Influence of architecture parameter and mode on compressive properties of an Al2O3p/high manganese steel spherical interpenetrating composite

-

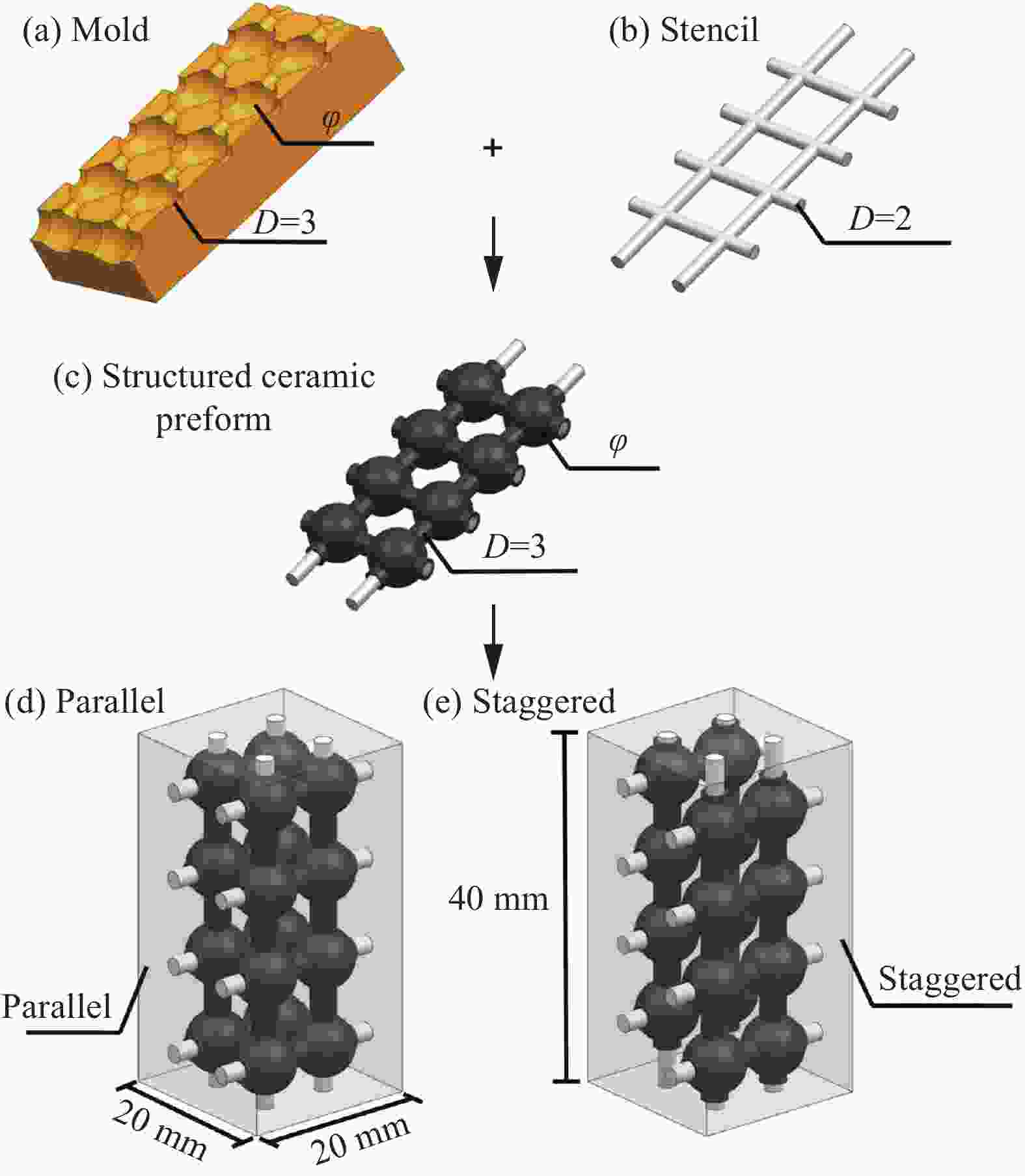

摘要: 传统的耐磨金属基复合材料普遍存在塑韧性低的问题。对氧化铝颗粒(Al2O3p)增强高锰钢复合材料进行球形网络构型设计,研究了构型方式、参数及热处理对复合材料压缩性能的影响。制备了3种构型参数(球径ϕ分别为6 mm、7 mm、8 mm)结合两种构型方式(平行、错落)的Al2O3p/高锰钢球形网络复合材料、均匀复合材料和基体材料。结果表明:同构型方式下,随着构型参数(复合区体积分数)的增加,材料的压缩性能降低,其中ϕ

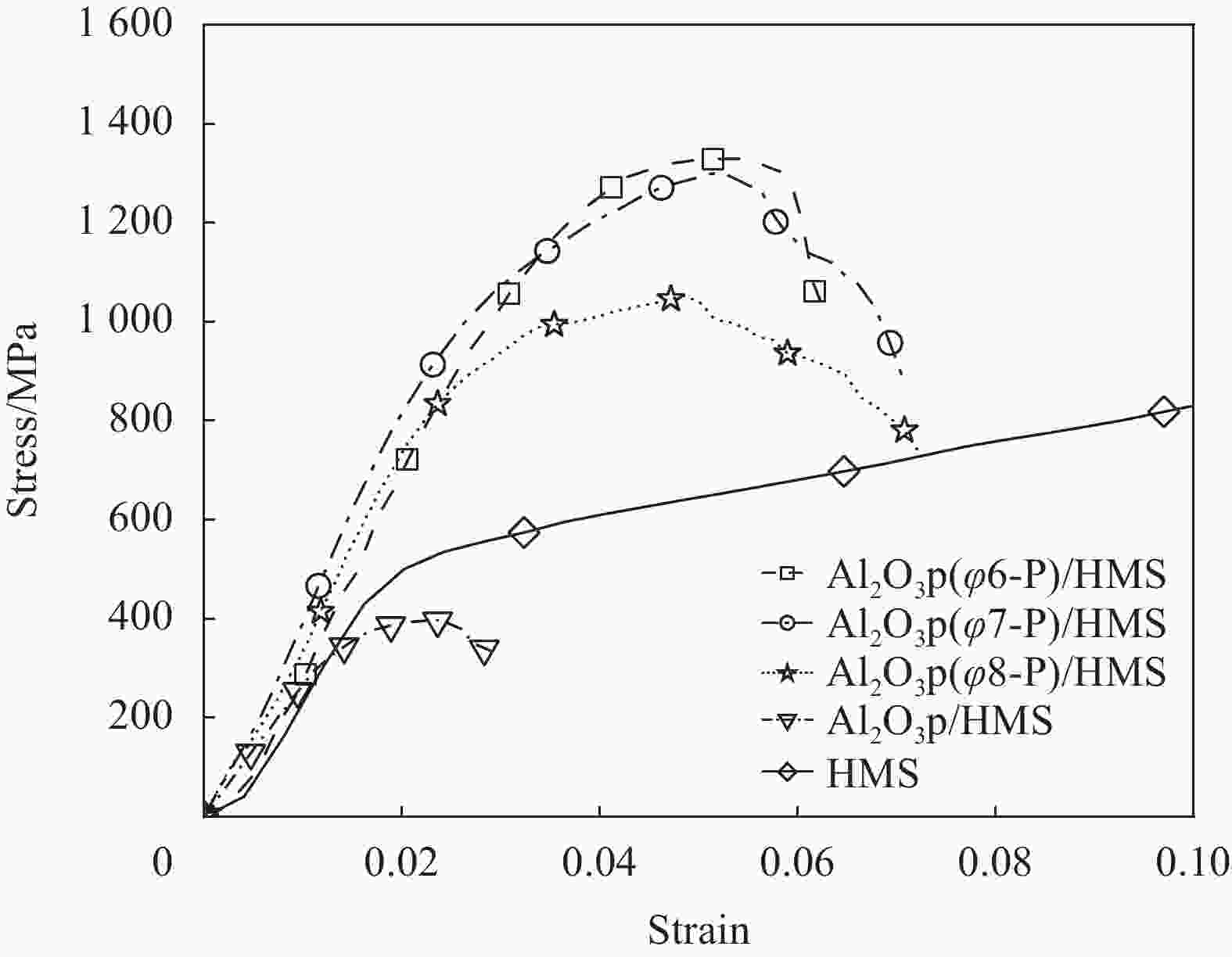

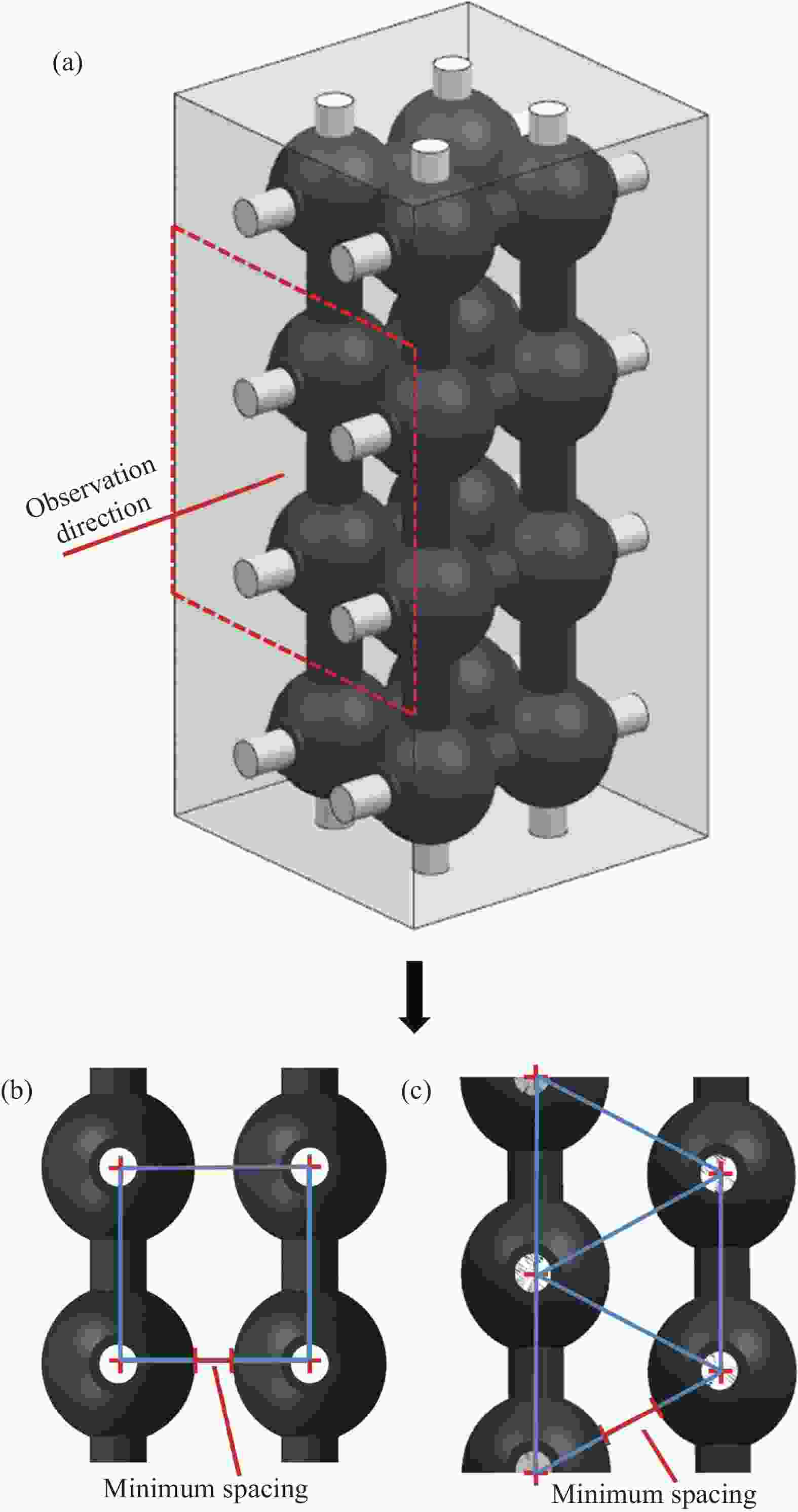

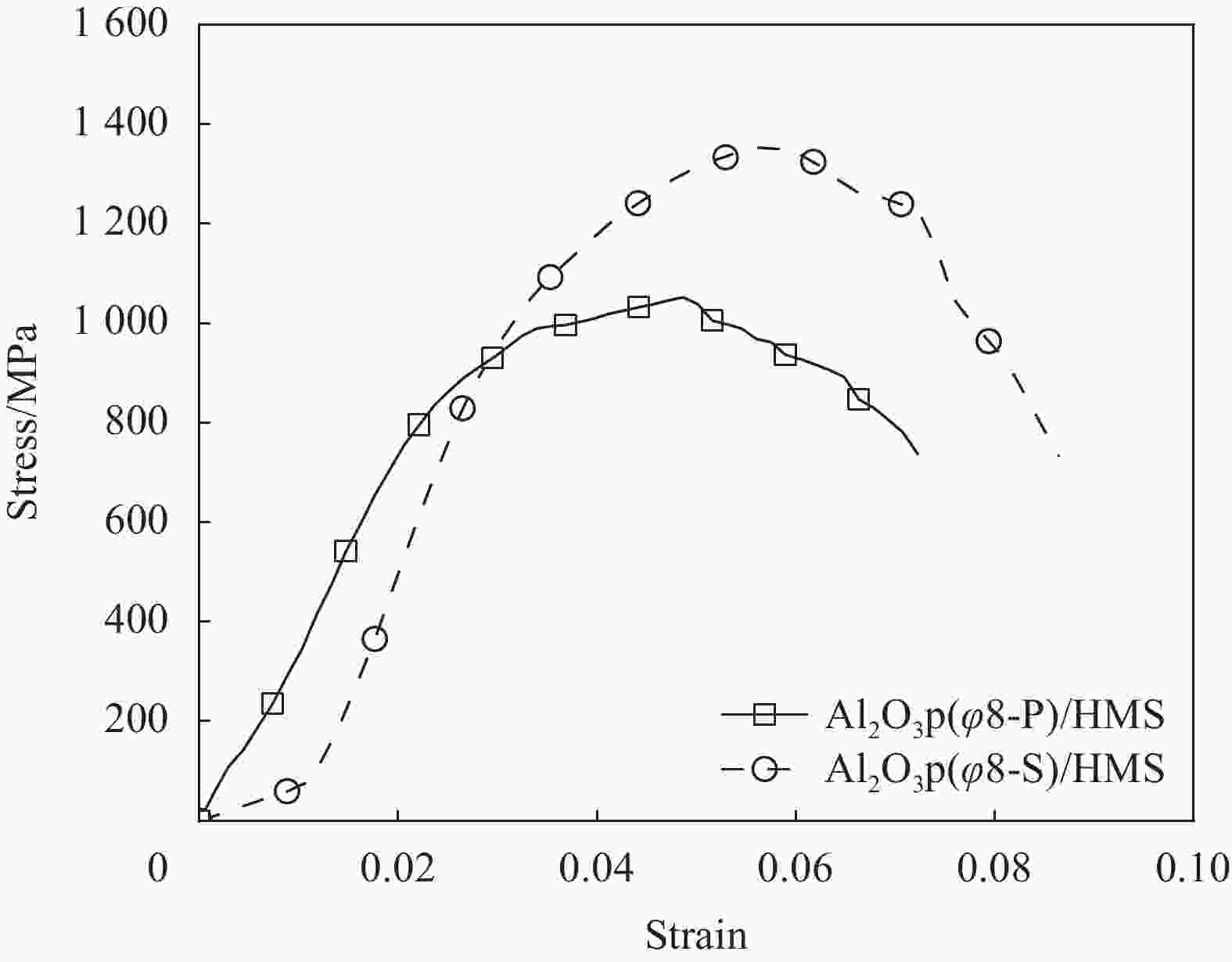

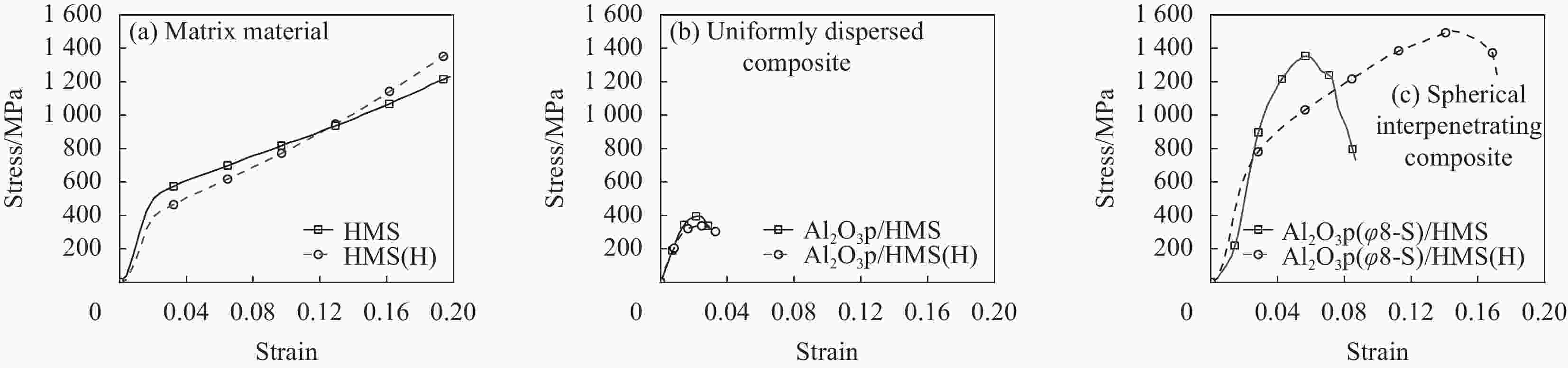

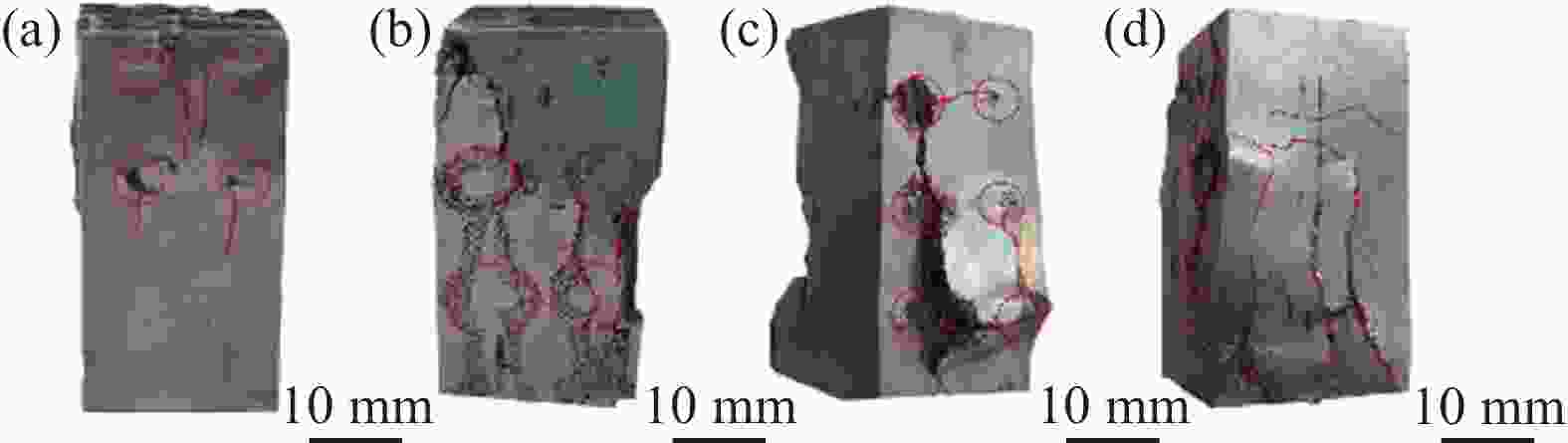

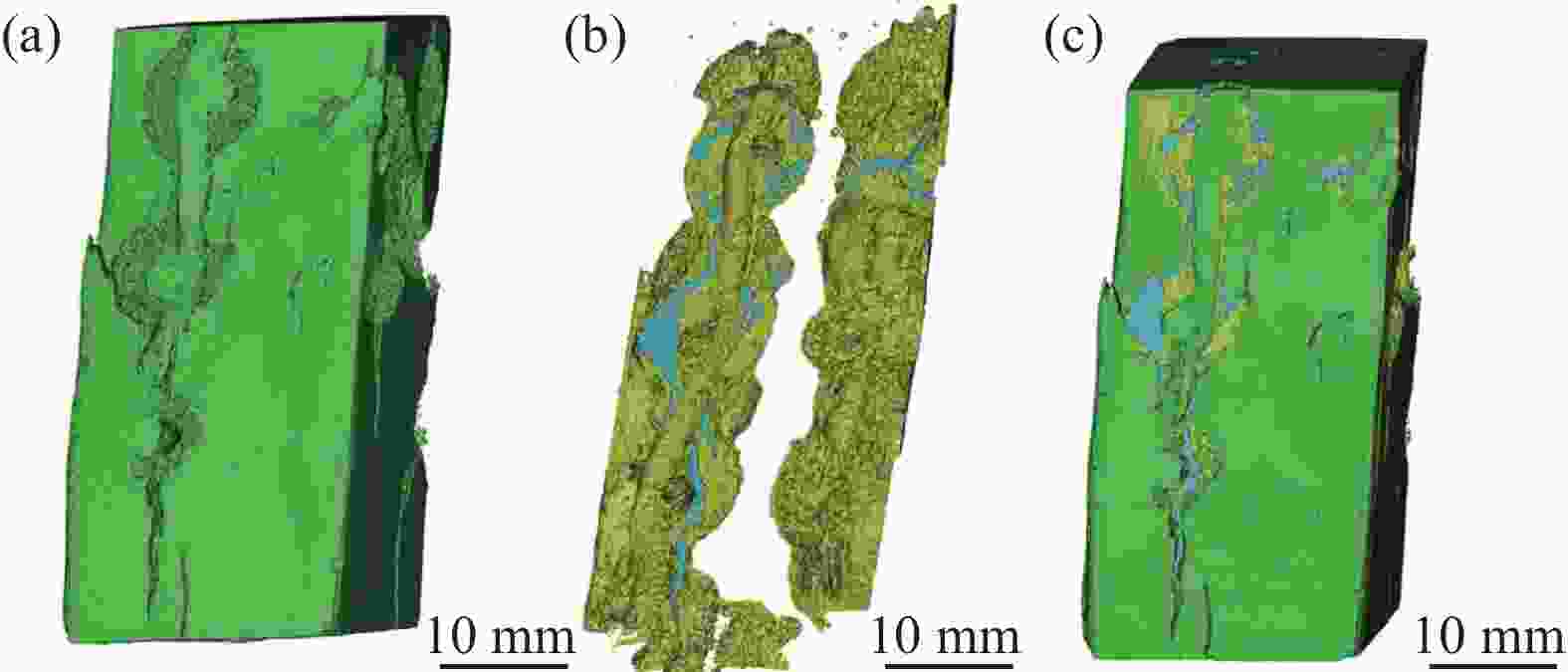

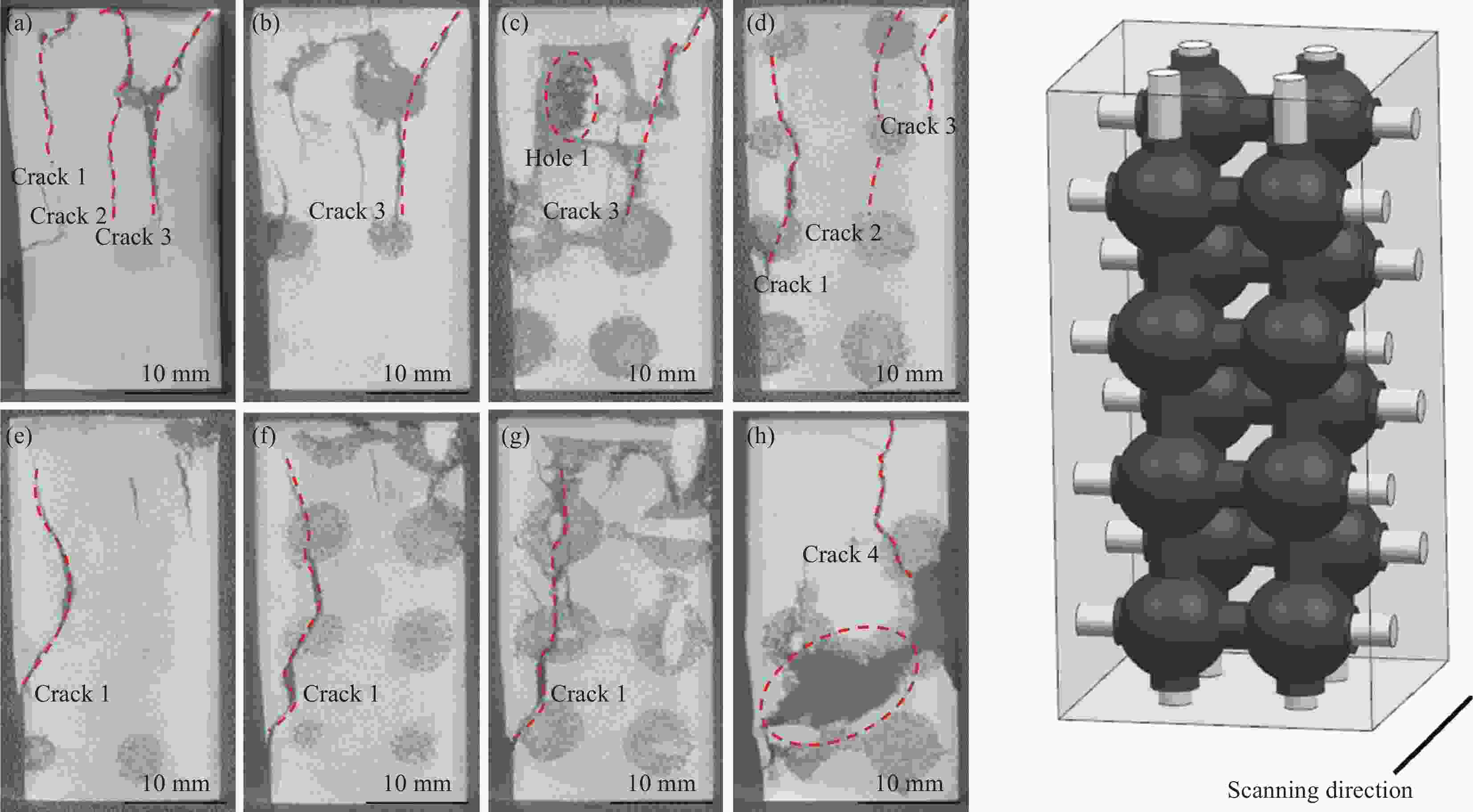

6材料的屈服强度、抗压强度和(抗压强度下)应变最佳,相比于均匀复合材料分别提升203.8%、236.1%和134.8%,屈服强度相比于基体材料提升107.5%;同构型参数下,错落排布比平行排布的屈服强度、抗压强度和应变分别提升10.9%、28.5%和16.3%;水韧处理后,错落排布材料的屈服强度降低35.2%,抗压强度提升11.0%,应变提升163.1%。裂纹易在基体区与复合区界面处萌生并进行扩展,基体能够阻碍裂纹的扩展;错落排布增大了复合区的最小间距,提升了塑性。 Abstract: Conventional wear-resistant metal matrix composites generally suffer from low plastic toughness. The spherical interpenetrating architecture design of Al2O3 ceramic particle (Al2O3p) reinforcement high manganese steel composites was carried out, and the effects of the architectured parameters, modes and heat treatment on the compressive properties of the composites were investigated. Al2O3p/high manganese steel spherical interpenetrating composites with three architectured parameters (ball diameter φ of 6 mm, 7 mm, 8 mm) combined with two architectured modes (parallel and staggered), uniformly dispersed composite, and matrix materials were prepared. The results show that the compressive properties of the materials decrease with the increase of the architectured parameters (volume fraction of the composite zone) under the same architectured mode, with the best yield strength, compressive strength, and (under compressive strength) strain for φ6 materials, increasing by 203.8%, 236.1%, and 134.8%, respectively compared with the uniform dispersed composites. The yield strength increases by 107.5% compared with the matrix materials. Under the same architectured parameter, the yield strength, compressive strength and strain of staggered-arrany are increased by 10.9%, 28.5%, and 16.3%, respectively, compared with the parallel-arrany. The yield strength is reduced by 35.2%, the compressive strength is increased by 11.0% and the strain is increased by 163.1% for staggered-arrany composites after water toughness treatment. Cracks tend to sprout and expand at the interface between the matrix and composite zones, but the matrix can hinder the crack expansion. Staggered-arrany increases the minimum spacing of the composites zones and enhances plasticity. -

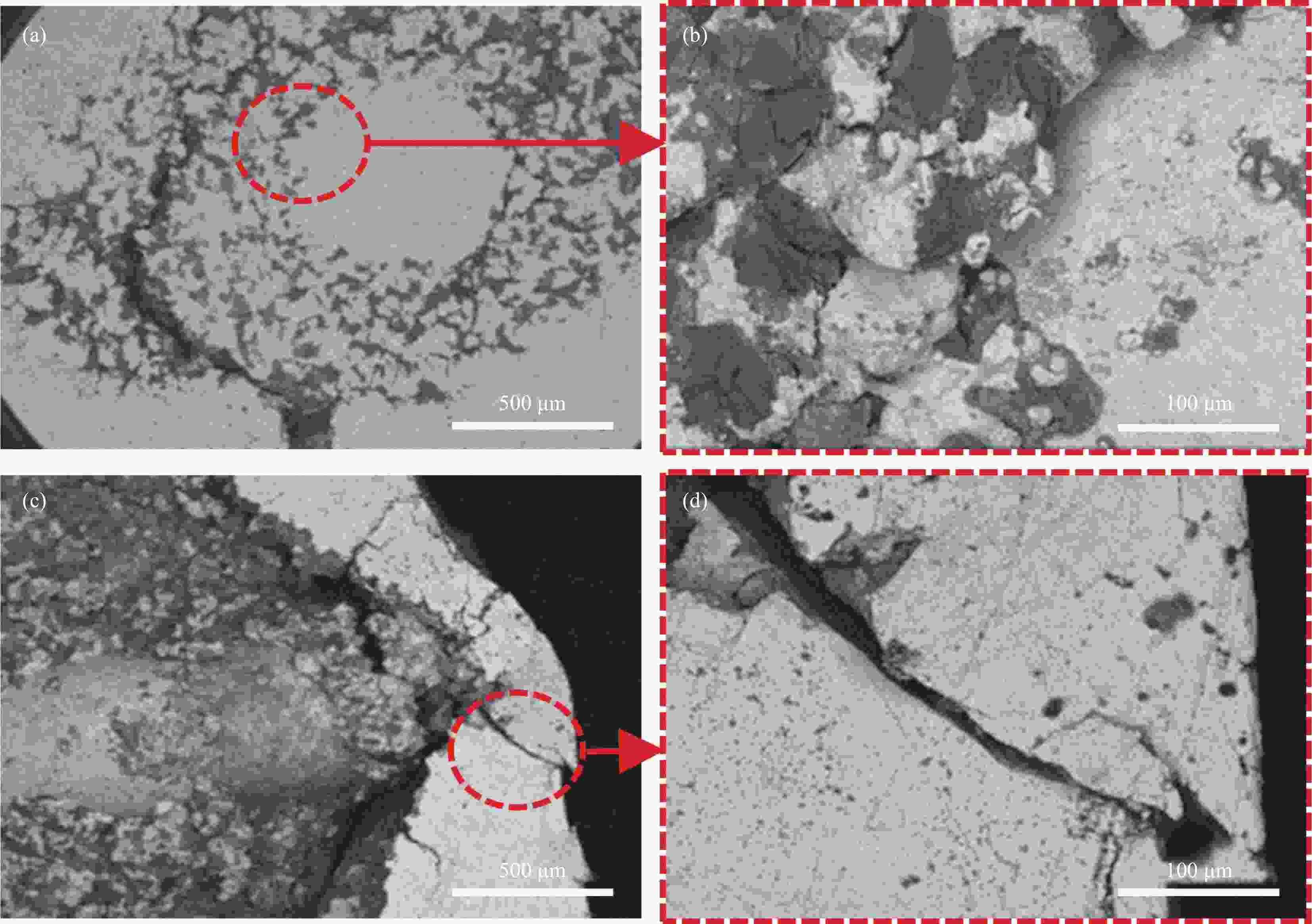

图 2 Al2O3p/高锰钢球形网络复合材料微观结构:(a) 基体区热处理前;(b) 基体区热处理后;(c) 复合区热处理前;(d)复合区热处理后

Figure 2. Microstructure of Al2O3p/HMS spherical interpenetrating composites: (a) Matrix zone before heat treatment; (b) Matrix zone after heat treatment; (c) Composite zone before heat treatment; (d) Composite zone after heat treatment

图 10 Al2O3p/高锰钢球形网络复合材料压缩失效后的微观形貌:(a) 复合区;(b) 放大后的复合区;(c)基体区最小壁厚;(d)放大后的最小壁厚处

Figure 10. Microscopic morphology after compression failure of Al2O3p/HMS spherical interpenetrating composite: (a) Composite zone; (b) Enlarged composite zone; (c) Minimum wall thickness of matrix zone; (d) Enlarged minimum wall thickness

表 1 各试验材料信息

Table 1. Information of researched materials

Codename Architecture method Architecture parameter

/mmComposite zone fraction/vol% HMS — — 0.0 Al2O3p/HMS — — 100.0 Al2O3p(φ6-P)

/HMSParallel 6 15.6 Al2O3p(φ7-P)

/HMSParallel 7 24.6 Al2O3p(φ8-P)

/HMSParallel 8 36.8 Al2O3p(φ8-S)

/HMSStaggered 8 36.8 Al2O3p(φ8-S)

/HMS(H)Staggered 8 36.8 Al2O3p/HMS(H) — — 100.0 HMS(H) — — 0.0 Notes:Al2O3p—Al2O3 ceramic particle; HMS—High manganese steel; φ—Ball diameter; P—Parallel-arrany; S—Staggered-arrany; H—Heat treatment. 表 2 Al2O3p/高锰钢球形网络复合材料界面成分

wt% Table 2. Interfacial composition of Al2O3p/HMS spherical interpenetrating composite

wt% Area\

ElementAl O Si Cr Mn Fe Al2O3 46.3 42.2 0.3 — 0.7 — Interface 14.7 21.8 11.6 0.6 22.2 4.7 Matrix — — 0.4 1.9 10.3 78.9 表 3 Al2O3p/高锰钢球形网络复合材料、均匀复合材料和基体材料的压缩性能

Table 3. Compressive properties for Al2O3p/HMS spherical interpenetrating composites, uniformly dispersed compositeand matrix material

Codename Yield

strength/MPaCompressive strength/MPa Strain HMS 528.3 — — Al2O3p/HMS 360.8 396.8 0.023 Al2O3p(φ6-P)/HMS 1096.4 1333.6 0.054 Al2O3p(φ7-P)/HMS 1048.6 1301.1 0.052 Al2O3p(φ8-P)/HMS 867.5 1053.5 0.049 表 4 相同构型参数下平行排布与错落排布的Al2O3p/高锰钢球形网络复合材料压缩性能

Table 4. Compression property for parallel-arrany and staggered-arrany Al2O3p/HMS spherical interpenetrating composites with the same architectured parameter

Codename Yield

strength/

MPaCompressive strength/

MPaStrain Al2O3p(φ8-P)/HMS 867.5 1053.5 0.049 Al2O3p(φ8-S)/HMS 962.1 1354.0 0.057 表 5 Al2O3p/高锰钢球形网络复合材料、均匀复合材料和基体材料热处理前后的压缩性能

Table 5. Compressive properties for Al2O3p/HMS spherical interpenetrating composites, uniformly dispersed composite and matrix materials before and after heat treatment

Codename Yield

strength/MPaCompressive strength/MPa Strain HMS 528.3 — — Al2O3p/HMS 360.8 396.8 0.023 Al2O3p(φ8-S)/HMS 962.1 1354.0 0.057 Al2O3p(φ8-S)/HMS(H) 623.7 1503.8 0.150 Al2O3p/HMS(H) 305.8 338.4 0.030 HMS(H) 406.9 — — -

[1] MORALES-ESPEJEL G E, RYCERZ P, KADIRIC A, et al. Prediction of micropitting damage in gear teeth contacts considering the concurrent effects of surface fatigue and mild wear[J]. Wear,2018,398-399:99-115. doi: 10.1016/j.wear.2017.11.016 [2] MARIMUTHU K P, HAN J, JEONG U, et al. Study on tribological characteristics of Zr-based BMG via nanoscratch techniques[J]. Wear,2021,486-487:204067. doi: 10.1016/j.wear.2021.204067 [3] MACHADO P C, PEREIRA J I, SINATORA A, et al. Abrasion wear of austenitic manganese steels via jaw crusher test[J]. Wear,2021,476:203726. doi: 10.1016/j.wear.2021.203726 [4] 胥长龙, 卢德宏, 唐露, 等. 复合区体积分数对氧化锆增韧氧化铝颗粒/40Cr空间结构复合材料冲击磨损性能的影响[J]. 复合材料学报, 2020, 37(9):2223-2229. doi: 10.13801/j.cnki.fhclxb.20200220.002XU Changlong, LU Dehong, TANG Lu, et al. Effect of composite volume fraction on impact wear proper ties of zirconium oxide toughene alumina particles/40Cr architecture composites[J]. Acta Materiae Compositae Sinica,2020,37(9):2223-2229(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200220.002 [5] PAGOUNIS E, LINDROOS V K, TALVITIE M. Influence of reinforcement volume fraction and size on the microstructure and abrasion wear resistance of hot isostatic pressed white iron matrix composites[J]. Metallurgical and Materials Transactions A,1996,27:4171-4181. doi: 10.1007/BF02595665 [6] 王娟, 郑开宏. ZTA颗粒增强铁基复合材料的高温磨料磨损性能研究[J]. 热加工工艺, 2018, 47(10):101-105, 109.WANG Juan, ZHENG Kaihong. Study on high temperature abrasive wear properties of ZTA particle reinforced iron matrix composites[J]. Hot Working Technology,2018,47(10):101-105, 109(in Chinese). [7] 宁嘉沛, 郑开宏, 王娟, 等. TiC增强高锰钢基复合材料的组织与磨料磨损性能[J]. 稀有金属材料与工程, 2020, 49(7):2407-2416.NING Jiapei, ZHENG Kaihong, WANG Juan, et al. Microstructure and abrasive wear properties of TiC-reinforced hadfield steel matrix composites[J]. Rare Metal Materials and Engineering,2020,49(7):2407-2416(in Chinese). [8] 陈奉锐, 山泉, 李祖来, 等. 重熔温度对WCp/Fe复合材料界面特征及压缩断裂机制的影响[J]. 复合材料学报, 2018, 35(11):3106-3113.CHEN Fengrui, SHAN Quan, LI Zulai, et al. Effect of remelting temperature on interface characteristics and com pression fracture mechanism of WCp/Fe composites[J]. Acta Materiae Compositae Sinica,2018,35(11):3106-3113(in Chinese). [9] LI Y, PHUNG L, WILLIAMS C. 3D multiscale modeling of fracture in metal matrix composites[J]. Journal of Materials Research,2019,34(13):2285-2294. doi: 10.1557/jmr.2019.60 [10] GUO R F, SHEN P, GUO N, et al. Al-7Si-5Cu/Al2O3-ZrO2 laminated composites with excellent and anisotropic wear resistance[J]. Advanced Engineering Materials,2018,20:1800540. doi: 10.1002/adem.201800540 [11] 卢德宏, 蒋业华. 构型陶瓷/钢铁耐磨复合材料研究进展[J]. 精密成型工程, 2021, 13(3):40-48.LU Dehong, JIANG Yehua. Research progress of wear performance of ceramic particulates reinforced iron matrix architecture composites[J]. Journal of Netshape Forming Engineering,2021,13(3):40-48(in Chinese). [12] LEMSTER K, DELPORTE A, GRAULE T, et al. Activation of alumina foams for fabricating MMCs by pressureless infiltration[J]. Ceramics International,2007,33:1179-1185. doi: 10.1016/j.ceramint.2006.04.002 [13] ZHOU M J, SUI Y D, CHONG X Y, et al. Wear resistance mechanism of ZTAP/HCCI composites with a honeycomb structure[J]. Metals,2018,8(8):588. doi: 10.3390/met8080588 [14] 赵馨月, 卢德宏, 郭红星, 等. 球状结构钢基MMCs/钢三维互穿网络复合材料的制备[J]. 特种铸造及有色合金, 2016, 36(8):852-855.ZHAO Xinyue, LU Dehong, GUO Hongxing, et al. Preparation of composites of MMCs and steel with three dimensional inter-penetrating network structure[J]. Special Casting & Nonferrous Alloys,2016,36(8):852-855(in Chinese). [15] MIKE A. Designing architectured materials[J]. Scripta Materialia,2013,68(1):4-7. doi: 10.1016/j.scriptamat.2012.04.033 [16] XIE H, JIN Y X, NIU M Y, et al. Effect of multilayer graphene/nano-Fe2O3 composite additions on dry sliding wear behavior of titanium matrix composites[J]. Journal of Iron and Steel Research International,2020,27:1117-1126. doi: 10.1007/s42243-020-00460-7 [17] HAN W, LI K, HU F, et al. Microstructure and mechanical properties of Mg-2.5Si-xCe in-situ particle reinforced composites prepared by rapid solidification process[J]. Results in Physics,2019,15:102509. doi: 10.1016/j.rinp.2019.102509 [18] 陈建华, 刘维良, 周华, 等. TiCp/W金属基复合材料的制备与性能研究[J]. 稀有金属与材料工程, 2017, 46(1): 242-246.CHEN Jianhua, LIU Weiliang, ZHOU Hua, et al. Study on preparation and properties of TiCp/W metal matrix composite[J]. Rare Metal Materials and Engineering, 2017, 46(1): 242-246(in Chinese). [19] NIU G, SUI Y D, ZENG H B, et al. Effect of centrifugal casting temperature on the microstructure and properties of ZTAP/HCCI matrix composites[J]. Materials Research Express,2021,8:26513. doi: 10.1088/2053-1591/abe012 [20] 韦鸿铭. ZTAp/高铬铸铁基蜂窝构型复合材料热物理性质和力学性能研究[D]. 昆明: 昆明理工大学, 2019.WEI Hongming. Study on thermophysical properties and mechanical properties of ZTAp/high chromium cast iron based honeycomb composites[D]. Kunming: Kunming University of Science and Technology, 2019(in Chinese). [21] GONG W H, LU D H, HE G Y. Effect of volume fraction of metal matrix composites framework on compressive mechanical properties of 3D interpenetrating ZTAp/40Cr architectured composites[J]. Journal of Iron and Steel Research International, 2022, 5(5): 859-865. [22] BAI M M, LI W X, LI Y H, et al. Preparation and properties of hot-pressed Al2O3/Al-steel mesh-Al laminated composites[J]. Journal of Inorganic Materials,2014,29(12):1339-1344. doi: 10.15541/jim20140410 [23] LU D H, HE G Y, WANG L K, et al. Compressive properties and cracking behaviour of 3D interpenetrating hierarchical Al2O3p/steel composite[J]. Materials Science and Technology,2019,35(6):716-724. doi: 10.1080/02670836.2019.1590504 [24] JIANG C Y, LU D H, MA W, et al. Mechanical behavior of ZTAp/40Cr three-dimensional interpenetrated composites under compression[J]. Materials Today Communications,2021,28:102623. doi: 10.1016/j.mtcomm.2021.102623 [25] MA W, LU D H, TANG L, et al. Effect of matrix hardness on the impact abrasive wear performance of ZTAp/steel architecture composite[J]. Materials Research Express,2021,8:026507. doi: 10.1088/2053-1591/abe019 -

下载:

下载: