Dynamic response and damage analysis of carbon fiber reinforced concrete beams under drop hammer impact

-

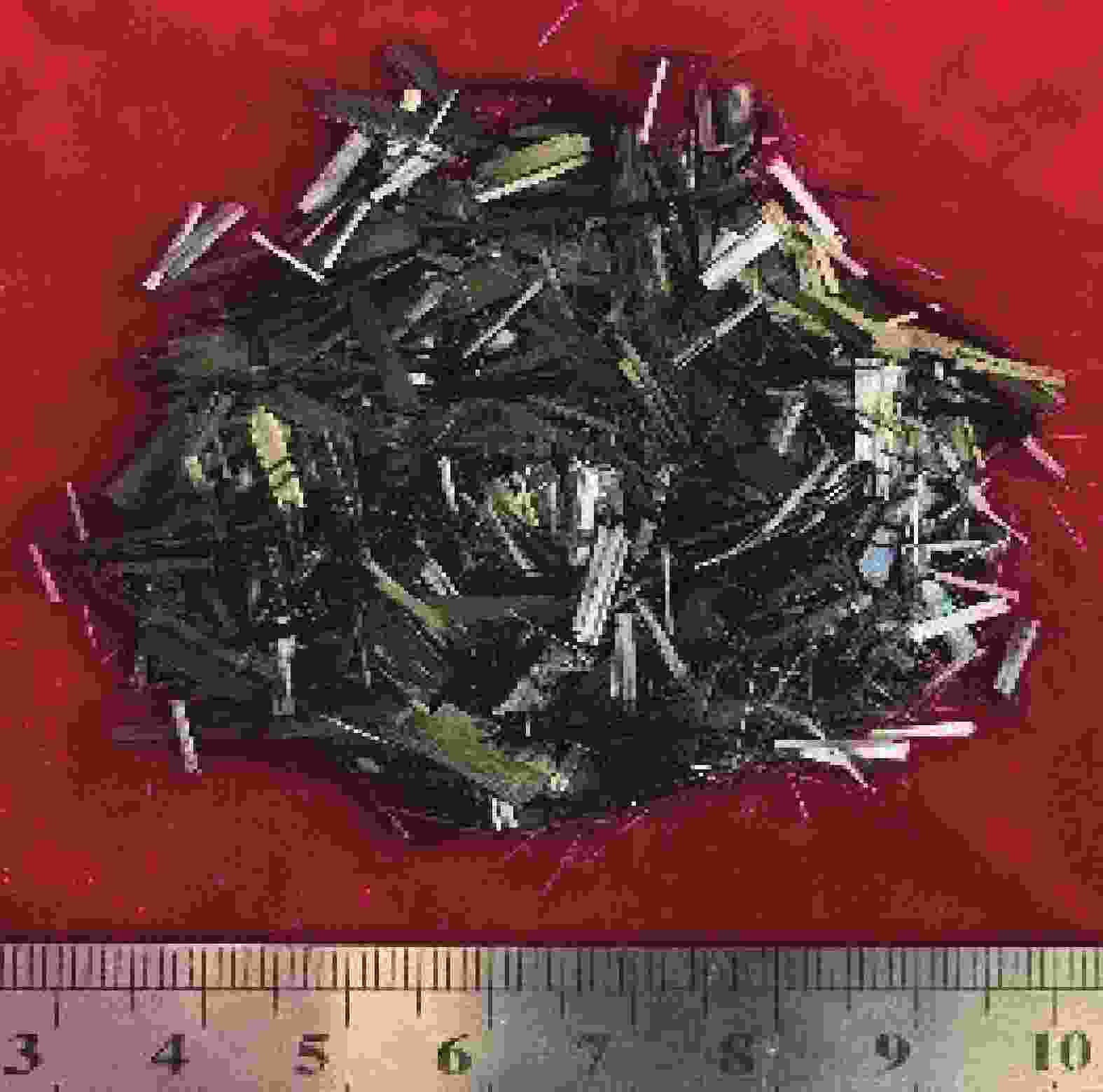

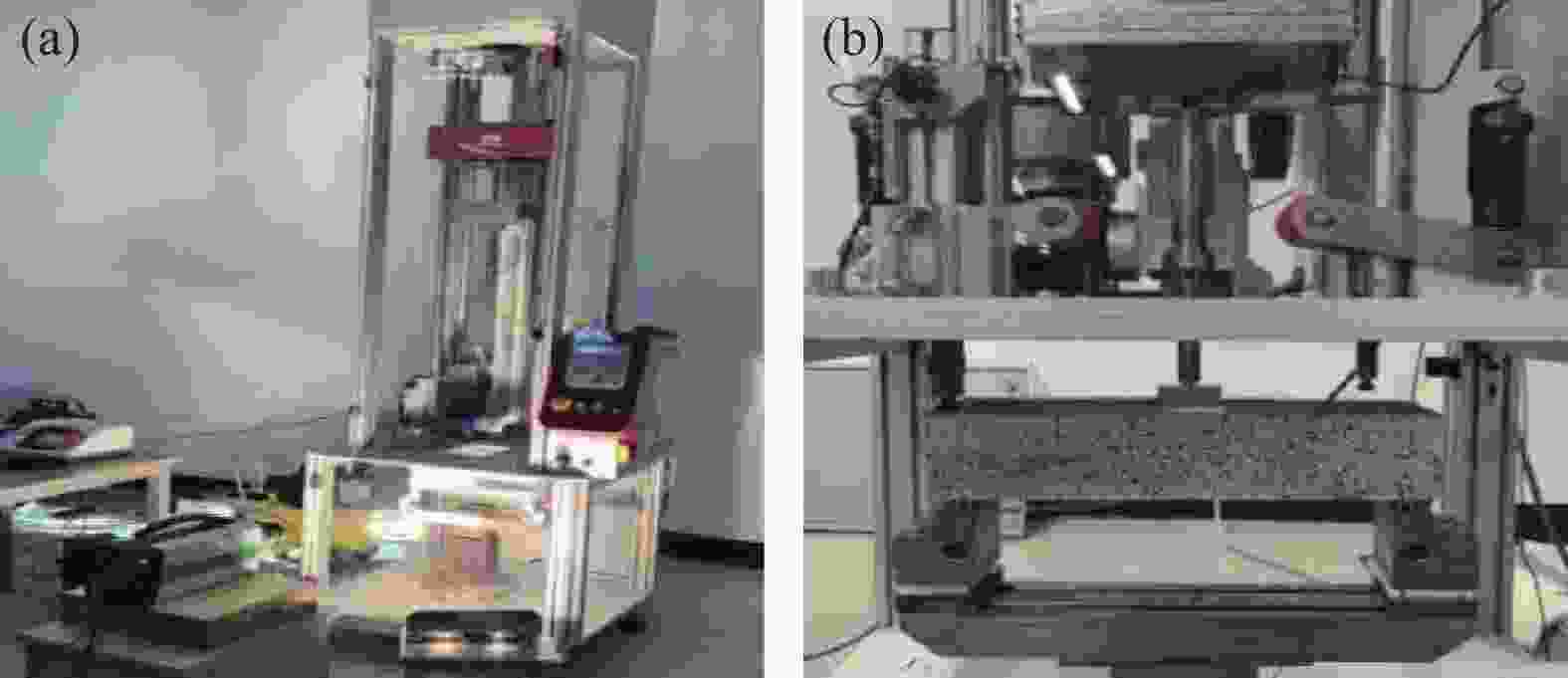

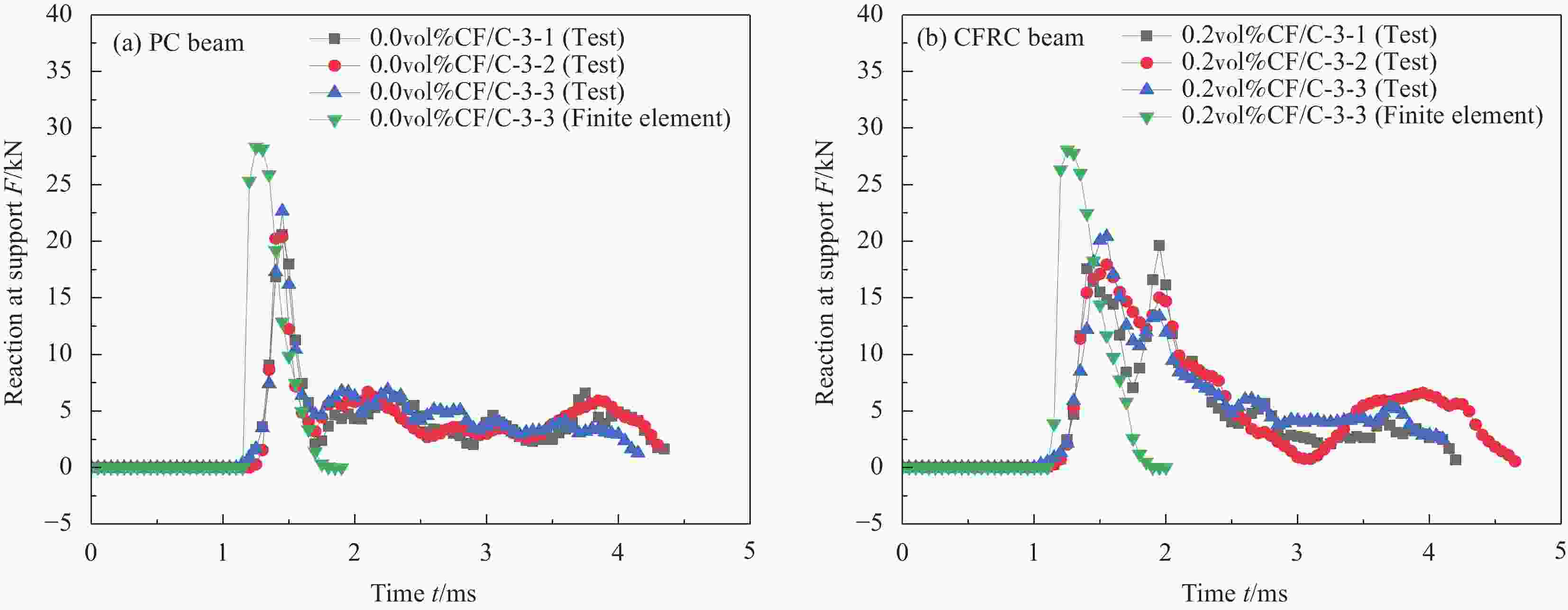

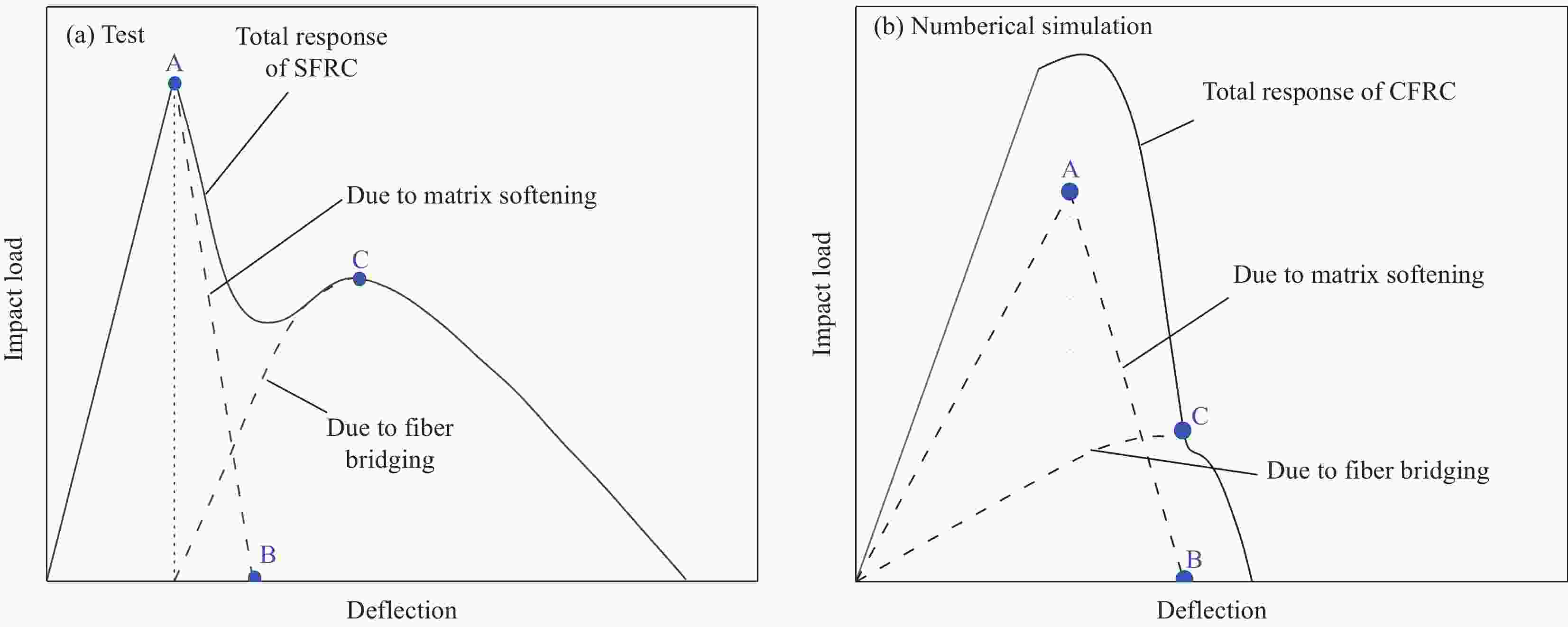

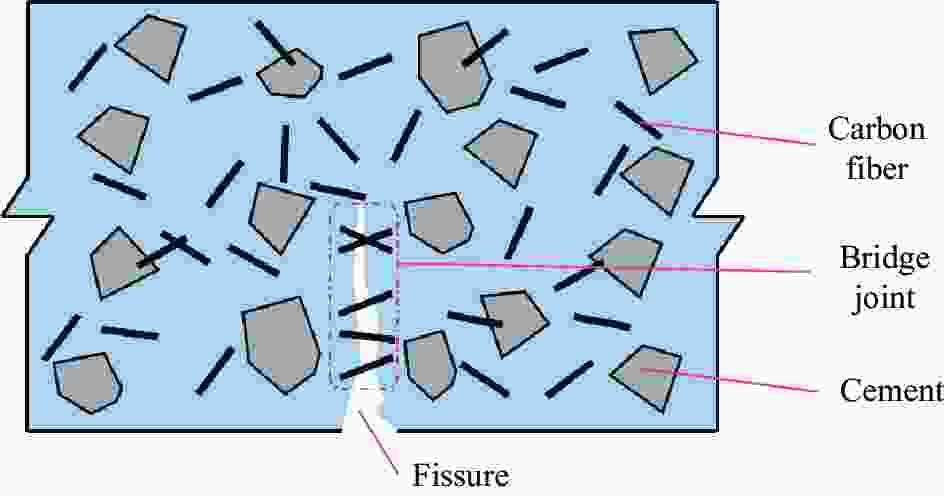

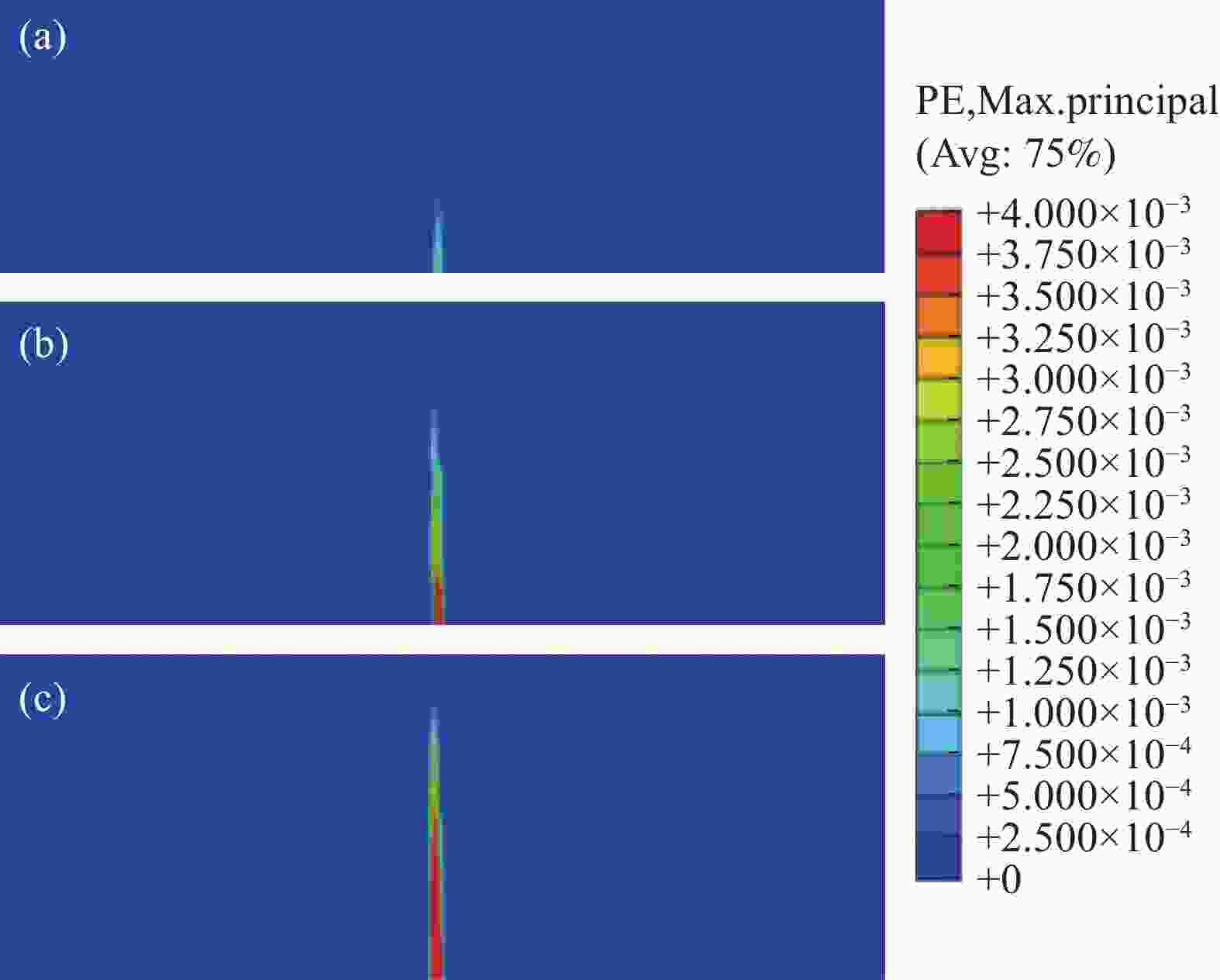

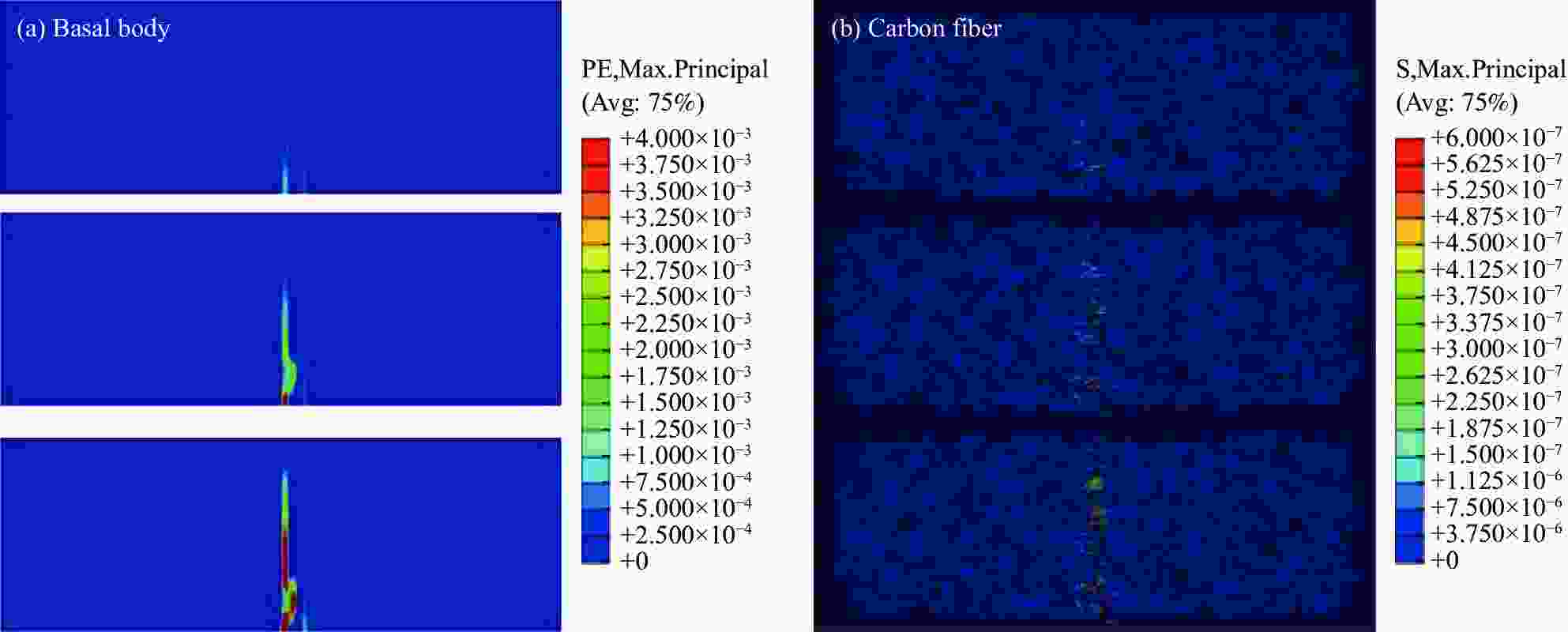

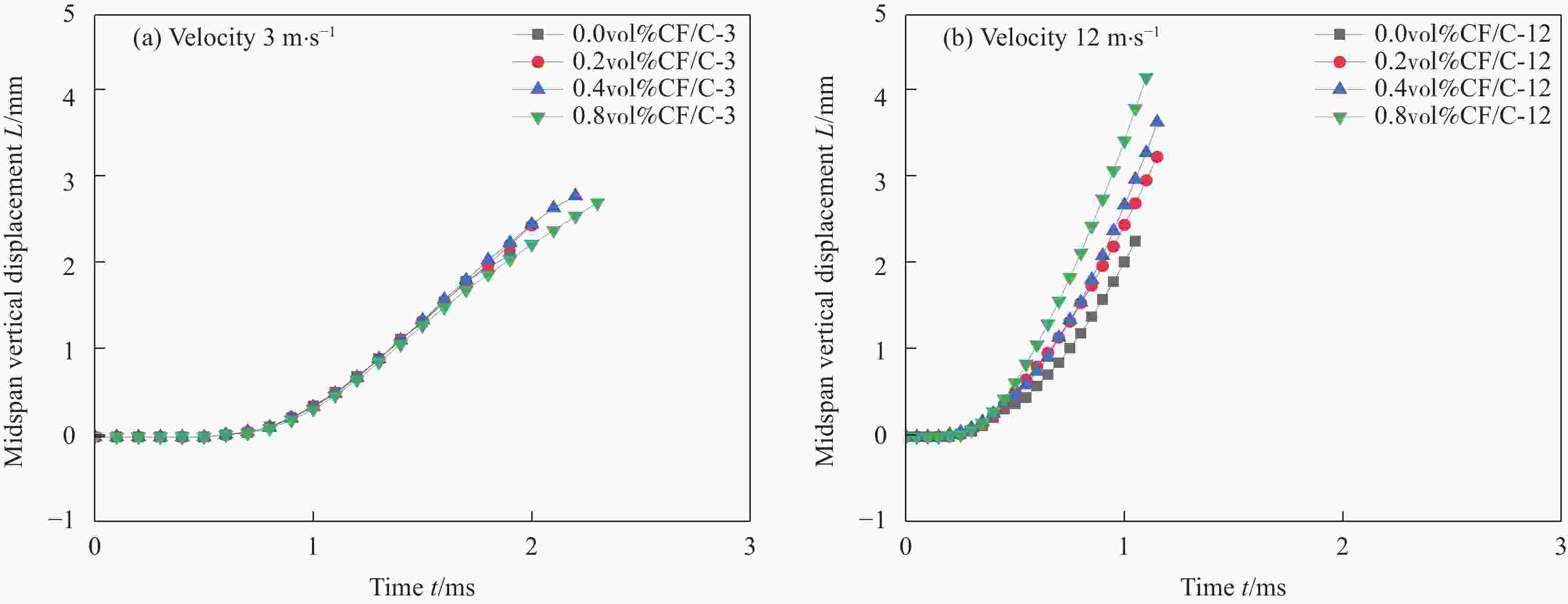

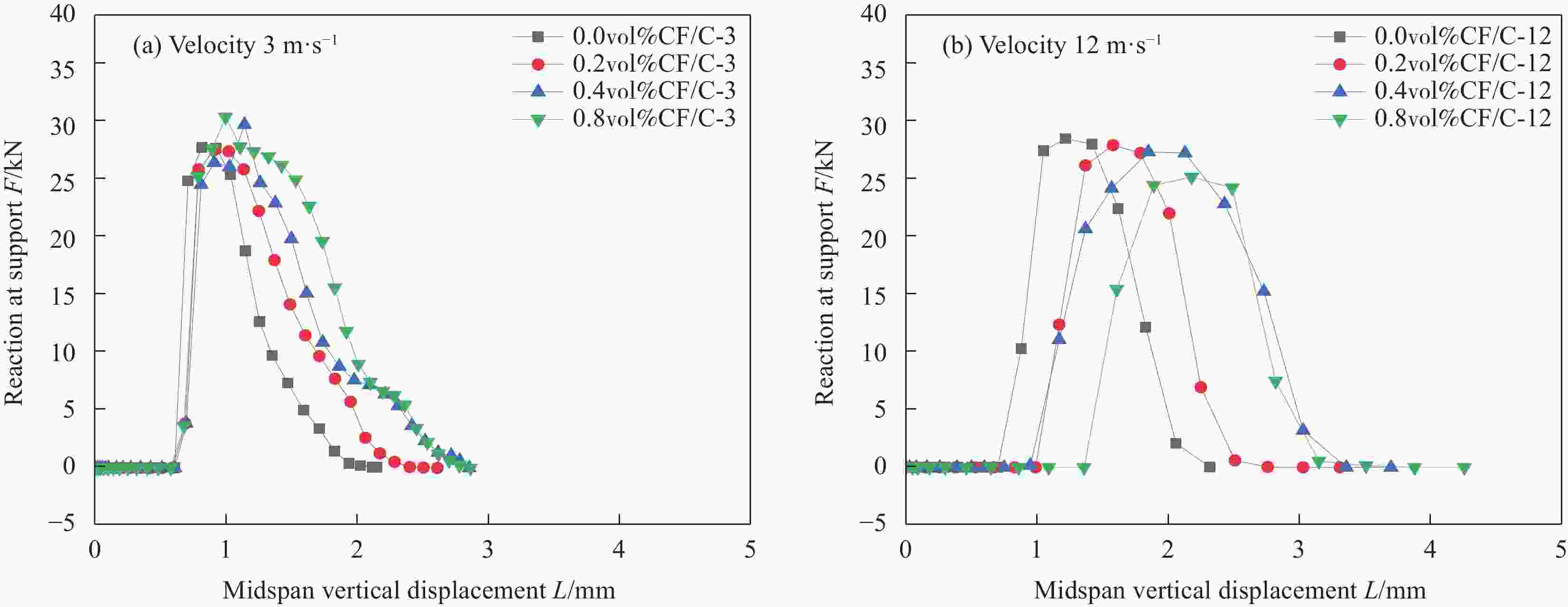

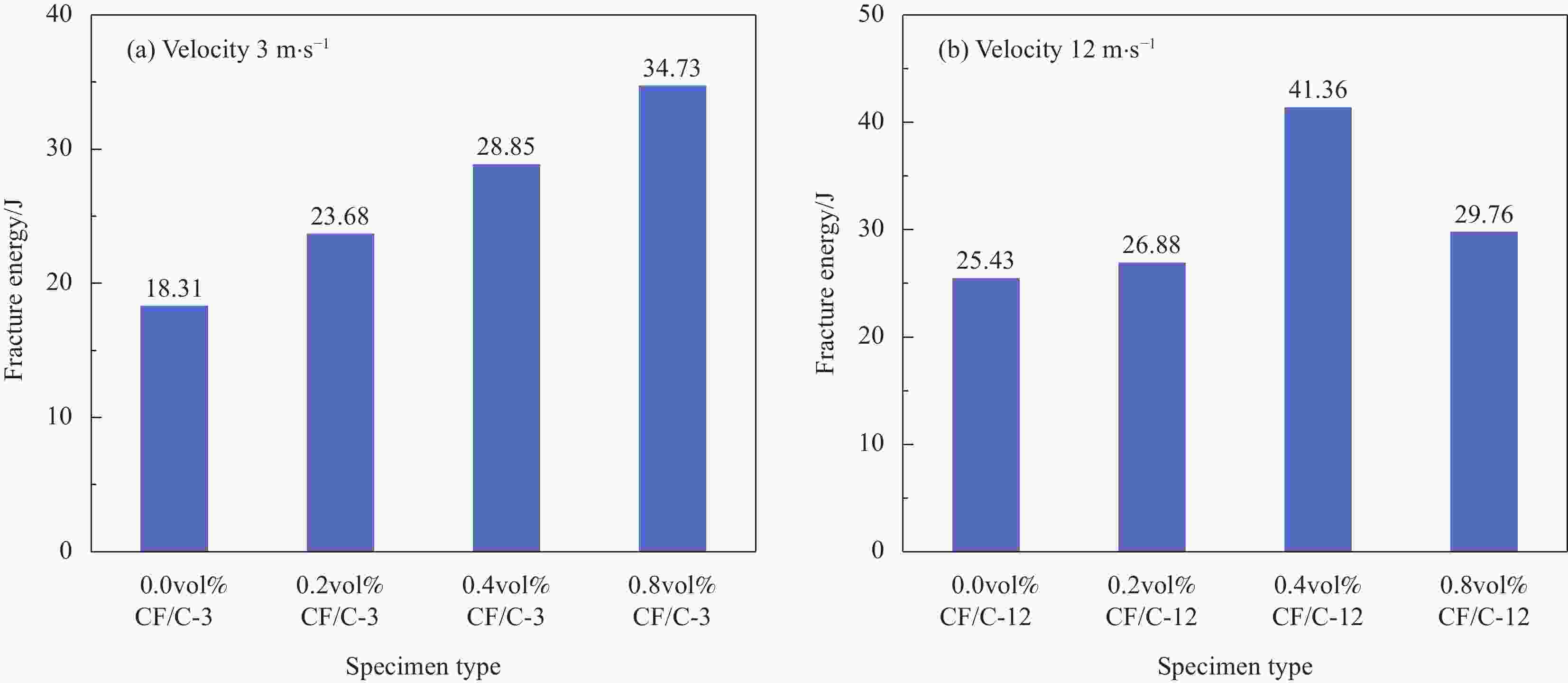

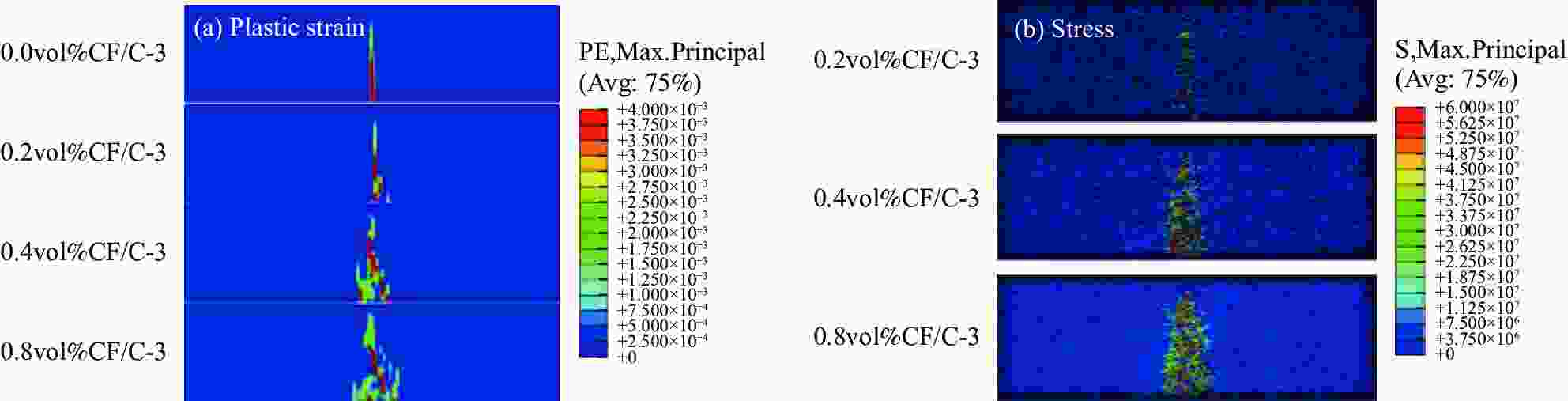

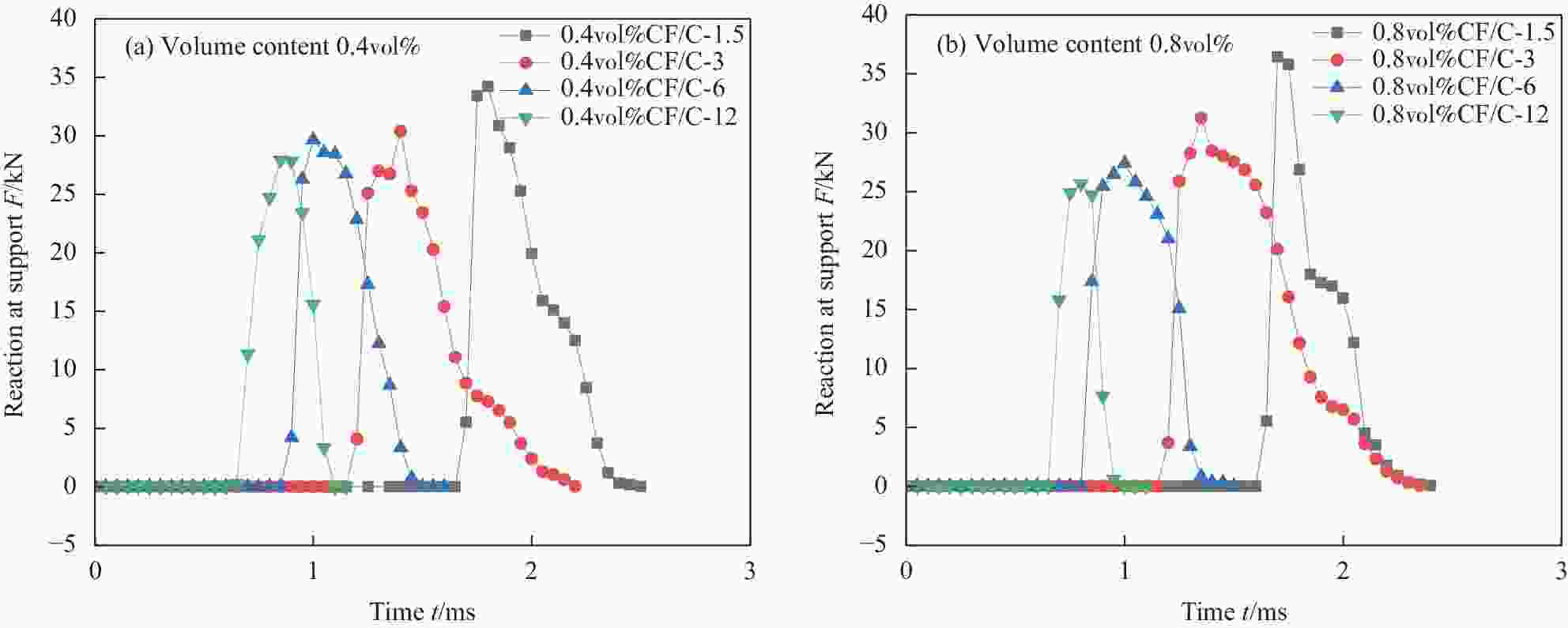

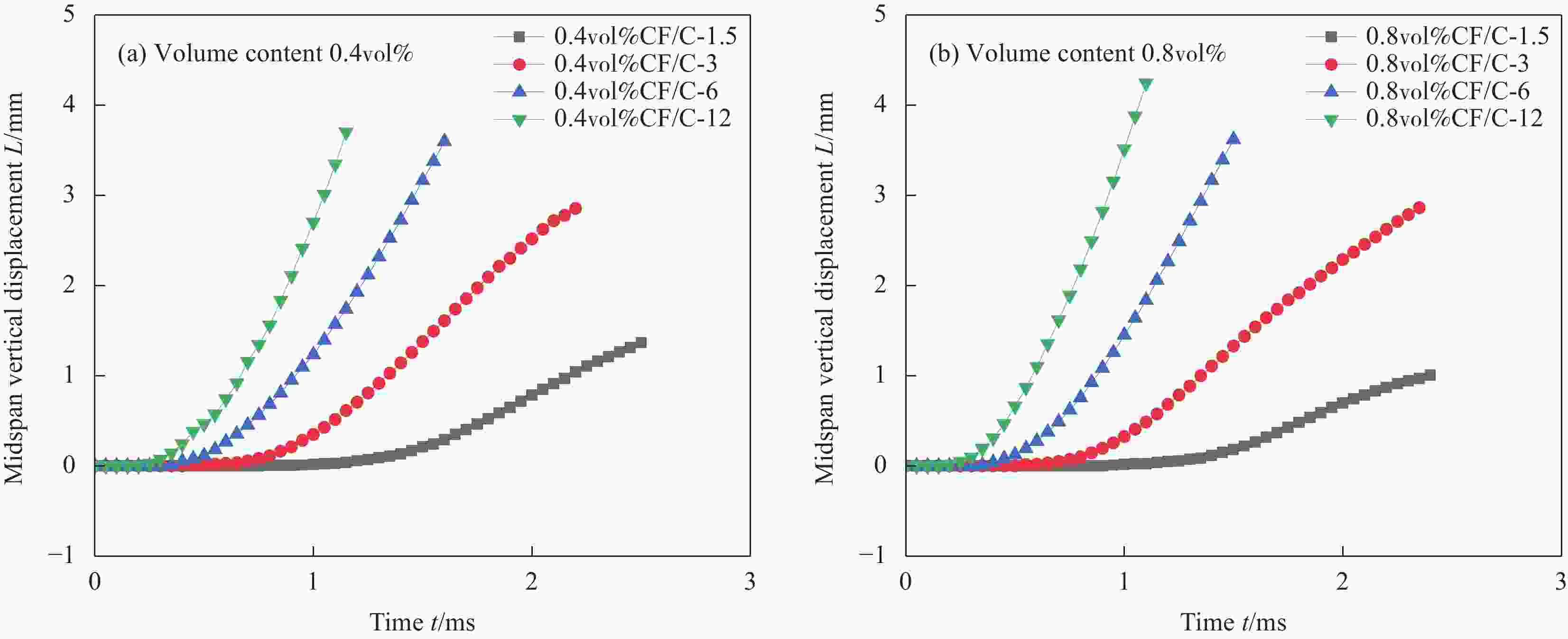

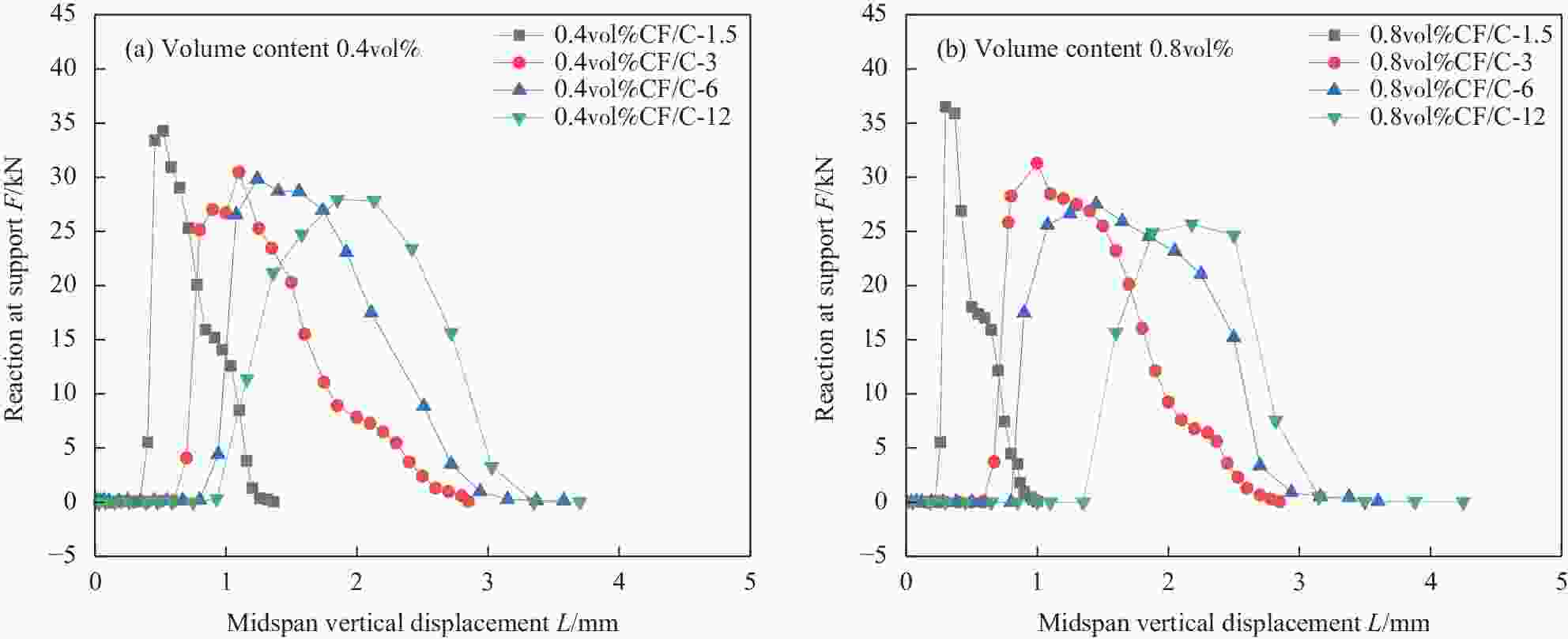

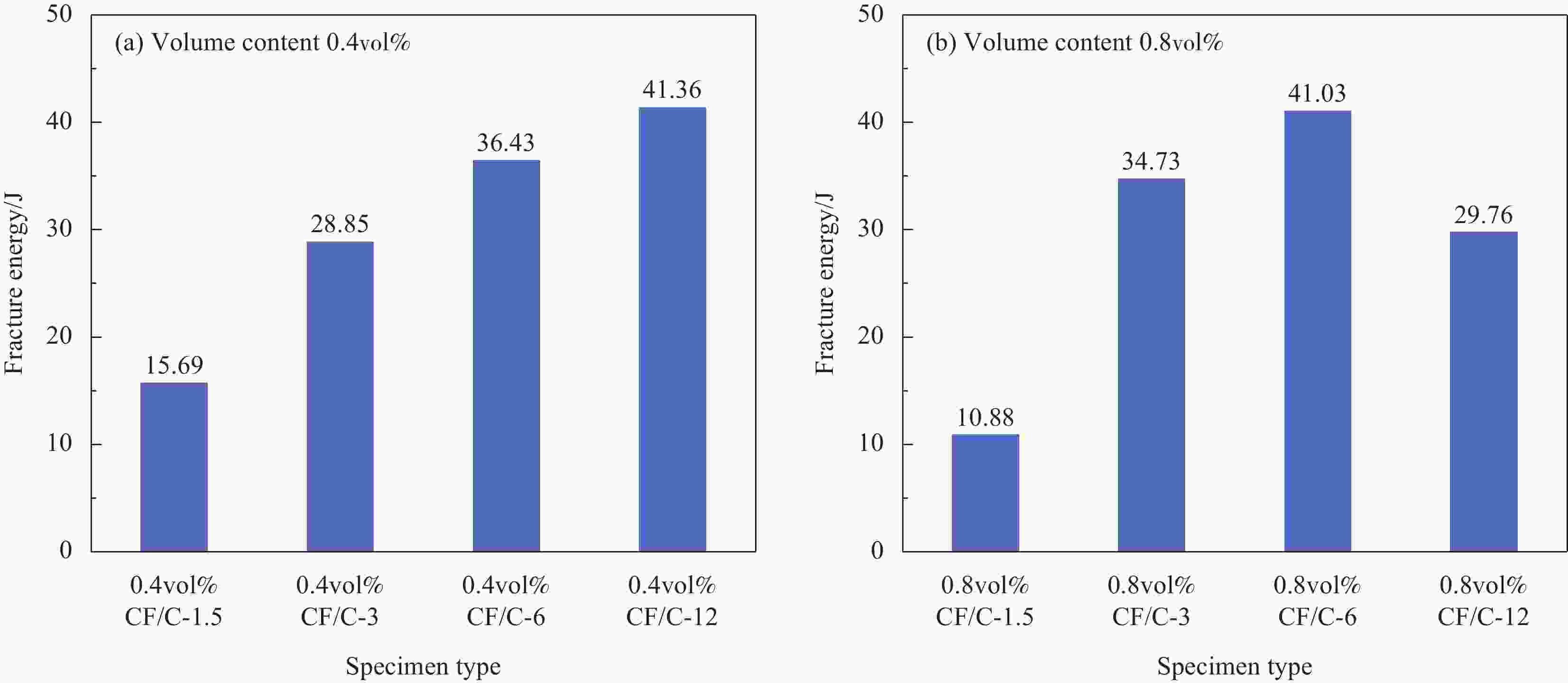

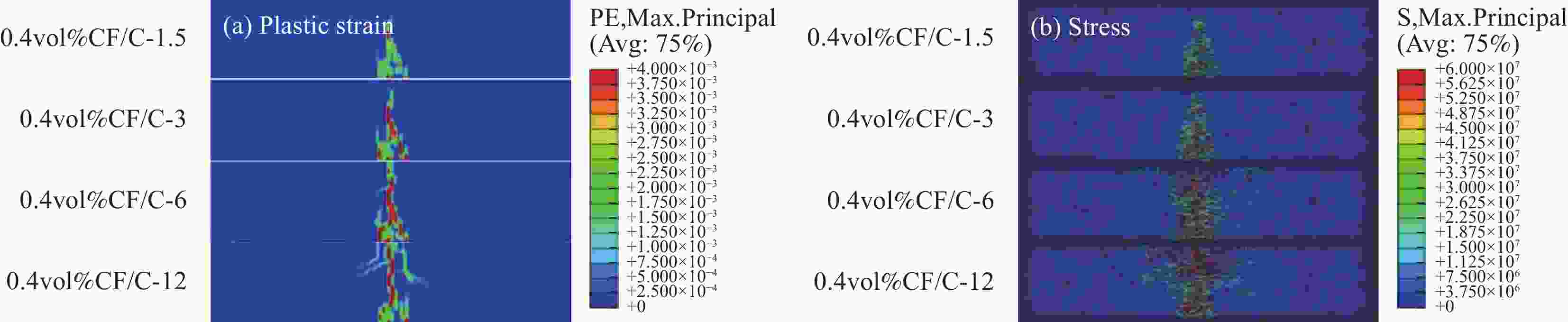

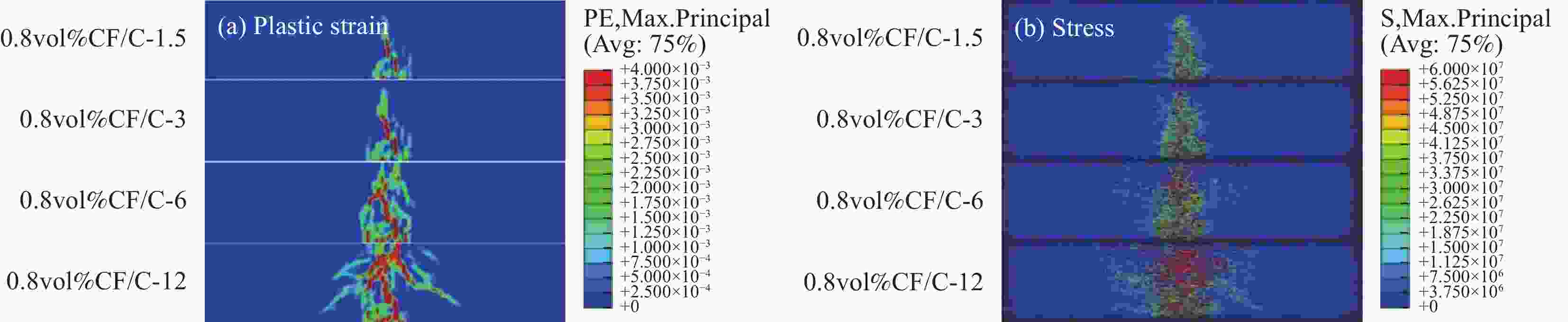

摘要: 普通混凝土在冲击载荷作用下断裂耗能能力差,而采用单丝态碳纤维掺入混凝土中制备的碳纤维增强混凝土(Carbon fiber reinforced concrete,CFRC)不仅可使混凝土衍生出多种功能性,同时可大大改善混凝土的抗冲击性能。利用落锤试验机对CFRC梁在低速冲击下的动态力学响应进行研究,在此基础上建立基于纤维随机分布的混凝土细观力学模型,研究不同纤维掺量和冲击速度对CFRC梁在低速冲击下力学响应、断裂耗能及破坏形态等的影响规律。结果表明:力学响应方面,基于随机纤维混凝土细观模型的仿真结果与试验结果符合较好;随着碳纤维体积掺量的增大,支座反力峰值变化不大,碳纤维掺量0.4vol%的混凝土梁跨中竖向位移较大,抗冲击韧性最佳。断裂耗能方面,当冲击速度低于6 m·s–1时,增大掺量有利于碳纤维于基体中发挥桥接作用,提升CFRC梁的断裂耗能能力;随着冲击速度的增大,为保证基体非裂缝区碳纤维与混凝土之间协同耗能,进一步提高碳纤维混凝土的纤维掺量是提升冲击下CFRC耗能的关键。破坏行为方面,碳纤维掺量0.8vol%的混凝土梁在冲击下在跨中主裂缝附近呈现数量较多的斜裂纹弥散开裂行为;当冲击速度达到12 m·s–1时,CFRC梁的破坏呈现弯剪破坏形态。本文的研究结果可为CFRC在工程中的推广应用提供参考。Abstract: The fracture energy dissipation capacity of ordinary concrete under impact load is poor, and the carbon fiber reinforced concrete (CFRC) prepared by adding single filament carbon fiber into concrete can not only make concrete derive a variety of functions, but also greatly improve the impact resistance of concrete. The dynamic mechanical response of CFRC beam under low velocity impact was studied by drop hammer test machine. On this basis, the meso-mechanical model of concrete based on random distribution of fiber was established, and the influences of the fiber content and impact velocity on the mechanical response, fracture energy consumption and failure mode of CFRC beam under low velocity impact were studied. The results show that in terms of mechanical response, the simulation results based on the meso-scale model of random fiber reinforced concrete are in good agreement with the experimental results. With the increase of carbon fiber volume content, the peak value of bearing reaction has little change. The mid-span vertical displacement of concrete beams with 0.4vol% carbon fiber content is larger, and the impact toughness is the best. In terms of fracture energy dissipation, when the impact velocity is lower than 6 m·s−1, increasing the content of carbon fiber is beneficial to bridge the matrix and improve the fracture energy dissipation capacity of CFRC beams. With the increase of impact velocity, in order to ensure the synergistic energy consumption between carbon fiber and concrete in non-crack zone of matrix, further improving the fiber content of carbon fiber concrete is the key to improve the energy consumption of CFRC concrete under impact. In terms of failure behavior, the concrete beam with 0.8vol% carbon fiber content presents a large number of diagonal crack dispersion cracking behaviors near the main crack in the midspan under impact. When the impact velocity reaches 12 m·s−1, the failure mode of CFRC beam is bending shear failure. The research results can provide reference for the application of carbon fiber reinforced concrete in engineering.

-

表 1 混凝土模型参数

Table 1. Parameters of concrete model

Parameter Dilation

angle/(°)Flow potential

offset/mmUltimate strength ratio

of biaxial compression to

uniaxial compressionInvariable

stress ratioCoefficient of viscosity/

(Ns·m−2)Density/

(kg·m−3)Young's

modulus/

GPaPoisson

ratioValue 38 0.1 1.16 0.667 0.00001 2400 32.5 0.2 表 2 纤维物理力学性能

Table 2. Physical and mechanical properties of fiber

Fiber type Density/(g·cm−3) Tensile strength/MPa Elastic modulus/GPa Percentage elongation/% Carbon fiber 1.78 3530 230 1.5 表 3 混凝土配合比

Table 3. Proportioning of concrete

kg·m−3 Water Cement Coarse

aggregateFine aggregate Dispersing agent Water reducer Defoaming agent 220 400 1200 680 0.8 0.8 0.12 表 4 CFRC试件编号

Table 4. CFRC test number

Number Drop hammer quality/kg Volume content of CF/vol% Impact velocity/(m·s−1) 0.0vol%CF/C-3 20.52 0.0 3 0.2vol%CF/C-3 20.52 0.2 3 0.4vol%CF/C-3 20.52 0.4 3 0.8vol%CF/C-3 20.52 0.8 3 0.0vol%CF/C-12 20.52 0.0 12 0.2vol%CF/C-12 20.52 0.2 12 0.4vol%CF/C-12 20.52 0.4 12 0.8vol%CF/C-12 20.52 0.8 12 Notes: CF—Carbon fiber; C—Concrete. 表 5 不同碳纤维体积掺量的CFRC梁模拟结果

Table 5. Simulation results of CFRC beams with different volume fraction of carbon fiber

Number Peak value of impact force/kN Maximum vertical displacement/mm 0.0vol%CF/C-3 28.36 2.15 0.2vol%CF/C-3 28.11 2.61 0.4vol%CF/C-3 30.37 2.85 0.8vol%CF/C-3 31.21 2.86 0.0vol%CF/C-12 29.03 2.31 0.2vol%CF/C-12 28.44 3.31 0.4vol%CF/C-12 27.94 3.71 0.8vol%CF/C-12 25.69 4.25 表 6 不同冲击速度下CFRC梁模拟结果

Table 6. Simulation results of CFRC beams under different impact velocities

Number Drop hammer quality/kg Peak value of impact force/kN Maximum vertical displacement/mm 0.4vol%CF/C-1.5 20.52 34.19 1.36 0.4vol%CF/C-3 20.52 30.37 2.85 0.4vol%CF/C-6 20.52 29.67 3.58 0.4vol%CF/C-12 20.52 27.94 3.71 0.8vol%CF/C-1.5 20.52 36.45 1.00 0.8vol%CF/C-3 20.52 31.21 2.86 0.8vol%CF/C-6 20.52 27.42 3.60 0.8vol%CF/C-12 20.52 25.69 4.25 -

[1] SOHEL K M A, AI-JABRI K, AI ABRI A H S. Behavior and design of reinforced concrete building columns subjected to low-velocity car impact structures[J]. Elsevier,2020,26:601-616. [2] 周晓宇, 马如进, 陈艾荣. 行车落物冲击下钢筋混凝土桥面板的安全性能[J]. 华南理工大学学报(自然科学版), 2018, 46(4):137-145.ZHOU Xiaoyu, MA Rujin, CHEN Airong. Safety perfor-mance of a bridge deck under impact of a massive falling cargo from passing truck[J]. Journal of South China University of Technology (Natural Science Edition),2018,46(4):137-145(in Chinese). [3] LIU S M, CUI K P, HE X, et al. Dynamic simulation analysis based on LS-DYNA about impact force on bridge pier caused by vehicle[J]. Railway Standard Design,2013(8):70-74. [4] BIBORA P, DRDLOVA M, PRACHAR V, et al. The impact of various types of steel fibres on the strength parameters and blast resistance of high performance concrete[J]. Materials Science and Engineering,2019,596:1-10. [5] YOO D Y, BANTHIA N. Impact resistance of fiber-reinforced concrete: A review[J]. Cement and Concrete Composites,2019,104:103389. doi: 10.1016/j.cemconcomp.2019.103389 [6] 刘玲玲. 碳纤维织物增强混凝土薄板力学性能研究[D]. 长沙: 湖南大学, 2017.LIU Lingling. Research on the mechanical properties of carbon textile reinforced concrete thin plates[D]. Changsha: Hunan University, 2017(in Chinese). [7] 程小全, 康炘蒙, 邹健, 等. 平面编织复合材料层合板低速冲击后的拉伸性能[J]. 复合材料学报, 2008, 25(5):163-168. doi: 10.3321/j.issn:1000-3851.2008.05.027CHENG Xiaoquan, KANG Xinmeng, ZOU Jian, et al. Tensile properties of plane woven composite laminates after low velocity impact[J]. Acta Materiae Compositae Sinica,2008,25(5):163-168(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.05.027 [8] TSESARSKY M, PELED A, KATZ A, et al. Strengthening concrete elements by confinement within textile reinforced concrete (TRC) shells static and impact properties[J]. Construction and Building Materials,2013,44:514-523. doi: 10.1016/j.conbuildmat.2013.03.031 [9] ZHU M, ZHU J H, UEDA T, et al. Bond behavior of carbon fabric reinforced cementitious matrix (FRCM) composites considering matrix impregnation[J]. Composite Structures,2021,262:113350. doi: 10.1016/j.compstruct.2020.113350 [10] ZAKI M A, RASHEED H A. Characterizing debonding strain in sand-lightweight high strength concrete T beams strengthened with CFRP sheets[J]. Composite Structures,2021,262:113630. doi: 10.1016/j.compstruct.2021.113630 [11] WEI A, AL-AMERI R, KOAY Y C, et al. Triple-functional carbon fibre reinforced polymer for strengthening and protecting reinforced concrete structures[J]. Composites Communications,2021,24:100648. doi: 10.1016/j.coco.2021.100648 [12] LI P, YANG T, ZENG Q, et al. Axial stress-strain behavior of carbon FRP-confined seawater sea-sand recycled aggre-gate concrete square columns with different corner radii[J]. Composite Structures,2021,262:113589. doi: 10.1016/j.compstruct.2021.113589 [13] SHAH S P. Concrete and fiber reinforced concrete subjected to impact loading[J]. MRS Online Proceedings Library,1985,64(1):181-201. [14] LAVAGNA L, MUSSO S, FERRO G, et al. Cement-based composites containing functionalized carbon fibers[J]. Cement and Concrete Composites,2018,88:165-171. doi: 10.1016/j.cemconcomp.2018.02.007 [15] WANG C, JIAO G S, LI B L, et al. Dispersion of carbon fibers and conductivity of carbon fiber-reinforced cement-based composites[J]. Ceramics International,2017,43(17):15122-15132. doi: 10.1016/j.ceramint.2017.08.041 [16] CHUNG D D L. Cement reinforced with short carbon fibers: A multifunctional material[J]. Composites Part B: Engineering,2000,31(6-7):511-526. doi: 10.1016/S1359-8368(99)00071-2 [17] 张剑, 王立峰, 叶见曙. 碳纤维增强复合材料筋混凝土梁非线性力学性能[J]. 复合材料学报, 2009, 26(4):156-162. doi: 10.3321/j.issn:1000-3851.2009.04.028ZHANG Jian, WANG Lifeng, YE Jianshu. Nonlinear mecha-nical properties of concrete beam with carbon fiber reinforced composite rebars[J]. Acta Materiae Compositae Sinica,2009,26(4):156-162(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.04.028 [18] ZAHRA S T, JEFFERY S, DARWIN I, et al. Experimental and numerical analysis of long carbon fiber reinforced concrete panels exposed to blast loading[J]. International Journal of Impact Engineering,2013,57:70-80. doi: 10.1016/j.ijimpeng.2013.01.006 [19] GAO N, LI B L, ZHAO L P, et al. Influences of molding processes and different dispersants on the dispersion of chopped carbon fibers in cement matrix[J]. Heliyon,2018,4(10):e00868. doi: 10.1016/j.heliyon.2018.e00868 [20] HAMBACH M, MOLLER H, NEUMANN T, et al. Portland cement paste with aligned carbon fibers exhibiting exceptionally high flexural strength (>100 MPa)[J]. Cement and Concrete Research,2016,89:80-86. doi: 10.1016/j.cemconres.2016.08.011 [21] TABATABAEI Z S, VOLZ J S, KEENER D I, et al. Compara-tive impact behavior of four long carbon fiber reinforced concretes[J]. Materials & Design,2014,55:212-223. [22] GAO J, LIU Z Z, SHA A, et al. Characterization of carbon fiber distribution in cement-based composites by computed tomography[J]. Construction and Building Materials,2018,177:134-147. doi: 10.1016/j.conbuildmat.2018.05.114 [23] XU Z, HAO H, LI H N. Mesoscale modelling of fibre reinforced concrete material under compressive impact loading[J]. Construction and Building Materials,2012,26(1):274-288. doi: 10.1016/j.conbuildmat.2011.06.022 [24] CHIARELLO M, ZINNO R. Electrical conductivity of self-monitoring CFRC[J]. Cement and Concrete Composites,2005,27(4):463-469. doi: 10.1016/j.cemconcomp.2004.09.001 [25] HAFNER S, ECKARDT S, LUTHER T, et al. Mesoscale modeling of concrete: Geometry and numerics[J]. Computers & Structures,2006,84(7):450-461. [26] 赵燕茹, 郝松, 王磊, 等. 基于数字图像相关的钢纤维增强水泥基复合材料的冲击损伤特性[J]. 复合材料学报, 2018, 35(5):1325-1331.ZHAO Yanru, HAO Song, WANG Lei, et al. Impact damage characteristics of steel fiber reinforced cement matrix composites based on digital image correlation[J]. Acta Materiae Compositae Sinica,2018,35(5):1325-1331(in Chinese). [27] FANG Q, ZHANG J H. Three-dimensional modelling of steel fiber reinforced concrete material under intense dynamic loading[J]. Construction and Building Materials,2013,44:118-132. doi: 10.1016/j.conbuildmat.2013.02.067 [28] LIANG X W, WU C Q. Meso-scale modelling of steel fibre reinforced concrete with high strength[J]. Construction and Building Materials,2018,165:187-198. doi: 10.1016/j.conbuildmat.2018.01.028 [29] 中国建筑科学研究院. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国建筑工业出版社, 2010.China Academy of Building Sciences. Code for design of concrete structures: GB/T 50010—2010[S]. Beijing: China Construction Industry Press, 2010(in Chinese). -

下载:

下载: