Influence of basalt fiber on the printability of 3D printing cement-based materials

-

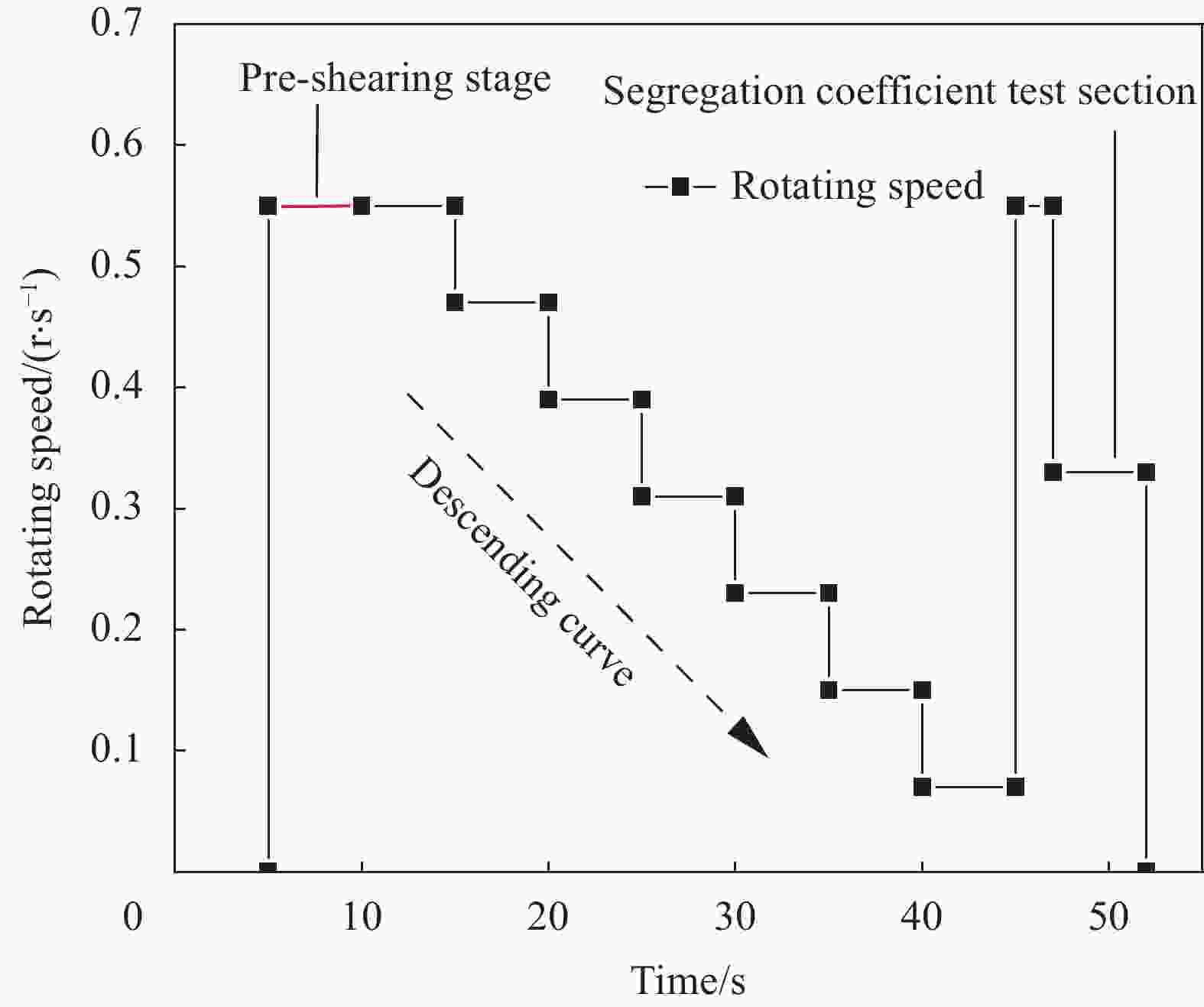

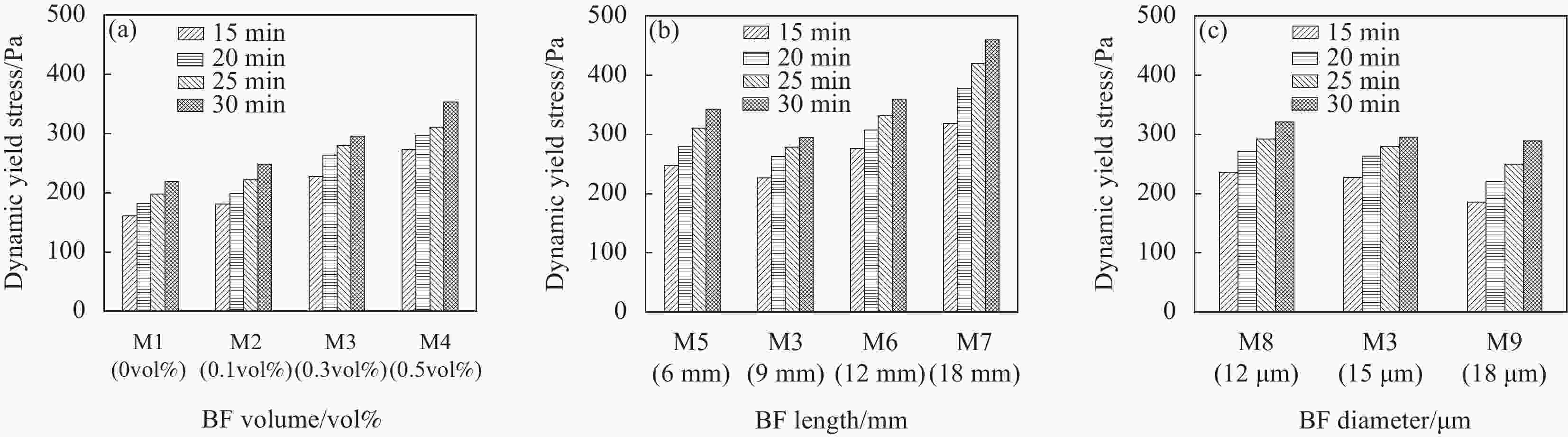

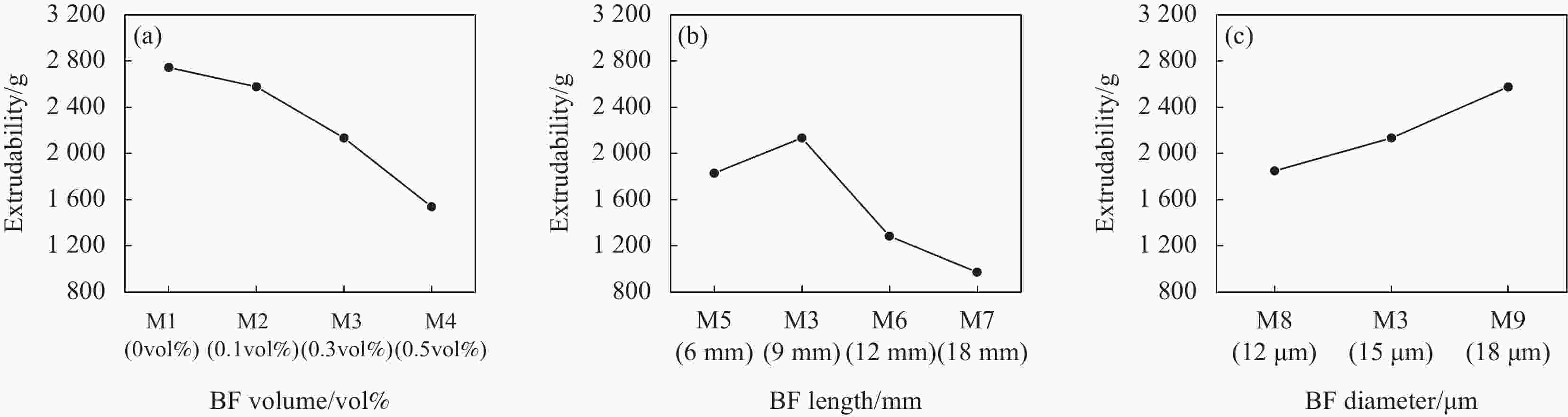

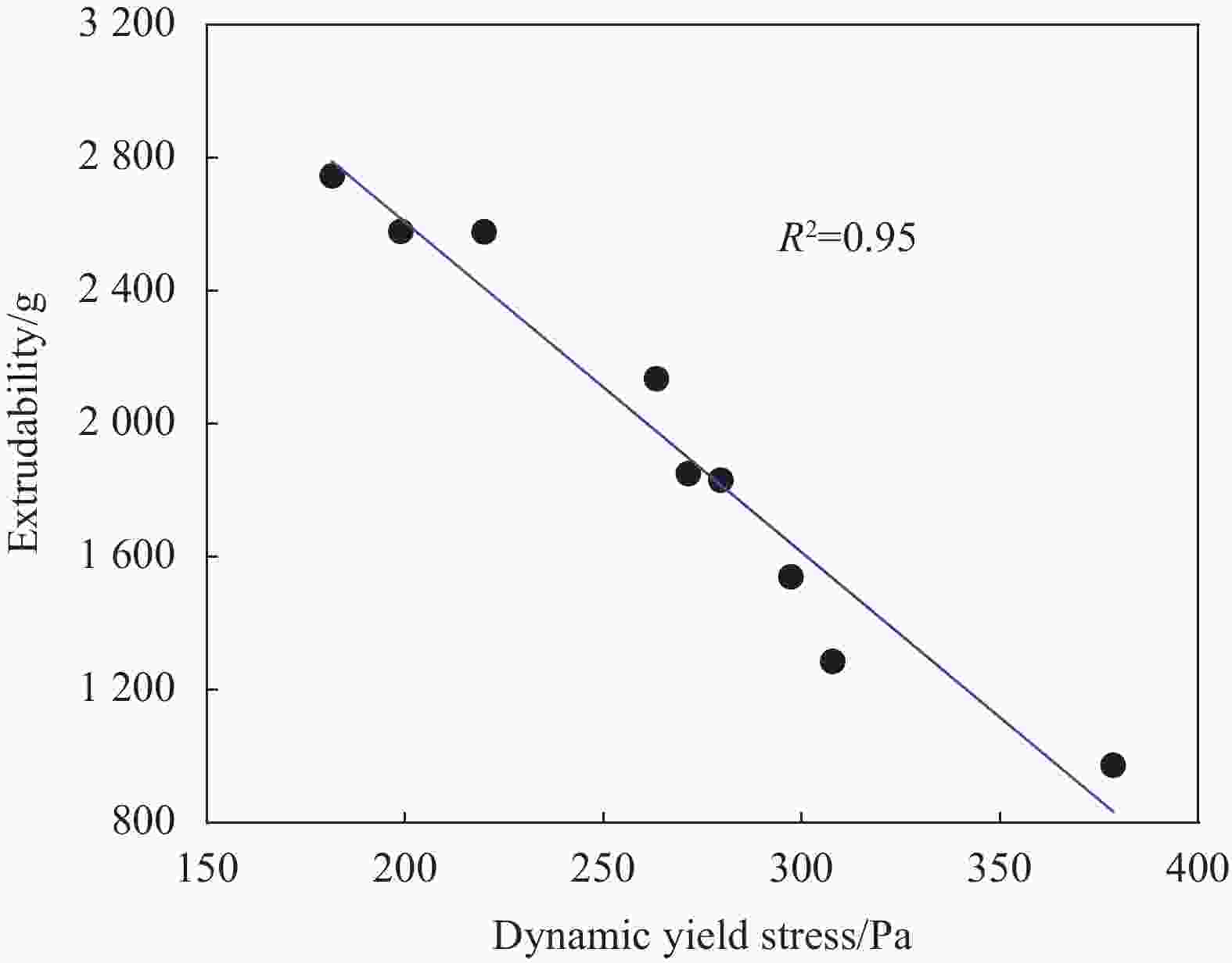

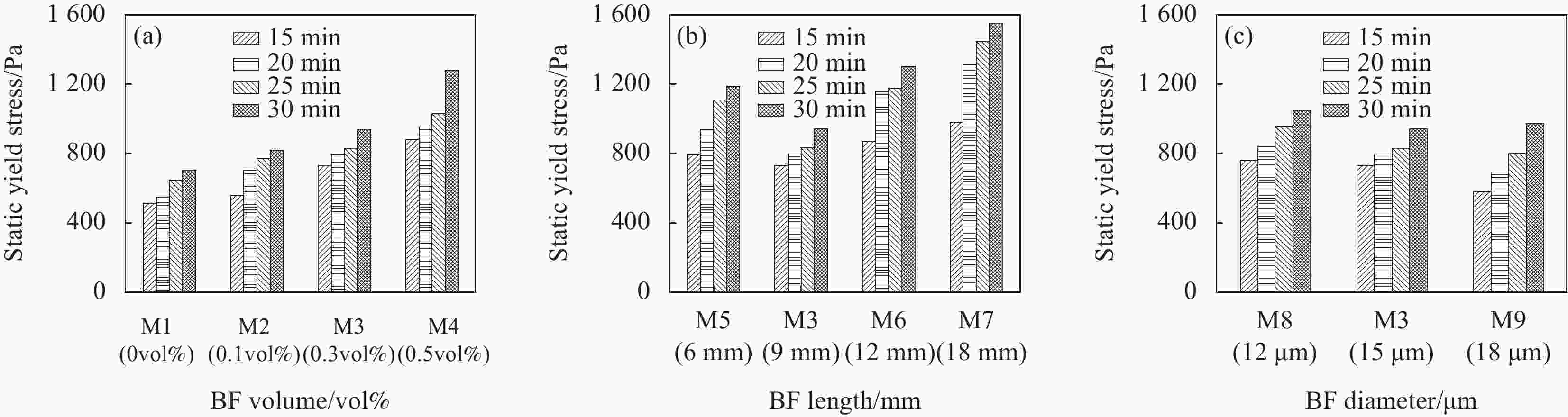

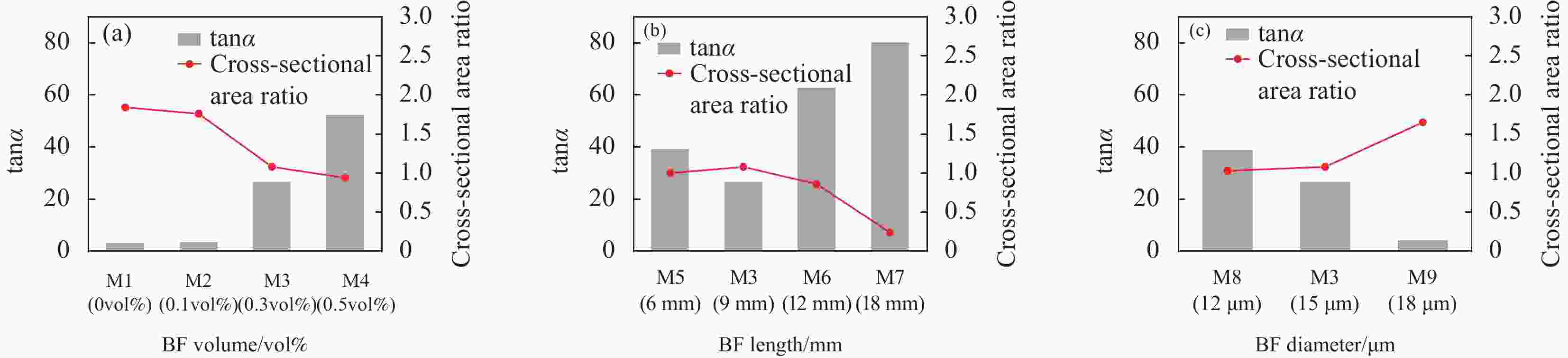

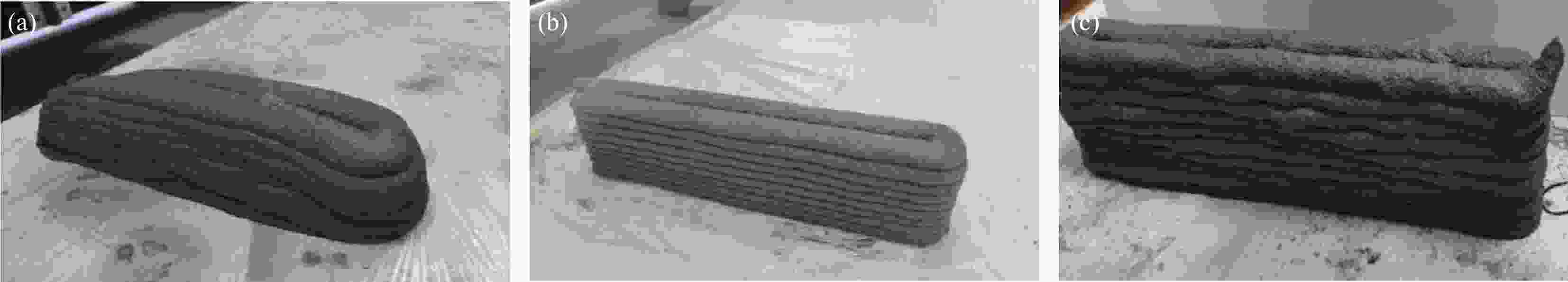

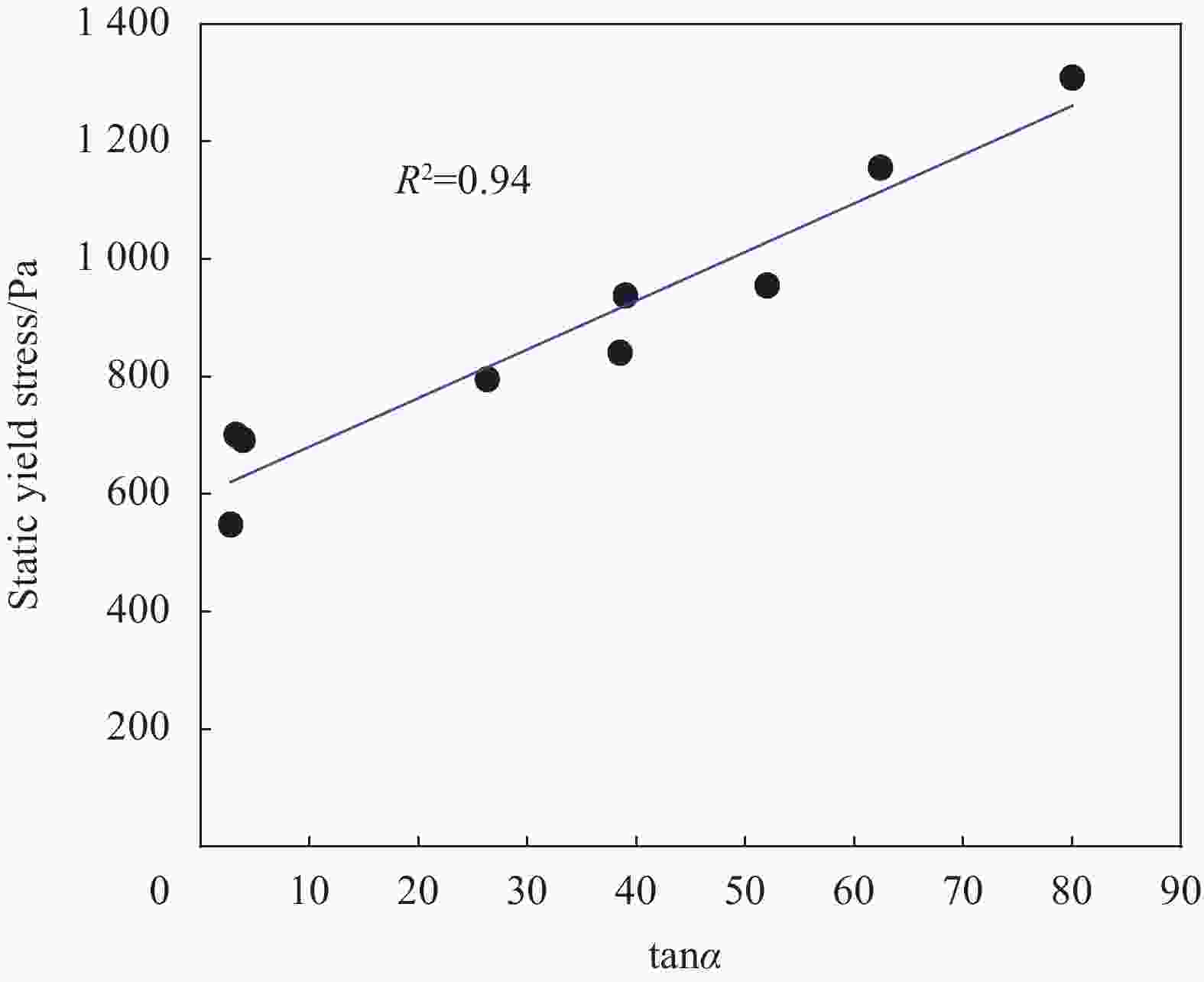

摘要: 玄武岩纤维是一种具备良好力学性能、优异耐腐蚀性且高性价比的纤维材料,将其掺入3D打印水泥基材料中可以起到抑制塑性收缩开裂的作用。而玄武岩纤维的掺入会显著改变3D打印水泥基材料的流变性能,从而对3D打印水泥基材料可挤出性及可建造性产生影响。通过改变纤维的掺量、直径及长度,研究了玄武岩纤维特性对3D打印水泥基材料流变性能、可挤出性及可建造性的影响,明确了流变性能与可挤出性和可建造性之间的关系。研究结果表明,玄武岩纤维的掺量对3D打印水泥基材料流变性能参数的影响权重最大,其次是直径。动态屈服应力与单位时间挤出量呈负相关,静态屈服应力与打印试件倾角呈正相关。打印试件横截面积比受动态屈服应力和静态屈服应力等综合因素影响。综合来看,优良的可挤出性需要适中的动态屈服应力,约为280 Pa。而优良的可建造性不仅需要适中的动态屈服应力,还需要静态屈服应力大于950 Pa。Abstract: Basalt fiber is a fiber material with good mechanical properties, excellent corrosion resistance and high cost performance. Incorporating it into 3D printing cement-based materials can inhibit plastic shrinkage and cracking. The addition of basalt fiber will significantly change the rheological properties of 3D printing cement-based materials, which will affect the extrudability and buildability of 3D printing cement-based materials. This article aimed to clarify the influence of basalt fiber on the printability of 3D printing cement-based materials. By changing the fiber content, diameter and length, the effects of basalt fiber properties on the rheological properties, extrudability and buildability of 3D printing cement-based materials were studied. The relationship between rheological properties and extrudability and buildability was clarified. The results show that the amount of basalt fiber has the largest influence on the rheological parameters of 3D printing cement-based materials, followed by the diameter. The dynamic yield stress is negatively correlated with the amount of extrusion per unit time. The static yield stress is positively correlated with the inclination angle of the printed specimen. The cross-sectional area ratio of the printed specimen is affected by comprehensive factors such as dynamic yield stress and static yield stress. Taken together, good extrudability requires moderate dynamic yield stress, about 280 Pa. Excellent buildability requires not only a moderate dynamic yield stress, but also the static yield stress greater than 950 Pa.

-

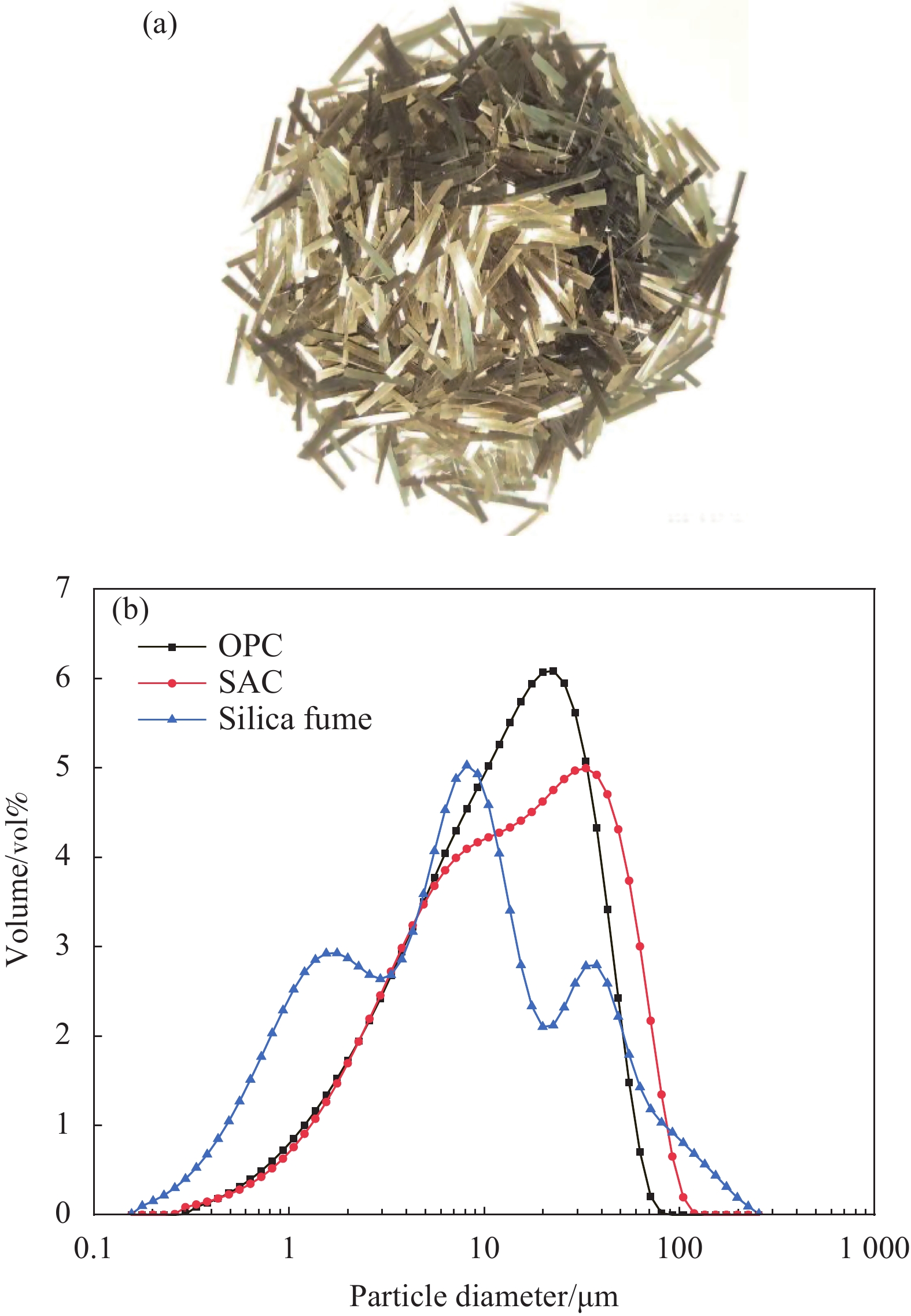

表 1 玄武岩纤维(BF)物理力学性能指标

Table 1. Physical and mechanical properties of basalt fiber (BF)

Sample Diameter/μm Length/mm Density/(g·cm−3) Elastic modulus/GPa Tensile strength/MPa Elongation at break/% BF 12 6, 9, 12 2.64 91-110 4000-4800 2.4-3.0 15 6, 9, 12, 18 2.64 91-110 4000-4800 2.4-3.0 18 6, 9, 12 2.64 91-110 4000-4800 2.4-3.0 表 2 3D打印水泥基材料配合比设计

Table 2. Mix design of 3D printing cement-based material

Group OPC/wt% SAC/wt% SF/wt% Sand/wt% FX/wt% Water/wt% HRWRA/wt% Basalt fiber M1 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 15 μm, 0vol% M2 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 15 μm, 0.10vol% M3 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 15 μm, 0.30vol% M4 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 15 μm, 0.50vol% M5 8.5 1 0.5 14 0.04 3.5 0.08 6 mm, 15 μm, 0.3vol% M6 8.5 1 0.5 14 0.04 3.5 0.08 12 mm, 15 μm, 0.3vol% M7 8.5 1 0.5 14 0.04 3.5 0.08 18 mm, 15 μm, 0.3vol% M8 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 12 μm, 0.3vol% M9 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 18 μm, 0.3vol% Notes: SF—Silica fume; FX—Dispersible latex powder; HRWRA—Polycarboxylic acid superplasticizer; All figures in the table are the weight ratio of SAC, except for fiber content (volume fraction). 表 3 BF特性正交试验设计方案

Table 3. Orthogonal test design scheme of BF properties

Group OPC/wt% SAC/wt% SF/wt% Sand/wt% FX/wt% Water/wt% HRWRA/wt% BF fiber Combination 1 8.5 1 0.5 14 0.04 3.5 0.08 6 mm, 0.1vol%, 12 μm A1B1C1 2 8.5 1 0.5 14 0.04 3.5 0.08 6 mm, 0.3vol%, 15 μm A1B2C2 3 8.5 1 0.5 14 0.04 3.5 0.08 6 mm, 0.5vol%, 18 μm A1B3C3 4 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 0.1vol%, 15 μm A2B1C2 5 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 0.3vol%, 18 μm A2B2C3 6 8.5 1 0.5 14 0.04 3.5 0.08 9 mm, 0.5vol%, 12 μm A2B3C1 7 8.5 1 0.5 14 0.04 3.5 0.08 12 mm, 0.1vol%, 18 μm A3B1C3 8 8.5 1 0.5 14 0.04 3.5 0.08 12 mm, 0.3vol%, 12 μm A3B2C1 9 8.5 1 0.5 14 0.04 3.5 0.08 12 mm, 0.5vol%, 15 μm A3B3C2 表 4 BF对3D打印水泥基材料的动态屈服应力和可挤出性正交试验测试结果

Table 4. Orthogonal test results of dynamic yield stress and extrudability of BF on 3D printing cement-based materials

Group Combination Dynamic yield stress/Pa Extrudability/g 20 min 20 min 1 A1B1C1 225.46 2485 2 A1B2C2 279.57 1830 3 A1B3C3 230.36 2515 4 A2B1C2 198.87 2578 5 A2B2C3 219.89 2577 6 A2B3C1 297.51 1330 7 A3B1C3 232.29 2199 8 A3B2C1 321.98 1255 9 A3B3C2 308.43 1200 表 5 BF对3D打印水泥基材料的动态屈服应力和可挤出性正交试验测试分析结果

Table 5. Orthogonal test analysis results of dynamic yield stress and extrudability of BF on 3D printing cement-based materials

Dynamic yield stress/Pa Extrudability/g Length (A) Dosage (B) Diameter (C) Length (A) Dosage (B) Diameter (C) T1 735.39 656.62 844.95 6830.00 7262.00 5070.00 T2 716.27 821.44 786.87 6485.00 5662.00 5608.00 T3 862.70 836.30 682.54 4654.00 5045.00 7291.00 t1 245.13 218.87 281.65 2276.67 2420.67 1690.00 t2 238.76 273.81 262.29 2161.67 1887.33 1869.33 t3 287.57 278.77 227.51 1551.33 1681.67 2430.33 Range R 48.81 59.89 54.14 725.34 739.00 740.33 Superior level A3 B2 C1 A3 B2 C2 Primary and secondary order B>C>A C>B>A Notes: Tx—Sum of the test results of the corresponding factors, such as: T1-Length (A)=225.46+279.57+230.36=735.39; tx—Mean value of the sum of the test results of the three-factor experiment, such as: t1-Length (A)=(225.46+279.57+230.36)/3=245.13; Range R—Difference between the maximum value and the minimum value in the tx value, such as: for extrudability testing, Range R-Dosage (B)=2420.67−1681.67=739.00; Primary and secondary order are judged based on range R. The larger the range R, the greater the influence weight. 表 6 BF对3D打印水泥基材料的可建造性单一变量试验测试结果

Table 6. Test results of single variable test for buildability of BF on 3D printing cement-based materials

Group BF fiber Buildability High/mm Upper width/mm Lower width/mm tanα Cross-sectional area ratio M1 9 mm, 15 μm, 0vol% 72 58 110 2.77 1.80 M2 9 mm, 15 μm, 0.10vol% 75 54 100 3.26 1.72 M3 9 mm, 15 μm, 0.30vol% 79 42 48 26.33 1.06 M4 9 mm, 15 μm, 0.50vol% 78 38 41 52.00 0.92 M5 6 mm, 15 μm, 0.3vol% 78 40 44 39.00 0.98 M6 12 mm, 15 μm, 0.3vol% 78 35 37.5 62.40 0.84 M7 18 mm, 15 μm, 0.3vol% 40 20 21 80.00 0.24 M8 9 mm, 12 μm, 0.3vol% 77 42 46 38.50 1.01 M9 9 mm, 18 μm, 0.3vol% 74 56 94 3.89 1.65 表 7 BF对3D打印水泥基材料的可建造性正交试验测试结果

Table 7. Orthogonal test results of buildability of BF on 3D printing cement-based materials

Group Combination Static yield stress/Pa Buildability 20 min High/mm Upper width/mm Lower width/mm tanα Cross-sectional area ratio 1 A1B1C1 740.38 75 50 78 5.36 1.43 2 A1B2C2 937.76 78 40 44 39.00 1.00 3 A1B3C3 751.08 76 48 76 5.43 1.40 4 A2B1C2 700.78 75 54 100 3.26 1.76 5 A2B2C3 691.97 74 56 94 3.89 1.65 6 A2B3C1 1034.53 77 37 40.5 44.00 0.89 7 A3B1C3 726.87 74 52 94 3.52 1.61 8 A3B2C1 1085.94 75 35 38 50.00 0.81 9 A3B3C2 1100.78 74 36 39 49.33 0.83 表 8 BF对3D打印水泥基材料的静态屈服应力和可建造性正交试验分析结果

Table 8. Orthogonal test analysis results of static yield stress and constructability of BF on 3D printing cement-based materials

Static yield stress/Pa tanα Cross-sectional area ratio Length (A) Dosage (B) Diameter (C) Length (A) Dosage (B) Diameter (C) Length (A) Dosage (B) Diameter (C) T1 2429.22 2168.03 2860.85 49.79 12.14 99.36 3.83 4.80 3.13 T2 2427.28 2715.67 2739.32 51.16 92.89 91.59 4.30 3.47 3.59 T3 2913.59 2886.39 2169.92 102.86 98.76 12.85 3.25 3.12 4.66 t1 809.74 722.68 953.62 16.60 4.05 33.12 1.28 1.60 1.04 t2 809.09 905.22 913.11 17.05 30.96 30.53 1.43 1.16 1.20 t3 971.20 962.13 723.31 34.29 32.92 4.28 1.08 1.04 1.55 Range R 162.10 239.45 230.31 17.69 28.87 28.84 0.35 0.56 0.51 Superior level A3 B3 C1 A3 B3 C1 A3 B3 C1 Primary and secondary order B>C>A B>C>A B>C>A -

[1] NGO T D, KASHANI A, IMBALZANO G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges[J]. Composites Part B: Engineering,2018,143:172-196. doi: 10.1016/j.compositesb.2018.02.012 [2] 马敬畏, 蒋正武, 苏宇峰. 3D打印混凝土技术的发展与展望[J]. 混凝土世界, 2014, 7:41-46.MA Jingwei, JIANG Zhengwu, SU Yufeng. The development and prospect of 3D printing concrete technology[J]. Concrete World,2014,7:41-46(in Chinese). [3] 丁烈云, 徐捷, 覃亚伟. 建筑3D打印数字建造技术研究应用综述[J]. 土木工程与管理学报, 2015, 32(3):1-10. doi: 10.3969/j.issn.2095-0985.2015.03.001DING Lieyun, XU Jie, QIN Yawei. Summary of research and application of digital construction technology of architectural 3D printing[J]. Journal of Civil Engineering and Management,2015,32(3):1-10(in Chinese). doi: 10.3969/j.issn.2095-0985.2015.03.001 [4] SCHUTTER G D, LESAGE K, MECHTCHERINE V, et al. Vision of 3D printing with concrete-technical, economic and environmental potentials[J]. Cement and Concrete Research,2018,112:25-36. doi: 10.1016/j.cemconres.2018.06.001 [5] WU P, WANG J, WANG X Y. A critical review of the use of 3D printing in the construction industry[J]. Automation in Construction,2016,68:21-31. doi: 10.1016/j.autcon.2016.04.005 [6] MECHTCHERINE V, GRAFE J, NERELLA V N, et al. 3D-printed steel reinforcement for digital concrete construction: Manufacture, mechanical properties and bond behaviour[J]. Construction and Building Materials,2018,179:125-137. doi: 10.1016/j.conbuildmat.2018.05.202 [7] 赵颖, 刘维胜, 王欢, 等. 石灰石粉对3D打印水泥基材料性能的影响[J]. 材料导报, 2020, 34(S2):1217-1220.ZHAO Ying, LIU Weisheng, WANG Huan, et al. The influence of limestone powder on the properties of 3D printing cement-based materials[J]. Materials Reports,2020,34(S2):1217-1220(in Chinese). [8] 朱彬荣, 潘金龙, 周震鑫, 等. 3D打印高延性水泥基复合材料的单轴受拉和受压行为[J]. 硅酸盐学报, 2021, 49(5):844-854.ZHU Binrong, PAN Jinlong, ZHOU Zhenxin, et al. Uniaxial tensile and compressive stress-strain behavior of 3D printed engineered cementitious composites[J]. Journal of the Chinese Ceramic Society,2021,49(5):844-854(in Chinese). [9] SOLTAN D G, LI V C. A self-reinforced cementitious composite for building-scale 3D printing[J]. Cement and Concrete Composites,2018,90:1-13. doi: 10.1016/j.cemconcomp.2018.03.017 [10] OGURA H, NERELLA V N, MECHTCHERINE V. Developing and testing of strain-hardening cement-based composites (SHCC) in the context of 3D-printing[J]. Materials, 2018, 11(8): 1375 [11] LE T T, AUSTIN S A, LIM S. Mix design and fresh properties for high-performance printing concrete[J]. Materials and Structure,2012,45(8):1221-1232. doi: 10.1617/s11527-012-9828-z [12] HAMBACH M, MOLLER H, NEUMANN T, et al. Portland cement paste with aligned carbon fibers exhibiting exceptionally high flexural strength (> 100 MPa)[J]. Cement and Concrete Research,2016,89:80-86. doi: 10.1016/j.cemconres.2016.08.011 [13] AL-QUTAIFI S, NAZARI A, BAGHERI A. Mechanical pro-perties of layered geopolymer structures applicable in concrete 3D-printing[J]. Construction and Building Materials,2018,176:690-699. doi: 10.1016/j.conbuildmat.2018.04.195 [14] PANDA B, PAUL S C, MING J T. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction materia[J]. Materials Letters,2017,209:146-149. [15] MA G W, LI Z J, WANG L, et al. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3D printing[J]. Construction and Building Materials,2019,202:770-783. doi: 10.1016/j.conbuildmat.2019.01.008 [16] HAMBACH M, VOLKMER D. Properties of 3D-printed fiber-reinforced portland cement paste[J]. Cement and Concrete Composites,2017,79:62-70. doi: 10.1016/j.cemconcomp.2017.02.001 [17] BEHZAD N, PRAFUL V, JAY S, et al. Effect of polypropylene fibre addition on properties of geopolymers made by 3D printing for digital construction[J]. Materials,2018,11:12. [18] 张超, 邓智聪, 汪智斌, 等. 纤维对3D打印混凝土打印性能与力学性能的影响[J]. 硅酸盐通报, 2021, 40(6):1870-1878, 1888.ZHANG Chao, DENG Zhicong, WANG Zhibin, et al. Effects of fibers on printing performance and mechanical properties of 3D printing concrete[J]. Bulletin of the Chinese Ceramic Society,2021,40(6):1870-1878, 1888(in Chinese). [19] 胡显奇, 申屠年. 连续玄武岩纤维在军工及民用领域的应用[J]. 高科技纤维与应用, 2005(6):7-13. doi: 10.3969/j.issn.1007-9815.2005.06.002HU Xianqi, SHEN Tunian. The applications of the CBF in war industry & civil fields[J]. Hi-Tech Fiber and Application,2005(6):7-13(in Chinese). doi: 10.3969/j.issn.1007-9815.2005.06.002 [20] 张雄, 张蕾. 流变学理论在水泥基材料中的应用[J]. 粉煤灰综合利用, 2013(4):9-13. doi: 10.3969/j.issn.1005-8249.2013.04.003ZHANG Xiong, ZHANG Lei. Application of rheology theory in cement-based materials[J]. Fly Ash Comprehensive Utilization,2013(4):9-13(in Chinese). doi: 10.3969/j.issn.1005-8249.2013.04.003 [21] ZHAO Y, DUAN Y H, ZHU L L, et al. Characterization of coarse aggregate morphology and its effect on rheological and mechanical properties of fresh concrete[J]. Construction and Building Materials,2021,286:122940. doi: 10.1016/j.conbuildmat.2021.122940 [22] 焦登武, 安晓鹏, 史才军, 等. 骨料裹浆厚度对混凝土流变性能的影响[J]. 硅酸盐学报, 2017, 45(9):1360-1366.JIAO Dengwu, AN Xiaopeng, SHI Caijun, et al. Effects of paste thickness on coated aggregates on rheological pro-perties of concrete[J]. Journal of the Chinese Ceramic Society,2017,45(9):1360-1366(in Chinese). [23] 杨钱荣, 匡志平, 李检保, 等. 3D 打印建筑砂浆工作性测试装置及应用: 中国专利, ZL 201410558243.7[P]. 2014-10-20.YANG Qianrong, KUANG Zhiping, LI Jianbao, et al. Workability test device and application of 3D printing mortar: China patent, ZL 201410558243.7[P]. 2014-10-20(in Chinese). [24] 王亚坤, 杨钱荣. 添加剂对3D打印轻骨料混凝土流变性和可打印性的影响[J]. 建筑材料学报, 2021, 24(4): 749-757.WANG Yakun, YANG Qianrong. Effects of additives on the rheology properties and printability of 3D printing lightweight aggregate concrete[J]. Journal of Building Materials, 2021, 24(4): 749-757(in Chinese). [25] LONG W J, TAO J L, LIN C, et al. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing[J]. Journal of Cleaner Production,2019,239:118054. doi: 10.1016/j.jclepro.2019.118054 [26] NERELLA V N, NATHER M, IQBAL A, et al. Inline quantifi-cation of extrudability of cementitious materials for digital construction[J]. Cement and Concrete Composites,2019,95:260-270. doi: 10.1016/j.cemconcomp.2018.09.015 [27] WANGLER T, ROUSSEL N, BOS F P, et al. Digital concrete: A review[J]. Cement and Concrete Research,2019,123:1057. -

下载:

下载: