Fabrication and optimization of dielectric elastomer actuator using MWCNT-CB/PDMS composite electrodes

-

摘要: 介电弹性体驱动器(DEA)的柔性电极发挥着产生电场和约束介电母体形变的重要作用。本文以一维的多壁碳纳米管(MWCNT)和零维的导电炭黑(CB)为共同导电填料,设计浇注了一系列不同尺寸、不同力学、电学性能的聚二甲基硅氧烷(PDMS)复合电极膜(MWCNT-CB/PDMS)。将电极膜黏附在聚氯乙烯凝胶膜的两侧表面,导入脉冲高压电信号,获得一系列电驱动行为变化的新型介电聚合物驱动器。驱动性能测试结果表明:电极覆盖率的增加有利于DEA位移输出;电极厚度的增加限制了DEA的位移输出;随着MWCNT掺杂量的增加,位移输出先增后减。正交实验结果表明:MWCNT掺杂量对DEA的驱动位移有显著的影响,电极覆盖率和厚度有高度显著的影响;最优组合下,驱动器的最大位移输出为1.71 mm。Abstract: Flexible electrode of dielectric elastomer actuator (DEA) plays important roles in generating electric fields and constraining dielectric matrix deformation. By using one-dimensional multi-wall carbon nanotubes (MWCNT) and zero-dimensional conductive carbon black (CB) as co-conductive fillers, a series of polydimethyl siloxane (PDMS) composite electrode films (MWCNT-CB/PDMS) were designed with varying size, mechanical and electrical properties. The electrode films were adhered to the lateral surfaces of a polyvinyl chloride gel matrix film and imported into a pulsed high-voltage signal to obtain novel dielectric polymer actuators with various electromechanical behaviors. Tests of electromechanical properties reveal that, the increase of electrode coverage is beneficial to DEA’s strain, the increase of electrode thickness hampers its strain, while the strain exhibits an initial increase following decrease trend with increasing MWCNT loading. Orthogonal experiments show that, the MWCNT loading has a significant effect on the displacement output, while the electrode coverage and thickness present high-level significances to the displacement output. Under the optimal condition, the displacement output of DEA is 1.71 mm at maximum.

-

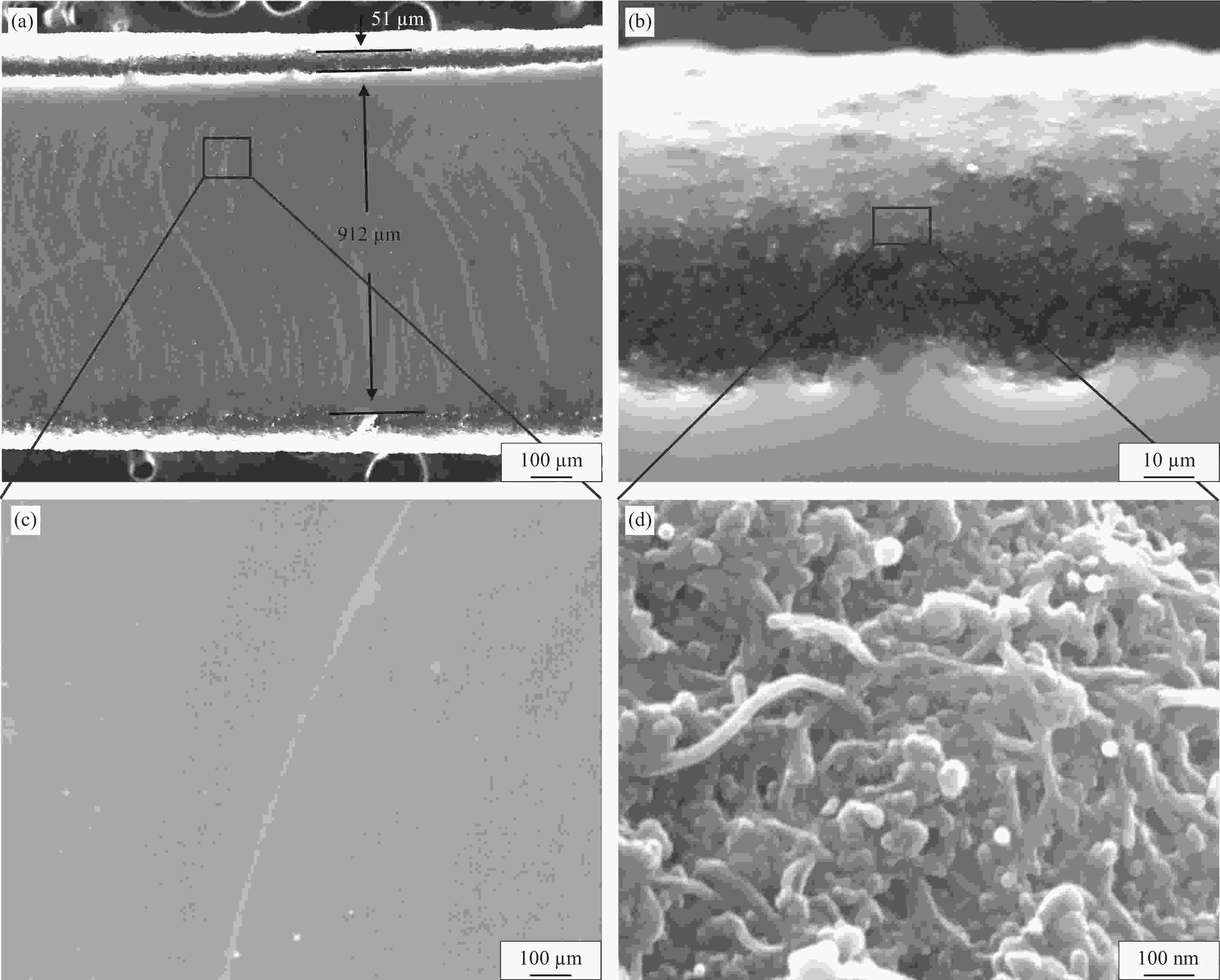

图 2 电极膜和母体膜的相关物性表征:(a) 不同MWCNT掺杂后多壁碳纳米管-导电炭黑/聚二甲基硅氧烷(MWCNT-CB/PDMS)复合电极膜的应力-应变曲线;(b) MWCNT-CB/PDMS复合膜弹性模量;(c) PVC母体膜的应力-应变曲线;(d) MWCNT-CB/PDMS复合膜的方块电阻

Figure 2. Related physical characterizations of the matrix and electrode films: (a) Typical stress-strain curves for the multi-wall carbon nanotubes-conductive carbon black/polydimethyl siloxane (MWCNT-CB/PDMS) electrode films with different MWCNT loadings; (b) Calculated Young’s moduli of MWCNT-CB/PDMS; (c) Stress-strain curves for the PVC matrixes; (d) Sheet resistances for MWCNT-CB/PDMS composite electrode films

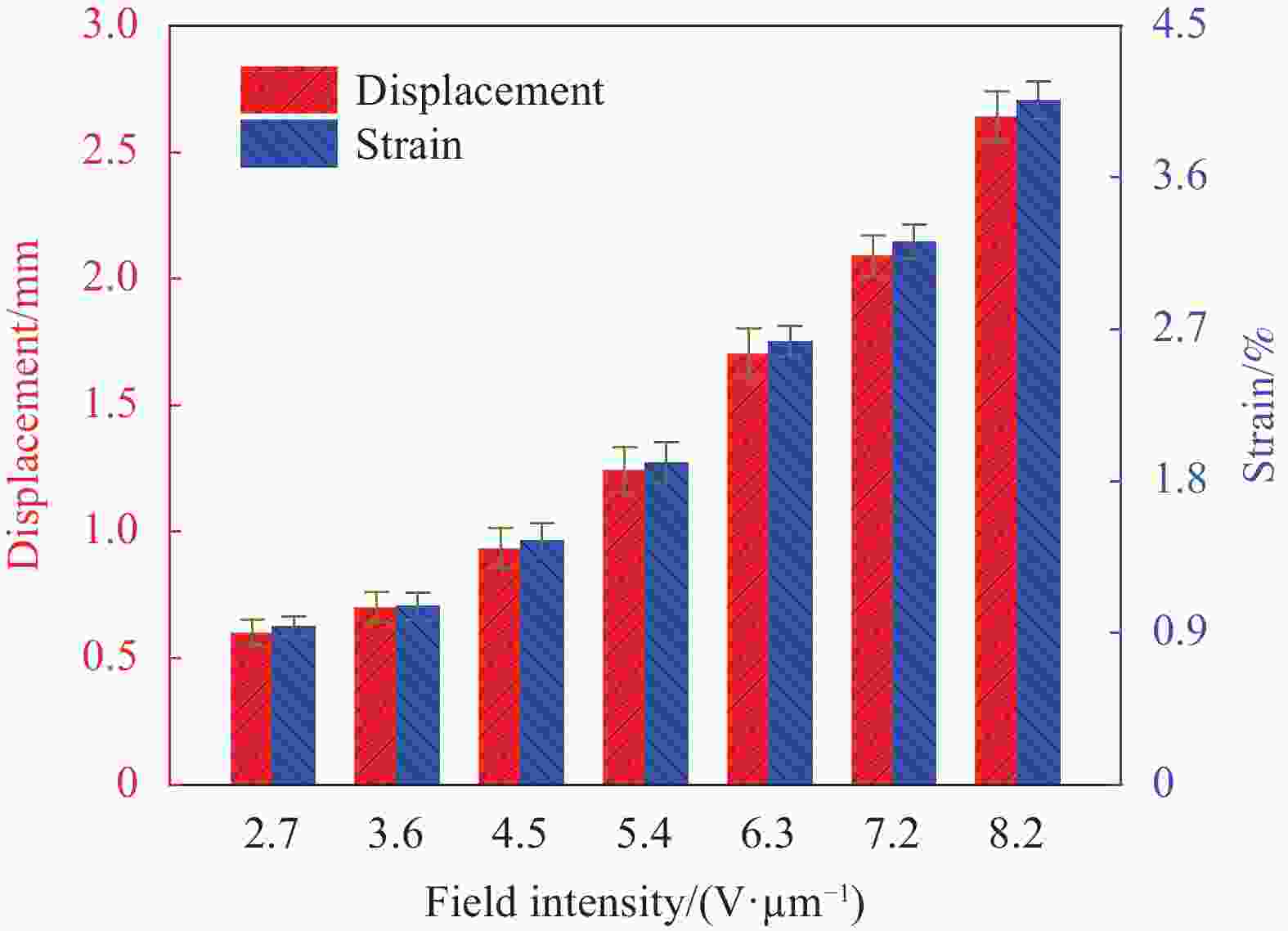

图 4 不同驱动电场下的DEA输出位移演变(PVC复合膜中含75wt%邻苯二甲酸二辛酯(DOP),PDMS电极含4wt%MWCNT,驱动信号为1.0 Hz、占空比为0.5的方波)

Figure 4. Evolution of DEA’s outputted displacement with electronic field (PVC matrix composite contained 75wt% dioctyl phthalate (DOP), PDMS electrode contained 4wt%MWCNT, driven signal is square wave with 1.0 Hz frequency and 0.5 duty ratio)

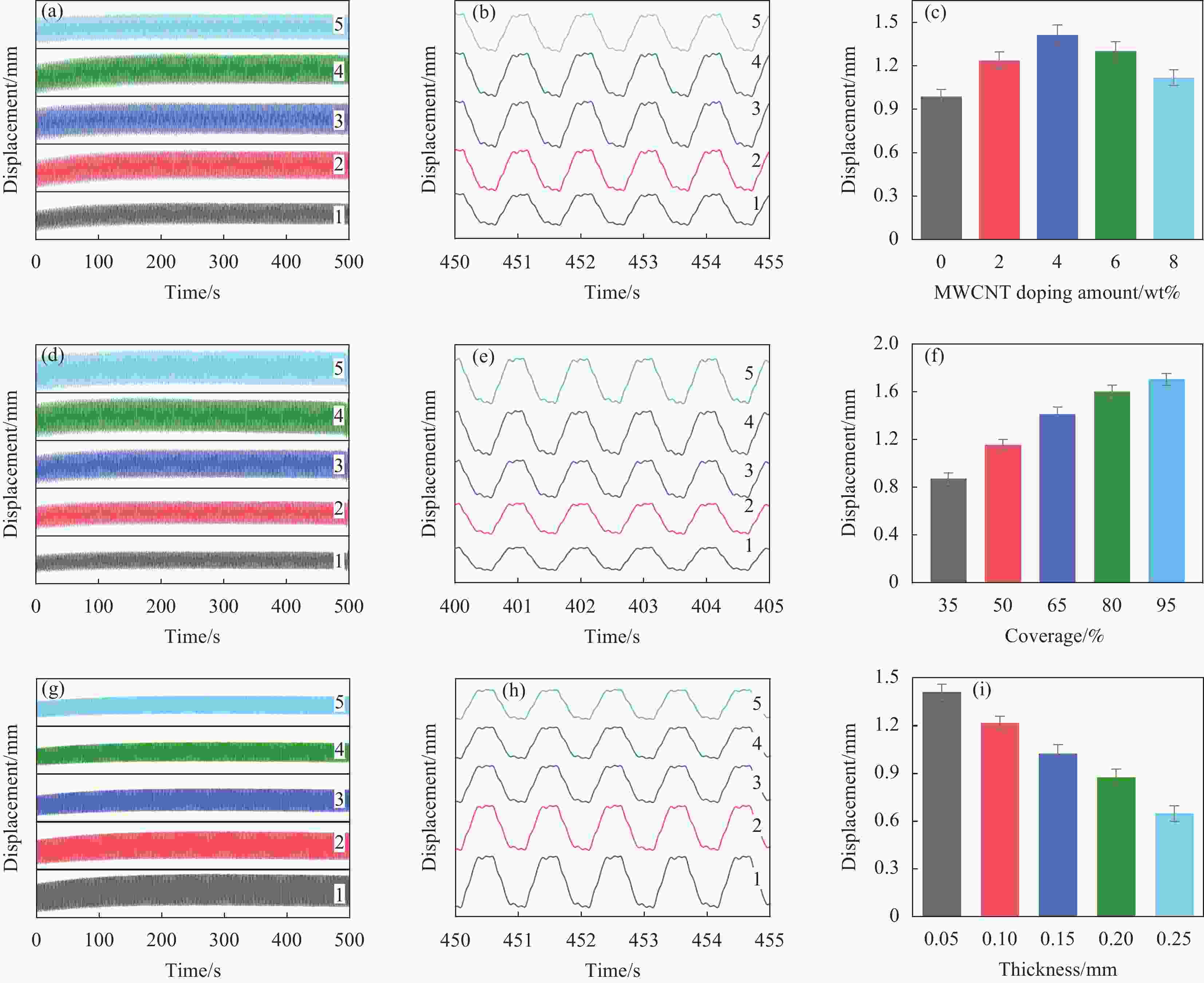

图 5 位移输出性能比较:不同MWCNT掺杂量、电极覆盖率、电极厚度下的位移响应曲线((a)、(d)、(g));局部位移图((b)、(e)、(h));具体的位移输出数据((c)、(f)、(i)) (((a)~(c)) 电极厚度为0.05 mm,覆盖率为65%;((b)~(f)) MWCNT含量为4wt%,电极厚度为0.05 mm;((g)~(i)) MWCNT含量为4wt%,覆盖率为65%;驱动信号均为1.0 Hz、占空比为0.5的方波)

Figure 5. Comparison of displacement output: Displacement curves for different MWCNT loadings ((a), (d), (g)), coating ratio ((b), (e), (h)) and thickness ((c), (f), (i)) (((a)-(c)) Electrode thickness is 0.05 mm and coating ratio is 65%; ((b)-(f)) Electrode thickness is 0.05 mm and MWCNT loading is 65%; ((g)-(i)) MWCNT loading is 65% and coating ratio is 65%. Driven signal is square wave with 1.0 Hz frequency and 0.5 duty ratio)

表 1 DEA相关参数与性能

Table 1. DEA-related parameters and properties

Mass fraction of

MWCNT/wt%Thickness/

mmElongation at

break/%Tensile strength/

MPaElastic modulus/

MPaElectrode resistance/

(Ω·sq−1)Electric conductivity/

(S·cm−1)0 0.306 326 1.118 0.612 1143 0.026 2 0.391 308 1.325 0.892 573 0.059 4 0.390 280 1.533 1.155 293 0.121 6 0.317 254 1.709 1.529 147 0.250 8 0.314 224 1.843 4.032 56 0.239 表 2 DEA电驱动响应数据

Table 2. DEA’s electromechanical response data

Mass fraction of MWCNT/wt% Displacementa

/mmCoverage ratio/% Displacementb

/mmThickness

/mmDisplacementc

/mm0 0.99 35 0.87 0.05 1.41 2 1.24 50 1.15 0.10 1.22 4 1.41 65 1.39 0.15 1.02 6 1.31 80 1.61 0.20 0.88 8 1.12 95 1.71 0.25 0.65 Notes: a—Electrode coverage is 65%, thickness is 0.05 mm, doping amount of MWCNT is changed; b—Doping amount of MWCNT is 4wt%, electrode thickness is 0.05 mm, electrode coverage is changed; c—Doping amount of MWCNT is 4wt%, electrode coverage is 65%, and electrode thickness is changed. 表 3 正交试验水平因素表

Table 3. Orthogonal experimental level factors

Factor A (MWCNT doping/wt%) C (Coverage ratio/%) D (Thickness/mm) 1 0 95 0.05 2 2 80 0.10 3 4 65 0.15 4 6 50 0.20 5 8 35 0.25 表 4 正交试验方法与设计

Table 4. Experimental design of an orthogonal array method

Experimental group A B C D (Blank group) Xi (Displacement/mm) 1 1 1 1 1 1.42 2 1 2 2 2 1.09 3 1 3 3 3 0.75 4 1 4 4 4 0.36 5 1 5 5 5 0.28 6 2 1 2 3 1.56 7 2 2 3 4 1.13 8 2 3 4 5 0.69 9 2 4 5 1 0.46 10 2 5 1 2 0.87 11 3 1 3 5 1.49 12 3 2 4 1 1.05 13 3 3 5 2 0.65 14 3 4 1 3 1.15 15 3 5 2 4 0.79 16 4 1 4 2 1.14 17 4 2 5 3 0.83 18 4 3 1 4 1.31 19 4 4 2 5 0.97 20 4 5 3 1 0.53 21 5 1 5 4 0.92 22 5 2 1 5 1.36 23 5 3 2 1 0.99 24 5 4 3 2 0.61 25 5 5 4 3 0.75 Ij 3.91 6.53 6.11 4.46 — IIj 4.71 5.47 5.41 4.37 — IIIj 5.13 4.38 4.51 5.04 — IVj 4.77 3.55 3.98 4.49 — Ⅴj 4.63 3.21 3.14 4.78 — Rj 1.23 3.32 2.97 0.67 — Sj 0.16 1.50 1.09 0.06 — Notes: Xi—Dispalcement; Ij, IIj, IIIj, IVj, Vj—Sum of Xi data corresponding to the level1, 2, 3, 4, 5 in column j; Rj—Range of factor; Sj—Sum of squared deviations of factor. 表 5 正交试验方差分析结果

Table 5. Orthogonal experimental analysis of variance results

Variance source Sum of deviation squares Degree of freedom Sum of squares of average deviation F value Significance A 0.16 4 0.04 2.97 ** B 1.50 4 0.38 27.49 *** C 1.09 4 0.27 19.87 *** D 0.06 4 0.02 1.15 — Notes: **—Factor has a significant impact on the experiment results; *** —Factor has a highly significant impact on the experiment results; F—Variance ratio. -

[1] JI X, LIU X, CACUCCIOLO V, et al. An autonomous untethered fast soft robotic insect driven by low-voltage dielectric elastomer actuators[J]. Science Robotics,2019,4(37):05-1-05-12. doi: 10.1126/scirobotics.aaz6451 [2] CHU H, HU X, WANG Z, et al. Unipolar stroke, electroosmotic pump carbon nanotube yarn muscles[J]. Science,2021,371(6528):494-498. doi: 10.1126/science.abc4538 [3] JI X, LIU X, CACUCCIOLO V, et al. Untethered feel-through haptics using 18-µm thick dielectric elastomer actuators[J]. Advanced Functional Materials,2021,31(39):2006639. doi: 10.1002/adfm.202006639 [4] LI G, CHEN X, ZHOU F, et al. Self-powered soft robot in the Mariana Trench[J]. Nature,2021,591(7848):66-71. doi: 10.1038/s41586-020-03153-z [5] CHEN Y, ZHAO H, MAO J, et al. Controlled flight of a microrobot powered by soft artificial muscles[J]. Nature,2019,575(7782):324-329. doi: 10.1038/s41586-019-1737-7 [6] YOU I, MACKANIC D G, MATSUHISA N, et al. Artificial multimodal receptors based on ion relaxation dynamics[J]. Science,2020,370(6519):961-965. doi: 10.1126/science.aba5132 [7] ZHAO H, HUSSAIN A M, ISRAR A, et al. A wearable soft haptic communicator based on dielectric elastomer actuators[J]. Soft Robotics,2020,7(4):451-461. doi: 10.1089/soro.2019.0113 [8] SHIAN S, BERTOLDI K, CLARKE D R. Dielectric elastomer based “grippers” for soft robotics[J]. Advanced Materials,2015,27(43):6814-6819. doi: 10.1002/adma.201503078 [9] SHINTAKE J, ROSSET S, SCHUBERT B, et al. Versatile soft grippers with intrinsic electroadhesion based on multifunctional polymer actuators[J]. Advanced Materials,2016,28(2):231-238. doi: 10.1002/adma.201504264 [10] PELRINE R, KORNBLUH R, PEI Q, et al. High-speed electrically actuated elastomers with strain greater than 100%[J]. Science,2000,287(5454):836-839. doi: 10.1126/science.287.5454.836 [11] TIAN M, YAO Y, LIU S, et al. Separated-structured all-organic dielectric elastomer with large actuation strain under ultra-low voltage and high mechanical strength[J]. Journal of Materials Chemistry A,2015,3(4):1483-1491. doi: 10.1039/C4TA04197F [12] SUN H, LIU X, LIU S, et al. Silicone dielectric elastomer with improved actuated strain at low electric field and high self-healing efficiency by constructing supramolecular network[J]. Chemical Engineering Journal,2020,384:123242. doi: 10.1016/j.cej.2019.123242 [13] YIN L J, ZHAO Y, ZHU J, et al. Soft, tough, and fast polyacrylate dielectric elastomer for non-magnetic motor[J]. Nature Communications,2021,12(1):1-10. doi: 10.1038/s41467-020-20314-w [14] BOZLAR M, PUNCKT C, KORKUT S, et al. Dielectric elastomer actuators with elastomeric electrodes[J]. Applied Physics Letters,2012,101(9):091907. doi: 10.1063/1.4748114 [15] ZHANG J, LIU L, CHEN H. Electromechanical properties of soft dissipative dielectric elastomer actuators influenced by electrode thickness and conductivity[J]. Journal of Applied Physics,2020,127(18):184902. doi: 10.1063/5.0001580 [16] MA G, WU X, CHEN L, et al. Characterization and optimization of elastomeric electrodes for dielectric elastomer artificial muscles[J]. Materials,2020,13(23):5542. doi: 10.3390/ma13235542 [17] 陈鹿民, 王晨, 王才东, 等. 不对称电极介电弹性体的电致动响应与有限元分析[J]. 功能材料, 2017, 48(6):6074-6079. doi: 10.3969/j.issn.1001-9731.2017.06.013CHEN Lumin, WANG Chen, WANG Caidong, et al. Electrodynamic response and finite element analysis of dielectric elastomers with asymmetric electrodes[J]. Functional Materials,2017,48(6):6074-6079(in Chinese). doi: 10.3969/j.issn.1001-9731.2017.06.013 [18] GUO D, HAN Y, DING Y, et al. Prestrain-free electrostrictive film sandwiched by asymmetric electrodes for out-of-plane actuation[J]. Chemical Engineering Journal,2018,352:876-885. doi: 10.1016/j.cej.2018.07.094 [19] PERUTZ S, WANG J, KRAMER E J, et al. Synthesis and surface energy measurement of semi-fluorinated, low-energy surfaces[J]. Macromolecules,1998,31(13):4272-4276. doi: 10.1021/ma9700993 [20] 邓火英, 梁馨, 顾轶卓, 等. MWCNTs 对环氧树脂及多尺度 MWCNTs-碳纤维/环氧树脂复合材料力学性能的影响[J]. 复合材料学报, 2018, 35(11):3073-3080.DENG Huoying, LIANG Xin, GU Yizhuo, et al. Effect of MWCNTs-CNTs on mechanical properties of epoxy resin and multi-scale MWCNTs carbon fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica,2018,35(11):3073-3080(in Chinese). [21] ROMASANTA L J, LÓPEZ-MANCHADO M A, VERDEJO R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective[J]. Progress in Polymer Science,2015,51:188-211. doi: 10.1016/j.progpolymsci.2015.08.002 [22] MADSEN F B, DAUGAARD A E, HVILSTED S, et al. The current state of silicone-based dielectric elastomer transducers[J]. Macromolecular Rapid Communications,2016,37(5):378-413. doi: 10.1002/marc.201500576 [23] HUANG J J, WANG F, MA L, et al. Vinylsilane-rich silicone filled by polydimethylsiloxane encapsulated carbon black particles for dielectric elastomer actuator with enhanced out-of-plane actuations[J]. Chemical Engineering Journal,2022,428:131354. doi: 10.1016/j.cej.2021.131354 [24] 赵中国, 艾桃桃, 刘国瑞, 等. 多壁碳纳米管-聚氨酯/聚丙烯复合材料导电网络结构的演变与性能调控[J]. 复合材料学报, 2021, 38(3):770-779.ZHAO Zhongguo, AI Taotao, LIU Guorui, et al. Evolution and performance control of conductive network structure of multi-walled carbon nanotubes-polyurethane/polypropylene composites[J]. Acta Materiae Compositae Sinica,2021,38(3):770-779(in Chinese). [25] OPRIS D M, MOLBERG M, WALDER C, et al. New silicone composites for dielectric elastomer actuator applications in competition with acrylic foil[J]. Advanced Functional Materials,2011,21(18):3531-3539. doi: 10.1002/adfm.201101039 [26] LI Y, HASHIMOTO M. PVC gel based artificial muscles: Characterizations and actuation modular constructions[J]. Sensors and Actuators A: Physical,2015,233:246-258. doi: 10.1016/j.sna.2015.07.010 [27] 石磊, 徐学诚. 多壁碳纳米管/聚苯乙烯-聚氯乙烯复合材料的导电特性[J]. 复合材料学报, 2013, 30(4):7-12.SHI Lei, XU Xuecheng. Electrical conductivity of multi-walled carbon nanotubes/polystyrene-polyvinyl chloride composites[J]. Acta Materiae Compositae Sinica,2013,30(4):7-12(in Chinese). [28] ROSSET S, SHEA H R. Flexible and stretchable electrodes for dielectric elastomer actuators[J]. Applied Physics A,2013,110(2):281-307. doi: 10.1007/s00339-012-7402-8 [29] 闫茜茜, 何田. 一种基于介电弹性体驱动的软体机器人设计方法[J]. 青岛大学学报(工程技术版), 2021, 36(3):1-5.YAN Qianqian, HE Tian. A design method of software robot based on dielectric elastomer drive[J]. Journal of Qingdao University (Engineering & Technology Edition),2021,36(3):1-5(in Chinese). [30] KEPLINGER C, KALTENBRUNNER M, ARNOLD N, et al. Röntgen’s electrode-free elastomer actuators without electromechanical pull-in instability[J]. Proceedings of the National Academy of Sciences,2010,107(10):4505-4510. doi: 10.1073/pnas.0913461107 [31] FOO C C, CAI S, KOH S J A, et al. Model of dissipative dielectric elastomers[J]. Journal of Applied Physics,2012,111:034102. doi: 10.1063/1.3680878 [32] 何青松, 于敏, 丁燕, 等. 正交实验设计优化离子聚合物金属复合材料的力输出性能[J]. 科学通报, 2011, 56(14):1144-1152.HE Qingsong, YU Min, DING Yan, et al. Force optimization of ionic polymer metal composite actuators by an orthogonal array method[J]. Chinese Science Bulletin,2011,56(14):1144-1152(in Chinese). -

下载:

下载: