Preparation of titanium dioxide/ZIF-8 composite superhydrophobic sponge and its oil-water separation performance

-

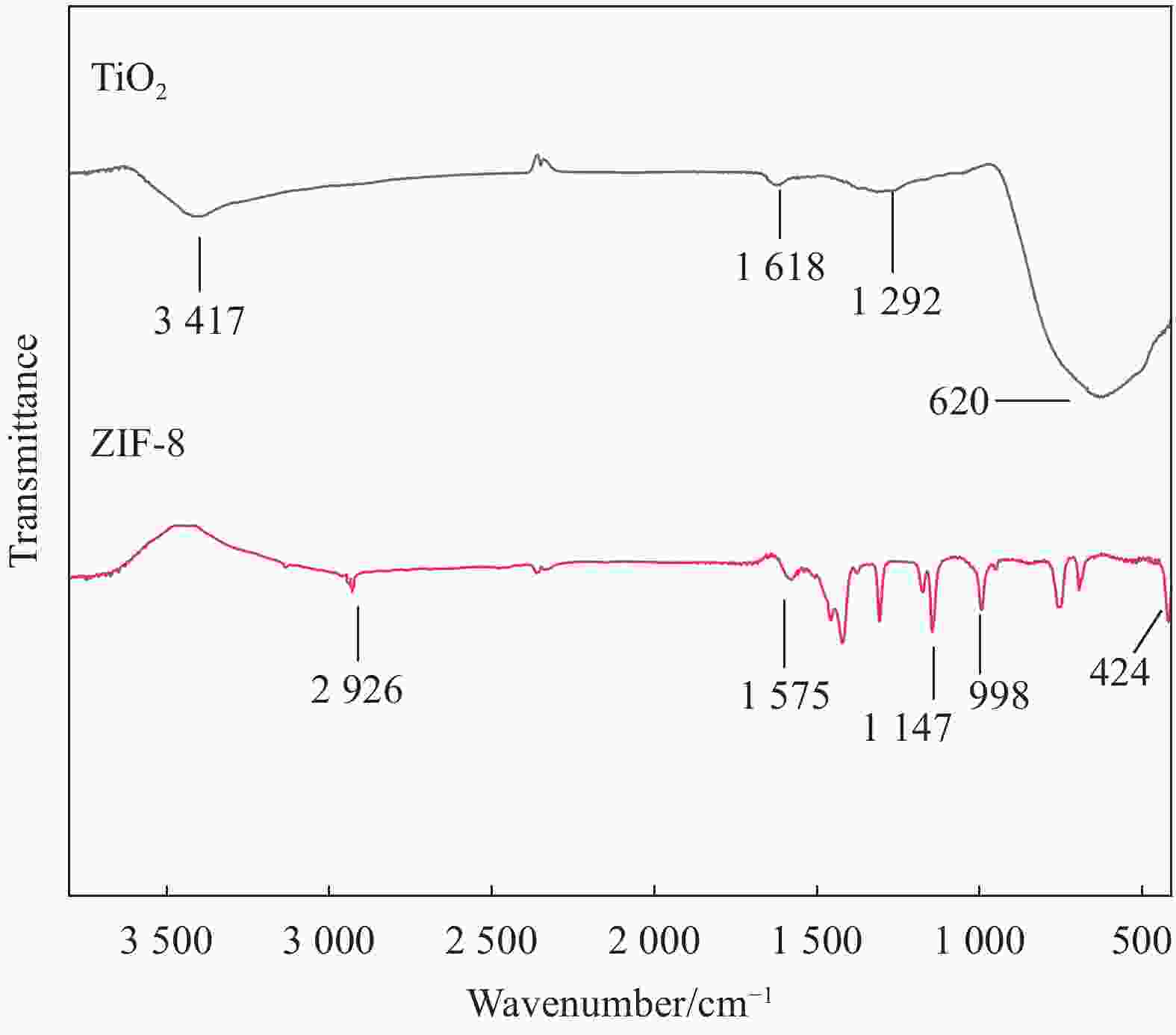

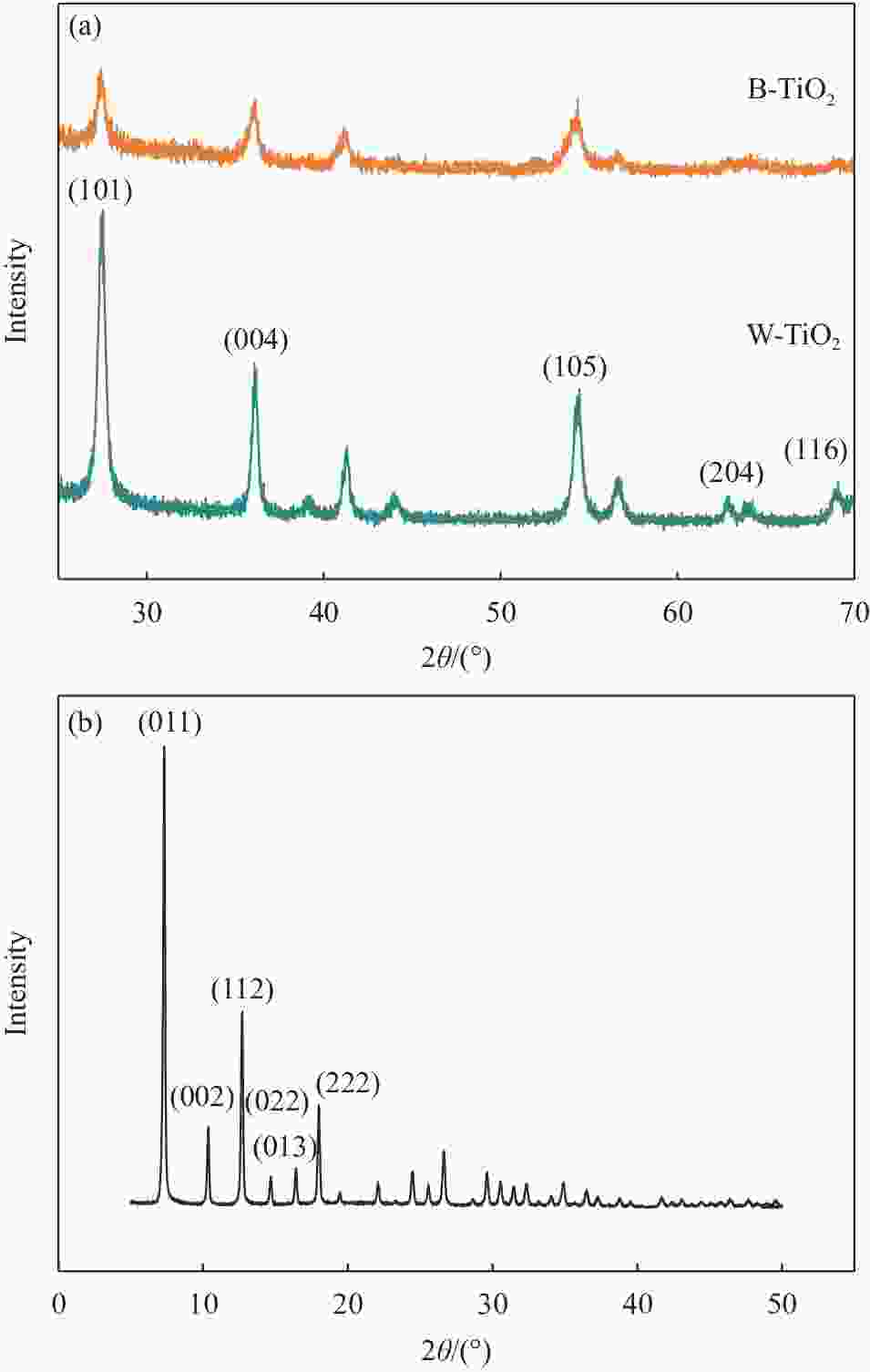

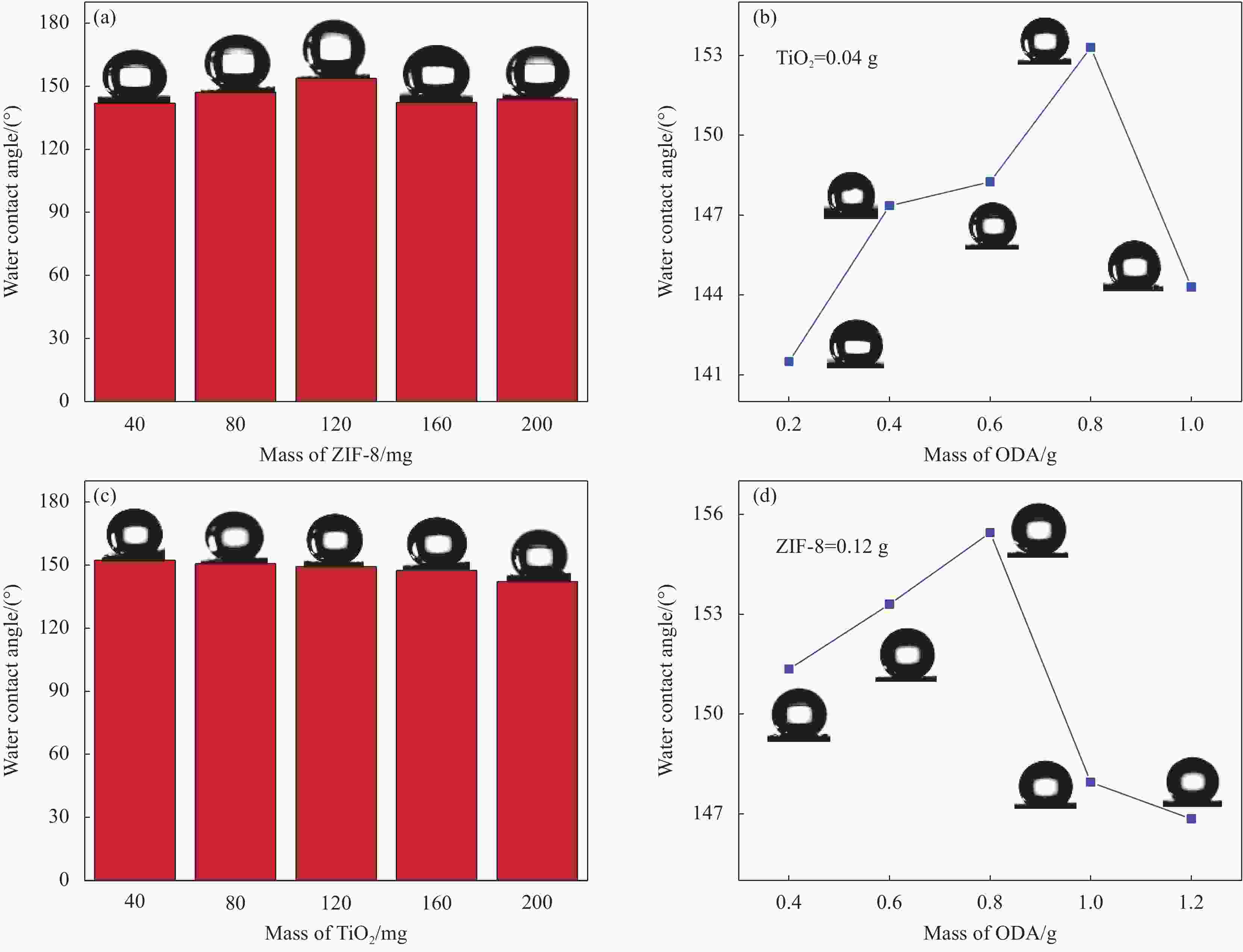

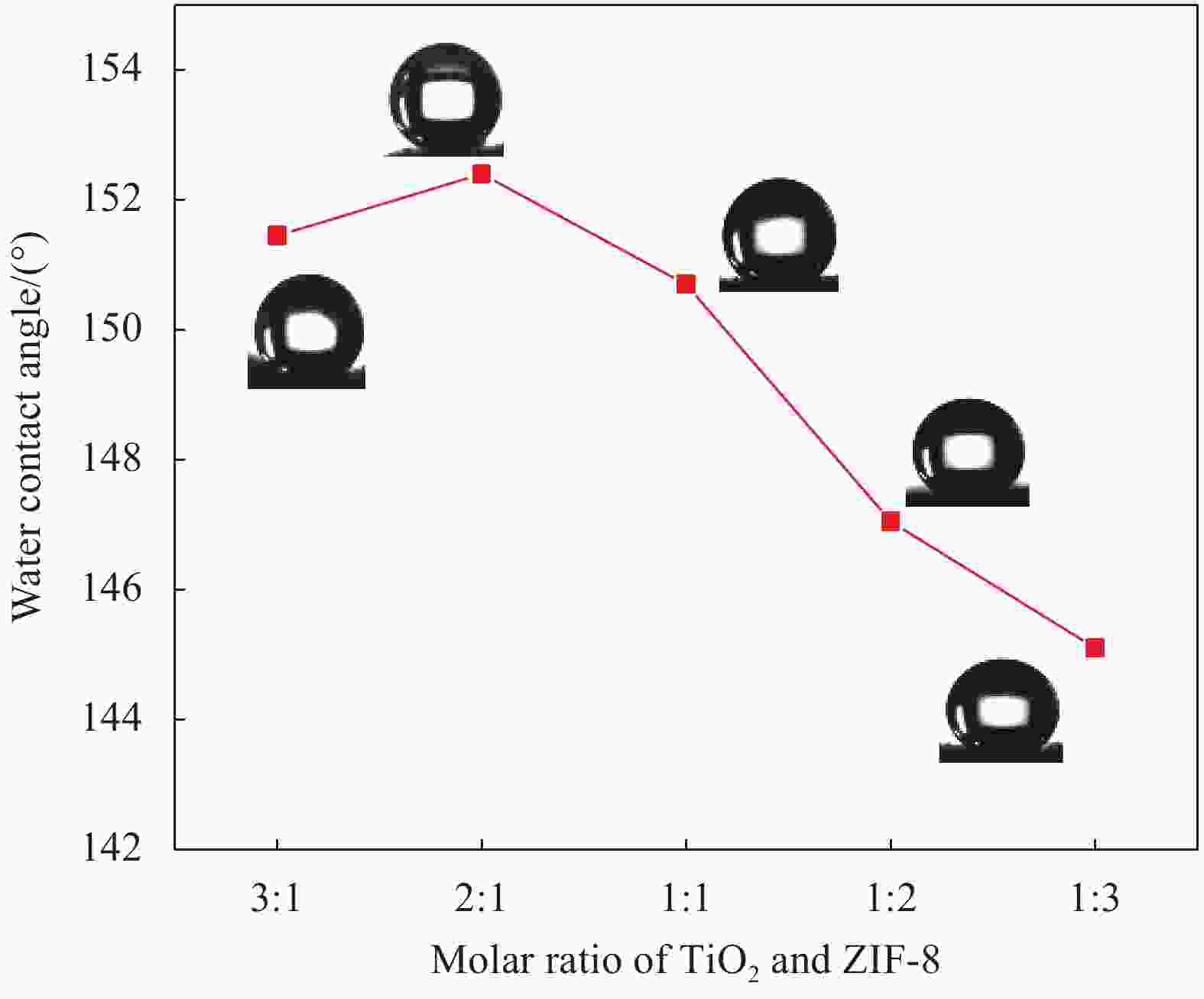

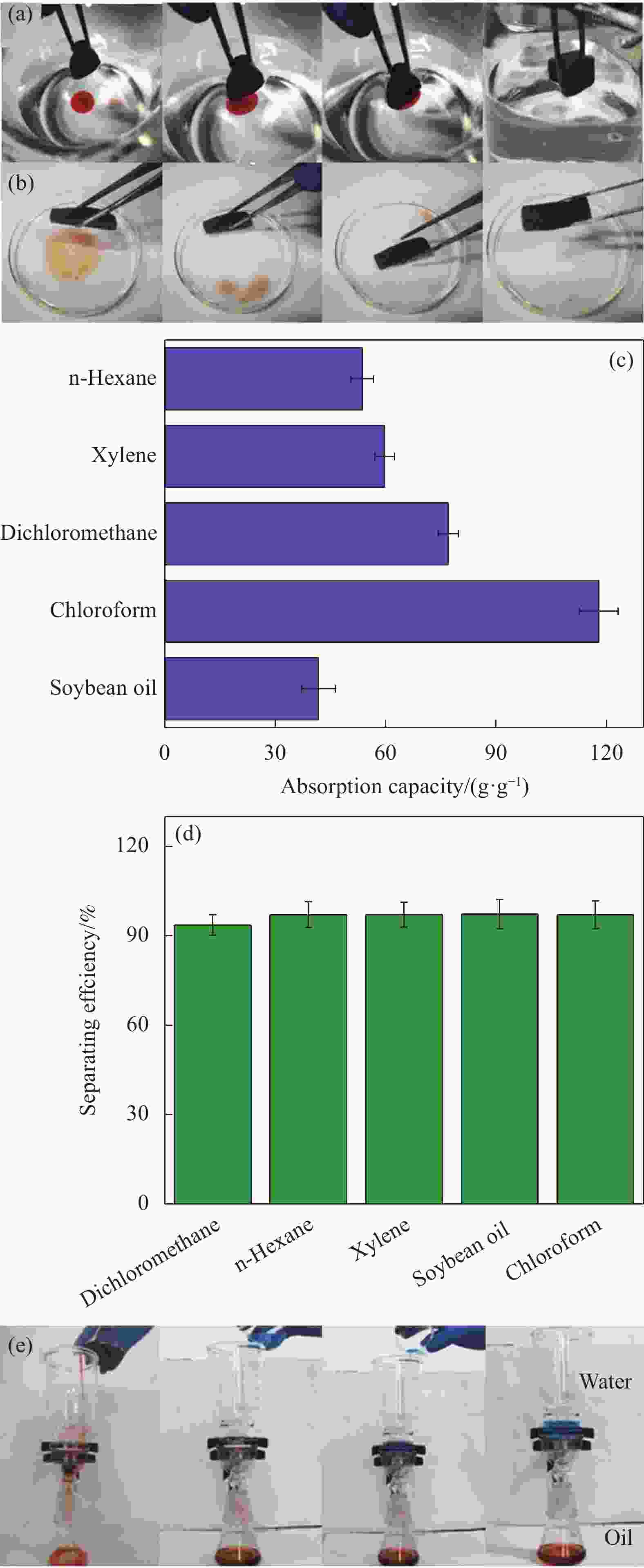

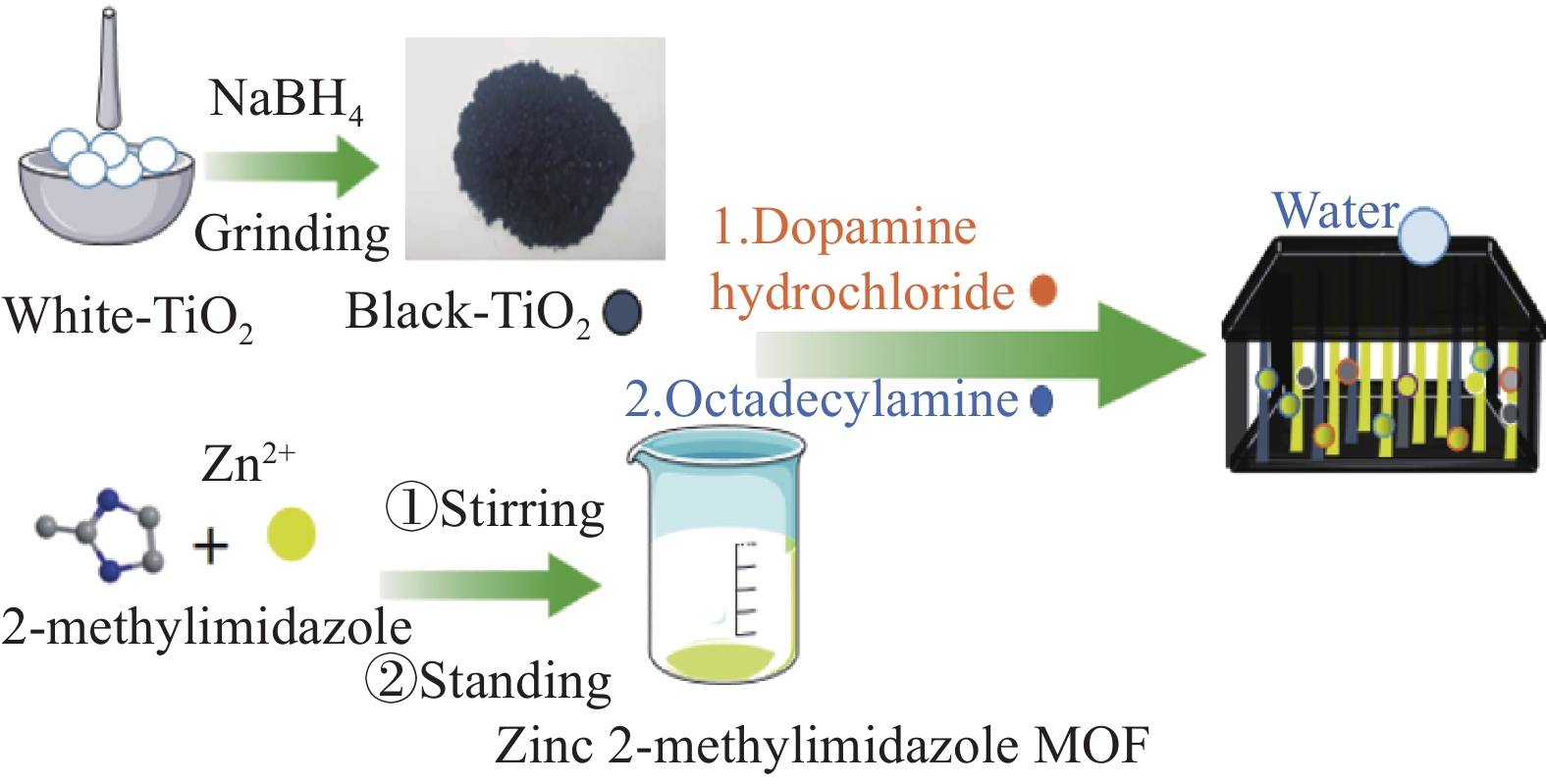

摘要: 含油废水的处理海上溢油问题及含油废水的排放对经济与环境带来了巨大的破坏。利用聚多巴胺将自制的双尺度ZIF-8/TiO2纳米粒子黏附到聚氨酯海绵,通过十八胺改性制备出超疏水油水分离海绵,通过FTIR、XRD等对其结构进行了表征分析;利用ZIF-8和TiO2两种纳米粒子构建双尺度粗糙结构,并深入探究了两种粒子的用量对复合涂层表面性能的影响。结果表明当纳米粒子ZIF-8和TiO2添加摩尔比为2∶1时,接触角达到最大值153°;复合海绵有良好的油水分离性能,吸收能力是其自重的40至118倍,分离效率平均在96%以上;在808 nm激光照射下10 s内温度可升高55.9℃,有良好的光热转换性能。Abstract: Treatment of oily wastewater problem of oil spills at sea and the discharge of oily wastewater have brought huge damage to the economy and the environment. This paper used polydopamine to adhere the self-made dual-scale ZIF-8/TiO2 nanoparticles to the polyurethane sponge, and prepared the superhydrophobic oil-water separation sponge by modification with octadecylamine. The structure was characterized and analyzed by FTIR, XRD, etc.. ZIF-8 and TiO2 two kinds of nano-particles constructed a two-scale rough structure, and the influence of the amount of the two kinds of particles on the surface performance of the composite coating was deeply explored. The results show that when the molar ratio of ZIF-8 and TiO2 nanoparticles is 2∶1, the contact angle reaches the maximum value of 153°.The composite sponge has good oil-water separation performance, the absorption capacity is 40 to 118 times its own weight, and the separation efficiency is on average more than 96%. The temperature can rise by 55℃ within 10 s under 808 nm laser irradiation, and it has good light-to-heat conversion performance.

-

Key words:

- superhydrophobic /

- ZIF-8 /

- titanium dioxide /

- oil-water separation /

- polyurethane sponge

-

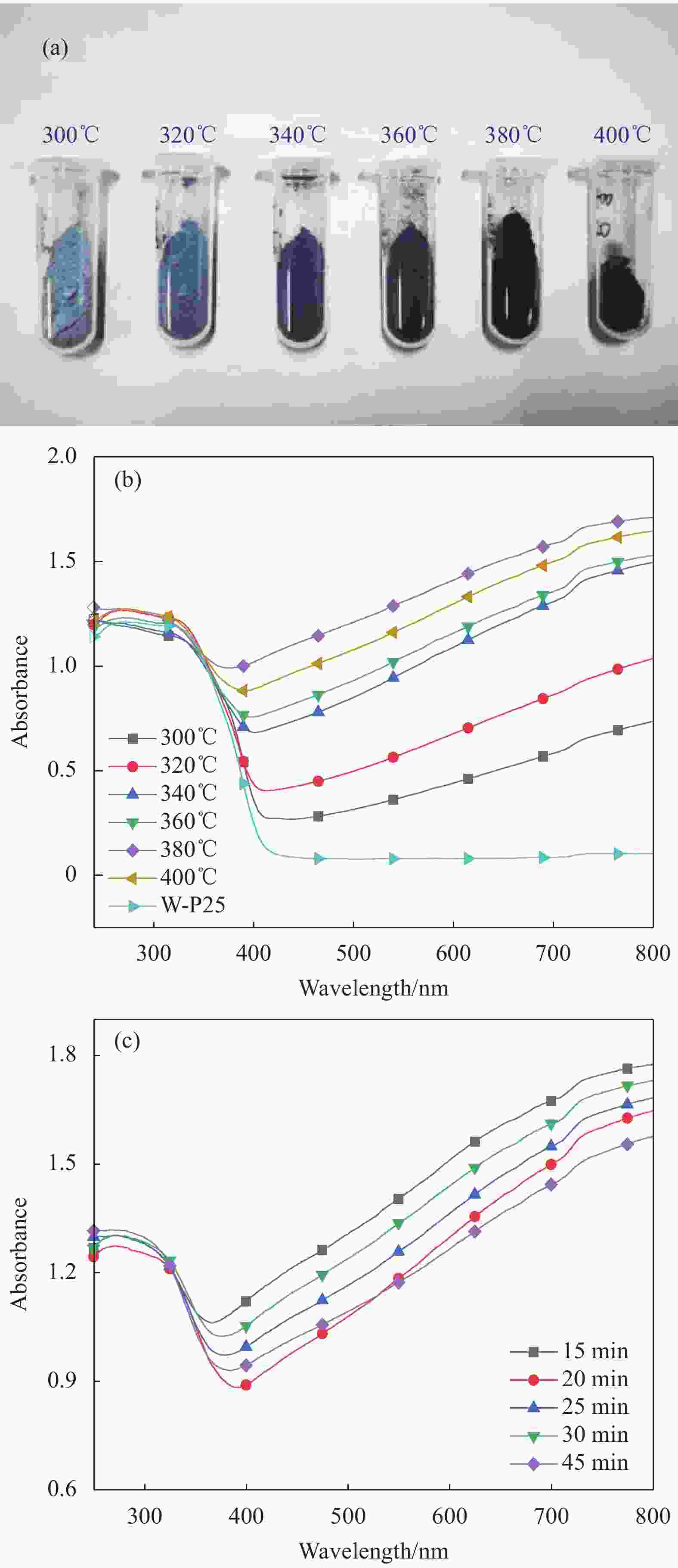

图 2 (a) 不同温度的下TiO2的颜色变化照片;(b) 不同温度下的紫外-吸收图;(c) 不同时间下400℃烧结的TiO2的紫外-吸收图

Figure 2. (a) Optical photos of titanium dioxide fired at different temperatures; (b) Ultraviolet absorption curves of titanium dioxide fired at different temperatures; (c) Ultraviolet absorption curves of titanium dioxide fired at 400℃ at different time

图 9 ((a)、(b)) TiO2/ZIF-8复合海绵的吸油过程;(c) 不同种类油的吸收容量;(d) 不同种类油的分离图;(e) 油水分离过程

Figure 9. ((a), (b)) Adsorption process of different oily substances in TiO2/ZIF-8 compound sponge; (c) Absorption capacity of different kinds of oil; (d) Separation efficiency of different types of oil; (e) Oil-water separation process

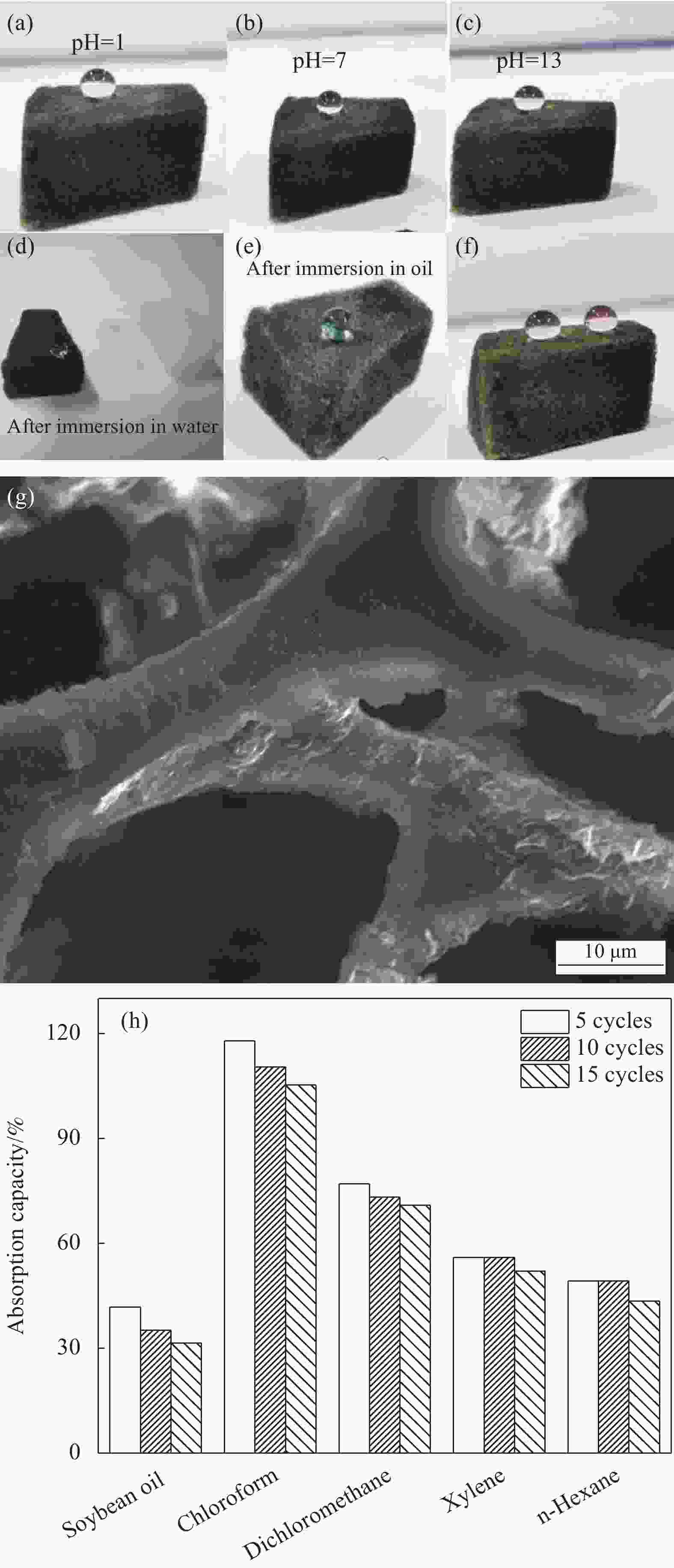

图 10 ((a)~(c)) 不同pH值下的TiO2/ZIF-8复合海绵超疏水效果;((d)~(f)) 疏水亲油现象的光学照片;(g) 摩擦100次后的SEM图像;(h) 吸油/回收循环图

Figure 10. ((a)-(c)) Superhydrophobic phenomenon under different pH of TiO2/ZIF-8 compound sponge; ((d)-(f)) Optical photographs of super-hydrophobic and super-lipophilic phenomena of composite sponge; (g) SEM image after 100 times of friction; (h) Diagram of the oil absorption/recovery cycle

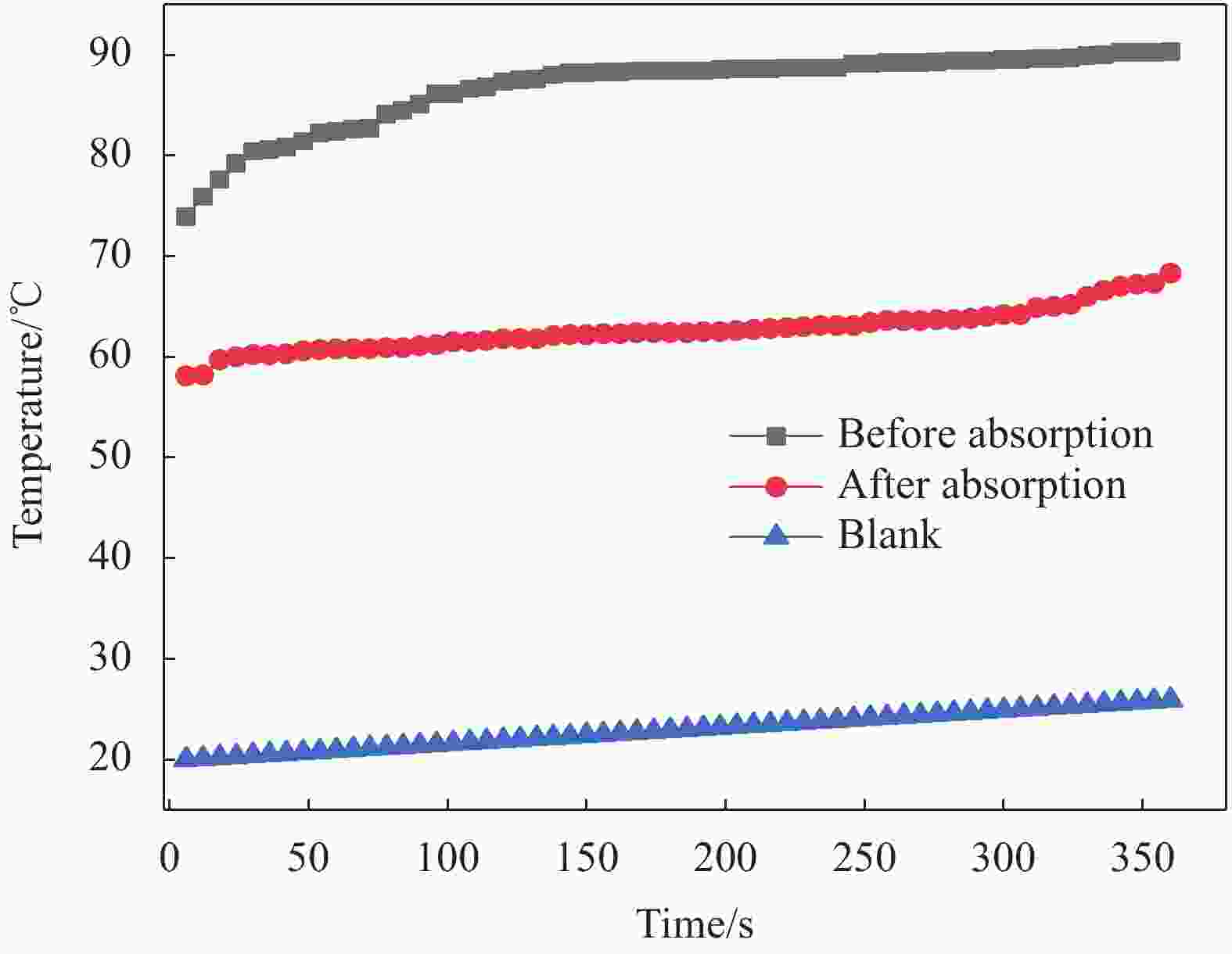

表 1 不同照射时间TiO2/ZIF-8复合海绵的温度

Table 1. Temperature of TiO2/ZIF-8 compound sponge before and after absorpting oil irradiating 10 s and 10 min

Sample Pure polyurethane sponge Super hydrophobic sponge

before oil absorptionSuper hydrophobic sponge

after oil absorptionTemperature (10 s)/℃ 20 75.9 58.1 Temperature (10 min)/℃ 25.9 90.3 68.3 -

[1] WANG B, YANG X, SHA D, et al. Silane functionalized polyvinyl-alcohol formaldehyde sponges on fast oil absorption[J]. ACS Applied Polymer Materials,2020,2(11):5309-5317. doi: 10.1021/acsapm.0c01052 [2] NISTICO R, FRANZOSO F, CESANO F, et al. Chitosan-derived iron oxide systems for magnetically guided and efficient water purification processes from polycyclic aromatic hydrocarbons[J]. ACS Sustainable Chemistry & Engineering,2017,5(1):793-801. [3] GE J, ZHAO H Y, ZHU H W, et al. Advanced sorbents for oil-spill cleanup: Recent advances and future perspectives[J]. Advanced Materials,2016,28(47):10459-10490. doi: 10.1002/adma.201601812 [4] TANG X, SHEN C, ZHU W, et al. A facile procedure to modify filter paper for oil–water separation[J]. RSC Advances,2017,7(48):30495-30499. doi: 10.1039/C7RA03754F [5] EMELYANENKO A M, BOINOVICH L B, BEZDOMNIKOV A A, et al. Reinforced superhydrophobic coating on silicone rubber for longstanding anti-icing performance in severe conditions[J]. ACS Applied Materials & Interfaces,2017,9(28):24210-24219. [6] GUPTA R K, DUNDERDALE G J, ENGLAND M W, et al. Oil/water separation techniques: A review of recent progresses and future directions[J]. Journal of Materials Chemistry A,2017,5(31):16025-16058. doi: 10.1039/C7TA02070H [7] WANG B, LIANG W, GUO Z, et al. Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: A new strategy beyond nature[J]. Chemical Society Reviews,2015,44(1):336-361. doi: 10.1039/C4CS00220B [8] CAI Y, CHEN D, LI N, et al. Self-healing and superwettable nanofibrous membranes for efficient separation of oil-in-water emulsions[J]. Journal of Materials Chemistry A,2019,7(4):1629-1637. doi: 10.1039/C8TA10254F [9] ZHU Y, WANG D, JIANG L, et al. Recent progress in developing advanced membranes for emulsified oil/water separation[J]. NPG Asia Materials,2014,6(5):e101. doi: 10.1038/am.2014.23 [10] WEN Q, DI J, JIANG L, et al. Zeolite-coated mesh film for efficient oil-water separation[J]. Chemical Science,2013,4(2):591-595. doi: 10.1039/C2SC21772D [11] WEI Y, QI H, GONG X, et al. Specially wettable membranes for oil-water separation[J]. Advanced Materials Interfaces,2018,5(23):1800576. doi: 10.1002/admi.201800576 [12] SUN S, TANG S, CHANG X, et al. A bifunctional melamine sponge decorated with silver-reduced graphene oxide nanocomposite for oil-water separation and antibacterial applications[J]. Applied Surface Science,2019,473:1049-1061. doi: 10.1016/j.apsusc.2018.12.215 [13] DONG B, GUO Y, SUN S, et al. Shish–kebab-structured UHMWPE coating for efficient and cost-effective oil–water separation[J]. ACS Applied Materials & Interfaces, 2020, 12(52): 58252-58262. [14] ZHANG Y, ZHANG N, ZHOU S, et al. Facile preparation of ZIF-67 coated melamine sponge for efficient oilwater separation[J]. Industrial & Engineering Chemistry Research,2019,58(37):17380-17388. [15] AZAM T, PERVAIZ E, JAVED S, et al. Tuning the hydrophobicity of MOF sponge for efficient oil/water separation[J]. Chemical Physics Impact,2020,1:100001. doi: 10.1016/j.chphi.2020.100001 [16] YU F, CAO L, MENG Z, et al. Crosslinked waterborne polyurethane with high waterproof performance[J]. Polymer Chemistry,2016,7(23):3913-3922. doi: 10.1039/C6PY00350H [17] 何影格, 陈媛媛, 刘维仪, 等. 超浸润性可逆切换的超双疏复合海绵材料的制备及油水分离应用[J]. 复合材料学报, 2021, 38(3):854-862.HE Yingge, CHEN Yuanyuan, LIU Weiyi, et al. Preparation of superamphiphobic composite sponge material with super-wetting reversible switching and applicationin oil-water separation[J]. Acta Materiae Compositae Sinica,2021,38(3):854-862(in Chinese). [18] 谢俊. 亲油疏水海绵和纺织布的制备及其性能研究[D]. 广州: 华南理工大学, 2020.XIE Jun. Preparation and properties of oleophilic and hydrophobic sponge and textile fabric[D]. Guangzhou: South China University of Technology, 2020(in Chinese). [19] ZHU H, YANG S, CHEN D, et al. A robust absorbent material based on light-responsive superhydrophobic melamine sponge for oil recovery[J]. Advanced Materials Interfaces,2016,3(5):1500683. doi: 10.1002/admi.201500683 [20] WANG Y B, SHANG B, HU X X, et al. Temperature control of mussel-inspired chemistry toward hierarchical superhydrophobic surfaces for oil/water separation[J]. Advanced Materials Interfaces, 2017, 4(2): 1095-1105. [21] GAO Z, ZHOU S, ZHOU Y, et al. Bio-inspired magnetic superhydrophobic PU-PDA-Fe3O4-Ag for effective oil-water separation and its antibacterial activity[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2021,613:126122. doi: 10.1016/j.colsurfa.2020.126122 [22] LIU C, YANG J, TANG Y, et al. Versatile fabrication of the magnetic polymer-based graphene foam and applications for oil-water separation[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2015,468:10-16. [23] 袁鹏程. 光响应g-C3N4/TiO2-PVDF膜的制备及油水分离性能研究[D]. 济南: 山东大学, 2021.YUAN Pengcheng. Preparation of photoresponsive g-C3N4/TiO2-PVDF membrane and its oil/water separation performance[D]. Jinan: Shandong University, 2021(in Chinese). [24] TAN H, ZHAO Z, NIU M, et al. A facile and versatile method for preparation of colored TiO2 with enhanced solar-driven photocatalytic activity[J]. Nanoscale,2014,6(17):10216-10223. doi: 10.1039/C4NR02677B [25] CHEN S, WANG Y, LI J, et al. Synthesis of black TiO2 with efficient visible-light photocatalytic activity by ultraviolet light irradiation and low temperature annealing[J]. Mate-rials Research Bulletin,2018,98:280-287. doi: 10.1016/j.materresbull.2017.10.036 [26] 谢浩, 杜晴, 刘俊逸. Ti3+自掺杂黑色TiO2薄膜的制备及可见光催化性能研究[J]. 化工新型材料, 2021, 49(9):267-275.XIE Hao, DU Qing, LIU Junyi. Syntheise of Ti3+ self-doped black TiO2 film with visible-light photocatalytic performance[J]. New Chemical Materials,2021,49(9):267-275(in Chinese). [27] DANN T, RAPJEL J, GAMMON S T, et al. Anatase titanium dioxide imparts photoluminescent properties to PA2200 commercial 3D printing material to generate complex optical imaging phantoms[J]. Materials, 2021, 14(7): 1813. [28] 樊婷玥, 任煜, 赵紫瑶, 等. Ag6Si2O7-TiO2/PP复合光催化材料的制备及其抗菌性能[J]. 复合材料学报, 2022, 39(8):3915-3921.FAN Tingyue, REN Yu, ZHAO Ziyao, et al. Preparation and antibacterial properties of Ag6Si2O7-TiO2/PP composite photocatalytic material[J]. ActaMateriae Compositae Sinica,2022,39(8):3915-3921(in Chinese). -

下载:

下载: