Experiment and numerical simulation of dynamic mechanical properties of X-lattice sandwich structure under local impact

-

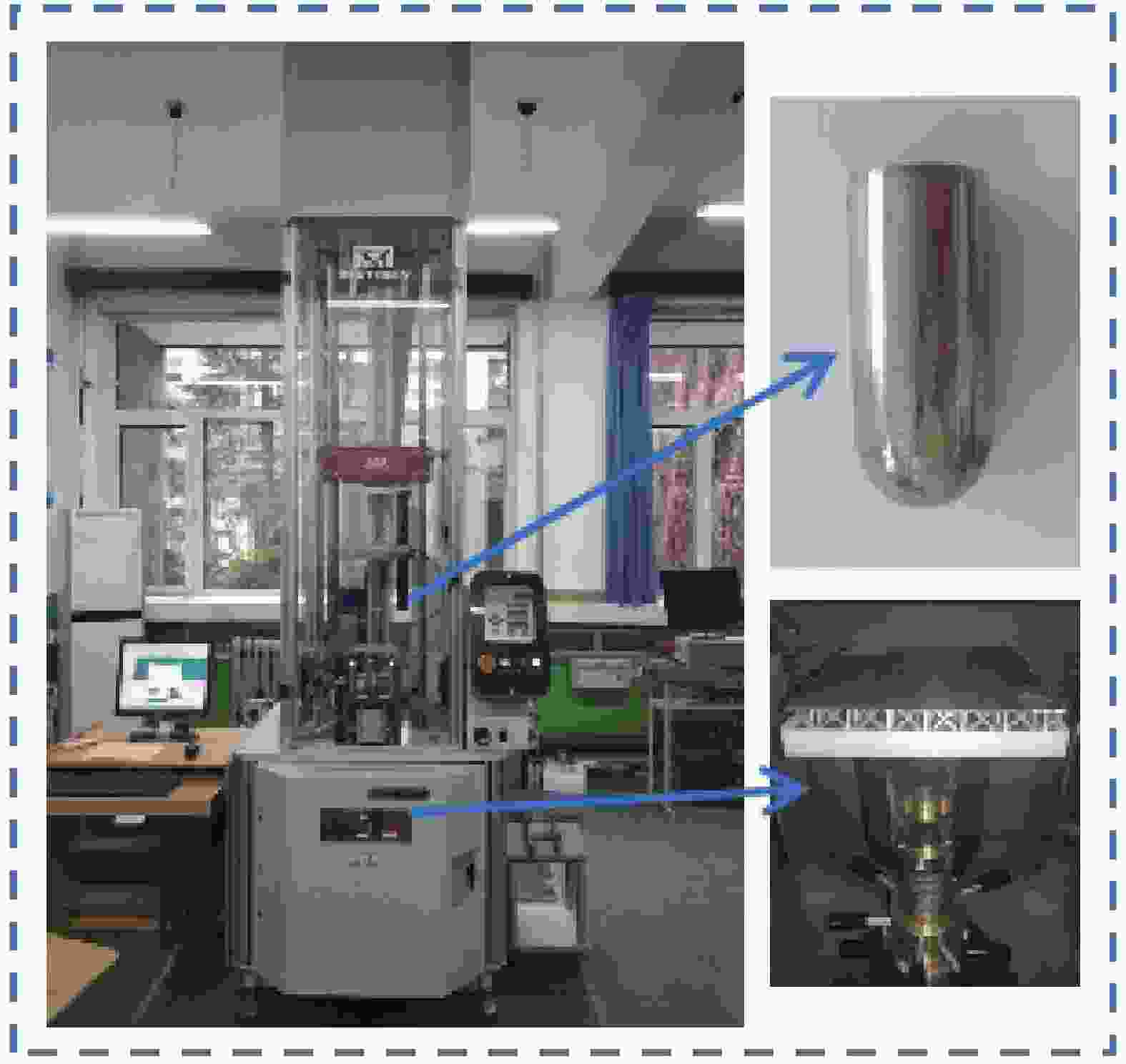

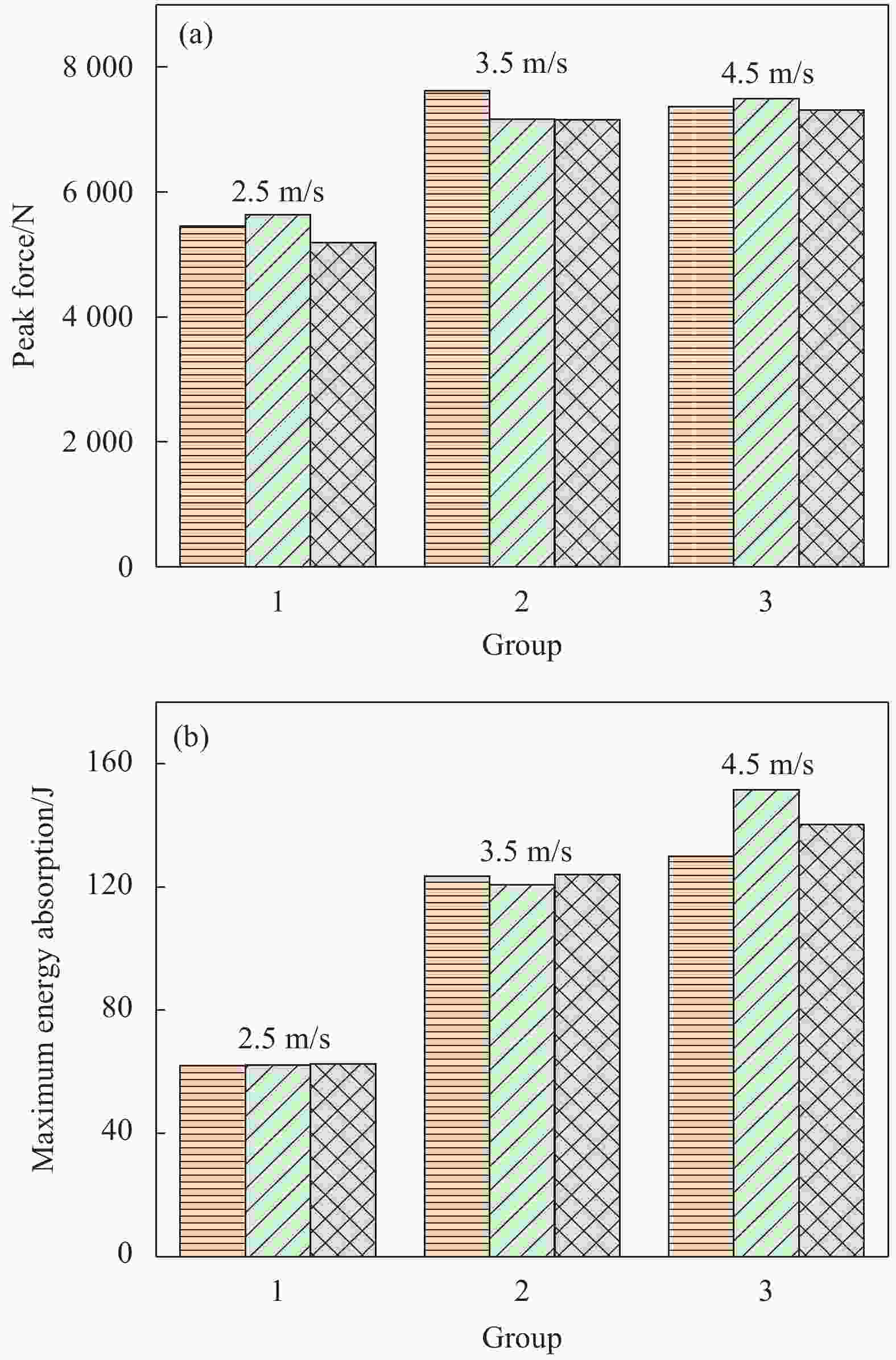

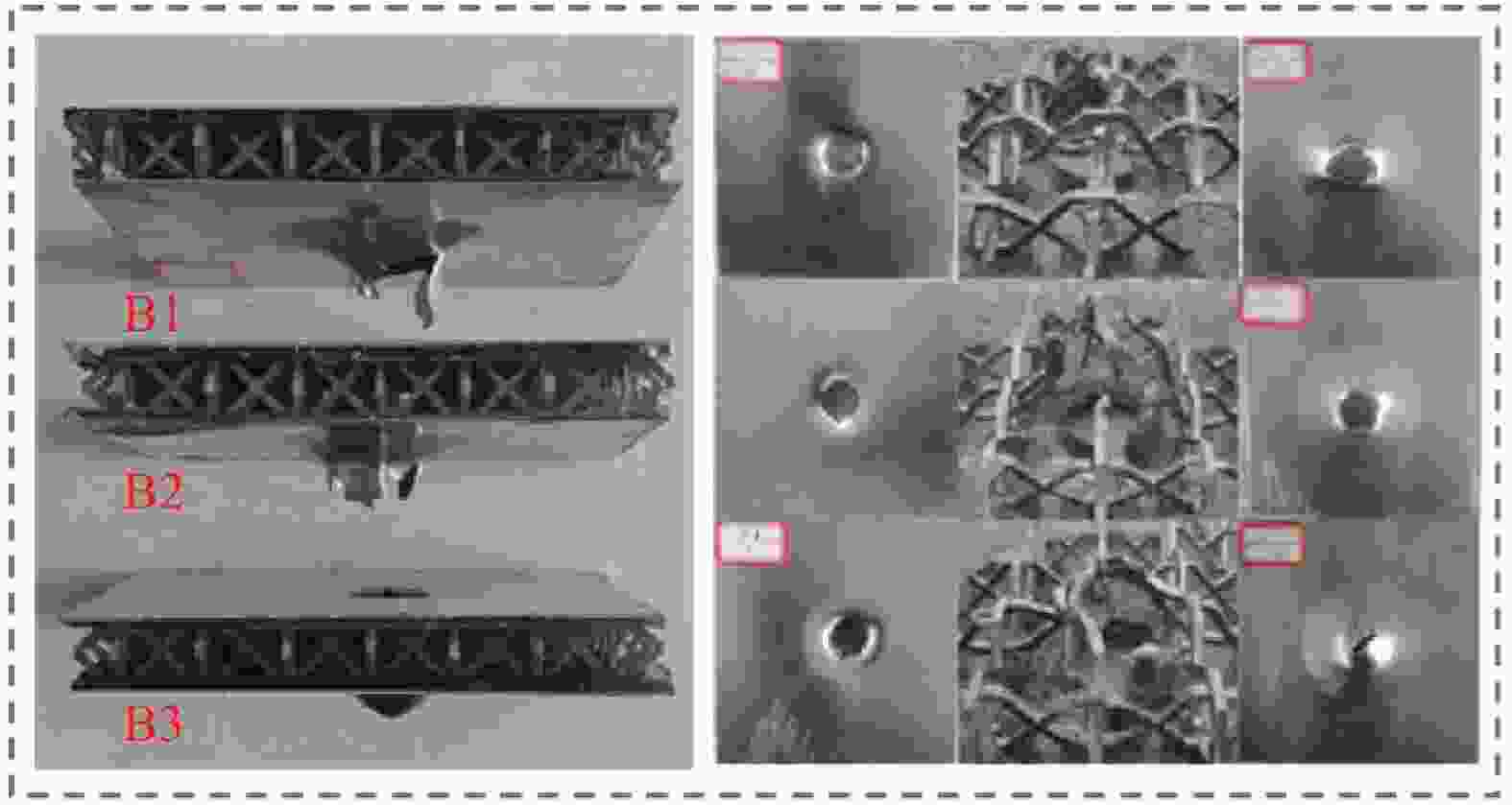

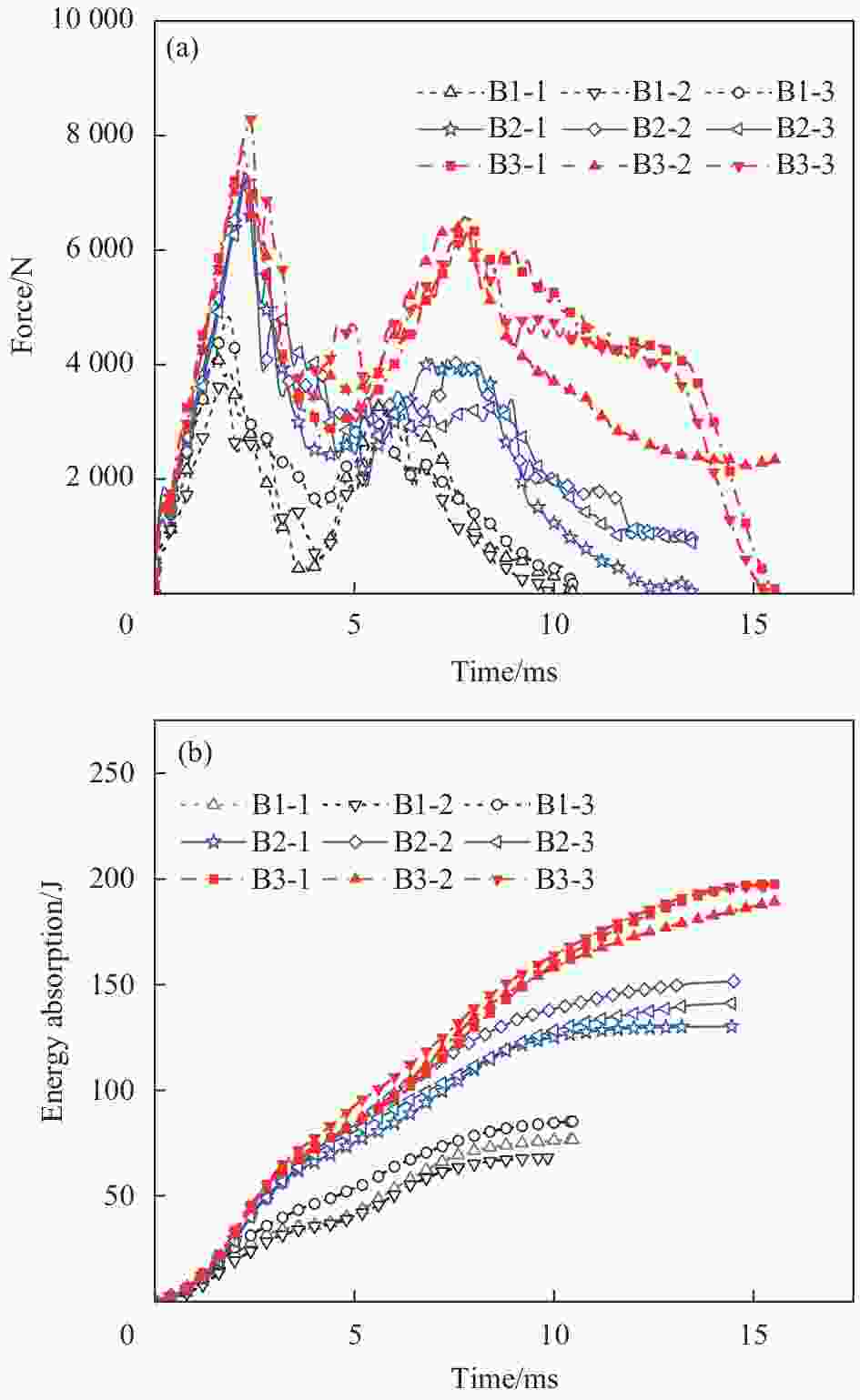

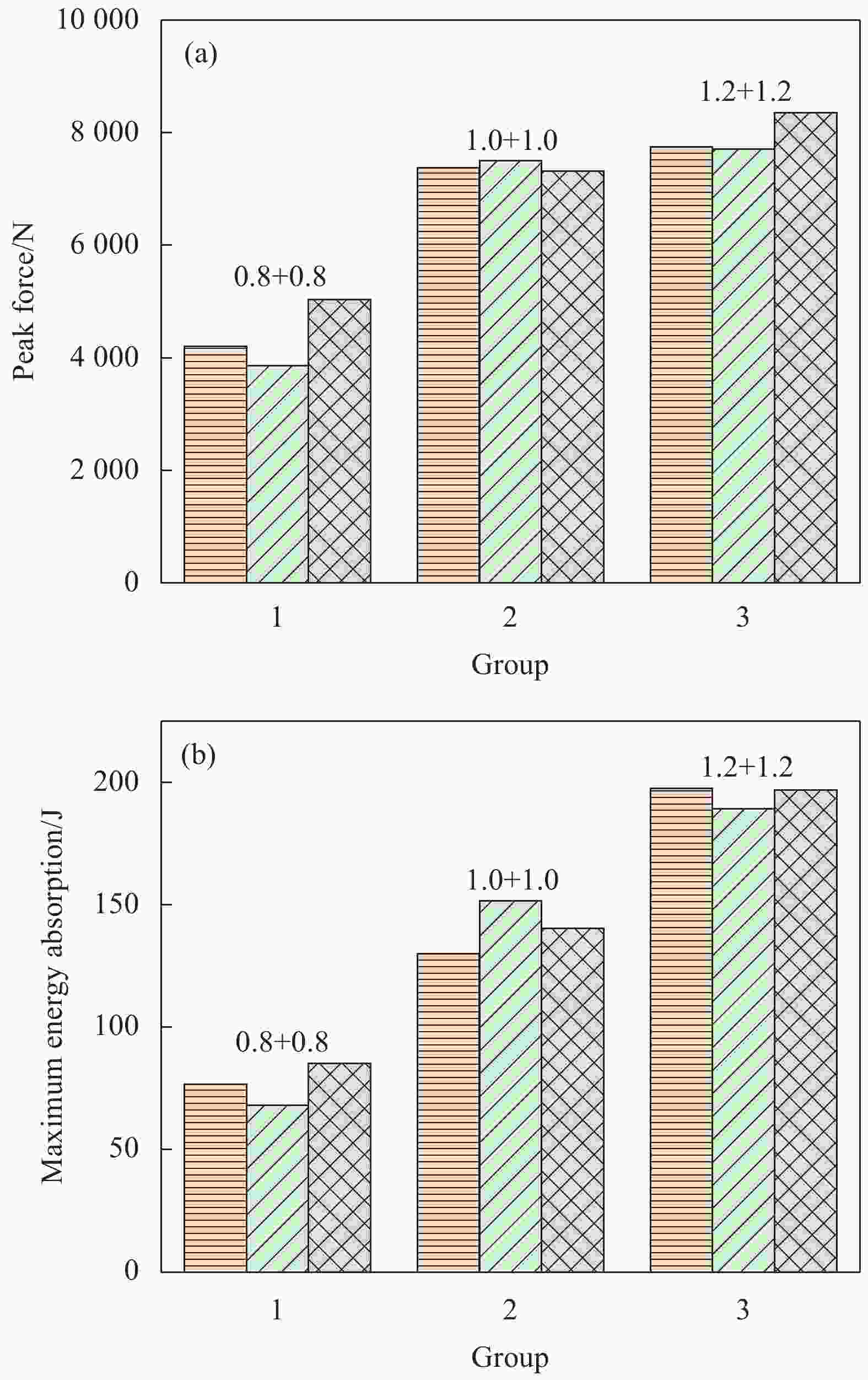

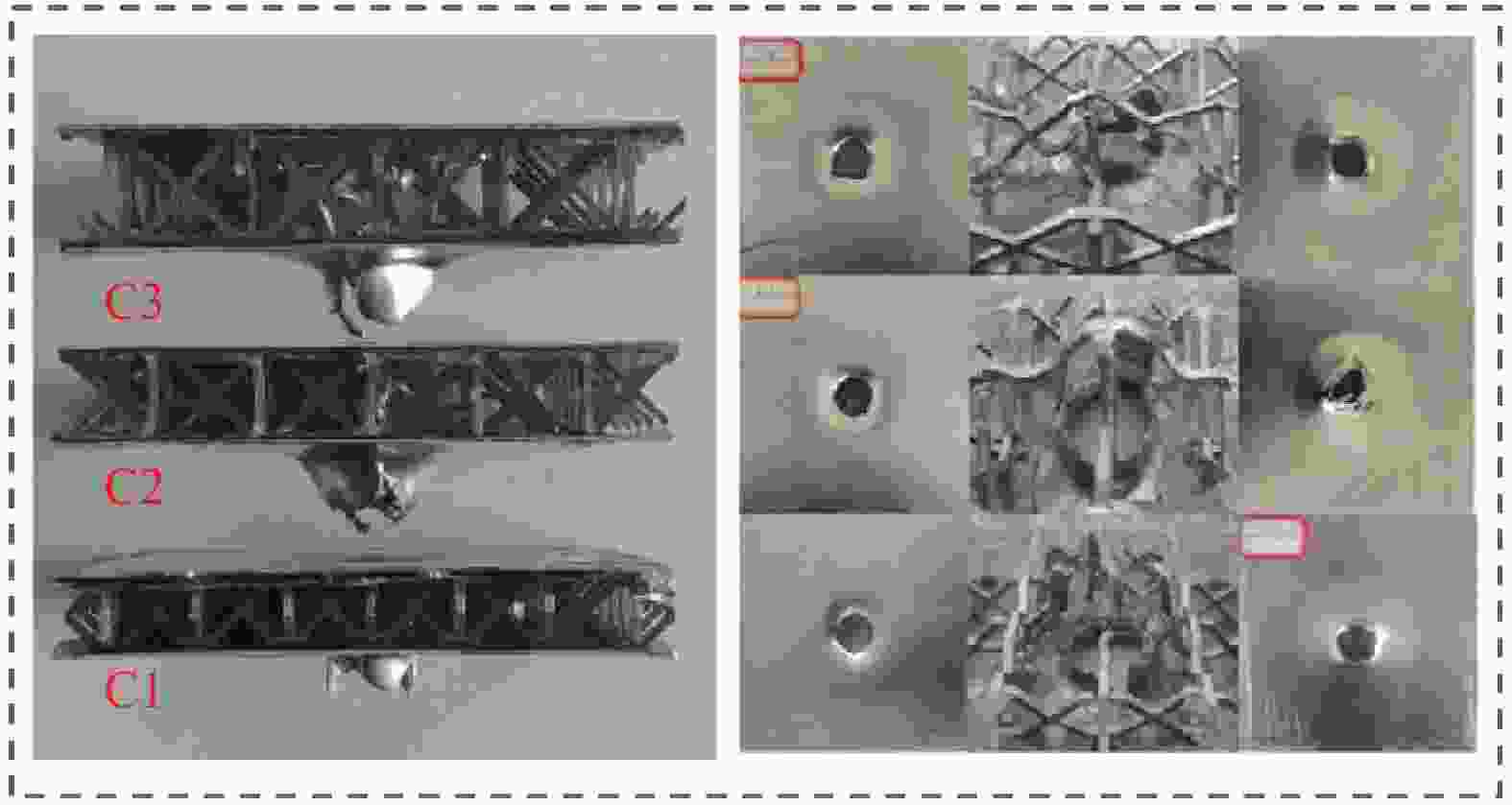

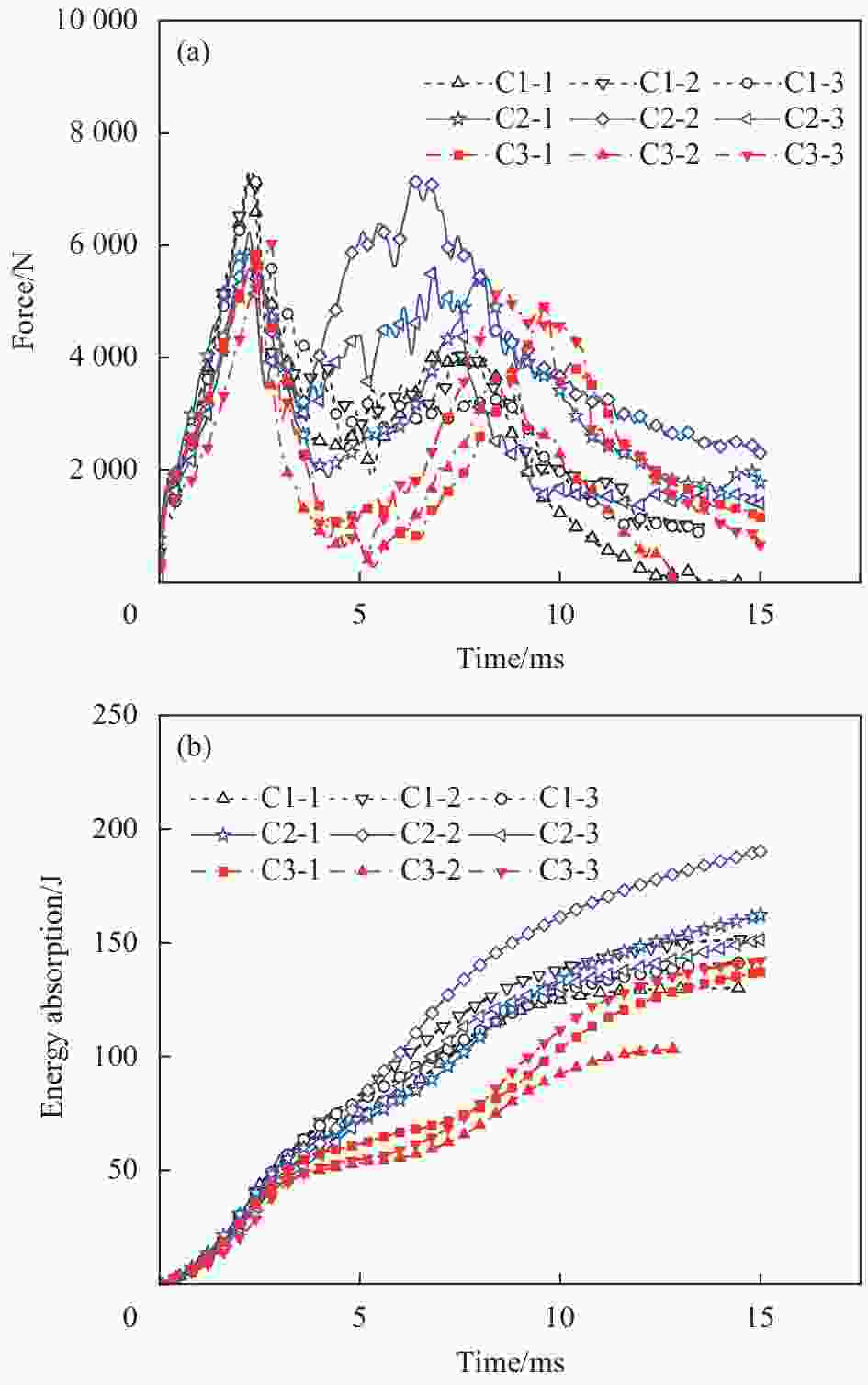

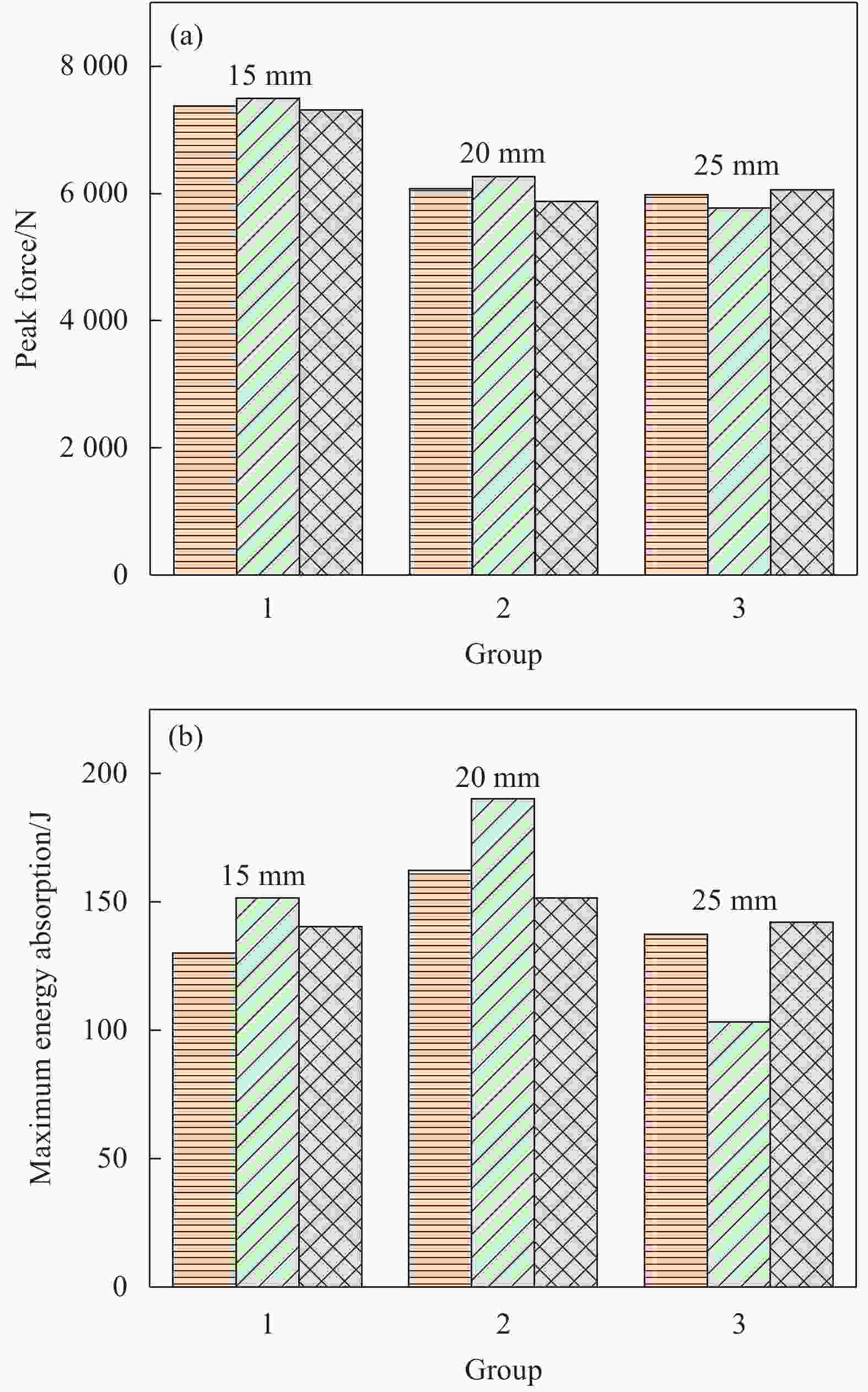

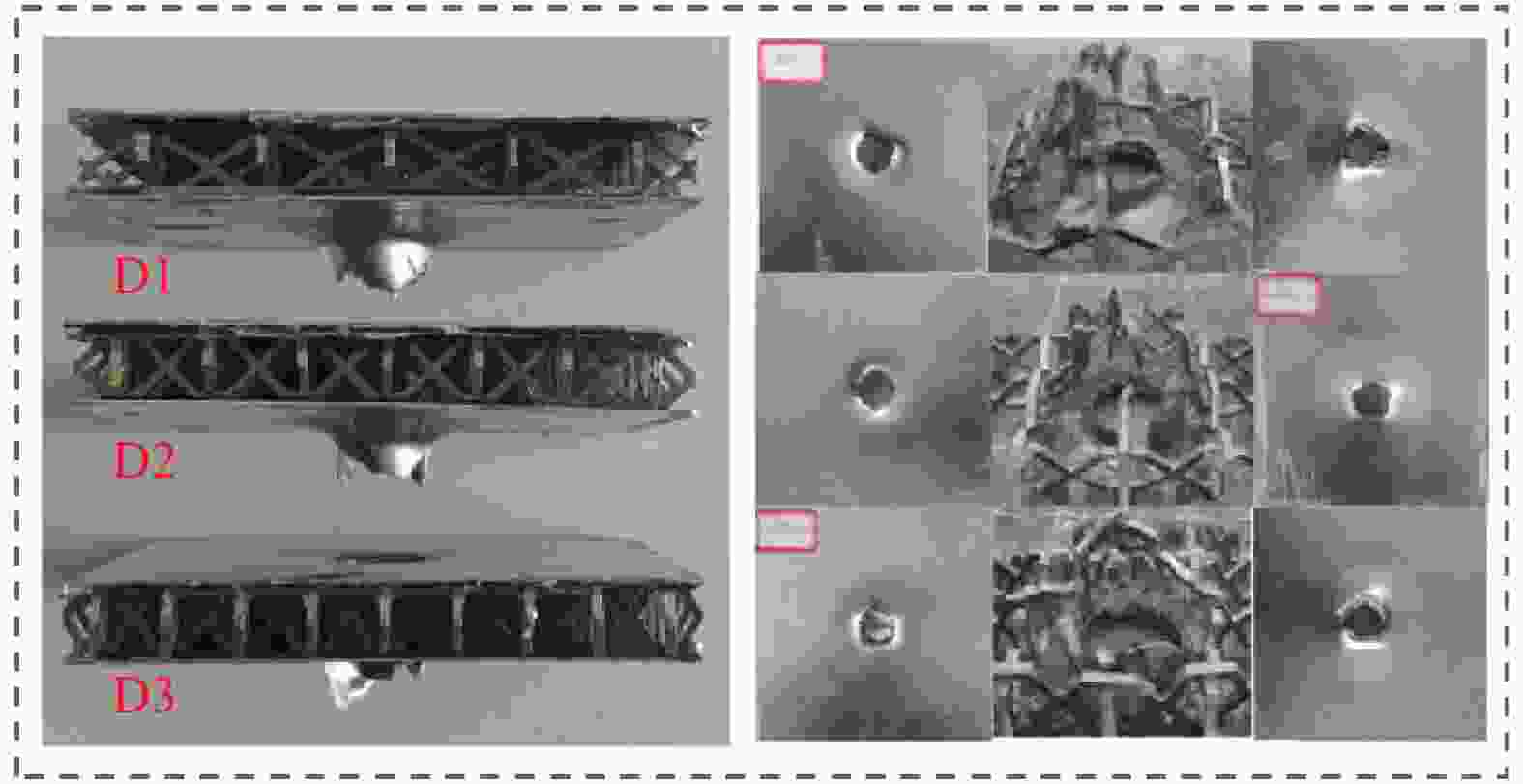

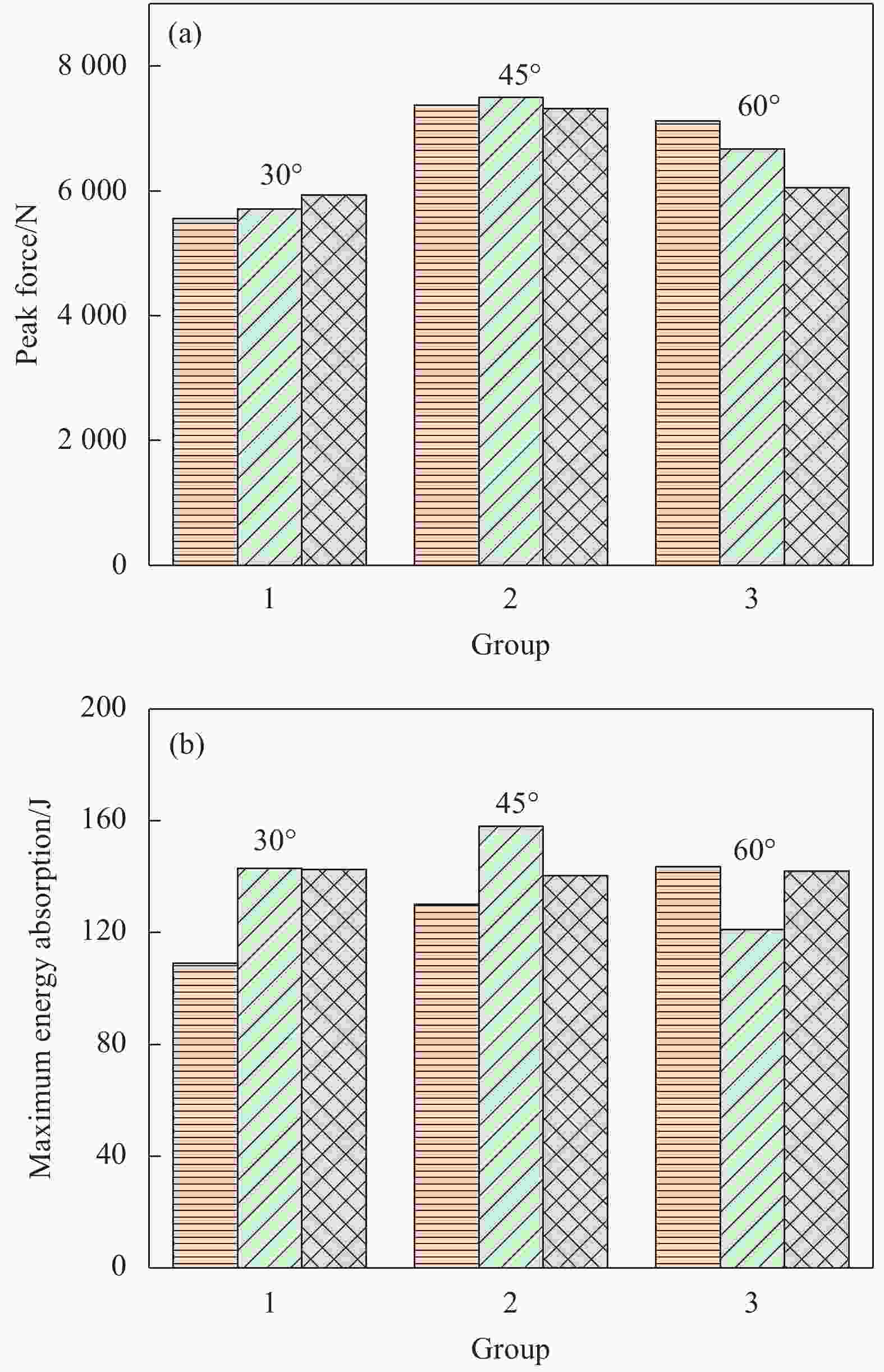

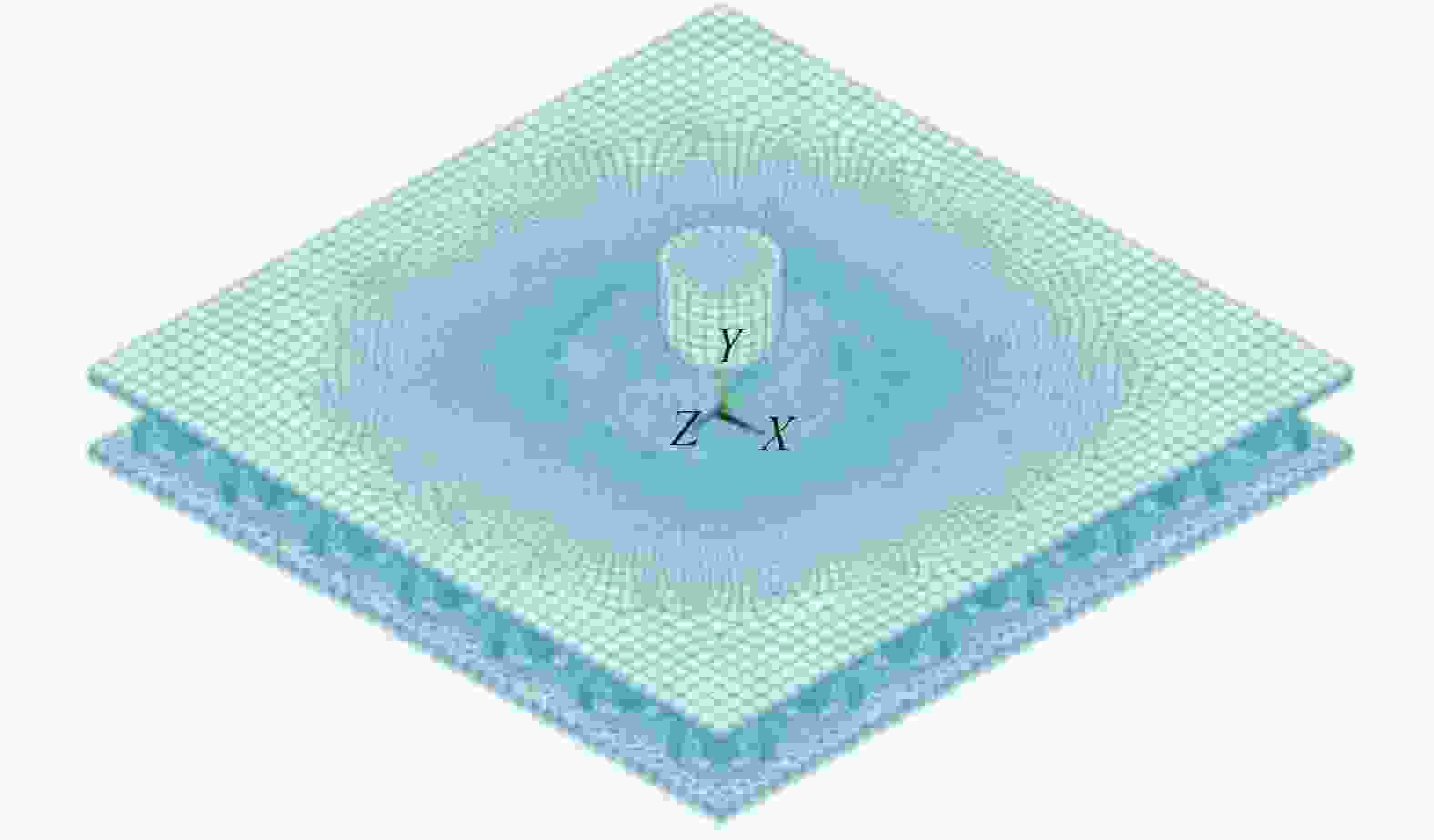

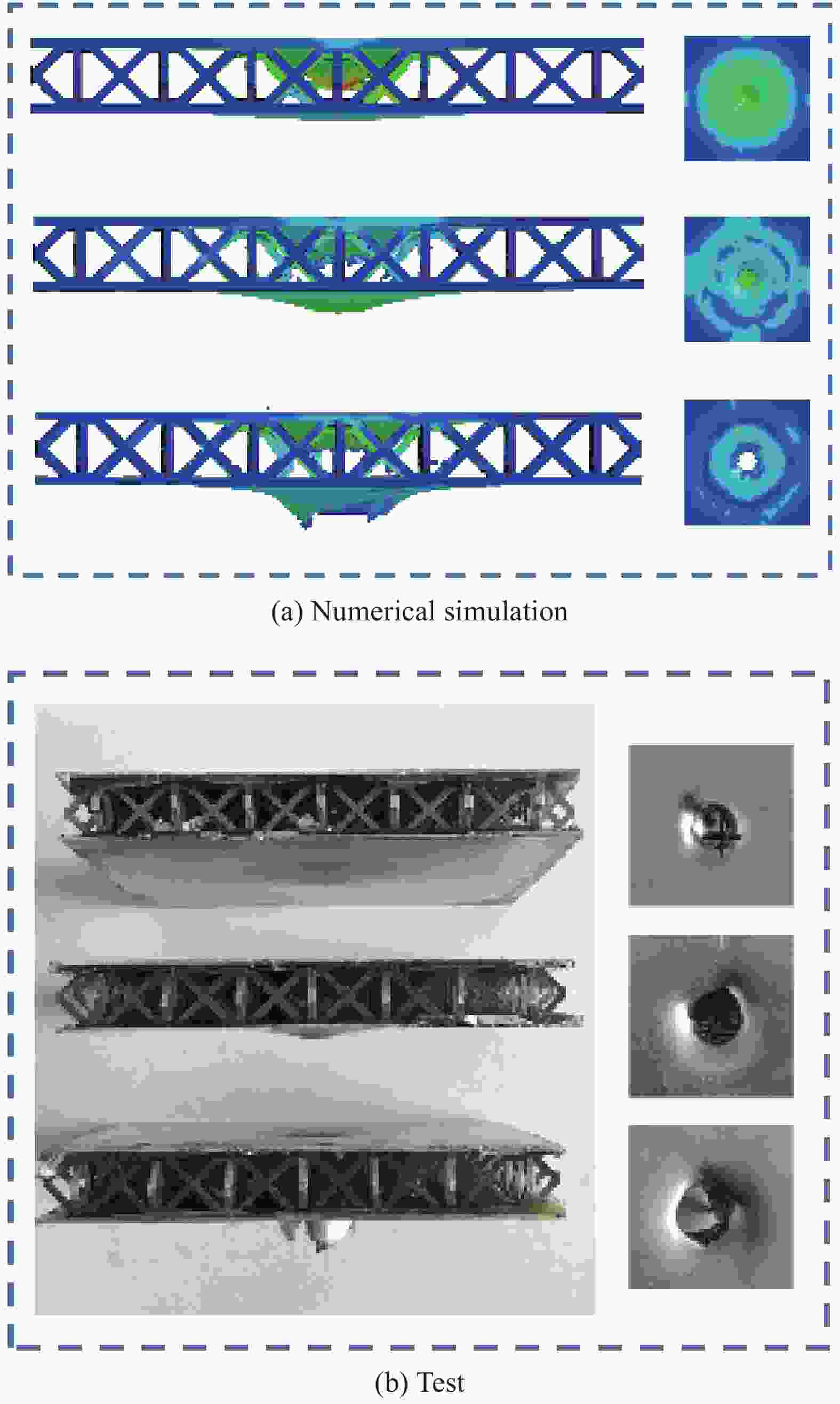

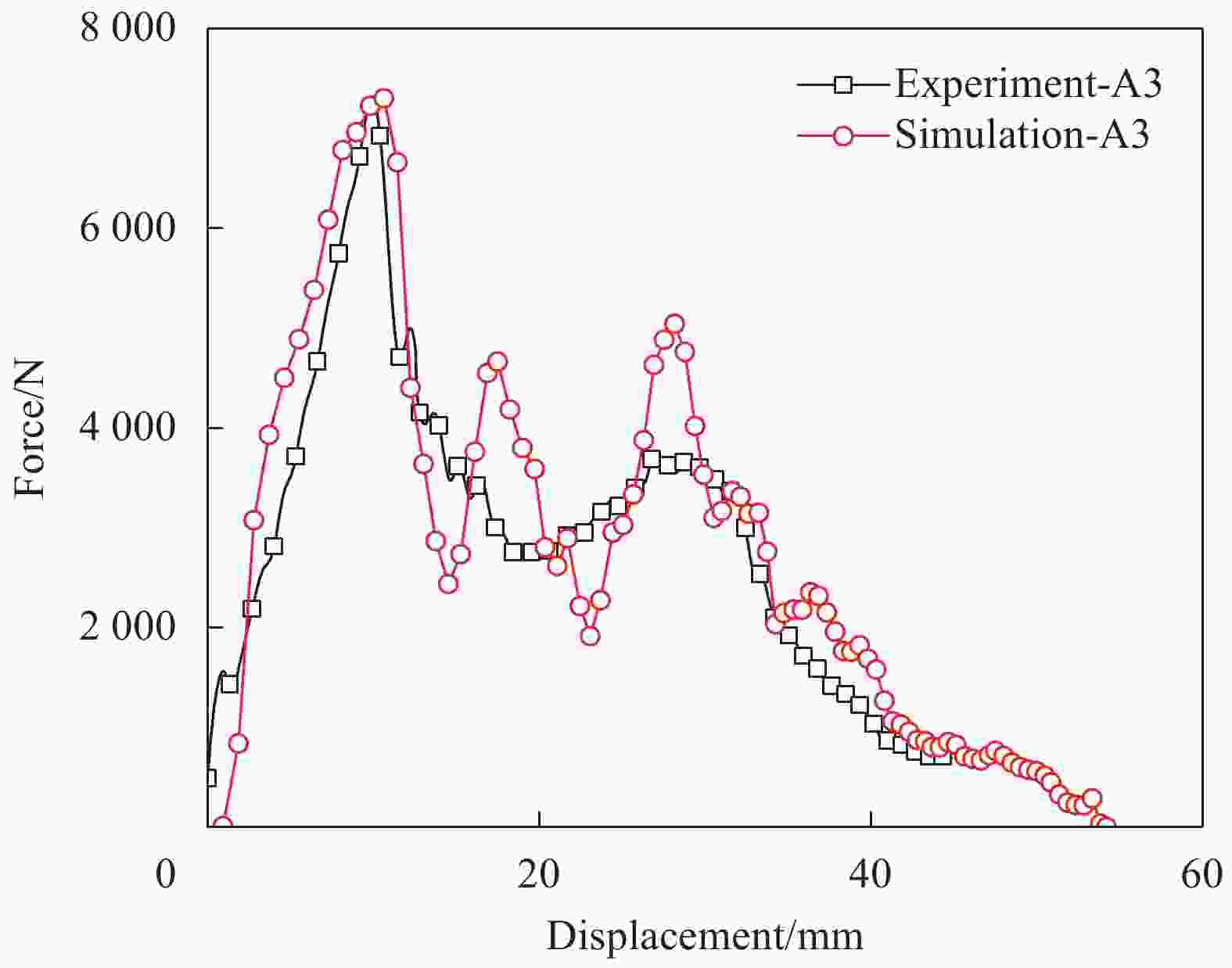

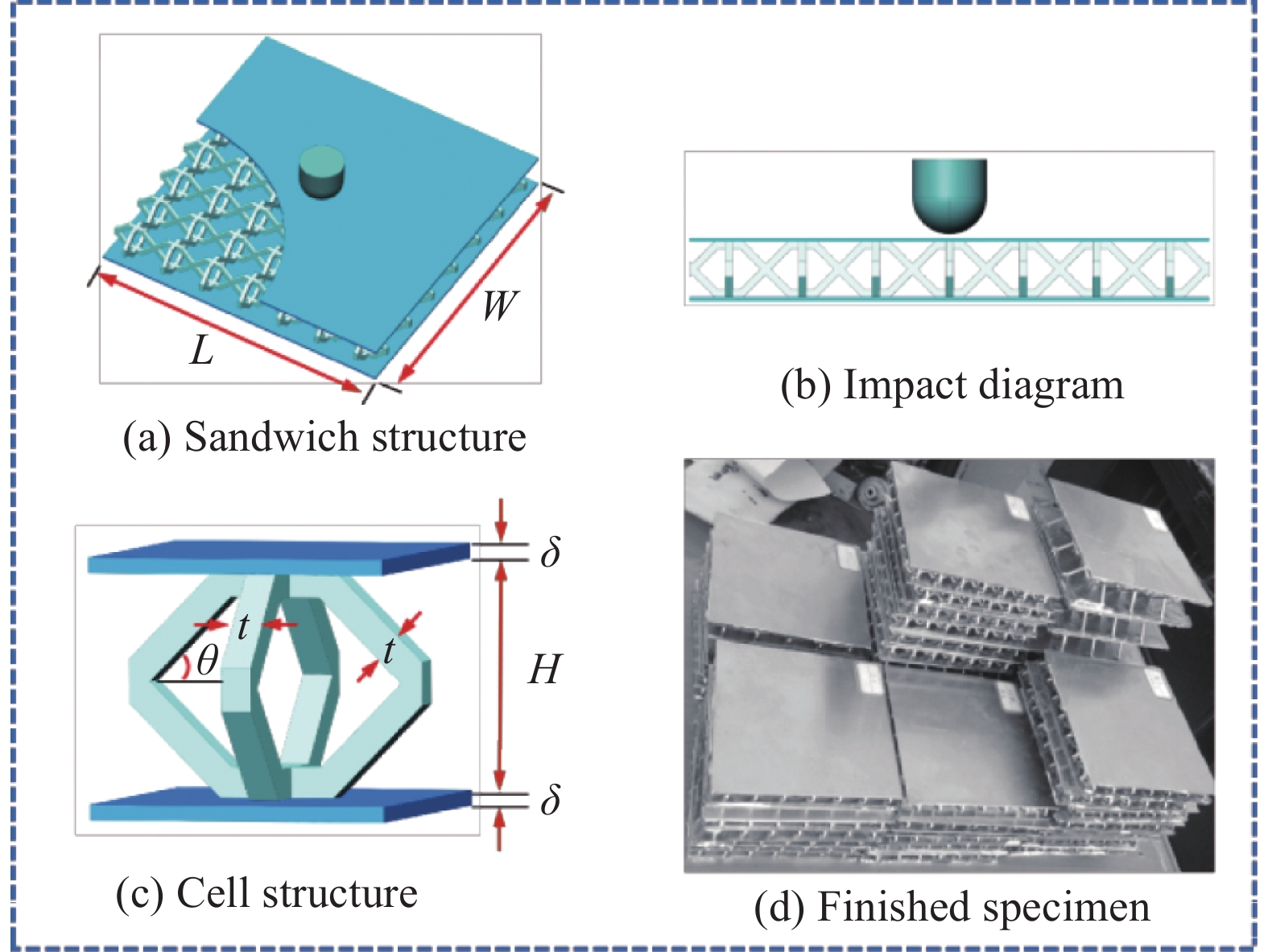

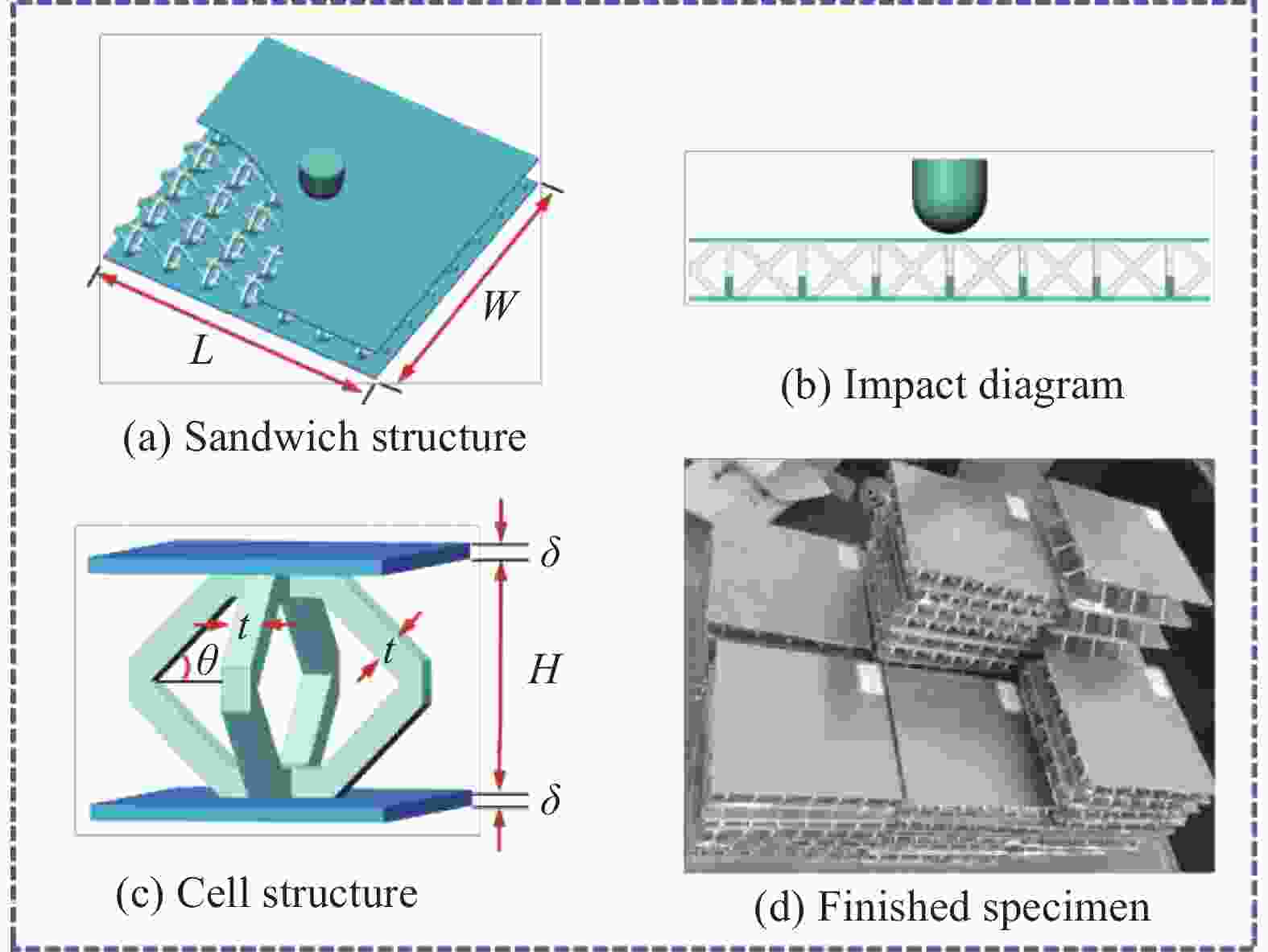

摘要: 利用落锤冲击试验研究了X型点阵夹芯结构局部冲击动态特性,并分析了不同参数对其冲击性能的影响。结果表明,冲击失效过程大致经历整体受力、上面板破坏、下面板受力强化和下面板破坏四个典型阶段,冲击速度和面板厚度对X型点阵夹芯结构的冲击极限荷载和吸能量影响较大,芯子厚度对X型点阵夹芯结构的冲击极限荷载和吸能量影响较小,而芯子角度对X型点阵夹芯结构的冲击极限荷载和吸能量有一定影响。利用有限元对X型点阵夹芯结构的局部冲击动态行为进行了数值模拟,通过破坏形态和荷载-时间曲线的对比分析验证了有限元模型的可靠性。Abstract: The local impact dynamic characteristics of X-type lattice sandwich structure were studied by using the drop weight impact test, and the effects of different parameters on the impact performance were analyzed. The results show that the impact failure process roughly goes through four typical stages: The overall bearing force stage, the upper panel failure stage, the lower panel stress strengthening stage and the lower panel failure stage. The impact velocity and panel thickness have great effects on the impact peak load and energy absorption of the X-type lattice sandwich structure. The core thickness has little effect on the impact peak load and energy absorption of X-shaped lattice sandwich structure, while the core angle has a certain effect on the impact peak load and energy absorption of X-shaped lattice sandwich structure. The local impact dynamic behavior of the X-type lattice sandwich structure was numerically simulated by finite element method. The reliability of the finite element model was verified by the comparative analysis of failure modes and force-time curves.

-

Key words:

- X lattice structure /

- sandwich structure /

- local impact /

- dynamic performance /

- numerical simulation

-

表 1 X型点阵夹芯结构试件参数

Table 1. Specimen parameters of X-type lattice sandwich structure

Specimen label Core thickness

H/mmImpact velocity

V/(m∙s−1)Core angle

θ/(°)Panel thickness

δ/mmA1 15 2.5 45 1.0+1.0 A2 15 3.5 45 1.0+1.0 A3 15 4.5 45 1.0+1.0 B1 15 4.5 45 0.8+0.8 B2 15 4.5 45 1.0+1.0 B3 15 4.5 45 1.2+1.2 C1 15 4.5 45 1.0+1.0 C2 20 4.5 45 1.0+1.0 C3 25 4.5 45 1.0+1.0 D1 15 4.5 30 1.0+1.0 D2 15 4.5 45 1.0+1.0 D3 15 4.5 60 1.0+1.0 表 2 X型点阵夹芯结构各部分的材料参数

Table 2. Material parameters of each part of X-type lattice sandwich plate

Core Panel Impactor Density/(kg·m−3) 2680 2700 $4.05 \times {10^6}$ Young’s modulus/GPa 69.4 72.5 200 Poisson’s ratio 0.28 0.33 0.3 Yield strength/MPa 173 153 − -

[1] 张钱城, 卢天健, 闻婷. 轻质高强点阵金属材料的制备及其力学性能强化的研究进展[J]. 力学进展, 2010, 40(2):157-169. doi: 10.6052/1000-0992-2010-2-J2008-152ZHANG Qiancheng, LU Tianjian, WEN Ting. Research progress in preparation and mechanical properties strengthening of light and high strength lattice metal materials[J]. Advances in Mechanics,2010,40(2):157-169(in Chinese). doi: 10.6052/1000-0992-2010-2-J2008-152 [2] 曾 嵩, 朱荣, 姜炜, 等. 金属点阵材料的研究进展[J]. 材料导报 A: 综述篇, 2012, 26(3):18-35.ZENG Song, ZHU Rong, JIANG Wei, et al. Research progress of metal lattice materials[J]. Materials Review A: Review,2012,26(3):18-35(in Chinese). [3] 赵冰, 李志强, 侯红亮, 等. 金属三维点阵结构制备技术研究进展[J]. 稀有金属材料与工程, 2016, 45(08):2189-2200.ZHAO Bing, LI Zhiqiang, HOU Hongliang, et al. Advances in fabrication of 3D lattice structures of metals[J]. Rare Metal Materials and Engineering,2016,45(08):2189-2200(in Chinese). [4] 易长炎, 柏龙, 陈晓红, 等. 金属三维点阵结构拓扑构型研究及应用现状综述[J]. 功能材料, 2017, 10(48):10055-10065.YI Changyan, BAI Long, CHEN Xiaohong, et al. A review of the research and application of metal three-dimensional lattice topological configurations[J]. Functional Materials,2017,10(48):10055-10065(in Chinese). [5] 陈东, 吴永鹏, 李忠盛, 等. 轻质高强多功能点阵夹层结构研究进展[J]. 装备环境工程, 2020, 17(4):77-84.CHEN Dong, WU Yongpeng, LI Zhongsheng, et al. Research progress of lightweight and high-strength multifunctional lattice sandwich structure[J]. Equipment Environmental Engineering,2020,17(4):77-84(in Chinese). [6] ZOK F W, WALTNER S A, WEI Z, et al. A protocol for characterizing the structural performance of metallic sandwich panels: Application to pyramidal truss cores[J]. International Journal of Solids Structures,2004,41(22):6249-6271. [7] XIONG J, MA L, WU L Z, et al. Fabrication and crushing behavior of low density carbon fiber composite pyramidal truss structures[J]. Composite Structures,2010,92(11):2695-2702. doi: 10.1016/j.compstruct.2010.03.010 [8] XIONG J, MA L, WU L Z, et al. Mechanical behavior and failure of composite pyramidal truss core sandwich columns[J]. Composites: Part B,2011,42(4):938-945. doi: 10.1016/j.compositesb.2010.12.021 [9] WEI K, YANG Q, LING B, et al. Mechanical responses of titanium 3D kagome lattice structure manufactured by selective laser melting[J]. Extreme Mechanics Letters,2018,23:41-48. doi: 10.1016/j.eml.2018.07.001 [10] 张晓刚, 张德龙, 张昊, 等. 三种单层点阵夹芯结构的抗压性能研究[J]. 机械研究与应用, 2020, 33(6):4-6.ZHANG Xiaogang, ZHANG Delong, ZHANG Hao, et al. Research on compressive properties of three single-layer lattice sandwich structures[J]. Mechanical Research and Application,2020,33(6):4-6(in Chinese). [11] 张甲瑞, 翟光涛, 李文礼. 连续纤维 Octet-truss 点阵夹芯结构制造及抗压缩性能[J]. 复合材料学报, 2021, 38(6):1767-1774.ZHANG Jiarui, ZHAI Guangtao, LI Wenli. Fabrication and compression resistance of continuous fiber octet truss lattice sandwich structure[J]. Acta Materiae Compositae Sinica,2021,38(6):1767-1774(in Chinese). [12] WANG B, HU J Q, LI Y Q, et al. Mechanical properties and failure behavior of the sandwich structures with carbon fiber-reinforced X-type lattice truss core[J]. Composite Structures,2018,185:619-633. doi: 10.1016/j.compstruct.2017.11.066 [13] 冀宾, 韩涵, 宋林郁, 等. 面内压缩超轻质点阵夹芯板的优化、试验与仿真[J]. 复合材料学报, 2019, 36(4):1045-1051.JI bin, HAN Han, SONG Linyu, et al. Optimization, test and simulation of in-plane compression ultra light lattice sandwich panel[J]. Acta Materiae Compositae Sinica,2019,36(4):1045-1051(in Chinese). [14] 王莉娜, 赵月帅, 尹钊, 等. 多层点阵夹心结构承压性能研究[J]. 载人航天, 2020, 26(1):41-47.WANG Lina, ZHAO Yueshuai, YIN Zhao, et al. Study on bearing capacity of multilayer lattice sandwich structure[J]. Manned Spaceflight,2020,26(1):41-47(in Chinese). [15] 郑权, 冀宾, 李昊, 等. 基于增材制造的多层金字塔点阵夹芯板抗压缩性能[J]. 航空材料学报, 2018, 38(3):77-82. doi: 10.11868/j.issn.1005-5053.2017.000036ZHENG Quan, JI bin, LI Hao, et al. Compressive properties of multilayer pyramid lattice sandwich panels based on additive manufacturing[J]. Journal of Aeronautical Materials,2018,38(3):77-82(in Chinese). doi: 10.11868/j.issn.1005-5053.2017.000036 [16] FENG L J, WEI G T, YU G C, et al. Underwater blast behaviors of enhanced lattice truss sandwich panels[J]. International Journal of Mechanical Sciences,2018,150:1-24. [17] 韩笑, 杨丽红, 于国财, 等. 多层梯度点阵夹芯结构抗爆性能研究[J]. 应用力学学报, 2018, 35(1):185-190.HAN Xiao, YANG Lihong, YU Guocai, et al. Study on explosion resistance of multilayer gradient lattice sandwich structure[J]. Journal of Applied Mechanics,2018,35(1):185-190(in Chinese). [18] ZHANG G Q, WANG B, XIONG J, et al. Response of sandwich structures with pyramidal truss cores under the compression and impact loading[J]. Composite Structures,2013,100(6):451-463. [19] 张振华, 钱海峰, 王媛欣. 球头落锤冲击下金字塔点阵夹芯板结构的动态响应实验[J]. 爆炸与冲击, 2015, 35(06):888-894.ZHANG Zhenhua, QIAN Haifeng, WANG Yuanxin. Experimental study on dynamic response of pyramid lattice sandwich plate under impact of ball drops[J]. Explosion and Shock Waves,2015,35(06):888-894(in Chinese). [20] 郭锐, 南博华, 周昊. 点阵金属夹层结构抗侵彻实验研究[J]. 振动与冲击, 2016, 35(24):45-50.GUO Rui, NAN Bohua, ZHOU Hao. Experimental study on penetration resistance of lattice metal sandwich structures[J]. Journal of Vibration and Shock,2016,35(24):45-50(in Chinese). [21] 郭锐, 周昊, 刘荣忠, 等. 陶瓷棒填充点阵金属夹层结构的制备及抗侵彻实验[J]. 复合材料学报, 2016, 33(4):921-928.GUO Rui, ZHOU Hao, LIU Rongzhong, et al. Preparation and penetration resistance experiment of ceramic rod filled lattice metal sandwich structure[J]. Acta Materiae Compositae Sinica,2016,33(4):921-928(in Chinese). [22] 牟金磊, 李玉江, 张振华, 等. 垂向冲击作用下金字塔点阵夹芯单元结构失效分析[J]. 海军工程大学学报, 2016, 28(6):5-9.MOU Jinlei, LI Yujiang, ZHANG Zhenhua, et al. Failure analysis of pyramid lattice sandwich element structure under vertical impact[J]. Journal of Naval University of engineering,2016,28(6):5-9(in Chinese). [23] HU J Q, LIU A K, ZHU S W, et al. Novel panel-core connection process and impact behaviors of CF/PEEK thermoplastic composite sandwich structures with truss cores[J]. Composite Structures,2020,251(1):1-16. -

下载:

下载: