Infrared-assisted automated fiber placement process on the structure and properties of continuous glass fiber reinforced polypropylene composites

-

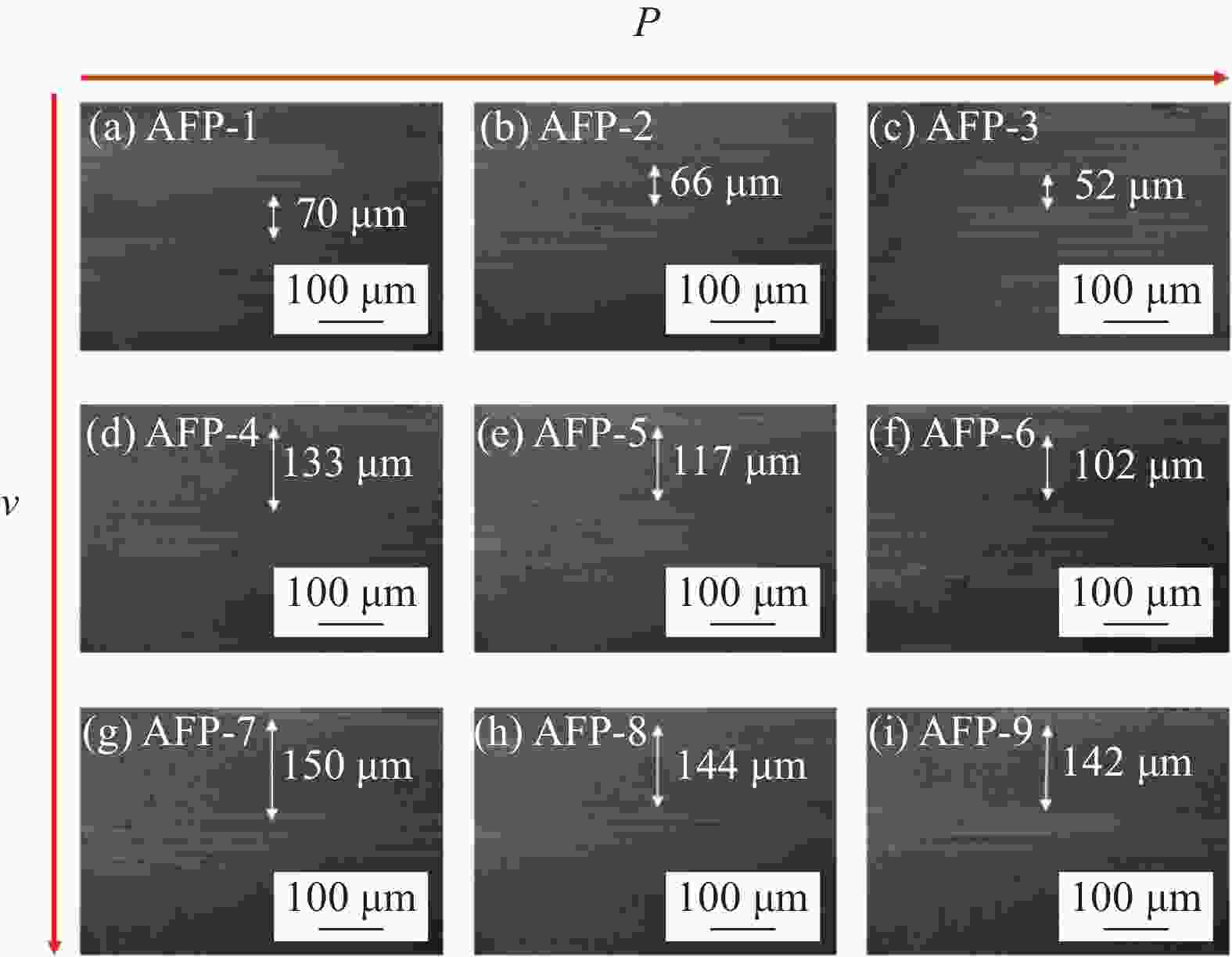

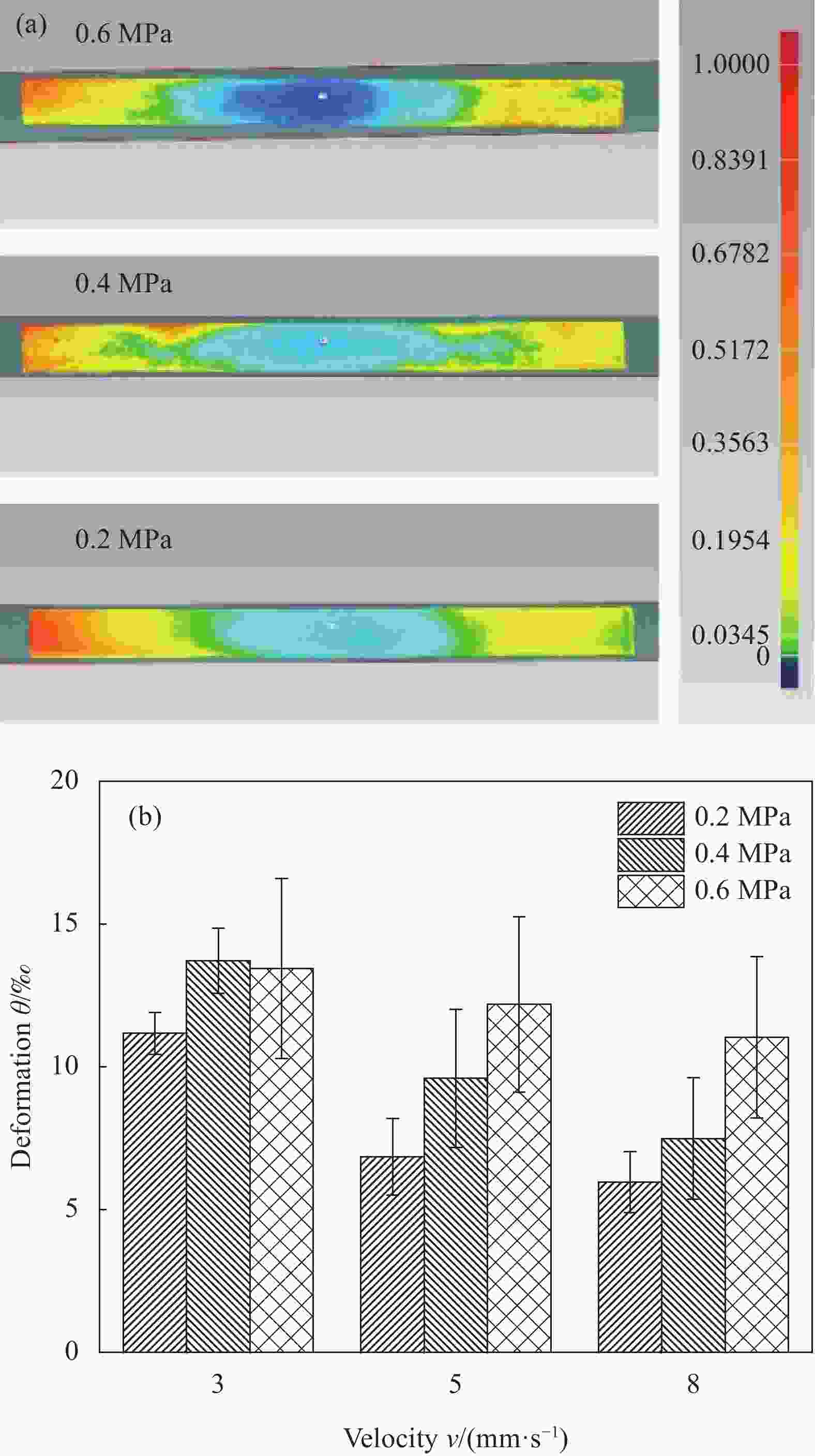

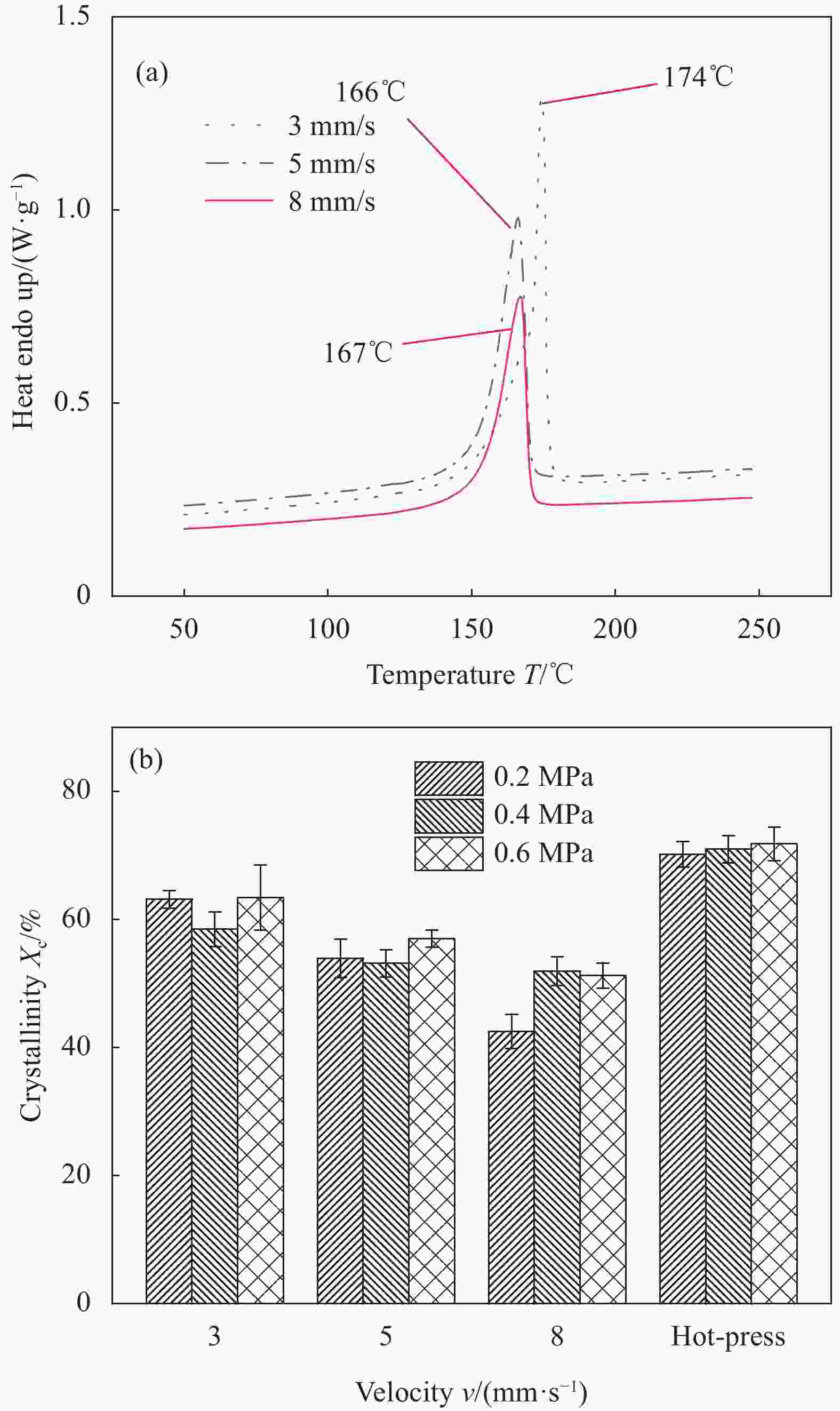

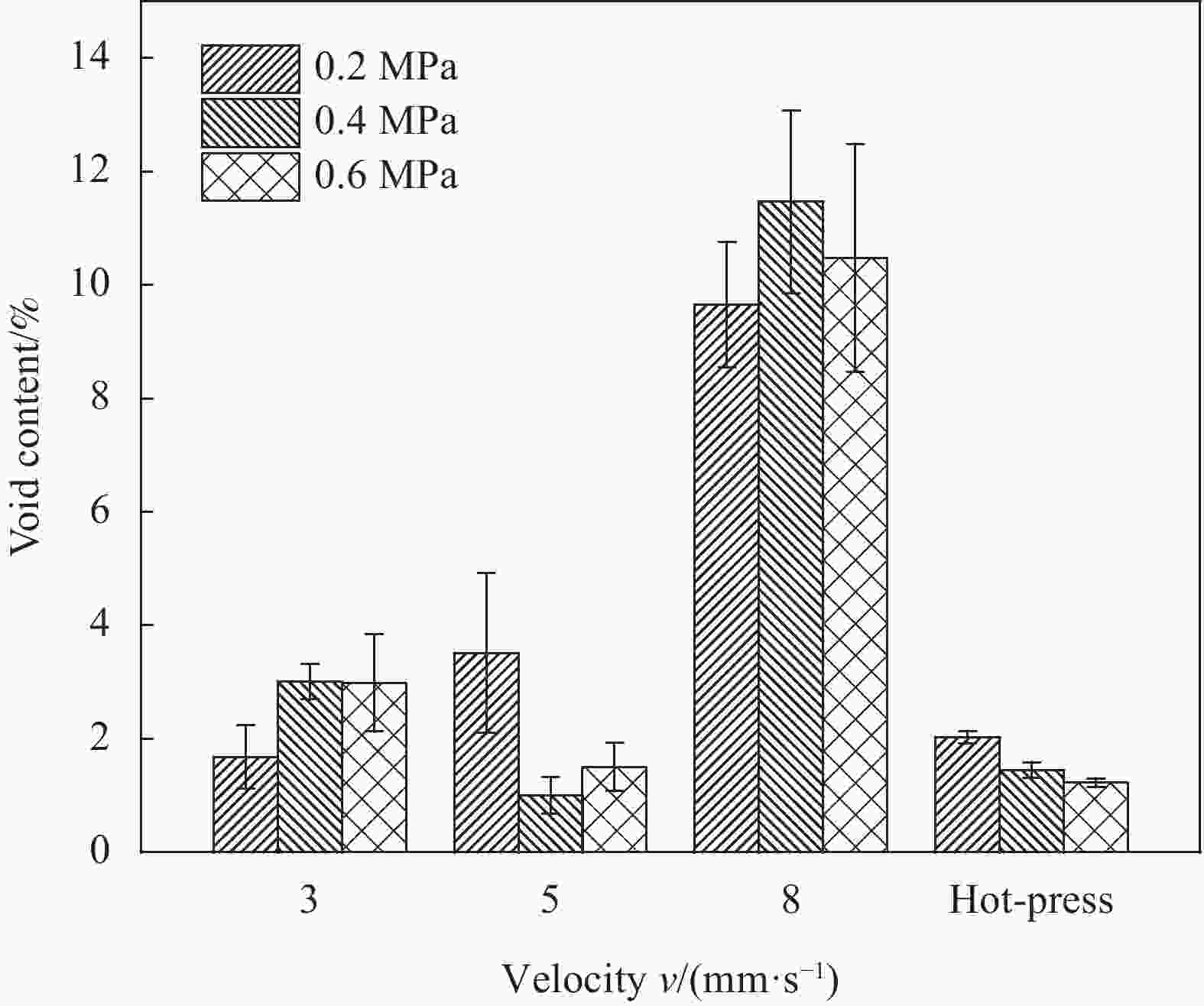

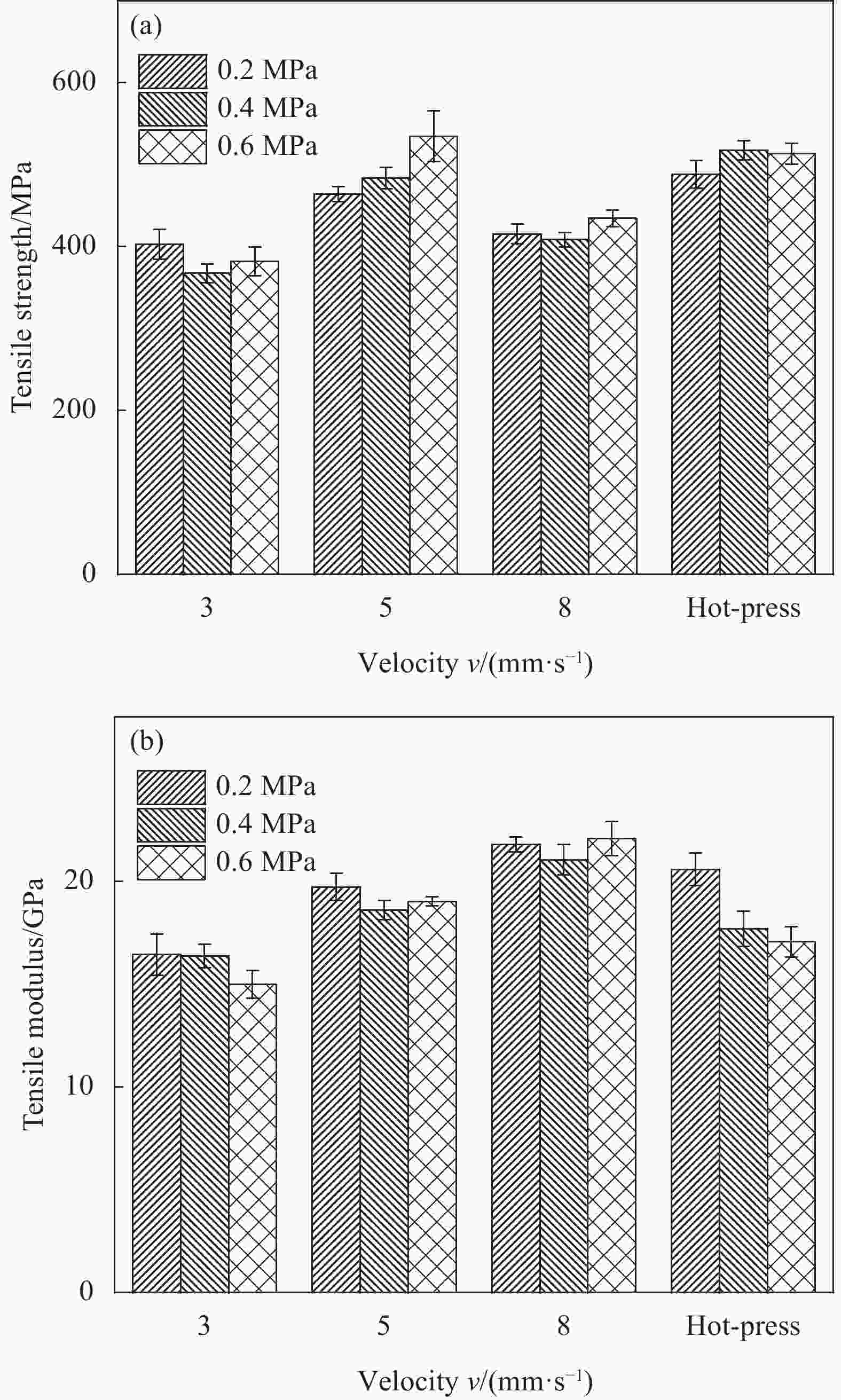

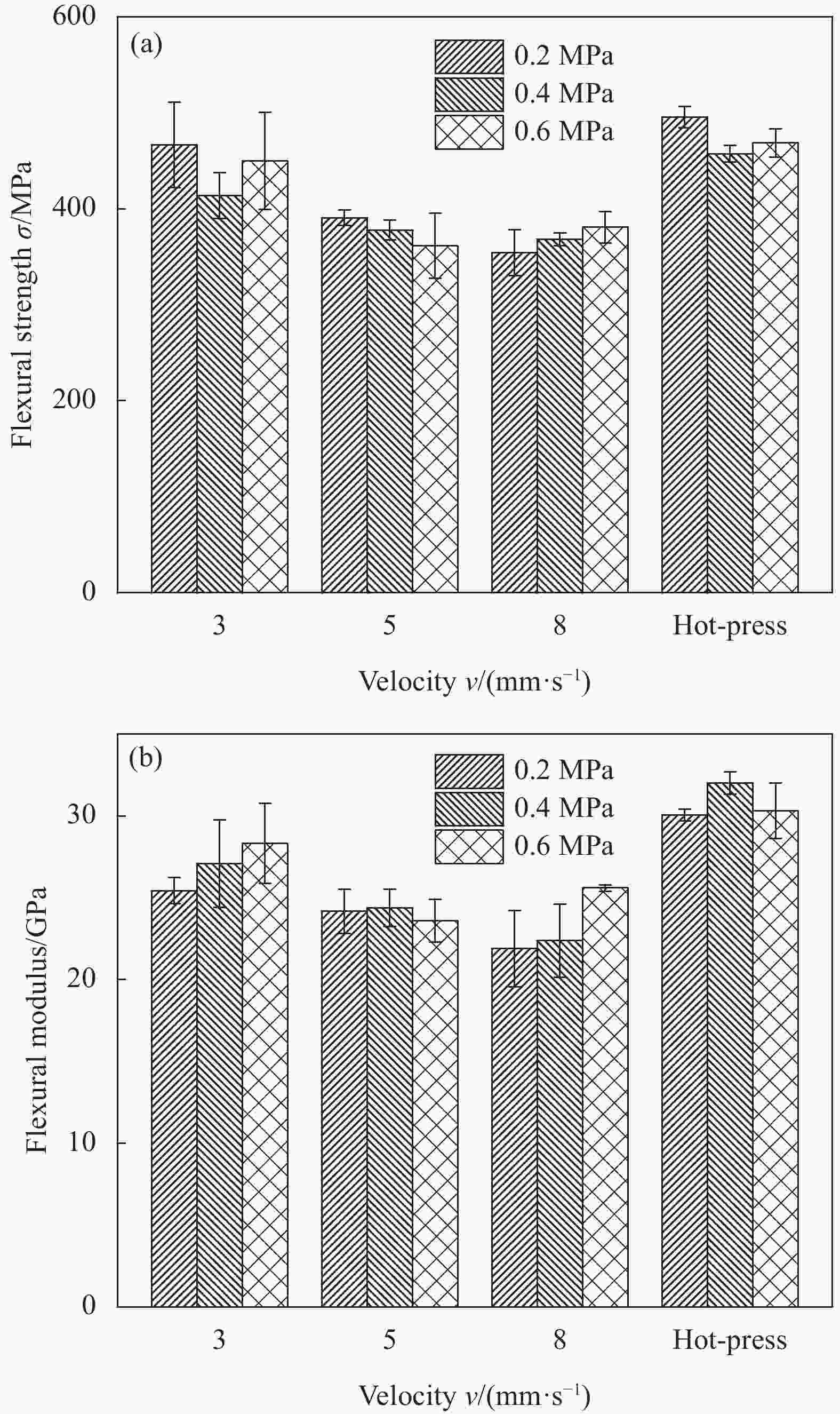

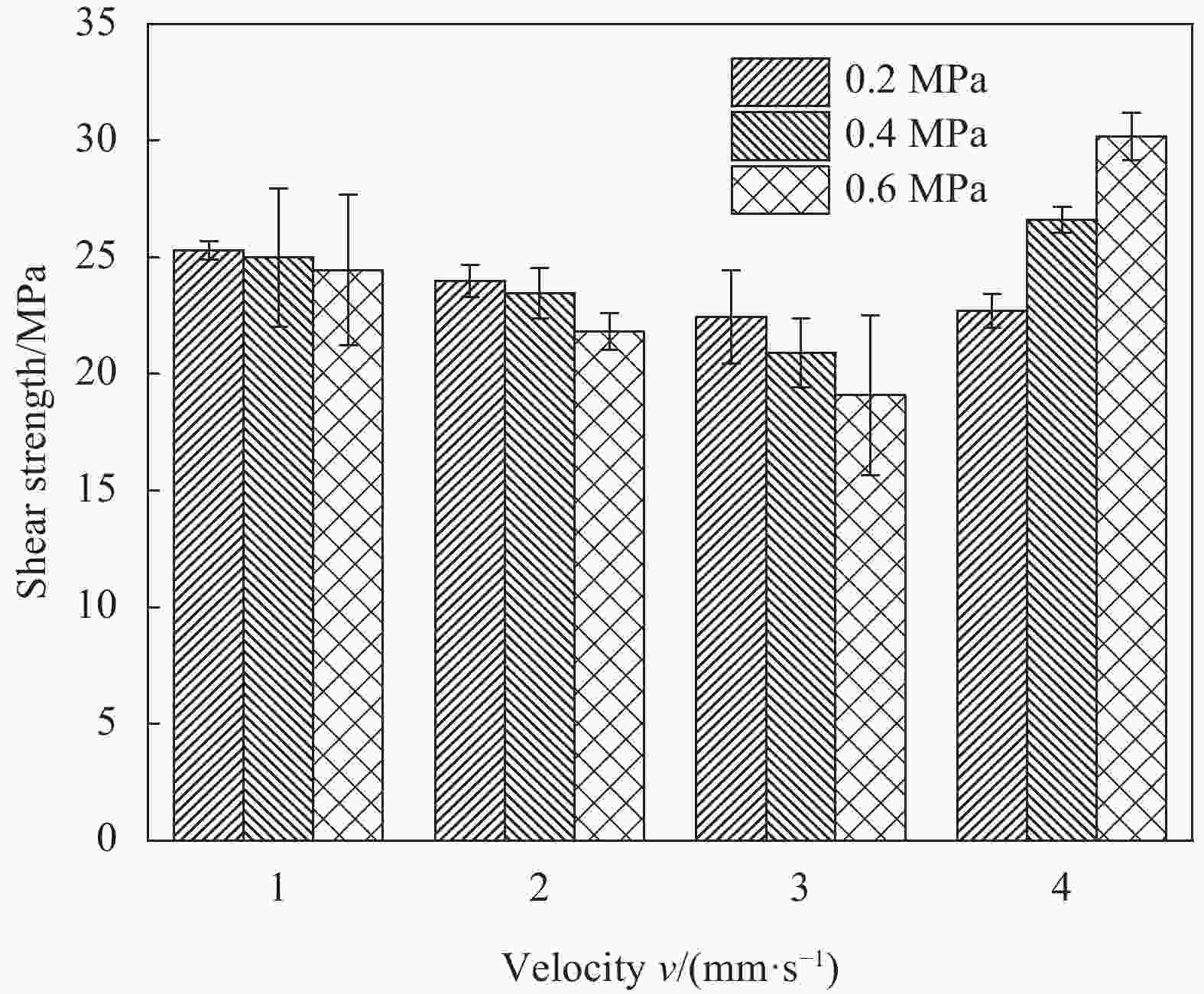

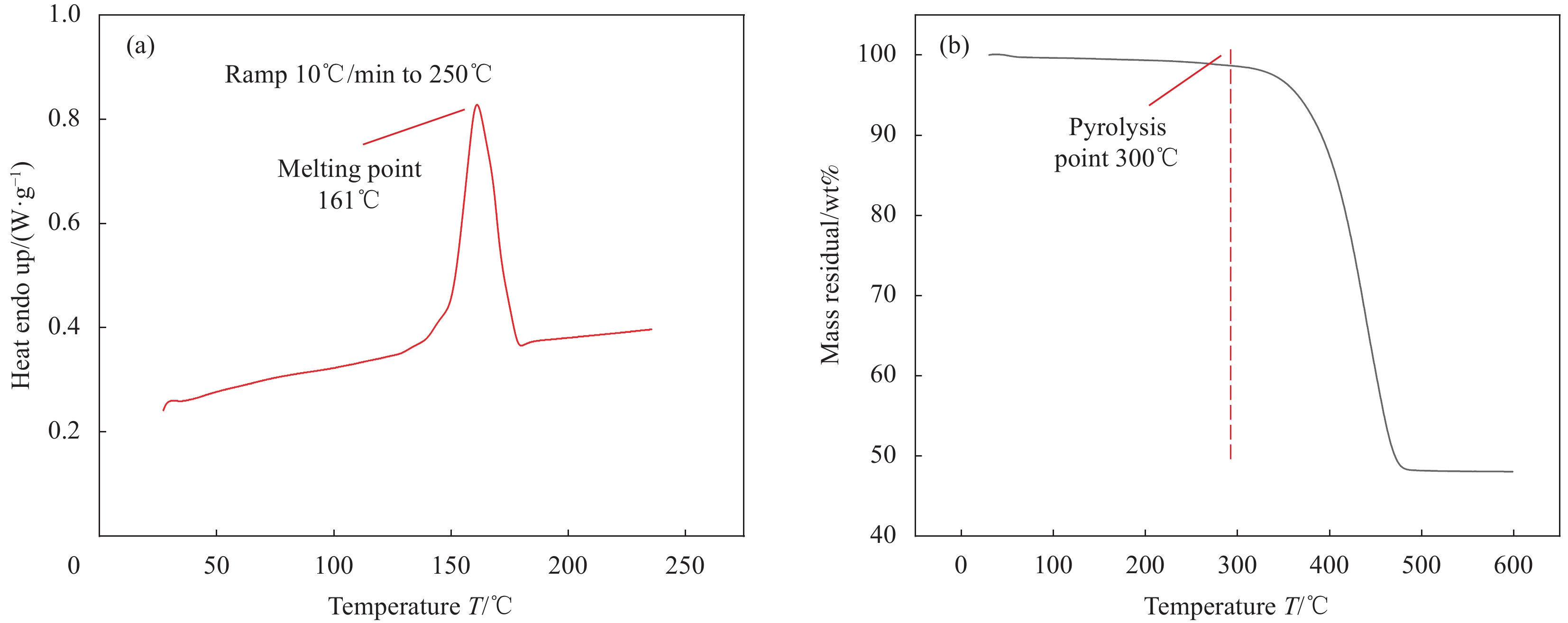

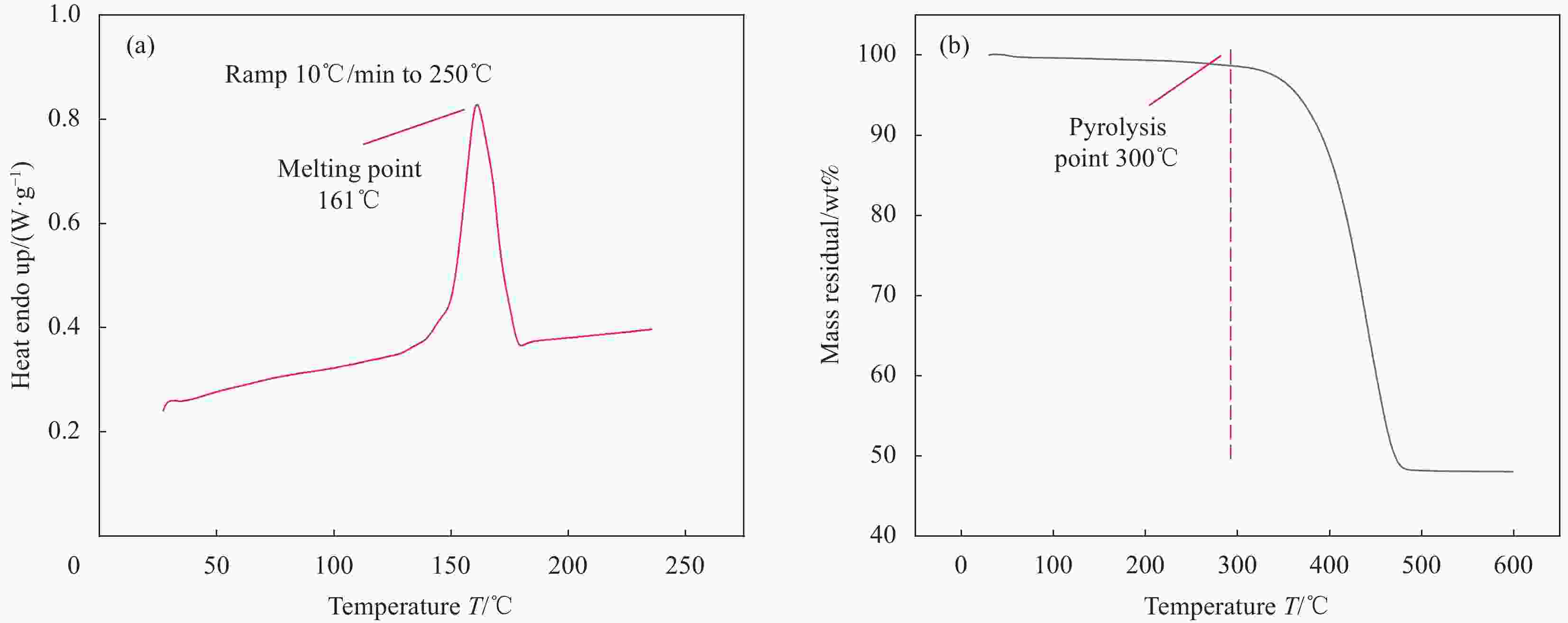

摘要: 与激光、热风加热相比,红外加热具有低成本、低污染等突出优势,是低熔点热塑性复合材料自动纤维铺放(Automated fiber placement,AFP)成形的理想热源。但是,红外辅助AFP工艺参数耦合性强,对成形精度、缺陷形成与宏观性能的影响尚不清晰,缺乏相关工艺的数据积累。本文针对红外辅助AFP原位成形工艺,通过调控铺放压力和速度制备了连续玻璃纤维增强聚丙烯复合材料单向层合板,研究了铺放温度与压力对减薄效应、翘曲变形、结晶度和孔隙率的影响,进一步探究了结构和缺陷对弯曲强度、层间剪切强度等宏观力学性能的影响规律。研究结果表明:温度过高会导致严重的减薄效应,过低则会导致高孔隙率;成形压力过高会造成严重的翘曲和纤维变形,降低层间剪切强度。通过对温度和压力的合理控制,可使孔隙率降至1%,满足民机复合材料构件2%阈值的要求;试样弯曲强度高达466 MPa,与热压成形相比仅降低6%。Abstract: Compared with laser and hot air heating, infrared (IR) heating has outstanding advantages such as low cost and low pollution, and is an ideal heat source for automated fiber placement (AFP) forming of low-melting thermoplastic composites. However, the coupling of IR-assisted AFP process parameters is strong, and the effects on forming accuracy, defect formation and macroscopic properties are still unclear, and there is a lack of data accumulation of related processes. In this paper, for the IR-assisted AFP in-situ forming process, continuous glass fiber reinforced polypropylene composite unidirectional laminates were prepared by regulating the lay-up pressure and speed, and the effects of lay-up temperature and pressure on the thinning effect, warpage deformation, crystallinity and porosity were investigated, and the influence of structure and defects on the macroscopic mechanical properties such as bending strength and interlaminar shear strength were further investigated. The results show that: Too high temperature leads to severe thinning effect, too low leads to high porosity; Too high forming pressure causes severe warpage and fiber deformation and reduces interlaminar shear strength. Through reasonable control of temperature and pressure, the porosity can be reduced to 1%, which meets the requirement of 2% threshold for civil-composite components; The bending strength of specimens is up to 466 MPa, which is only 6% lower compared with hot pressing forming.

-

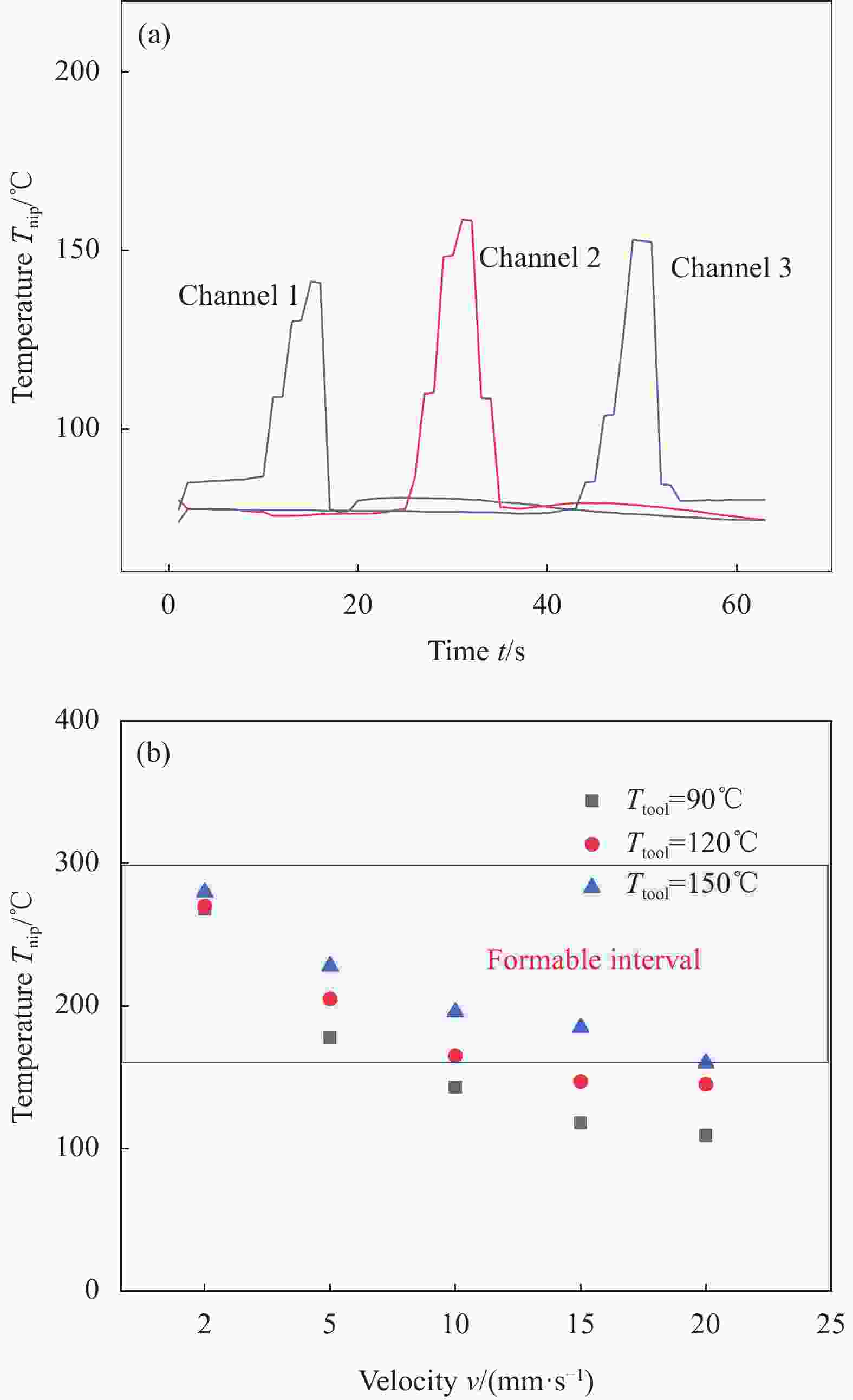

图 3 自动铺放GF/PP工艺参数对啮合点峰值温度影响:(a) 热电偶在铺放路径前、中、后3个预埋位置与测量曲线;(b) 不同工艺条件下啮合点峰值温度

Figure 3. Influence of automated placement GF/PP process parameters on peak temperature of the nip points: (a) Thermocouple in the front, middle and back of the laying path with measurement curves; (b) Peak temperature of the nip points under different process conditions

Ttool—Mold temperature

表 1 红外灯管参数

Table 1. Parameters of Infrared lamp

Infrared lamp type Lc/mm PI/(W·cm−1) λ/μm TI/℃ t/s Carbon wire radiation 15 40 2.0 1200 1-2 Notes: Lc—Length of carbon wire; PI—Infrared lamp unit density; λ—Peak wavelength of infrared lamp radiation; TI—Infrared filament maximum temperature; t—Response time for the infrared filament to reach its maximum temperature. 表 2 工艺实验方案

Table 2. Process experiment groups

Group ν/(mm·s−1) P/MPa Th/℃ th/s AFP-1 3 0.2 − − AFP-2 3 0.4 − − AFP-3 3 0.6 − − AFP-4 5 0.4 − − AFP-5 5 0.6 − − AFP-6 5 0.2 − − AFP-7 8 0.6 − − AFP-8 8 0.4 − − AFP-9 8 0.2 − − HP-1 − 0.2 180 300 HP-2 − 0.4 180 300 HP-3 − 0.6 180 300 Notes: HP—Hot-pressing process; ν—Velocity of AFP; P—Pres-sure of the forming process of AFP and HP; Th—Temperature of the hot-pressing process; th—Pressurization time of the hot-pressing process. -

[1] 王凯, 刘寒松, 肇研. 连续纤维增强热塑性树脂基复合材料自动铺放技术研究进展[J]. 航空制造技术, 2021, 64(11):41-49.WANG Kai, LIU Hansong, ZHAO Yan. Research progress of automatic lay-up technology for continuous fiber reinforced thermoplastic resin matrix composites[J]. Aeronautical Manufacturing Technology,2021,64(11):41-49(in Chinese). [2] 文立伟, 肖军, 王显峰, 等. 中国复合材料自动铺放技术研究进展[J]. 南京航空航天大学学报, 2015, 47(5):637-649. doi: 10.16356/j.1005-2615.2015.05.003WEN Liwei, XIAO Jun, WANG Xianfeng, et al. Research progress of automatic lay-up technology for composite materials in China[J]. Journal of Nanjing University of Aeronautics and Astronautics,2015,47(5):637-649(in Chinese). doi: 10.16356/j.1005-2615.2015.05.003 [3] BAHO O, AUSIAS G, GROHENS Y, et al. Simulation of laser heating distribution for a thermoplastic composite: Effects of AFP head parameters[J]. International Journal of Advanced Manufacturing Technology,2020,110(7-8):2105-2117. doi: 10.1007/s00170-020-05876-9 [4] ZAAMI A, BARAN I, BOR T C, et al. New process optimization framework for laser assisted tape winding of composite pressure vessels: Controlling the unsteady bonding temperature[J]. Materials & Design,2020,196:109130. [5] HOSSEINI S M A, SCHÄKEL M, BARAN I, et al. A new global kinematic-optical-thermal process model for laser-assisted tape winding with an application to helical-wound pressure vessel[J]. Materials & Design,2020,193:108854. [6] REICHARDT J, BARAN I, AKKERMAN R. New analytical and numerical optical model for the laser assisted tape winding process[J]. Composites Part A: Applied Science and Manufacturing, 2018, 107: 647-656. [7] CLANCY G, PEETERS D, OLIVERI V, et al. A study of the influence of processing parameters on steering of carbon fibre/PEEK tapes using laser-assisted tape placement[J]. Composites Part B: Engineering, 2019, 163: 243-251. [8] OROMIEHIE E, GAIN A K, PRUSTY B G. Processing parameter optimisation for automated fibre placement (AFP) manufactured thermoplastic composites[J]. Composite Structures,2021,272:114223. doi: 10.1016/j.compstruct.2021.114223 [9] 赵尧旭. 热塑性复合材料机器人铺放设备及工艺研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.ZHAO Yaoxu. Research on robotic lay-up equipment and process of thermoplastic composites[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [10] WEN L W, SUN T F, NI J H, et al. Infrared heating technology for automated fiber placement[J]. Transactions of Nanjing University of Aeronautics and Astronautics,2015,32(6):631-638. doi: 10.16356/j.1005-1120.2015.06.631 [11] TANABE D, IMAMURA S, NISHIYABU K, et al. Effects of near-infrared heating and high frequency induction roller heating in continuous tape layup molding of CFRTP[J]. Transactions of the JSME (in Japanese),2016,82(843):16-00115. doi: 10.1299/transjsme.16-00115 [12] VENKATESAN C, VELU R, VAHEED N, et al. Effect of process parameters on polyamide-6 carbon fibre prepreg laminated by IR-assisted automated fibre placement[J]. The International Journal of Advanced Manufacturing Technology,2020,108(4):1275-1284. doi: 10.1007/s00170-020-05230-z [13] DELL’ANNA R, LIONETTO F, MONTAGNA F, et al. Lay-up and consolidation of a composite pipe by in situ ultrasonic welding of a thermoplastic matrix composite tape[J]. Materials,2018,11(5):786. doi: 10.3390/ma11050786 [14] RIZZOLO R H, WALCZYK D F. Ultrasonic consolidation of thermoplastic composite prepreg for automated fiber placement[J]. Journal of Thermoplastic Composite Materials,2016,29(11):1480-1497. doi: 10.1177/0892705714565705 [15] WILLIAMS D, BROWN M. Xenon flashlamp heating for automated fibre placement[C]//Automated Composites Manufacturing-Third International Symposium. Montreal, Canada, 2017. [16] 宋清华, 肖军, 文立伟, 等. 热塑性复合材料自动纤维铺放装备技术[J]. 复合材料学报, 2016, 33(6):1214-1222.SONG Qinghua, XIAO Jun, WEN Liwei, et al. Automatic fiber placement equipment technology for thermoplastic composites[J]. Acta Materiae Compositae Sinica,2016,33(6):1214-1222(in Chinese). [17] 陈吉平, 李岩, 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成形技术的航空发展现状[J]. 复合材料学报, 2019, 36(4):784-794.CHEN Jiping, LI Yan, LIU Weiping, et al. Current status of aerospace development of automatic lay-up in-situ molding technology for continuous fiber-reinforced thermoplastic resin matrix composites[J]. Acta Materiae Compositae Sinica,2019,36(4):784-794(in Chinese). [18] ENGELHARDT R, IRMANPUTRA R, BRATH K, et al. Thermoset prepreg compaction during automated fiber placement and vacuum debulking[J]. Procedia CIRP,2019,85:153-158. doi: 10.1016/j.procir.2019.09.025 [19] WANG H, WANG W W, WANG H J, et al. Thermal management for thermoset automated fiber placement based on infrared heater structure arrangement[J]. Chinese Journal of Aeronautics, 2022, 1: 173-183. [20] HÖRMANN P, STELZL D, LICHTINGER R, et al. On the numerical prediction of radiative heat transfer for thermoset automated fiber placement[J]. Composites Part A: Applied Science and Manufacturing,2014,67:282-288. doi: 10.1016/j.compositesa.2014.08.019 [21] BUIJS J, NEDERVEEN P J. A study of consolidation in filament winding with thermoplastic prepregs[J]. Journal of Thermoplastic Composite Materials,1992,5(4):276-286. doi: 10.1177/089270579200500401 [22] PITCHUMANI R, GILLESPIE JR J W, LAMONTIA M A. Design and optimization of a thermoplastic tow-placement process with in-situ consolidation[J]. Journal of Composite Materials,1997,31(3):244-275. doi: 10.1177/002199839703100302 [23] JANSSEN H, PETERS T, BRECHER C. Efficient production of tailored structural thermoplastic composite parts by combining tape placement and 3D printing[J]. Procedia CIRP,2017,66:91-95. doi: 10.1016/j.procir.2017.02.022 [24] 宋清华. 热塑性复合材料自动铺放过程温度场分析及构件性能研究[D]. 南京: 南京航空航天大学, 2016.SONG Qinghua. Temperature field analysis and component performance study of thermoplastic composites during automatic lay-up[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016(in Chinese). [25] 宋清华, 刘卫平, 肖军, 等. 热塑性复合材料自动铺放过程中红外加热技术研究[J]. 材料工程, 2019, 47(1):77-83. doi: 10.11868/j.issn.1001-4381.2017.000346SONG Qinghua, LIU Weiping, XIAO Jun, et al. Research on infrared heating technology in automatic lay-up process of thermoplastic composites[J]. Materials Engineering,2019,47(1):77-83(in Chinese). doi: 10.11868/j.issn.1001-4381.2017.000346 [26] 郑兵. 编织碳纤维增强热塑性复合材料热压-注塑整体化成形关键技术[D]. 武汉: 华中科技大学, 2019.ZHENG Bing. Key technologies for hot-pressing-injection molding of braided carbon fiber reinforced thermoplastic composites[D]. Wuhan: Huazhong University of Science and Technology, 2019(in Chinese). [27] American Society for Testing and Materials. Standard test method for tensile properties of polymer matrix composites materials: ASTM D3039[S]. West Conshohocken: ASTM International, 2017. [28] American Society for Testing and Materials. Standard test method for flexural properties of polymer matrix composites materials: ASTM D7264[S]. West Conshohocken: ASTM International, 2021. [29] American Society for Testing and Materials. Standard test method for short-beam strength of polymer matrix composites materials and their laminates: ASTM D2344[S]. West Conshohocken: ASTM International, 2016. [30] SAENZ-CASTILLO D, MARTÍN M I, CALVO S, et al. Effect of processing parameters and void content on mechanical properties and NDI of thermoplastic composites[J]. Composites Part A: Applied Science and Manufacturing,2019,121:308-320. doi: 10.1016/j.compositesa.2019.03.035 [31] American Society for Testing and Materials. American standard test methods for void content of reinforced plastics: ASTM D2374[S]. West Conshohocken: ASTM International, 2016. [32] 周健, 李茂东, 杨燕青, 等. 石墨烯/聚丙烯复合材料力学性能, 结晶行为与微观结构[J]. 江苏理工学院学报, 2019, 25(6):1-7. doi: 10.3969/j.issn.1674-8522.2019.06.001ZHOU Jian, LI Maodong, YANG Yanqing, et al. Mechanical properties, crystallization behavior and microstructure of graphene/polypropylene composites[J]. Journal of Jiangsu Institute of Technology,2019,25(6):1-7(in Chinese). doi: 10.3969/j.issn.1674-8522.2019.06.001 [33] MIAO Q, DAI Z, MA G, et al. Effect of consolidation force on interlaminar shear strength of CF/PEEK laminates manufactured by laser-assisted forming[J]. Composite Structures,2021,266:113779. doi: 10.1016/j.compstruct.2021.113779 [34] 刘鑫. 热塑性预浸带自动铺放制品缺陷探究及等温结晶工艺优化研究[D]. 北京: 北京化工大学, 2021.LIU Xin. Exploration of defects in automatic lay-up products of thermoplastic prepreg tape and optimization of isothermal crystallization process[D]. Beijing: Beijing University of Chemical Technology, 2021(in Chinese). [35] COMER A J, RAY D, OBANDE W O, et al. Mechanical characterisation of carbon fibre-PEEK manufactured by laser-assisted automated-tape-placement and autoclave[J]. Composites Part A: Applied Science and Manufacturing,2015,69:10-20. doi: 10.1016/j.compositesa.2014.10.003 [36] 廉伟. 民用飞机复合材料结构孔隙率的影响及测量[C]//中国航空学会. 北京: 中国航空学会, 2014.LIAN Wei. Influence and detection of porosity of civil aircraft composite structures[C]//Chinese Aeronautical Society. Beijing: Chinese Aeronautical Society, 2014(in Chinese). [37] 孙守政, 赵尧旭, 王扬, 等. 热塑性复合材料机器人铺放系统设计及工艺优化研究[J]. 机械工程学报, 2021, 57(23): 209-219.SUN Shouzheng, ZHAO Yaoxu, WANG Yang, et al. Design and process optimization of robotic lay-up system for thermoplastic composites[J]. Journal of Mechanical Engineering, 2021, 57(23): 209-219(in Chinese). -

下载:

下载: