Bulletproof performance of polyimide/UHMWPE fiber hybrid reinforced composites

-

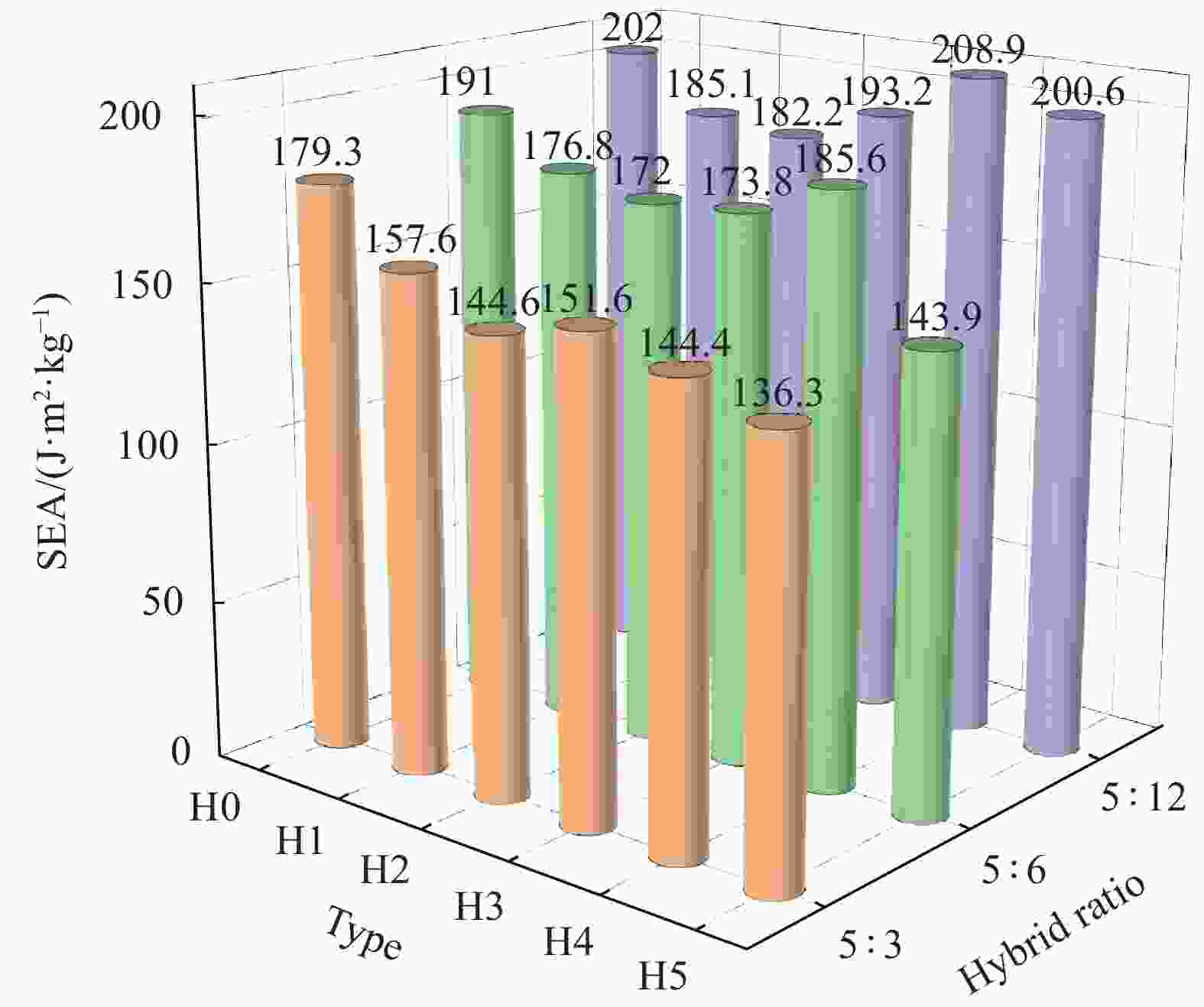

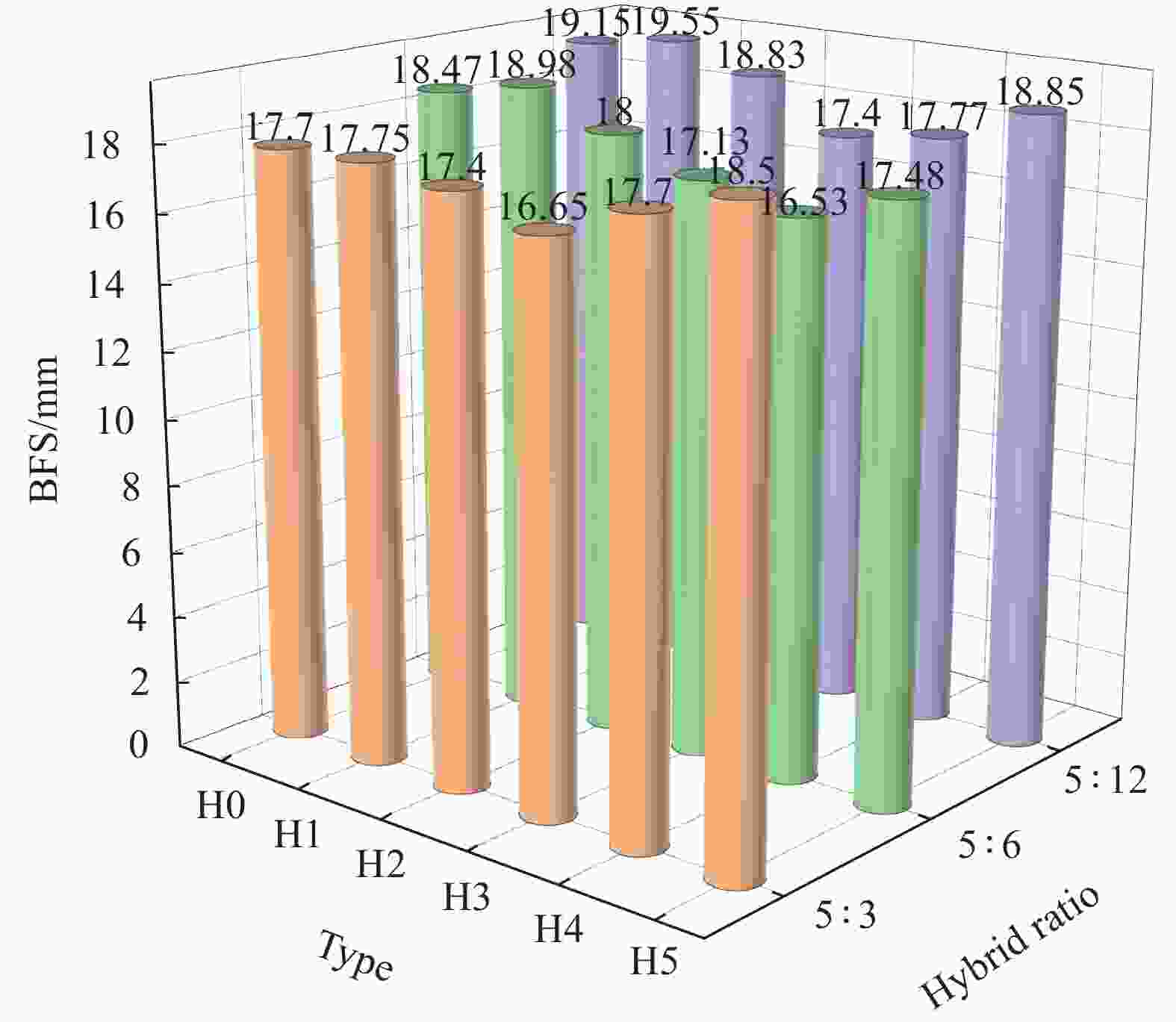

摘要: 针对超高分子量聚乙烯(UHMWPE)纤维增强防弹复合材料背部凸起(BFS)较高的不足,本研究充分利用聚酰亚胺(PI)纤维耐高温、高模量的优势,制备了一系列PI和UHMWPE纤维混杂复合材料靶板,研究了混杂靶板的铺层结构和混杂比例对比吸收能(SEA)值和背部凸起(BFS)值的影响,分析了混杂靶板防护作用机制。结果显示:PI纤维的使用可以在不影响SEA值的情况下有效限制BFS值,其中两极铺层结构(H3、UHMWPE/PI)和夹芯铺层结构(H4、PI/UHMWPE/PI)表现出混杂正效应,两种结构的SEA值和BFS值分别可达193.2 J·m2/kg,17.40 mm和208.9 J·m2/kg,17.77 mm,表现出优异的防弹性能。Abstract: Aiming at the deficiency of high back-face signature (BFS) of ultra-high molecular weight polyethylene (UHMWPE) fiber-reinforced ballistic composites, a series of polyimide (PI) and UHMWPE fiber hybrid composites were prepared by making full use of the advantages of high temperature resistance and high modulus of PI fibers in this study. The effects of layer structure and mixing ratio on the specific energy absorption (SEA) and BFS values of the hybrid composites and the protective mechanism were investigated. The results show that the use of PI fibers can effectively limit the BFS without affecting the SEA value. The bipolar layer structure (H3, UHMWPE/PI) and the sandwich layer structure (H4, PI/UHMWPE/PI) exhibit positive mixed effect. SEA and BFS values of the two structures can reach 193.2 J·m2/kg, 17.40 mm and 208.9 J·m2/kg, 17.77 mm, respectively, demonstrated excellent bulletproof performance.

-

Key words:

- polyimide fiber /

- UHMWPE fiber /

- composite material /

- bulletproof /

- specific energy absorption /

- back-face signature

-

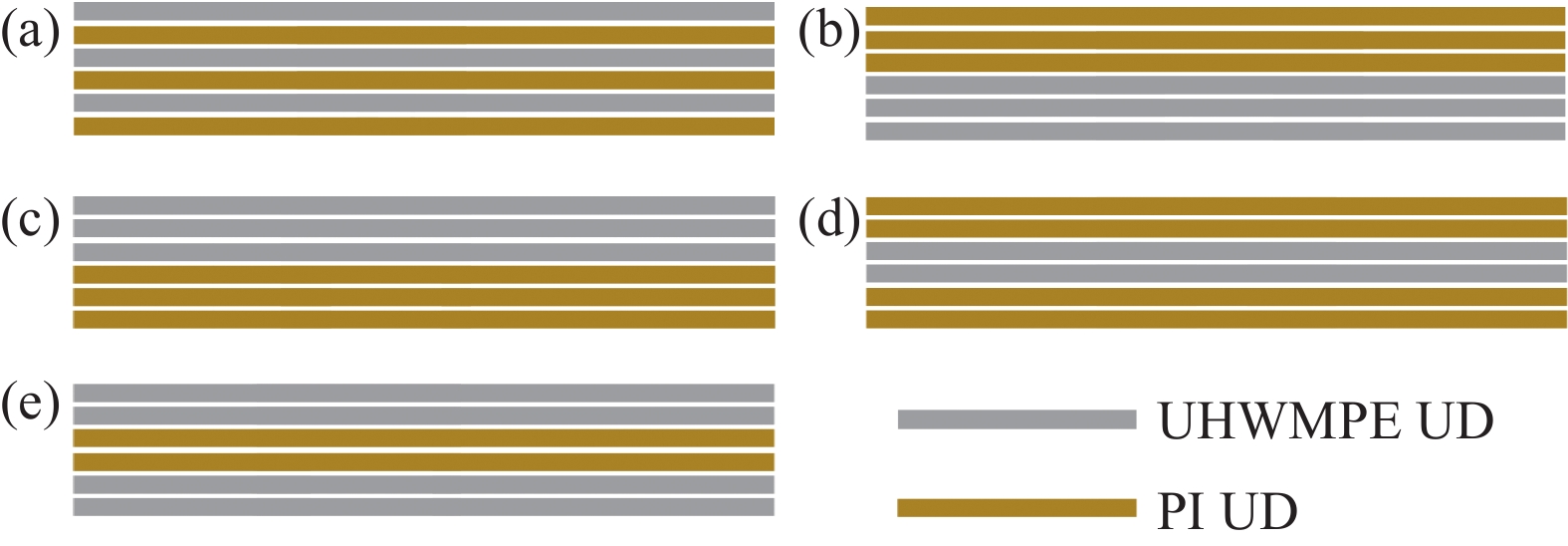

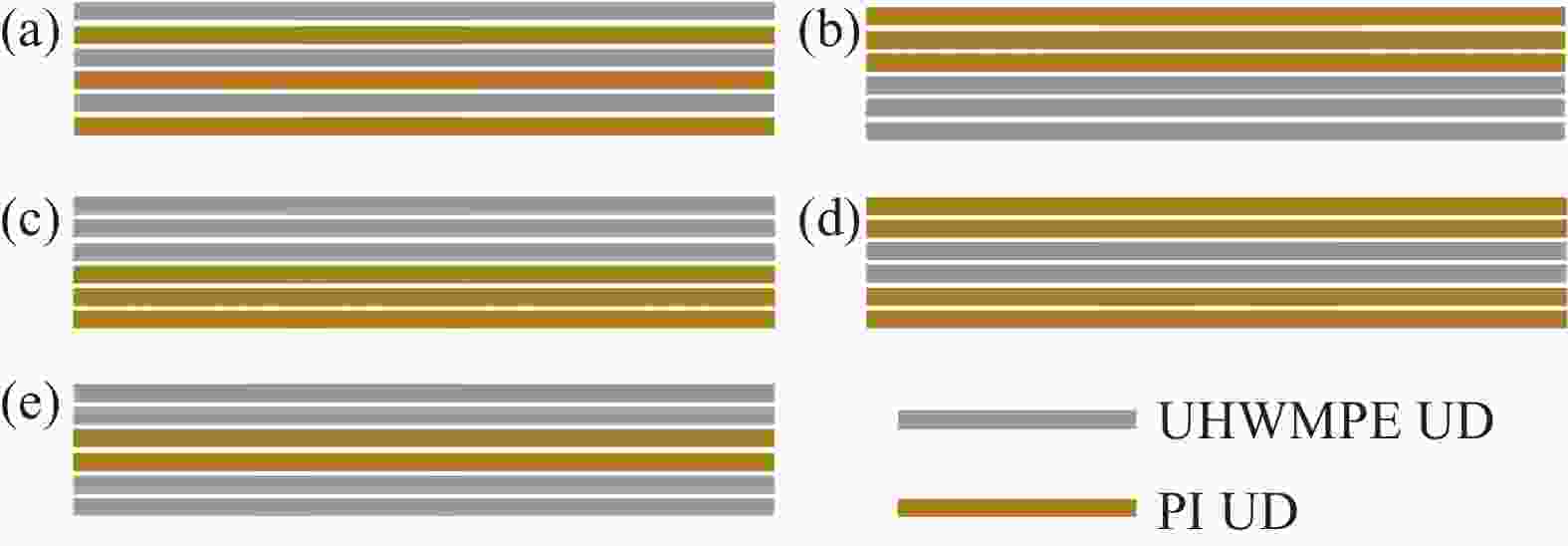

图 1 层合板铺层结构示意图(厚度方向):(a) 交替铺层结构(H1);(b) 两极非对称铺层结构(H2);(c) 两极非对称铺层结构(H3);(d) 夹芯铺层结构(H4);(e) 夹芯铺层结构(H5)

Figure 1. Schematic diagram of laminate lay-up structure (thickness direction): (a) Alternating lay-up structure (H1); (b) Two-pole asymmetric lay-up structure (H2); (c) Two-pole asymmetric lay-up structure (H3); (d) Sandwich lay-up structure (H4); (e) Sandwich lay-up structure (H5)

UHWMPE—Ultra-high molecular weight polyethylene; UD—Unidirectional; PI—Polyimide

图 2 PI/UHMWPE纤维混杂增强复合材料靶板SEA值与铺层结构和混杂比例的关系(H0为复合材料混杂定律按照质量分数计算的理论值)

Figure 2. Relationship between SEA value of PI/UHMWPE fiber hybrid reinforced composite target plate and the layer structure and hybrid ratio (H0 is the theoretical value calculated according to the mass fraction of the hybrid law of composite materials)

图 3 PI/UHMWPE纤维混杂增强复合材料靶板BFS值与铺层结构和混杂比例的关系(同一类型靶板的弹道极限速度V50值和BFS由两块完全相同的靶板分别测得)

Figure 3. Relationship between BFS value of PI/UHMWPE fiber hybrid reinforced composite target plate and layer structure and hybrid ratio (V50 and BFS of the same type of target plate are measured by two identical target plates separately)

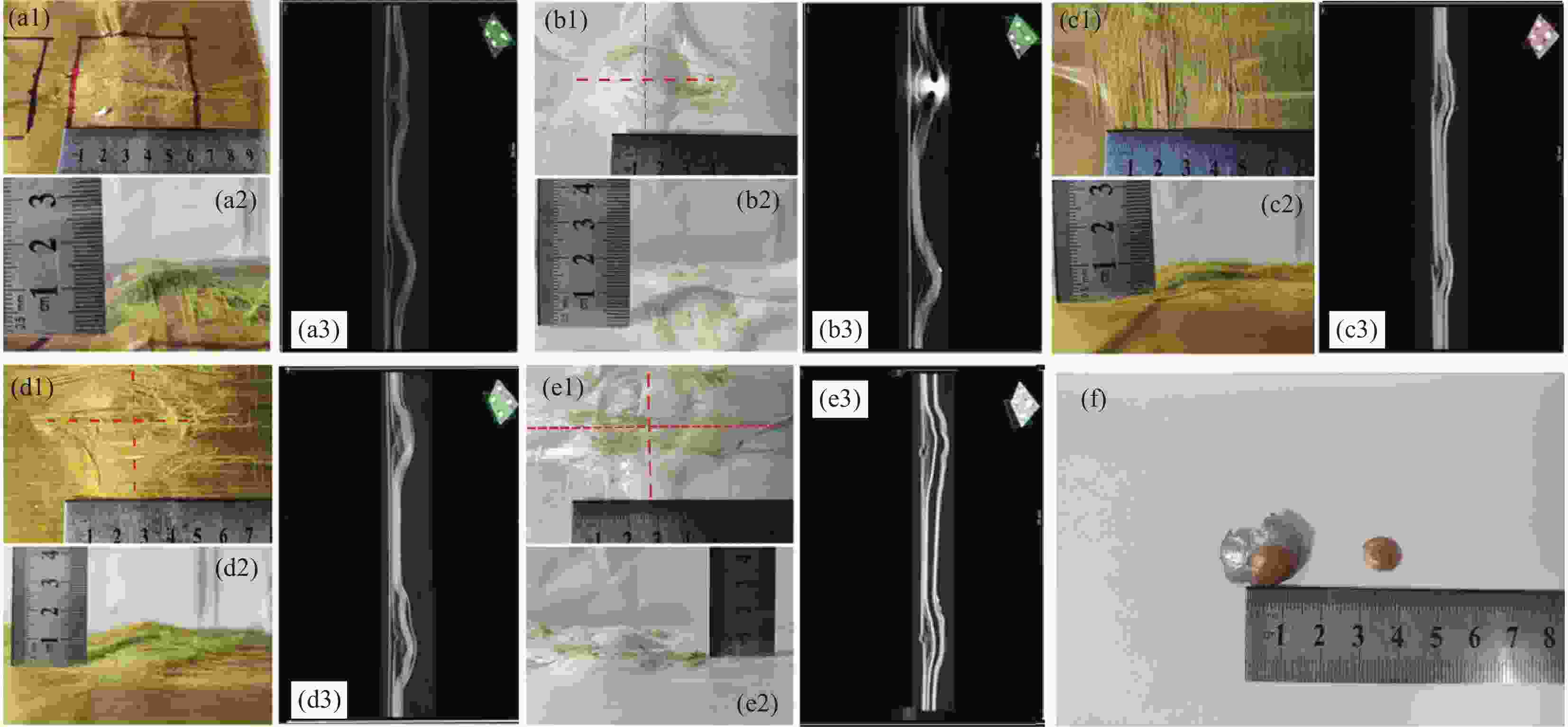

图 4 PI/UHMWPE纤维混杂增强复合材料宏观形貌 ((a)~(e)分别对应H1~H5靶板,混杂比均为5∶12,下标1、2、3分别为背弹面凸起宏观形貌、厚度方向凸起形貌、厚度方向微纳米焦点CT无损检测切片图;(f) 子弹宏观形貌)

Figure 4. Macroscopic morphology of PI/UHMWPE fiber hybrid reinforced composites ((a)-(e) Correspond to H1-H5 target plate, mixing ratio are 5∶12, subscripts 1, 2, 3 are the macroscopic morphologies of the projection of the back elastic surface, thickness direction projection morphology, thickness direction micro-nano-focus CT nondestructive inspection section; (f) Macroscopic morphology of the bullet)

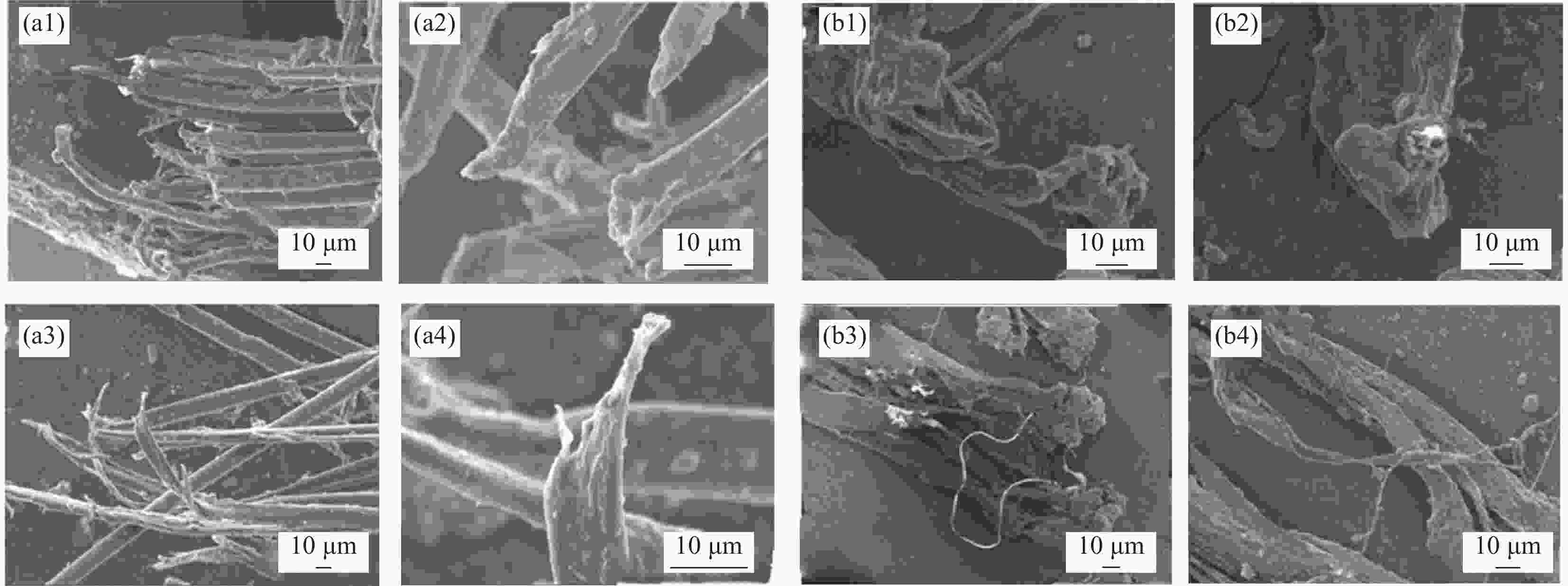

图 5 PI/UHMWPE纤维混杂增强复合材料迎/背弹面纤维微观形貌:((a1), (a2)) H4-3靶板迎弹面弹孔处PI纤维微观形貌;((a3), (a4)) H4-3靶板背弹面弹孔处PI纤维微观形貌;((b1), (b2)) H5-3靶板迎弹面弹孔处UHMWPE纤维微观形貌;((b3), (b4)) H5-3靶板背弹面弹孔处UHMWPE纤维微观形貌

Figure 5. Micromorphologies of PI/UHMWPE fiber hybrid reinforced composites on the front and back elastic surfaces: ((a1), (a2)) Microscopic morphologies of PI fibers at the bullet holes on the face of H4-3 target plate; ((a3), (a4)) Microscopic morphologies of PI fibers at the bullet holes on the back surface of H4-3 target plate. ((b1), (b2)) Microscopic morphologies of UHMWPE fibers at the bullet holes on the face of H5-3 target plate; ((b3), (b4)) Microscopic morphologies of UHMWPE fibers at the bullet holes on the back of H5-3 target plate

表 1 聚酰亚胺/超高分子量聚乙烯(PI/UHMWPE)纤维混杂增强复合材料靶板铺层结构

Table 1. Laminated structure of PI/UHMWPE fiber hybrid reinforced composite target plate

Type of structure Mass ratio (PI∶UHMWPE) Layers structure Surface density/(kg·m−2) PI — 1∶0 P70 6.60 UHMWPE — 0∶1 U70 4.02 H1 H1-1

H1-2

H1-35∶3

5∶6

5∶12(U2P2)18

(U4P2)12

(U8P2)75.45

4.99

4.58H2 H2-1

H2-2

H2-35∶3

5∶6

5∶12P36U36

P24U48

P14U565.45

5.02

4.55H3 H3-1

H3-2

H3-35∶3

5∶6

5∶12U36P36

U48P24

U56P145.45

5.04

4.62H4 H4-1

H4-2

H4-35∶3

5∶6

5∶12P18U36P18

P12U48P12

P6U56P85.47

5.03

4.93H5 H5-1

H5-2

H5-35∶3

5∶6

5∶12U18P36U18

U24P24U24

U28P14U285.47

5.03

4.61Note: U stands for UHMWPE fiber and P stands for PI fiber, P36U36 stands for 36 layers of PI UD and 36 layers of UHMWPE UD lay-up structure, and PI fiber is used as the spring-return surface. 表 2 单一纤维PI/UHMWPE纤维混杂增强复合材料比吸收能(SEA)值与背部凸起(BFS)值

Table 2. Specific energy absorption (SEA) value and back-face signature (BFS) value of single fiber PI/UHMWPE fiber hybrid reinforced composites

Type of structure V50

/(m·s−1)SEA

/(J·m2·kg−1)BFS

/mmPI 601.4 153.4 16.15 UHMWPE 565.1 222.4 20.40 Note: V50—Ballistic limit velocity of the target plate. -

[1] ABTEW M A, BOUSSU F, BRUNIAUX P, et al. Ballistic impact mechanisms—A review on textiles and fibre-reinforced composites impact responses[J]. Composite Structures,2019,223:110966. doi: 10.1016/j.compstruct.2019.110966 [2] TAM T, BHATNAGAR A. 1—High-performance ballistic fibers and tapes[M]. Lightweight Ballistic Composites (Second Edition). Cambridge: Woodhead Publishing, 2016: 3-30. [3] MAWKHLIENG U, MAJUMDAR A, LAHA A. A review of fibrous materials for soft body armour applications[J]. RSC Advances,2020,10(2):1066-1086. doi: 10.1039/C9RA06447H [4] 叶卓然, 罗靓, 潘海燕, 等. 超高分子量聚乙烯纤维及其复合材料的研究现状与分析[J]. 复合材料学报, 2022, 39(9): 4286-4309.YE Zhuoran, LUO Liang, PAN Haiyan, et al. Research status and analysis of ultra-high molecular weight polyethylene fibers and their composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4286-4309(in Chinese). [5] 莫根林, 刘静, 金永喜, 等. 超高分子量聚乙烯纤维防护机理研究综述[J]. 兵器装备工程学报, 2021, 42(10):23-28. doi: 10.11809/bqzbgcxb2021.10.004MO Genlin, LIU Jing, JIN Yongxi, et al. A review of research on protective mechanism of ultra-high molecular weight polyethylene fibers[J]. Chinese Journal of Weaponry and Equipment Engineering,2021,42(10):23-28(in Chinese). doi: 10.11809/bqzbgcxb2021.10.004 [6] 董彬, 魏汝斌, 王小伟, 等. 纤维增强树脂基复合材料防弹头盔研究进展[J]. 兵器材料科学与工程, 2022, 45(4):125-132. doi: 10.14024/j.cnki.1004-244x.20220329.002DONG Bin, WEI Rubin, WANG Xiaowei, et al. Research progress on fiber-reinforced resin matrix composite bulletproof helmets[J]. Weapon Materials Science and Engineering,2022,45(4):125-132(in Chinese). doi: 10.14024/j.cnki.1004-244x.20220329.002 [7] VARGAS-GONZALEZ L R, GURGANUS J C. Hybridized composite architecture for mitigation of non-penetrating ballistic trauma[J]. International Journal of Impact Engineering,2015,86:295-306. doi: 10.1016/j.ijimpeng.2015.08.014 [8] PEIJS A A J M, CATSMAN P, GOVAERT L E, et al. Hybrid composites based on polyethylene and carbon fibres part 2: Influence of composition and adhesion level of polyethylene fibres on mechanical properties[J]. Composites,1990,21(6):513-521. doi: 10.1016/0010-4361(90)90424-U [9] ZHOU Y, LI H, XIONG Z, et al. The structural effects on the impact response of ultra-high-molecular-weight polyethylene plain weaves[J]. Textile Research Journal,2021,91(7-8):911-924. doi: 10.1177/0040517520966728 [10] PRAT N, RONGIERAS F, SARRON J C, et al. Contemporary body armor: Technical data, injuries, and limits[J]. European Journal of Trauma and Emergency Surgery,2012,38(2):95-105. doi: 10.1007/s00068-012-0175-0 [11] 周越松, 梁森, 王得盼, 等. 层间混杂铺层复合材料装甲抗侵彻性能研究[J]. 化工新型材料, 2022, 50(10): 118-123, 129.ZHOU Yuesong, LIANG Sen, WANG Depan, et al. Study on anti-penetration performance of interlayer hybrid laminated composite armor[J]. New Chemical Materials, 2022, 50(10): 118-123, 129(in Chinese) [12] 肖露, 程建芳, 柴晓明, 等. 层间混杂复合材料的弹道侵彻性能研究[J]. 浙江理工大学学报, 2013, 30(4):471-476.XIAO Lu, CHENG Jianfang, CHAI Xiaoming, et al. Ballistic penetration performance of interlayer hybrid composites[J]. Journal of Zhejiang Sci-Tech University,2013,30(4):471-476(in Chinese). [13] 王晓宏, 张丰发, 刘长喜, 等. 陶瓷/纤维层间混杂复合材料设计制作及抗弹体冲击性能测试[J]. 复合材料学报, 2021, 38(8):2684-2693.WANG Xiaohong, ZHANG Fengfa, LIU Changxi, et al. Design, fabrication and impact resistance testing of ceramic/fiber interlayer hybrid composites[J]. Acta Materiae Compositae Sinica,2021,38(8):2684-2693(in Chinese). [14] 周庆, 何业茂, 刘婷. 层间混杂复合材料装甲板防弹性能及其防弹机制[J]. 复合材料学报, 2019, 36(4):837-847.ZHOU Qing, HE Yemao, LIU Ting. Bulletproof performance and bulletproof mechanism of interlayer hybrid composite armor plate[J]. Acta Materiae Compositae Sinica,2019,36(4):837-847(in Chinese). [15] ZULKIFLI F, STOLK J, HEISSERER U, et al. Strategic positioning of carbon fiber layers in an UHMWPE ballistic hybrid composite panel[J]. International Journal of Impact Engineering,2019,129:119-127. doi: 10.1016/j.ijimpeng.2019.02.005 [16] ZHANG M, NIU H, WU D. Polyimide fibers with high strength and high modulus: Preparation, structures, properties, and applications[J]. Macromolecular Rapid Communications,2018,39(20):1800141. doi: 10.1002/marc.201800141 [17] HE B, WANG B, WANG Z, et al. Mechanical properties of hybrid composites reinforced by carbon fiber and high-strength and high-modulus polyimide fiber[J]. Polymer,2020,204:122830. doi: 10.1016/j.polymer.2020.122830 [18] JIANG M, YUAN D, HAN E, et al. Structure and properties of BPDA/PDA polyimide fibers[J]. High Performance Polymers,2021,33(6):646-656. doi: 10.1177/0954008320980514 [19] LIN D, LI T, LI R, et al. Structures and properties of polyimide fibers prepared via gel spinning induced by chemical imidization[J]. Polymer,2022,238:124377. doi: 10.1016/j.polymer.2021.124377 [20] WANG Z, ZHANG J, NIU H, et al. Influences of different imidization conditions on polyimide fiber properties and structure[J]. Journal of Applied Polymer Science,2021,138(40):51189. doi: 10.1002/app.51189 [21] WANG B, ZHANG M, HAN E, et al. Mechanical behavior of polyimide filament tows under high strain rate tension[J]. High Performance Polymers,2020,32(7):842-848. doi: 10.1177/0954008320904148 [22] 中国人民解放军总后勤部. 军用防弹衣安全技术性能要求: GJB 4300 A—2012[S]. 北京: 中国标准出版社, 2012.General Logistics Department of the PLA. Requirements of safety technical performance for military body armor: GJB 4300 A—2012[S]. Beijing: Standars Press of China, 2012(in Chinese). [23] ZIÓŁKOWSKI G, PACH J, PYKA D, et al. X-ray computed tomography for the development of ballistic composite[J]. Materials,2020,13(23):5566. doi: 10.3390/ma13235566 -

下载:

下载: