fit the experimental hardening curve. -

[1] WANG J, CALLUS P J, BANNISTER M K. Experimental and numerical investigation of the tension and compression strength of un-notched and notched quasi-isotropic lami-nates[J]. Composite Structures,2004,64(3/4):297-306. [2] LAFARIE-FRENOT M C, TOUCHARD F. Comparative in-plane shear behaviour of long-carbon-fibre composites with thermoset or thermoplastic matrix[J]. Composites Science and Technology,1994,52(3):417-425. [3] VOGLER T J, KYRIAKIDES S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part I: Experiments[J]. International Journal of Plasticity,1999,15(8):783-806. doi: 10.1016/S0749-6419(99)00011-X [4] HSU S Y, VOGLER T J, KYRIAKIDES S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part II: Modeling[J]. International Journal of Plasticity,1999,15(8):807-836. doi: 10.1016/S0749-6419(99)00012-1 [5] SODEN P D, HINTON M J, KADDOUR A S. Lamina properties, lay-up configurations and loading conditions for a range of fibre-reinforced composite laminates[J]. Composites Science and Technology,1998,58(7):1011-1022. doi: 10.1016/S0266-3538(98)00078-5 [6] HARDING J. Effect of strain rate and specimen geometry on the compressive strength of woven glass-reinforced epoxy laminates[J]. Composites,1993,24(4):323-332. doi: 10.1016/0010-4361(93)90042-7 [7] El-HABAK A. Compressive resistance of unidirectional GFRP under high rate of loading[J]. Journal of Compo-sites, Technology and Research,1993,15(4):311-317. doi: 10.1520/CTR10384J [8] HSIAO H M. Strain rate effects on the transverse compressive and shear behavior of unidirectional composites[J]. Journal of Composite Materials,1999,33(17):1620-1642. doi: 10.1177/002199839903301703 [9] HOSUR M V, VAIDYA U K, ABRAHAM A, et al. Static and high strain rate compression response of thick section twill weave S-2 glass/vinyl ester composites manufactured by affordable liquid molding processes[J]. Journal of Engineering Materials and Technology,1999,121(4):468-475. doi: 10.1115/1.2812403 [10] HOSUR M V, ALEXANDER J, VAIDYA U K, et al. High strain rate compression response of carbon/epoxy laminate composites[J]. Composite Structures,2001,52(3):405-417. [11] GRIMES G C. Composite materials: Testing and design (Tenth volume) || A method for evaluating the high strain rate compressive properties of composite materials[J]. 1992: 54-54-12. [12] DANIEL I M, WERNER B T, FENNER J S. Strain-rate-dependent failure criteria for composites[J]. Composites Science and Technology,2010,71(3):357-364. [13] AZZI V D, TSAI S W. Anisotropic strength of composites[J]. Experimental Mechanics,1965,5(9):283-288. doi: 10.1007/BF02326292 [14] HOFFMAN O. The brittle strength of orthotropic materials[J]. Journal of Composite Materials,1967,1(2):200-206. doi: 10.1177/002199836700100210 [15] TSAI S. A general theory of strength for anisotropic materials[J]. Journal of Composite Materials,1971,5(1):58-80. doi: 10.1177/002199837100500106 [16] HASHIN Z. A fatigue failure criterion for fiber reinforced materials[J]. Journal of Composite Materials,1973,7(4):448-464. doi: 10.1177/002199837300700404 [17] HASHIN Z. Failure criteria for unidirectional fiber composites[J]. Journal of Applied Mechanics,1980,47(2):329-334. doi: 10.1115/1.3153664 [18] PUCK A, SCHUMANN H. Failure analysis of FRP laminates by means of physically based phenomenological models[J]. Composites Science and Technology,2002,62(12):1633-1662. [19] PUCK A, SCHUMANN H. Failure analysis of FRP laminates by means of physically based phenomenological models[J]. Composites Science and Technology,1998,58(7):1045-1067. doi: 10.1016/S0266-3538(96)00140-6 [20] 杨凤祥, 陈静芬, 陈善富, 等. 基于剪切非线性三维损伤本构模型的复合材料层合板失效强度预测[J]. 复合材料学报, 2020, 37(9):2207-2222.YANG F X, CHEN J F, CHEN S F, et al. Failure strength prediction of composite laminates using 3D damage constitutive model with nonlinear shear effects[J]. Acta Materiae Compositae Sinica,2020,37(9):2207-2222(in Chinese). [21] DAVILA C G. Failure criteria for FRP laminates[J]. Journal of Composite Materials,2003,39(4):404-408. [22] PINHO S T, DAVILA C G, CAMANHO P P, et al. Failure models and criteria for FRP under in-plane or three-dimensional stress states including shear non-linearity[R]. NASA/TM-2005-213530, 2005. [23] PINHO S. T. Modelling failure of laminated composites using physically-based failure models[D]. London: Imperial College London, 2005. [24] PINHO S T, IANNUCCI L, ROBINSON P. Physically-based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking: Part I: Development[J]. Composites Part A: Applied Science and Manufacturing,2005,37(1):63-73. [25] PINHO S T, IANNUCCI L, ROBINSON P. Physically based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking. Part II: FE implementation[J]. Composites Part A: Applied Science & Manufacturing,2006,37(5):766-777. [26] PINHO S T, DARVIZEH R, ROBINSON P, et al. Material and structural response of polymer-matrix fibre-reinforced composites[J]. Journal of Composite Materials,2012,46(19-20):2313-2341. doi: 10.1177/0021998312454478 [27] ARGON A S. Fracture of composites[J]. Treatise on Materials Science and Technology,1972,1:79-114. [28] GIANNADAKIS K, VARNA J. Analysis of non-linear shear stress-strain response of unidirectional GF/EP composite[J]. Composites Part A: Applied Science and Manufacturing,2014,62(17):67-76. [29] CHEN J F, MOROZOV E V, SHANKAR K. A combined elastoplastic damage model for progressive failure analysis of composite materials and structures[J]. Composite Structures,2012,94(12):3478-3489. [30] 陈静芬. 基于弹塑性损伤本构模型的复合材料层合板破坏荷载预测[J]. 复合材料学报, 2017, 34(4):545-557.CHEN J F. Failure loads prediction of composite laminates using a combined elastoplastic damage model[J]. Acta Materiae Compositae Sinica,2017,34(4):545-557(in Chinese). [31] SUN C T, CHEN J L. A simple flow rule for characterizing nonlinear behavior of fiber composites[J]. Journal of Composite Materials,1989,23(10):1009-1020. doi: 10.1177/002199838902301004 [32] 薛康, 肖毅, 王杰, 等. 单向纤维增强聚合物复合材料压缩渐进破坏[J]. 复合材料学报, 2019, 36(6):1398-1412.XUE K, XIAO Y, WANG J, et al. Compression progressive failure of unidirectional fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2019,36(6):1398-1412(in Chinese). [33] CHEN J F, MOROZOV E V. A consistency elasto-viscoplastic damage model for progressive failure analysis of composite laminates subjected to various strain rate loadings[J]. Composite Structures,2016,148:224-235. [34] THIRUPPUKUZHI S V, SUN C T. Models for the strain-rate-dependent behavior of polymer composites[J]. Composites Science and Technology,2001,61(1):1-12. [35] BAZANT Z P, OH B H. Crack band theory for fracture of concrete[J]. Matériaux et Construction,1983,16(3):155-177. [36] WINN V M, SRIDHARAN S. An investigation into the accuracy of a one-parameter nonlinear model for unidirectional composites[J]. Journal of Composite Materials,2001,35(16):1491-1507. doi: 10.1106/M99D-14RL-NHHF-CHWN [37] SCHULTHEISZ C R, WAAS A M. Compressive failure of composites, part I: Testing and micromechanical theories[J]. Progress in Aerospace Sciences,1996,32(1):1-42. doi: 10.1016/0376-0421(94)00002-3 [38] SCHAEFER J D, WERNER B T, DANIEL I M. Strain-rate-dependent failure of a toughened matrix composite[J]. Experimental Mechanics,2014,54(6):1111-1120. doi: 10.1007/s11340-014-9876-0 [39] MUKHOPADAYAY S, JONES M I, STEPHEN R, et al. Compressive failure of laminates containing an embedded wrinkle: Experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing,2015,73:132-142. -

下载:

下载: