Preparation and modification of nano-TiO2 and its application in polymer matrix composites research progress

-

摘要: 基于纳米二氧化钛 (TiO2) 作为添加剂制备的复合材料具有优异的耐温性、抗老化性等,而且由于其特殊的光催化活性,在通过吸收紫外光能量后具有较强的抗菌杀菌能力,因此在涂料、化妆品和医学等领域具有广泛的应用。然而,受纳米尺寸效应影响,纳米TiO2在聚合物基体中存在易团聚、难分散的缺点,使其应用受到限制。因此,需要通过多种表面改性方法调控纳米TiO2的表面性质,增强其与聚合物基体相容性。本论文首先详细阐述了纳米TiO2的制备、表面改性方法及机制,并综述了近期纳米TiO2改性聚合物基复合材料方面的研究进展。最后,讨论了纳米TiO2聚合物复合材料研究中存在的主要问题,并展望了其未来的发展方向。Abstract: The composite materials prepared based on the titanium dioxide (TiO2) nanoparticles as additives have excellent heat resistance, aging resistance, etc. The TiO2 nanoparticles have special photocatalytic activity, such as, it has strong antibacterial and bactericidal ability after absorbing ultraviolet energy. Currently, TiO2 nanoparticles have a wide range of applications in various fields of coatings, cosmetics and medicine. However, affected by the nano-dimensional effect, the TiO2 nanoparticles in the polymer matrix have the disadvantages of being easy to agglomerate and difficult to disperse, which limits its application. Therefore, it is necessary to regulate the surface properties of nano-TiO2 by various surface modification methods to enhance its compatibility with the polymer matrix. This paper first described the preparation, surface modification method and mechanism of TiO2 nanoparticles in detail, subsequently, and the research progress on the TiO2 nanoparticles modified polymer compound composite material is reviewed in the recent years. Finally, this paper discussed the TiO2 nanoparticles exist problems in the research of polymer composites, and prospected its development direction in the future.

-

Key words:

- nano-TiO2 /

- surface modification /

- aggregation /

- polymers /

- nanocomposites

-

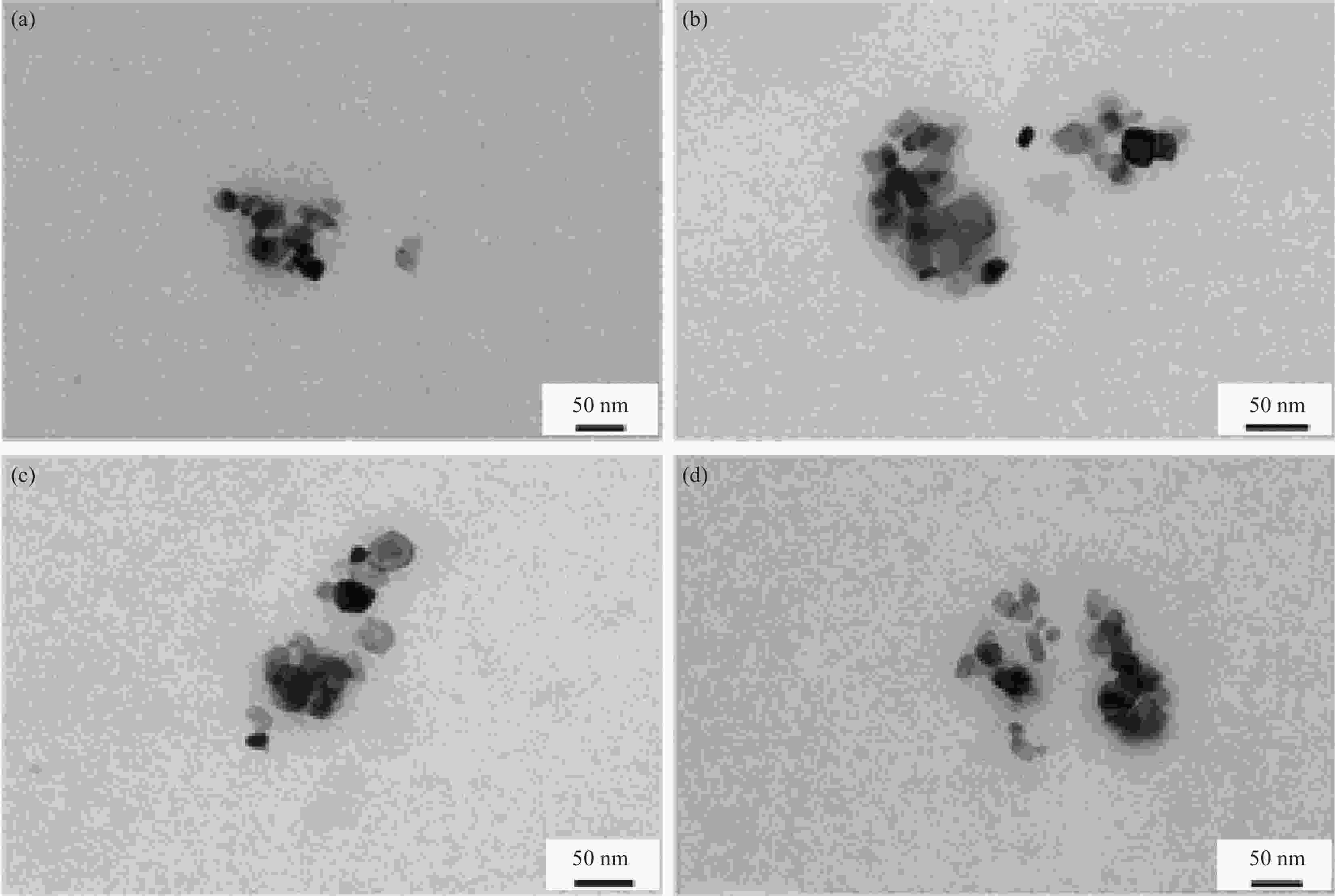

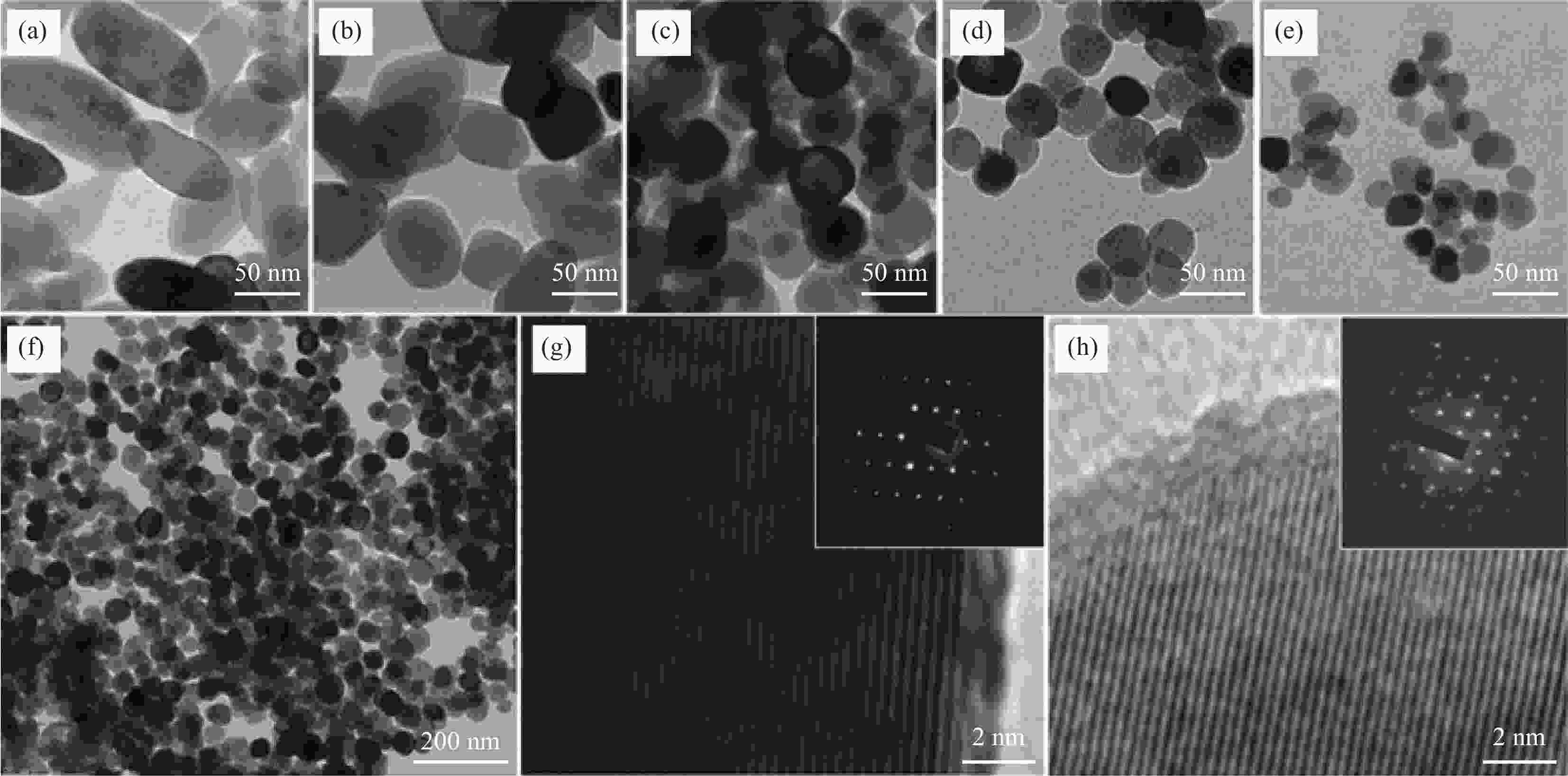

图 1 ((a)~(e)) 乙醇体积占比为0.1、0.3、0.5、0.7、0.85时制备纳米TiO2粒径为100、65、50、40、30 nm的TEM图像; (f) 50 nm TiO2的低放大TEM图像; ((g), (h)) 50 nm和 65 nm TiO2选定区域电子衍射 (SAED) 图像[45]

Figure 1. ((a)-(e)) TEM images of ethanol volume ratio of 0.1, 0.3, 0.5, 0.7, 0.85 were prepared with 100, 65, 50, 40, 30 nm particle size; (f) Low magnification TEM images of 50 nm TiO2; ((g), (h)) Electron diffraction patterns of selected regions (SAED) of 50 nm TiO2 and 65 nm TiO2[45]

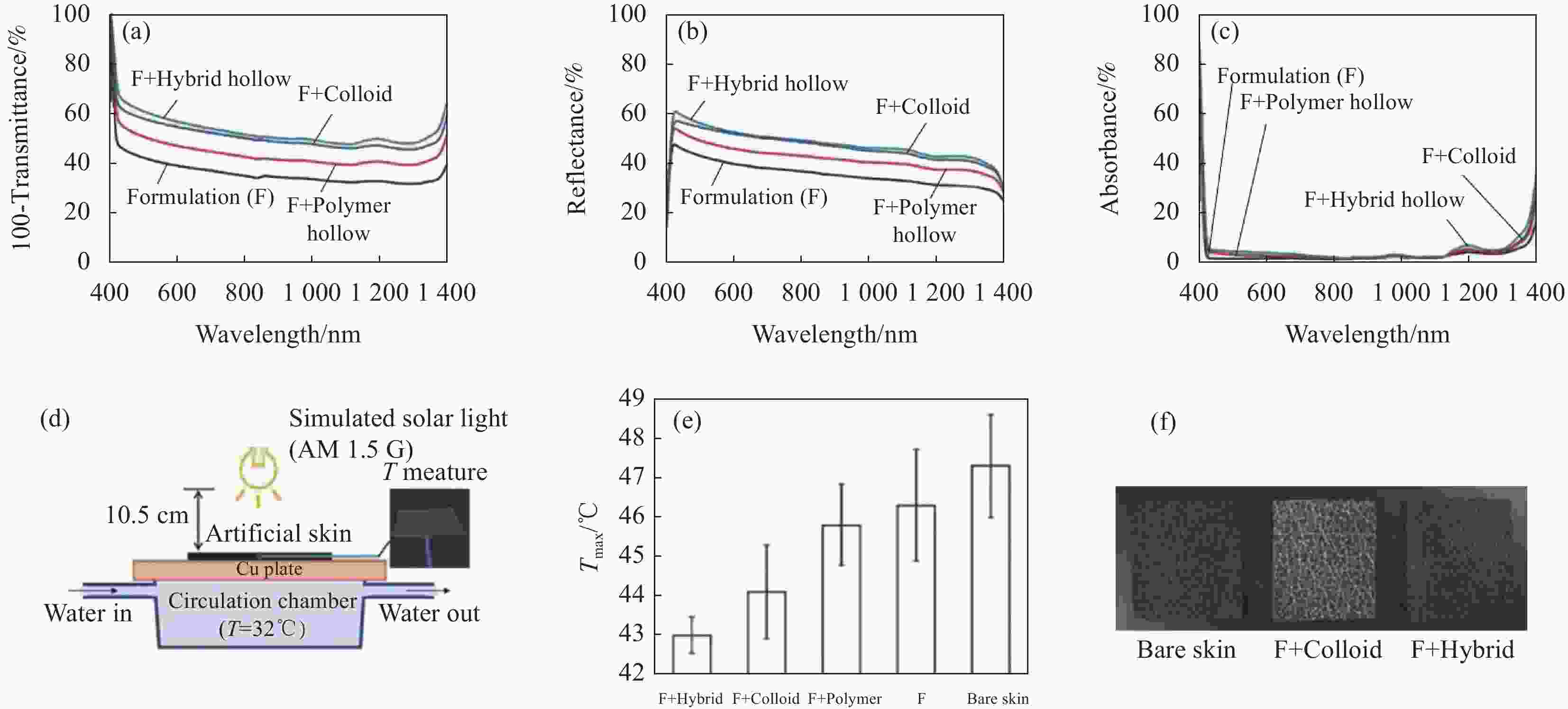

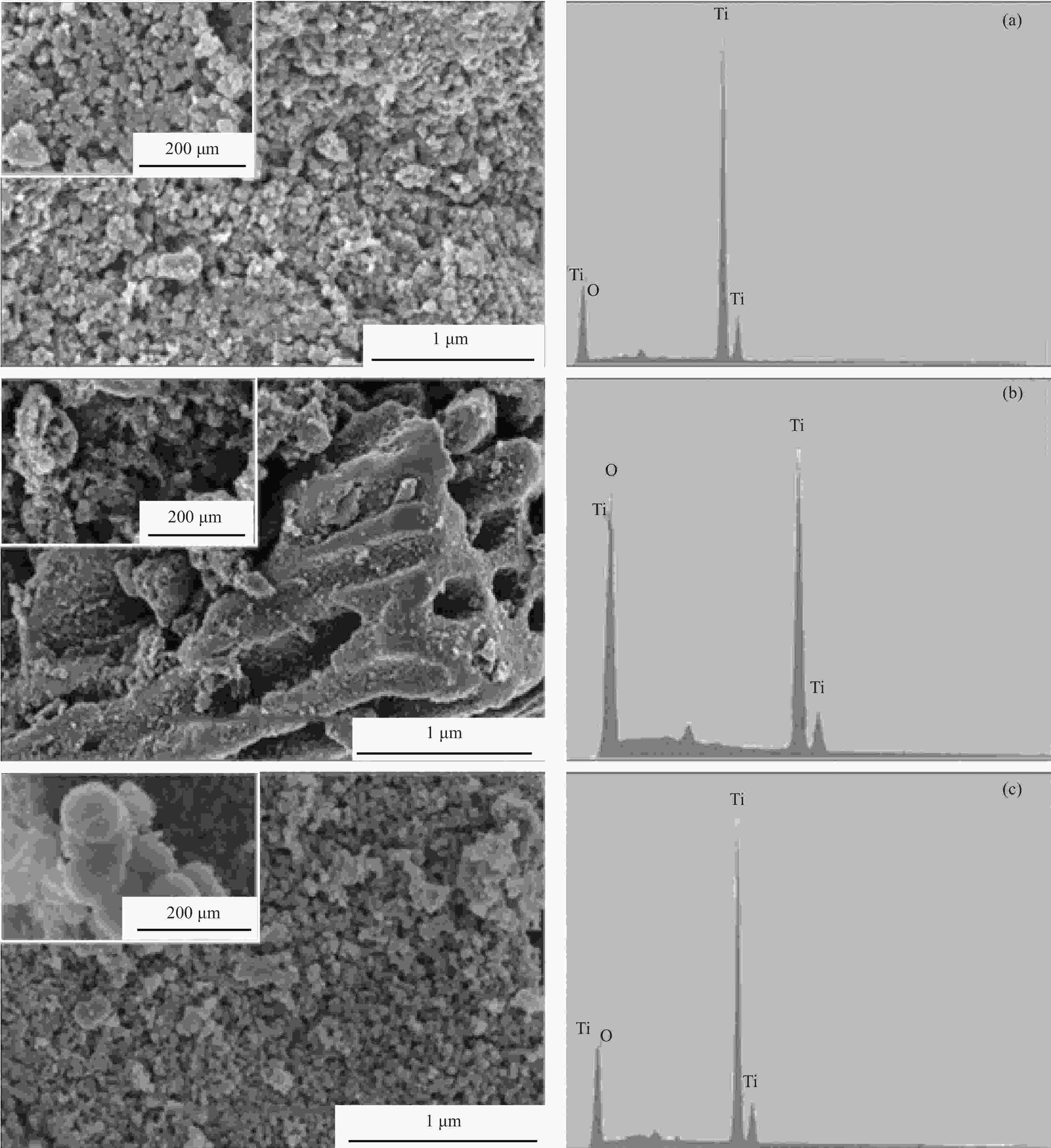

图 2 含有不同颗粒样品的消光光谱 (a)、反射光谱 (b) 和吸收光谱 (c);(d) 测量人造皮肤表面温度装置图;模拟阳光照射300 s后,人造皮肤达到最高平衡温度 (e) 和未进行任何处理/使用含有TiO2@Al(OH)3胶体和混合空心粒子的化妆品配方后人造皮肤外观 (f)[54]

Figure 2. Extinction (a), reflectance (b) and absorption spectra of the cosmetic formulations containing various particles (c); (d) Diagram of device for measuring surface temperature of artificial skin; Maximum equilibrium temperatures of the artificial skin reached after 300 s illumination of the simulated sunlight (e) and artificial skin appearances under no treatment, and after applying the cosmetic formulations containing TiO2@Al(OH)3 colloids and hybrid hollow particles (f)[54]

AM 1.5 G—Global spectrum; T—Temperature; Tmax—Maximum equilibrium temperatures of the artificial skin reached after 300 s illumination of the simulated sunlight

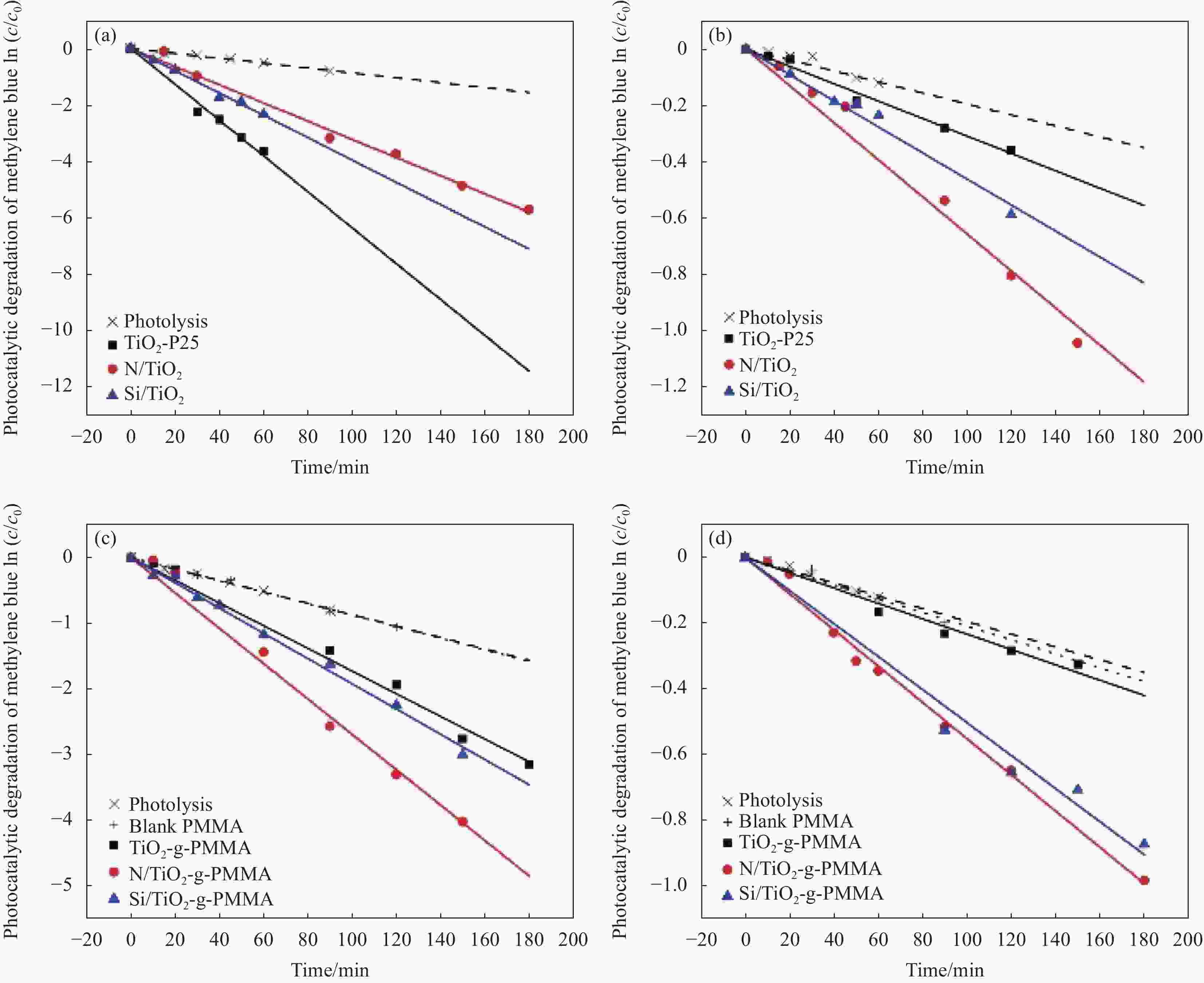

图 3 样品改性前后在紫外光((a), (c))和可见光((b), (d))照射下降解亚甲基蓝的反应活性图[56]

Figure 3. Reaction activity of powder samples under UV ((a), (c)) and visible light ((b), (d)) irradiation grafted film for methylene blue degradation[56]

PMMA—Poly(methyl methacrylate); P25—Average particle size is 25 nm; c0—Concentration of methylene blue at initial time; c—Concentration of methylene blue at t time

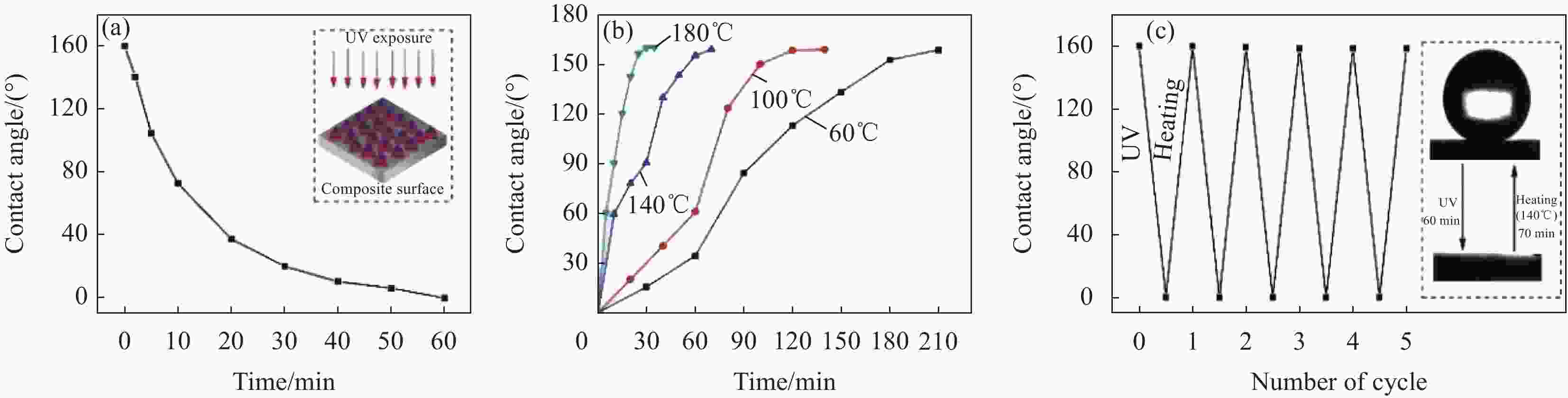

图 5 (a) 接触角 (CA) 与UV辐照时间的关系;(b)复合材料表面CA随加热时间的变化;(c)复合材料表面在紫外线照射和加热下可逆的超疏水-超亲水性切换[69]

Figure 5. (a) Relationship between contact angle (CA) and UV irradiation time; (b) Variations in the CA of the composite surface with heating time; (c) Reversible superhydrophobicity-superhydrophilicity switching of the composite surface under UV irradiation and heating[69]

表 1 全氟化膜(Nafion-117)为基准测试膜的拉伸强度、吸水率、氧化稳定性、离子电导率和BH4–渗透性[59]

Table 1. Tensile strength, water uptake, oxidative stability, ionic conductivity and BH4– permeability of the prepared membranes and benchmark Nafion macromolecule (Nafion-117)[59]

Membrane Tensile

strength/MPaWater

uptake/%Oxidative

stability/%Ionic conductivity/

(mS·cm−1)BH4– permeability/(cm2·s−1) PVA-PEO-PVP 2.7 >100 81 13.1 2.10×10−5 PVA-PEO-PVP/SPTO-1.0wt% 10.6 47 81 14.4 6.30×10−6 PVA-PEO-PVP/SPTO-2.5wt% 12.3 14 99 15.6 0.41×10−6 PVA-PEO-PVP/SPTO-5wt% 17.2 11 98 16.0 0.12×10−6 Nafion-117 25.0 15 92 45.0 0.40×10−6 Notes: PVA—Poly(vinyl alcohol); PEO—Ethylene oxide; PVP—Vinyl pyrrolidone; SPTO—Sulphated and phosphated titanium dioxide; SPTO-1.0wt%, SPTO-2.5wt%, SPTO-5wt%—Amount of SPTO added is 1wt%, 2.5wt% and 5wt%. -

[1] ALI N, SAID A, ALI F, et al. Development and characterization of functionalized titanium dioxide-reinforced sulfo-nated copolyimide (SPI/TiO2) nanocomposite membranes with improved mechanical, thermal, and electrochemical properties [J]. Journal of Inorganic and Organometallic Polymers and Materials, 2020, 30(11): 4585-4596. [2] MOHANAPRIYA M K, DESHMUKH K, KADLEC J, et al. Dynamic mechanical analysis and broadband electromagnetic interference shielding characteristics of poly (vinyl alcohol)-poly(4-styrenesulfonic acid)-titanium dioxide nanoparticles based tertiary nanocomposites [J]. Polymer-Plastics Technology and Materials, 2020, 59(8): 847-863. [3] SUN Y C, D'CUNHA J, NAGUIB H E. Microcellular structure assisted phase transformation of polyvinylidene fluoride/titanium dioxide nanocomposites [J]. Journal of Cellular Plastics, 2021, 57(4): 545-562. [4] SHIRDAR M R, FARAJPOUR N, SHAHBAZIAN-YASSAR R, et al. Nanocomposite materials in orthopedic applications[J]. Frontiers of Chemical Science and Engineering, 2019, 13(1): 1-13. [5] LI M, HONG Y, YU H, et al. A novel high solar reflective coating based on potassium silicate for track slab in high-speed railway[J]. Construction and Building Materials, 2019, 225: 900-908. [6] ZHOU H, SUN S, DING H. Surface organic modification of TiO2 powder and relevant characterization [J]. Advances in Materials Science and Engineering, 2017, 2017: 9562612. [7] HE X L, PU Y, WANG J X, et al. Surface engineering of titanium dioxide nanoparticles for silicone-based transparent hybrid films with ultrahigh refractive indexes[J]. Langmuir, 2021, 37(8): 2707-2713. [8] YU M Z, WU L N, MIAO J N, et al. Titanium dioxide and polypyrrole molecularly imprinted polymer nanocompo-sites based electrochemical sensor for highly selective detection of p-nonylphenol[J]. Analytica Chimica Acta, 2019, 1080: 84-94. [9] LIANG F, FAN Y J, KUANG S Y, et al. Layer-by-layer assembly of nanofiber/nanoparticle artificial skin for strain-insensitive UV shielding and visualized UV detection[J]. Advanced Materials Technologies, 2020, 5(4): 1900976. [10] JEON J P, KWEON D H, JANG B J, et al. Enhancing the photocatalytic activity of TiO2 catalysts[J]. Advanced Sustainable Systems, 2020, 4(12): 2000197. [11] ANDRONIC L, ENESCA A. Black TiO2 synthesis by chemical reduction methods for photocatalysis applications [J]. Frontiers in Chemistry, 2020, 8: 565489. [12] WU S, HU H, LIN Y, et al. Visible light photocatalytic degradation of tetracycline over TiO2[J]. Chemical Engi-neering Journal, 2020, 382: 122842. [13] BUGAKOVA D, SLABOV V, SERGEEVA E, et al. Comprehensive characterization of TiO2 inks and their application for inkjet printing of microstructures[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 586: 124146. [14] WANG C L, YAN K, LUO X, et al. Preparation of polyurethane acrylate-based titanium dioxide pigment and its use in blue light-curable ink [J]. Coloration Technology, 2021, 137(4): 348-360. [15] POURHASHEM S, DUAN J, GUAN F, et al. New effects of TiO2 nanotube/g-C3N4 hybrids on the corrosion protection performance of epoxy coatings [J]. Journal of Molecular Liquids, 2020, 317: 114214. [16] GONZALEZ-CALDERON J A, PÉREZ-PÉREZ C, PÉREZ RODRÍGUEZ R Y, et al. Silanization of di-n-octyldichlorosi-lane as a route to improve the integration of titanium dio-xide in polypropylene [J]. Journal of Thermal Analysis and Calorimetry, 2019, 138(2): 1069-1079. [17] RAEISI M, KAZEROUNI Y, MOHAMMADI A, et al. Superhydrophobic cotton fabrics coated by chitosan and titanium dioxide nanoparticles with enhanced antibacterial and UV-protecting properties [J]. International Journal of Biologi-cal Macromolecules, 2021, 171: 158-165. [18] CAO C, WANG Y, ZHENG S, et al. Poly (butylene adipate-co-terephthalate)/titanium dioxide/silver composite biofilms for food packaging application [J]. LWT, 2020, 132: 109874. [19] TREEKAMOL Y, SCHIEDA M, HERRMANN-GEPPERT I, et al. Optimized photoactive coatings prepared with functionalized TiO2 [J]. International Journal of Hydrogen Energy, 2019, 44(60): 31800-31807. [20] PURCAR V, RADITOIU V, DUMITRU A, et al. Antireflective coating based on TiO2 nanoparticles modified with coupling agents via acid-catalyzed sol-gel method [J]. Applied Surface Science, 2019, 487: 819-824. [21] CHEN X D, WANG Z, LIAO Z F, et al. Roles of anatase and rutile TiO2 nanoparticles in photooxidation of polyurethane [J]. Polymer Testing, 2007, 26(2): 202-208. [22] CHEN P Q, WEI B Z, ZHU X, et al. Fabrication and characterization of highly hydrophobic rutile TiO2-based coatings for self-cleaning [J]. Ceramics International, 2019, 45(5): 6111-6118. [23] CAZAN C, ENESCA A, ANDRONIC L. Synergic effect of TiO2 filler on the mechanical properties of polymer nanocomposites [J]. Polymers, 2021, 13(12): 2017. [24] LIU Y, YANG T, ZHANG B, et al. Structural insight in the interfacial effect in ferroelectric polymer nanocomposites [J]. Advanced Materials, 2020, 32(49): 2005431. [25] FENG M N, HUANG Y M, CHENG T, et al. Synergistic effect of graphene oxide and carbon nanotubes on sulfonated poly(arylene ether nitrile)-based proton conducting membranes [J]. International Journal of Hydrogen Energy, 2017, 42(12): 8224-8232. [26] ALI N, ALI F, SAEED S, et al. Structural characteristics and electrochemical properties of sulfonated polyimide clay-based composite fabricated by a solution casting method [J]. Journal of Materials Science: Materials in Electronics, 2019, 30(21): 19164-19172. [27] NGUYEN T C, NGUYEN T D, VU D T, et al. Modification of titanium dioxide nanoparticles with 3-(trimethoxysilyl)propyl methacrylate silane coupling agent [J]. Journal of Chemistry, 2020, 2020: 1381407. [28] VASUDEVAN S, FULLERTON-SHIREY S K. Effect of nanoparticle shape on the electrical and thermal properties of solid polymer electrolytes [J]. Journal of Physical Che-mistry C, 2019, 123(17): 10720-10726. [29] THOMASON J. A review of the analysis and characterisation of polymeric glass fibre sizings [J]. Polymer Testing, 2020, 85: 106421. [30] ZINDANI D, KUMAR K. An insight into additive manufacturing of fiber reinforced polymer composite [J]. International Journal of Lightweight Materials and Manufacture, 2019, 2(4): 267-278. [31] DEMIRCI S, SUNOL A K, SAHINER N. Catalytic activity of amine functionalized titanium dioxide nanoparticles in methanolysis of sodium borohydride for hydrogen generation [J]. Applied Catalysis B: Environmental, 2020, 261: 118242. [32] RAHIMI N, PAX R A, GRAY E M. Review of functional titanium oxides. I: TiO2 and its modifications [J]. Progress in Solid State Chemistry, 2016, 44(3): 86-105. [33] MARCHAND R, BROHAN L, TOURNOUX M. TiO2(B) a new form of titanium dioxide and the potassium octatitanate K2Ti8O17[J]. Materials Research Bulletin, 1980, 15(8): 1129-1133. [34] WANG Z M, WANG K, PENG X Y, et al. Comparative study of ultraviolet light and visible light on the photo-assisted conductivity and gas sensing property of TiO2 [J]. Sensors and Actuators B-Chemical, 2017, 248: 724-732. [35] TAO J J, MA H P, YUAN K P, et al. Modification of 1D TiO2 nanowires with gaoxny by atomic layer deposition for TiO2@GaOxNy core-shell nanowires with enhanced photoelectrochemical performance [J]. Nanoscale, 2020, 12(13): 7159-7173. [36] LI N, XU Z, ZHENG S, et al. Superamphiphilic TiO2 composite surface for protein antifouling [J]. Advanced Materials, 2021, 33(25): 2003559. [37] WANG L, JIANG X, WANG C, et al. Titanium dioxide grafted with silane coupling agents and its use in blue light curing ink [J]. Coloration Technology, 2019, 136(1): 15-22. [38] RAHIMINEZHAD-SOLTANI M, SABERYAN K, SIMCHI A. New insight into reaction mechanisms of TiCl4 for the synthesis of TiO2 nanoparticles in H2O-assisted atmospheric-pressure CVS process [J]. Materials Science and Engi-neering: B, 2021, 264: 114958. [39] REN L, LI Y, HOU J, et al. Fabrication and cavity-size-dependent photocatalytic property of TiO2 hollow nanoparticles with tunable cavity size [J]. Materials Research Bulletin, 2020, 126: 110744. [40] FARHADIAN AZIZI K, BAGHERI-MOHAGHEGHI M M. The effect of solution flow rate and substrate temperature on structural and optical properties of TiO2 films deposited by spray pyrolysis technique [J]. Thin Solid Films, 2017, 621: 98-101. [41] ZHANG Q, LI C. High temperature stable anatase phase titanium dioxide films synthesized by mist chemical vapor deposition [J]. Nanomaterials, 2020, 10(5): 911. [42] RAHIMINEZHAD-SOLTANI M, SABERYAN K, SIMCHI A, et al. New approaches in lowering the gas-phase synthesis temperature of TiO2 nanoparticles by H2O-assisted atmospheric pressure cvs process [J]. Journal of Materials Research and Technology, 2019, 8(3): 3024-3035. [43] WANG C, SHENG X, XIE D, et al. High-performance TiO2/polyacrylate nanocomposites with enhanced thermal and excellent UV-shielding properties [J]. Progress in Organic Coatings, 2016, 101: 597-603. [44] KOTSOKECHAGIA T, CELLESI F, THOMAS A, et al. Prepa-ration of ligand-free TiO2 (anatase) nanoparticles through a nonaqueous process and their surface functionalization [J]. Langmuir, 2008, 24(13): 6988-6997. [45] SUNG S D, OJHA D P, YOU J S, et al. 50 nm Sized spherical TiO2 nanocrystals for highly efficient mesoscopic perovskite solar cells [J]. Nanoscale, 2015, 7(19): 8898-8906. [46] XIAO Y, WANG C, KONDAMAREDDY K K, et al. Efficient electron transport scaffold made up of submicron TiO2 spheres for high-performance hole-transport material free perovskite solar cells [J]. ACS Applied Energy Materials, 2018, 1(10): 5453-5462. [47] BI X, DU G, SUN D, et al. Room-temperature synthesis of yellow TiO2 nanoparticles with enhanced photocatalytic properties [J]. Applied Surface Science, 2020, 511: 145617. [48] KHAN S, PARK B I, HAN J S, et al. Flame synthesized Y2O3:Tb3+-Yb3+ phosphors as spectral convertors for solar cells [J]. Research on Chemical Intermediates, 2018, 44(8): 4619-4632. [49] KHAN S, YAIRI T. A review on the application of deep learning in system health management [J]. Mechanical Systems and Signal Processing, 2018, 107: 241-265. [50] AGUSTIN A R, TAMURA K. Surface modification of TiO2 nanoparticles with terephthalic acid in supercritical carbon dioxide [J]. Journal of Supercritical Fluids, 2021, 174: 9. [51] KONG L, LI Z C, HUANG S Q, et al. Boosting photocatalytic performance and stability of CuInS2/ZnS-TiO2 heterostructures via sol-gel processed integrate amorphous titania gel [J]. Applied Catalysis B-Environmental, 2017, 204: 403-410. [52] SEOK T J, LIU Y H, JUNG H J, et al. Field-effect device using quasi-two-dimensional electron gas in mass-producible atomic-layer-deposited Al2O3/TiO2 ultrathin (<10 nm) film heterostructures [J]. ACS Nano, 2018, 12(10): 10403-10409. [53] LIU F, LIU G. TiO2-SiO2 composite nanoparticles containing hindered amine light stabilizers encapsulated by MMA-PMPM copolymers[J]. Iranian Polymer Journal,2017,26(10):785-795. doi: 10.1007/s13726-017-0564-7 [54] HAN N, KIM M G, KIM S W, et al. Enhanced near-infrared shielding and light scattering using surface-roughened hybrid hollow microparticles synthesized with polymer and TiO2@Al(OH)3 for cosmetic applications [J]. Particle & Particle Systems Characterization, 2018, 35(6): 1800057. [55] LIN Y M, JIANG Z Y, ZHU C Y, et al. The electronic structure, optical absorption and photocatalytic water splitting of (Fe plus Ni)-codoped TiO2: A DFT + U study [J]. International Journal of Hydrogen Energy, 2017, 42(8): 4966-4976. [56] KLAYSRI R, PREECHAWAN V, THAMMACHAI N, et al. Photocatalytic activity of nitrogen and silica doping on TiO2 nanocatalyst and grafted onto pmma film [J]. Materials Chemistry and Physics, 2018, 211: 420-427. [57] DHANDOLE L K, MAHADIK M A, KIM S G, et al. Boosting photocatalytic performance of inactive rutile TiO2 nano-rods under solar light irradiation: Synergistic effect of acid treatment and metal oxide co-catalysts [J]. ACS Applied Materials & Interfaces, 2017, 9(28): 23602-23613. [58] LI Z J, QU Y, HU K, et al. Improved photoelectrocatalytic activities of biocl with high stability for water oxidation and mo degradation by coupling RGO and modifying phosphate groups to prolong carrier lifetime [J]. Applied Catalysis B-Environmental, 2017, 203: 355-362. [59] GOUDA M H, GOUVEIA W, ELESSAWY N A, et al. Simple design of pva-based blend doped with SO4(PO4)-functionalised TiO2 as an effective membrane for direct borohydride fuel cells [J]. International Journal of Hydrogen Energy, 2020, 45(30): 15226-15238. [60] AZIZ T, ULLAH A, FAN H, et al. Recent progress in silane coupling agent with its emerging applications [J]. Journal of Polymers and the Environment, 2021, 29(11): 3427-3443. [61] ZHONG H, HU Y, WANG Y H, et al. TiO2/silane coupling agent composed two layesrs structure: A novel stability super-hydrophilic self-cleaning coating applied in PV panels [J]. Applied Energy. 2017, 204: 932-938. [62] XIE J, PAN X B, WANG M Y, et al. The role of surface modification for TiO2 nanoparticles in cancer cells [J]. Colloids and Surfaces B-Biointerfaces, 2016, 143: 148-155. [63] HUANG C, HUANG Z X, LV X S, et al. Surface modification of hollow glass microsphere with different coupling agents for potential applications in phenolic syntactic foams [J]. Journal of Applied Polymer Science, 2017, 134(4): 14. [64] SILVEIRA-HORNUNG P, ÁVILA S, APEA-BAH F B, et al. Sustainable use of ilex paraguariensis waste in improving biodegradable corn starch films’ mechanical, thermal and bioactive properties [J]. Journal of Polymers and the Envi-ronment, 2020, 28(6): 1696-1709. [65] KHATTAK N S, AHMAD A S, SHAH L A, et al. Thermal and rheological study of nanocomposites, reinforced with Bi-phase ceramic nanoparticles [J]. Zeitschrift Für Physikalische Chemie, 2019, 233(9): 1233-1246. [66] AHMED N, FAN H, DUBOIS P, et al. Nano-engineering and micromolecular science of polysilsesquioxane materials and their emerging applications [J]. Journal of Materials Chemistry A, 2019, 7(38): 21577-21604. [67] ZHENG W, TANG C, XIE J, et al. Micro-scale effects of nano-SiO2 modification with silane coupling agents on the cellulose/nano-SiO2 interface [J]. Nanotechnology, 2019, 30(44): 445701. [68] NAKAMURA T, TABUCHI H, HIRAI T, et al. Effects of silane coupling agent hydrophobicity and loading method on water absorption and mechanical strength of silica particle-filled epoxy resin [J]. Journal of Applied Polymer Science, 2020, 137(17): 48615. [69] QING Y Q, YANG C N, YU N N, et al. Superhydrophobic TiO2/polyvinylidene fluoride composite surface with reversible wettability switching and corrosion resistance [J]. Chemical Engineering Journal, 2016, 290: 37-44. [70] YANG D, RUAN M N, HUANG S, et al. Improved electromechanical properties of nbr dielectric composites by poly(dopamine) and silane surface functionalized TiO2 nanoparticles [J]. Journal of Materials Chemistry C, 2016, 4(33): 7724-7734. [71] SHI Y, ZHANG Q, LIU Y, et al. Preparation of amphiphilic TiO2 janus particles with highly enhanced photocatalytic activity [J]. Chinese Journal of Catalysis, 2019, 40(5): 786-794. [72] ROY K, SIKDAR D, MANDAL S K, et al. Surface modification of nano titanium dioxide (TiO2) by cationic surfac-tants and investigation of its effect on the properties of natural rubber (NR) nanocomposites [J]. Rubber Chemistry and Technology, 2020, 93(2): 346-359. [73] BEHNAJADY M A, ESKANDARLOO H, MODIRSHAHLA N, et al. Investigation of the effect of sol-gel synthesis variables on structural and photocatalytic properties of TiO2 nanoparticles [J]. Desalination, 2011, 278(1/3): 10-17. [74] RONG M Z, ZHANG M Q, ZHENG Y X, et al. Structure-pro-perty relationships of irradiation grafted nano-inorganic particle filled polypro-pylene composites [J]. Polymer, 2001, 42(1): 167-183. [75] TRAN M L, FU C C, CHIANG L Y, et al. Immobilization of TiO2 and TiO2-GO hybrids onto the surface of acrylic acid-grafted polymeric membranes for pollutant removal: Analysis of photocatalytic activity [J]. Journal of Environmental Chemical Engineering, 2020, 8(5): 104422. [76] CHIEN H W, CHEN X Y, TSAI W P. Poly(methyl methacrylate)/titanium dioxide (PMMA/TiO2) nanocomposite with shark-skin structure for preventing biofilm formation[J]. Materials Letters,2021,285:129098. [77] LIU Y, GAO J, YAO R, et al. Enhanced energy storage performance in a PVDF/PMMA/TiO2 blending nanodielectric material[J]. Materials Chemistry and Physics,2020,250:123155. [78] MAGISETTY R, SHUKLA A, KANDASUBRAMANIAN B. Magnetodielectric microwave radiation absorbent materials and their polymer composites [J]. Journal of Electronic Materials, 2018, 47(11): 6335-6365. [79] HONG H, SONG S A, KIM S S. Phase transformation of poly (vinylidene fluoride)/TiO2 nanocomposite film prepared by microwave-assisted solvent evaporation: An experimental and molecular dynamics study[J]. Composites Science and Technology,2020,199:108375. doi: 10.1016/j.compscitech.2020.108375 [80] COLOMBO A, TASSONE F, SANTOLINI F, et al. Nanoparticle-doped large area PMMA plates with controlled optical diffusion[J]. Journal of Materials Chemistry C,2013,1(16):2927-2934. doi: 10.1039/c3tc00767g [81] TEKIN D, BIRHAN D, KIZILTAS H. Thermal, photocatalytic, and antibacterial properties of calcinated nano-TiO2/polymer composites [J]. Materials Chemistry and Physics, 2020, 251: 123067. [82] LI S, CHEN G, QIANG S, et al. Synthesis and evaluation of highly dispersible and efficient photocatalytic TiO2/poly lactic acid nanocomposite films via sol-gel and casting processes[J]. International Journal of Food Microbiology,2020,331:108763. doi: 10.1016/j.ijfoodmicro.2020.108763 [83] MAEDA S, FUJITA M, IDOTA N, et al. Preparation of transparent bulk TiO2/PMMA hybrids with improved refractive indices via an in situ polymerization process using TiO2 nanoparticles bearing pmma chains grown by surface-initiated atom transfer radical polymerization [J]. ACS Applied Materials & Interfaces, 2016, 8(50): 34762-34769. [84] DING T, WU J, CHEN Z, et al. Synthesis of hierarchically mesoporous TiO2 spheres via a emulsion polymerization route for superior lithium-ion batteries[J]. Journal of Electroanalytical Chemistry,2018,818:1-9. doi: 10.1016/j.jelechem.2018.04.023 [85] DONG C C, JI J H, YANG Z, et al. Research progress of photocatalysis based on highly dispersed titanium in mesopo-rous SiO2 [J]. Chinese Chemical Letters, 2019, 30(4): 853-862. [86] LIKODIMOS V. Photonic crystal-assisted visible light acti-vated TiO2 photocatalysis [J]. Applied Catalysis B-Environmental, 2018, 230: 269-303. [87] 潘素素, 郑智阳, 惠俊杰, 等. 纳米二氧化钛-聚合物复合材料去除无机/有机污染物的研究进展 [J]. 湿法冶金, 2019, 38(1): 1-6.PAN Susu, ZHENG Zhiyang, HUI Junjie, et al. Research progress in the removal of inorganic/organic pollutants by nano-TiO2/polymer composites[J]. Hydrometallurgy, 2019, 38(1): 1-6(in Chinese). [88] KAMAL T, ANWAR Y, KHAN S B, et al. Dye adsorption and bactericidal properties of TiO2/chitosan coating layer [J]. Carbohydrate Polymers, 2016, 148: 153-160. [89] ZHANG J, CAO S, XU S, et al. Study on stability of poly(3-hexylthiophene)/titanium dioxide composites as a visible light photocatalyst [J]. Applied Surface Science, 2015, 349: 650-656. [90] SHI Y, YU Z, LI Z, et al. In-situ synthesis of TiO2@GO nanosheets for polymers degradation in a natural environment[J]. Polymers,2021,13(13):2158. doi: 10.3390/polym13132158 [91] NEVES J C, MOHALLEM N D S, VIANA M M. Polydimethylsiloxanes-modified TiO2 coatings: The role of structural, morphological and optical characteristics in a self-cleaning surface [J]. Ceramics International, 2020, 46(8): 11606-11616. [92] XI Y, QI Y, MAO Z, et al. Surface hydrophobic modification of TiO2 and its application to preparing PMMA/TiO2 composite cool material with improved hydrophobicity and anti-icing property [J]. Construction and Building Materials, 2021, 266: 120916. [93] HONG W, WANG R, LI N, et al. Facile preparation and excellent ultraviolet shielding application of polyurethane-TiO2 composite microcapsules[J]. Particle & Particle Systems Characterization,2021,38(1):2000265. [94] MOHR L C, CAPELEZZO A P, BARETTA C R D M, et al. Titanium dioxide nanoparticles applied as ultraviolet radiation blocker in the polylactic acid bidegradable polymer [J]. Polymer Testing, 2019, 77: 105867. [95] ZHANG Z, WANG Y, LI T, et al. High-performance polylac-tic acid materials enabled by TiO2-polydopamine hybrid nanoparticles [J]. Industrial & Engineering Chemistry Research, 2021, 60(10): 3999-4008. [96] MO X, WANG Y, XIAO Q, et al. Conjugated polymer sensi-tized hyperbranched titanium dioxide based photoelectrochemical biosensor for detecting AFP in serum[J]. Surfaces and Interfaces,2021,24:101103. doi: 10.1016/j.surfin.2021.101103 [97] GHOSAL K, AGATEMOR C, SPITALSKY Z, et al. Electrospinning tissue engineering and wound dressing scaffolds from polymer-titanium dioxide nanocomposites [J]. Chemical Engineering Journal, 2019, 358: 1262-1278. [98] XIAN P, CHEN Y, GAO S, et al. Polydopamine (PDA) mediated nanogranular-structured titanium dioxide (TiO2) coating on polyetheretherketone (PEEK) for oral and maxillofacial implants application [J]. Surface and Coatings Technology, 2020, 401: 126282. -

下载:

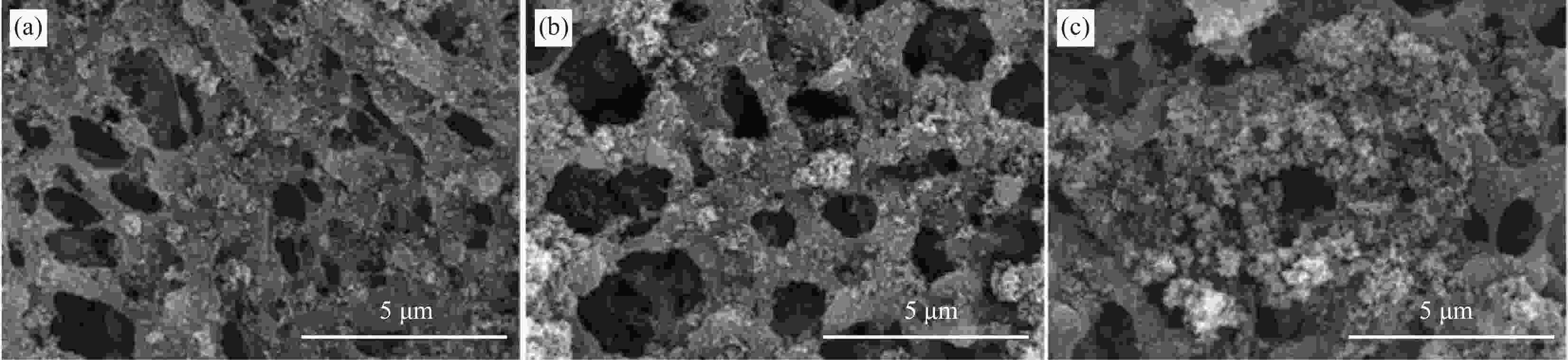

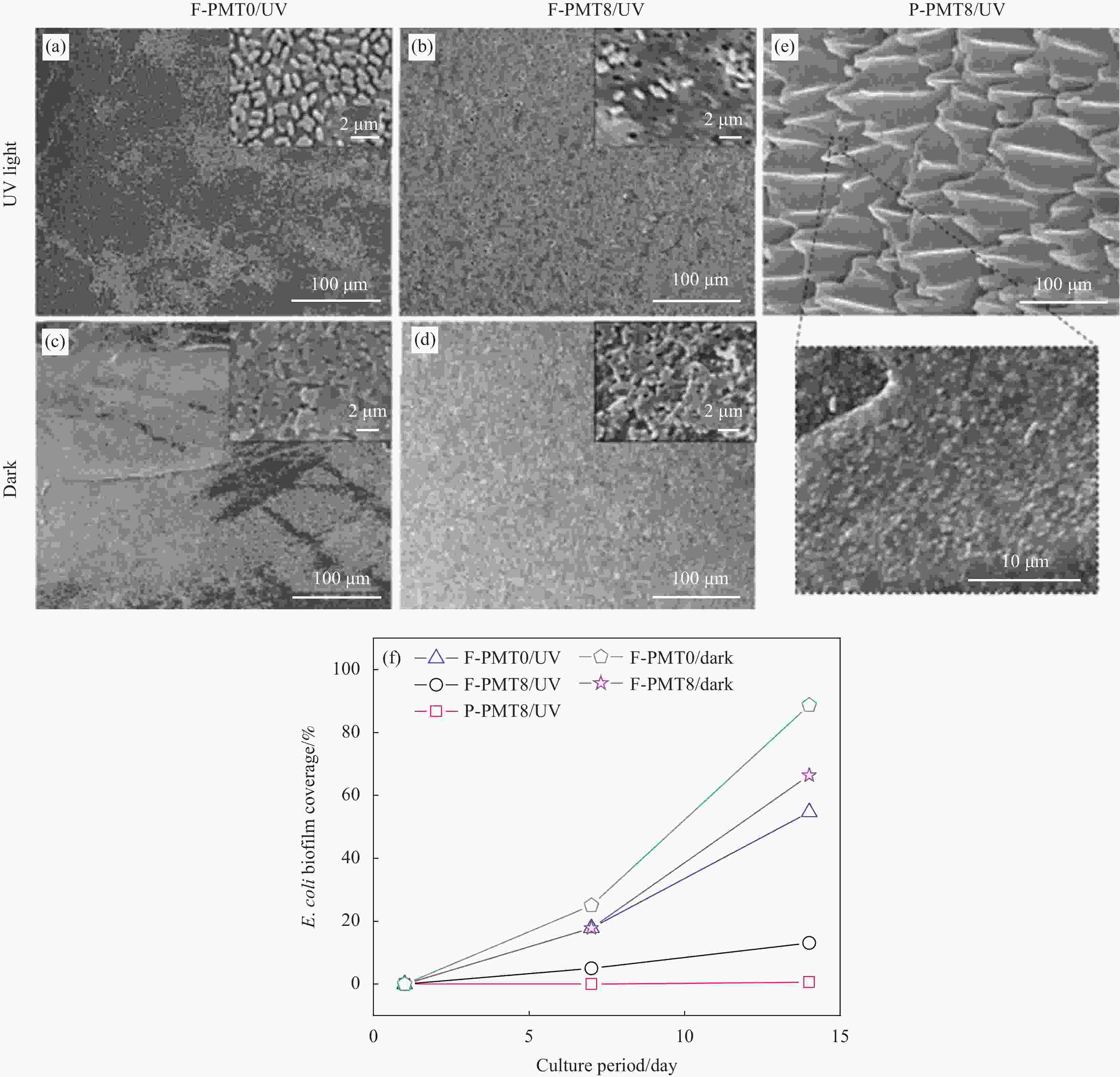

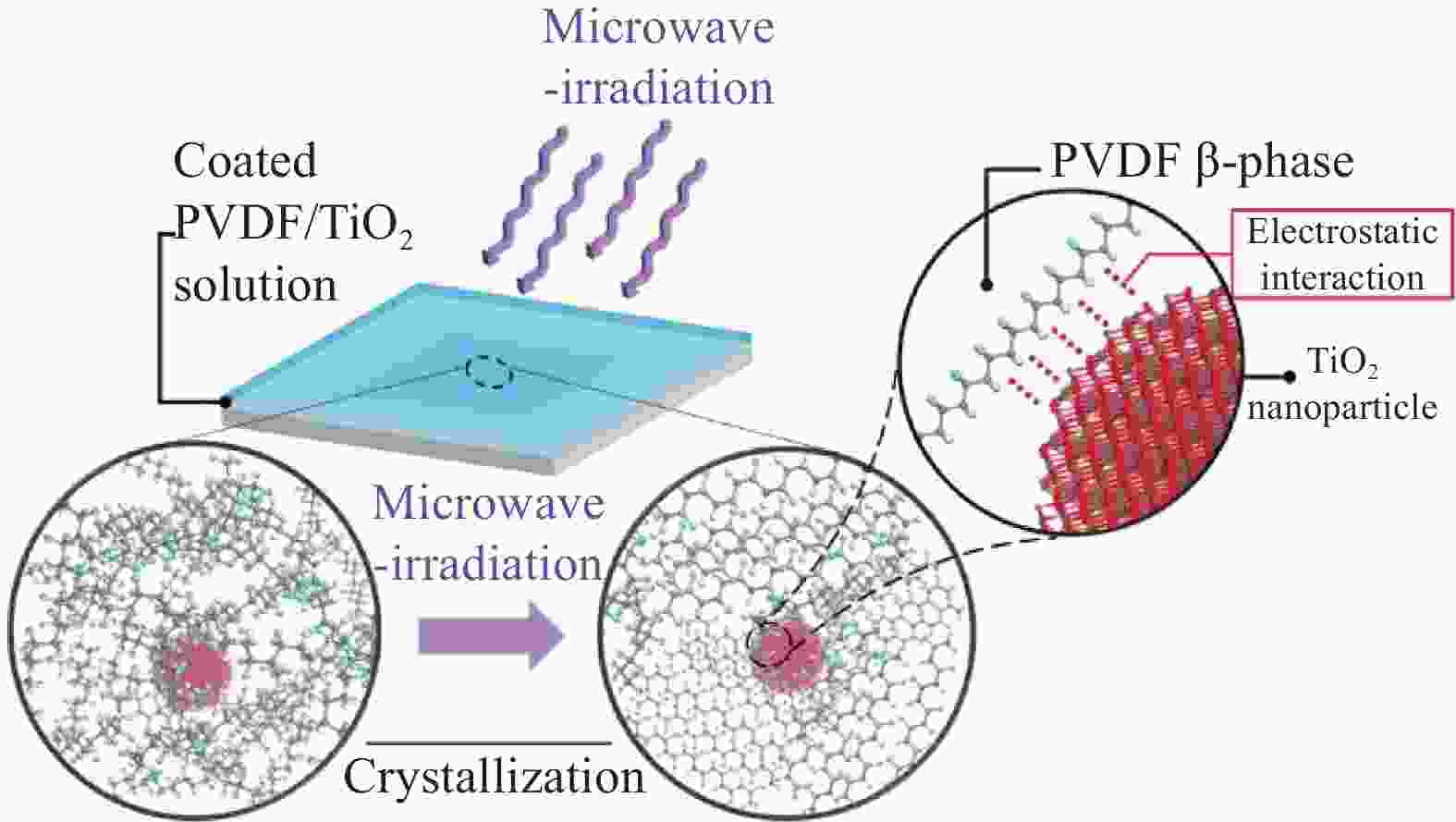

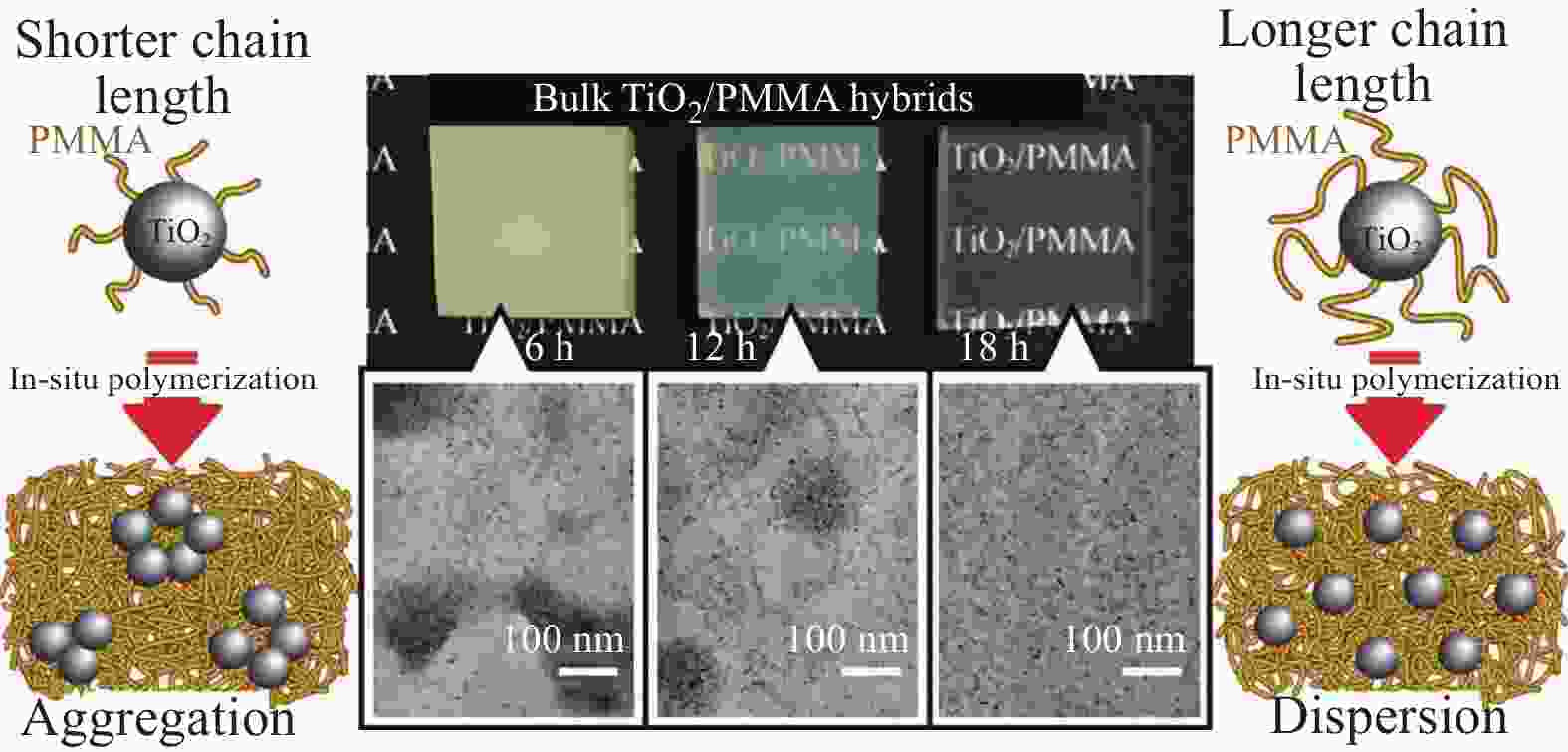

下载: