Interlaminar properties and micro morphology of reduced graphene oxide modified carbon fiber/polyphenylene sulfide composites

-

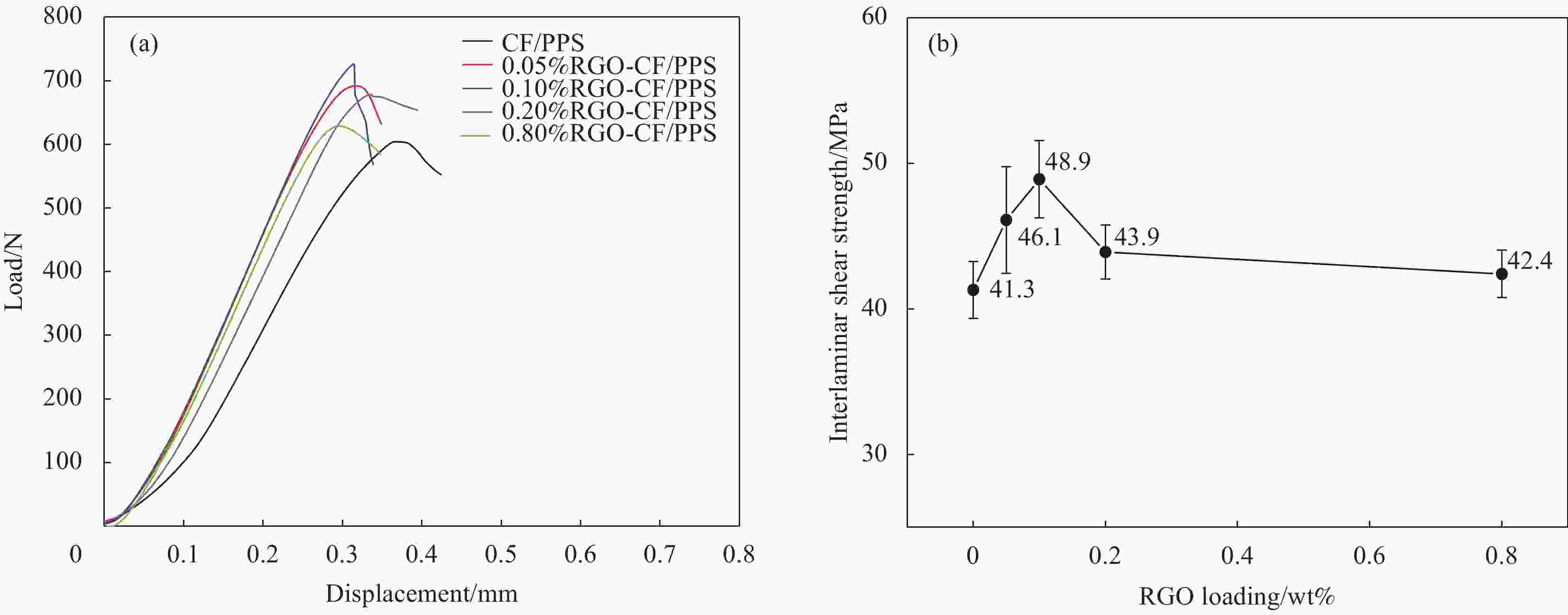

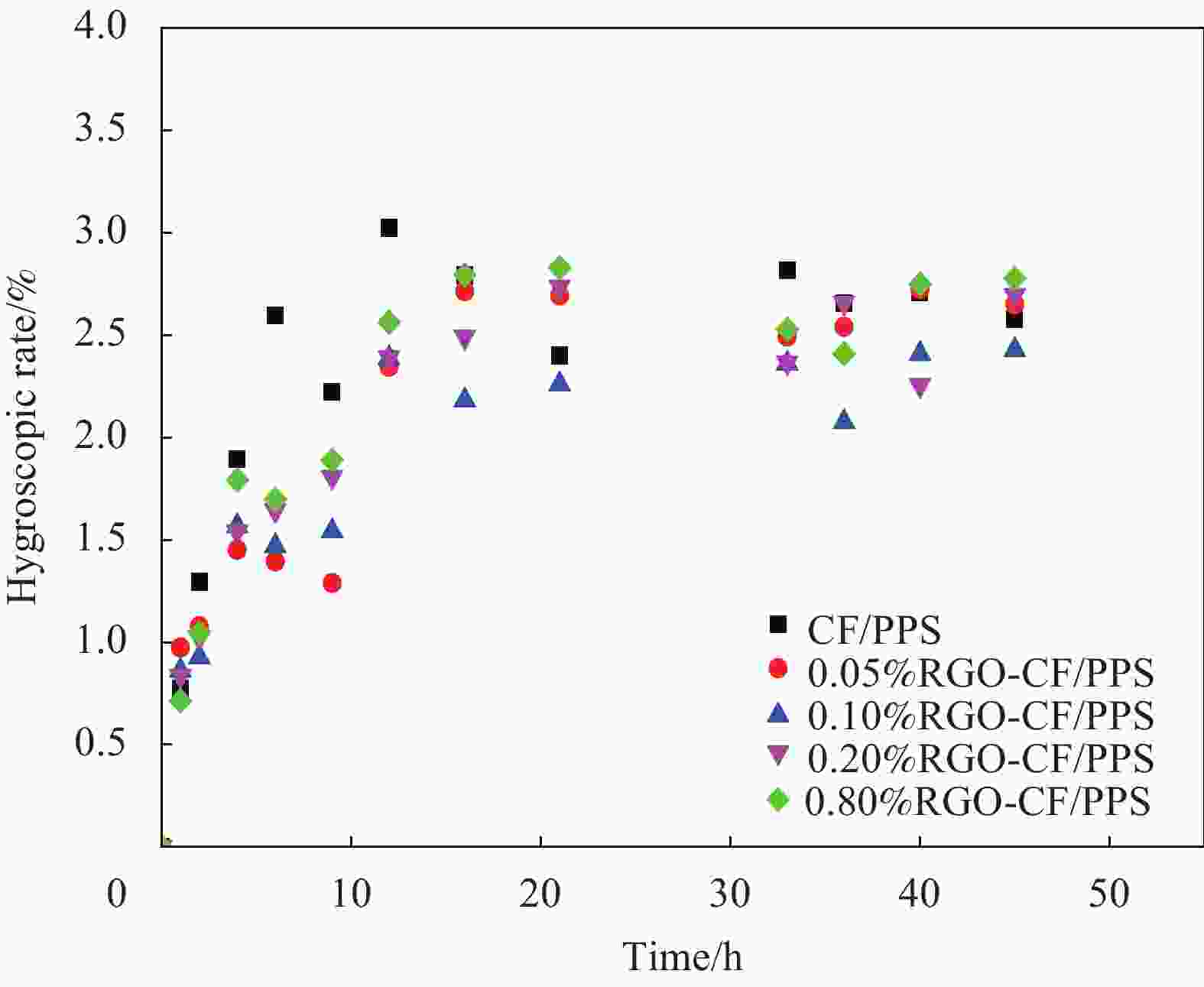

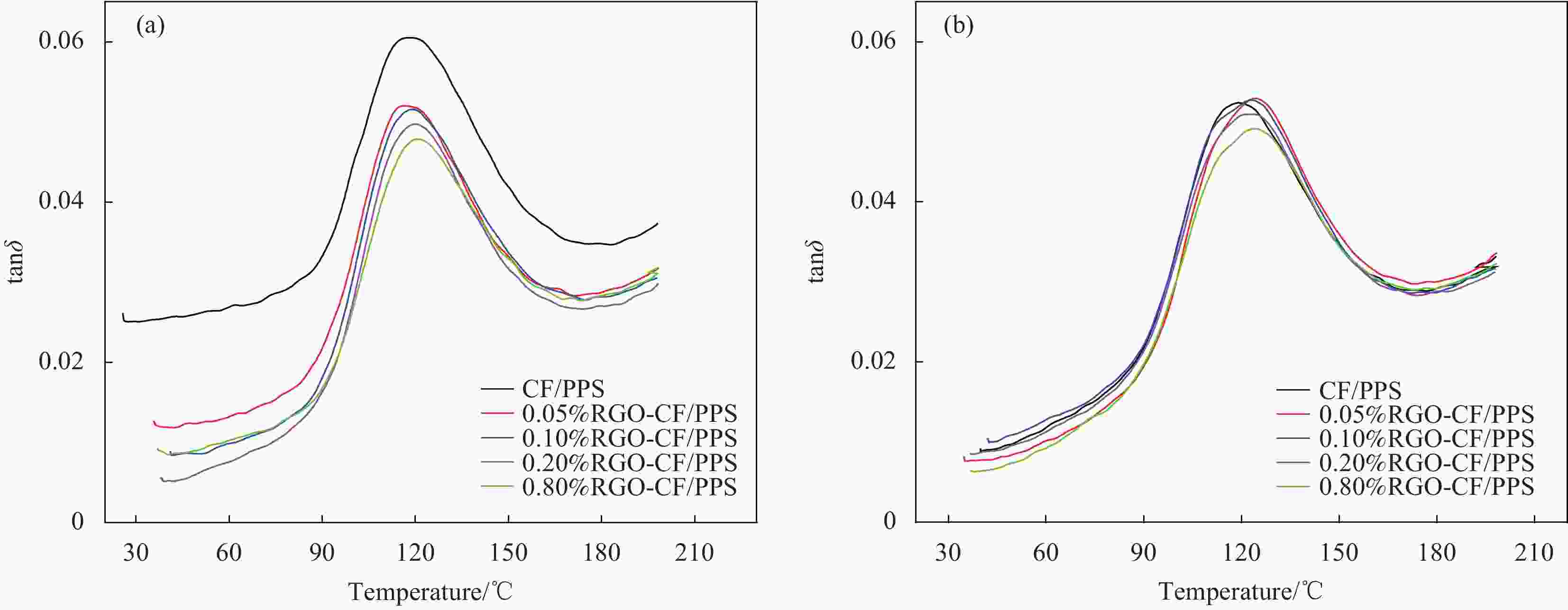

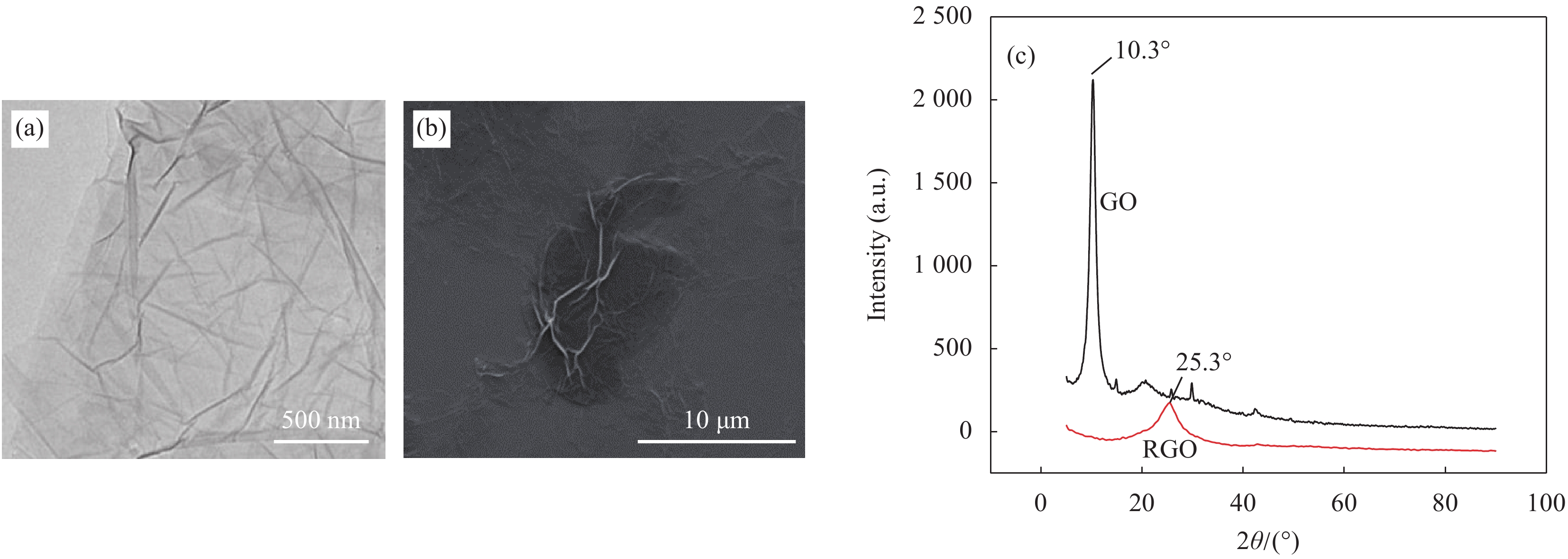

摘要: 采用粉末叠层方法和热压工艺制备了还原氧化石墨烯改性碳纤维/聚苯硫醚(RGO-CF/PPS)复合材料,考察了复合材料在室温干态和湿热处理两种条件下的层间剪切性能和微观形貌及RGO对复合材料界面性能的影响。结果表明,室温干态0.1%RGO-CF/PPS的层间剪切强度(ILSS)比CF/PPS的提高了18.4%;湿热处理后RGO-CF/PPS的ILSS发生了下降,且湿热处理RGO-CF/PPS的ILSS强度保持率均低于CF/PPS;复合材料的动态热机械行为结果表明,RGO有助于改善复合材料的界面黏结性能;微观形貌分析表明RGO使复合材料中裂纹更易发生偏转从而提高室温干态复合材料的ILSS。Abstract: Reduced graphene oxide(RGO) modified carbon fiber/polyphenylene sulfide composites (RGO-CF/PPS) were prepared by powder lamination methodand hot pressing process. Interlaminar shear properties and micromorphology of the RGO-CF/PPS composites at room temperature and hygrothermal environment were investi-gated. Meanwhile, the effect of RGO on the interface performance of the composites was analyzed. Results show that the interlaminar shear strength (ILSS) of the 0.1%RGO-CF/PPS composites in the dry state at room tempera-ture is 18.4% higher than that of the CF/PPS composites. After hygrothermal treatment, the ILSS of the RGO-CF/PPS composites are decreased and the ILSS strength retention rate of the RGO-CF/PPS composites is lower than that of the CF/PPS composites. Dynamic thermomechanical behavior results of the composites show that the RGO is helpful to enhance the interface bonding performance of the RGO-CF/PPS composites. Micromorphology shows that the RGO effectively improves the ILSS of the RGO-CF/PPS composites in the dry state at room temperature.

-

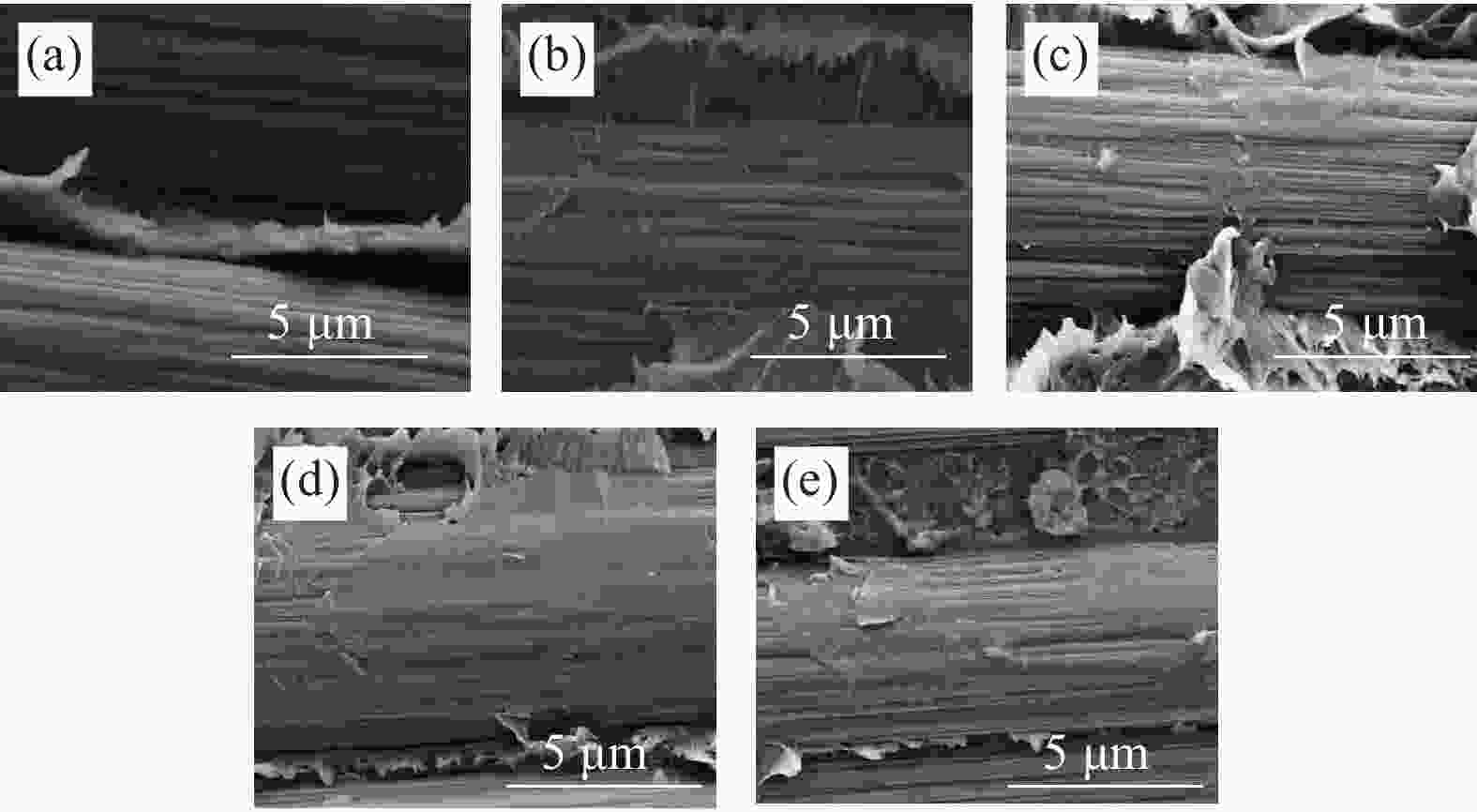

图 3 室温干态RGO-CF/PPS层间剪切破坏后微观形貌的SEM图像((a) CF/PPS; (b) 0.05%RGO-CF/PPS; (c) 0.1%RGO-CF/PPS; (d) 0.2%RGO-CF/PPS; (e) 0.8%RGO-CF/PPS)

Figure 3. SEM images of the composites after interlaminar shear test atroom temperature and dry environment ((a) CF/PPS; (b) 0.05%RGO-CF/PPS; (c) 0.1%RGO-CF/PPS; (d) 0.2%RGO-CF/PPS; (e) 0.8%RGO-CF/PPS)

图 5 湿热RGO-CF/PPS的层间剪切破坏面微观形貌SEM图像((a) CF/PPS; (b) 0.05%RGO-CF/PPS; (c) 0.1%RGO-CF/PPS; (d) 0.2%RGO-CF/PPS; (e) 0.8%RGO-CF/PPS)

Figure 5. SEM images of RGO-CF/PPS composites after hygrothermal treatment and interlaminar shear test((a) CF/PPS; (b) 0.05%RGO-CF/PPS; (c) 0.1%RGO-CF/PPS; (d) 0.2%RGO-CF/PPS; (e) 0.8%RGO-CF/PPS)

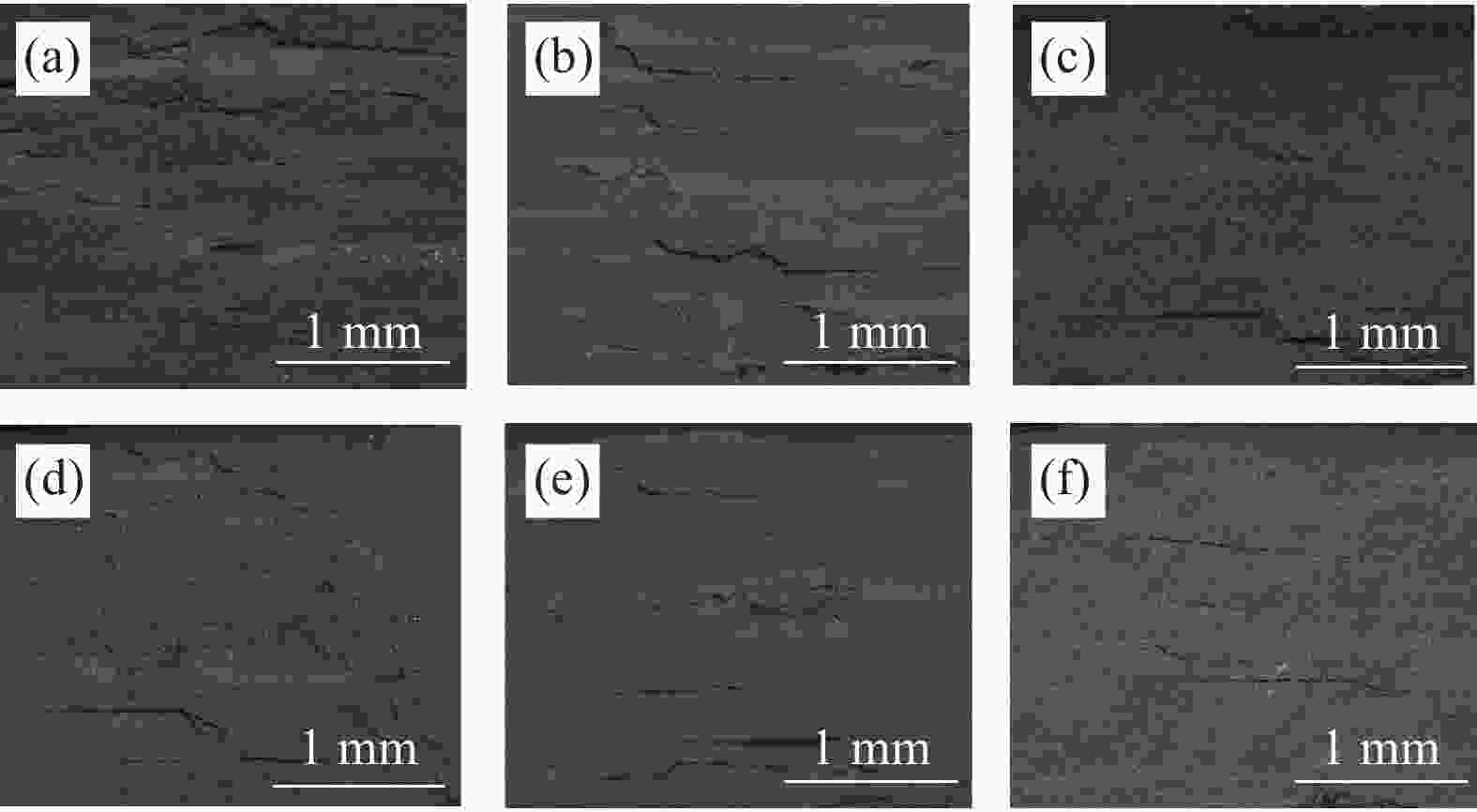

图 6 复合材料的层间剪切样品的SEM图像(室温干态下: (a) CF/PPS; (c) 0.1%RGO-CF/PPS; (e) 0.8%RGO-CF/PPS; 湿热处理后: (b) CF/PPS; (d) 0.1%RGO-CF/PPS; (f) 0.8%RGO-CF/PPS)

Figure 6. SEM images of the composites after interlaminar shear test At room temperature and dry environment ((a) CF/PPS; (c) 0.1%RGO-CF/PPS; (e) 0.8%RGO-CF/PPS; After hygrothermal treatment: (b) CF/PPS; (d) 0.1%RGO-CF/PPS; (f) 0.8%RGO-CF/PPS))

-

[1] NAM J D, KIM J, LEE S, et al. Morphology and thermal properties of PPS/ABS blend systems[J]. Journal of Applied Polymer Science,2003,87(4):661-665. doi: 10.1002/app.11401 [2] XU R, LIU H, SHI W. Photofluorescence of hyperbranched poly(phenylene sulfide)[J]. Journal of Polymer Science, Part B (Polymer Physics),2006,44(5):826-831. doi: 10.1002/polb.20744 [3] 刘保英, 王孝军, 杨杰, 等. 碳纤维表面改性研究进展[J]. 化学研究, 2015(2):5-14.LIU B Y, WANG X J, YANG J, et al. Research progress of carbon fiber surface modification[J]. Chemical Research,2015(2):5-14(in Chinese). [4] LI F, LIU Y, QU C B, et al. Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone compo-sites by graphene oxide coating[J]. Polymer,2015,59:155-165. doi: 10.1016/j.polymer.2014.12.067 [5] XU J, XU D, WANG X, et al. Improved interfacial shear strength of carbon fiber/polyphenylene sulfide compo-sites by graphene[J]. High Performance Polymers,2017,29(8):913-921. doi: 10.1177/0954008316664398 [6] ZHANG X, FAN X, YAN C, et al. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials & Interfaces,2012,4(3):1543-1552. [7] LI Y, PENG Q, HE X, et al. Synthesis and characterization of a new hierarchical reinforcement by chemically grafting graphene oxide onto carbon fibers[J]. Journal of Materials Chemistry,2012,22:18748-18752. doi: 10.1039/c2jm32596a [8] LEE W, LEE J U, CHA H J, et al. Partially reduced graphene oxide as a multi-functional sizing agent for carbon fiber composites by electrophoretic deposition[J]. RSC Advances,2013,3(48):25609-25613. doi: 10.1039/c3ra44155e [9] MA Y, JIN S, UEDA M, et al. Higher performance carbon fiber reinforced thermoplastic composites from thermoplastic prepreg technique: Heat and moisture effect[J]. Composites Part B: Engineering,2018,154:90-98. doi: 10.1016/j.compositesb.2018.07.060 [10] 孙丽, 黄远, 万怡灶, 等. 碳/环氧树脂复合材料吸湿水分浓度场的有限元分析[J]. 兵器材料科学与工程, 2007, 30(4): 5-8.SUN L, HUANG Y, WAN Y Z, et al. Finite element analysis of moisture concentration field of carbon/epoxy resin composite material[J]. Ordnance Material Science and Engi-neering, 2007, 30(4): 5-8(in Chinese). [11] EFTEKHARI M, FATEMI A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects[J]. Polymer Testing,2016,51:151-164. doi: 10.1016/j.polymertesting.2016.03.011 [12] HUMMERS W S, OFFEMAN R E. Preparation of graphitic oxide[J]. American Chemical Society,1958,208:1334-1339. [13] 中国标准化管理委员会. 聚合物基复合材料短梁剪切强度试验方法: GB/T 30969—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People's Republic of China. Test method for short-beam shear strength of polymer matrix composite materials: GB/T 30969—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [14] American Society for Testing and Materials. Standard test method for glass transition temperature (DMA Tg) of polymer matrix composites by dynamic mechanical analysis (DMA): ASTM D 7028—2007e1[S]. Philadelphia: American Society for Testing and Materials International, 2007. [15] 陈祥宝. 聚合物基复合材料手册(精)[M]. 北京: 化学工业出版社, 2004: 132-134.CHEN X B. Handbook of polymer matrix composites[M]. Beijing: Chemical Industry Press, 2004: 132-134(in Chinese). [16] DREYER D R, PARK S, BIELAWSKI C W, et al. The che-mistry of graphene oxide[J]. Chemical Society Reviews,2009,39(1):228-240. [17] 杨云雪. 氧化石墨的制备及其热剥离产物的性能研究[D]. 天津: 天津大学, 2013.YANG Y X. Study on the preparation of graphite oxide and its thermal exfoliation products[D]. Tianjin: Tianjin University, 2013(in Chinese). [18] NIU Y, ZHANG Q, LI Y, et al. Reduction, dispersity and electrical properties of graphene oxide sheets under low-temperature thermal treatments[J]. Journal of Materials Science: Materials in Electronics,2017,28(1):729-733. doi: 10.1007/s10854-016-5583-1 [19] MCALLISTER M J, LI J L, ADAMSON D H, et al. Single sheet functionalized graphene by oxidation and thermal expansion of graphite[J]. Chemistry of Materials,2007,19(18):4396-4404. doi: 10.1021/cm0630800 [20] 胡泽旭, 陈姿晔, 相恒学, 等. 石墨烯改性聚苯硫醚纤维光稳定性及其增强机制[J]. 纺织学报, 2017(11):6-13.HU Z X, CHEN Z Y, XIANG H X, et al. The light stability of graphene modified polyphenylene sulfide fiber and its enhancement mechanism[J]. Journal of Textile Research,2017(11):6-13(in Chinese). [21] SINGH D K, GIRI P K, IYER P K. Evidence for defect-enhanced photoluminescence quenching of fluorescein by carbon nanotubes[J]. The Journal of Physical Chemistry C,2011,115(49):24067-24072. doi: 10.1021/jp207392d [22] 杨杰. 聚苯硫醚树脂及其应用[M]. 北京: 化学工业出版社, 2006: 106-123.YANG J. Polyphenylene sulfide resin and its application[M]. Beijing: Chemical Industry Press, 2006: 106-123(in Chinese). [23] 巩天琛. 湿热环境对CFRP层板性能影响及机理研究[D]. 天津: 中国民航大学, 2017.GONG T C. Influence of hygrothermal environments on properties and mechanism of CFRP laminates[D]. Tianjin: Civil Aviation University of China, 2017(in Chinese). [24] 齐肖. 碳纤维复合材料耐湿热性能的多尺度模拟研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.QI X. Multi-scale simulation study on the heat and humidity resistance of carbon fiber composites[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [25] PAPLHAM W P, BROWN R A, SALIN I M, et al. Absorption of water in polyimide resins and composites[J]. Journal of Applied Polymer Science,1995,57(2):133-137. doi: 10.1002/app.1995.070570202 [26] 过梅丽. 高聚物与复合材料的动态力学热分析[M]. 北京: 化学工业出版社, 2002: 29-60.GUO M L. Dynamic mechanical thermal analysis of polymer and composite materials[M]. Beijing: Chemical Industry Press, 2002: 29-60(in Chinese). [27] 何国仁, 曾汉民, 杨桂成. 混杂短纤维增强聚苯硫醚复合材料的老化研究Ⅰ:破坏行为研究[J]. 复合材料学报, 1991(3):29-36.HE G R, ZENG H M, YANG G C. Study on aging of hybrid short fiber reinforced polyphenylene sulfide composites Ⅰ:Study on failure behavior[J]. Journal of Composite Materials,1991(3):29-36(in Chinese). [28] 何国仁, 曾汉民, 杨桂成. 混杂短纤维增强聚苯硫醚的老化研究—Ⅱ:滑动摩擦磨损行为[J]. 塑料工业, 1992(1):35-38.HE G R, ZENG H M, YANG G C. Study on Aging of hybrid short fiber reinforced polyphenylene sulfide—Ⅱ:Sliding friction and wear behavior[J]. Plastics Industry,1992(1):35-38(in Chinese). [29] BRADY D G. The crystallinity of poly(phenylene sulfide) and its effect on polymer properties[J]. Journal of Applied Polymer Science,1976,20(9):2541-2551. doi: 10.1002/app.1976.070200921 -

下载:

下载: