Research progress of laser drilling technology for carbon fiber reinforced composites

-

摘要: 碳纤维增强树脂基复合材料(CFRP)具有抗疲劳性好、比强度高、耐热性好等优良的热物性能,已在航空、航天等领域得到广泛应用。作为主要的承力构件,CFRP板之间的机械连接所需加工的装配孔数量众多。然而,CFRP作为高硬度且各向异性的难加工材料,传统机械钻孔存在刀具磨损严重、制孔工序多等缺点;相比于机械钻孔,激光“不怕硬”,激光制孔无刀具磨损、经济性好、易于实现自动化控制。首先对CFRP激光制孔加工技术进行了综述,着重分析了CFRP激光制孔常见工艺;其次,剖析了CFRP激光制孔加工常见缺陷及其抑制研究现状;随后,阐述了CFRP激光加工工艺参数对制孔质量及效率的影响;为了阐明CFRP激光制孔材料移除机制,还综述了CFRP激光制孔加工数值仿真和基于高速摄像的加工过程动态观测研究进展;最后,展望了CFRP激光制孔技术的发展趋势。

-

关键词:

- 碳纤维增强树脂基复合材料 /

- 激光制孔 /

- 制孔缺陷 /

- 工艺研究 /

- 数值仿真

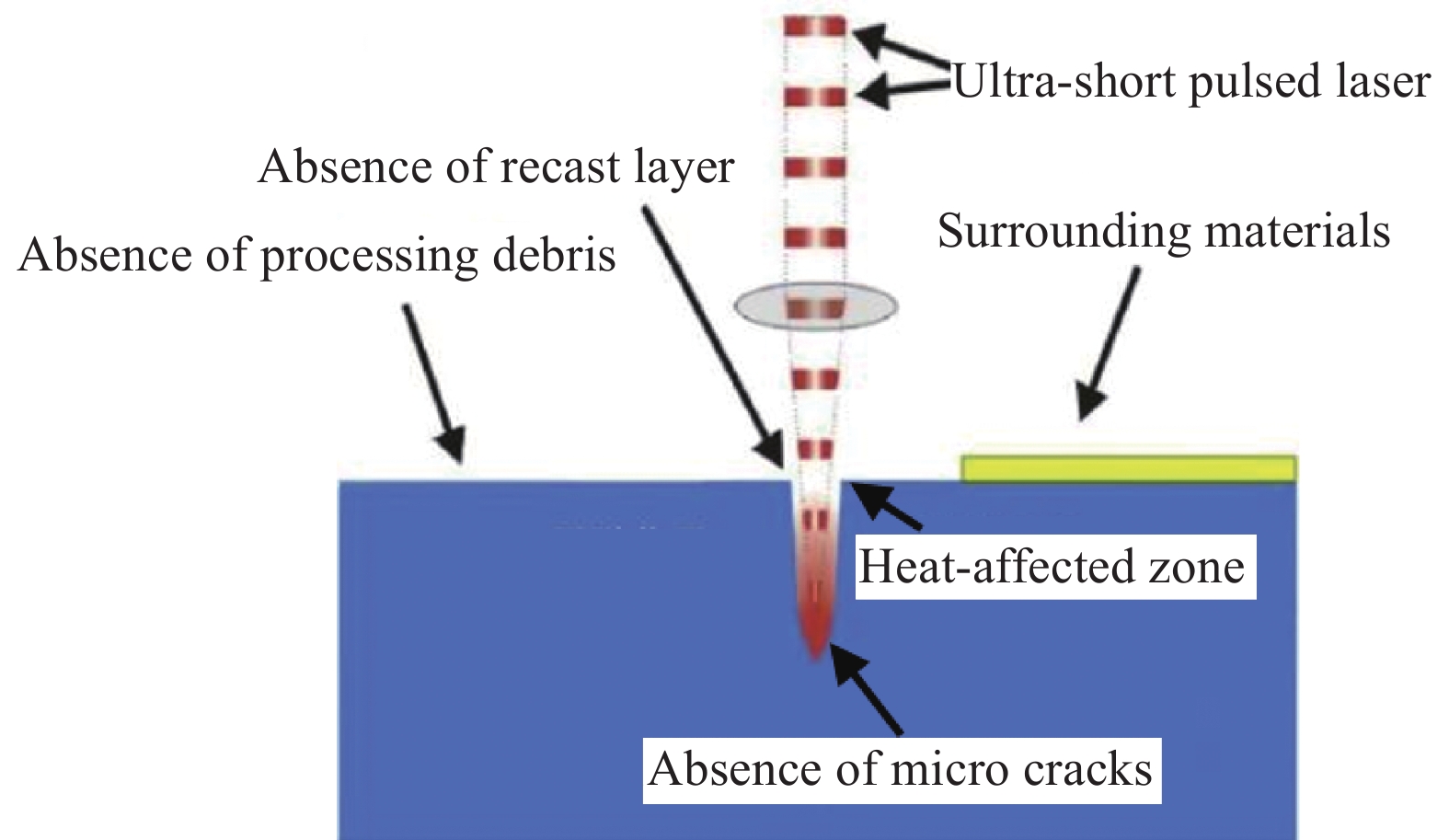

Abstract: Due to its excellent thermal physical properties such as good fatigue resistance, high specific strength and good heat resistance, carbon fiber reinforced plastic composites (CFRP) have been widely used in rail transportation, aerospace, aircraft, etc. industries. As the main load-bearing parts, a large number of assembly holes need to be machined for the mechanical connection between CFRP plates. However, as a hard-to-machining material with high hardness and anisotropy, traditional mechanical drilling has many disadvantages, such as many drilling procedures, serious tool wear and so on. Compared with the traditional mechanical drilling process, the laser can machine any hardness materials, and laser drilling shows the advantages such as no tool wear, good economy and easy to realize automatic control. First, this paper summarized the laser drilling technology of CFRP plates, and the common processes of laser drilling CFRP were emphatically analyzed. Then, the research status of defects and their suppression in CFRP laser drilling was analyzed. Subsequently, the influences of laser processing parameters on CFRP processing quality and efficiency were discussed. Aiming to reveal the material removal mechanism of laser drilling CFRP, the numerical simulation and dynamic process observation based on high-speed camera were emphatically analyzed. Finally, the development trends of CFRP laser drilling technology were forecasted. -

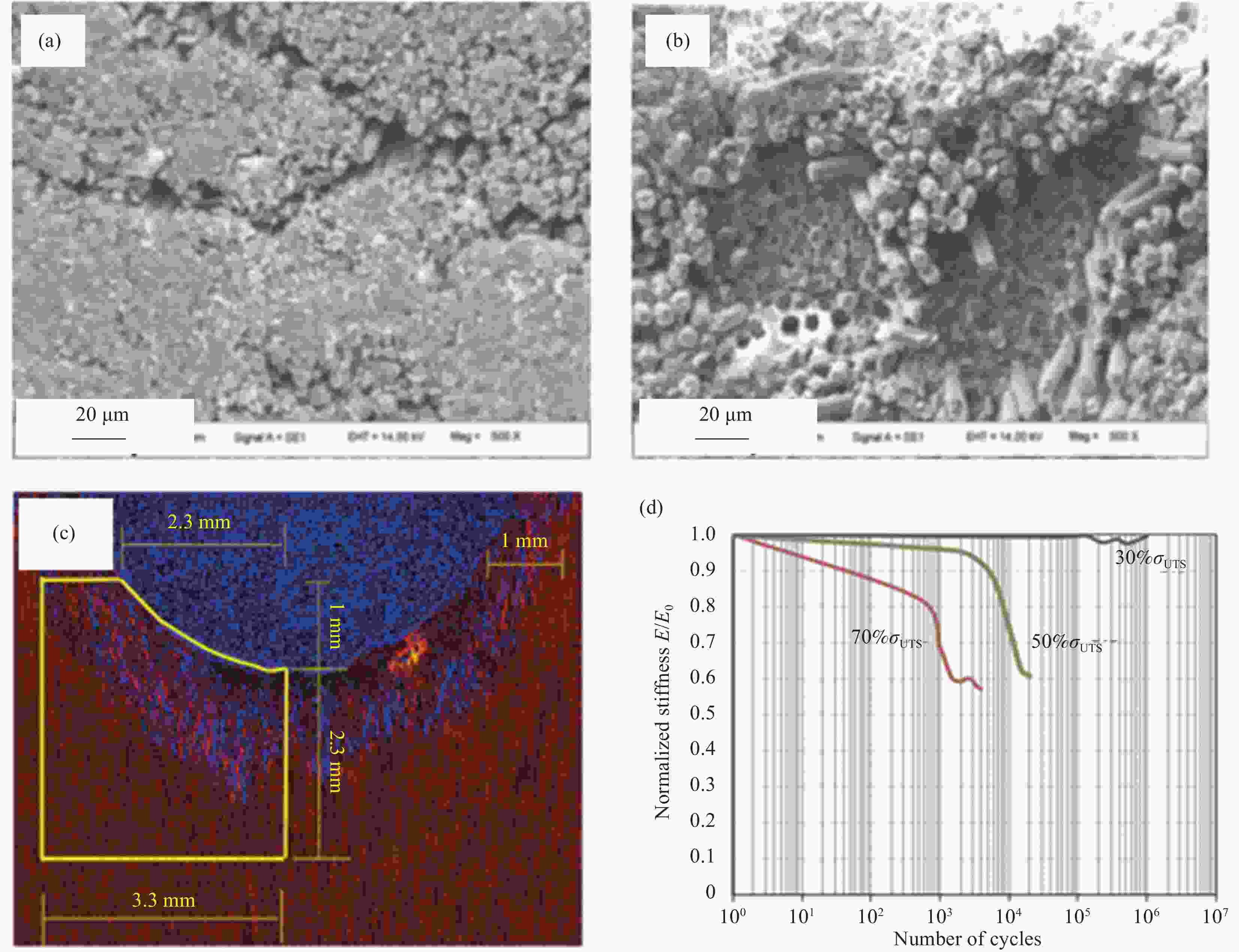

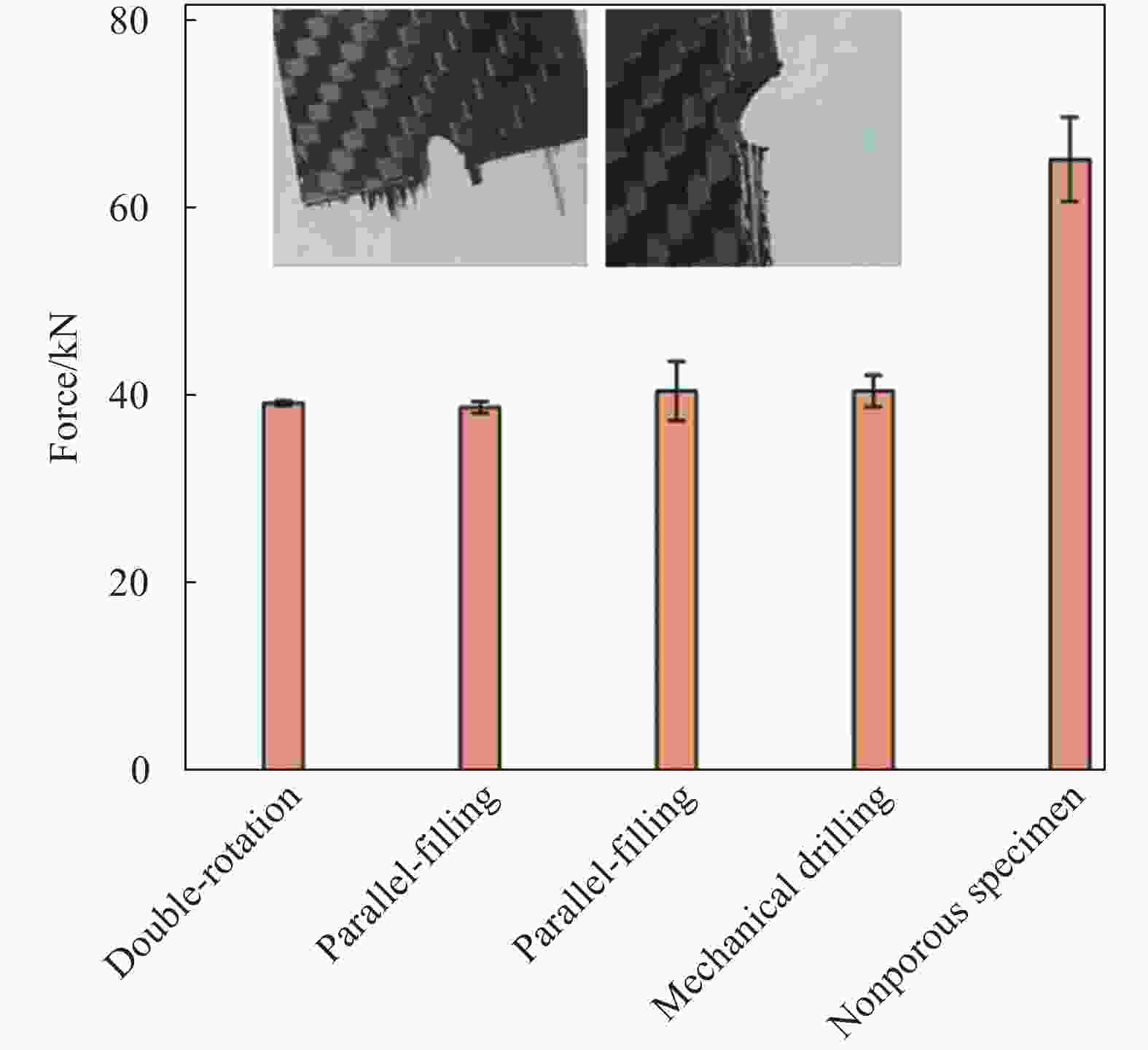

图 10 激光/机械加工CFRP板拉伸断裂界面和力学特性:(a) 机械加工后拉伸失效断面形貌;(b) 激光加工后拉伸失效断面形貌;(c)疲劳裂纹扩展;(d) 样件刚度降解

Figure 10. Tensile fracture section and mechanical properties of laser/mechanical drilling of CFRP plates: (a) Morphology of tensile failure section after mechanical processing; (b) Morphology of tensile failure section after laser processing; (c) Fatigue crack propagation; (d) Stiffness degradation of the sample

σUTS—Ultimate tensile strength

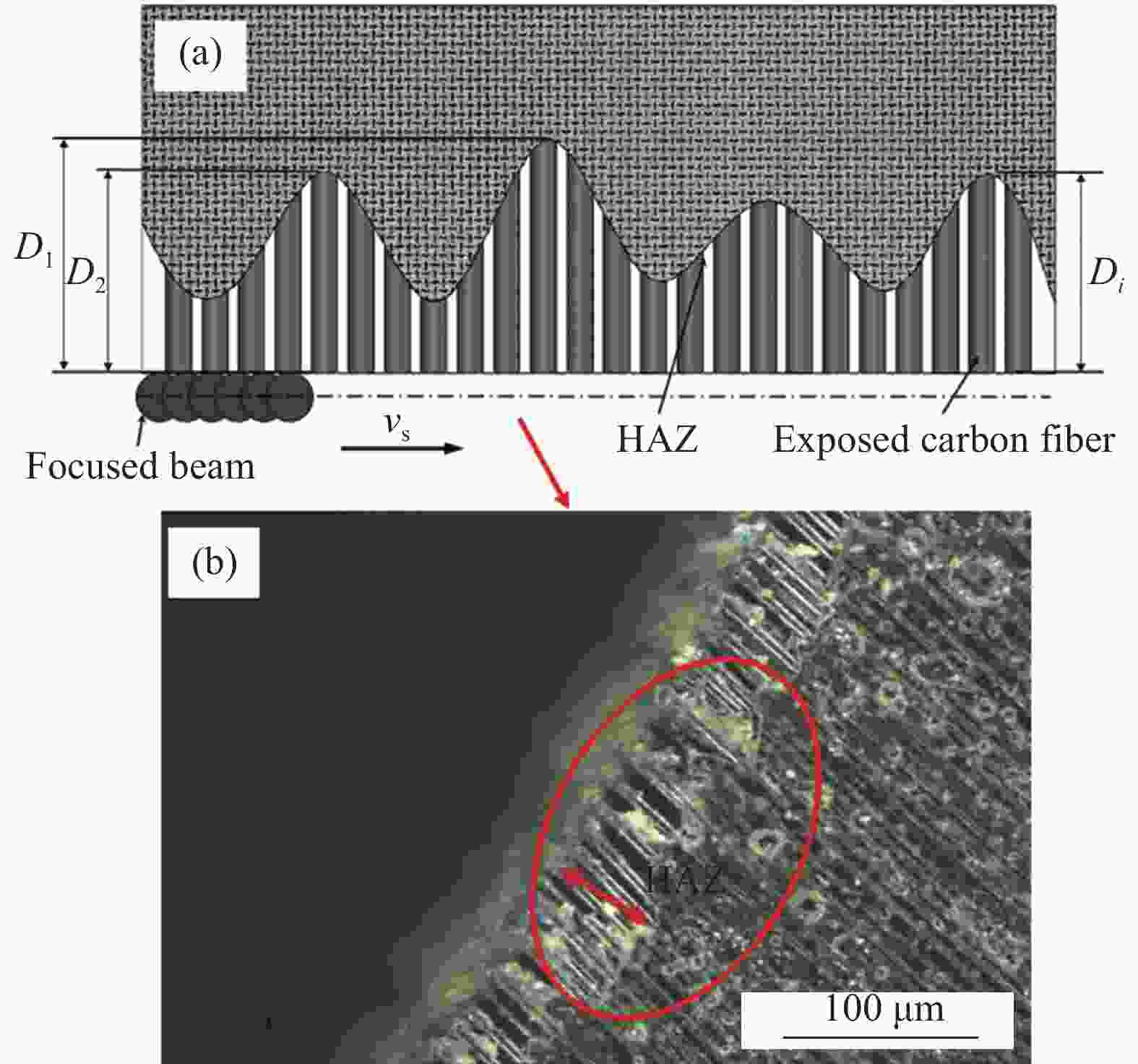

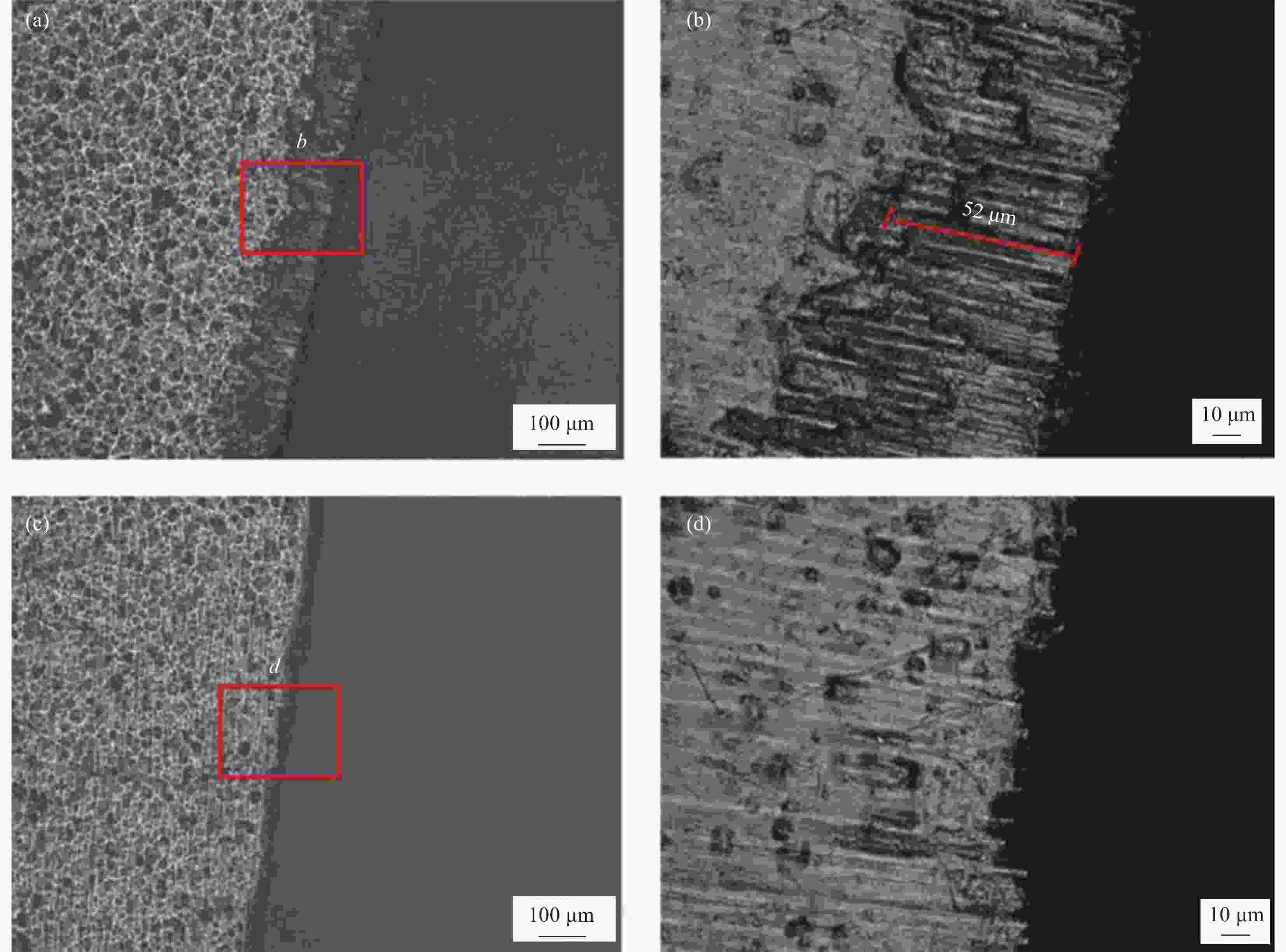

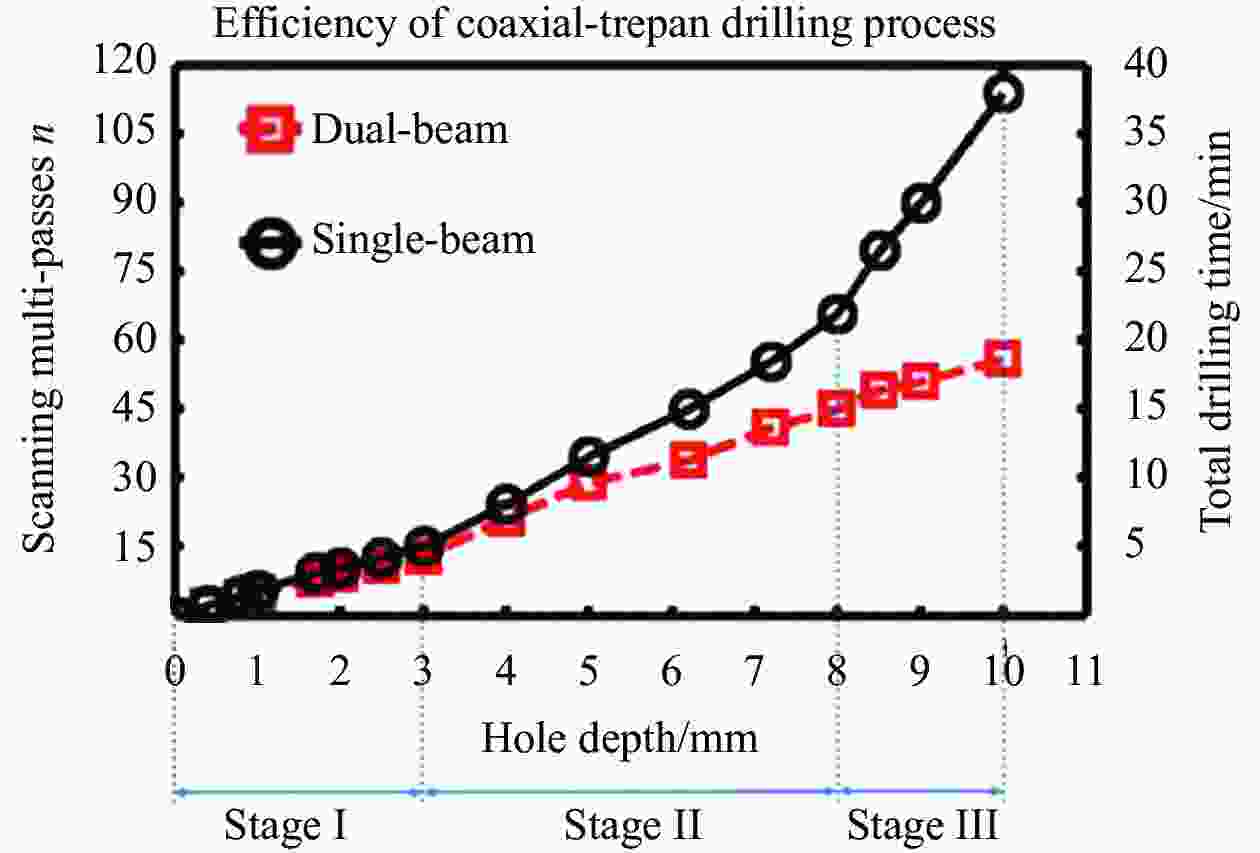

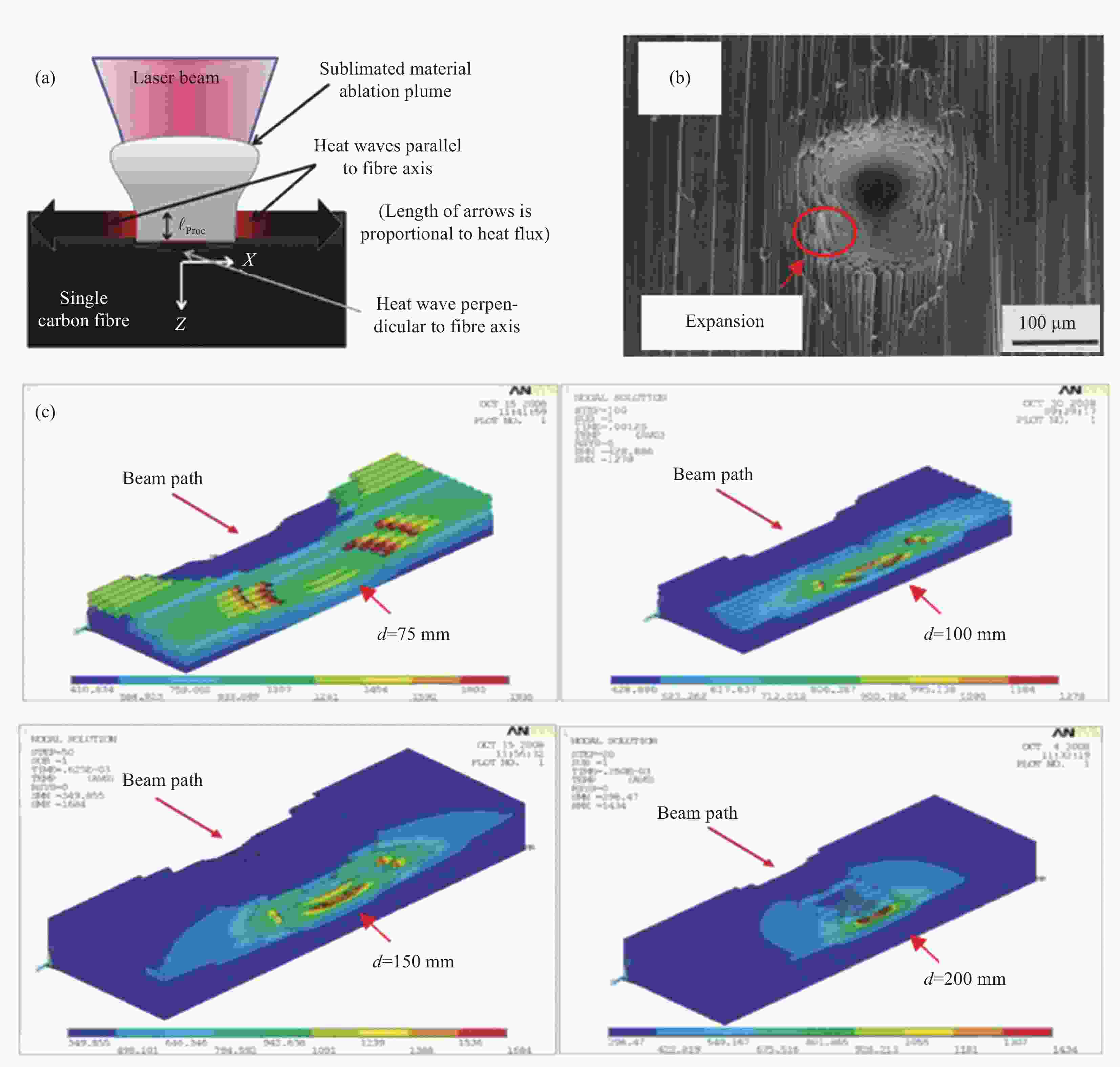

图 16 CFRP激光加工数值仿真:(a) 激光与CFRP单层碳纤维作用示意图;(b) 孔周边碳纤维膨胀现象;(c) 不同环间距下CFRP材料移除深度预测

Figure 16. Numerical simulation of laser machining CFRP: (a) Schematic of CFRP interaction process on a single carbon fiber layer; (b) Fiber expansion around the processed hole; (c) Predicted material removal depth for various values of spacing distance

$\ell _{\rm{Proc}} $—Processing depth

表 1 CFRP激光制孔常见工艺

Table 1. Common processes of CFRP laser drilling

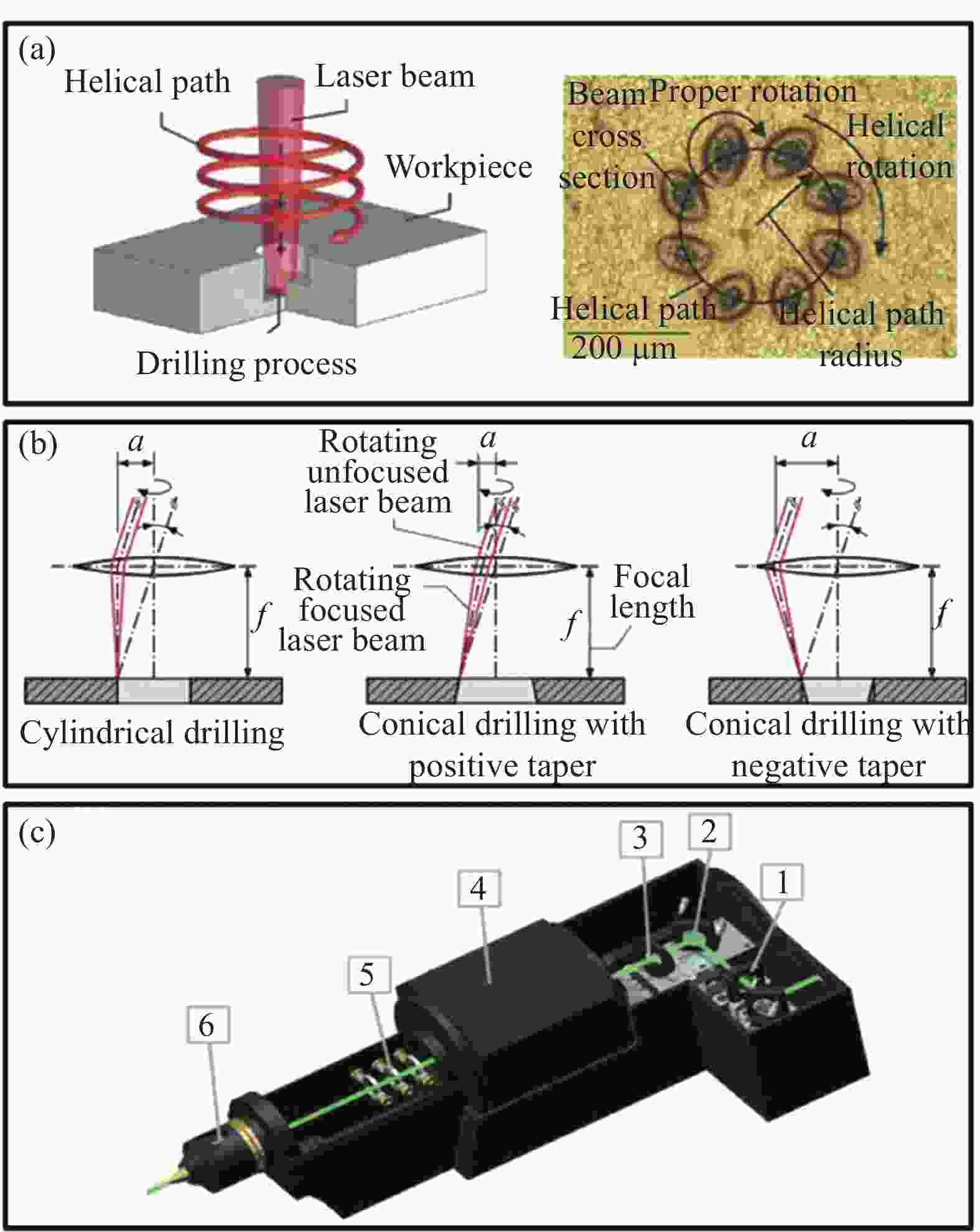

Drilling process Thickness of plate Drilling diameter Taper of drilled hole HAZ of drilled hole Drilling efficiency Coaxial-trepan drilling Thin Large Large Large Low Dual-beam drilling High Large Large Small Medium Helical drilling Medium Small Small Medium high Double-rotation drilling Medium Medium Small Medium high -

[1] EMMELMANNA C, PETERSEN M, GOEKE A, et al. Analysis of laser ablation of CFRP by ultra-short laser pulses with short wavelength[J]. Physics Procedia,2011,12:565-571. doi: 10.1016/j.phpro.2011.03.071 [2] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1) : 1-12.DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, 24(1): 1-12(in Chinese). [3] 吴志刚. 碳纤维增强环氧树脂基复合材料的研究进展[J]. 天津科技, 2018, 45(7):53-58. doi: 10.3969/j.issn.1006-8945.2018.07.019WU Z G. Carbon fiber reinforced epoxy resin composites: A review of research progress[J]. Tianjin Science & Technology,2018,45(7):53-58(in Chinese). doi: 10.3969/j.issn.1006-8945.2018.07.019 [4] 包建文, 钟翔屿, 张代军, 等. 国产高强中模碳纤维及其增强高韧性树脂基复合材料研究进展[J]. 材料工程, 2020, 48(8):33-48. doi: 10.11868/j.issn.1001-4381.2020.000208BAO J W, ZHONG X Y, ZHANG D J, et al. Progress in high strength intermediate modulus carbon fiber and its high toughness resin matrix composites in china[J]. Journal of Materials Engineering,2020,48(8):33-48(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000208 [5] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316.CHEN Y, GE E D, FU Y C, et al. Review and prospect of drilling technologies for carbon fiber reinforced polymer[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese). [6] 李光友, 倪亭, 郭辉. 轨道交通用碳纤维复合材料的技术进展与应用[J]. 纺织导报, 2020, 7:25-29. doi: 10.3969/j.issn.1003-3025.2020.10.022LI G Y, NI T, GUO H. Technical progress and application of carbon fiber composites for rail transit[J]. China Textile Leader,2020,7:25-29(in Chinese). doi: 10.3969/j.issn.1003-3025.2020.10.022 [7] 孙延. 碳纤维增强复合材料在新能源汽车上的应用形式及进展[J]. 粘接, 2019(9):71-74. doi: 10.3969/j.issn.1001-5922.2019.09.017SUN Y. Application forms and progress of carbon fiber reinforced composites in new energy vehicles[J]. Adhesion,2019(9):71-74(in Chinese). doi: 10.3969/j.issn.1001-5922.2019.09.017 [8] JIA Z, FU R, NIU B, et al. Novel drill structure for damage reduction in drilling CFRP composites[J]. International Journal of Machine Tools and Manufacture,2016,110:55-65. doi: 10.1016/j.ijmachtools.2016.08.006 [9] TAN C, SU J, ZHU B, et al. Effect of scanning speed on laser joining of carbon fiber reinforced PEEK to titanium alloy[J]. Optics & Laser Technology,2020,129:106273. [10] 张厚江, 陈五一, 陈鼎昌, 碳纤维复合材料钻削孔分层缺陷的研究[J]. 中国机械工程, 2003, 14: 1978-1981.ZHANG H J, CHEN W Y, CHEN D C. Study on delamination defects in drilling holes of carbon fiber composites[J]. China Mechanical Engineering, 2003, 48 (15): 1978-1983(in Chinese). [11] TSAO C C. Thrust force and delamination of core-saw drill during drilling of carbon fiber reinforced plastics (CFRP)[J]. The International Journal of Advanced Manufacturing Technology,2007,37:23-28. [12] SHYHA I S, ASPINWALL D K, SOO S L, et al. Drill geometry and operating effects when cutting small diameter holes in CFRP[J]. International Journal of Machine Tools and Manu-facture,2009,49:1008-1014. doi: 10.1016/j.ijmachtools.2009.05.009 [13] 王奔, 高航, 毕铭智, 等. C/E复合材料螺旋铣削制孔方法抑制缺陷产生的机理[J]. 机械工程学报, 2012, 48(15):173-181. doi: 10.3901/JME.2012.15.173WANG B, GAO H, BI M Z, et al. Mechanism of reduction of damage during orbital drilling of C/E composites[J]. Journal of Mechanical Engineering,2012,48(15):173-181(in Chinese). doi: 10.3901/JME.2012.15.173 [14] 王福吉, 殷俊伟, 贾振元, 等. CFRP复合材料铣削力、温度及表层损伤分析[J]. 机械工程学报, 2018, 3:186-195.WANG F J, YIN J W, JIA Z Y, et al. Measurement and analysis of cutting force, temperature and cutting-induced top-layer damage in edge trimming of CFRPs[J]. Journal of Mechanical Engineering,2018,3:186-195(in Chinese). [15] 赵文辉, 张伟东, 段振云, 等. 基于分层损伤分析的碳纤维增强树脂复合材料-金属传动轴扭转性能[J]. 复合材料学报, 2021, 38(5):1476-1486.ZHAO W H, ZHANG W D, DUAN Z Y, et al. Torsion properties of carbon fiber-metal transmission shaft based on delamination damage analysis[J]. Acta Materiae Compo-sitae Sinica,2021,38(5):1476-1486(in Chinese). [16] 张博宇. 铣/钴削CFRP表层损伤抑制关键技术研究[D]. 大连: 大连理工大学, 2020.ZHANG B Y. Research on key technolofies for surface damages suppression in edge trimming/drilling of CFRP composites[D]. Dalian: Dalian University of Technology, 2020(in Chinese). [17] EL-HOFY M H, EL-HOFY H. Laser beam machining of carbon fiber reinforced composites: A review[J]. The International Journal of Advanced Manufacturing Technology,2018,101:2965-2975. [18] REINHART P. Tailored light 2 laser application technology[M]. Berlin: Springer, 2011. [19] QI Y, CHEN G, DENG S, et al. Periodic root humps in thick-plate laser welding using steady electromagnetic force[J]. Journal of Materials Processing Technology, 2019, 273: 116247. [20] 顾波. 激光加工技术及产业的现状与应用发展趋势[J]. 金属加工(热加工), 2020, 10:37-42.GU B. The present status and development trend of laser processing technology and industry[J]. Machinist Metal Forming,2020,10:37-42(in Chinese). [21] CHEN X, LOTSHAW W T, ORTIZ A L, et al. Laser drilling of advanced materials: Effects of peak power, pulse format, and wavelength[J]. Journal of Laser Applications,1996,8(5):233-239. doi: 10.2351/1.4745427 [22] 孙岳, 黄海明, 高锁文. 激光烧蚀机理研究进展[J]. 失效分析与预防, 2008, 3(2):58-63. doi: 10.3969/j.issn.1673-6214.2008.02.012SUN Y, HUANG H M, GAO S W. Progress of research in laser ablation mechanism[J]. Failure Analysis and Prevention,2008,3(2):58-63(in Chinese). doi: 10.3969/j.issn.1673-6214.2008.02.012 [23] 蒋翼. 碳纤维复合材料皮秒激光切割及其与铝合金连接研[D]. 长沙: 湖南大学, 2017.JIANG Y. Research on cutting carbon-fiber reinforced plastic with picosecond pulsed laser and its connection with aluminum alloy[D]. Changsha: Hunan University, 2017(in Chinese). [24] 周典瑞, 高亮, 霍红宇, 等. 热塑性树脂基复合材料用碳纤维上浆剂研究进展[J]. 复合材料学报. 2020, 37(8): 1785-1795.ZHOU D R, GAO L, HUO H Y, et al. Research progress of carbon fiber sizing agents for thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2020, 37(8): 1785-1795(in Chinese). [25] WEBER R, HAFNER M, MICHALOWSKI A, et al. Minimum damage in CFRP laser processing[J]. Physics Procedia,2011,12:302-307. doi: 10.1016/j.phpro.2011.03.137 [26] ROMOLI L, FISCHER F, KLING R. A study on UV laser drilling of PEEK reinforced with carbon fibers[J]. Optics and Lasers in Engineering. 2012, 50(3): 449-457. [27] LI Z L, ZHENG H Y, LIM G C. Study on UV laser machining quality of carbon fibre reinforced composites[J]. Compo-sites Part A: Applied Science and Manufacturing,2010,41:1403-1408. doi: 10.1016/j.compositesa.2010.05.017 [28] DIRK H, MATTHIAS S L, MAX O, et al. Laser cutting of carbon fibre reinforced plastics of high thickness[J]. Materials and Design, 2016, 92 : 742-749. [29] TAO N R, CHEN G Y, YU T Y, et al. Dual-beam laser drilling process for thick carbon fiber reinforced plastic compo-sites plates[J]. Journal of Materials Processing Technology, 2020, 281: 116590. [30] LI W, ZHANG G, HUANG Y, et al . UV laser high-quality drilling of CFRP plate with a new interlaced scanning mode [J]. Composite Structures , 2021, 273: 114258. [31] FORNAROLI C, HOLTKAMP J, GILLNER A. Laser-beam helical drilling of high quality micro holes[J]. Physics Procedia,2013,41:661-669. doi: 10.1016/j.phpro.2013.03.130 [32] SHIN J, MAZUMDER J. Shallow Angle drilling of inconel 718 using a helical laser drilling technique[J]. Journal of Manufacturing Science and Engineering,2017,139:031004. doi: 10.1115/1.4034718 [33] KASPAR J, LUFT A, NOLTE S, et al. Laser helical drilling of silicon wafers with ns to fs pulses: Scanning electron microscopy and transmission electron microscopy characterization of drilled through-holes[J]. Journal of Laser Applications,2006,18:85-92. doi: 10.2351/1.2164480 [34] 叶逸云, 贾少辉, 徐子法, 等. 碳纤维复合材料激光切割制孔工艺研究[J]. 航空制造技术, 2019, 62(19):50-55.YE Y Y, JIA S H, XU Z F, et al. Research on hole drilling in carbon fiber reinforced composite by using laser cutting method[J]. Aeronautical Manufacturing Technology,2019,62(19):50-55(in Chinese). [35] OUYANG W, JIAO J, XU Z, et al. Experimental study on CFRP drilling with the picosecond laser “double rotation” cutting technique[J]. Optics & Laser Technology, 2021, 142: 107238. [36] OH S, LEE I, PARK Y B, et al. Investigation of cut quality in fiber laser cutting of CFRP[J]. Optics& Laser Technology,2019,113:129-140. [37] JIANG H, MA C, LI M, et al. Femtosecond laser drilling of cylindrical holes for carbon fiber-reinforced polymer (CFRP) composites[J]. Molecules, 2021, 26: 2953. [38] ZHANG Y, SHEN Z, NI X. Modeling and simulation on long pulse laser drilling processing[J]. International Journal of Heat and Mass Transfer,2014,73:429-437. doi: 10.1016/j.ijheatmasstransfer.2014.02.037 [39] ALWAIDH A, BAKER I, HAY N, et al. High throughput cutting and drilling of carbon fibre reinforced polymer with nanosecond pulsed solid state lasers[C]. San Diego: International Congress on Applications of Lasers & Electro-Optics, 2014: 1208-1214. [40] HERRMANN T, STOLZE M, LHUILLIER J. Laser drilling of carbon fiber reinforced plastics (CFRP) by picosecond laser pulses: Comparative study of different drilling tools[J]. International Society for Optics and Photonics,2014,8972:89721. [41] SCHLÜTER H, WEBER P. 5-axis scanner for precession drilling[C]. Puchheim: 9th International conference on Photonic Technologies LANE, 2016. [42] OLIVEIRA V, SHARMA S P, MOURA M F S F, et al. Surface treatment of CFRP composites using femtosecond laser radiation[J]. Optics and Lasers in Engineering,2017,94:37-43. [43] LEONE C, PAPA I, TAGLIAFERRI F, et al. Investigation of CFRP laser milling using a 30W Q-switched Yb: YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation[J]. Composites Part A: Applied Science and Manufacturing, 2013, 55: 129-142. [44] LI M, GAN G, ZHANG Y, et al. Thermal damage of CFRP laminate in fiber laser cutting process and its impact on the mechanical behavior and strain distribution[J]. Archives of Civil and Mechanical Engineering, 2019, 19(4): 1511-1522. [45] KALYANASUNDARAM D, GURURAJA S, PRABHUNE P, et al. Open hole fatigue testing of laser machined MD-CFRPs[J]. Composites Part A: Applied Science and Manufacturing, 2018, 111: 33-41. [46] HE F J, SINGH D, KUBHER S, et al. Machining damage in FRPs: Laser versus conventional drilling[J]. Composites Part A: Applied Science and Manufacturing, 2016, 82: 42-52. [47] HU J, ZHU D. Experimental study on the picosecond pulsed laser cutting of carbon fiber-reinforced plastics[J]. Journal of Reinforced Plastics and Composites, 2018, 37(15): 993-1003. [48] WOLYNSKI A, HERRMANN T, MUCHA P, et al. Laser ablation of CFRP using picosecond laser pulses at different wavelengths from UV to IR[J]. Physics Procedia,2011,12(1):292-301. [49] YALUKOVA O, SÁRADY I. Investigation of interaction mechanisms in laser drilling of thermoplastic and thermoset polymers using different wavelengths[J]. Compo-sites Science and Technology,2006,66:1289-1296. doi: 10.1016/j.compscitech.2005.11.002 [50] JAESCHKE P, STOLBERG K, BASTICK S, et al. Cutting and drilling of carbon fiber reinforced plastics (CFRP) by 70W short pulse nanosecond laser[C]//Spie Lase. High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications III. Brussel, 2014. [51] 贺龙宇. 基于飞秒激光的CFRP制孔质量研究[D]. 天津: 天津工业大学, 2019: 65-75.HE L Y. Research on the drilling quality of CFRP based on femtosecond laser[D]. Tianjin: Tianjin University of Technology, 2019, 65-75 (in Chinese). [52] FREITAG C, WIEDENMANN M, NEGEL J P, et al. High-quality processing of CFRP with a 1.1-kW picosecond laser[J]. Applied Physics A,2015,119(4):1237-1243. doi: 10.1007/s00339-015-9159-3 [53] XU J Y, AN Q L, CHEN M. A comparative evaluation of polycrystalline diamond drills in drilling high-strength T800S/250F CFRP[J]. Composite Structures,2014,117:71-82. doi: 10.1016/j.compstruct.2014.06.034 [54] PAUL S, KUDRYASHOV S I, LYON K, et al. Nanosecond laser plasma-assisted ultra-deep microdrilling of optically opaque and transparent solids[J]. Journal of Applied Physics,2007,101:043106. doi: 10.1063/1.2434829 [55] KIM M J, CHEN Z H, MAJUMDAR P. Finite element modeling of the laser cutting process[J]. Computers & Structures, 1993, 49: 231-241. [56] SCHULZ W, EPPELT U. The theory of laser materials processing (2th Ed)[M]. Netherlands: Springer, 2009: 170-178. [57] SALAMA A, LI L, MATIVENGA P, et al. High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites[J]. Applied Physics A,2016,122(2):73-83. doi: 10.1007/s00339-016-9607-8 [58] TAKAHASHI K, TSUKAMOTO M, MASUNO S, et al. Heat conduction analysis of laser CFRP processing with IR and UV laser light[J]. Composites Part A: Applied Science and Manufacturing, 2016, 84: 114-122. [59] SALAMA A, YAN Y, LI L, et al. Understanding the self-limiting effect in picosecond laser single and multiple parallel pass drilling/machining of CFRP composite and mild steel[J]. Materials & Design,2016,107:461-469. [60] WAHAB M S, RAHMAN N A, MOHAMED M A S, et al. Optimization of laser cutting parameters on the laminated carbon fibre reinforced plastics (CFRP) composites using DOE technique[J]. Applied Mechanics & Materials,2014,660:60-64. [61] JOHANNES S, MICHAEL F Z, MARKUS C. Remote laser cutting of CFRP: Improvements in the cut surface[J]. Physics Procedia,2012,39:161-170. [62] STAEHR R, BASTICK S, BLUEMEL S, et al. High precision laser macro drilling of carbon fiber reinforced plastics with a new nanosecond pulsed laser—Optimized toward industrial needs[J]. Journal of Laser Applications,2019,31:022207. doi: 10.2351/1.5096120 [63] 宋维建, 万瓦级激光切割装备及技术[J]. 金属加工(热加工), 2018, 3: 22-24.SONG W J. 10000 W laser cutting equipments and technology[J]. Metal Processing (Hot-work), 2018, 3: 22-24(in Chinese). [64] CHENG C F, TSUI Y C, CLYNE T W. Application of a three-dimensional heat flow model to treat laser drilling of carbon fibre composites[J]. Acta Materialia,1998,46(12):4273-4285. doi: 10.1016/S1359-6454(98)00090-1 [65] NEGARESTANI R, SUNDAR M, SHEIKH M A, et al. Numerical simulation of laser machining of carbon-fibre-reinforced composites[J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manu-facture,2010,224(7):1017-1027. doi: 10.1243/09544054JEM1662 [66] OHKUBO T, SATO Y, MATSUNAGA E I, et al. Three-dimensional numerical simulation during laser processing of CFRP[J]. Applied Surface Science,2017,417:104-107. doi: 10.1016/j.apsusc.2017.02.249 [67] WU F F, PILKINGTON R D. Model predicting the microhole profiles of laser drilling processes in carbon fiber composite[J]. International Society for Optics and Photonics,2000,3933:445-456. [68] WANG L, ZHOU Z, LIU Y C, et al. Interaction between pulsed infrared laser and carbon fiber reinforced polymer composite laminates[J]. International Conference Proceedings of SPIE,2016,10152:101520X.1-101520X.6. [69] FAAS S, FREITAG C, BOLEY S, et al. Flow speed of the ablation vapors generated during laser drilling of CFRP with a continuous-wave laser beam[J]. Applied Physics A,2017,123(3):156. doi: 10.1007/s00339-017-0781-0 [70] BLUEMEL S, KUKLIK J, STAEHR R, et al. Time resolved analysis of nanosecond pulsed laser processing of carbon fiber reinforced plastics[J]. Journal of Laser Applications,2017,29(2):022406. doi: 10.2351/1.4983242 [71] ACQUAVIVA S, GIORGI M L D. Fast photography of XeCl laser-induced plasma of graphite in vacuum and in nitrogen atmosphere[J]. Journal of Physics B Atomic Molecular & Optical Physics,2003,36:247-260. [72] WIEDENMANN M, HAIST C, FREITAG C, et al. Ablation dynamics and shock wave expansion during laser processing of CFRP with ultrashort laser pulses[J]. Proceedings of Spie the International Society for Optical,2014,8967:2039468. [73] 汪建新, 吴耀文, 张广义, 等. 碳纤维增强复合材料水导激光切割试验研究[J]. 中国机械工程, 2021, 32(13): 1608-1616.WANG J X, WU Y W, ZHANG G Y, et al. The experimental research on carbon fiber reinforced plastic cutting by using waterjet guided laser processing[J]. China Mechanical Engineering, 2021, 32(13): 9(in Chinese). -

下载:

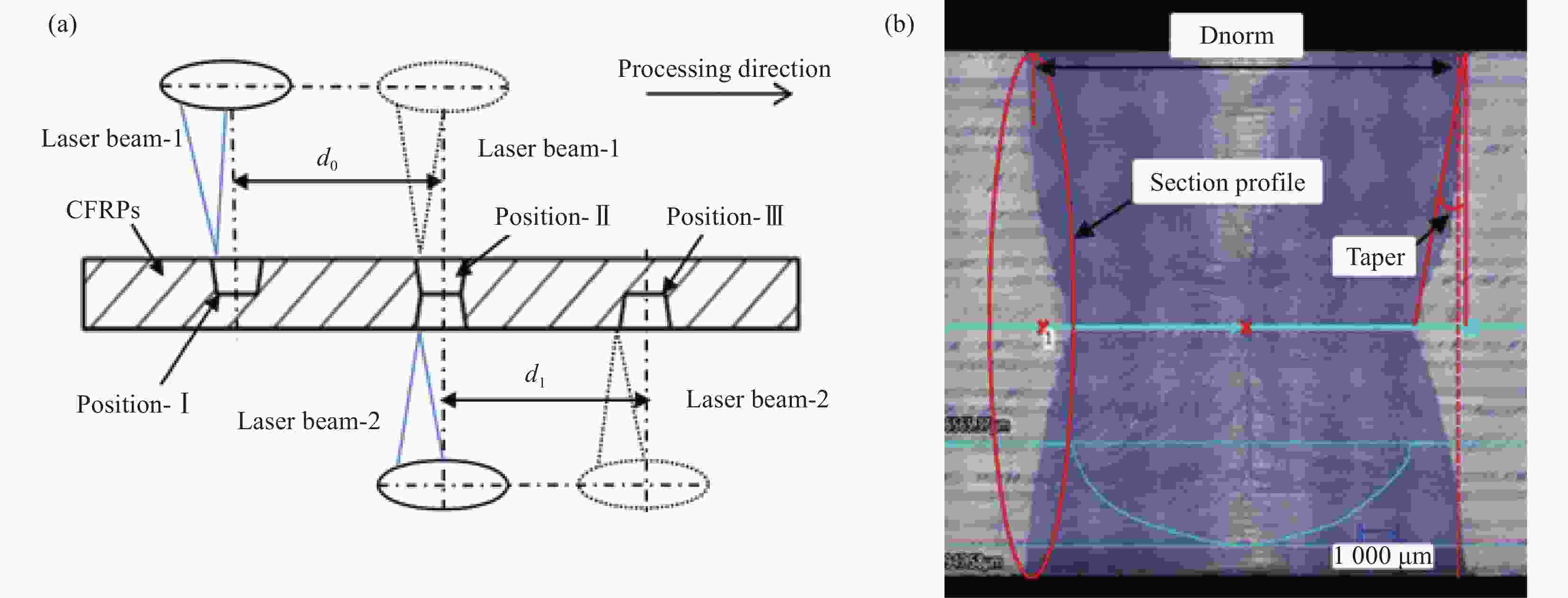

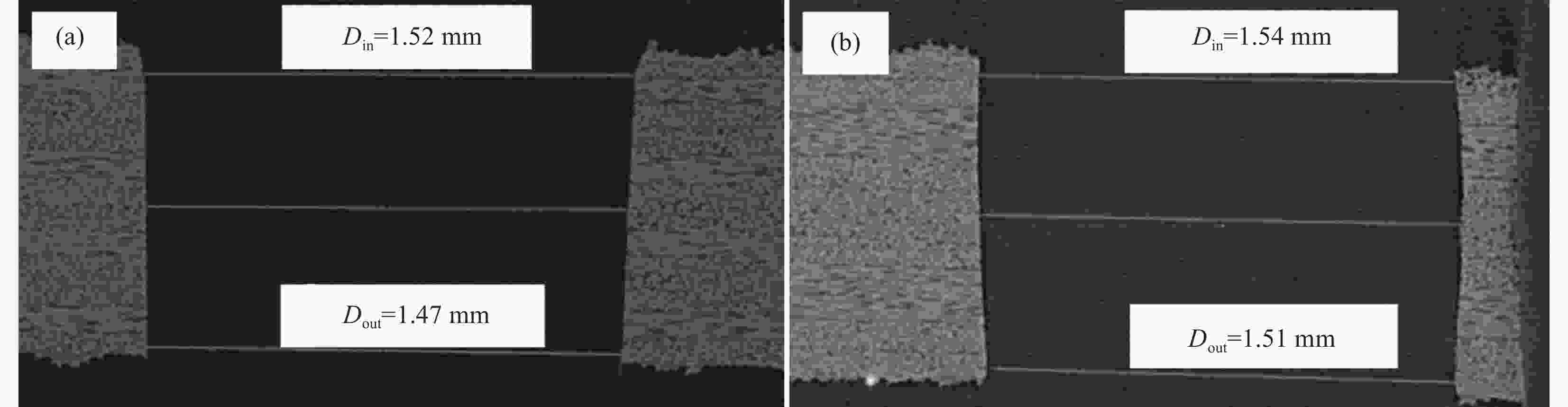

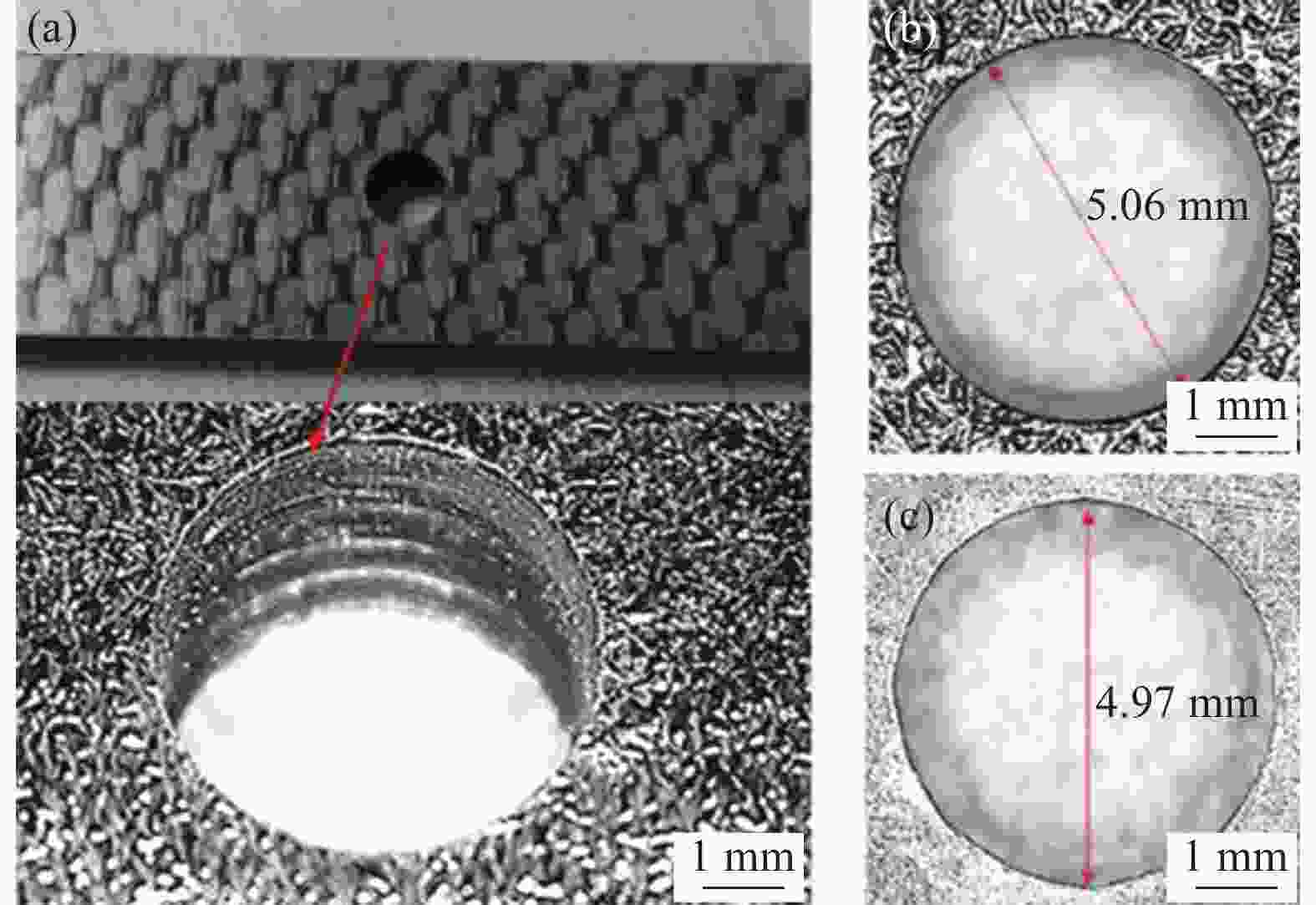

下载: