Effect of laminated structures on thermo-formability of continuous CF/PEEK composites

-

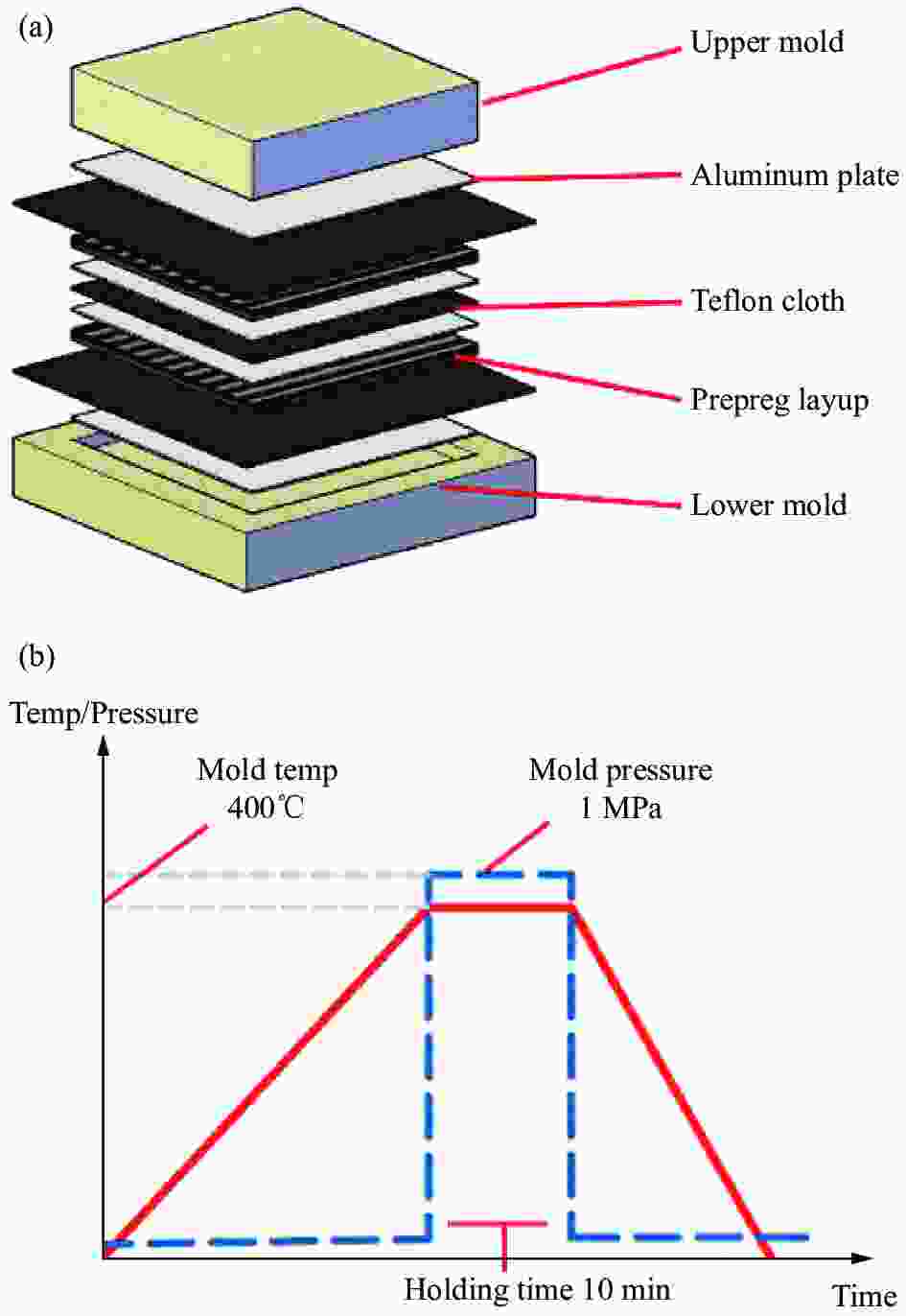

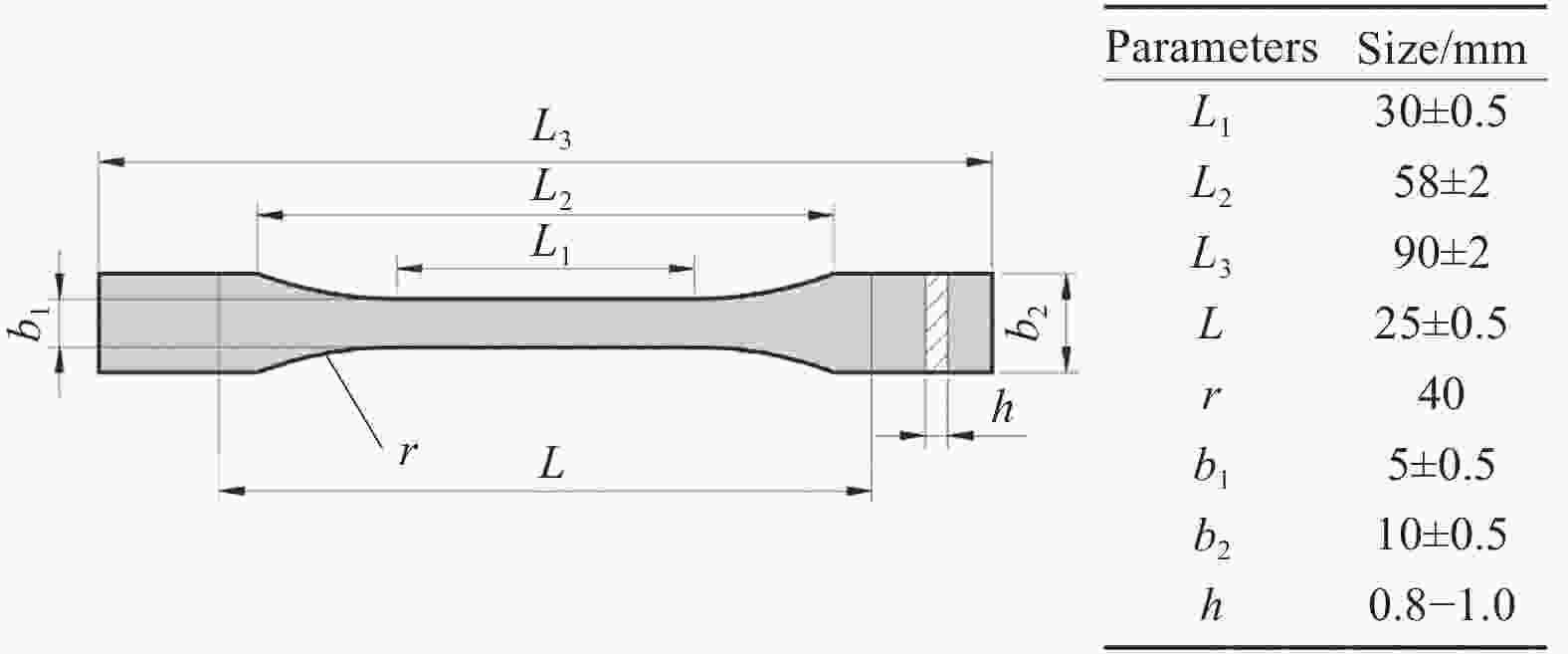

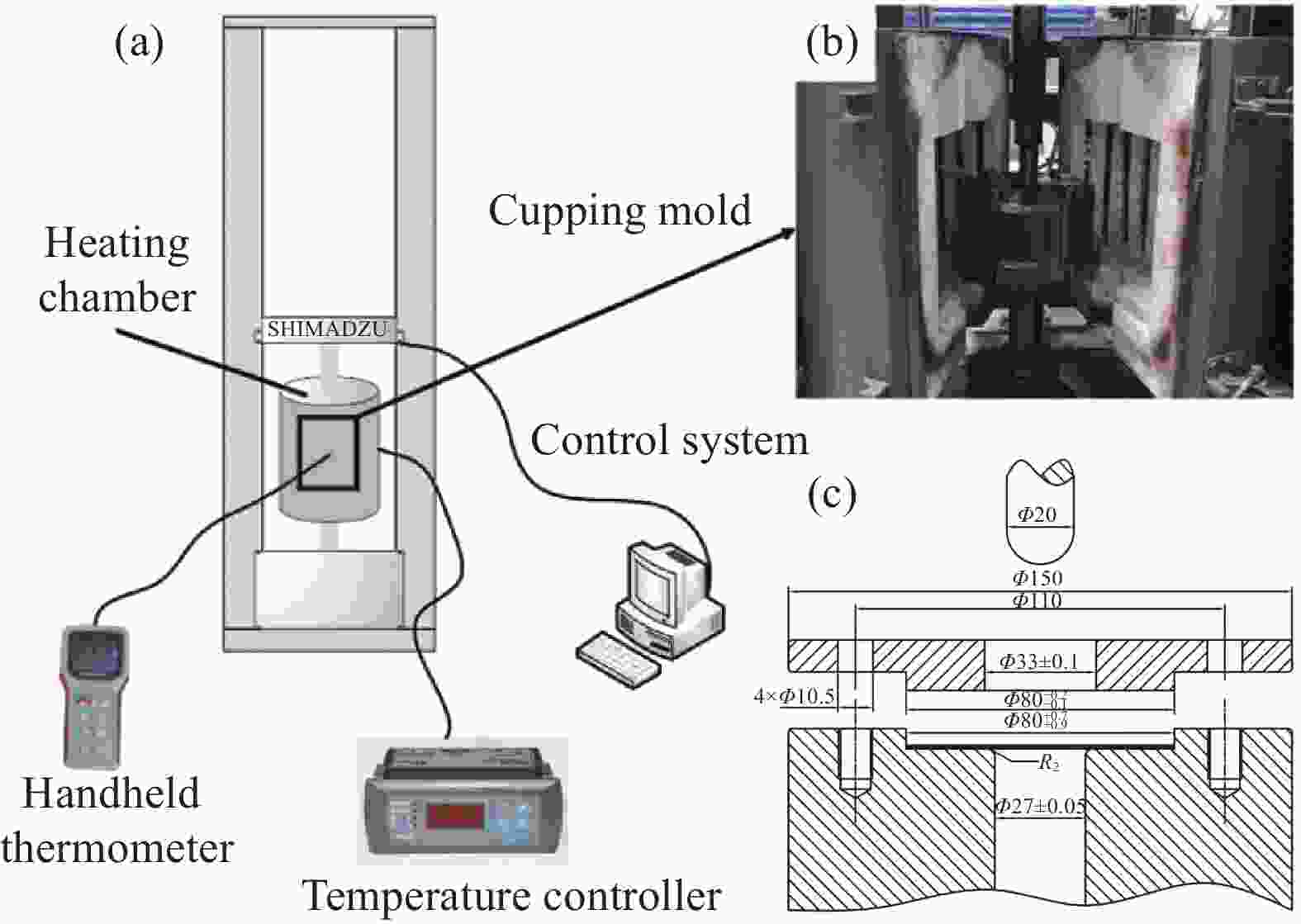

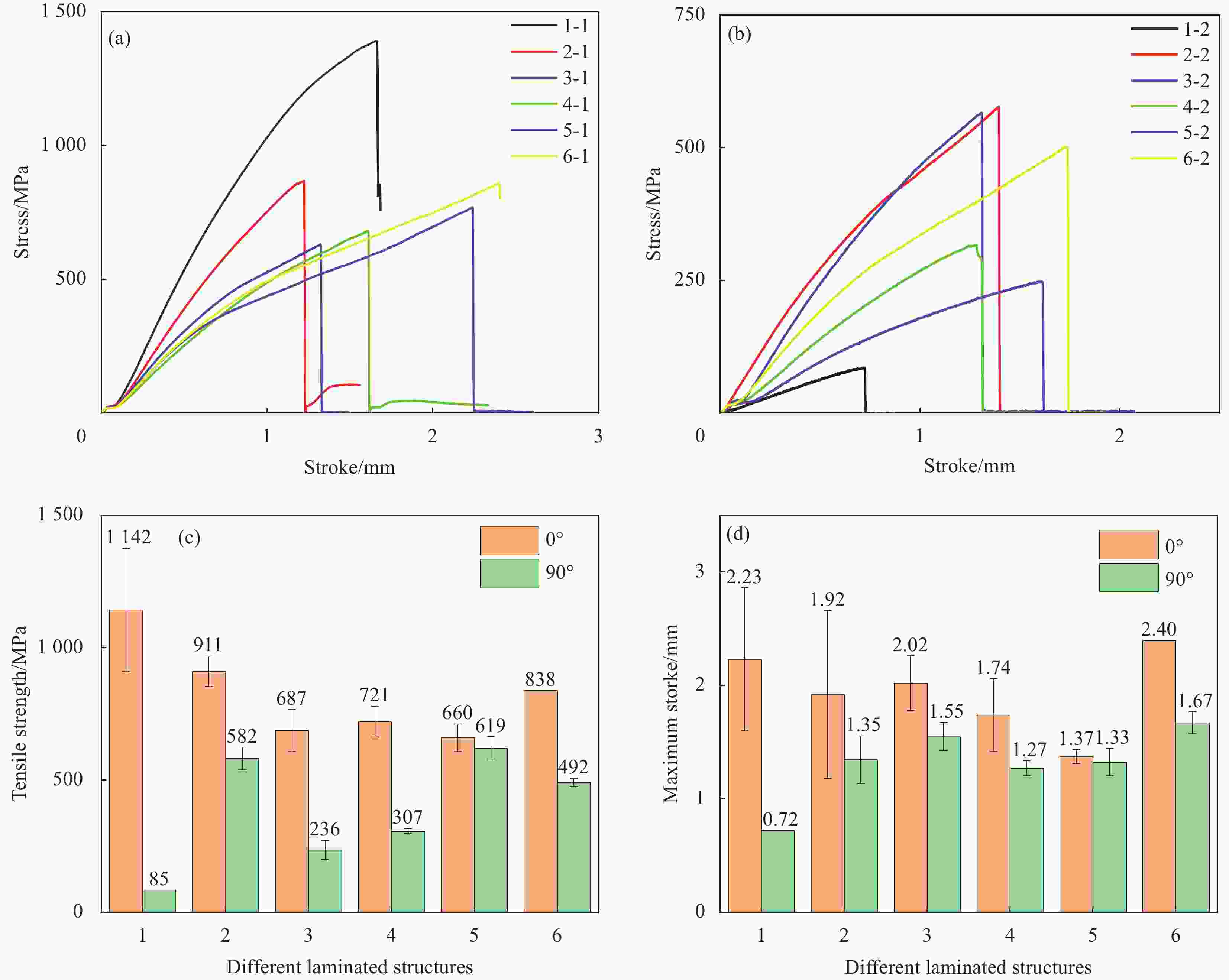

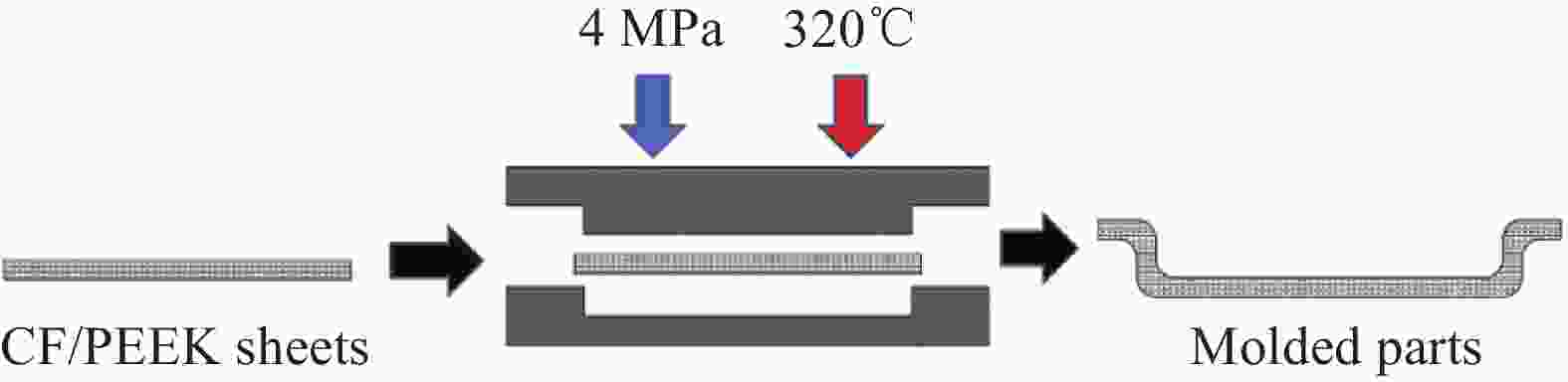

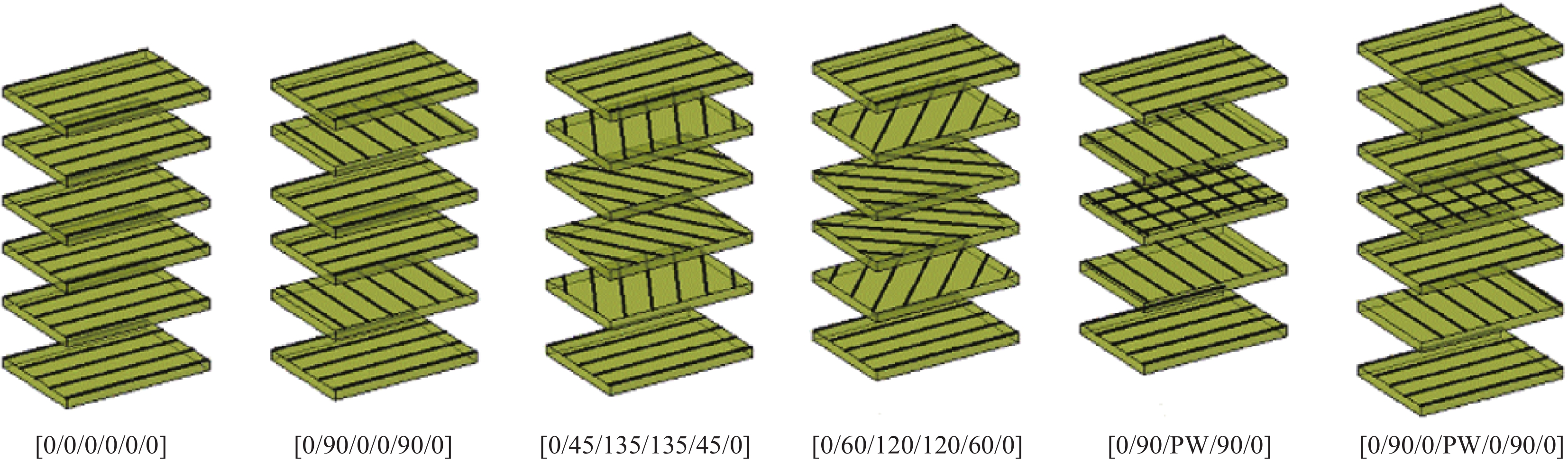

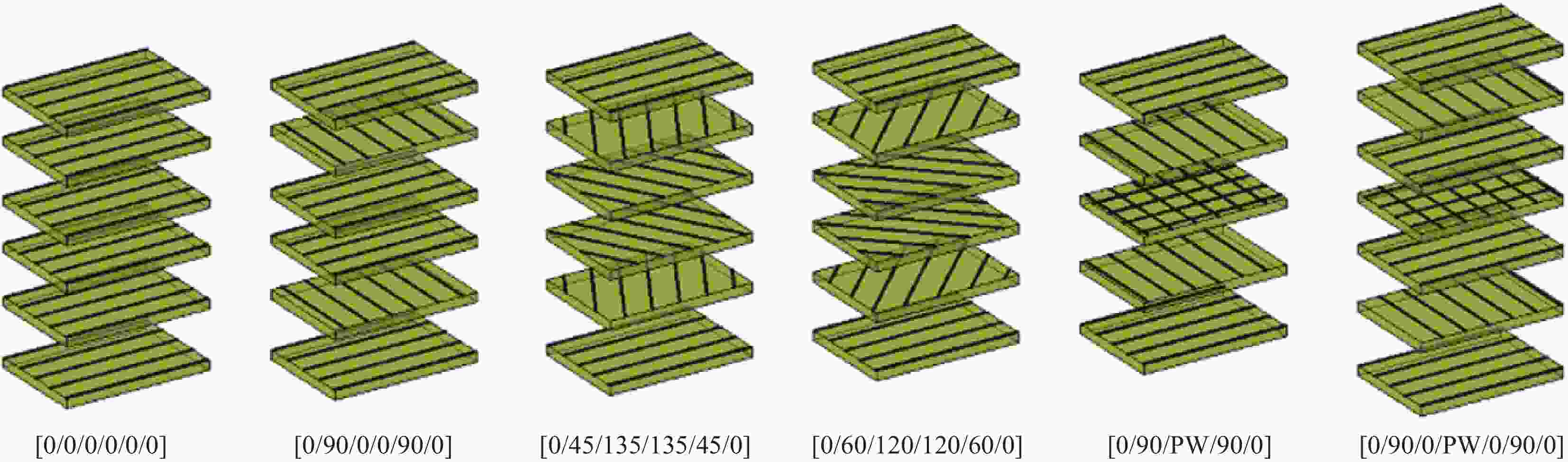

摘要: 碳纤维增强聚醚醚酮复合材料(CF/PEEK)在航空航天等领域有着日益广泛的应用。本文研究了叠层结构对CF/PEEK板材的力学性能和热成形性的影响,并讨论了相关机制。在同种工艺参数下设计并制造了6种不同叠层结构的板材,其力学性能和热成形性能分别通过0°和90°下的常温拉伸试验及320℃下的杯突试验来表征。实验结果表明正交叠层结构[0/90/0/0/90/0]的拉伸强度和热成形性能最好,而加入编织层或采用非正交叠层均使热成形性能有不同程度的下降,这是由于编织层为整个叠层结构中的薄弱项,而非正交结构在不同方向的拉伸强度差异较大,容易发生纤维-基体失效。Abstract: Carbon fiber reinforced polyether-ether-ketone composites (CF/PEEK) are increasingly used in aerospace and other fields. In this study, the influence of laminated structures on mechanical properties and thermo-formability of CF/PEEK sheets were investigated, and the associated mechanisms were discussed. Six different laminated structures of CF/PEEK sheets were designed, and the sheets were fabricated under the same process parameters. The mechanical properties and thermo-formability were characterized by tensile tests at 0° and 90° directions and Erichsen tests at 320℃, respectively. The results show that the tensile strength and thermo-formability of orthogonal structure [0/90/0/0/90/0] is the best. However, the thermo-formability of the structure added woven laminates or non-orthogonal structure are decreased. This is because the added woven laminate is observed to be a weak part in the structure, and the non-orthogonal structure has distinct mechanical properties in 0° and 90° directions and is prone to fiber-matrix failure.

-

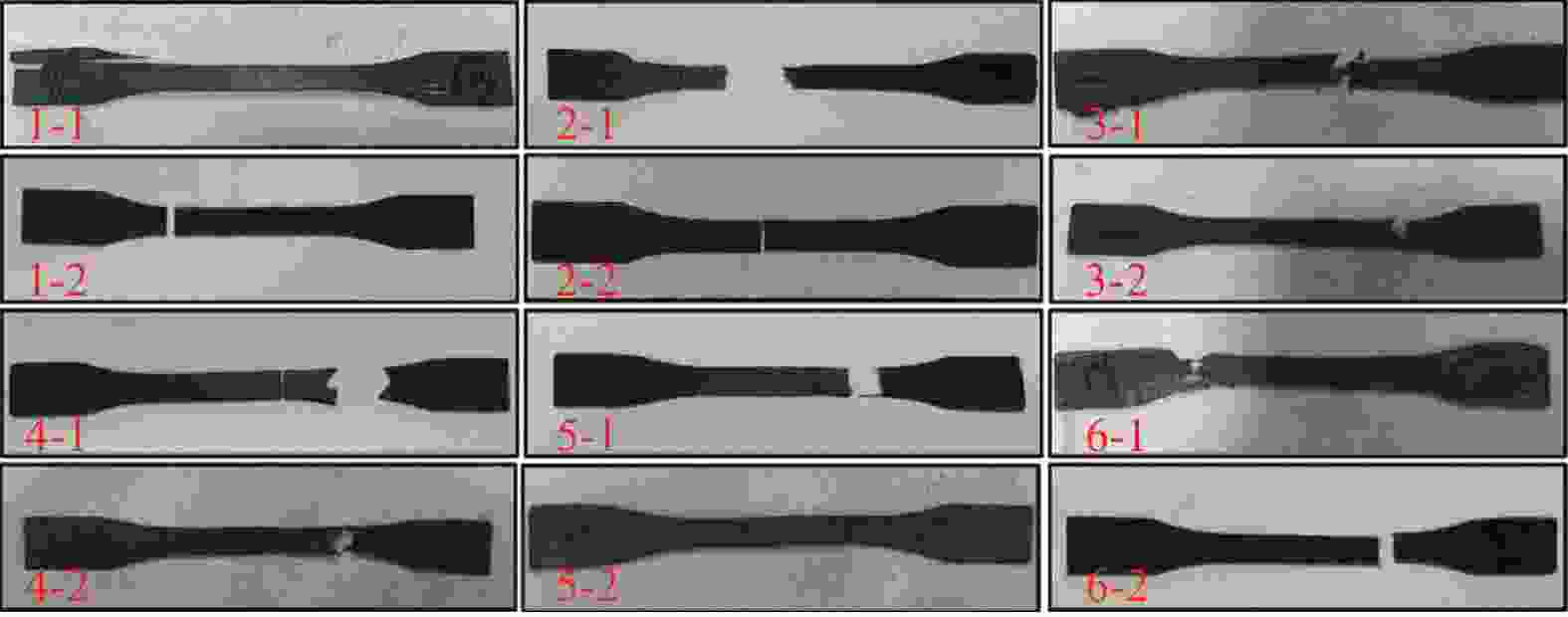

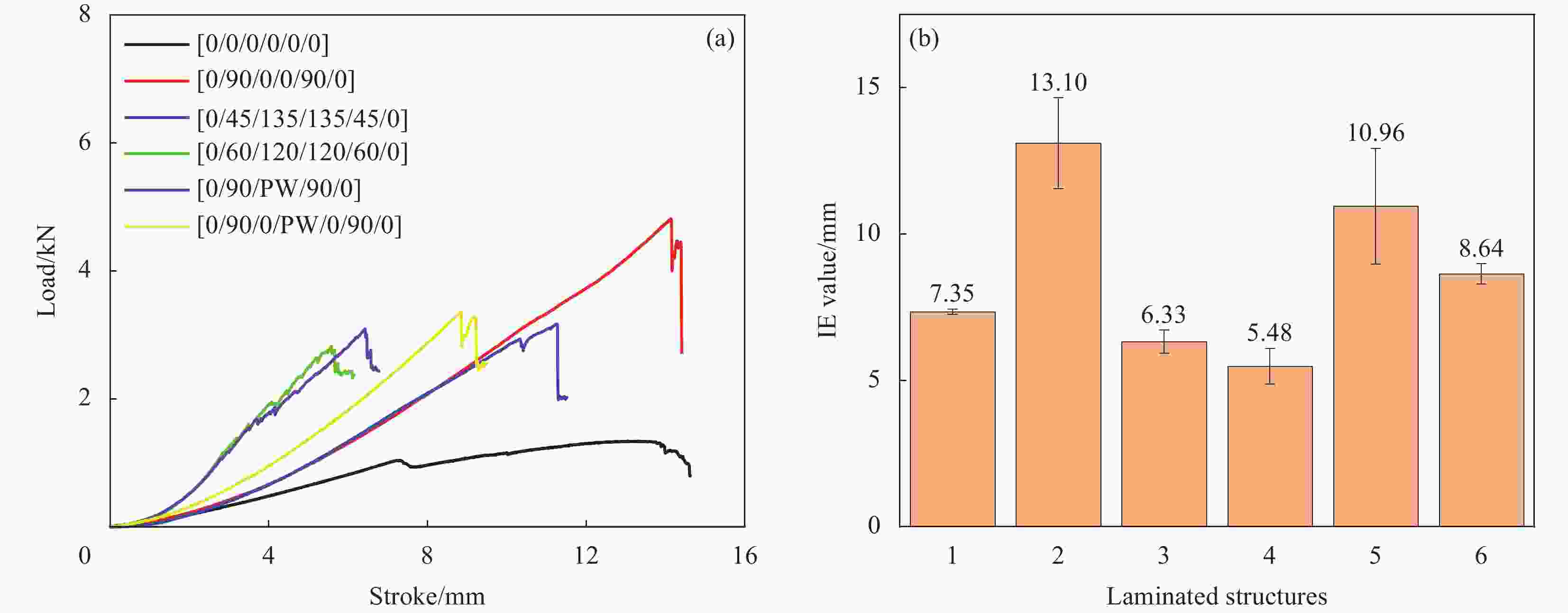

图 5 CF/PEEK板材拉伸试验结果:(a) 0°拉伸方向应力应变曲线;(b) 90°拉伸方向应力应变曲线;(c) 0°/90°方向拉伸强度;(d) 0°/90°拉伸方向最大行程

Figure 5. Tensile tests results of CF/PEEK sheets: (a) Stress/stroke curves at 0° tensile direction; (b) Stress/stroke curves at 90° tensile direction; (c) Tensile strength at 0°/90° directions; (d) Maximum stroke at 0°/90° directions

1-1—Parallel structure with 0° tensile direction; 2-1—Orthogonal structure with 0° tensile direction; 3-1—45° structure with 0° tensile direction; 4-1—60° structure with 0° tensile direction; 5-1—Orthogonal structure replaced by woven laminate with 0° tensile direction; 6-1—Orthogonal structure added woven laminate with 0° tensile direction; 1-2—Parallel structure with 90° tensile direction; 2-2—Orthogonal structure with 90° tensile direction; 3-2—45° structure with 90° tensile direction; 4-2—60° structure with 90° tensile direction; 5-2—Orthogonal structure replaced by woven laminate with 90° tensile direction; 6-2—Orthogonal structure added woven laminate with 90° tensile direction

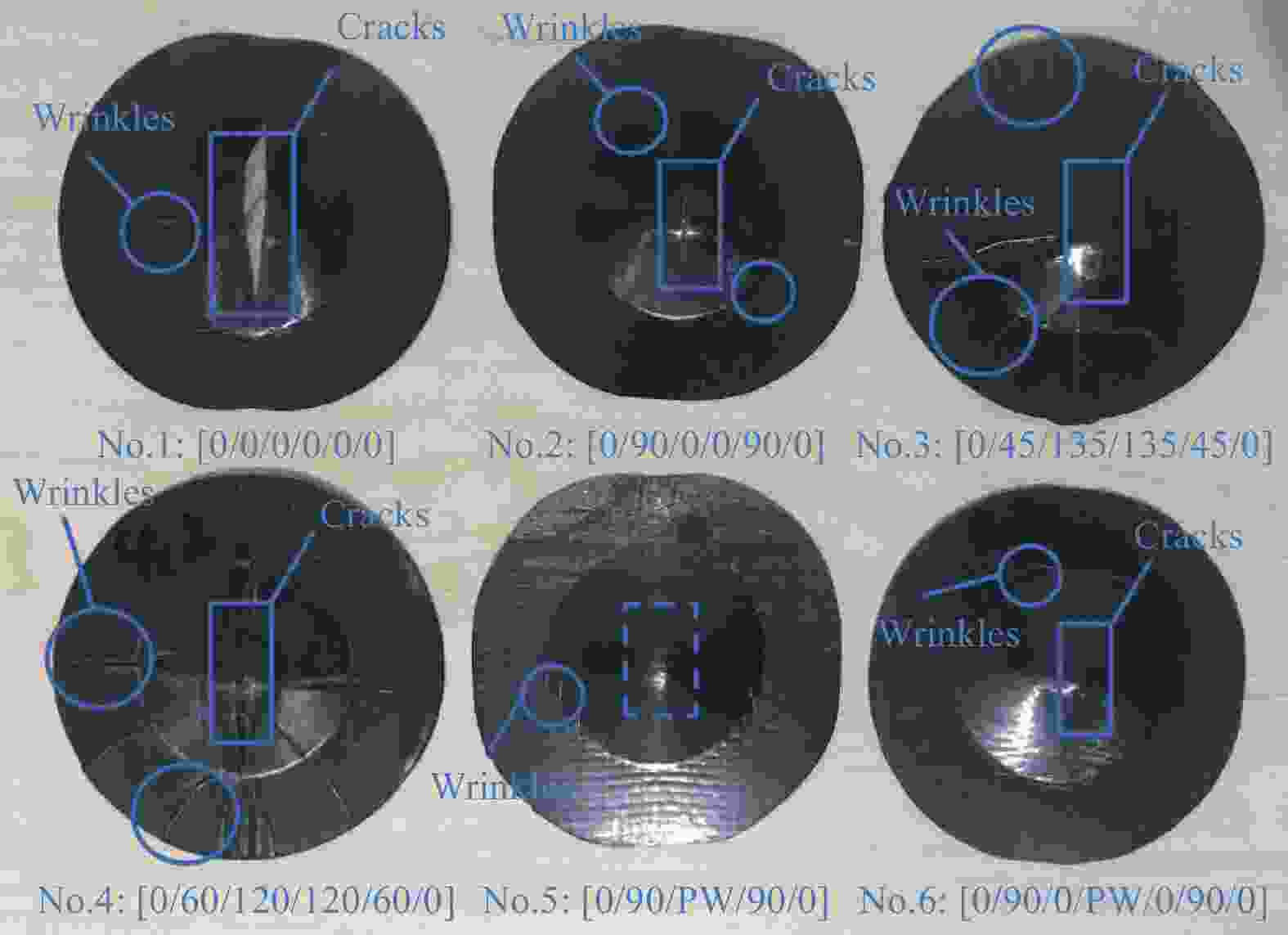

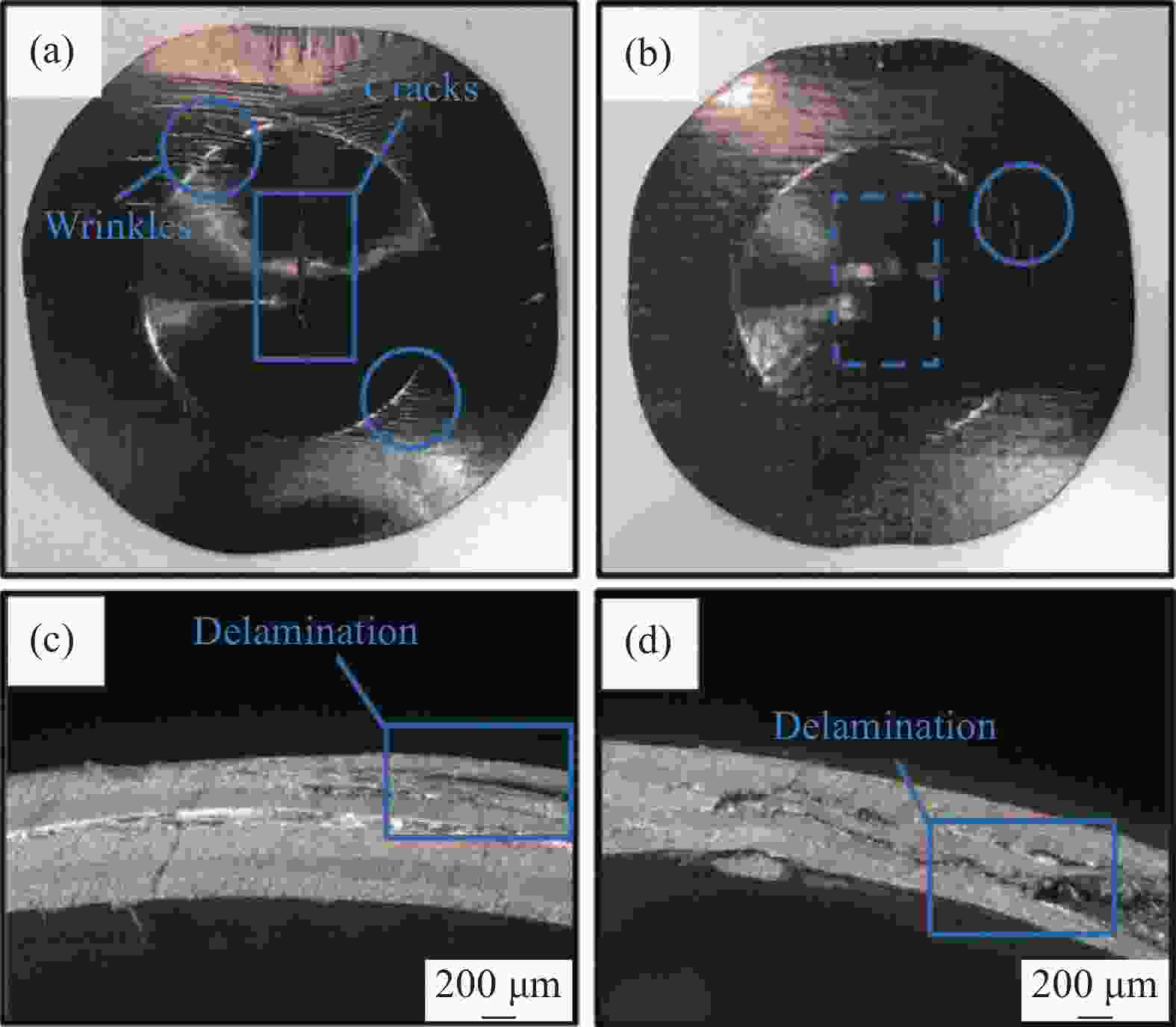

图 10 CF/PEEK板材杯突试样的失效位置:(a) 2号结构[0/90/0/0/90/0]杯突试样;(b) 5号结构[0/90/PW/90/0]杯突试样;(c) 2号结构数字显微镜(DM)图像;(d) 5号DM图像

Figure 10. Failure position of cupping samples of CF/PEEK sheets: (a) No.2 structure [0/90/0/0/90/0] cupping sample; (b) No.5 structure [0/90/PW/90/0] cupping sample; (c) Digital microscope (DM) image of No.2 sample; (d) DM image of No.5 sample

表 1 单向(UD)纤维预浸料物理性能

Table 1. Physical properties of the unidirection (UD) prepregs

Property Value Areal weight/gsm 218 Resin content/wt% 34 Fiber content/vol% 59 Tensile strength (0°)/MPa 2280 Tensile strength (90°)/MPa 86 表 2 不同叠层结构CF/PEEK板材的力学性能

Table 2. Mechanical properties of CF/PEEK sheets of different laminated structures

Numbers Laminated structures Directions Thickness/mm Tensile stress

/MPaMaximum stroke/mm 1-1 [0/0/0/0/0/0] 0° 0.81 1142.26 2.23 1-2 [0/0/0/0/0/0] 90° 0.80 84.95 0.72 2-1 [0/90/0/0/90/0] 0° 0.83 910.50 1.92 2-2 [0/90/0/0/90/0] 90° 0.76 581.79 1.35 3-1 [0/45/135/135/45/0] 0° 0.85 687.43 2.02 3-2 [0/45/135/135/45/0] 90° 0.83 236.20 1.35 4-1 [0/60/120/120/60/0] 0° 0.80 720.61 1.74 4-2 [0/60/120/120/60/0] 90° 0.84 307.22 1.27 5-1 [0/90/PW/90/0] 0° 0.80 660.17 1.37 5-2 [0/90/PW/90/0] 90° 0.78 619.27 1.33 6-1 [0/90/0/PW/0/90/0] 0° 0.91 858.20 2.40 6-2 [0/90/0/PW/0/90/0] 90° 1.04 490.39 1.67 表 3 不同叠层结构CF/PEEK板材的IE值

Table 3. IE values of CF/PEEK sheets of different laminated structures

Numbers Laminated structures Thickness/mm IE value/mm 1 [0/0/0/0/0/0] 0.81 7.35 2 [0/90/0/0/90/0] 0.83 13.10 3 [0/45/135/135/45/0] 0.80 6.33 4 [0/60/120/120/60/0] 0.81 5.48 5 [0/90/PW/90/0] 0.83 10.96 6 [0/90/0/PW/0/90/0] 1.04 8.64 -

[1] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):50-56. doi: 10.13801/j.cnki.fhclxb.20200824.005XING Liying, FENG Zhihai, BAO Jianwen, et al. Opportuni-ties and challenges for the development of carbon fiber and resin matrix composites industry[J]. Acta Materiae Compositae Sinica,2020,37(11):50-56(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200824.005 [2] BOUDEAU N, LIKSONOV D, BARRIERE T, et al. Composite based on polyetheretherketone reinforced with carbon fibres, an alternative to conventional materials for femoral implant: Manufacturing process and resulting structural behaviour[J]. Materials & Design,2012,40:148-156. [3] HUANG Y, ZHANG L, JIANG Q, LAN, et al. A review on concrete structures strengthened with CFRP sheets bonded with organic and inorganic cementation materials[J]. Advances in Civil Engineering Materials,2019,8:1-8. [4] 谌广昌, 姚佳楠, 张金栋, 等. 高性能热塑性复合材料在直升机结构上的应用与展望[J]. 航空材料学报, 2019, 39(5):24-33. doi: 10.11868/j.issn.1005-5053.2019.000035CHEN Guangchang, YAO Jia'nan, ZHANG Jindong, et al. Application and prospect of high performance thermo-plastic composites in helicopter structure[J]. Journal of Aeronautical Materials,2019,39(5):24-33(in Chinese). doi: 10.11868/j.issn.1005-5053.2019.000035 [5] VISHWANATH R, ROHIT B. A review on inspection and maintenance of FRP structures[J]. InIOP Conference Series: Materials Science and Engineering,2019,520:012003. doi: 10.1088/1757-899X/520/1/012003 [6] YAO S S, JIN F L, RHEE K, et al. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review[J]. Composites Part B: Engineering,2018,142:241-250. doi: 10.1016/j.compositesb.2017.12.007 [7] MA Y, UEDA M, YOKOZEKI T, et al. A comparative study of the mechanical properties and failure behavior of carbon fiber/epoxy and carbon fiber/polyamide 6 unidirectional composites[J]. Composite Structures,2019,160:89-99. [8] CALIRI M, FERREIRA A, TITA V. A review on plate and shell theories for laminated and sandwich structures highlighting the finite element method[J]. Composite Structures,2016,156:63-77. doi: 10.1016/j.compstruct.2016.02.036 [9] NIKBAKT S, KAMARIAN S, SHAKERI M. A review on optimization of composite structures Part I: Laminated composites[J]. Composite Structures,2018,195:158-185. doi: 10.1016/j.compstruct.2018.03.063 [10] MARIATTI M, CHUM P. Effect of laminate configuration on the properties of glass fiber-reinforced plastics (GFRPs) mixed composites[J]. Journal of Reinforced Plastics and Composites,2005,24:1713-1721. doi: 10.1177/0731684405051654 [11] WU C, GAO Y, FANG J, et al. Discrete topology optimization of ply orientation for a carbon fiber reinforced plastic (CFRP) laminate vehicle door[J]. Materials & Design,2017,128:9-19. [12] JING Z, FAN X, SUN Q. Global shared-layer blending method for stacking sequence optimizationdesign and blending of composite structures[J]. Composites Part B: Engineering,2015,69:181-190. doi: 10.1016/j.compositesb.2014.09.039 [13] LIU Q, PAAVOLA J. Lightweight design of composite laminated structures with frequency constraint[J]. Composite Structures,2016,156:356-360. doi: 10.1016/j.compstruct.2015.08.116 [14] HO-HUU V, DO-THI T, DANG-TRUNG H, et al. Optimization of laminated composite plates for maximizing buckling load using improved differential evolution and smoothed finite element method[J]. Composite Structures,2016,146:132-147. doi: 10.1016/j.compstruct.2016.03.016 [15] AYDIN L, AYDIN O, ARTEM H, et al. Design of dimensionally stable composites using efficient global optimization method[J]. Proceedings of the ImechE,2019,233:156-168. [16] MONTE S, INFANTE V, MADEIRA J, et al. Optimization of fibers orientation in a composite specimen[J]. Mechanics of Advanced Materials and Structures,2017,24:410-416. doi: 10.1080/15376494.2016.1191099 [17] URIYA Y, IKEUCHI K, YANAGIMOTO J. Enhanced formability of thin carbon fiber reinforced plastic sheets in cold/warm embossing with ductile dummy sheets of different thicknesses[J]. International Journal of Material Forming,2015,8:415-421. doi: 10.1007/s12289-014-1184-9 [18] URIYA Y, YANAGIMOTO J. Suitable structure of thermosetting CFRP sheet for cold/warm forming[J]. International Journal of Material Forming,2016,9:243-252. doi: 10.1007/s12289-015-1227-x [19] URIYA Y, YANAGIMOTO J. Erichsen cupping test on thermosetting CFRP sheets[J]. International Journal of Material Forming,2017,10:527-534. doi: 10.1007/s12289-016-1298-3 [20] ALTIN K, GÖKKAYA H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials[J]. Defence Technology,2018,14:318-326. doi: 10.1016/j.dt.2018.02.001 [21] HAANAPPEL S P, TEN THIJE R H W, SACHS U, et al. Formability analyses of uni-directional and textile reinforced thermoplastics[J]. Composites Part A: Applied Science and Manufacturing,2014,56:80-92. doi: 10.1016/j.compositesa.2013.09.009 [22] ISOGAWA S, AOKI H, TEJIMA M. Isothermal forming of CFRTP sheet by penetration of hemispherical punch[J]. Procedia Engineering,2014,81:1620-1626. doi: 10.1016/j.proeng.2014.10.201 [23] ZHENG B, GAO X P, LI M Y, et al. Formability and failure mechanisms of woven CF/PEEK composite sheet in solid-state thermoforming[J]. Polymers,2019,11:966. doi: 10.3390/polym11060966 [24] LEE J, KIM B, LEE S, et al. A study on the process design of prepreg compression forming using rapid heating and cooling system[J]. Procedia Engineering,2017,207:84-89. doi: 10.1016/j.proeng.2017.10.742 [25] ZHANG J, YANAGIMOTO J. Design and fabrication of formable CFRTP core sandwich sheets[J]. CIRP Annals,2019,68(1):281-284. doi: 10.1016/j.cirp.2019.04.060 [26] ISO. Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics: ISO-527-2[S]. Geneva: ISO, 1993. [27] ISO. Metallic materials. Sheet and strip. Erichsen cupping test: ISO20482:2013[S]. London: British Standards Institution, 2013. [28] VANCLOOSTER K, LOMOV S, VERPOEST I. On the formability of multi-layered fabric composites[C]//17th International Conference on Composite Materials, ICCM-17. Edinburgh: ICCM, 2009, 17: 1-10. -

下载:

下载: