Preparation of polyethylene grafted acrylic acid composite membrane by pre-irradiation grafting

-

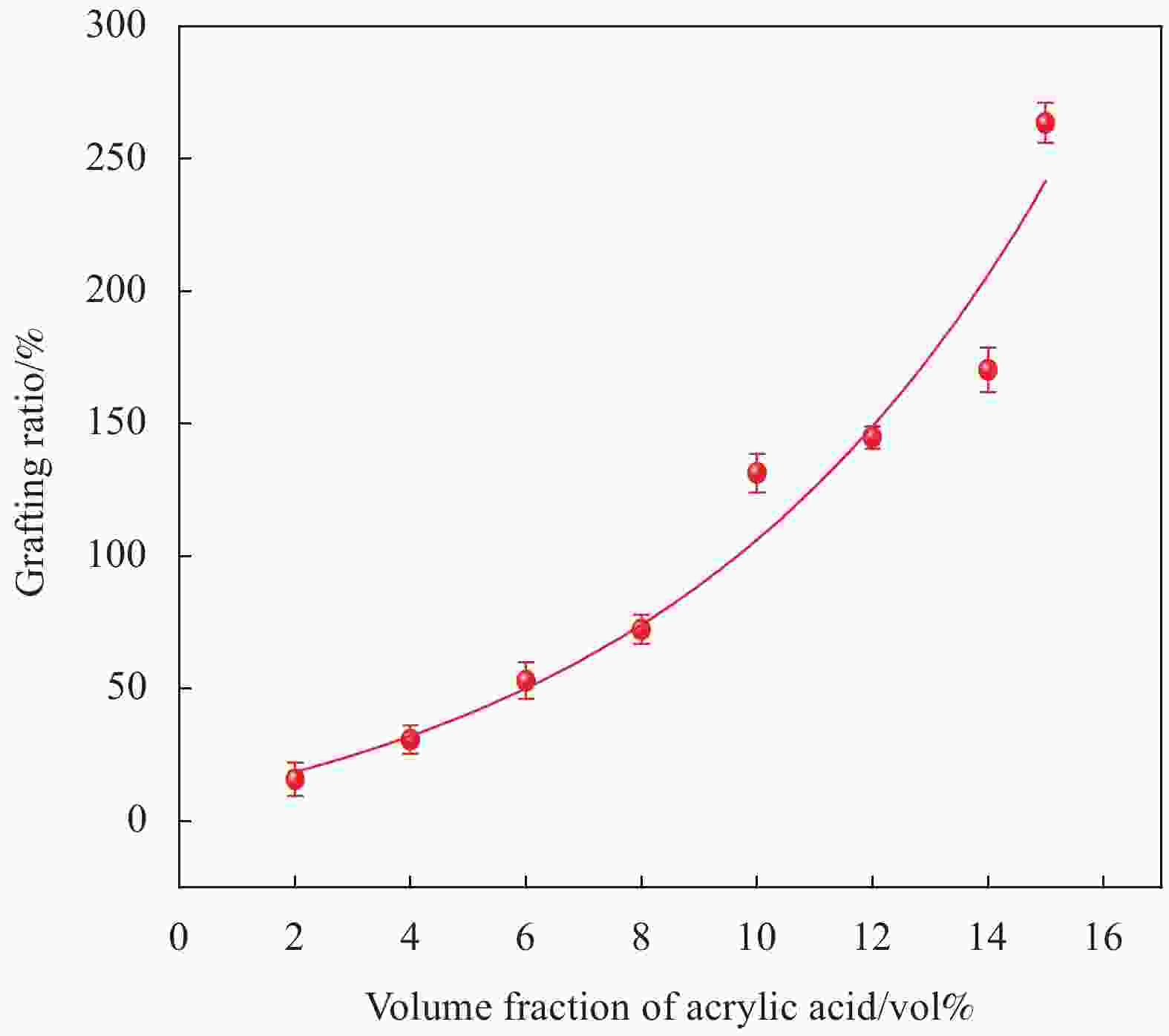

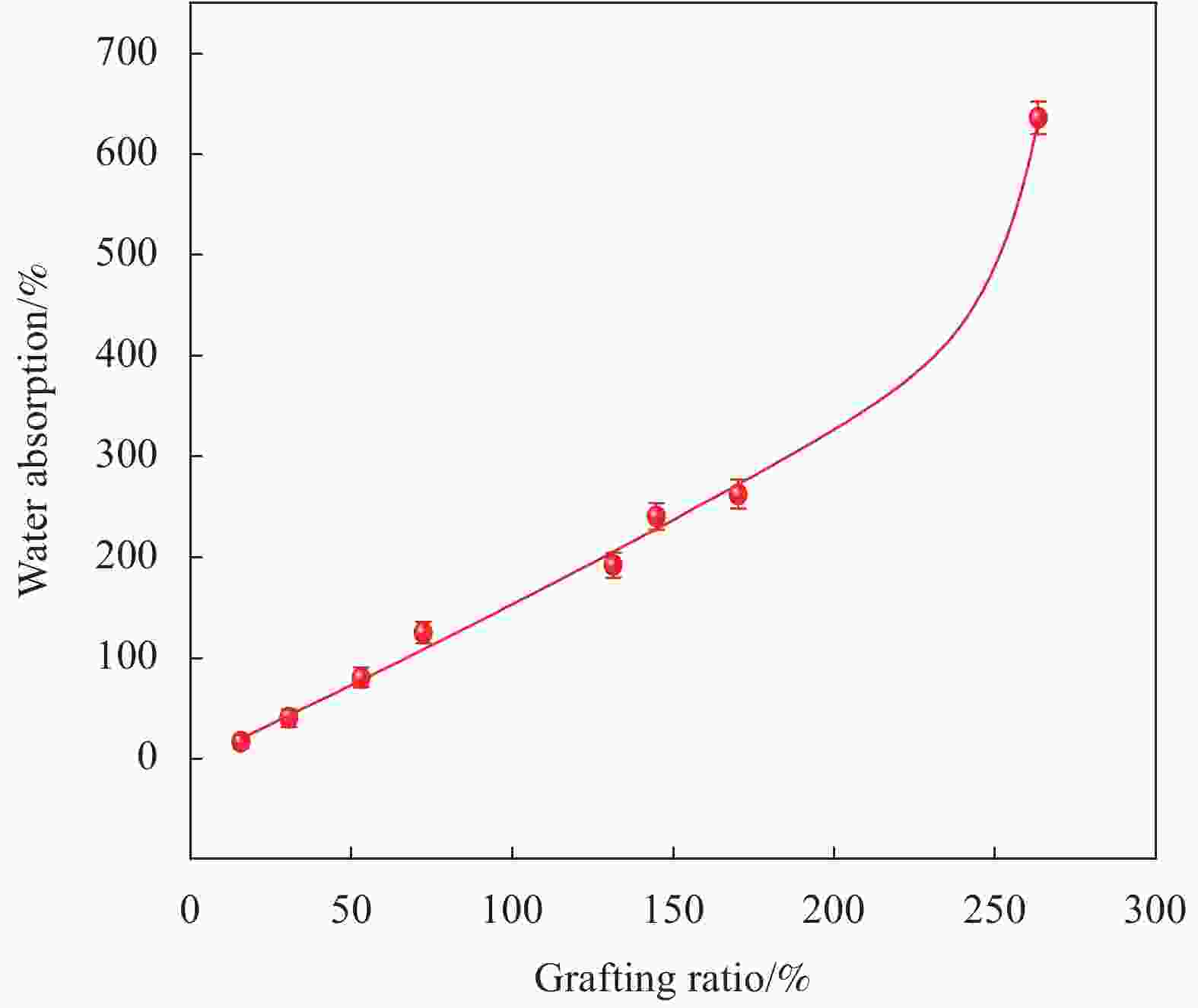

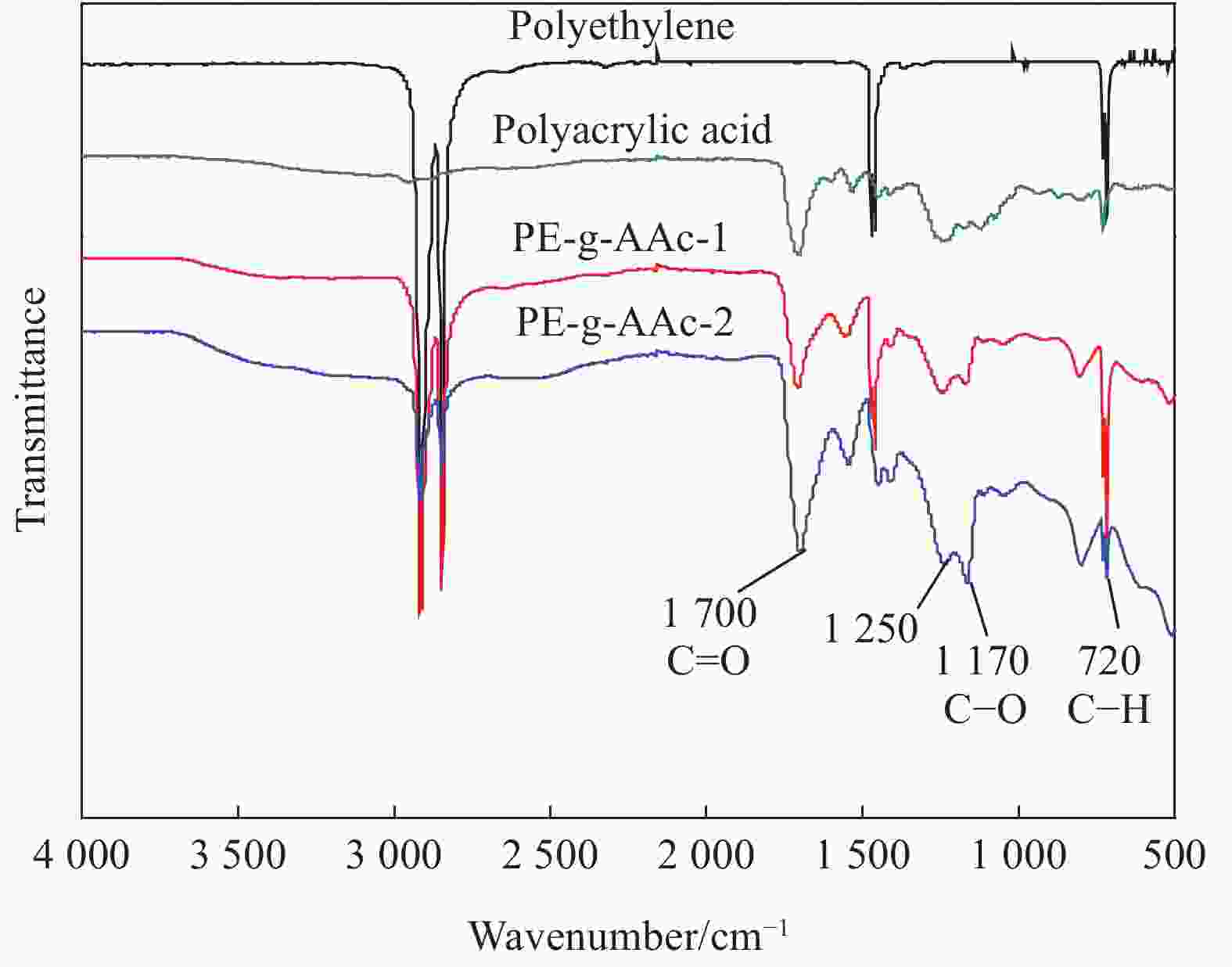

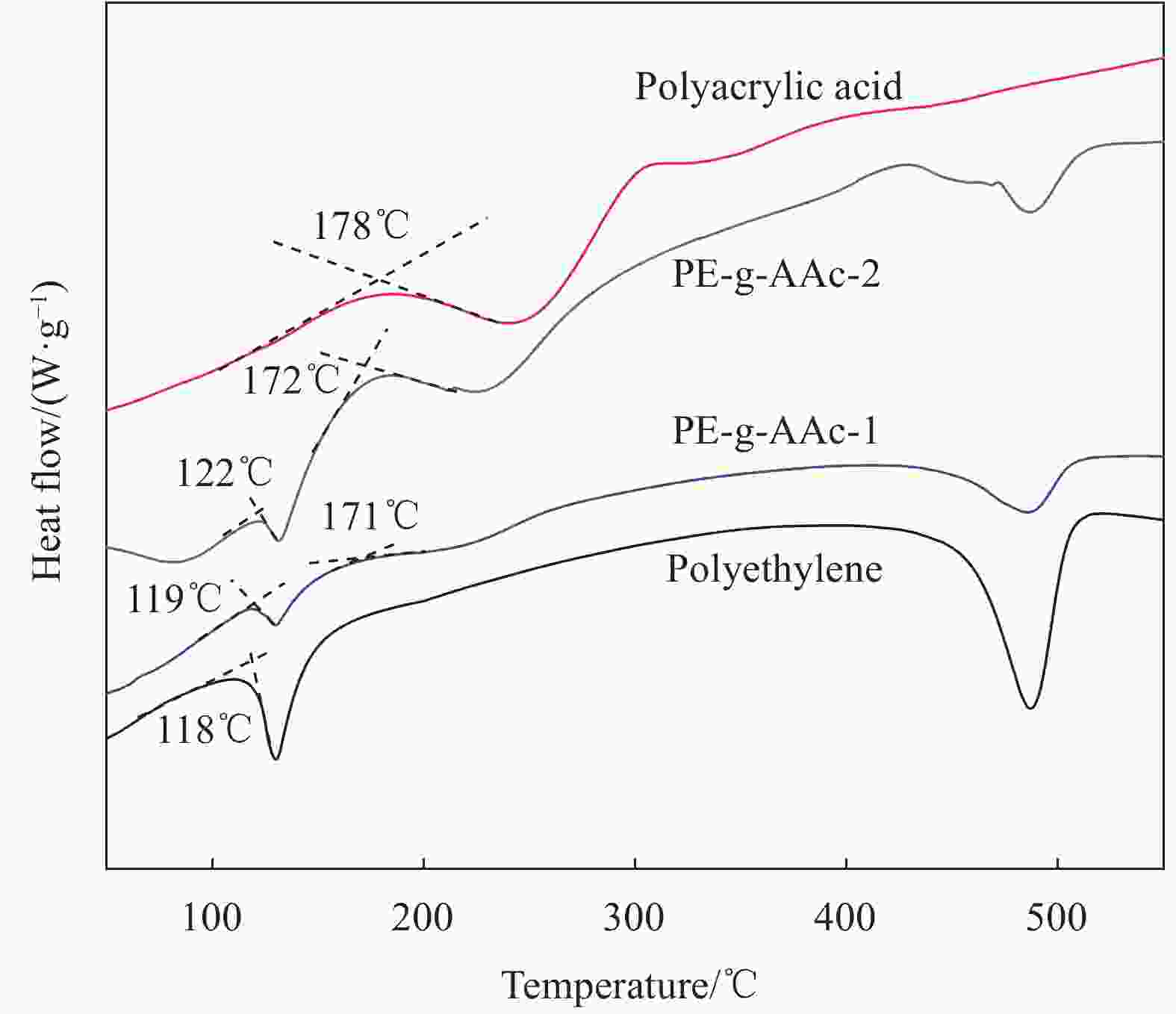

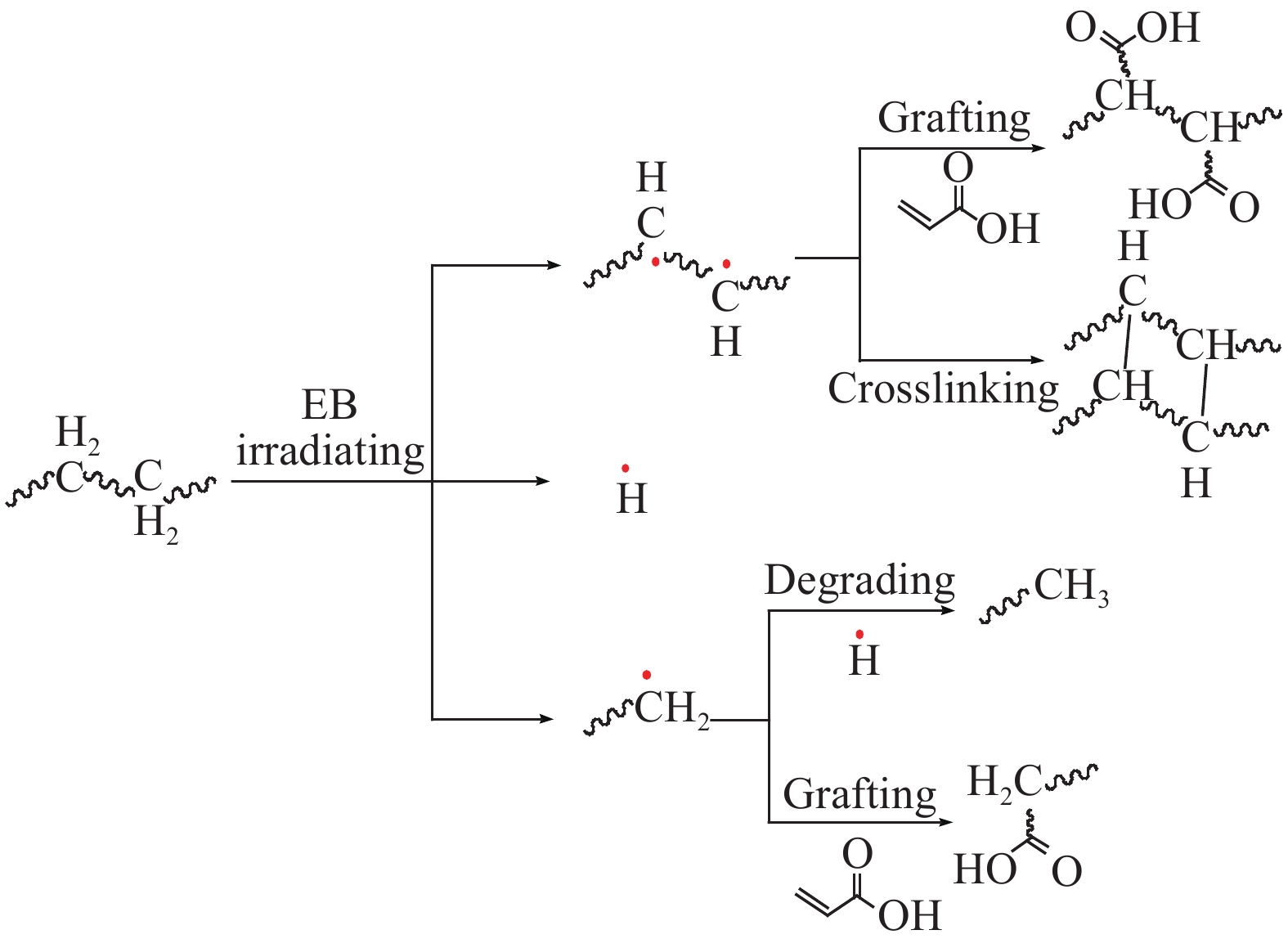

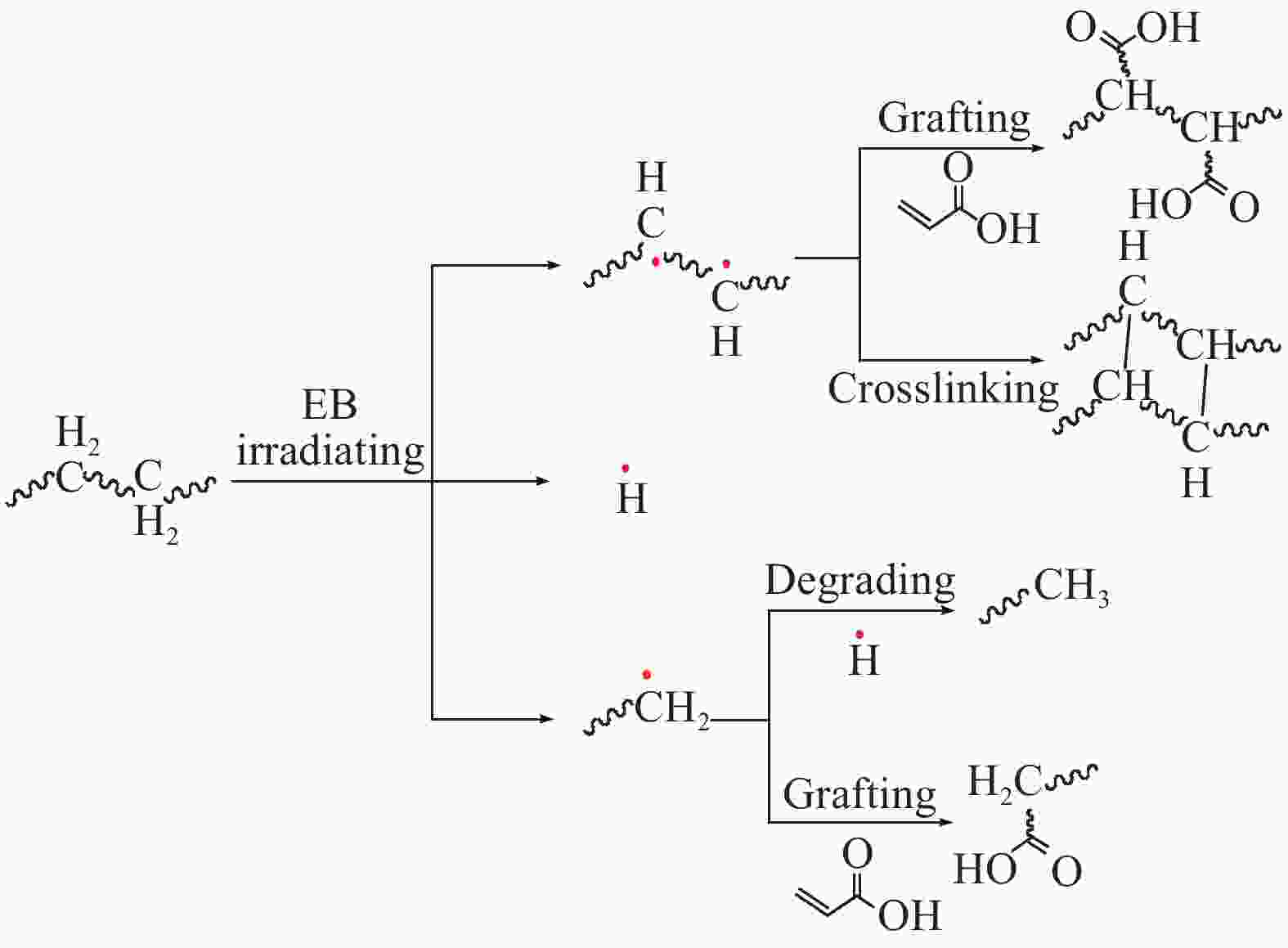

摘要: 通过电子束预辐射接枝技术制备不同接枝率的聚乙烯接枝丙烯酸(PE-g-AAc)复合膜,研究探讨了接枝率对复合膜性能影响。结果表明:PE-g-AAc复合膜随丙烯酸浓度增加,接枝率增加,吸水率也随之增加,当丙烯酸体积分数15vol%时,接枝率最大为263%,吸液率最大为635%。PE-g-AAc复合膜随丙烯酸接枝率增加,面电阻降低,当接枝率为30.4%时,PE-g-AAc复合膜面电阻由接枝前45000 mΩ·cm2降低至870.9 mΩ·cm2,接枝率最高263%时,面电阻最低为70.1 mΩ·cm2。拉伸强度随接枝率增加先降低后升高,接枝率最高263%时,拉伸强度最大45.6 MPa;断裂伸长率随接枝率的增加而降低。接枝率分析表明,一定的吸收剂量和反应条件下,丙烯酸浓度越高,链增长速率与链终止速率比值就越大,丙烯酸聚合度越大。吸水率与面电阻分析表明,丙烯酸有效提高聚乙烯膜表面能,增强亲水性,提高离子传导速率,降低聚乙烯膜面电阻。该研究将对聚乙烯接枝丙烯酸膜用于电池隔膜及离子交换膜的制备提供直接的借鉴价值。Abstract: The polyethylene grafted acrylic acid (PE-g-AAC) composite films with different grafting ratios were prepared by electron beam pre-irradiation. The study explored the effect of grafting ratio on the performance of composite membranes. The results show that the grafting ratio and water absorption ration of PE-g-AAc composite membrane increase with the increase of acrylic acid concentration. When the volume fraction of acrylic acid is 15vol%, the maximum grafting ratio is 263%, and the maximum water absorption ratio is 635%. The area resistance of PE-g-AAc composite membrane decreases with the increase of acrylic acid grafting ratio. When the grafting ratio is 30.4%, the area resistance of PE-g-AAc composite membrane decreases from 45000 mΩ·cm2 (without grafting) to 870.9 mΩ·cm2. When the grafting ratio is 263%, the area resistance is 70.1 mΩ·cm2. The tensile strength first decreases and then increases with the increase of grafting ratio. The maximum tensile strength reaches 45.6 MPa when the grafting ratio is 262%. The elongation at break decreases with the increase of grafting ratio. The grafting ratio result shows that under certain absorbed dose and reaction conditions, the higher the concentration of acrylic acid, the greater the ratio of chain growth rate to chain termination rate, and the greater the degree of acrylic acid polymerization. The results on water absorption and area resistance study show that, acrylic acid can effectively increase the surface energy of the polyethylene film, enhance the hydrophilicity, increase the ion conductivity, and reduce the area resistance of the polyethylene film. This study will provide direct reference value for the preparation of polyethylene grafted acrylic membrane for battery separator and ion exchange membrane.

-

Key words:

- pre-irradiation /

- polyethylene /

- acrylic acid /

- grafting /

- area resistance /

- composite membrane

-

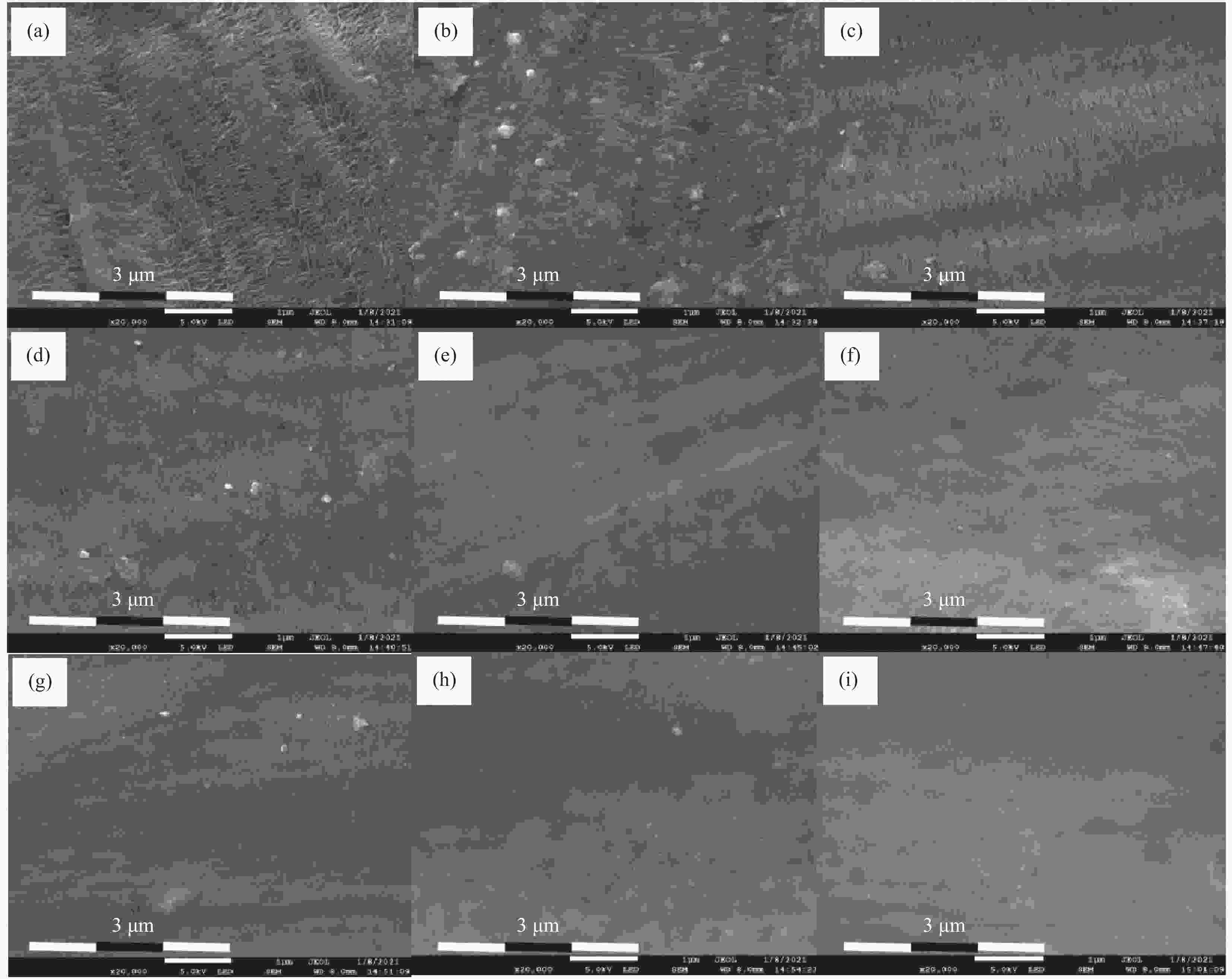

图 10 不同接枝率的PE-g-AAc复合膜表面形貌的SEM图像((a)~(i)接枝率依次为0、15.7%、30.7%、53.0%、72.4%、131.4%、144.8%、170.3%、263.6%)

Figure 10. SEM images of surface morphologies of PE-g-AAc composite membrane with different grafting ratios (Grafting ratios of (a)-(i) are 0, 15.7%, 30.7%, 53.0%, 72.4%, 131.4%, 144.8%, 170.3%, 263.6%)

-

[1] FAVAKEH M, BAZGIR S, KARBASI M. Dynamically vulcanized thermoplastic elastomer nanocomposites based on linear low-densitypolyethylene/styrene-butadiene rubber/ nanoclay/bitumen: morphology and rheological behavior[J]. Iranian Polymer Journal,2020,29(3):209-217. doi: 10.1007/s13726-020-00786-9 [2] DALHAT M A, AL-ADHAM K, ADESINA A Y. High-temperature performance of recycled low-density polyethylene-modified asphalt binder reinforced with thermally treated polyacrylonitrile fiber[J]. Arabian Journal for Science and Engineering,2020,45(5):4257-4272. doi: 10.1007/s13369-020-04431-8 [3] DANA M, ZOHURI G H, ASADI S. Improvement in volume resistivity and morphology of a blend of polyolefin elastomer with linear low-density polyethylene[J]. Iranian Polymer Journal,2019,28(7):587-595. doi: 10.1007/s13726-019-00725-3 [4] 袁娜娜, 马雪飞, 李妍, 等. 常压共面介质阻挡放电对聚乙烯隔膜表面改性研究[J]. 真空科学与技术学报, 2021, 41(1):89-94.YUAN Nana, MA Xuefei, LI Yan, et al. Surface modification of polyethylene membrane by coplanar dielectric barrier discharge plasma in atmospheric pressure[J]. Journal of Vacuum Science and Technology,2021,41(1):89-94(in Chinese). [5] 解林坤, 黄元波, 代沁伶, 等. RF-Ar等离子体对聚乙烯薄膜的表面改性[J]. 真空科学与技术学报, 2012, 32(7):545-549. doi: 10.3969/j.issn.1672-7126.2012.07.01XIE Linkun, HUANG Yuanbo, DAI Qinling, et al. Surface modification of polyethylene film by RF-Ar plasma treatment[J]. Journal of Vacuum Science and Technology,2012,32(7):545-549(in Chinese). doi: 10.3969/j.issn.1672-7126.2012.07.01 [6] 牛家嵘, 顾振亚. 利用低温空气等离子体改善聚酯和聚乙烯薄膜表面亲水性的研究[J]. 天津工业大学学报, 2004, 23(4):40-43, 47. doi: 10.3969/j.issn.1671-024X.2004.04.011NIU Jiarong, GU Zhenya. Research on surface hydrophilic modification of PET and PE films by low temperature air plasma[J]. Journal of Tianjin Polytechnic University,2004,23(4):40-43, 47(in Chinese). doi: 10.3969/j.issn.1671-024X.2004.04.011 [7] 杨静. 超高分子量聚乙烯膜的改性方法及其在医用材料中的应用[J]. 化工设计通讯, 2020, 46(6):80, 147.YANG Jing. Modification methods of UHMWPE film and its application in medical materials[J]. Chemical Engineering Design Communications,2020,46(6):80, 147(in Chinese). [8] 程序, 汪志伟, 张素梅, 等. 聚乙烯醇交联改性聚乙烯锂离子电池隔膜的制备[J]. 合成树脂及塑料, 2021, 38(1):22-26.CHENG Xu, WANG Zhiwei, ZHANG Sumei, et al. Preparation of polyvinyl alcohol crosslinking modified PE separator for lithium-ion battery[J]. Synthetic Resin and Plastics,2021,38(1):22-26(in Chinese). [9] 欧军飞, 周金芳, 简令奇, 等. 聚合物表面改性方法概述[J]. 塑料工业, 2007, 35(11):5-10. doi: 10.3321/j.issn:1005-5770.2007.11.002OU Junfei, ZHOU Jinfang, JIAN Lingqi, et al. Outline of surface modification technology for polymer[J]. Plastics Industry,2007,35(11):5-10(in Chinese). doi: 10.3321/j.issn:1005-5770.2007.11.002 [10] WU W Q, TU J Y, LI H R, et al. Suppressed dielectric loss and enhanced thermal conductivity in poly(vinylidene fluoride) nanocomposites using polyethylene glycol-grafted grapheneoxide[J]. Journal of Materials Science,2020,31(1):807-813. [11] HAN Y S, XIA Y Y, SUO C Y, et al. Dielectric properties and surface potential decay characteristics of low density polyethylene/ZnO microvaristor composites[J]. Journal of Materials Science,2019,30(11):10644-10650. [12] WANG L Q, PENG X, MUSTAIN W E, et al. Radiation-grafted anion-exchange membranes: The switch from low-to high-density polyethylene leads to remarkably enhanced fuel cell performance[J]. Energy & Environmental Science,2019,12(5):1575-1579. [13] YAMADA K, ISHIGURO Y, KIMURA Y, et al. Two-step grafting of 2-hydroxyethyl methacrylate (HEMA) and 2-(dimethylamino)ethyl methacrylate (DMAEMA) onto a polyethylene plate for enhancement of Cr(Ⅵ) ion adsorption[J]. Environmental Technology,2019,40(5-8):855-869. [14] CHEN Daitao, SHI Nai, XIE Liqing, et al. Study of electron beam preirradiation-induced Graft copolymerization of acrylic acid onto powdered isotactic polypropylene[J]. Acta Polymerica Sinica,2000(1):32-35. [15] WANG H L, XU L, LI R, et al. Highly hydrophilic ultra-high molecular weight polyethylene powder and film prepared by radiation grafting of acrylic acid[J]. Applied Surface Science,2016,382:162-169. doi: 10.1016/j.apsusc.2016.03.175 [16] PENG C Z. The preparation and characteristic of maleic anhydride grafted polyethylene (PE-g-MA) filled CNT/PMMA composite film[J]. Journal of Experimental Nanoscience,2017,12(1):338-345. doi: 10.1080/17458080.2017.1342876 [17] ZAKI A. Grafting of polyethylene films with N-vinyl imidazole and acrylic acid for potential use in wastewater treatment[J]. Revue Roumaine de Chimie,2015,60(9):867-873. [18] ZHU B D, MA D Z, LI H L, et al. Modification of low density polyethylene with 2-hydroxyethyl acrylate by a swollen-phase grafting method[J]. Journal of Macromolecular Science Part B,2016,55:188-200. [19] HE P X, ZHANG Y H, FENG D D, et al. Effects of synthesis conditions on chemically initiated oil-swellable suspension graft copolymerization of acrylic acid and acrylamide onto solid-state chlorinated polyethylene[J]. Journal of Elastomers & Plastics,2007,39(3):239-251. [20] DEMIS B, EMMANUEL B, PHILIPPE C, et al. Effect of nitroxyl-based radicals on the melt radical grafting of maleic anhydride onto polyethylene in presence of a peroxide[J]. European Polymer Journal,2015,66:342-351. doi: 10.1016/j.eurpolymj.2015.02.012 [21] CHUAI C Z, MAHMOOD I, TIAN S X. A study on melt grafting of maleic anhydride onto low-density polyethylene and its blend with polyamide 6[J]. Journal of Polymer Science,2010,48(3):267-275. [22] 李万新, 王自强, 俞初红, 等. 聚乙烯膜表面辐射接枝甲基丙烯酸-4, 5-二甲氧基-2-硝基苯甲酯实现光敏化[J]. 辐射研究与辐射工艺学报, 2015, 33(2):38-42.LI Wanxin, WANG Ziqiang, YU Chuhong, et al. Photosensitizing modification of polyethylene film by irradiation grafting with 4, 5-dimethyl-2-nitrobenzene methacrylate[J]. Journal of Radiation Research and Radiation Processing,2015,33(2):38-42(in Chinese). [23] 张凤英, 侯铮迟, 虞鸣谢, 等. 聚乙烯薄膜辐射接枝丙烯酸羟丙酯诱导CaCO3晶体生长的研究[J]. 辐射研究与辐射工艺学报, 2004(3):139-142. doi: 10.3969/j.issn.1000-3436.2004.03.002ZHANG Fengying, HOU Zhengchi, YU Mingxie, et al. Growth of CaCO3 crystal on polyethylene film grafted with 2-hydroxypropyl acrylate by γ-rays[J]. Journal of Radiation Research and Radiation Processing,2004(3):139-142(in Chinese). doi: 10.3969/j.issn.1000-3436.2004.03.002 [24] 国家质量技术监督局. 塑料-薄膜拉伸性能试验方法: GB/T 13022—91[S]. 北京: 北京标准出版社, 1991.The State Bureau of Quality and Technical Supervision. Plastic-Determination tensile properties of films: GB/T 13022—91[S]. Beijng: Beijing Standards Press, 1991(in Chinese). [25] 赵康, 赵红英, 崔国士, 等. 电子束固化制备聚丙烯/铝箔复合膜[J]. 高分子材料科学与工程, 2020, 36(8):29-35.ZHAO Kang, ZHAO Hongying, CUI Guoshi, et al. Preparation of polypropylene/Al foil laminate by electronic beam curing technology[J]. Polymer Materials Science and Engineering,2020,36(8):29-35(in Chinese). [26] 龙复, 唐黎明, 赵津, 等. 聚乙烯预辐射接枝丙烯酸研究[J]. 天津大学学报, 1993(3):73-77.LONG Fu, TANG Liming, ZHAO Jin, et al. Pre-irradiation grafting of acrylic acid onto polyethylene[J]. Journal of Tianjin University,1993(3):73-77(in Chinese). [27] 李星, 刘东辉, 杨明, 等. 辐射交联聚乙烯薄膜的研究[J]. 现代塑料加工应用, 2002, 14(2):5-8. doi: 10.3969/j.issn.1004-3055.2002.02.002LI Xing, LIU Donghui, YANG Ming, et al. Study of radiation-crosslinking polyethylene films[J]. Modern Plastics Processing and Applications,2002,14(2):5-8(in Chinese). doi: 10.3969/j.issn.1004-3055.2002.02.002 [28] 唐黎明, 龙复. 聚乙烯-丙烯酸接枝物的制备及表征[J]. 天津大学学报, 1996(2):273-277.TANG Liming, LONG Fu. Preparation and characterization of polyethylene-acrylic acid grafted copolymer[J]. Journal of Tianjin University,1996(2):273-277(in Chinese). [29] 翟红波, 李咏梅, 郭汉洋, 等. PE-g-MAH及其纳米复合材料的制备与表征[J]. 高分子材料科学与工程, 2005(4):252-255. doi: 10.3321/j.issn:1000-7555.2005.04.065ZHAI Hongbo, LI Yongmei, GUO Hanyang, et al. Preparation and characterization of functional polyethylene and its nanocomposites[J]. Polymer Materials Science and Engineering,2005(4):252-255(in Chinese). doi: 10.3321/j.issn:1000-7555.2005.04.065 -

下载:

下载: