Impact of Fe content of coal fly ash magnetospheres and the grinding size upon microstructure and microwave absorption properties of Fe3C@C-CNTs nanocomposites

-

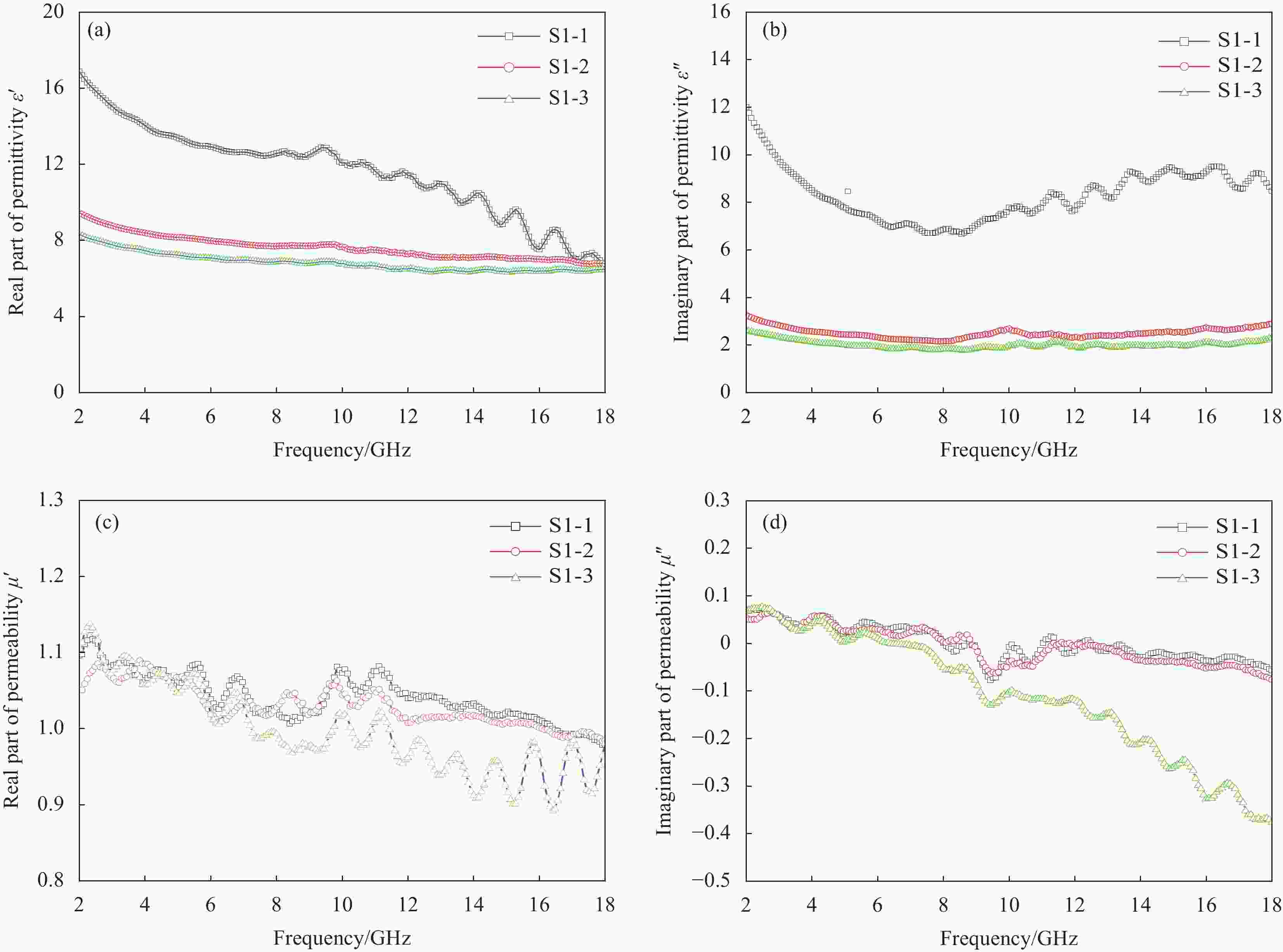

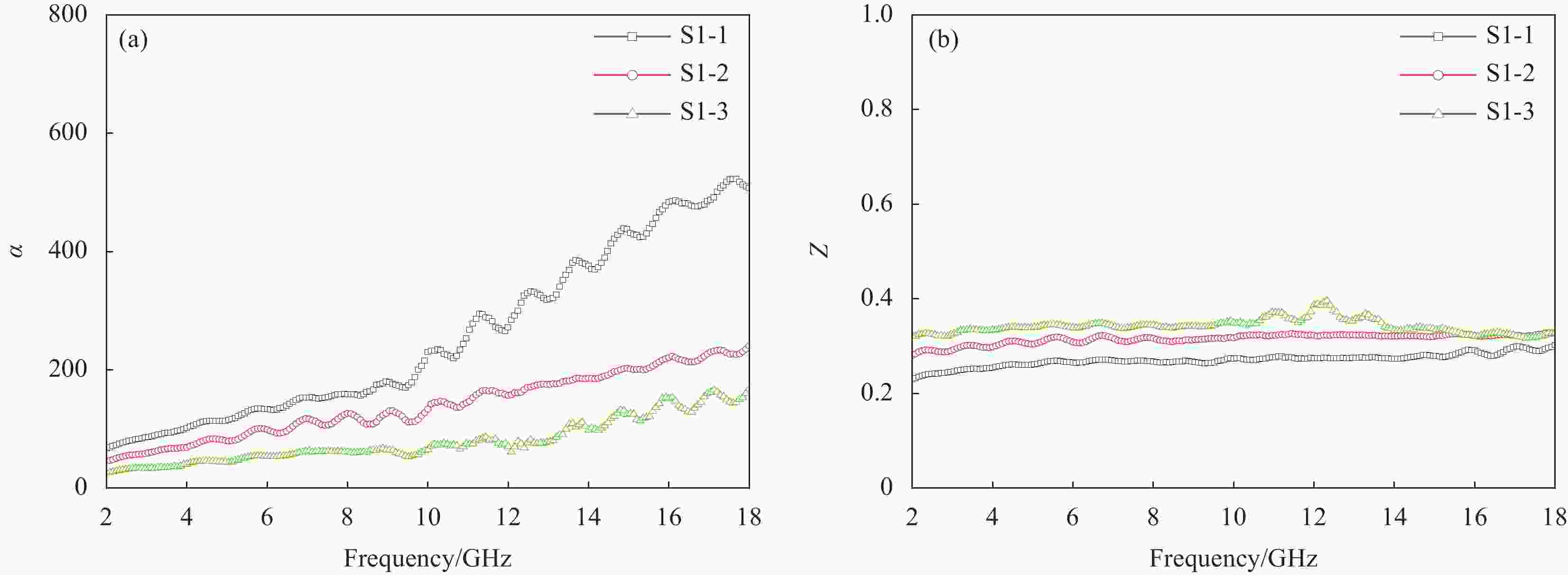

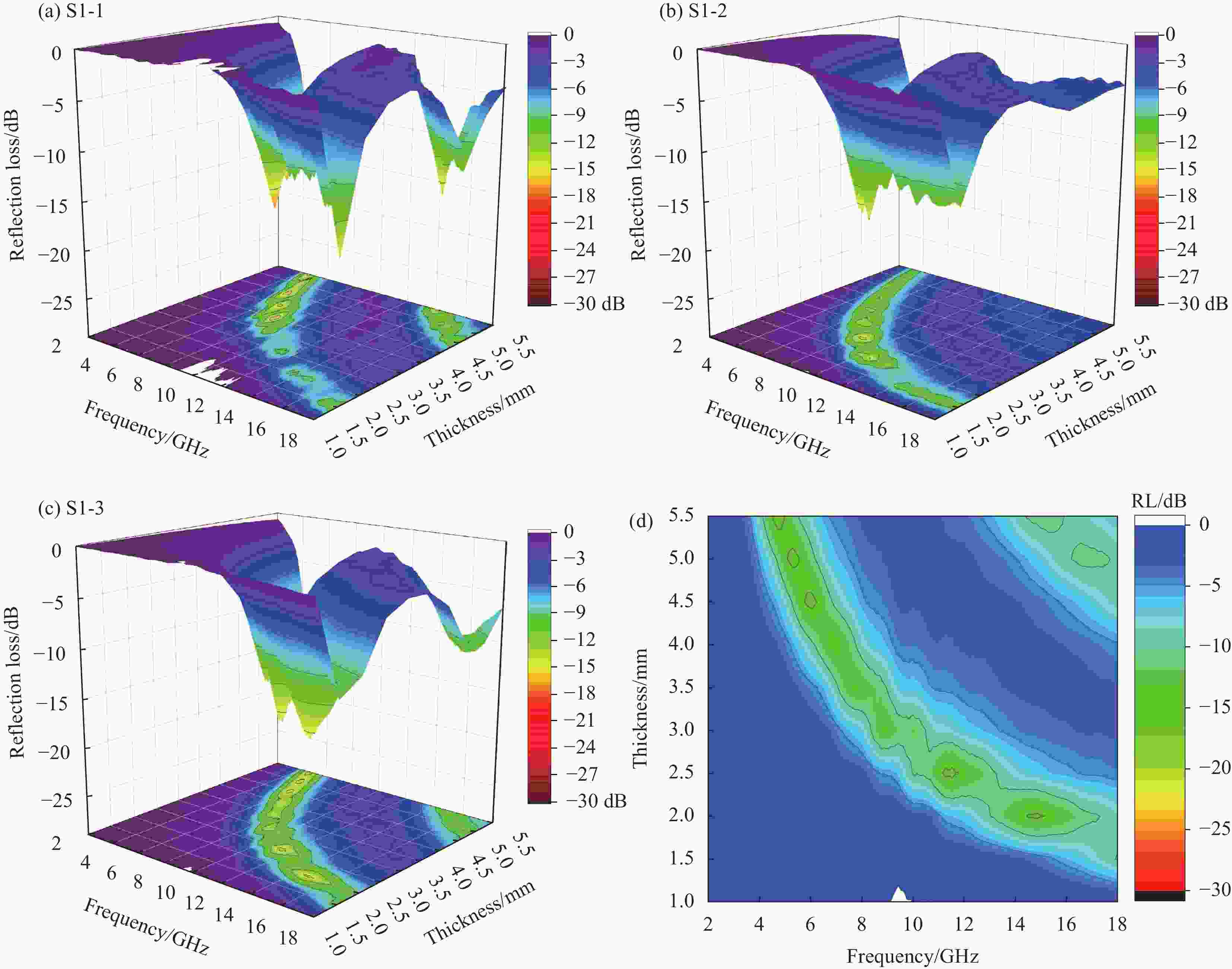

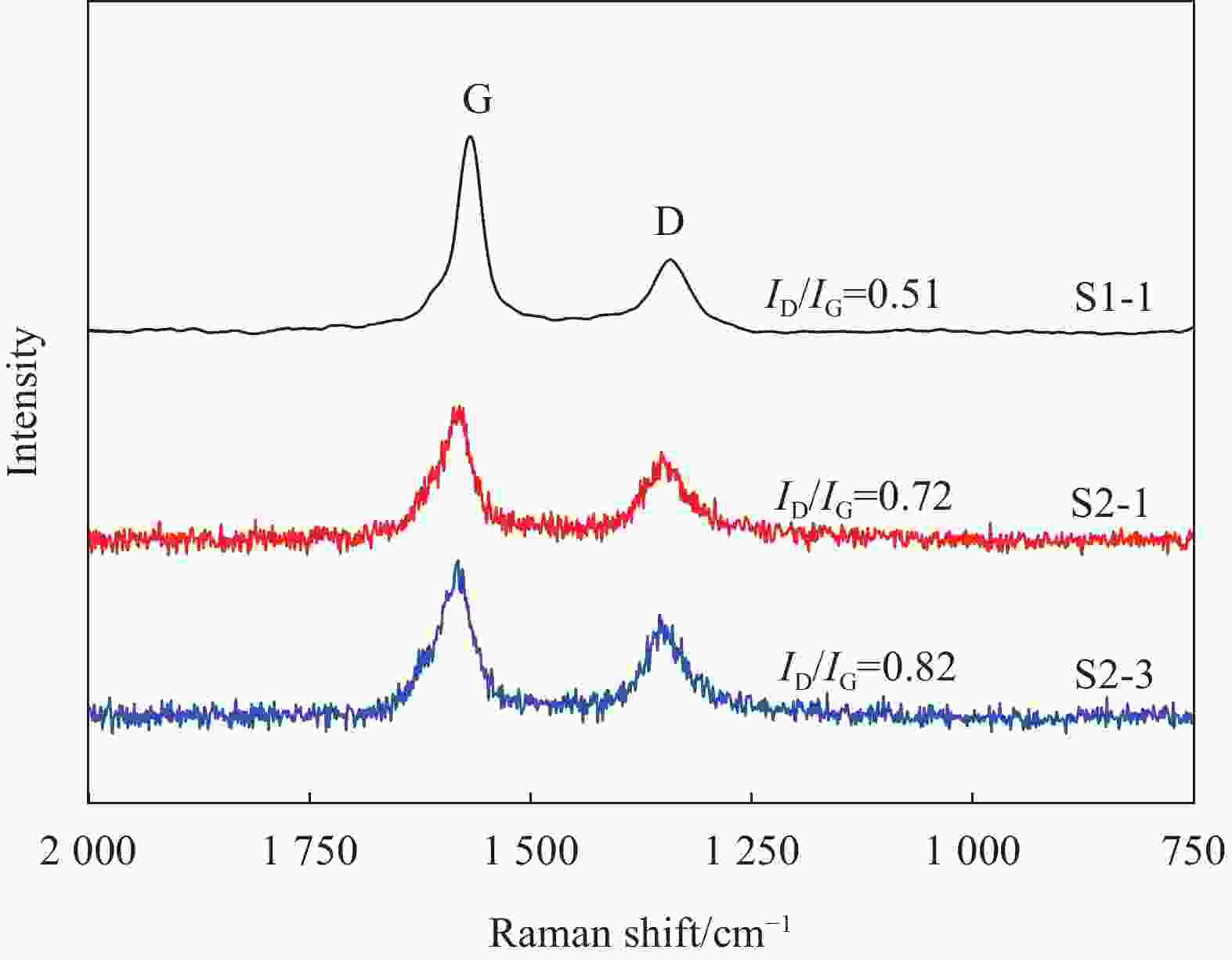

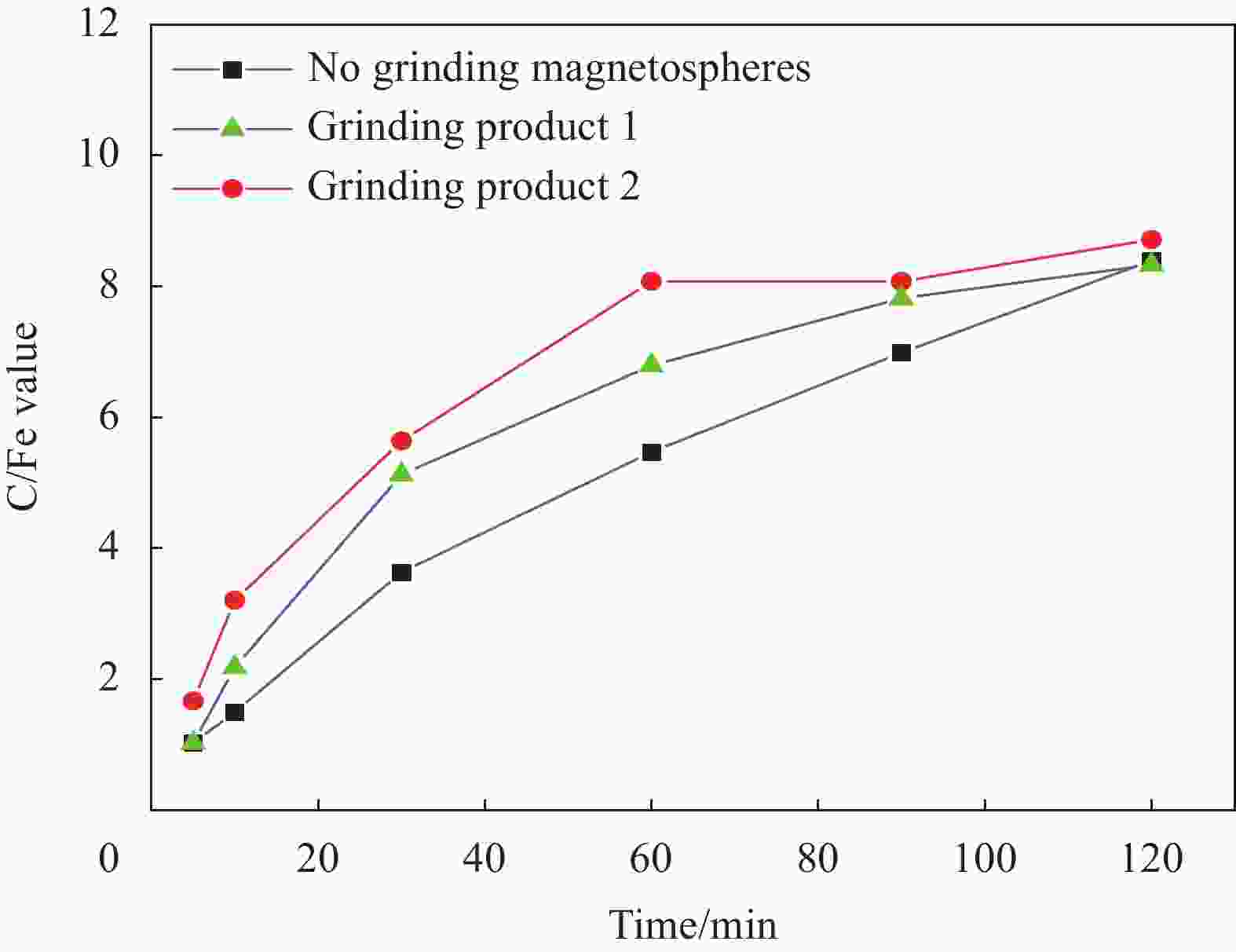

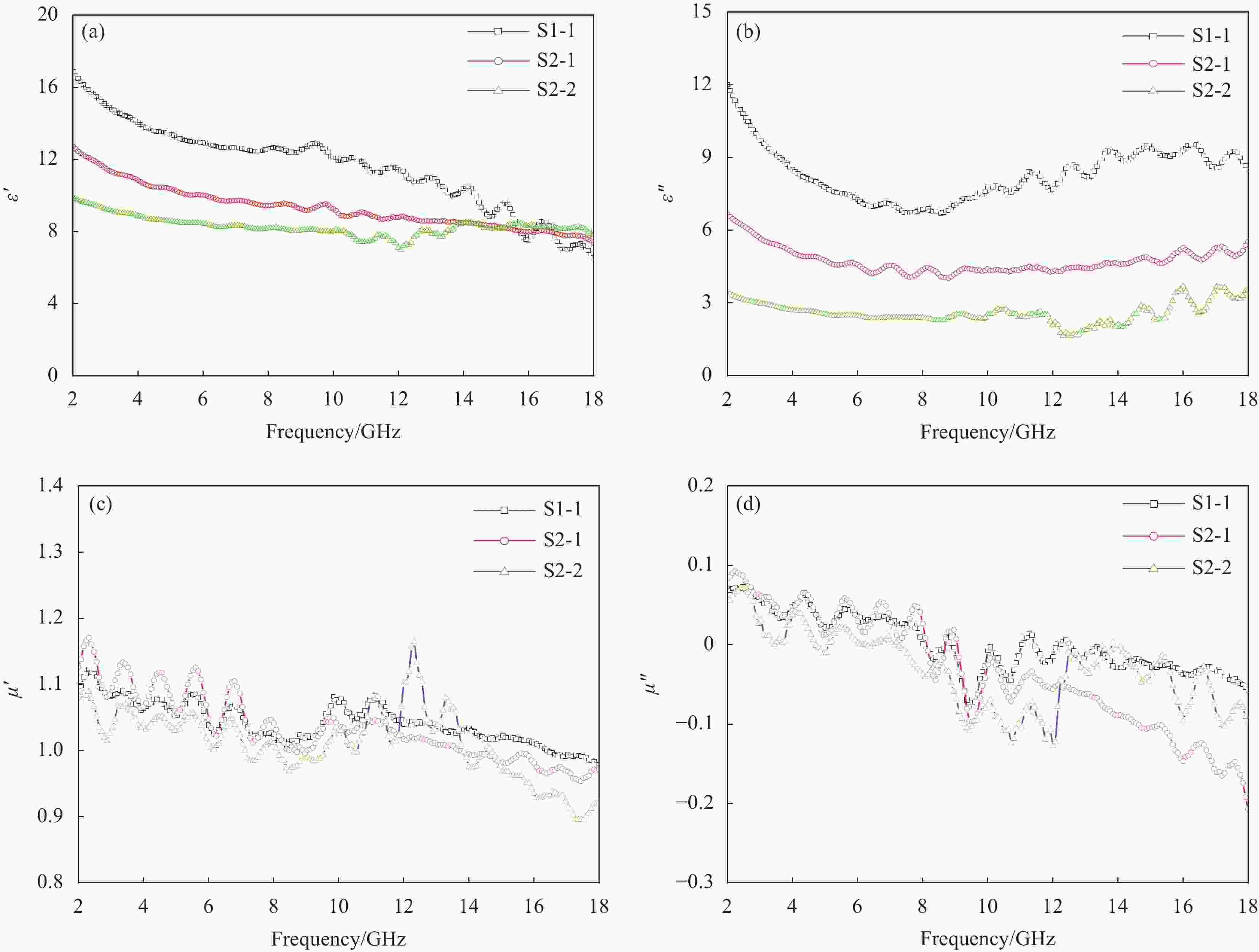

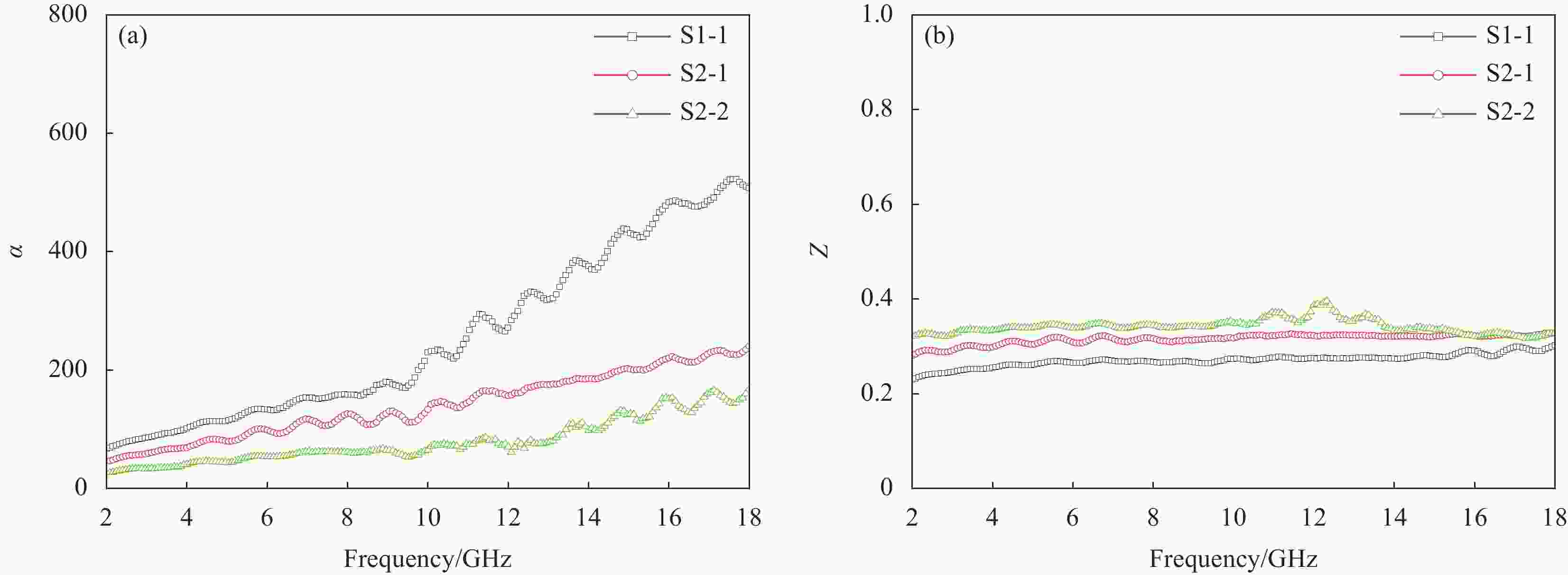

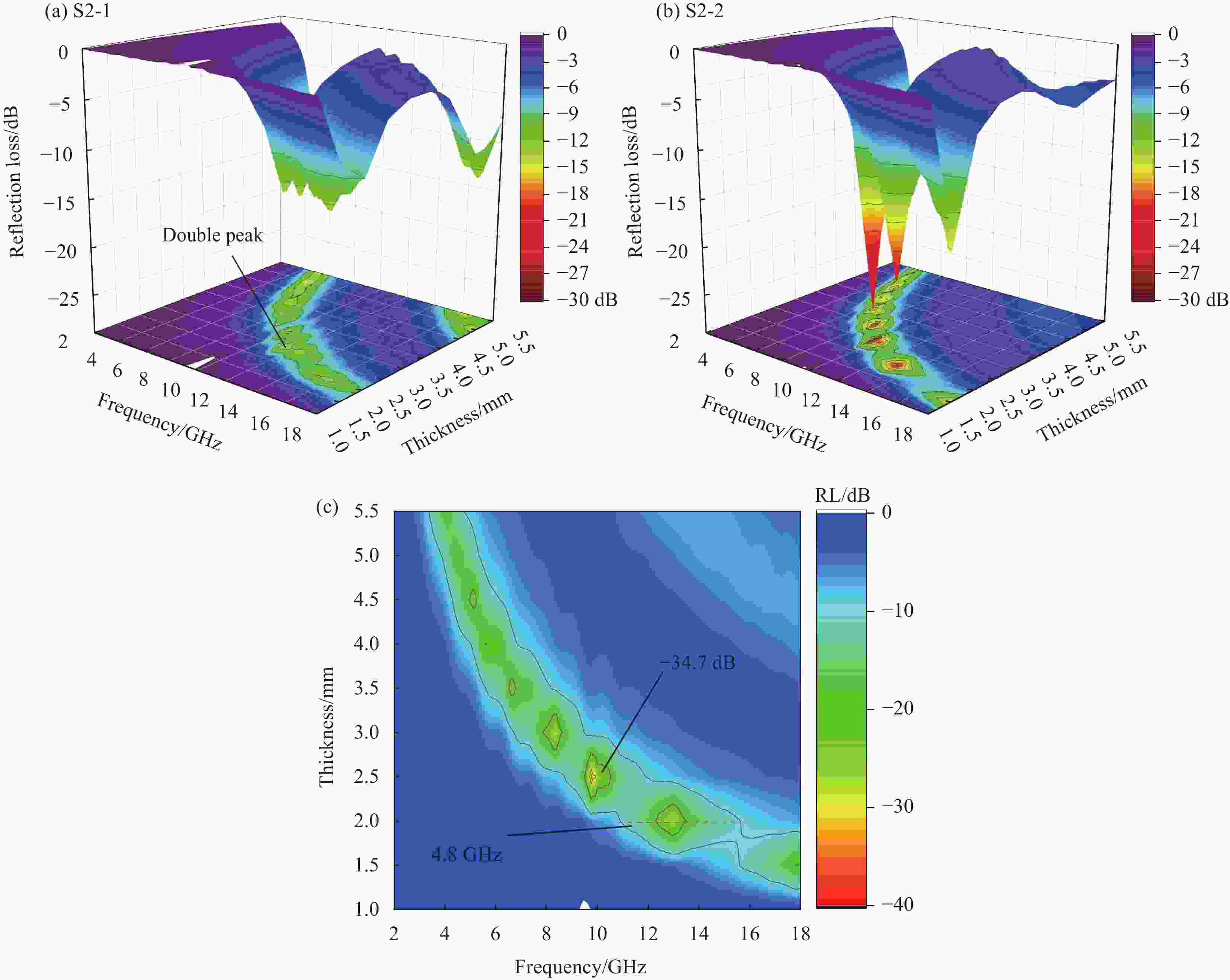

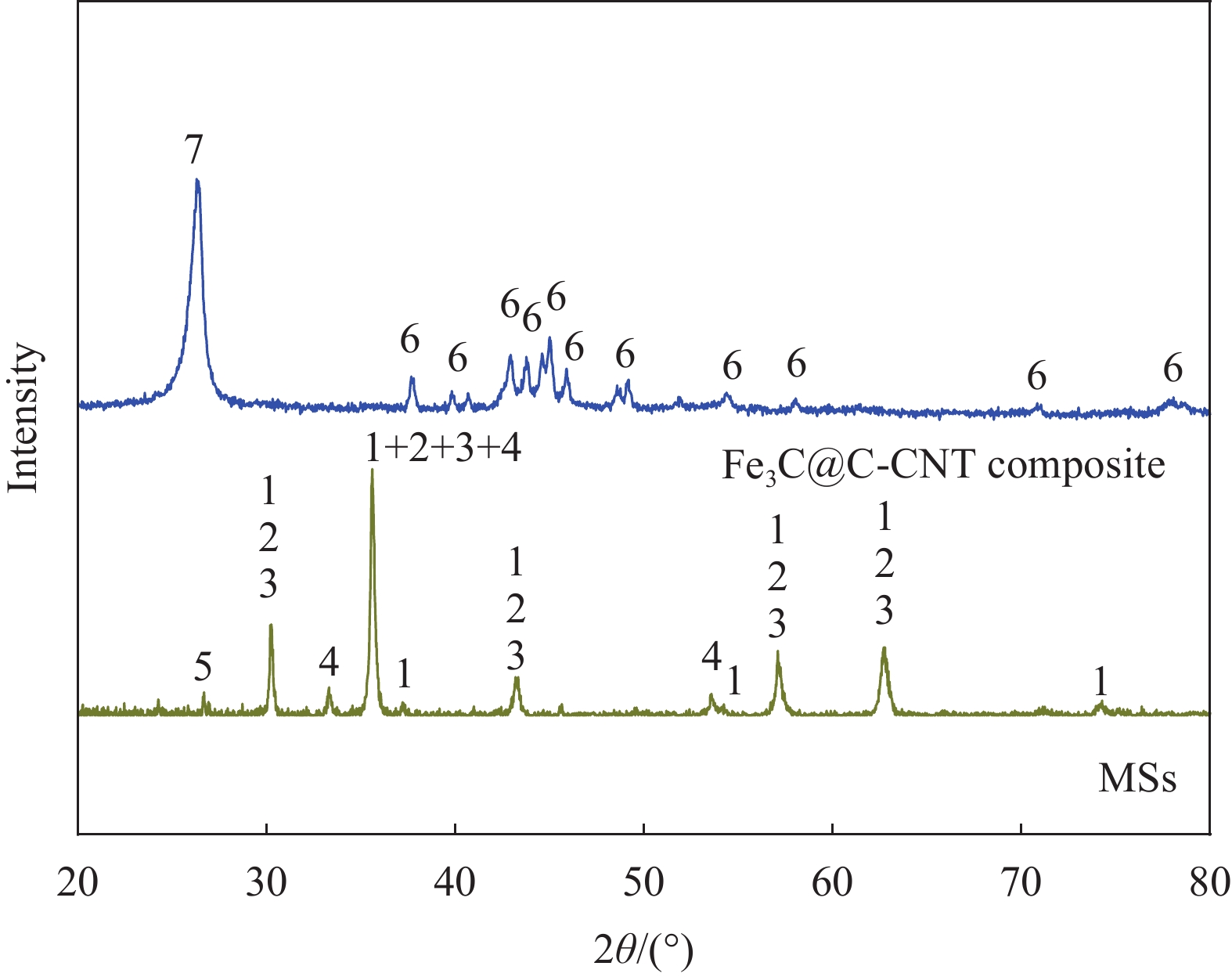

摘要: 以粉煤灰磁珠作为原料,采用化学气相沉积(CVD)方法制备纳米结构铁/碳复合材料。该复合材料呈现良好的吸波性能,但存在磁珠性质不均一、结构调控难等问题。本文采用摇床方法对磁珠进行分选,并进行研磨处理,考察了磁珠Fe含量和研磨粒径对CVD生成产物的影响。结果表明,富铁磁珠CVD生成产物为碳包覆磁性颗粒与碳纳米管组成的复合材料(Fe3C@C-CNTs),该复合材料呈现多孔团簇球形结构。磁珠Fe含量增加,复合材料的相对碳沉积量(C/Fe值)减小,石墨化程度降低(D峰和G峰面积比ID/IG值升高),导致材料阻抗匹配值升高,吸波性能获得提升。磁珠Fe含量为71.43wt%时,复合材料有效吸收频带达到4.5 GHz,最小反射损耗(RLmin)达到−16.1 dB。对磁珠进行研磨后,CVD生成产物的C/Fe值不变,但碳沉积速率增大,ID/IG值升高,电磁波衰减常数下降,但阻抗匹配明显提高,吸波性能大幅度提升。研磨粒径为18.23 μm时,复合材料有效吸收频带达到4.8 GHz,RLmin可达到−34.7 dB。分析表明,复合材料优异的吸波性能得益于CNTs和Fe3C@C对电磁波的协同吸收作用;独特的多孔团簇结构增强了电磁波在材料中多次反射,促进了界面极化。Abstract: Nano-structured iron/carbon composites can be prepared by chemical vapor deposition (CVD) using coal fly ash magnetospheres as raw materials, showing good microwave absorption properties. However, there are problems such as uneven properties of magnetospheres and difficulty in structural regulation. In this paper, the magnetospheres were separated by the shaking bed method, and then were grinded. The effects of the magnetospheres Fe content and the grinding particle size on the CVD products were investigated. The results show that the CVD product of Fe-rich magnetospheres is Fe3C@C-CNTs, and the composite exhibits a porous cluster spherical structure. With the increase of magnetic bead Fe content, the relative carbon deposition (C/Fe value) of the composite decreases, and the graphitization degree decreases (Higher D/G peak intensity ratio ID/IG value increases), resulting in the increase of impedance matching value and the improvement of wave absorption performance. When the Fe content is 71.43wt%, the effective absorption band of the composite reaches 4.5 GHz, and the minimum reflection loss (RLmin) reaches −16.1 dB. After grinding the magnetospheres, the C/Fe value of CVD products is unchanged, but the carbon deposition rate increases, the ID/IG value increases, and the electromagnetic wave attenuation constant decreases, but the impedance matching is significantly improved, and the microwave absorption performance is greatly improved. When the grinding particle size is 18.23 μm, the effective absorption band of the composite is 4.8 GHz, and the RLmin can reach −34.7 dB. The excellent microwave absorption properties of the composites benefit from the synergistic absorption of CNTs and Fe3C@C. Multiple reflections of microwave are supposed to be enhances in the porous cluster aggregated spheres, and the promoted interface polarization is also attributed to the excellent microwave absorption properties.

-

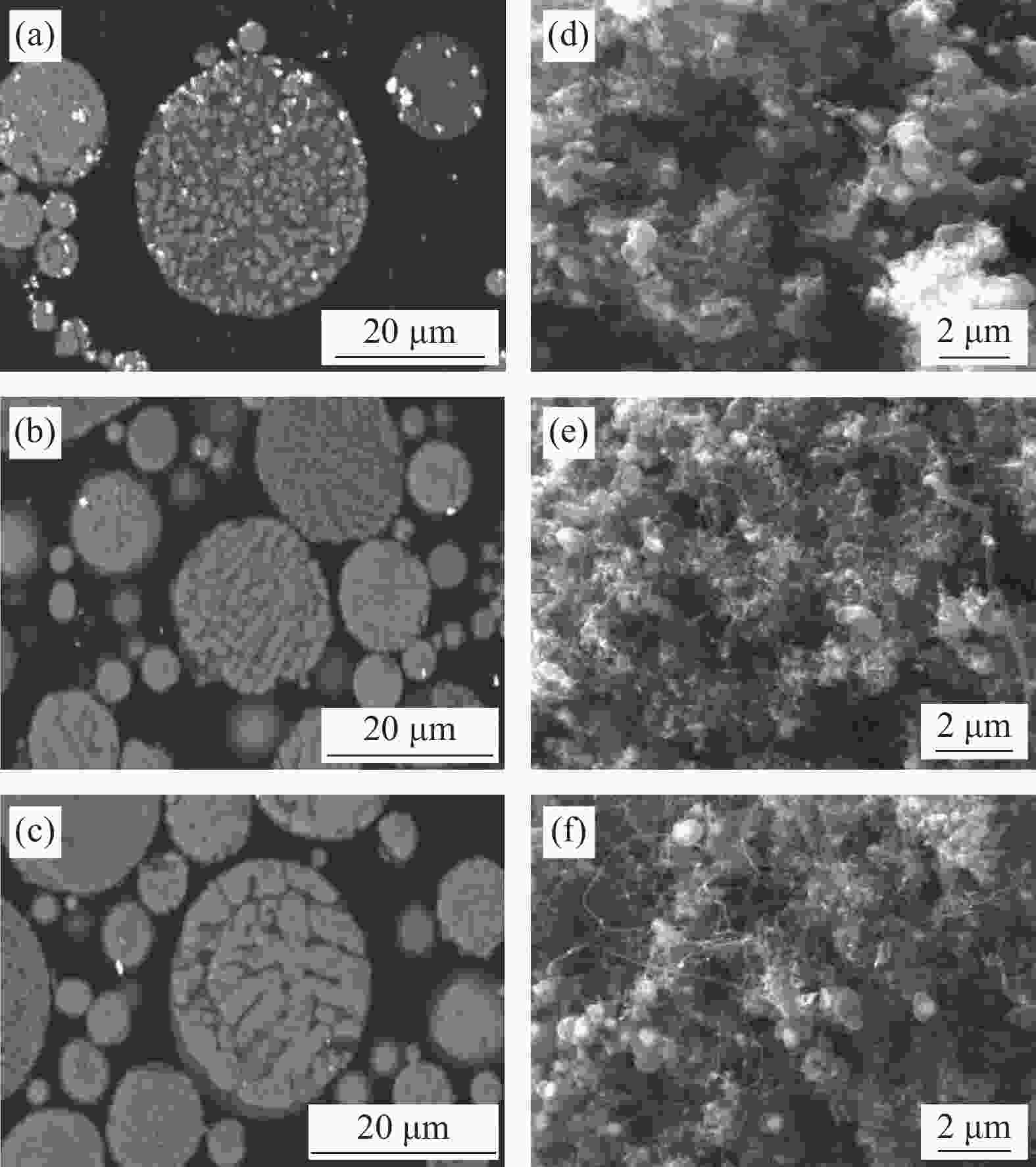

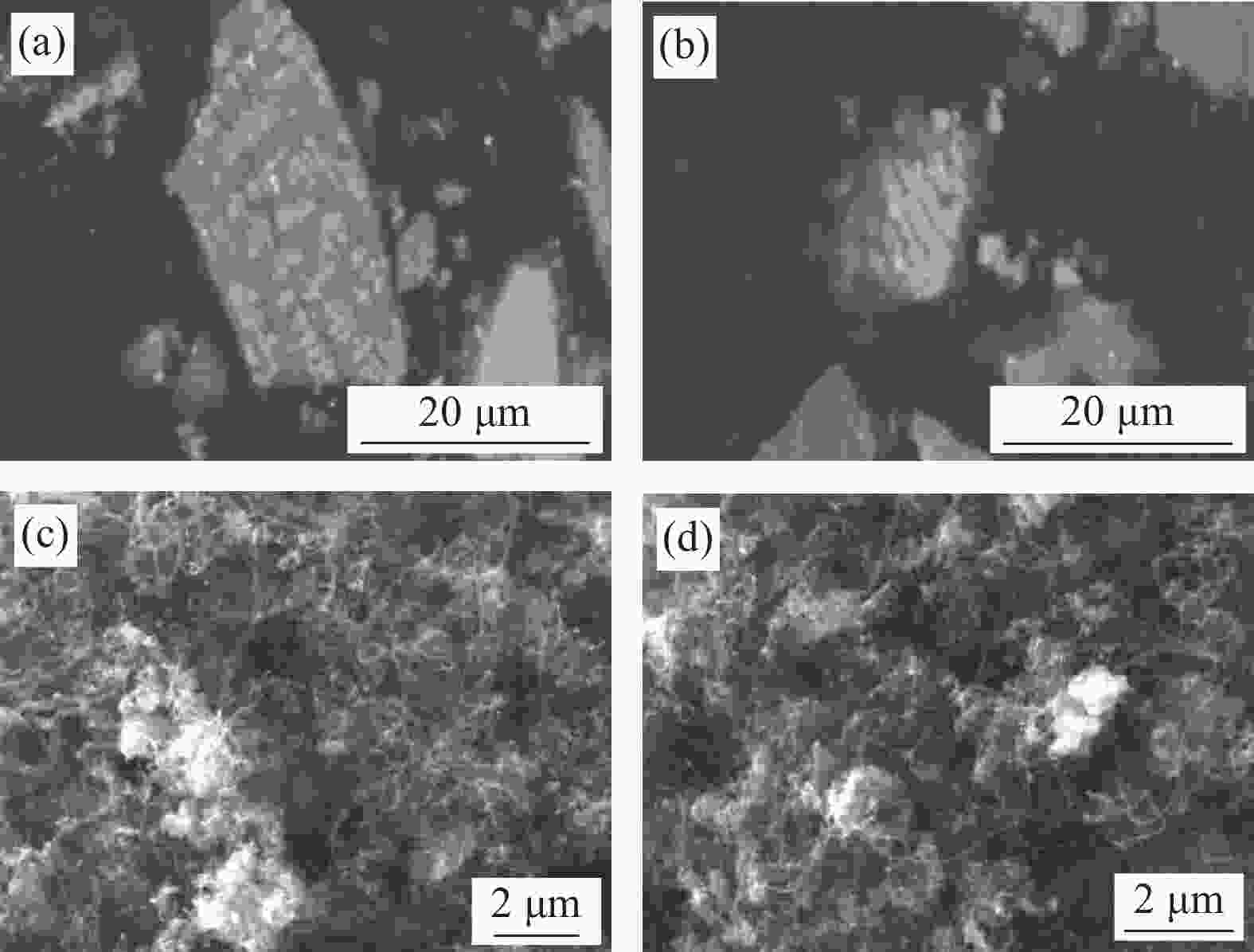

图 3 摇床分选产物磁珠剖面SEM图像:(a) 1#;(b) 2#;(c) 3#;摇床分选产物制备的Fe3C@C-CNTs复合材料SEM图像:(d) S1-1;(e) S1-2;(f) S1-3

Figure 3. SEM images of magnetospheress section of specific gravity product: (a ) 1#; (b) 2#; (c) 3#; SEM images of Fe3C@C-CNTs composites prepared by shaker separation products: (d) S1-1; (e) S1-2; (f) S1-3

表 1 −38 μm磁珠(MSs) EDX结果

Table 1. −38 μm magnetospheres (MSs) EDX results

Element Mass fraction/wt% O 32.3 Fe 52.4 Si 5.7 Al 2.6 Ca 3.3 Mg 2.5 Mn 0.9 Ti 0.3 表 2 MSs摇床分选产物1#、2#、3#的产率、密度、Fe含量

Table 2. Yield, density, and Fe content of MSs shaker separation products 1#, 2#, 3#

Shaker separation

productsYield/% Density/(g·cm−3) Fe/wt% 1# 49.08 4.07 47.49 2# 31.42 4.44 64.36 3# 17.96 5.01 71.43 表 3 Fe3C@C-CNTs复合材料的C/Fe值

Table 3. C/Fe value of Fe3C@C-CNTs composites

Sample C/Fe value S1-1 8.06 S1-2 6.71 S1-3 6.34 Note:C/Fe value—Mass ratio of C to Fe. 表 4 磁珠研磨产物的粒径变化

Table 4. Particle size change of grinding products of magnetospheres

Grinding products Dav/μm No grinding magnetospheres 28.82 Product 1 22.62 Product 2 18.23 Note: Dav—Average grain diameter. 表 5 碳基吸波材料的性能对比

Table 5. Performance comparison of carbon-based absorbing materials

Sample Mass fraction

/wt%Bandwith/GHz RLmin/dB Ref. 3D Fe3O4/CNTs 50 3.9 −51.0 [4] Fe@RC 45 5.3 −47.1 [10] MCNO /MWCNT — 4.3 −25.6 [11] C@Fe@Fe3O4 50 5.2 −40.0 [34] Fe/C nanofibers 30 4.0 −20.2 [38] Fe3O4/C 29 2.5 −29.4 [39] Fe@CNCs 30 3.0 −22.5 [40] S1-3 15 4.5 −16.1 This work S2-2 4.8 −34.7 Notes: RC—Residual carbon; MCNO—Magnetic carbon nano-onion matrix; MWCNT—Multi-walled carbon nanotubes; CNCs—Cored carbon nanocapsules; RLmin—Minimum reflection loss. -

[1] 谢文瀚, 耿浩然, 柳扬, 等. MoS2/生物质碳复合材料的制备与吸波性能[J]. 复合材料学报, 2022, 39(5): 2238-2248.XIE Wenhan, GENG Haoran, LIU Yang, et al. Preparation and microwave absorbing properties of MoS2/biomass carbon composite[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2238-2248(in Chinese). [2] 张开创, 高欣宝, 张倩, 等. 碳包覆磁改性碳纳米管基复合材料制备及吸波性能研究[J]. 兵器装备工程学报, 2019, 40(4):46-49. doi: 10.11809/bqzbgcxb2019.04.012ZHANG Kaichuang, GAO Xinbao, ZHANG Qian, et al. Preparation and absorbing properties of carbon-coated magnetic modified carbon nanotube composites[J]. Journal of Equipment Engineering,2019,40(4):46-49(in Chinese). doi: 10.11809/bqzbgcxb2019.04.012 [3] CUI L, HAN X, WANG F, et al. A review on recent advances in carbon-based dielectric system for microwave absorption[J]. Journal of Materials Science,2021,56(18):10782-10811. doi: 10.1007/s10853-021-05941-y [4] ZHU L, ZENG X, CHEN M, et al. Controllable permittivity in 3D Fe3O4/CNTs network for remarkable microwave absorption performances[J]. RSC Advances,2017,7(43):26801-26808. doi: 10.1039/C7RA04456A [5] FAN G, JIANG Y, XIN J, et al. Facile synthesis of Fe@Fe3C/C nanocomposites derived from bulrush for excellent electromagnetic wave-absorbing properties[J]. ACS Sustainable Chemistry & Engineering,2019,7(23):18765-18774. doi: 10.1021/acssuschemeng.9b02913 [6] WEI B, ZHOU C, YAO Z, et al. Lightweight and high-efficiency microwave absorption of reduced graphene oxide loaded with irregular magnetic quantum dots[J]. Journal of Alloys and Compounds,2021,886:161330. doi: 10.1016/j.jallcom.2021.161330 [7] 刘渊, 贾瑛, 李茸. 碳纤维表面羰基铁的原位生长及吸波性能[J]. 无机化学学报, 2020, 36(2): 210-216.LIU Yuan, JIA Ying, LI Rong. In-situ growth and microwave absorption properties of carbonyl iron on carbon fiber surface[J]. Chinese Journal of Inorganic Chemistry, 2020, 36(2): 210-216(in Chinese). [8] WANG B, WU Q, FU Y, et al. A review on carbon/magnetic metal composites for microwave absorption[J]. Journal of Materials Science & Technology,2021,86(27):91-109. [9] LI G, WANG L, LI W, XU Y. Mesoporous Fe/C and core-shell Fe-Fe3C@C composites as efficient microwave absorbents[J]. Microporous & Mesoporous Materials,2015,211:97-104. doi: 10.1016/j.micromeso.2015.02.054 [10] GAO S, CHEN L, ZHANG Y, et al. Fe nanoparticles decorated in residual carbon from coal gasification fine slag as an ultra-thin wideband microwave absorber[J]. Composites Science and Technology,2021,213:108921. doi: 10.1016/j.compscitech.2021.108921 [11] 邓钏, 张卫珂, 杨艳青, 等. 磁性纳米洋葱碳基复合材料的制备及其吸波性能[J]. 新型炭材料, 2019, 34(2):170-180.DENG Chuan, ZHANG Weike, YANG Yanqing, et al. Preparation and microwave absorption properties of magnetic carbon nano-onion matrix composites[J]. New Carbon Materials,2019,34(2):170-180(in Chinese). [12] KUANG D, HOU L, WANG S, et al. Large-scale synthesis and outstanding microwave absorption properties of carbon nanotubes coated by extremely small FeCo-C core-shell nanoparticles[J]. Carbon,2019,153:52-61. doi: 10.1016/j.carbon.2019.06.105 [13] ZHANG Z, WU X, ZHOU T, et al. The effect of iron-bearing mineral melting behavior on ash deposition during coal combustion[J]. Proceedings of the Combustion Institute,2011,33(2):2853-2861. doi: 10.1016/j.proci.2010.07.061 [14] VASSILEV S V, MENENDEZ R, BORREGO A G, et al. Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 3. Characterization of magnetic and char concentrates[J]. Fuel,2004,83(11-12):1563-1583. doi: 10.1016/j.fuel.2004.01.010 [15] SHARONOVA O M, ANSHITS N N, SOLOVYOV L A, et al. Relationship between composition and structure of globules in narrow fractions of ferrospheres[J]. Fuel,2013,111:332-343. doi: 10.1016/j.fuel.2013.03.059 [16] ZHANG X M, LI J, HE B, et al. Bamboo-shaped carbon nanotubes on coal fly ash cenospheres for Pb(II) adsorption[J]. Journal of Nanoscience and Nanotechnology,2020,20(8):5089-5095. doi: 10.1166/jnn.2020.18480 [17] ZHANG X M, LI J, HE B, et al. Phase transformation and carbon precipitation of coal fly ash magnetospheres during a CVD process for microwave adsorption[J]. Ceramics International,2019,45(15):18980-18987. doi: 10.1016/j.ceramint.2019.06.138 [18] SOKOL E V, KALUGIN V M, NIGMATULINA E N, et al. Ferrospheres from fly ashes of Chelyabinsk coals: Chemical composition, morphology and formation conditions[J]. Fuel,2002,81(7):867-876. doi: 10.1016/S0016-2361(02)00005-4 [19] KOSHY N, SINGH D N. Fly ash zeolites for water treatme[J]. Journal of Environmental Chemical Engineering,2016,4(2):1460-1472. doi: 10.1016/j.jece.2016.02.002 [20] XUE Q, LU S. Microstructure of ferrospheres in fly ashes: SEM, EDX and ESEM analysis[J]. Journal of Zhejiang University-SCIENCE A,2008,9(11):1595-1600. doi: 10.1631/jzus.A0820051 [21] 王欣, 展仁礼, 张晓民, 等. 粉煤灰磁珠精细化分级试验研究[J]. 选煤技术, 2021, 5(288):43-49.WANG Xin, ZHAN Renli, ZHANG Xiaomin, et al. Experimental study on fine classification of magnetosphere from coal fly ash[J]. Coal Preparation Technology,2021,5(288):43-49(in Chinese). [22] DONG S, ZHANG X, LI X, et al. SiC whiskers-reduced graphene oxide composites decorated with MnO nanoparticles for tunable microwave absorption[J]. Chemical Engineering Journal,2020,392:123817. doi: 10.1016/j.cej.2019.123817 [23] GAO S, ZHANG Y, XING H, et al. Controlled reduction synthesis of yolk-shell magnetic@void@C for electromagnetic wave absorption[J]. Chemical Engineering Journal,2020,387:124149. doi: 10.1016/j.cej.2020.124149 [24] DING D, WANG Y, LI X, et al. Rational design of core-shell Co@C microspheres for high-performance microwave absorption[J]. Carbon,2017,111:722-732. doi: 10.1016/j.carbon.2016.10.059 [25] LIU W, SHAO Q, JI G, et al. Metal-organic-frameworks derived porous carbon-wrapped Ni composites with optimized impedance matching as excellent lightweight electromagnetic wave absorber[J]. Chemical Engineering Journal,2017,313:734-744. doi: 10.1016/j.cej.2016.12.117 [26] STRZALKOWSKA E. Morphology, chemical and mineralogical composition of magnetic fraction of coal fly ash[J]. International Journal of Coal Geology,2021,240:103746. doi: 10.1016/j.coal.2021.103746 [27] BARDE A A, KLAUSNER J F, MEI R. Solid state reaction kinetics of iron oxide reduction using hydrogen as a reducing agent[J]. International Journal of Hydrogen Energy,2016,41(24):10103-10119. doi: 10.1016/j.ijhydene.2015.12.129 [28] BAJWA N, LI X, AJIYAN P M, et al. Mechanisms for catalytic CVD growth of multiwalled carbon nanotubes[J]. Journal of Nanoscience and Nanotechnology,2008,8(11):6054-6064. doi: 10.1166/jnn.2008.SW02 [29] 刘盼盼, 李汉超, 杨林, 等. 退火温度对金属催化四面体非晶碳转变为石墨烯过程的影响[J]. 材料研究学报, 2018, 32(5):341-347. doi: 10.11901/1005.3093.2017.107LIU Panpan, LI Hanchao, YANG Lin, et al. Influence of annealing temperature on the metal-catalyzed crystallization of tetrahedral amorphous carbon to graphene[J]. Chinese Journal of Materials Research,2018,32(5):341-347(in Chinese). doi: 10.11901/1005.3093.2017.107 [30] WANG D T, WANG X C, ZHANG X, et al. Tunable dielectric properties of carbon nanotube@polypyrrole core-shell hybrids by the shell thickness for electromagnetic wave absorption[J]. Chinese Physics Letters,2020,37(4):045201. doi: 10.1088/0256-307X/37/4/045201 [31] CHENG Y, ZHAO H, ZHAO Y, et al. Structure-switchable mesoporous carbon hollow sphere framework toward sensitive microwave response[J]. Carbon,2020,161:870-879. doi: 10.1016/j.carbon.2020.02.011 [32] LIU L, HE P, ZHOU K C, et al. Microwave absorption properties of helical carbon nanofibers-coated carbon fibers[J]. AIP Advances,2013,3(8):082112. doi: 10.1063/1.4818495 [33] GAO S, YANG S H, WANG H Y, et al. Excellent electromagnetic wave absorbing properties of two-dimensional carbon-based nanocomposite supported by transition metal carbides Fe3C[J]. Carbon,2020,162:438-444. doi: 10.1016/j.carbon.2020.02.031 [34] LV H, JI G, LIU W, et al. Achieving hierarchical hollow carbon@Fe@Fe3O4 nanospheres with superior microwave absorption properties and lightweight features[J]. Journal of Materials Chemistry C,2015,3(39):10232-10241. doi: 10.1039/C5TC02512E [35] LI S, LIN L, YAO L, et al. MOFs-derived Co-C@C hollow composites with high-performance electromagnetic wave absorption[J]. Journal of Alloys and Compounds,2021,856:158183. doi: 10.1016/j.jallcom.2020.158183 [36] 杨喜, 曹敏, 简煜, 等. 多孔木炭/Fe3O4复合吸波材料的制备与性能[J]. 复合材料学报, 2022, 39(10): 4590-4601.YANG Xi, CAO Min, JIAN Yu, et al. Preparation and microwave absorption properties of porous charcoal/Fe3O4 composites[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4590-4601(in Chinese). [37] 叶喜葱, 欧阳宾, 杨超, 等. 石墨烯-羰基铁粉线材的制备及其吸波性能分析[J]. 复合材料学报, 2022, 39(7): 3292-3302.YE Xicong, OUYANG Bin, YANG Chao, et al. Preparation of graphene-carbonyl iron powder wire and analysis of its wave absorption performance[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3292-3302(in Chinese). [38] ZHENG Q, YU M, WANG W, et al. Enhanced microwave absorption performance of Fe/C nanofibers by adjusting the magnetic particle size using different electrospinning solvents[J]. Ceramics International,2020,46(18):28603-28612. doi: 10.1016/j.ceramint.2020.08.018 [39] KHANI O, SHOUSHTARI M Z, JAZIREHPOUR M, et al. Effect of carbon shell thickness on the microwave absorption of magnetite-carbon core-shell nanoparticles[J]. Ceramics International,2016,42(13):14548-14556. doi: 10.1016/j.ceramint.2016.06.069 [40] WANG Y, WANG W, SUN J, et al. Microwave-based preparation and characterization of Fe-cored carbon nanocapsules with novel stability and super electromagnetic wave absorption performance[J]. Carbon,2018,135:1-11. doi: 10.1016/j.carbon.2018.04.026 -

下载:

下载: