Laser-grinding compound processing of 2.5 dimensional C/SiC composite grooves

-

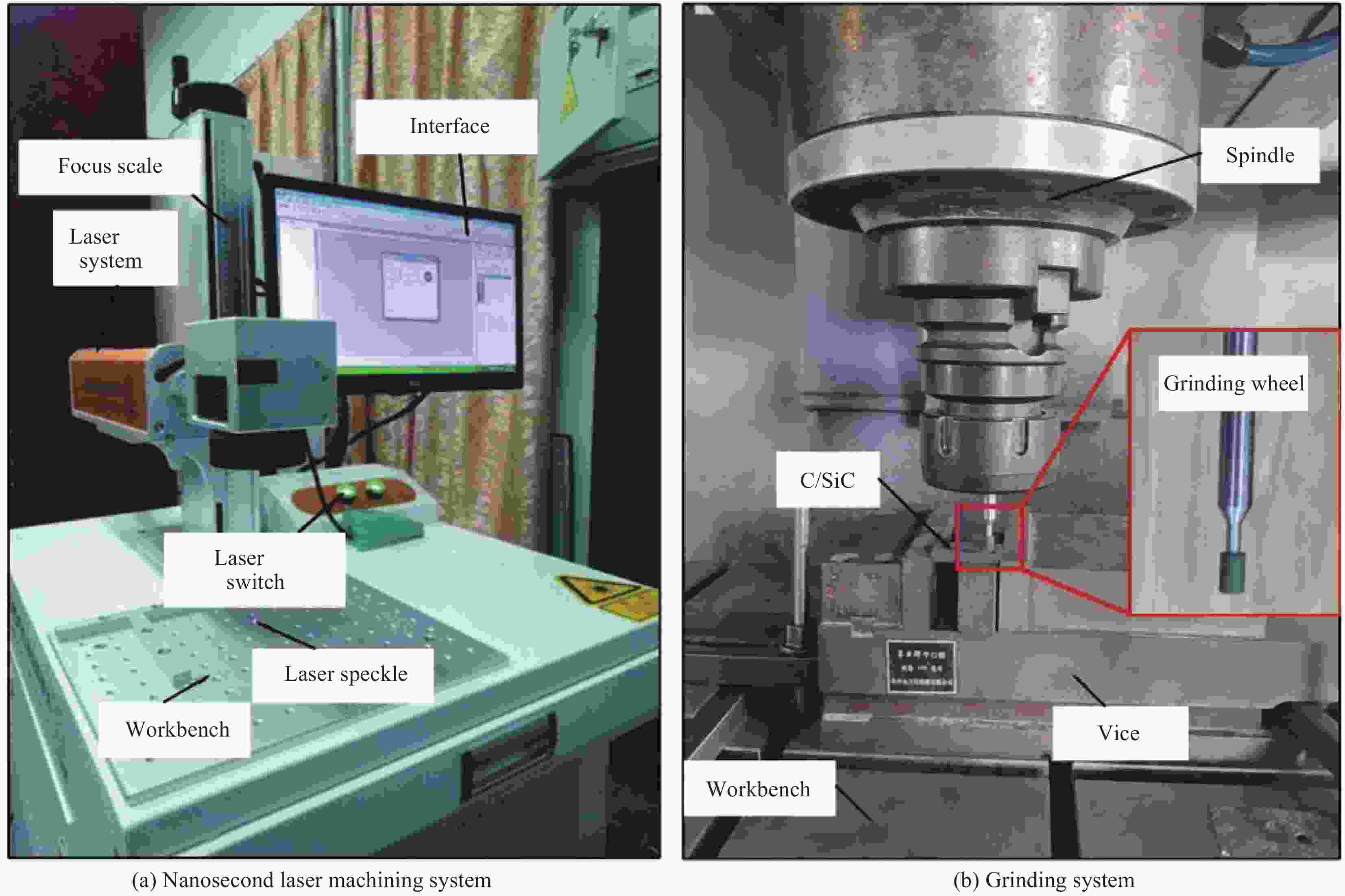

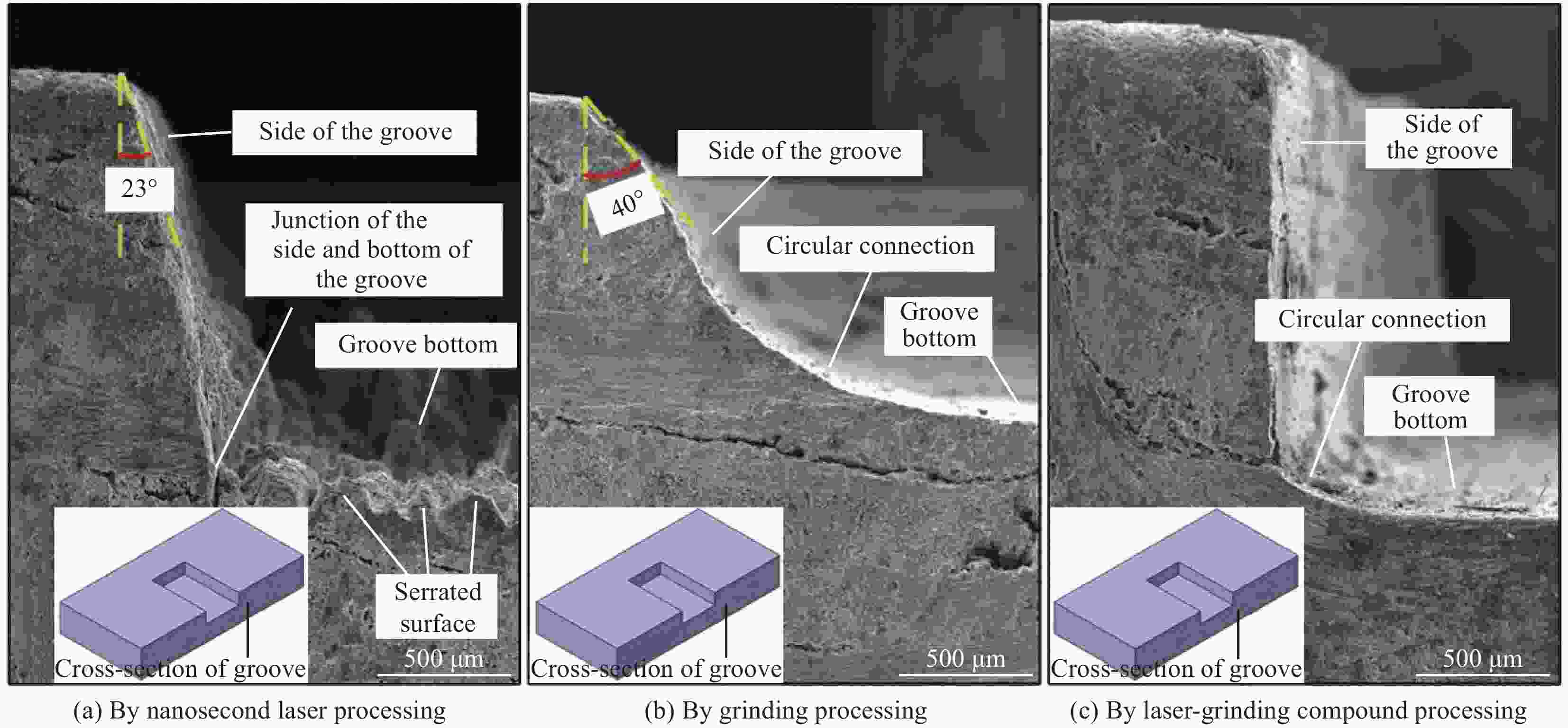

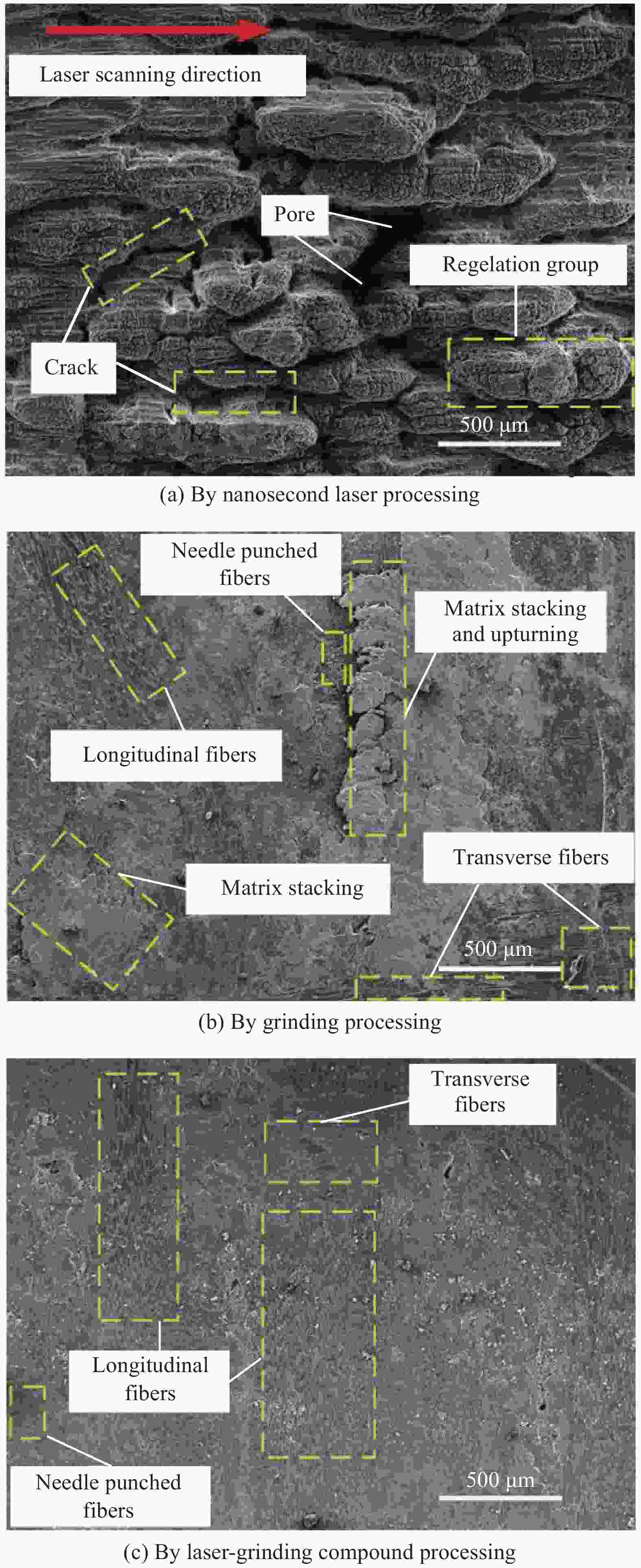

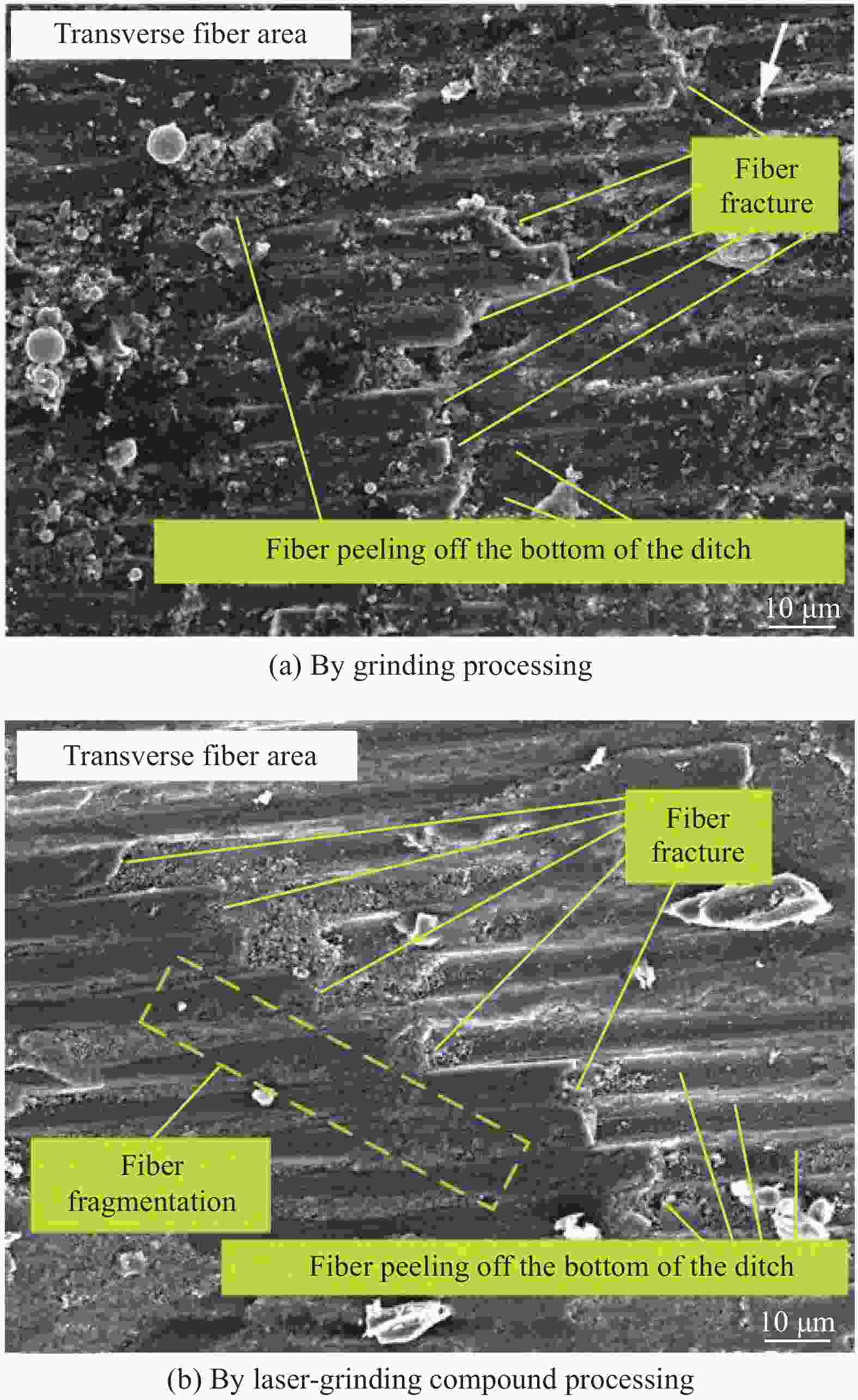

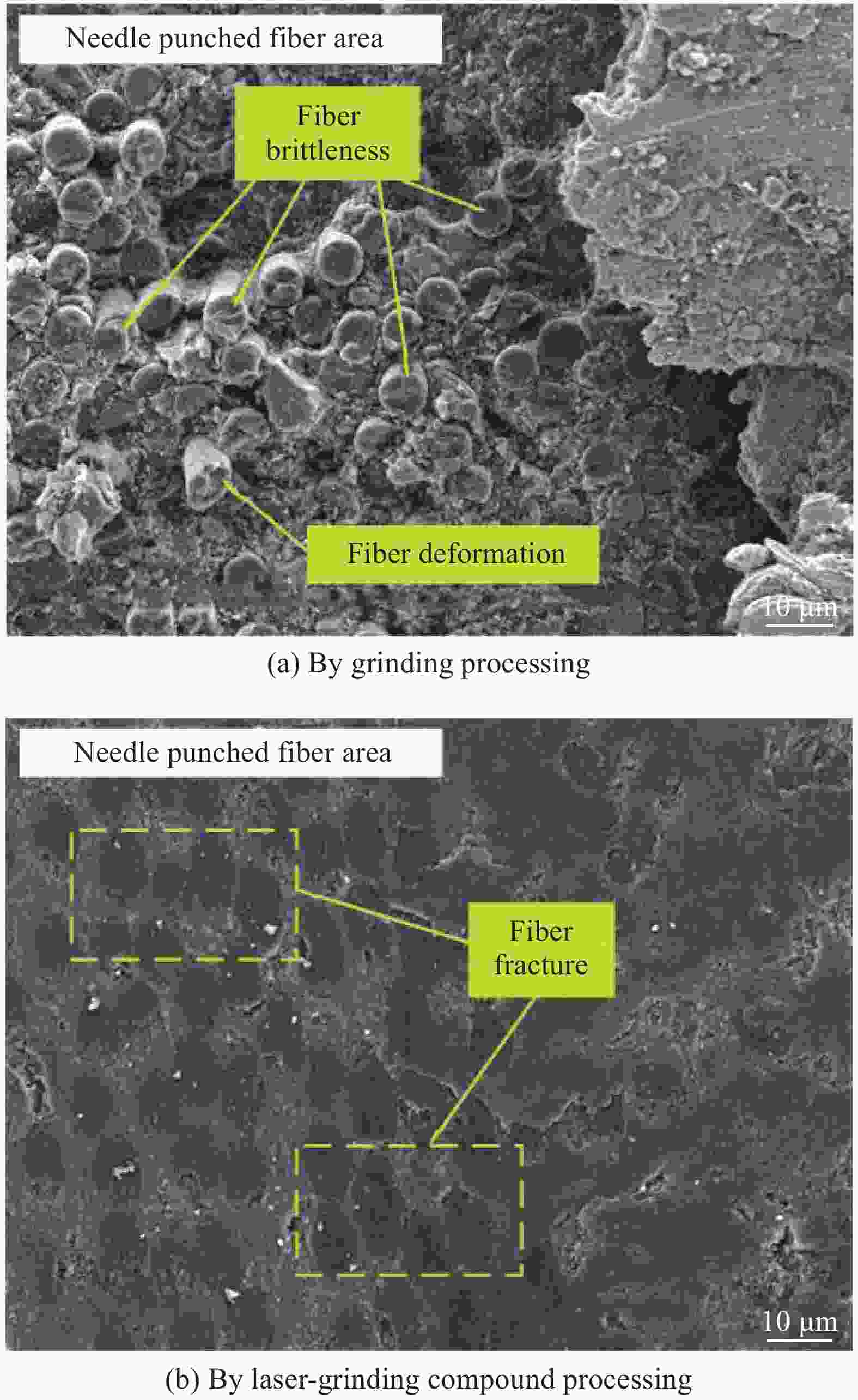

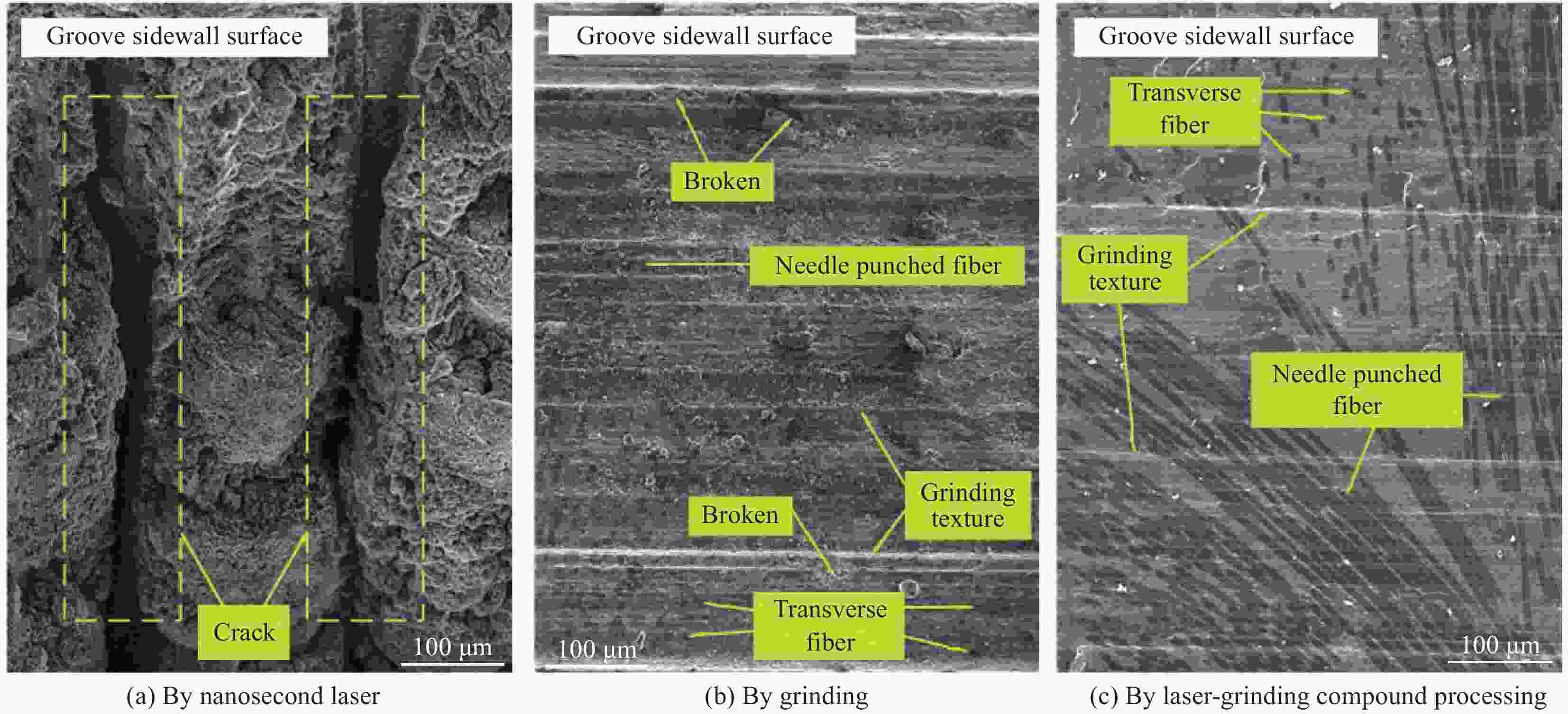

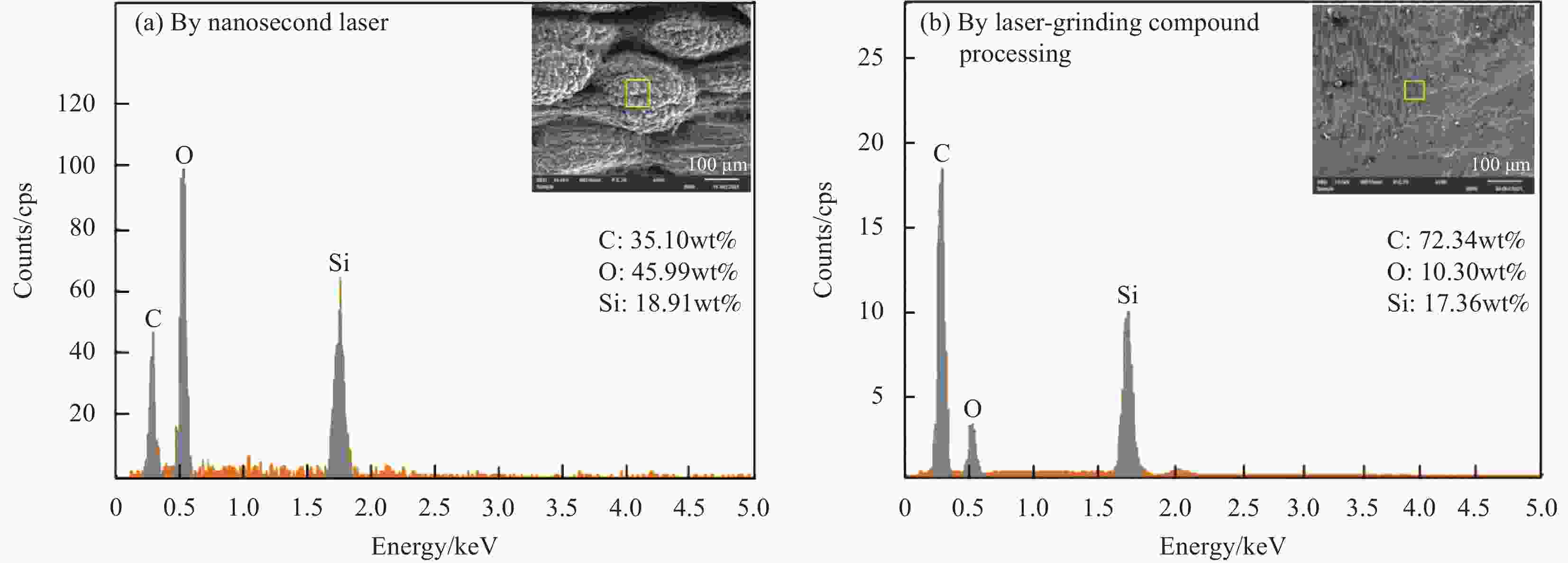

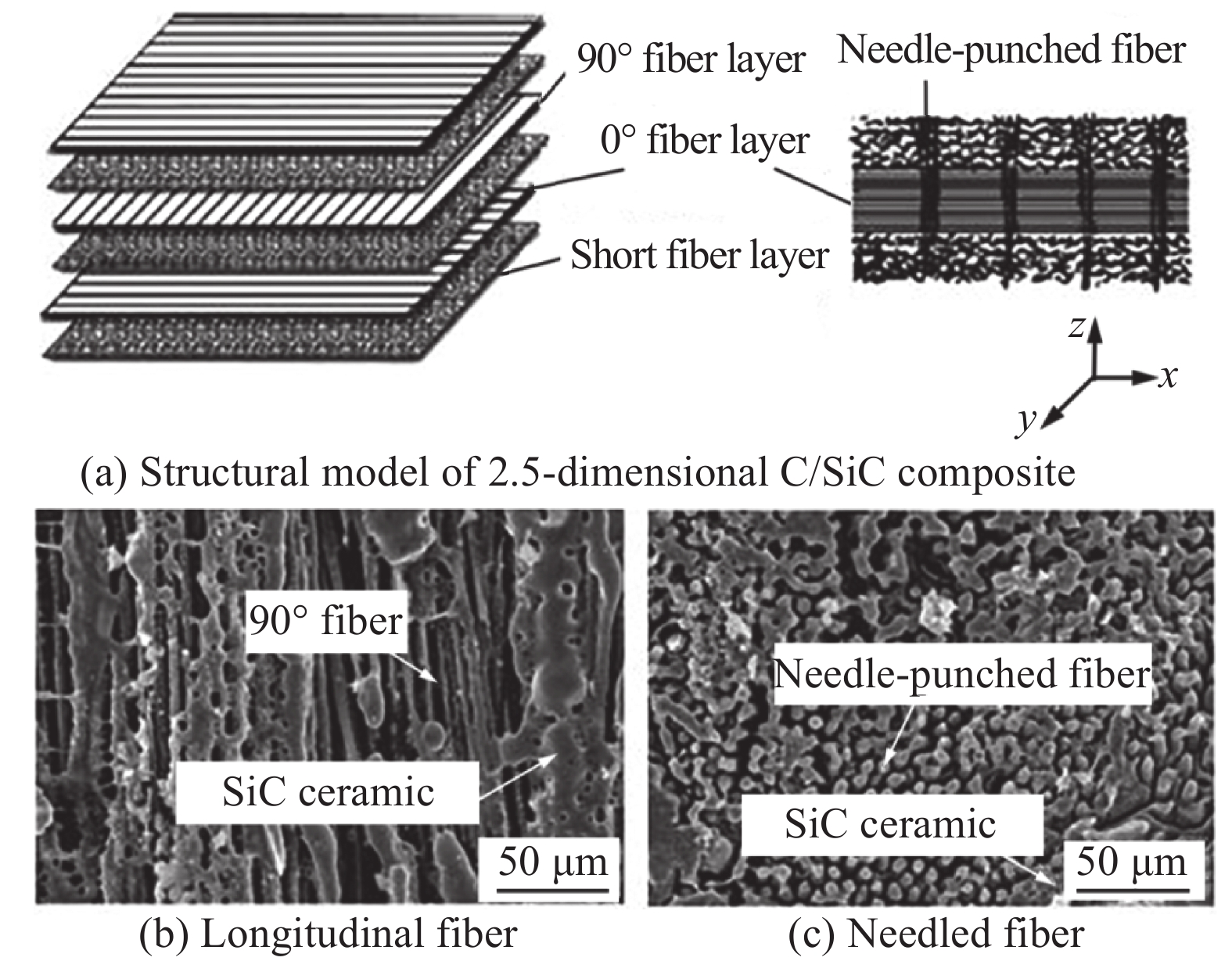

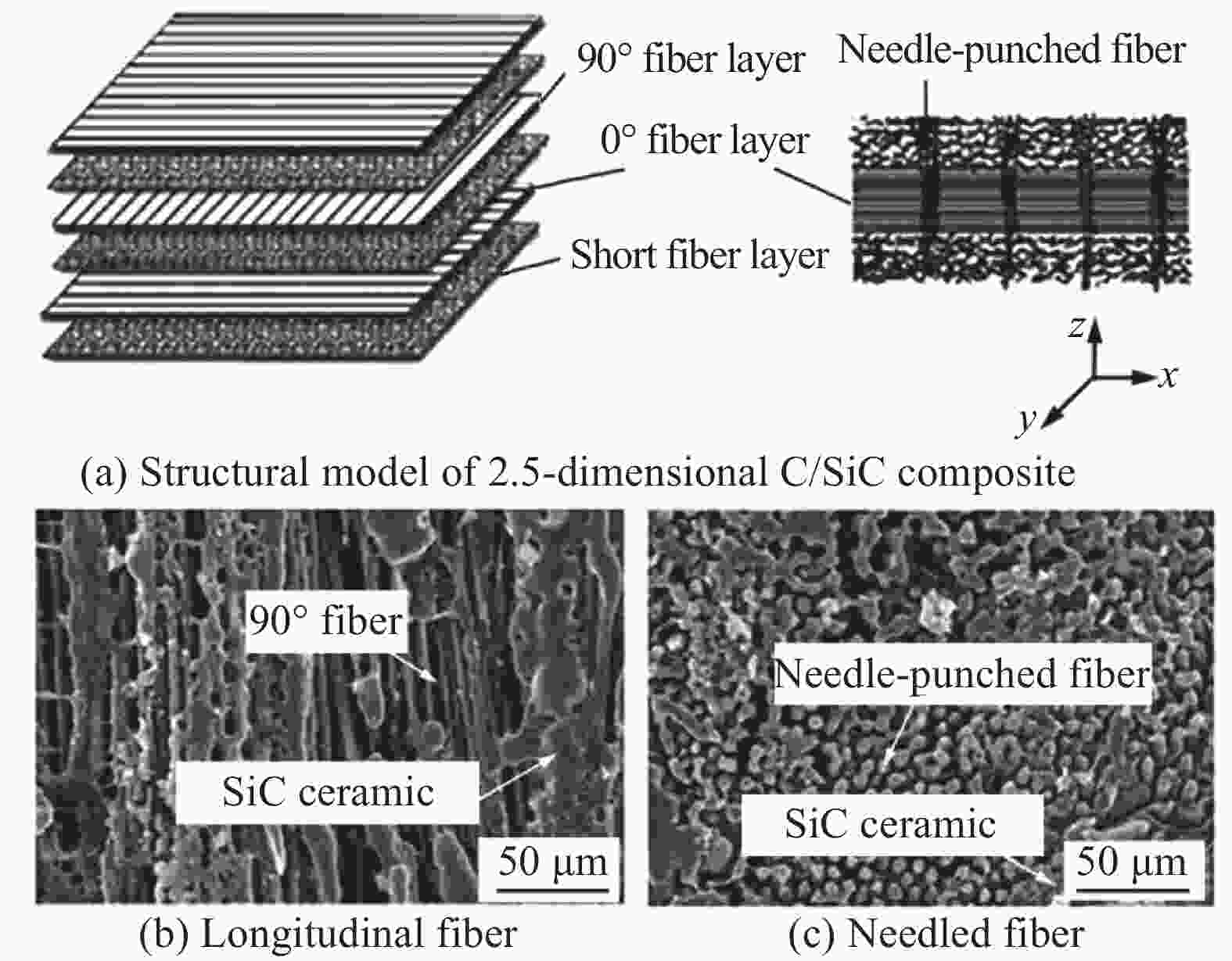

摘要: 针对2.5维碳纤维增强碳化硅陶瓷基(C/SiC)复合材料凹槽在激光加工后存在一定的烧蚀氧化层、侧壁倾斜、底面不平坦和磨削加工后易出现破碎、纤维断裂、刀具磨损、形状精度低、效率低等问题,提出激光-磨削复合加工的方法。为探索激光-磨削复合加工2.5维C/SiC复合材料凹槽的可行性,进行了激光加工、磨削加工和激光-磨削复合加工凹槽的对比实验。研究表明:激光加工后的凹槽侧壁倾斜约23°,底面和侧壁表面质量均较差,但加工效率高;磨削加工后的凹槽表面质量得到一定提升,但是由于砂轮磨损剧烈,使磨削后的凹槽形状精度极差,且加工效率较低;而激光-磨削复合加工后的凹槽侧壁倾斜度被去除,砂轮磨损大幅降低,表面质量显著提升,凹槽表面粗糙度比磨削后的表面粗糙度提高了1.27~1.96倍,加工时间约为磨削加工的0.3倍。因此,激光-磨削复合加工不仅能克服激光加工和磨削加工的缺点,还能发挥激光加工效率高和磨削加工精度高的特点,同时兼顾了2.5维C/SiC复合材料凹槽加工的质量和效率。该研究结果可为2.5维C/SiC复合材料凹槽的高效、精密、低损伤加工提供理论支持。Abstract: There were many problems after 2.5 dimensional carbon fiber reinforced SiC ceramic matrix (C/SiC) composite processed by nanosecond lasers, such as ablative oxide layer, sidewall slope, uneven bottom surface, and many problems also remained in grinding processing, breakage of fiber and matrix, fiber fracture, tool wear, low shape accuracy, low efficiency and so on, the laser-grinding compound processing method was proposed. To explore the feasibility of laser-grinding compound processing of 2.5 dimensional C/SiC composite grooves, the grooves experiment of laser processing, grinding processing and laser-grinding composite processing were carried out. The results show that the slope of the side wall of the groove by laser processing is about 23°, the surface quality of the bottom and side wall is poor, but the processing efficiency is high. To a certain extent, the surface quality of the grooves by grinding is improved, but the shape precision of the grooves after grinding is extremely poor and the processing efficiency is lower because of the severe wear of the grinding wheel. However, after laser-grinding compound processing, slope of groove sidewall is removed, the grinding wheel wear is greatly reduced, and the surface quality is significantly improved, roughness of the groove surface is 1.27-1.96 times higher than that after grinding, the processing time is about 0.3 of that of grinding. Therefore, the laser-grinding compound processing can not only overcome the shortcomings of laser processing and grinding processing, but also give play to the characteristics of high laser processing efficiency and grinding accuracy, and take into account the quality and efficiency of groove processing of 2.5 dimensional C/SiC composites. The results can provide theoretical support for efficient, precise and low damage processing of 2.5 dimensional C/SiC composite grooves.

-

Key words:

- C/SiC composite /

- laser-grinding compound processing /

- sidewall slope /

- surface quality /

- wheel wear

-

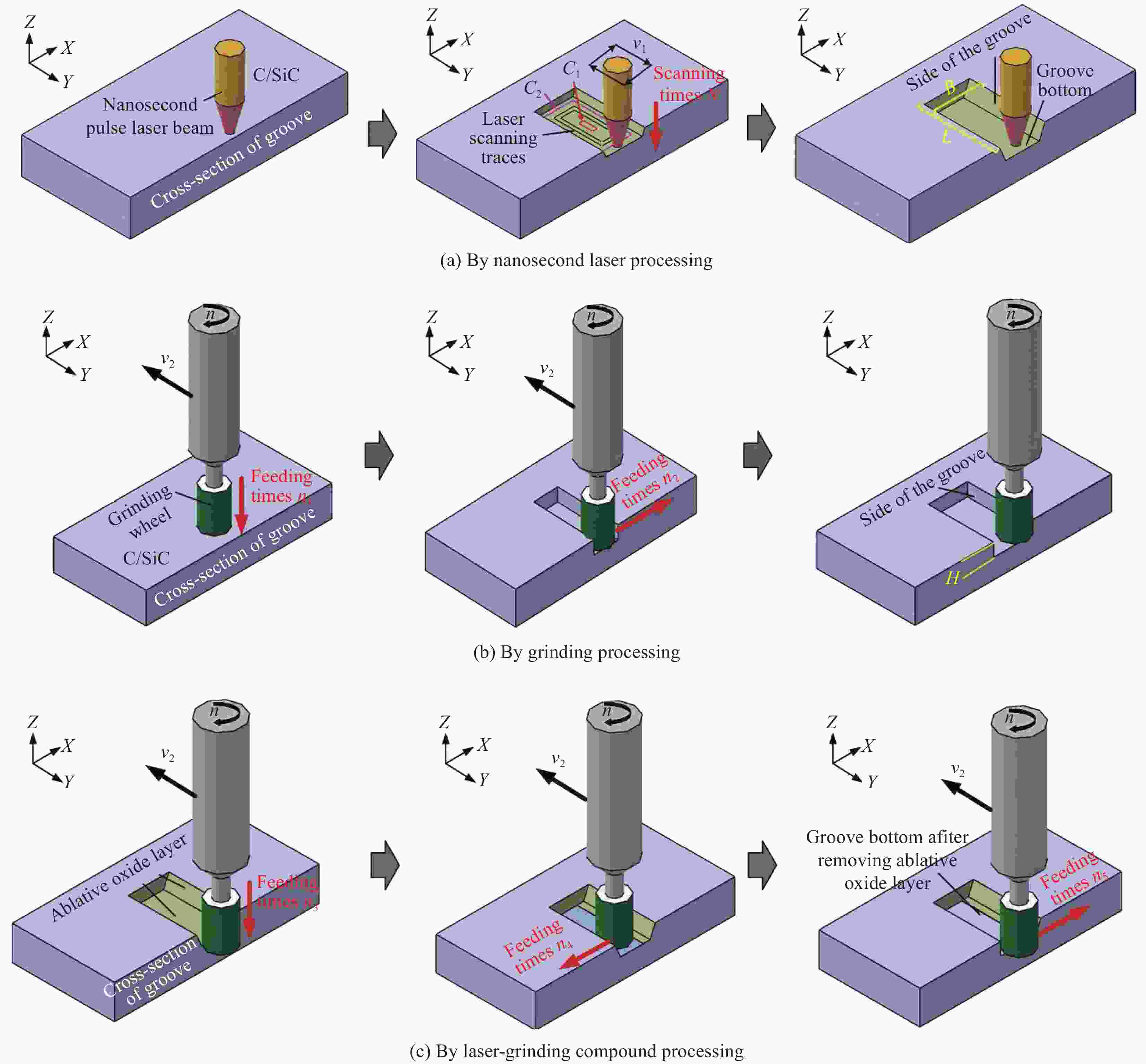

图 2 C/SiC复合材料的加工过程图

Figure 2. Processing diagram of C/SiC composite

C1, C2—Maximum rectangular trajectory perimeter during laser scanning, minimum rectangular trajectory perimeter during laser scanning; v1, v2—Nanosecond laser scanning speed, grinding wheel feed speed; B—Width of the groove; L—Length of the groove; n—Grinding wheel speed; H—Depth of the groove; L—Length of the groove

表 1 碳纤维增强碳化硅陶瓷基(C/SiC)复合材料的参数

Table 1. Mechanical properties of carbon fiber reinforced SiC ceramic matrix (C/SiC) composites

Parameter Value Density/(g·cm−3) 1.85-1.95 Porosity/% <10 Tensile strength/MPa 75-100 Bending strength/MPa 240-300 Compressive strength/MPa 420-500 Shear strength/MPa 15-25 Rockwell hardness/HRC 85-90 Thermal diffusivity/(cm2·s−1) 0.03-0.06 Thermal conductivity/(W·(m·K)−1) 8-10 表 2 纳秒激光加工的特征参数

Table 2. Properties of nanosecond laser processing

Parameter Pulse-width/ns Repetition rate/kHz Power/W Focal displacement/μm Scanning speed v1/(mm·s−1) Value 20 200 90 100 300 表 3 C/SiC复合材料不同加工方式下所用的加工时间及加工后的表面粗糙度

Table 3. Processing time used in different processing methods and the surface roughness after processing C/SiC composite

Processing methods Nanosecond laser Grinding Laser-grinding compound

processingProcessing time/s 80 8000 2420 Roughness of bottom surface Ra/μm – 3.43 1.16 Sidewall surface roughness/μm – 3.48 1.53 -

[1] YANG Y, XU F, GAO X Y, et al. Impact resistance of 2D plain-woven C/SiC composites at high temperature[J]. Materials & Design,2016,90:635-641. [2] KUMAR S, CHANDRA R, KUMAR A, et al. C/SiC compo-sites for propulsion application[J]. Composites and Nanostructures,2015,7(4):225-230. [3] 苏纯兰, 周长灵, 徐鸿照, 等. 碳纤维增韧陶瓷基复合材料的研究进展[J]. 佛山陶瓷, 2020, 30(2):10-21.SU Chunlan, ZHOU Changling, XU Hongzhao, et al. Progress in carbon fiber reinforced ceramic matrix compo-sites[J]. Foshan Ceramics,2020,30(2):10-21(in Chinese). [4] 张立峰. 陶瓷基复合材料界面强度与磨削过程材料去除机理研究[D]. 天津: 天津大学, 2015.ZHANG Lifeng. Research on the interfacial strength and grinding mechanism of material removal for ceramic matrix composites[D]. Tianjin: Tianjin University, 2015(in Chinese). [5] 王平, 张权明, 李良. Cf/SiC陶瓷基复合材料车削加工工艺研究[J]. 火箭推进, 2011, 37(2):67-70.WANG Ping, ZHANG Quanming, LI Liang. Research on turning technology of Cf/SiC ceramic matrix composites[J]. Journal of Rocket Propulsion,2011,37(2):67-70(in Chinese). [6] DIAZ O G, LUNA G G, LIAO Z R, et al. The new challenges of machining ceramic matrix composites (CMCs): Review of surface integrity[J]. International Journal of Machine Tools and Manufacture,2019,139:24-36. doi: 10.1016/j.ijmachtools.2019.01.003 [7] XING Y Q, DENG J X, ZHANG G D, et al. Assessment in drilling of C/C-SiC composites using brazed diamond drills[J]. Journal of Manufacturing Processes,2017,26:31-43. doi: 10.1016/j.jmapro.2017.01.006 [8] DU J G, MING W Y, MA J, et al. New observations of the fiber orientations effect on machinability in grinding of C/SiC ceramic matrix composite[J]. Ceramics International,2018,44(12):13916-13928. doi: 10.1016/j.ceramint.2018.04.240 [9] YUAN S M, LI Z, ZHANG C, et al. Research into the transition of material removal mechanism for C/SiC in rotary ultrasonic face machining[J]. The International Journal of Advanced Manufacturing Technology,2018,95(5):1751-1761. [10] WEI C J, ZHAO L, HU D J, et al. Electrical discharge machining of ceramic matrix composites with ceramic fiber reinforcements[J]. The International Journal of Advanced Manufacturing Technology,2013,64(1):187-194. [11] HASHISH M, KOTCHON A, RAMULU M. Status of AWJ machining of CMCS and hard materials[C]//Proceedings of Intertech 2015. Indianapolis, 2015. [12] TUERSLEY I P, HOULT T P, PASHBY I R. The processing of SiC/SiC ceramic matrix composites using a pulsed Nd-YAG laser: Part II the effect of process variables[J]. Journal of Materials Science,1998,33(4):963-967. doi: 10.1023/A:1004307710899 [13] 毕铭智. C/SiC复合材料钻、铣加工技术的试验研究[D]. 大连: 大连理工大学, 2013.BI Mingzhi. Experimental research on drilling and milling of C/SiC composites[D]. Dalian: Dalian University of Technology, 2013(in Chinese). [14] 刘琼, 黄国钦. 2D C/C-SiC复合材料钻削加工试验研究[J]. 福建工程学院学报, 2019, 17(1):7-16.LIU Qiong, HUANG Guoqin. Experimental study on drilling processing of 2D C/C-SiC composites[J]. Journal of Fujian University of Technology,2019,17(1):7-16(in Chinese). [15] ZHANG L F, REN C Z, JI C H, et al. Effect of fiber orientations on surface grinding process of unidirectional C/SiC composites[J]. Applied Surface Science,2016,366:424-431. doi: 10.1016/j.apsusc.2016.01.142 [16] DING K, FU Y C, SU H S, et al. Study on surface/subsurface breakage in ultrasonic assisted grinding of C/SiC compo-sites[J]. The International Journal of Advanced Manufacturing Technology,2017,91(9):3095-3105. [17] FENG P F, WANG J J, ZHANG J F, et al. Drilling induced tearing defects in rotary ultrasonic machining of C/SiC composites[J]. Ceramics International,2017,43(1):791-799. doi: 10.1016/j.ceramint.2016.10.010 [18] RAMULU M, JENKINS M G, GUO Z. Abrasive water jet machining mechanisms in continuous fiber ceramic compo-sites[J]. Journal of Composites, Technology and Research,2001,23(2):82-91. doi: 10.1520/CTR10916J [19] HU W Q, SHIN Y C, KING G B. Micromachining of metals, alloys, and ceramics by picosecond laser ablation[J]. Journal of Manufacturing Science and Engineering,2010,132(1):165-174. [20] ZHAI Z Y, WANG W J, ZHAO J, et al. Influence of surface morphology on processing of C/SiC composites via femtosecond laser[J]. Composites Part A: Applied Science and Manufacturing,2017,102:117-125. doi: 10.1016/j.compositesa.2017.07.031 [21] 焦浩文, 陈冰, 罗良, 等. 纳秒激光加工2.5维Cf/SiC复合材料的烧蚀孔洞特征[J]. 中国机械工程, 2020, 31(8):983-990. doi: 10.3969/j.issn.1004-132X.2020.08.014JIAO Haowen, CHEN Bing, LUO Liang, et al. Ablation hole characteristic of 2.5-dimensional Cf/SiC composites processed by nanosecond laser[J]. China Mechanical Engi-neering,2020,31(8):983-990(in Chinese). doi: 10.3969/j.issn.1004-132X.2020.08.014 [22] JIAO H W, CHEN B, DENG Z H. Influence of laser parameters on processing micro-grooves of 2.5 dimensional C/SiC composites via nanosecond laser[J]. The International Journal of Advanced Manufacturing Technology,2021,118:85-101. [23] 焦浩文. 2.5维C/SiC复合材料的纳秒激光加工机理研究[D]. 湘潭: 湖南科技大学, 2021.JIAO Haowen. Research on nanosecond laser processing mechanism of 2.5 dimensional C/SiC composites[D]. Xiangtan: Hunan University of Science Technology, 2021(in Chinese). [24] ZHAI Z, WEI C, ZHANG Y, et al. Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser[J]. Applied Surface Science,2020,502:144131. doi: 10.1016/j.apsusc.2019.144131 [25] 徐洲. 圆弧形树脂金刚石砂轮激光修整实验研究[D]. 湘潭: 湖南科技大学, 2020.XU Zhou. Experimental research on laser dressing of arc-shaped resin-bonded diamond grinding wheels[D]. Xiangtan: Hunan University of Science Technology, 2020(in Chinese). [26] YILBAS B, BHUSHAN B. Laser treatment of sintered silicon carbide surface for enhanced hydrophobicity[J]. The Journal of the Minerals, Metals & Materials Society,2014,66(1):87-94. -

下载:

下载: