Study on the optimization strategy of variable stiffness laminate considering out-of-plane fiber waviness

-

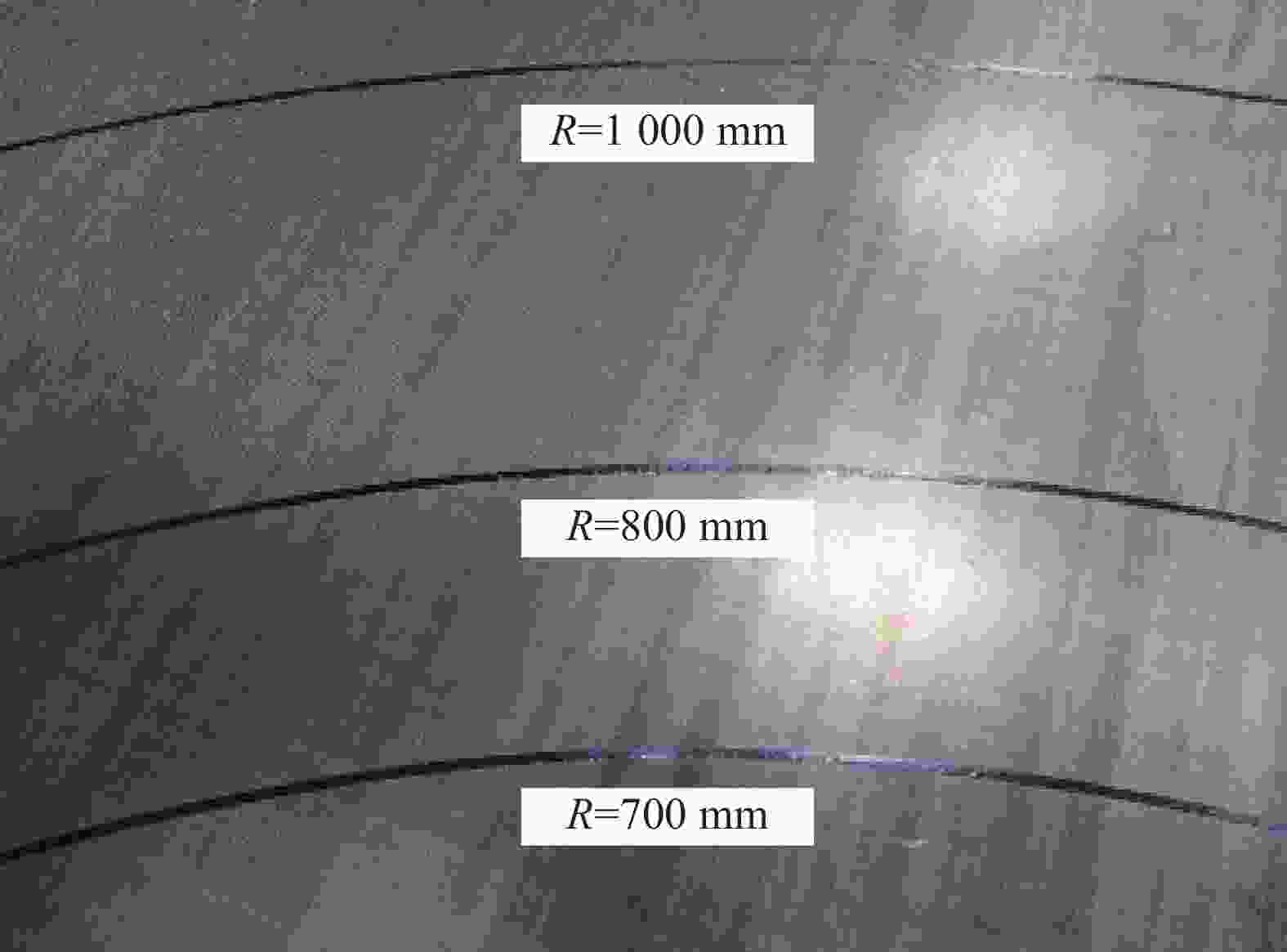

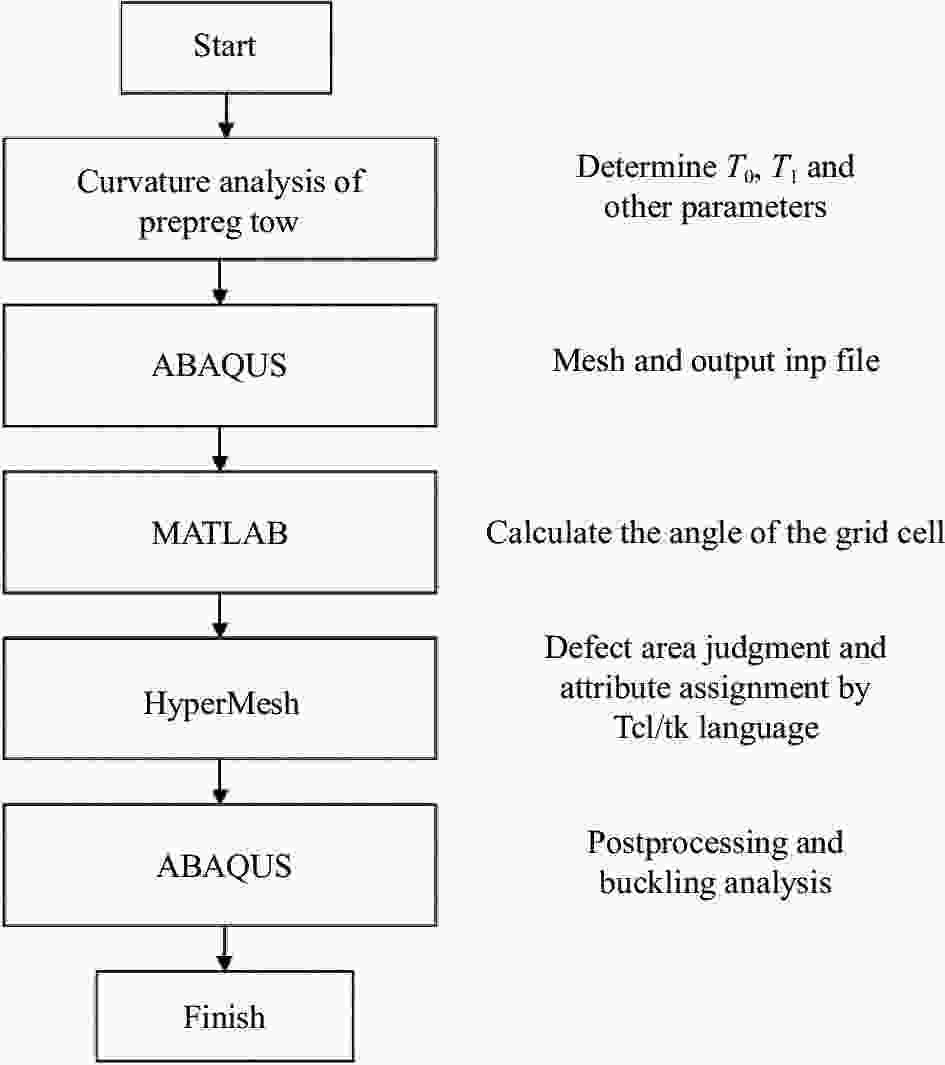

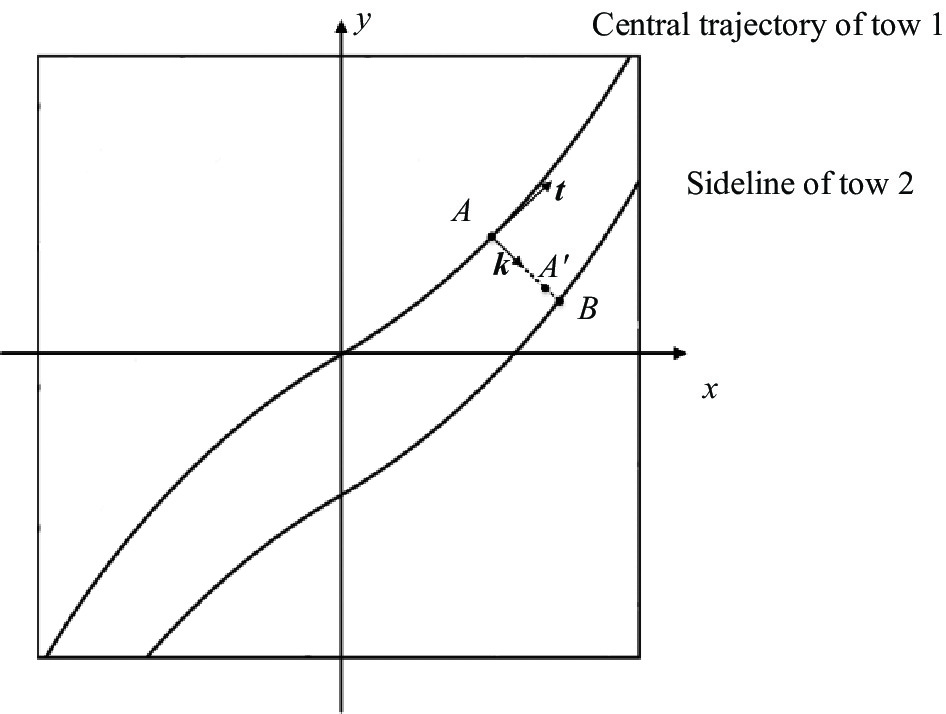

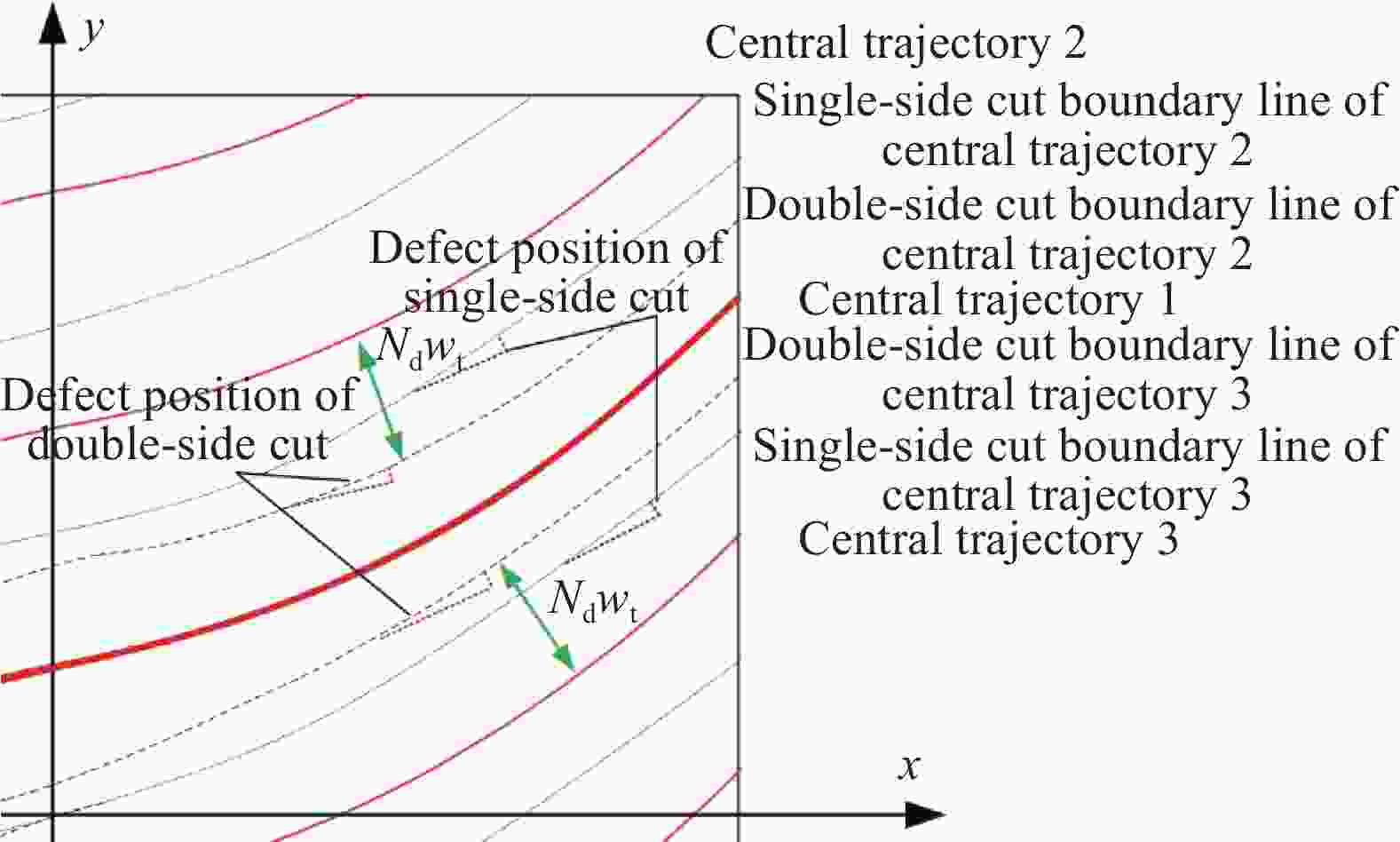

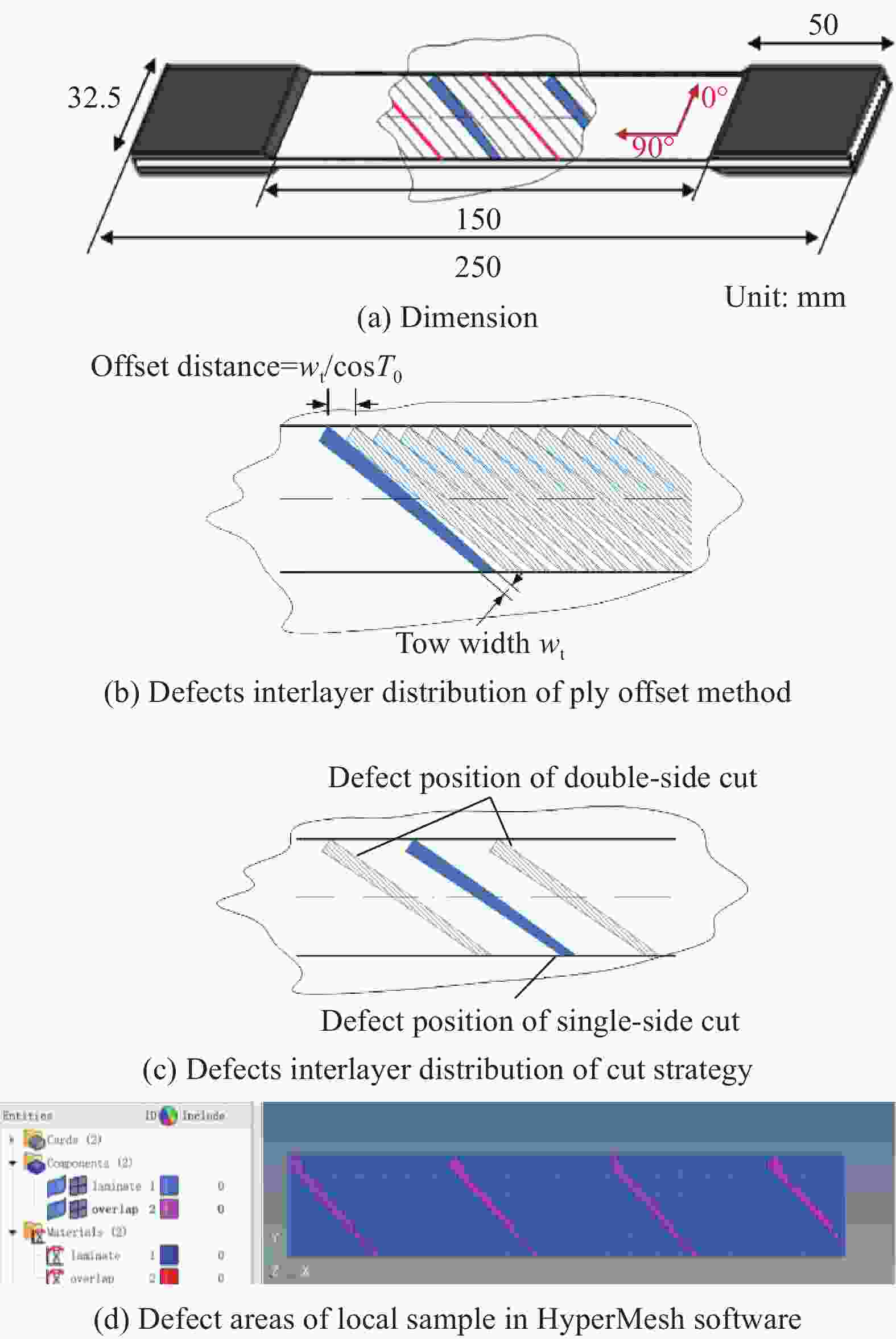

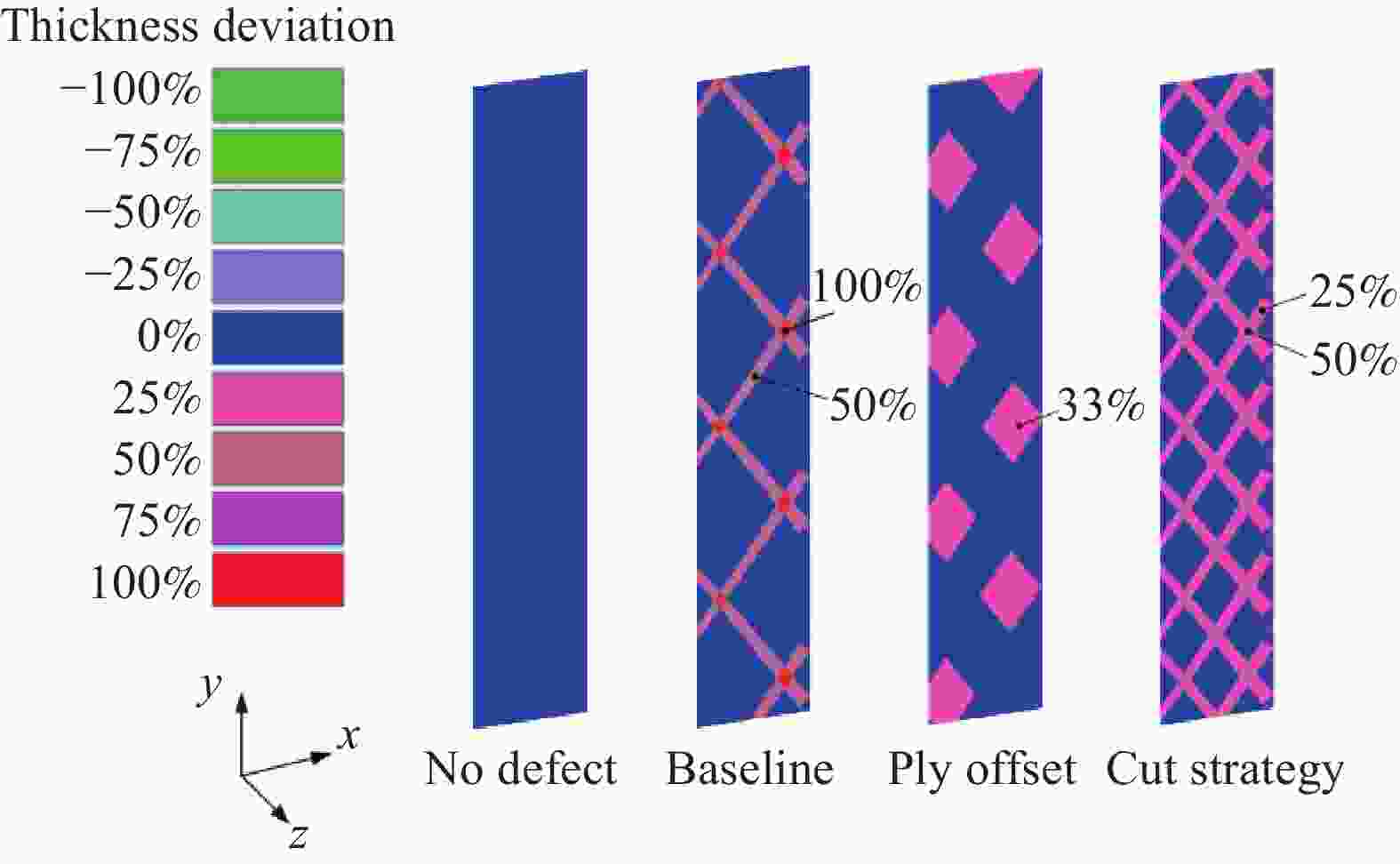

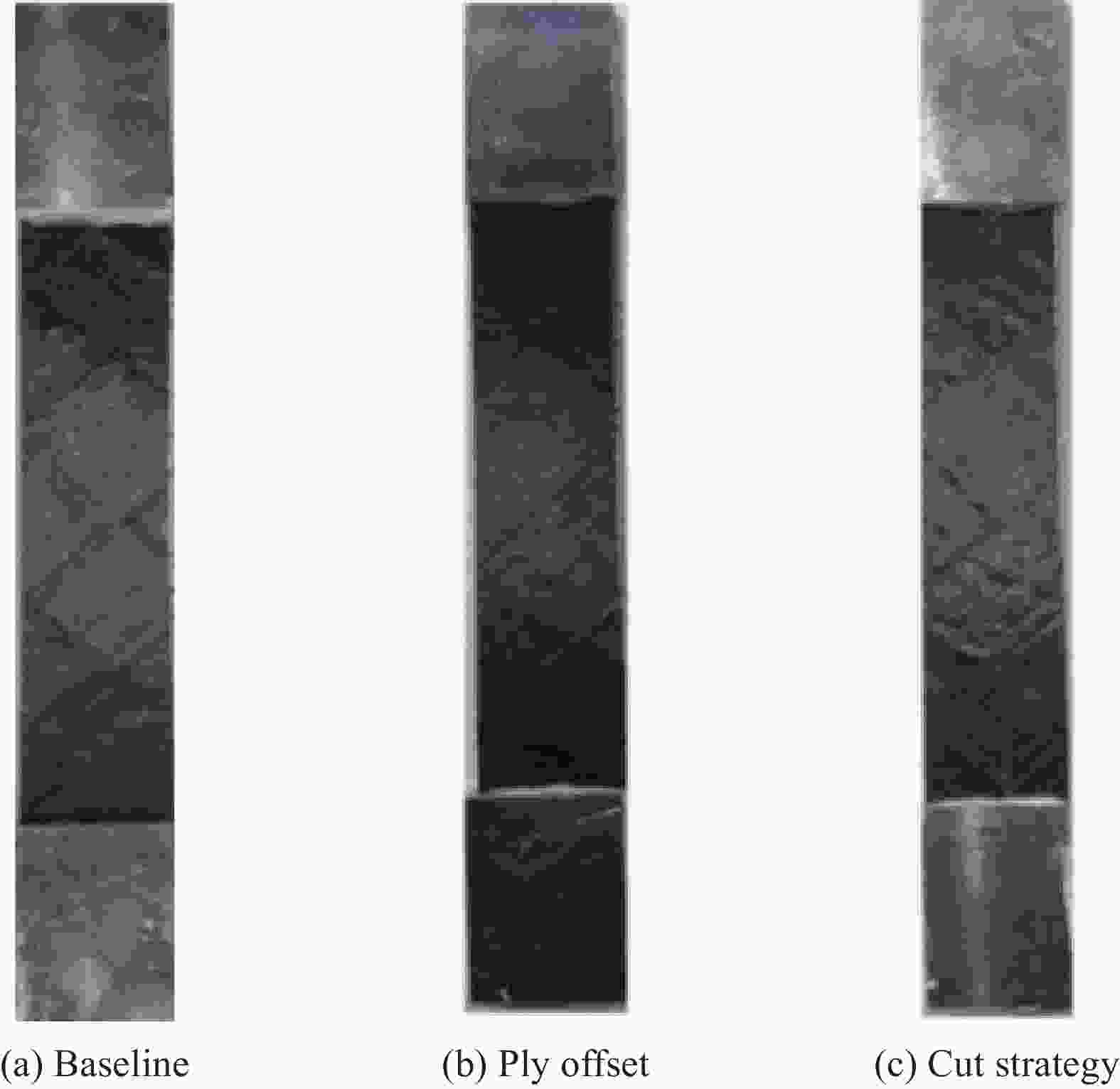

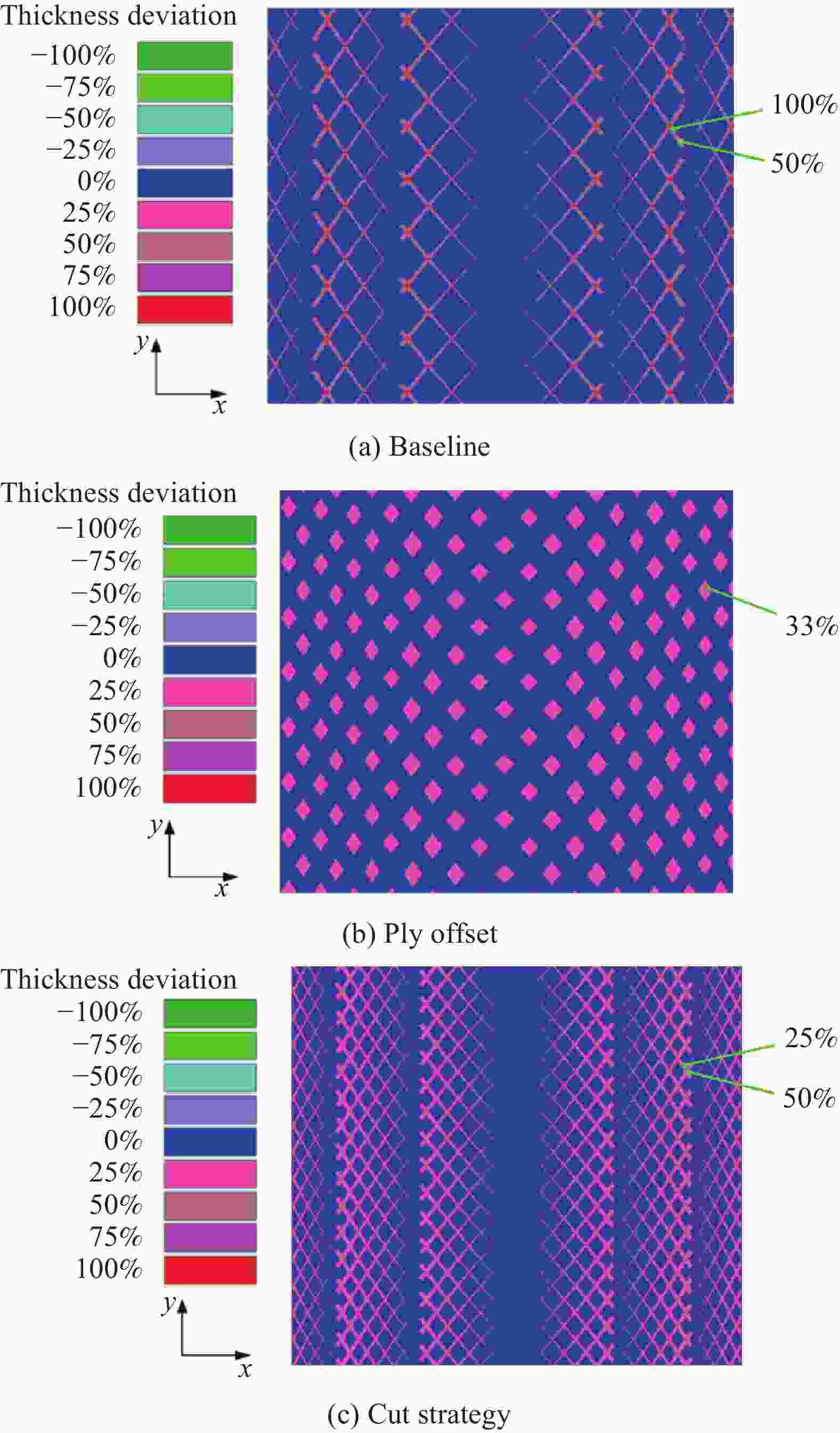

摘要: 针对变刚度层合板在自动铺放制造过程中因间隙/重叠缺陷产生大量纤维面外起伏缺陷的问题,提出采用铺层偏移法与断送纱策略两种铺层优化策略来进行变刚度层合板的铺层设计,在研究过程中同时引入考虑间隙/重叠缺陷建模的方法。根据变刚度层合板铺层的特点提出缺陷重复单元的概念,通过对缺陷重复单元的分析来反映纤维面外起伏的影响,并提出通过纤维面外系数来表征变刚度层合板的纤维面外起伏尺度,最后对不同优化策略的变刚度层合板的屈曲性能进行分析。研究表明:基准设计方案、铺层偏移法与断送纱策略所对应的纤维面外起伏系数为0.83、0.95、0.93,所提出的优化策略对变刚度层合板的纤维面外起伏尺度有着明显的抑制作用。铺层偏移法优化后的[±<50/65>]6s变刚度层合板最大厚度超差为33%,所对应的屈曲载荷为9117.1 N,屈曲载荷提升17.6%;断送纱策略优化后的[±<50/65>]6s变刚度层合板最大厚度超差为50%,所对应的屈曲载荷为9716.3N,屈曲载荷提升25.3%。Abstract: Aiming at the problem of a large number of out-of-plane fiber waviness defects due to gap/overlap defects formed in the automated fiber placement process of variable stiffness laminate, two optimization strategies of ply offset and cut strategy were proposed to design variable stiffness laminate, and the modeling method considering gap/overlap defects was introduced. According to the characteristics of variable stiffness laminate, the influence of out-of-plane fiber waviness was reflected through the analysis of defect-repeating elements, and the out-of-plane fiber coefficient was proposed to characterize the scale of waviness in variable stiffness laminate. Finally, the bending performance of variable stiffness laminate with different optimization strategies was analyzed. The coefficients of out-of-plane waviness corresponding to the benchmark scheme, the optimization strategy of ply offset method and the cut strategy are 0.83, 0.95 and 0.93. The proposed optimization strategy has an obvious inhibitory effect on the scale of out-of-plane waviness of variable stiffness laminate. The maximum thickness deviation of [±<50/65>]6s variable stiffness laminate optimized by ply offset method is 33%, the corresponding buckling load is 9117.1 N, increasing by 17.6%; The maximum thickness deviation of [±<50/65>]6s variable stiffness laminate optimized by the cut strategy is 50%, the corresponding buckling load is 9716.3N, increasing by 25.3%.

-

表 1 考虑间隙/重叠建模所需的材料力学性能

Table 1. Mechanical properties of materials considering gap/overlap modeling

EM118 carbon

fiber/A10

epoxy laminate$ {E_1} $/GPa $ {E_2} $=$ {E_3} $/GPa $ {G_{12}} $=$ {G_{13}} $/GPa $ {G_{23}} $/GPa $ {v_{12}} $=$ {v_{13}} $ $ {v_{23}} $ 140 7.5 3.69 4 0.3 0.4 $ h $/mm $ {\rho _{\text{l}}} $/(g·mm−3) 0.15 1.85 Epoxy resin $ {E_{\text{r}}} $/GPa $ {v_{\text{r}}} $ $ {\rho _{\text{r}}} $/(g·mm−3) 2 0.25 1.117 Notes: E1, E2, E3—Elastic modulus of laminate; G12, G13, G23—Shear modulus of laminate; v12, v13, v23—Poisson’s ratio of laminate; h—Thickness of laminate; ρl—Density of laminate; Er—Elastic modulus of resin; vr—Poisson’s ratio of resin; ρr—Density of resin. 表 2 [±<50/65>]6s层合板纤维面外起伏系数τc

Table 2. Coefficient τc of [±<50/65>]6s laminate with out-of-plane fiber waviness

Name Baseline Ply offset Cut strategy ${\tau _{\rm{c}}}$ 0.83 0.95 0.93 表 3 不同优化策略的[±<50/65>]6s层合板铺层厚度与屈曲载荷

Table 3. Ply thickness and buckling load of [±<50/65>]6s laminate with different optimization strategies

Ply type Ply angle Maximum thickness

deviation before

optimization/%Design

factorBuckling load

before

optimization /NOptimization

strategyMaximum thickness

deviation after

optimization/%Buckling load

after

optimization /NBuckling change/% Linear ply [45/90/−45/0]3s − − 7751.5 − − − − Curved ply [±<50/65>]6s +100 No defect − − − − +10.3 [±<50/65>]6s 100% Coverage 8551.4 Ply offset +33.3 9117.1 +17.6 [±<50/65>]6s 100% Coverage − Cut strategy +50 9716.3 +25.3 -

[1] 陈吉平, 李岩, 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成型技术的航空发展现状[J]. 复合材料学报, 2019, 36(4):784-794.CHEN Jiping, LI Yan, LIU Weiping, et al. Development of AFP in-situ consolidation technology on continuous fiber reinforced thermoplastic matrix composites in aviation[J]. Acta Materiae Compositae Sinica,2019,36(4):784-794(in Chinese). [2] 王显峰, 张育耀, 赵聪, 等. 复合材料自动铺丝设备研究现状[J]. 航空制造技术, 2018, 61(14): 83-90.WANG Xianfeng, ZHANG Yuyao, ZHAO Cong, et al. Research status of automatic fiber placement equipment for composite materials[J]. Aeronautical Manufacturing Technology, 2018, 61(14): 83-90(in Chinese). [3] 曹忠亮, 郭登科, 林国军, 等. 碳纤维复合材料自动铺放关键技术的现状与发展趋势[J]. 材料导报, 2021, 35(21):21185-21194.CAO Zhongliang, GUO Dengke, LIN Guojun, et al. Current situation and development trend of key technologies for automated placement of carbon fiber composites[J]. Materials Reports,2021,35(21):21185-21194(in Chinese). [4] 卫宇璇, 张明, 刘佳, 等. 基于自动铺放技术的高精度变刚度复合材料层合板屈曲性能[J]. 复合材料学报, 2020, 37(11):2807-2815.WEI Yuxuan, ZHANG Ming, LIU Jia, et al. Buckling performance of high-precision variable stiffness composites laminate based on automatic placement technology[J]. Acta Materiae Compositae Sinica,2020,37(11):2807-2815(in Chinese). [5] 欧阳小穗, 刘毅. 高速流场中变刚度复合材料层合板颤振分析[J]. 航空学报, 2018, 39(3):111-121.OUYANG Xiaosui, LIU Yi. Panel flutter of variable stiffness composite laminates in supersonic flow[J]. Acta Aeronauticaet Astronautica Sinica,2018,39(3):111-121(in Chinese). [6] 孔斌, 顾杰斐, 陈普会, 等. 变刚度复合材料结构的设计, 制造与分析[J]. 复合材料学报, 2017, 34(10):2121-2133.KONG Bin, GU Jiefei, CHEN Puhui, et al. Design, manufacture and analysis of variable-stiffness composite structures[J]. Acta Materiae Compositae Sinica,2017,34(10):2121-2133(in Chinese). [7] CAO Z L, DONG M J, SHI Q H, et al. Research on buckling characteristics and placement processability of variable stiffness open-hole laminates[J]. Composites Part C: Open Access,2022,7:100233. doi: 10.1016/j.jcomc.2022.100233 [8] MAROUENE A, BOUKHILI R, CHEN J, et al. Effects of gaps and overlaps on the buckling behavior of an optimally designed variable-stiffness composite laminates—A numerical and experimental study[J]. Composite Structures,2016,140:556-566. doi: 10.1016/j.compstruct.2016.01.012 [9] XIN Z, DUAN Y, XU W, et al. Review of the mechanical performance of variable stiffness design fiber-reinforced composites[J]. Science and Engineering of Composite Materials,2018,25(3):425-37. doi: 10.1515/secm-2016-0093 [10] NIK M A, FAYAZBAKHSH K, PASINI D, et al. Optimization of variable stiffness composites with embedded defects induced by automated fiber placement[J]. Composite Structures,2014,107:160-166. doi: 10.1016/j.compstruct.2013.07.059 [11] BLOM A W, LOPES C S, KROMWIJK P J, et al. A theoretical model to study the influence of tow-drop areas on the stiffness and strength of variable-stiffness laminates[J]. Journal of composite materials,2009,43(5):403-425. doi: 10.1177/0021998308097675 [12] FAYAZBAKHSH K, NIK M A, PASINI D, et al. Defect layer method to capture effect of gaps and overlaps in variable stiffness laminates made by automated fiber placement[J]. Composite Structures,2013,97:245-251. doi: 10.1016/j.compstruct.2012.10.031 [13] WU K C. Thermal and structural performance of tow-placed, variable stiffness panels[D]. Delft: Delft University of Technology, 2006. [14] LI X, HALLETT S R, WISNOM M R. Modelling the effect of gaps and overlaps in automated fibre placement (AFP)-manufactured laminates[J]. Science and Engineering of Composite Materials,2015,22(2):115-129. doi: 10.1515/secm-2013-0322 [15] ELHAJJAR R F, SHAMS S S. Compression testing of continuous fiber reinforced polymer composites with out-of-plane fiber waviness and circular notches[J]. Polymer Testing, 2014, 35: 45-55. [16] WANG J, POTTER K D, WISNOM M R, et al. Failure mechanisms under compression loading in composites with designed out-of-plane fibre waviness[J]. Plastics, Rubber and Composites,2013,42(6):231-238. doi: 10.1179/1743289812Y.0000000019 [17] ALVES M P, JUNIOR C C, HA S K. Fiber waviness and its effect on the mechanical performance of fiber reinforced polymer composites: An enhanced review[J]. Composites Part A: Applied Science and Manufacturing,2021,149:106526. [18] KULKARNI P, MALI K D, SINGH S. An overview of the formation of fibre waviness and its effect on the mechanical performance of fibre reinforced polymer composites[J]. Composites Part A: Applied Science and Manufacturing,2020,137:106013. doi: 10.1016/j.compositesa.2020.106013 [19] HSIAO H M, DANIEL I M. Elastic properties of composites with fiber waviness[J]. Composites Part A: Applied Science and Manufacturing,1996,27(10):931-41. doi: 10.1016/1359-835X(96)00034-6 [20] SUTCLIFFE M P F. Modelling the effect of size on compressive strength of fibre composites with random waviness[J]. Composites Science and Technology,2013,88:142-150. doi: 10.1016/j.compscitech.2013.09.002 [21] CHUN H J, SHIN J Y, DANIEL I M. Effects of material and geometric nonlinearities on the tensile and compressive behavior of composite materials with fiber waviness[J]. Composites Science and Technology,2001,61(1):125-134. doi: 10.1016/S0266-3538(00)00201-3 [22] GÜRDAL Z, OLMEDO R. In-plane response of laminates with spatially varying fiber orientations-variable stiffness concept[J]. AIAA Journal,1993,31(4):751-758. doi: 10.2514/3.11613 [23] 顾杰斐, 陈普会, 孔斌, 等. 考虑制造因素的变刚度层合板的抗屈曲铺层优化设计[J]. 复合材料学报, 2018, 35(4):866-875.GU Jiefei, CHEN Puhui, KONG Bin, et al. Layup optimization for maximum buckling load of variable-stiffness laminates considering manufacturing factors[J]. Acta Materiae Compositae Sinica,2018,35(4):866-875(in Chinese). [24] WOIGK W, HALLETT S R, JONES M I, et al. Experimental investigation of the effect of defects in automated fibre placement produced composite laminates[J]. Composite Structures,2018,201:1004-1017. doi: 10.1016/j.compstruct.2018.06.078 [25] 宋桂林, 王显峰, 赵聪, 等. 规则回转体自动铺丝轨迹规划与丝束增减[J]. 航空学报, 2020, 41(11):423704-423704.SONG Guilin, WANG Xianfeng, ZHAO Cong, et al. Fiber placement trajectory planning and tows increase or decrease algorithm for revolution body[J]. Acta Aeronauticaet Astronautica Sinica,2020,41(11):423704-423704(in Chinese). [26] MISHRA V, PEETERS D M J, ABDALLA M M. Stiffness and buckling analysis of variable stiffness laminates including the effect of automated fibre placement defects[J]. Composite Structures,2019,226:111233. doi: 10.1016/j.compstruct.2019.111233 -

下载:

下载: