Influence of interfacial effect on heat conduction behavior of functional composites

-

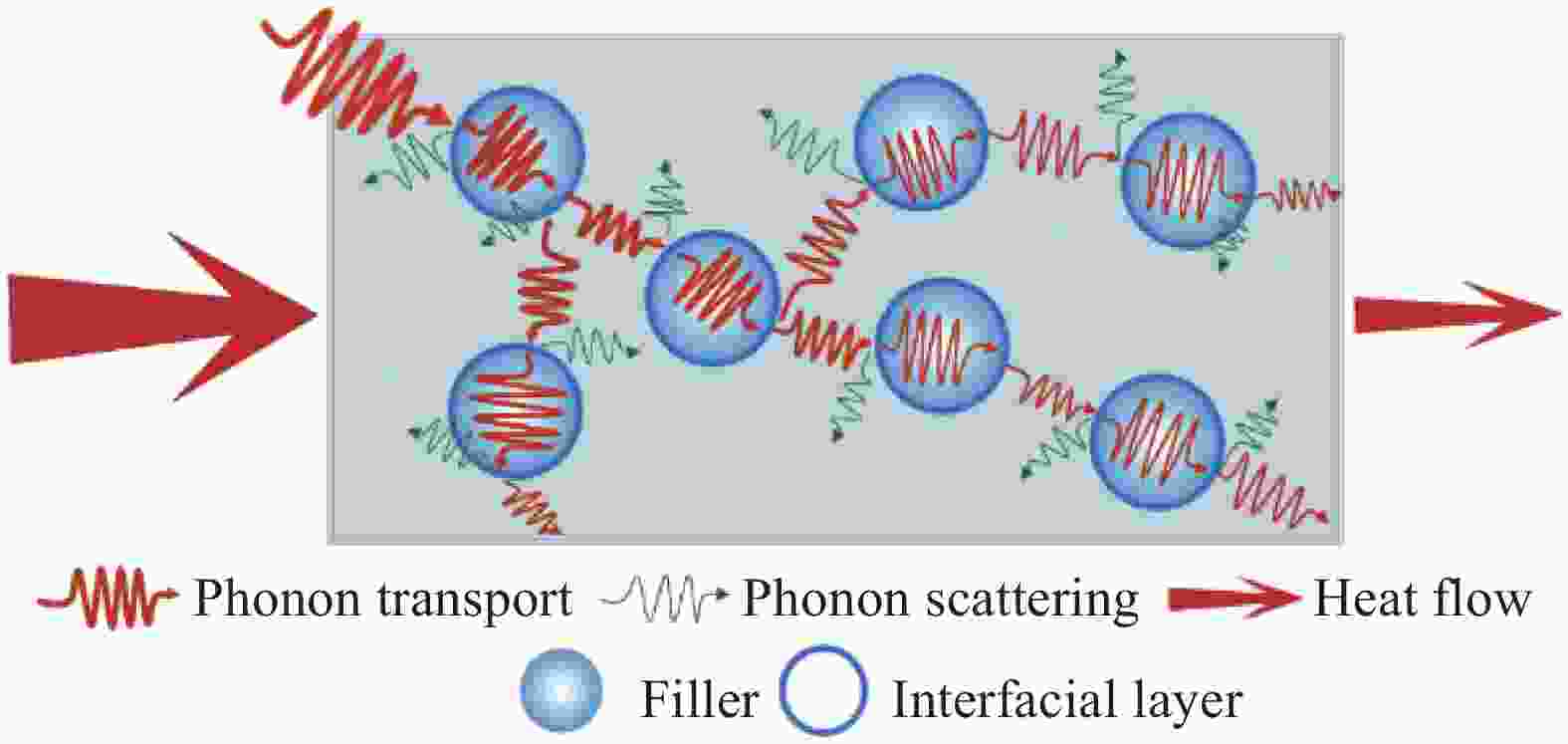

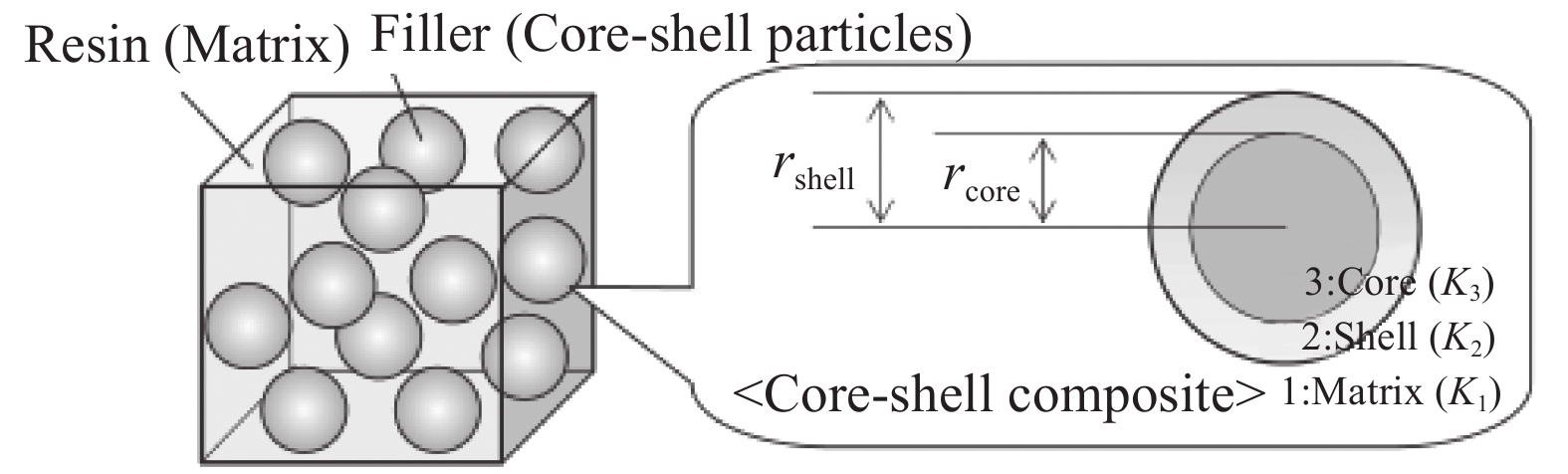

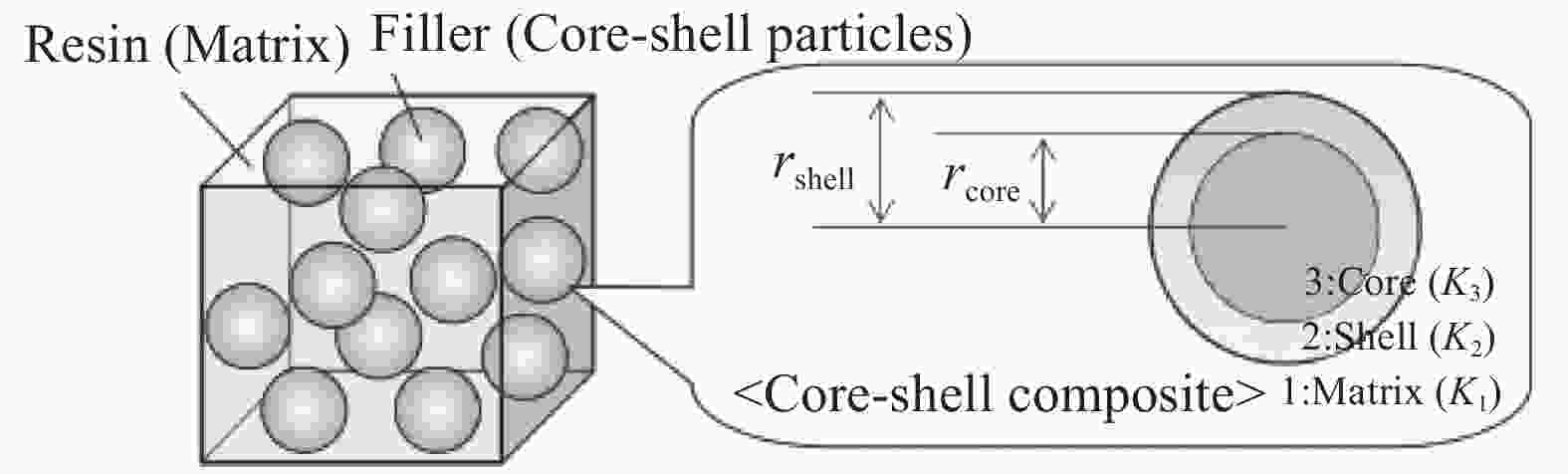

摘要: 界面是复合材料内部连接不同两相的桥梁,极大地影响着复合材料的热学、电学、力学等各项性能。作为复合材料领域中的一个新的分支,导热复合材料近年来因电子电器的高速发展的需求而受到越来越多的关注。然而,研究发现,即使采用了高填料填充方案,复合材料的导热系数也很难达到导热填料的百分之几,其中界面热阻是影响复合材料导热系数提升的关键因素。本文从界面层及界面传热效应的角度出发,分析了复合材料内部界面热阻的产生原因,并从界面的理论研究方法、实验表征手段及影响材料内部热传导行为的界面因素等方面对界面效应在功能复合材料热传导上的影响规律进行了讨论。最后,对界面及界面热传导行为的研究状况进行了总结与展望。Abstract: The interface is a bridge connecting different two phases inside the composite material, which greatly affects the thermal, electrical, mechanical and other properties of the composites. As a new branch in the field of composite materials, thermal conductive composites have attracted more and more attention in recent years due to the rapid development of electronic and electrical appliances. However, it is found that the thermal conductivity of the composites is difficult to reach a few percent of the thermal conductivity of the conductive filler even if the high packing scheme is adopted, and the interfacial thermal resistance is the key factor affecting the improvement of the thermal conductivity of the composites. This paper analyzes the reasons for the thermal resistance of the internal interface inside the composites from the perspective of the interface layer and the heat transfer effect of the interface. In addition, the influence of interface effects on the heat conduction of functional composites was discussed in terms of theoretical research methods, experimental characterization techniques, and interface factors that affect the internal heat conduction behavior of materials. Finally, the development of interface and interfacial heat transfer research were summarized and prospected.

-

表 1 改善界面后复合材料热导率的提升效果

Table 1. Enhancement of thermal conductivity of composites after improving interface

Composite Filler loading The ways to improve interface Thermal conductivity/(W·m−1·K−1) Enhancement in thermal conductivity/% Ref. Graphite film/EP − Graft functional group 0.587 42 [56] BN/PC 18.5vol% Increase the effective area for heat conduction 3.09 221.9 [57] Al2O3-PP/POE 2.8vol% Selective localization at the interface 0.44 60 [58] Al2O3@HGO/EP 70wt% HGO coating reinforces the interfacial interaction of Al2O3 in EP 1.38 72.5 [59] GO/EP 0.5wt% Graft functional group 0.624 117 [60] BN/XSBR 47.4wt% Graft functional group 0.54 18.6 [61] Microdiamond/PLA 60vol% Octadecylamine (ODA) coating on the microdiamond particles improves the interface compatibility between the filler and the matrix 1.66 102.4 [62] Ag-MXene/EP 0.12vol%

(MXene)MXene bridges the isolated Ag particles to further complete the thermal conductive network 72.7 24.7 [63] Notes: EP—Epoxy; PC—Polycarbonate; PP—Polypropylene; POE—Polyolefin elastomer; HGO—Hybrid graphene oxide; GO—Graphene oxide; XSBR—Carboxylated styrene-butadiene rubber; PLA—Poly lactic acid. -

[1] GASKA K, RYBAK A, KAPUSTA C, et al. Enhanced thermal conductivity of epoxy-matrix composites with hybrid fillers[J]. Polymers for Advanced Technologies,2015,26(1):26-31. doi: 10.1002/pat.3414 [2] 孙颖颖. 高分子复合材料导热性能的调控机制研究[D]. 北京: 华北电力大学, 2018.SUN Y Y. Research of thermal conductivity regulatory mechanism of polymer composites[D]. Beijing: North China Electric Power University, 2018(in Chinese). [3] LV F, QIN M, ZHANG F, et al. High cross-plane thermally conductive hierarchical composite using graphene-coated vertically aligned carbon nanotubes/graphite[J]. Carbon,2019,149:281-289. doi: 10.1016/j.carbon.2019.04.043 [4] QIN M, XU Y, CAO R, et al. Efficiently controlling the 3D thermal conductivity of a polymer nanocomposite via a hyperelastic double-continuous network of graphene and sponge[J]. Advanced Functional Materials,2018,28(45):1805053. doi: 10.1002/adfm.201805053 [5] ZHANG F, FENG Y, QIN M, et al. Stress controllability in thermal and electrical conductivity of 3D elastic graphene-crosslinked carbon nanotube sponge/polyimide nanocomposite[J]. Advanced Functional Materials,2019,29(25):1901383. doi: 10.1002/adfm.201901383 [6] 石零. 低温固—固接触界面热传输研究[D]. 武汉: 华中科技大学, 2006.SHI L. Investigation of heat transport on the solid-solid contact interface at low temperature [D]. Wuhan: Huazhong University of Science and Technology, 2006(in Chinese). [7] YANG X, BISWAS S K, HAN J, et al. Surface and interface engineering for nanocellulosic advanced materials[J]. Advanced Materials,2020:2002264. [8] SHEN R, JIANG C, XIANG Q, et al. Surface and interface engineering of hierarchical photocatalysts[J]. Applied Surface Science,2019,471:43-87. doi: 10.1016/j.apsusc.2018.11.205 [9] ZHANG X Y, XU R X, GAO X Y, et al. Achieving ohmic conduction behavior at high electric field via interface manipulation[J]. Applied Surface Science,2020,516:146093. doi: 10.1016/j.apsusc.2020.146093 [10] KASHFIPOUR M A, MEHRA N, ZHU J. A review on the role of interface in mechanical, thermal, and electrical properties of polymer composites[J]. Advanced Composites and Hybrid Materials,2018,1(3):415-439. doi: 10.1007/s42114-018-0022-9 [11] FUKUSHIMA K, TAKWZAWA Y, ADSCHIRI T. Evaluation of thermal conductive resistance at organic–inorganic interface and effect of interfaces on thermal conductivity of composite materials[J]. Japanese Journal of Applied Physics,2013,52(8R):081601. doi: 10.7567/JJAP.52.081601 [12] 周文英. 高导热绝缘高分子复合材料研究[D]. 西安: 西北工业大学, 2007.ZHOU W Y. High thermal conductivity and electrical insulation polymeric composites[D]. Xi'an: Northwestern Polytechnical University, 2007(in Chinese). [13] ZHANG Y, HEO Y J, SON Y R, et al. Recent advanced thermal interfacial materials: A review of conducting mechanisms and parameters of carbon materials[J]. Carbon,2019,142:445-460. doi: 10.1016/j.carbon.2018.10.077 [14] LI L, ZHOU B, HAN G, et al. Understanding the effect of interfacial engineering on interfacial thermal resistance in nacre-like cellulose nanofiber/graphene film[J]. Compo-sites Science and Technology,2020,197:108229. doi: 10.1016/j.compscitech.2020.108229 [15] GUO Y, RUAN K, SHI X, et al. Factors affecting thermal conductivities of the polymers and polymer composites: A review[J]. Composites Science and Technology,2020,193:108134. doi: 10.1016/j.compscitech.2020.108134 [16] KAPITZA P L. Heat transfer and superfluidity of helium II[J]. Physical Review,1941,60(4):354. doi: 10.1103/PhysRev.60.354 [17] MEHRA N, MU L, JI T, et al. Thermal transport in polymeric materials and across composite interfaces[J]. Applied Materials Today,2018,12:92-130. doi: 10.1016/j.apmt.2018.04.004 [18] 吴宇明, 虞锦洪, 曹勇, 等. 高导热低填量聚合物基复合材料研究进展[J]. 复合材料学报, 2018, 35(4):760-766.WU Y M, YU J H, CAO Y, et al. Review of polymer-based composites with high thermal conductivity and low filler loading[J]. Acta Materiae Compositae Sinica,2018,35(4):760-766(in Chinese). [19] 吴祥水, 汤雯婷, 徐象繁. 二维材料热传导研究进展[J]. 物理学报, 2020, 69(19):37-69.WU X S, TANG W T, XU X F. Recent progresses of thermal conduction in two-dimensional materials[J]. Acta Physica Sinica,2020,69(19):37-69(in Chinese). [20] 田恐虎, 吴阳, 盛绍顶, 等. 聚合物基绝缘导热复合材料中碳系填料的研究进展[J]. 复合材料学报, 2021, 38(4):1054-1065.TIAN K H, WU Y, SHENG S D, et al. Research progress of carbon-based fillers in polymer matrix insulating and thermally conductive composites[J]. Acta Materiae Compositae Sinica,2021,38(4):1054-1065(in Chinese). [21] HUANG J, ZHU Y, XU L, et al. Massive enhancement in the thermal conductivity of polymer composites by trapping graphene at the interface of a polymer blend[J]. Compo-sites Science and Technology,2016,129:160-165. doi: 10.1016/j.compscitech.2016.04.029 [22] 葛鑫, 陈循军, 吴淑芳, 等. 聚合物/氮化硼填充型导热界面材料研究进展[J]. 广州化工, 2017, 45(10):7-11. doi: 10.3969/j.issn.1001-9677.2017.10.004GE X, CHEN X J, WU S F, et al. Research progress on thermal interface materials filled by BN[J]. Guangzhou Chemical Industry,2017,45(10):7-11(in Chinese). doi: 10.3969/j.issn.1001-9677.2017.10.004 [23] 李宾, 李壮, 郑彬, 等. 聚合物基导热绝缘复合材料的性能及界面效应[J]. 华东理工大学学报(自然科学版), 2008(2):219-224+241.LI B, LI Z, ZHENG B, et al. Properties and interfacial treatment effect on thermal conductivity and electrical insulativity of the polymer composites[J]. Journal of East China University of Science and Technology(Natural Science Edition),2008(2):219-224+241(in Chinese). [24] 王家俊. 聚酰亚胺/氮化铝复合材料的制备与性能研究[D]. 杭州: 浙江大学, 2001.WANG J J. Preparation and investigation on the polyimide/AlN composite materials[D]. Hangzhou: Zhe-jiang University, 2001(in Chinese). [25] EUCKEN A. Thermal conductivity of ceramic refractory materials-calculation from the thermal conductivity of the components[J]. Engineering Research,1932,3:16. [26] BRUGGEMAN D A G. Effective medium model for the optical properties of composite materials[J]. Annalen der Physik,1935,24:636. [27] RUSSELL H W. Principles of heat flow in porous insulators[J]. Journal of the American Ceramic Society,1935,18(1-12):1-5. [28] CHU K, LI W, DONG H, et al. Modeling the thermal conductivity of graphene nanoplatelets reinforced compo-sites[J]. Europhysics Letters,2012,100(3):36001. doi: 10.1209/0295-5075/100/36001 [29] 胡松青, 薛庆忠, 徐文美. 考虑界面效应的纳米流体的热传导模型[J]. 山东师范大学学报(自然科学版), 2006(2):56-57, 67.HU S Q, XUE Q Z, XU W M. Model for thermal conductivity of nanofluids with interfacial effect[J]. Journal of Shandong Normal University (Natural Science),2006(2):56-57, 67(in Chinese). [30] 谢航, 李娇娇, 王小勇, 等. 模拟研究石墨烯/生物基尼龙复合材料的界面热阻[J]. 高分子学报, 2021, 52(4):399-405.XIE H, LI J J, WANG X Y, et al. Simulation study on the interface thermal resistance of graphene/bio-nylon composites[J]. Acta Polymerica Sinica,2021,52(4):399-405(in Chinese). [31] HASSELMAN D P H, DONALDSON K Y, GEIGER A L. Effect of reinforcement particle size on the thermal conductivity of a particulate-silicon carbide-reinforced aluminum matrix composite[J]. Journal of the American Ceramic Society,1992,75(11):3137-3140. doi: 10.1111/j.1151-2916.1992.tb04400.x [32] HASSELMAN D P H. Effective thermal conductivity of composites with interfacial thermal barrier resistance[J]. Journal of Composite Materials,1987,21(6):508-515. doi: 10.1177/002199838702100602 [33] EVERY A G, TZOU Z, HASSELMAN D P H, et al. The effect of particle size on the thermal conductivity of ZnS/diamond composites[J]. Acta Metallurgica et Materialia,1992,40(1):123-129. doi: 10.1016/0956-7151(92)90205-S [34] 庞旭明, 周剑秋, 杨晶歆, 等. 含孔隙及界面热阻的复合材料有效导热系数[J]. 中国有色金属学报, 2016, 26(8):1668-1674.PANG X M, ZHOU J Q, YANG J X, et al. Effective thermal conductivity of composite materials containing pore and interface thermal resistance[J]. The Chinese Journal of Nonferrous Metals,2016,26(8):1668-1674(in Chinese). [35] 张保林, 弋楠, 朱蓉英, 等. 透射电镜与扫描电镜分析[J]. 无线互联科技, 2016(23):25-26. doi: 10.3969/j.issn.1672-6944.2016.23.011ZHANG B L, GE N, ZHU R Y, et al. Analysis of transmission electron microscope and scanning electron microscope[J]. Wireless Internet Technology,2016(23):25-26(in Chinese). doi: 10.3969/j.issn.1672-6944.2016.23.011 [36] JAGANNADHAM K, WANG H. Thermal resistance of interfaces in AlN–diamond thin film composites[J]. Journal of Applied Physics,2002,91(3):1224-1235. doi: 10.1063/1.1428103 [37] SHEN H, CAI C, GUO J, et al. Fabrication of oriented hBN scaffolds for thermal interface materials[J]. RSC Advances,2016,6(20):16489-16494. doi: 10.1039/C6RA00980H [38] FAN B, LIU Y, HE D, et al. Enhanced thermal conductivity for mesophase pitch-based carbon fiber/modified boron nitride/epoxy composites[J]. Polymer,2017,122:71-76. doi: 10.1016/j.polymer.2017.06.060 [39] CHEN J, HUANG X, SUN B, et al. Vertically aligned and interconnected boron nitride nanosheets for advanced flexible nanocomposite thermal interface materials[J]. ACS Applied Materials & Interfaces,2017,9(36):30909-30917. [40] 余振华, 詹建波, 王浩, 等. X射线能谱在卷烟纸钾和钠元素含量快速检测中的应用[J]. 中国造纸学报, 2020, 35(2):59-63.YU Z H, ZHAN J B, WANG H, et al. Application of X-ray energy dispersive spectrometer in rapid determination of potassium and sodium in cigarette paper[J]. Transactions of China Pulp and Paper,2020,35(2):59-63(in Chinese). [41] ROOHOLLAHI H, HALLADJ R, ASKARI S, et al. SAPO-34/AlMCM-41, as a novel hierarchical nanocomposite: Preparation, characterization and investigation of synthesis factors using response surface methodology[J]. Journal of Solid State Chemistry,2018,262:273-281. [42] CHANG-JIAN C W, CHO E C, LEE K C, et al. Thermally conductive polymeric composites incorporating 3D MWCNT/PEDOT: PSS scaffolds[J]. Composites Part B: Engineering,2018,136:46-54. doi: 10.1016/j.compositesb.2017.10.004 [43] ZHAO Z, TENG K, LI N, et al. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface[J]. Composite Structures,2017,159:761-772. doi: 10.1016/j.compstruct.2016.10.022 [44] BOUKHVALOV D W, ZHIDKOV I S, KUKHARENKO A I, et al. Stability of boron-doped graphene/copper interface: DFT, XPS and OSEE studies[J]. Applied Surface Science,2018,441:978-983. doi: 10.1016/j.apsusc.2018.02.074 [45] SHTEIN M, NADIV R, BUZAGLO M, et al. Thermally conductive graphene-polymer composites: size, percolation, and synergy effects[J]. Chemistry of Materials,2015,27(6):2100-2106. doi: 10.1021/cm504550e [46] KIM H S, BAE H S, YU J, et al. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets[J]. Scientific Reports,2016,6(1):1-9. doi: 10.1038/s41598-016-0001-8 [47] PUTZ B, MILASSIN G, BUTENKO Y, et al. Combined TEM and XPS studies of metal-polymer interfaces for space applications[J]. Surface and Coatings Technology,2017,332:368-375. doi: 10.1016/j.surfcoat.2017.07.079 [48] 高红霞, 王蒙, 樊江磊, 等. 混杂颗粒增强铝基复合材料的研究进展[J]. 粉末冶金工业, 2019, 29(3):1-7.GAO H X, WANG M, FAN J L, et al. Research progress of hybrid particles reinforced aluminum matrix composites[J]. Powder Metallurgy Industry,2019,29(3):1-7(in Chinese). [49] XU C, CHEN J, WU D, et al. Polylactide/acetylated nanocrystalline cellulose composites prepared by a continuous route: a phase interface-property relation study[J]. Carbohydrate Polymers,2016,146:58-66. doi: 10.1016/j.carbpol.2016.03.058 [50] COLSON J, ANDORFER L, NYPELO T E, et al. Comparison of silicon and OH-modified AFM tips for adhesion force analysis on functionalised surfaces and natural polymers[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2017,529:363-372. [51] LI X, FENG Y, CHU G, et al. Directly and quantitatively studying the interfacial interaction between SiO2 and elastomer by using peak force AFM[J]. Composites Communications,2018,7:36-41. doi: 10.1016/j.coco.2017.12.006 [52] ZHENG N, HE J, GAO J, et al. Adhesion force measured by atomic force microscopy for direct carbon fiber-epoxy interfacial characterization[J]. Materials & Design,2018,145:218-225. [53] 邹爱华. 颗粒增强铝基复合材料微结构与热传导关联研究[D]. 南京: 南京航空航天大学, 2016.ZOU A H. Study on the correlation between the microstructures and thermal conductivity of particle reinforced aluminum matrix composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016(in Chinese). [54] LI Y, MEHRA N, JI T, et al. The stiffness-thermal conduction relationship at the composite interface: the effect of particle alignment on the long-range confinement of polymer chains monitored by scanning thermal microscopy[J]. Nanoscale,2018,10(4):1695-1703. doi: 10.1039/C7NR06780A [55] SINGH I V, TANAKA M, ENDO M. Effect of interface on the thermal conductivity of carbon nanotube composites[J]. International Journal of Thermal Sciences,2007,46(9):842-847. doi: 10.1016/j.ijthermalsci.2006.11.003 [56] WANG H, WANG S, LU W, et al. Through-thickness thermal conductivity enhancement of graphite film/epoxy compo-site via short duration acidizing modification[J]. Applied Surface Science,2018,442:170-177. doi: 10.1016/j.apsusc.2018.02.125 [57] SUN N, SUN J, ZENG X, et al. Hot-pressing induced orientation of boron nitride in polycarbonate composites with enhanced thermal conductivity[J]. Composites Part A: Applied Science and Manufacturing,2018,110:45-52. doi: 10.1016/j.compositesa.2018.04.010 [58] ZHANG X, MAIRA B, HASHIMOTO Y, et al. Selective localization of aluminum oxide at interface and its effect on thermal conductivity in polypropylene/polyolefin elastomer blends[J]. Composites Part B: Engineering,2019,162:662-670. doi: 10.1016/j.compositesb.2019.01.043 [59] FENG Y, HE C, WEN Y, et al. Multi-functional interface tailoring for enhancing thermal conductivity, flame retardancy and dynamic mechanical property of epoxy/Al2O3 composites[J]. Composites Science and Technology,2018,160:42-49. doi: 10.1016/j.compscitech.2018.03.009 [60] XU H, ZHANG X, HU G, et al. High thermal conductivity EP adhesive based on the GO/EP interface optimized by TDI[J]. Polymers for Advanced Technologies,2020,31(6):1356-1364. doi: 10.1002/pat.4865 [61] ZHANG Y, CHOI J R, PARK S J. Enhancing the heat and load transfer efficiency by optimizing the interface of hexagonal boron nitride/elastomer nanocomposites for thermal management applications[J]. Polymer,2018,143:1-9. doi: 10.1016/j.polymer.2018.03.067 [62] SU S H, HUANG Y, QU S, et al. Microdiamond/PLA composites with enhanced thermal conductivity through improving filler/matrix interface compatibility[J]. Diamond and Related Materials,2018,81:161-167. doi: 10.1016/j.diamond.2017.12.011 [63] WANG D, WEI H, LIN Y, et al. Achieving ultrahigh thermal conductivity in Ag/MXene/epoxy nanocomposites via filler-filler interface engineering[J]. Composites Science and Technology,2021,213:108953. doi: 10.1016/j.compscitech.2021.108953 [64] DEVPURA, PATRICK E. PHELAN, RAVI S. PRASHER A. Size effects on the thermal conductivity of polymers laden with highly conductive filler particles[J]. Microscale Thermophysical Engineering,2001,5(3):177-189. doi: 10.1080/108939501753222869 [65] KUMAR A, KOSONOWSKI A, WYZGA P, et al. Effective thermal conductivity of SrBi4Ti4O15-La0.7Sr0.3MnO3 oxide composite: Role of particle size and interface thermal resistance[J]. Journal of the European Ceramic Society,2021,41(1):451-458. doi: 10.1016/j.jeurceramsoc.2020.08.069 [66] MORADI S, CALVENTUS Y, ROMAN F, et al. Achieving high thermal conductivity in epoxy composites: Effect of boron nitride particle size and matrix-filler interface[J]. Polymers,2019,11(7):1156. doi: 10.3390/polym11071156 [67] SONG J, ZHANG Y. Effect of an interface layer on thermal conductivity of polymer composites studied by the design of double-layered and triple-layered composites[J]. International Journal of Heat and Mass Transfer,2019,141:1049-1055. [68] ZHOU Y, ZHANG X, HU M. An excellent candidate for largely reducing interfacial thermal resistance: A nano-confined mass graded interface[J]. Nanoscale,2016,8(4):1994-2002. doi: 10.1039/C5NR06855J [69] 邹文奇, 温变英, 张扬. 酯交换反应对PBT/PC/Al2O3复合材料导热性能的影响[J]. 高分子学报, 2016(5):606-613.ZOU W Q, WEN B Y, ZHANG Y. Effects of transesterification on thermal conductivity of PBT/PC/Al2O3 compo-sites[J]. Acta Polymerica Sinica,2016(5):606-613(in Chinese). [70] 李婷. 石墨烯和六方氮化硼界面热特性的研究[D]. 大连: 大连理工大学, 2018.LI T. A study on the interfacial thermal performance of graphene and hexagonal boron nitride[D]. Dalian: Dalian University of Technology, 2018(in Chinese). [71] 王鹏鹏. 金刚石/铜复合材料的界面表征及调控研究[D]. 北京: 北京有色金属研究总院, 2014.WANG P P. Research of diamond/copper composite interface characterization and control[D]. Beijing: General Research Institute for Nonferrous Metals, 2014(in Chinese). [72] SAIR S, OUSHABI A, KAMMOUNI A, et al. Effect of surface modification on morphological, mechanical and thermal conductivity of hemp fiber: Characterization of the interface of hemp–polyurethane composite[J]. Case Studies in Thermal Engineering,2017,10:550-559. doi: 10.1016/j.csite.2017.10.012 [73] 王俊伟, 张现周, 薛晨, 等. 石墨表面镀Si对石墨/Al复合材料热物理性能的影响[J]. 复合材料学报, 2017, 34(4):836-843.WANG J W, ZHANG X Z, XUE C, et al. Effects of Si coated on graphite surface on the thermal and mechanical properties of graphite/Al composites[J]. Acta Materiae Compositae Sinica,2017,34(4):836-843(in Chinese). [74] KUMAR A, AYYAGARI N, FISHER T S. Effects of graphene nanopetal outgrowths on internal thermal interface resistance in composites[J]. ACS Applied Materials & Interfaces,2016,8(10):6678-6684. [75] REN L, LI Q, LU J, et al. Enhanced thermal conductivity for Ag-deposited alumina sphere/epoxy resin composites through manipulating interfacial thermal resistance[J]. Composites Part A: Applied Science and Manufacturing,2018,107:561-569. doi: 10.1016/j.compositesa.2018.02.010 [76] SHENOGIN S, XUE L, OZISIK R, et al. Role of thermal boundary resistance on the heat flow in carbon-nanotube composites[J]. Journal of Applied Physics,2004,95(12):8136-8144. doi: 10.1063/1.1736328 [77] 汪蔚, 曹建达, 郑敏敏, 等. BN 表面沉积纳米Sn对BN/环氧树脂复合材料导热绝缘性能的影响[J]. 复合材料学报, 2020, 37(7):1547-1554.WANG W, CAO J D, ZHENG M M, et al. Effects of BN surface deposited with nano Sn on thermal conductivity andelectrical insulation of BN/epoxy composites[J]. Acta Materiae Compositae Sinica,2020,37(7):1547-1554(in Chinese). [78] 汪蔚, 曹万荣, 陈婷婷. BN表面改性BN/环氧树脂复合材料导热性能的影响[J]. 复合材料学报, 2018, 35(2):275-281.WANG W, CAO W R, CHEN T T. Effects of BN surface modification on thermal conductivity of BN/epoxy composites[J]. Acta Materiae Compositae Sinica,2018,35(2):275-281(in Chinese). [79] GUO Y, LYU Z, YANG X, et al. Enhanced thermal conductivities and decreased thermal resistances of functionalized boron nitride/polyimide composites[J]. Composites Part B: Engineering,2019,164:732-739. doi: 10.1016/j.compositesb.2019.01.099 [80] LI A, ZHANG C, ZHANG Y F. Thermal conductivity of graphene-polymer composites: Mechanisms, properties, and applications[J]. Polymers,2017,9(9):437. doi: 10.3390/polym9090437 [81] WANG Y, ZHAN H F, XIANG Y, et al. Effect of covalent functionalization on thermal transport across graphene–polymer interfaces[J]. The Journal of Physical Chemistry C,2015,119(22):12731-12738. doi: 10.1021/acs.jpcc.5b02920 [82] TANG B, HU G, GAO H, et al. Application of graphene as filler to improve thermal transport property of epoxy resin for thermal interface materials[J]. International Journal of Heat and Mass Transfer,2015,85:420-429. doi: 10.1016/j.ijheatmasstransfer.2015.01.141 [83] BURGER N, LAACHACHI A, FERRIOL M, et al. Review of thermal conductivity in composites: Mechanisms, parameters and theory[J]. Progress in Polymer Science,2016,61:1-28. doi: 10.1016/j.progpolymsci.2016.05.001 [84] SEO J M, TAN L S, BAEK J B. Defect/edge-selective functionalization of carbon materials by “Direct” friedel-crafts acylation reaction[J]. Advanced Materials,2017,29(19):1606317. doi: 10.1002/adma.201606317 [85] SHEN X, WANG Z, WU Y, et al. Effect of functionalization on thermal conductivities of graphene/epoxy composites[J]. Carbon,2016,108:412-422. doi: 10.1016/j.carbon.2016.07.042 [86] ZHENG X, WEN B. Practical PBT/PC/GNP composites with anisotropic thermal conductivity[J]. RSC Advances,2019,9(62):36316-36323. doi: 10.1039/C9RA07168G [87] WEN B Y, ZHENG X L. Effect of the selective distribution of graphite nanoplatelets on the electrical and thermal conductivities of a polybutylene terephthalate/polycarbonate blend[J]. Composites Science and Technology,2019,174:68-75. [88] YANG S Q, WANG Q, WEN B Y. Highly thermally conductive and superior electrical insulation polymer composites via in situ thermal expansion of expanded graphite and in situ oxidation of aluminum nanoflakes[J]. ACS Applied Materials & Interfaces, 2020, 13(1): 1132-1151. [89] 秦国锋, 张婧婧, 徐子威, 等. BN纤维对石墨烯微片/聚丙烯复合材料导热绝缘性能的影响[J]. 复合材料学报, 2020, 37(3):546-552.QIN G F, ZHANG J J, XU Z W, et al. Effect of BN fiber on thermal conductivity and insulation properties of graphene nanoplatelets/polypropylene composites[J]. Acta Materiae Compositae Sinica,2020,37(3):546-552(in Chinese). [90] ZHAO Y H, WU Z K, BAI S L. Study on thermal properties of graphene foam/graphene sheets filled polymer compo-sites[J]. Composites Part A: Applied Science and Manufacturing,2015,72:200-206. doi: 10.1016/j.compositesa.2015.02.011 [91] TEKCE H S. Effect of particle shape on thermal conductivity of copper reinforced polymer composites[J]. Journal of Reinforced Plastics and Composites, 2007, 26(1): 113-121. [92] 邹文奇, 温变英. 填充型导热塑料导热性能影响因素探析[J]. 高分子材料科学与工程, 2015, 31(7):178-183.ZOU W Q, WEN B Y. Influence factors of the thermal conductivity for filled thermal conductive plastic composite[J]. Polymeric Materials Science and Engineering,2015,31(7):178-183(in Chinese). [93] 史青, 彭勃, 朱爱萍. 膨胀石墨-碳纤维/尼龙三元导热复合材料制备[J]. 复合材料学报, 2019, 36(3):555-562.SHI Q, PENG B, ZHU A P. Preparation of expanded graphite-carbon fiber/nylon ternary thermally conductive composites[J]. Acta Materiae Compositae Sinica,2019,36(3):555-562(in Chinese). [94] LI M, LI L, HOU X, et al. Synergistic effect of carbon fiber and graphite on reducing thermal resistance of thermal interface materials[J]. Composites Science and Technology,2021,212(5):108883. [95] ZHU Z, LI C, E S F, et al. Enhanced thermal conductivity of polyurethane composites via engineering small/large sizes interconnected boron nitride nanosheets[J]. Composites Science and Technology,2019,170:93-100. doi: 10.1016/j.compscitech.2018.11.035 [96] ZHANG F, FENG Y, FENG W. Three-dimensional interconnected networks for thermally conductive polymer composites: design, preparation, properties, and mechanisms[J]. Materials Science and Engineering: R: Reports,2020,142:100580. doi: 10.1016/j.mser.2020.100580 [97] ZENG X, YAO Y, GONG Z, et al. Ice-templated assembly strategy to construct 3D boron nitride nanosheet networks in polymer composites for thermal conductivity improvement[J]. Small,2015,11(46):6205-6213. doi: 10.1002/smll.201502173 [98] HAN J, DU G, GAO W, et al. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network[J]. Advanced Functional Materials,2019,29(13):1900412. doi: 10.1002/adfm.201900412 -

下载:

下载: