Effect of aeolian sand and recycled composite micro-powder on mechanical properties of ultra-high performance concrete

-

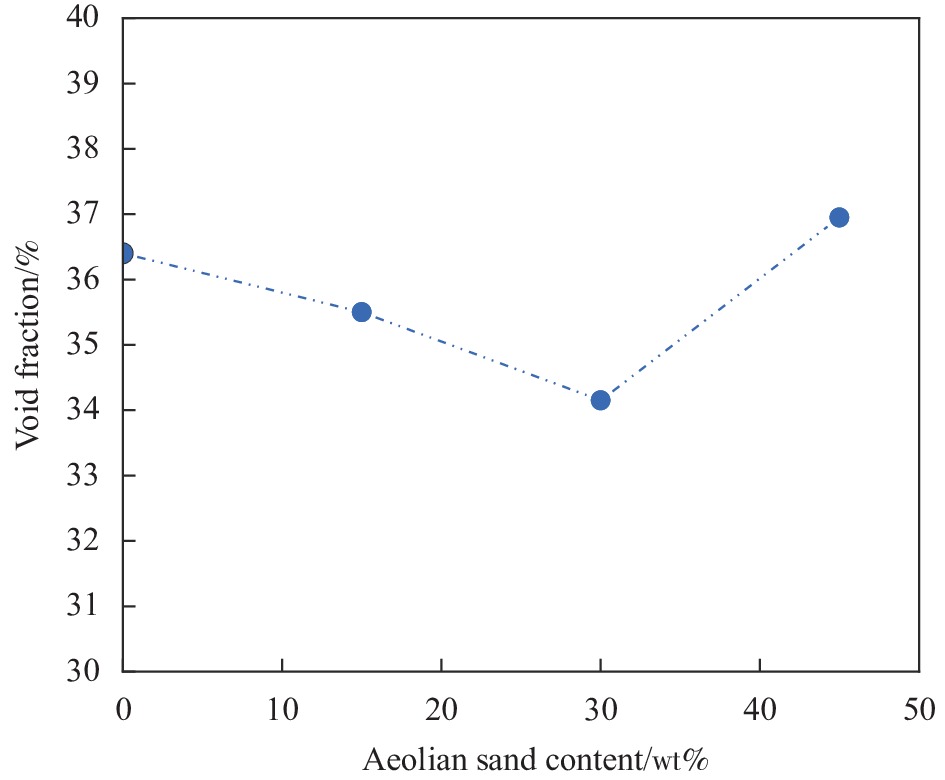

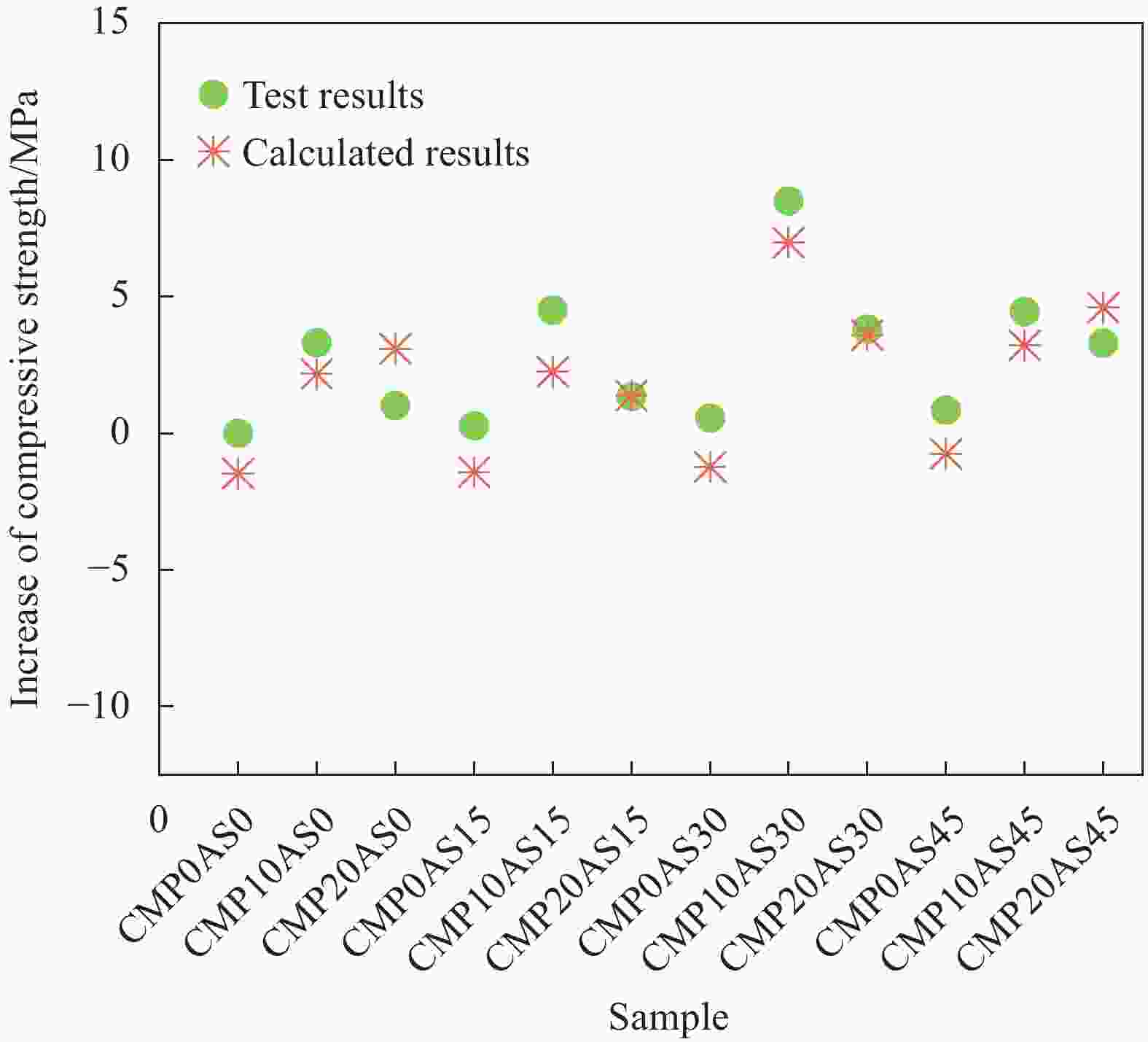

摘要: 以废弃砖和混凝土制成再生复合微粉部分取代水泥作为辅助胶凝材料,以风积沙部分取代河砂协同制备超高性能混凝土(Ultra-high performance concrete,UHPC),采用修正的Andreasen-Andersen (MAA)颗粒堆积模型设计配合比。建立了考虑风积沙和再生复合微粉火山灰活性的抗压强度增长预测模型。研究了风积沙和复合微粉对UHPC力学性能的影响。结果表明:风积沙等质量取代河砂的取代率为30wt%、复合微粉等质量取代水泥的取代率为10wt%时,UHPC力学性能最优。颗粒材料的粒径分布最佳,形成了较高密实度的基体。同时,风积沙和复合微粉活性成分的水化贡献改善了UHPC的微观结构,进而提高其力学性能。Abstract: Ultra-high performance concrete (UHPC) was prepared by partially replacing cement with recycled composite micronized powder. The waste bricks and concrete were used as an auxiliary cementitious material. The river sand was partially replaced with anthracitic sand. The modified Andreasen-Andersen (MAA) particle accumulation model was used to design the proportions. A concrete strength growth prediction model considering the pozzolanic activity of aeolian sands and composite micro-powder was built. The effect mechanism of composite micro-powder and aeolian sand on the mechanical property of UHPC was studied. The results show that the mechanical properties of UHPC are optimal when the replacement rate of river sand by the equivalent mass of aeolian sand is 30wt% and the replacement rate of cement by the equivalent mass of composite micro-powder is 10wt%. The particle size distribution of granular materials is the best, forming a matrix with high compactness. At the same time, the hydration contribution of aeolian sand and composite micro-powder active components improves the microstructure and mechanical properties of UHPC.

-

表 1 超高性能混凝土(UHPC)配合比

Table 1. Mix proportions of ultra-high performance concrete (UHPC)

Mix Binder compositions/(kg·m−3) Water/

(kg·m−3)Superplasticizer/

(kg·m−3)Steel fiber/% RS/

(kg·m−3)AS/

(kg·m−3)C Brick powder (BP) Concrete powder (CP) SF UFA CMP0AS0 595 0 0 85 170 136 21.25 2.5 850.0 0.0 CMP10AS0 510 51 34 85 170 850.0 0.0 CMP20AS0 425 102 68 85 170 850.0 0.0 CMP0AS15 595 0 0 85 170 722.5 127.5 CMP10AS15 510 51 34 85 170 722.5 127.5 CMP20AS15 425 102 68 85 170 722.5 127.5 CMP0AS30 595 0 0 85 170 590.0 225.0 CMP10AS30 510 51 34 85 170 590.0 225.0 CMP20AS30 425 102 68 85 170 590.0 225.0 CMP0AS45 595 0 0 85 170 467.5 382.5 CMP10AS45 510 51 34 85 170 467.5 382.5 CMP20AS45 425 102 68 85 170 467.5 382.5 表 2 不同UHPC试件的风积沙与水泥掺量比值(S/C)和复合微粉掺量与胶凝材料总量比值(Cc/C0)

Table 2. Ratio of aeolian sand content to cement content (S/C) and composite micro-powder content to total cementitious material (Cc/C0) values of different UHPC specimens

Sample S/C Cc/C0 CMP0AS0 0.00 0.0 CMP10AS0 0.00 0.1 CMP20AS0 0.00 0.2 CMP0AS15 0.21 0.0 CMP10AS15 0.25 0.1 CMP20AS15 0.30 0.2 CMP0AS30 0.38 0.0 CMP10AS30 0.44 0.1 CMP20AS30 0.53 0.2 CMP0AS45 0.63 0.0 CMP10AS45 0.75 0.1 CMP20AS45 0.90 0.2 -

[1] MENGXI D, RUI Y, YUAN F, et al. Possibility and advan-tages of producing an ultra-high performance concrete (UHPC) with ultra-low cement content[J]. Construction and Building Materials,2021,273:122023. doi: 10.1016/j.conbuildmat.2020.122023 [2] LI Y, ZHANG H, LIU X, et al. Time-varying compressive strength model of aeolian sand concrete considering the harmful pore ratio variation and heterogeneous nucleation effect[J]. Advances in Civil Engineering,2019,2019(3):1-15. [3] LI Y, ZHANG H, LIU G, et al. Multi-scale study on mecha-nical property and strength prediction of aeolian sand concrete[J]. Construction and Building Materials,2020,247:118538. doi: 10.1016/j.conbuildmat.2020.118538 [4] LUO F J, HE L, PAN Z, et al. Effect of very fine particles on workability and strength of concrete made with dune sand[J]. Construction and Building Materials,2013,47:131-137. doi: 10.1016/j.conbuildmat.2013.05.005 [5] DONG W, SHEN X D, XUE H J, et al. Research on the freeze-thaw cyclic test and damage model of aeolian sand lightweight aggregate concrete[J]. Construction and Building Materials,2016,123:792-799. doi: 10.1016/j.conbuildmat.2016.07.052 [6] SHAO J H, GAO J M, ZHAO Y S, et al. Study on the pozzola-nic reaction of clay brick powder in blended cement pastes[J]. Construction and Building Materials,2019,213:209-215. doi: 10.1016/j.conbuildmat.2019.03.307 [7] 刘超, 胡天峰, 刘化威, 等. 再生复合微粉对混凝土力学性能及微观结构的影响[J]. 建筑材料学报, 2021, 24(4): 726-735.LIU Chao, HU Tianfeng, LIU Huawei, et al. Effect of recycled composite micro-powder on mechanical properties and microstructure of concrete[J]. Journal of Building Materials, 2021, 24(4): 726-735(in Chinese). [8] JIANG J Y, FENG T T, CHU H Y, et al. Quasi-static and dynamic mechanical properties of eco-friendly ultra-high-performance concrete containing aeolian sand[J]. Cement and Concrete Composites,2019,97:369-378. doi: 10.1016/j.cemconcomp.2019.01.011 [9] CHU H Y, WANG F J, WANG L G, et al. Mechanical properties and environmental evaluation of ultra-high-perfor-mance concrete with aeolian sand[J]. Materials,2020,13(14):3148. doi: 10.3390/ma13143148 [10] YU R, SPIESZ P, BROUWERS H J H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC)[J]. Cement and Concrete Research,2014,56:29-39. doi: 10.1016/j.cemconres.2013.11.002 [11] 中华人民共和国住房和城乡建设部. 普通混凝土拌合物性能试验方法标准: GB/T 50080—2016[S]. 北京: 中国建筑工业出版社, 2016.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for test method of performance on ordinary fresh concrete: GB/T 50080—2016[S]. Beijing: China Architecture & Buiding Press, 2016(in Chinese). [12] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 活性粉末混凝土: GB/T 31387—2015[S]. 北京: 中国标准出版社, 2015.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. Reactive powder concrete: GB/T 31387—2015[S]. Beijing: Standards Press of China, 2015(in Chinese). [13] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 建设用砂: GB/T 14684—2001[S]. 北京: 中国标准出版社, 2001.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. Sand for building: GB/T 14684—2001[S]. Beijing: Standards Press of China, 2001(in Chinese). [14] 李玉根, 张慧梅, 刘光秀, 等. 风积砂混凝土基本力学性能及影响机理[J]. 建筑材料学报, 2020, 23(5): 1212-1221.LI Yugen, ZHANG Huimei, LIU Guangxiu, et al. Mechani-cal properties and influence mechanism of aeolian sand concrete[J]. Journal of Building Materials, 2020, 23(5): 1212-1221(in Chinese). [15] 牛旭婧, 朋改非, 尚亚杰, 等. 热水-干热组合养护对超高性能混凝土力学性能的影响[J]. 硅酸盐学报, 2018, 46(8):1141-1148.NIU Xujing, PENG Gaifei, SHANG Yajie, et al. Influence of combined curing composed of precuring in hot water and heating in dry air on mechanical properties of ultra-high performance concrete[J]. Journal of the Chinese Ceramic Society,2018,46(8):1141-1148(in Chinese). [16] 李根峰, 申向东, 吴俊臣, 等. 风积沙混凝土早期自收缩变形的影响因素研究及数值模拟[J]. 硅酸盐通报, 2018, 37(3): 996-1002.LI Genfeng, SHEN Xiangdong, WU Junchen, et al. Experimental study and numerical simulation on the influence factors of self-shrinkage deformation of aeolian sand concrete[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(3): 996-1002(in Chinese). [17] FLOREA M V A, NING Z, BROUWERS H J H. Activation of liberated concrete fines and their application in mortars[J]. Construction and Building Materials,2014,50:1-12. doi: 10.1016/j.conbuildmat.2013.09.012 [18] REIG L, SORIANO L, BORRACHERO M V, et al. Influence of calcium aluminate cement (CAC) on alkaline activation of red claybrick waste (RCBW)[J]. Cement and Concrete Composites,2016,65:177-185. doi: 10.1016/j.cemconcomp.2015.10.021 [19] XIAO J Z, MA Z M, SUI T B, et al. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste[J]. Journal of Cleaner Production,2018,188:720-731. doi: 10.1016/j.jclepro.2018.03.277 [20] LAWRENCE P, CYR M, RINGOT E. Mineral admixtures in mortars: Effect of inert materials on short-term hydration[J]. Cement & Concrete Research,2003,33(12):1939-1947. [21] CYR M, LAWRENCE P, RINGOT E. Mineral admixtures in mortars: Quantification of the physical effects of inert materials on short-term hydration[J]. Cement & Concrete Research,2005,35(4):719-730. [22] LAWRENCE P, CYR M, RINGOT E. Mineral admixtures in mortars effect of type, amount and fineness of fine constituents on compressive strength[J]. Cement & Concrete Research,2005,35(6):1092-1105. [23] CYR M, LAWRENCE P, RINGOT E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength[J]. Cement & Concrete Research,2006,36(2):264-277. [24] 王慧慧, 商涛平, 龙广成, 等. UHPC抗压强度与组成参数之间的关系模型研究[J]. 铁道科学与工程学报, 2020, 17(11): 2816-2822.WANG Huihui, SHANG Taoping, LONG Guangcheng, et al. Study on relationship between compressive strength and composition parameters of UHPC[J]. Journal of Railway Science and Engineering, 2020, 17(11): 2816-2822(in Chinese). [25] DUAN Z H, HOU S D, XIAO J Z, et al. Study on the essential properties of recycled powders from construction and demolition waste[J]. Journal of Cleaner Production,2020,253:119865. doi: 10.1016/j.jclepro.2019.119865 -

下载:

下载: