Process optimization of high-performance soft magnetic composite based on phosphate and bismaleimide coated iron powders

-

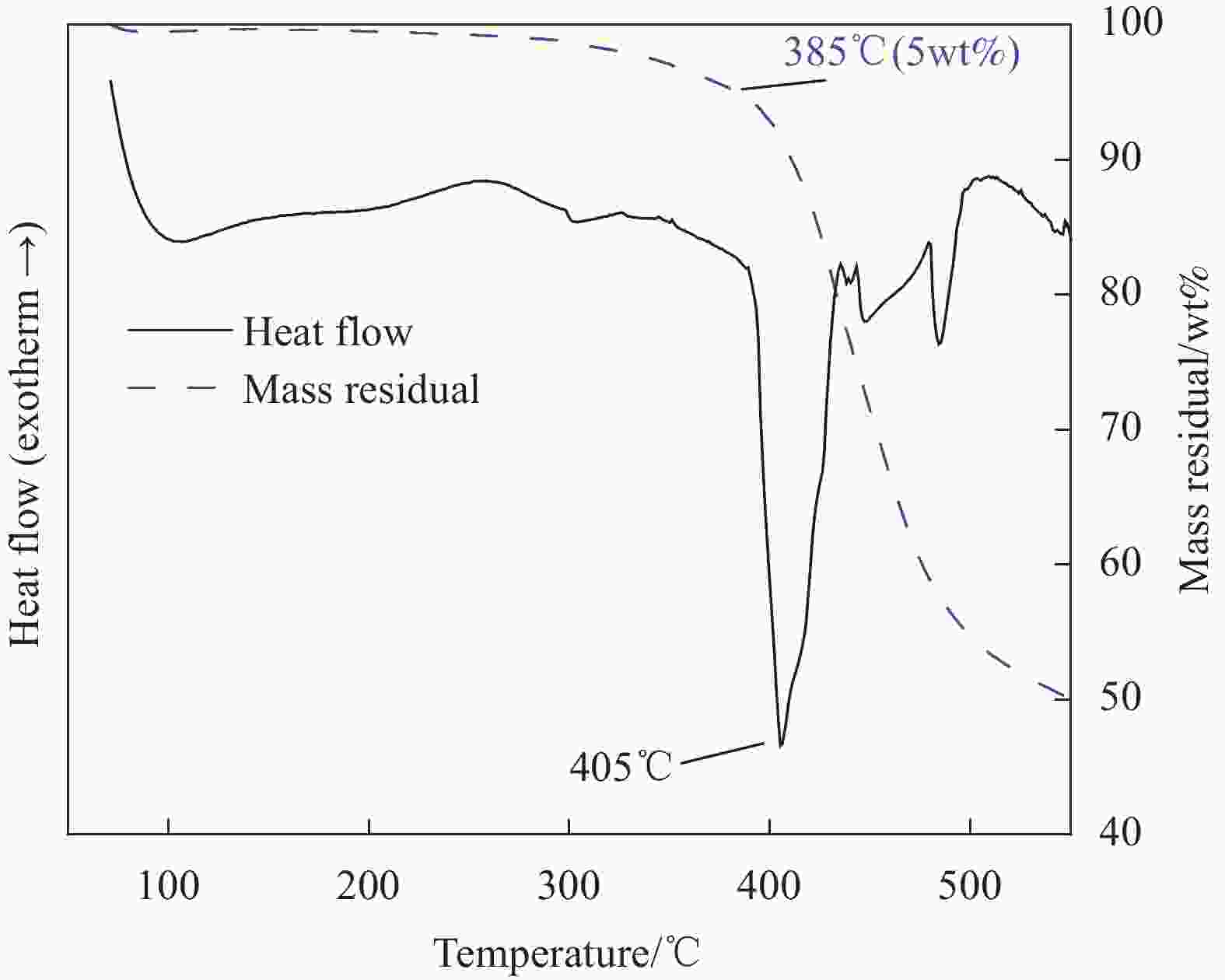

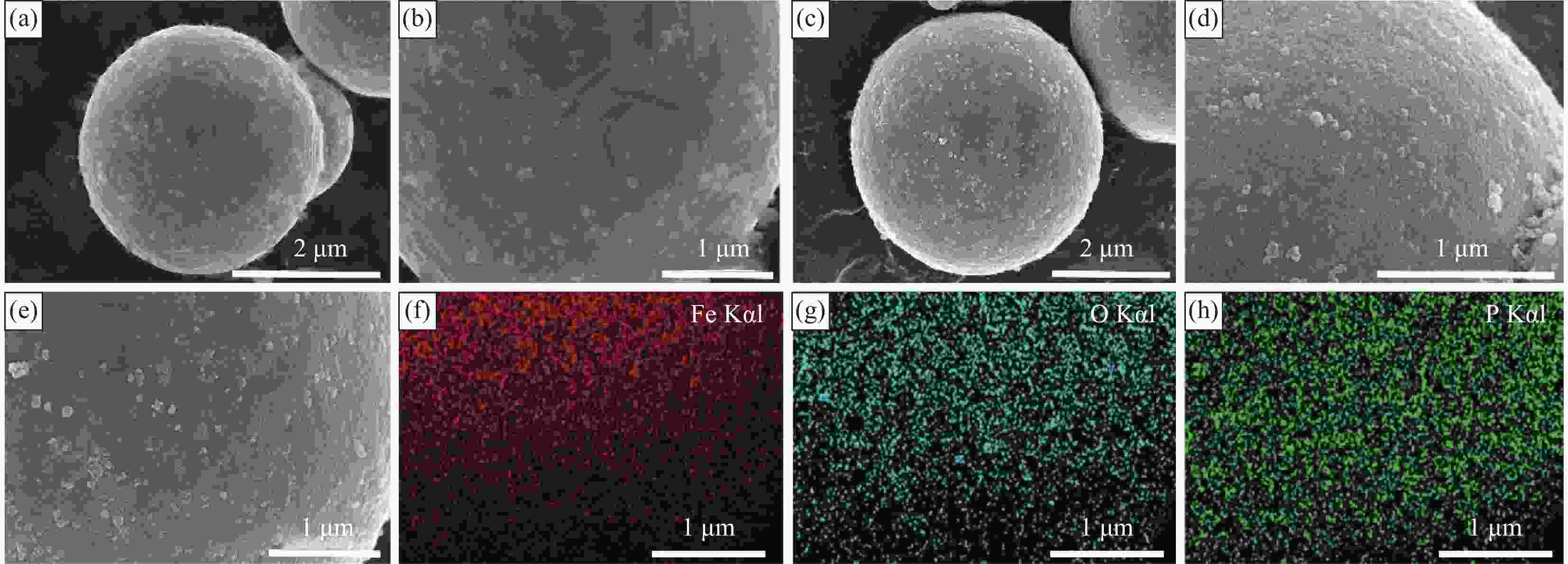

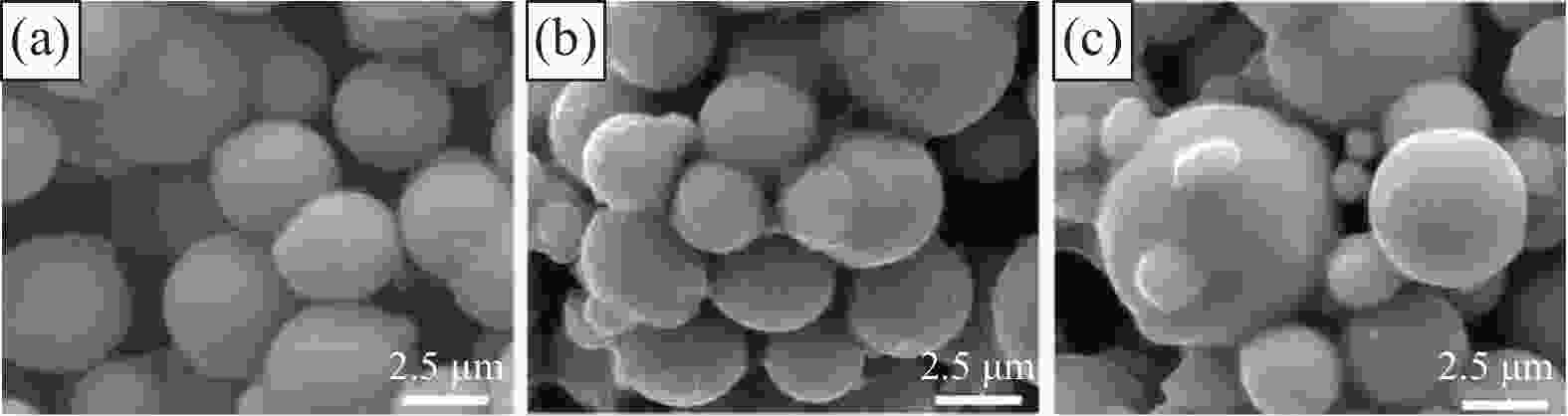

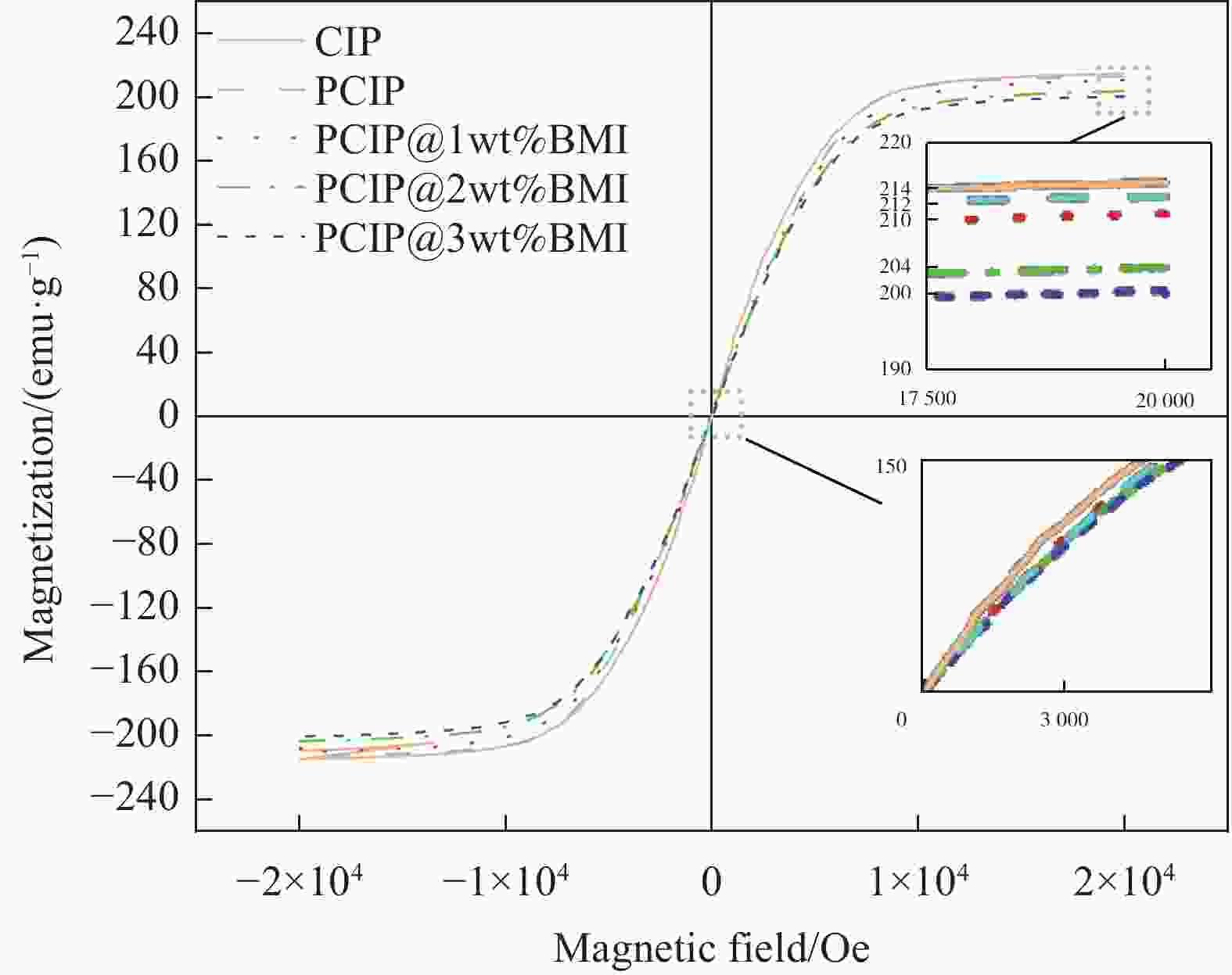

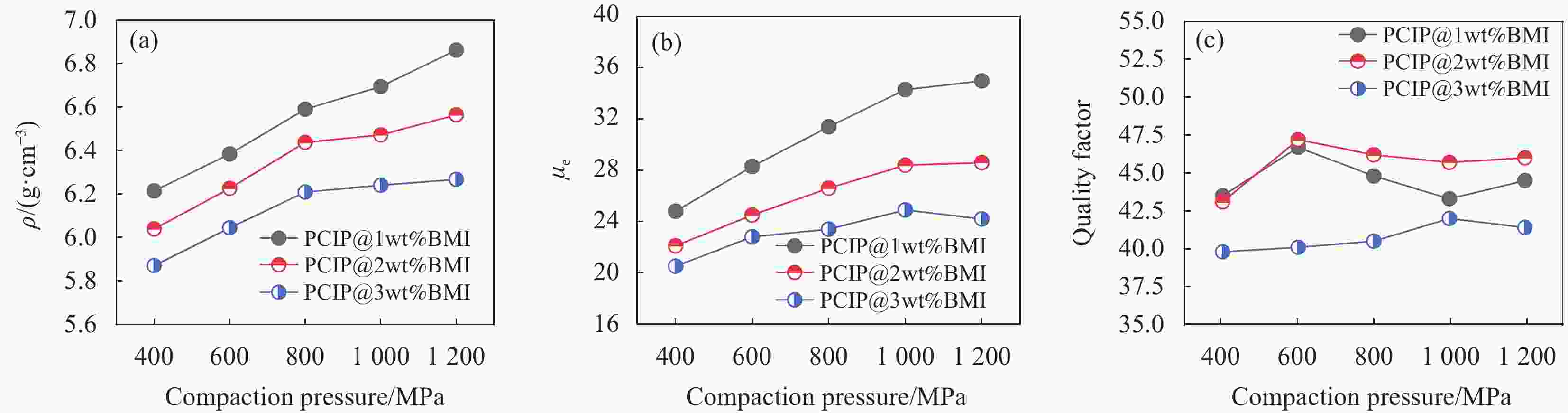

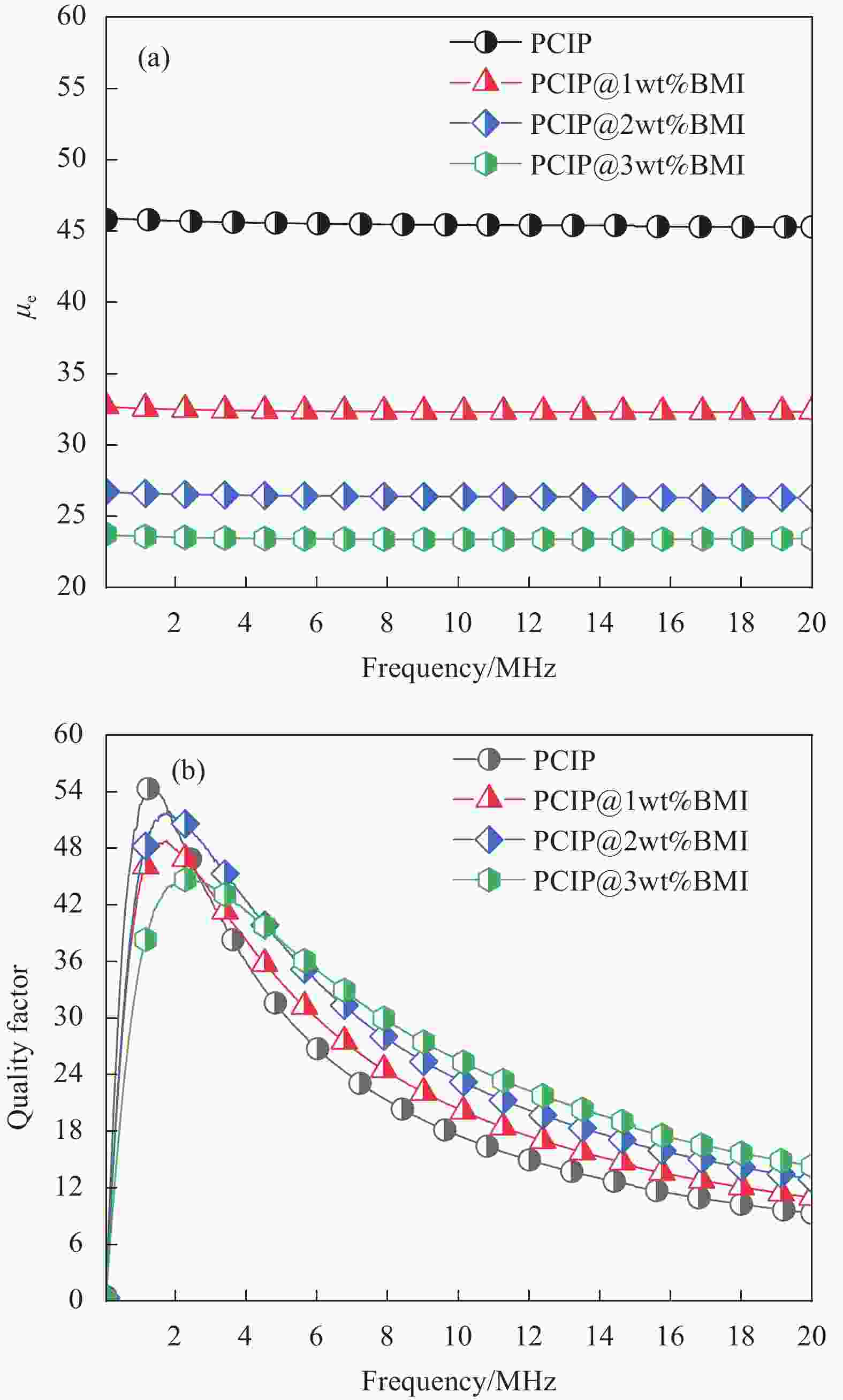

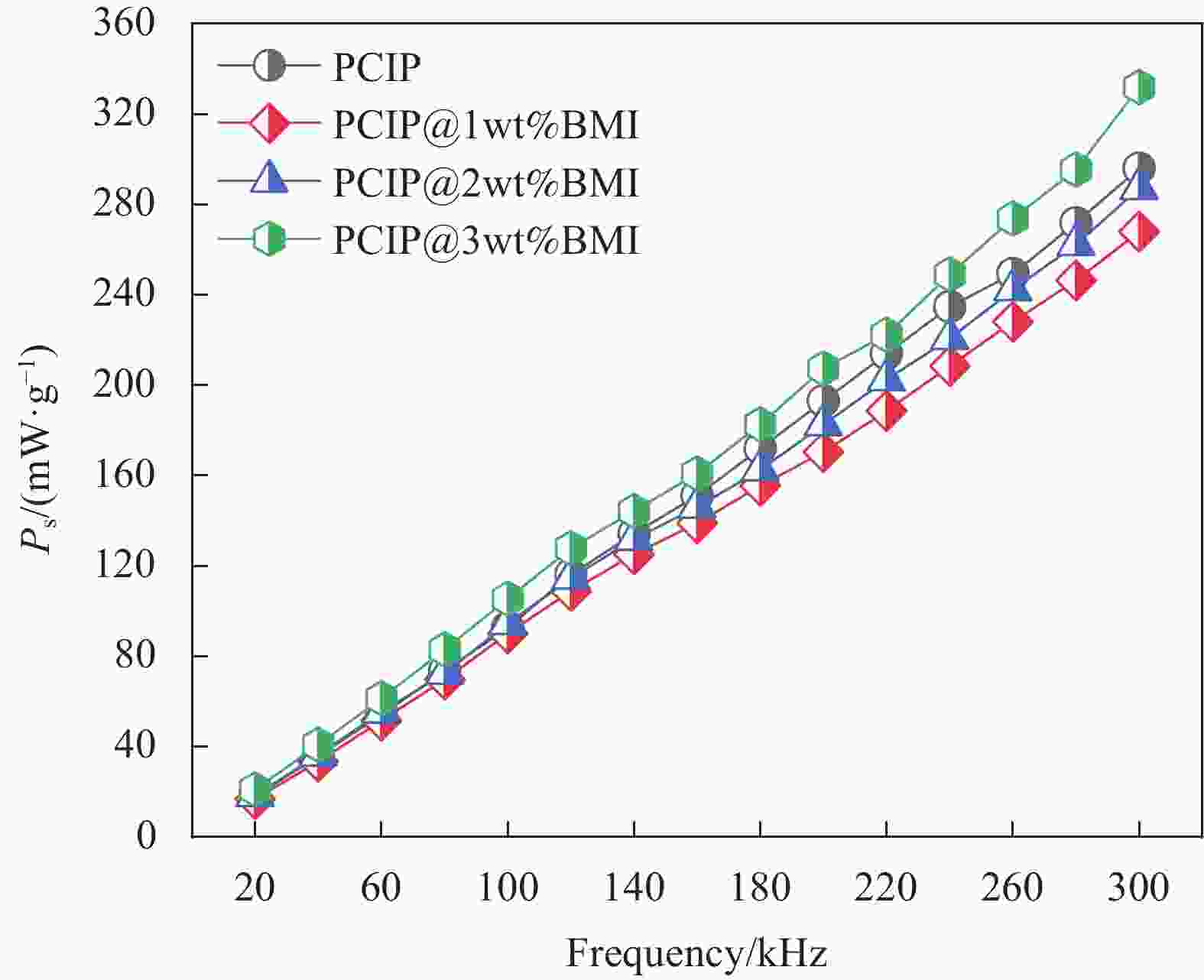

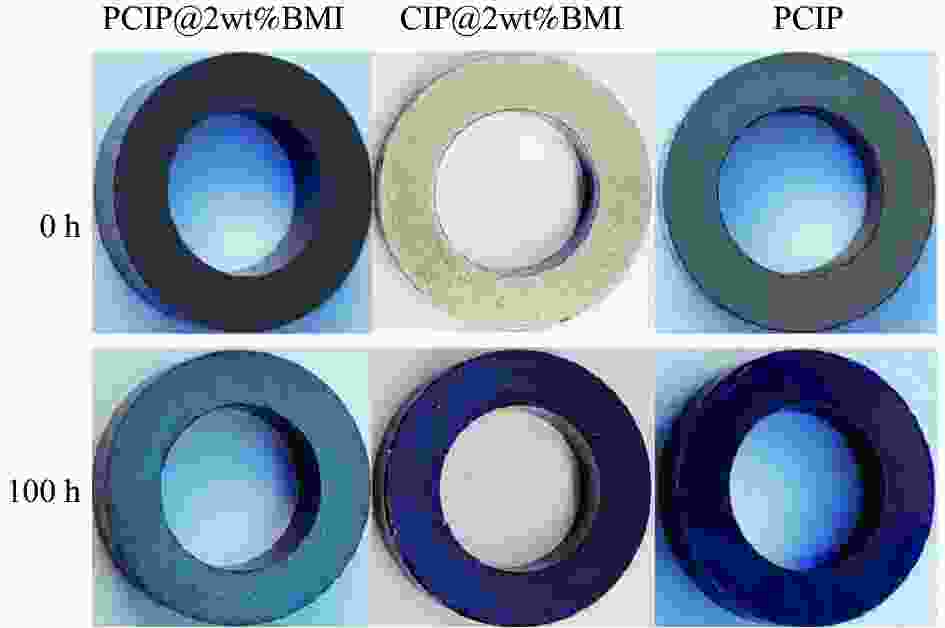

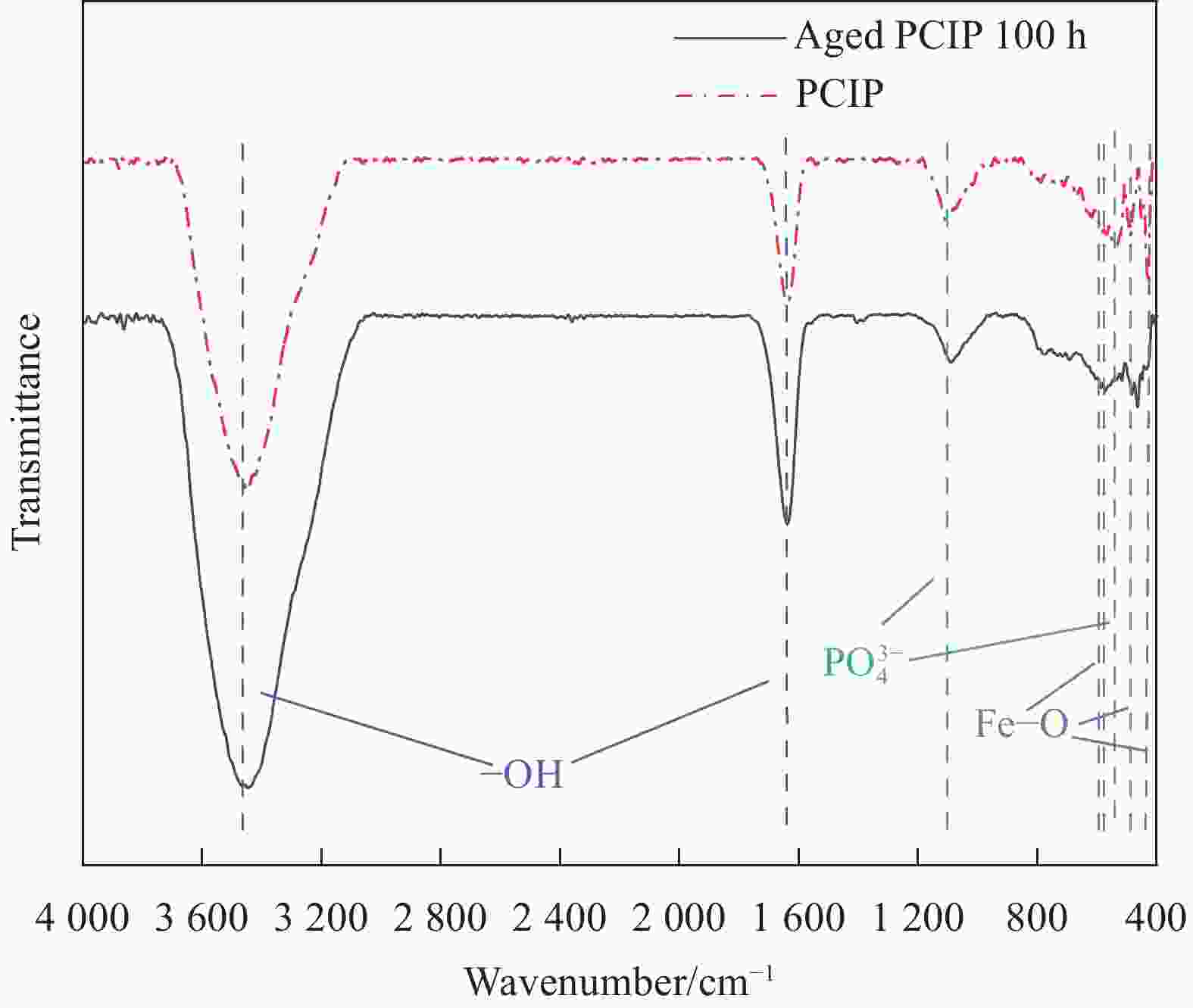

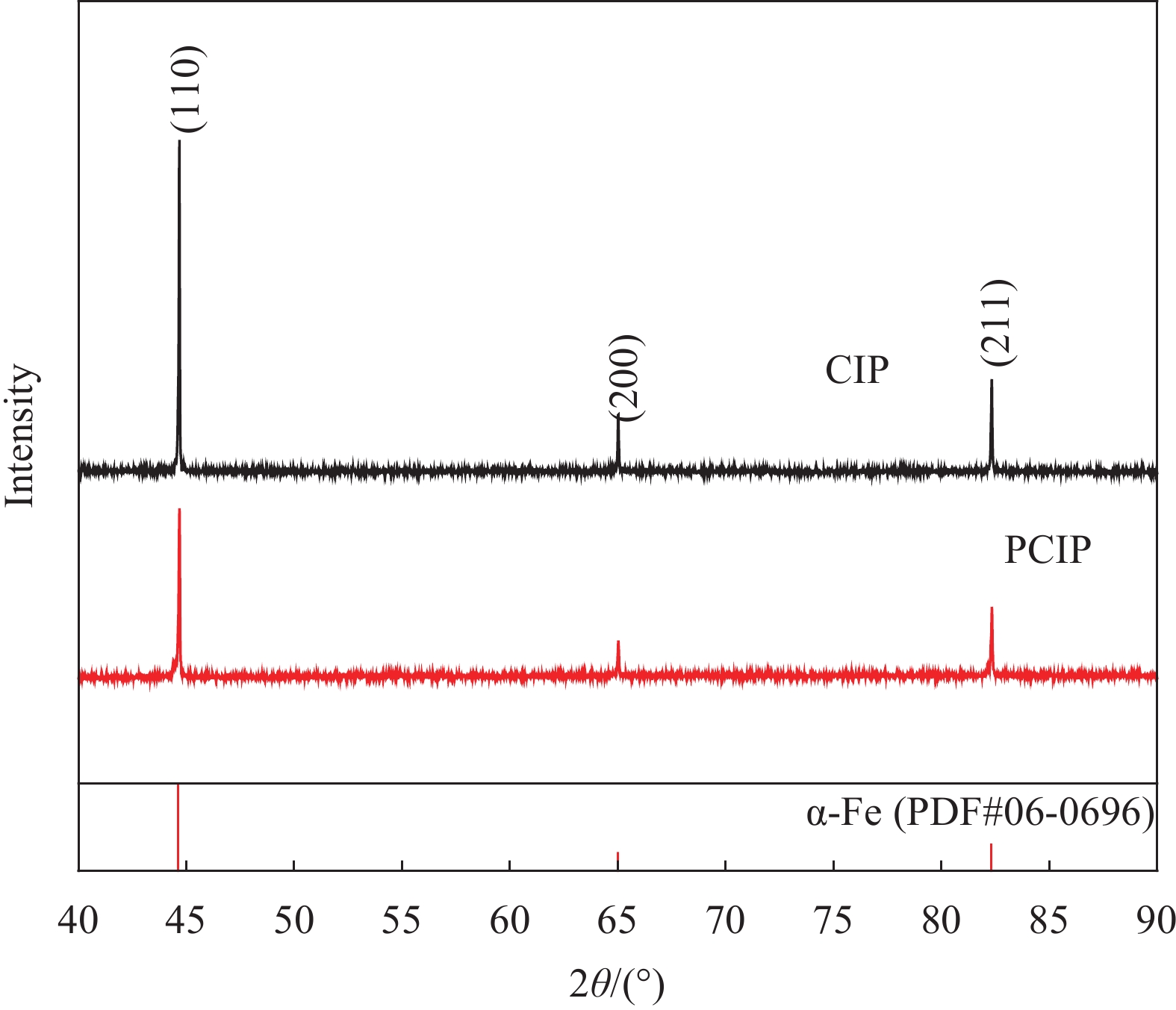

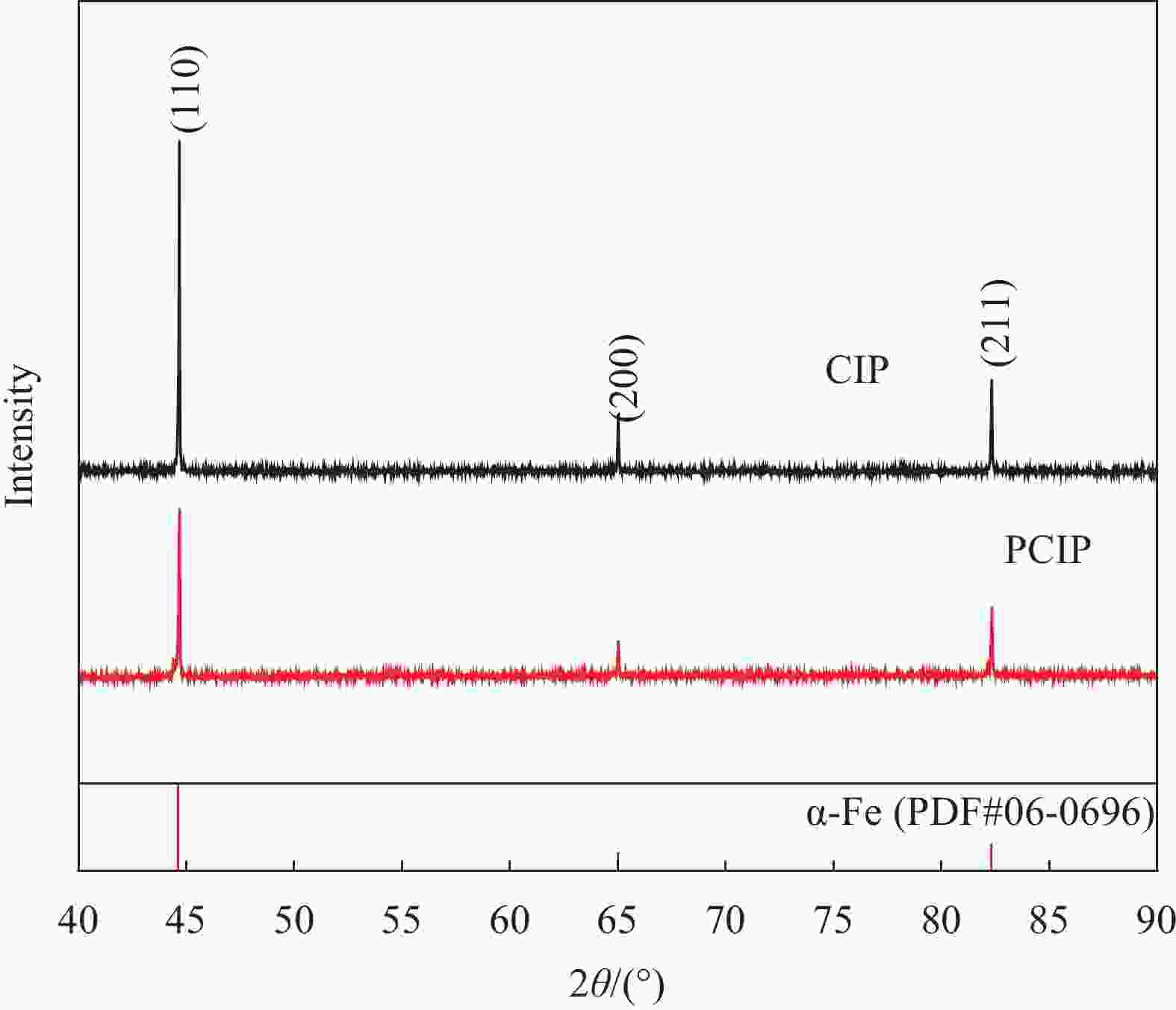

摘要: 随着电子行业的迅速发展,电子器件正朝着小型化、集成化和高频化方向发展。磁粉芯材料会因应用频率提高引起磁损耗剧烈增加和严重发热而出现磁性能下降,磁粉芯材料的高频应用对其损耗特性和可靠性提出更高的要求。本文通过磷化处理和双马来酰亚胺树脂(BMI)包覆制备出了具有磷化-双马来酰亚胺@Fe结构的高性能磁粉芯,并研究了包覆方式对磁粉芯可靠性的影响。当BMI树脂添加量为2wt%,压制压力为800 MPa时,磁粉芯的综合磁性能最佳,有效磁导率为32.2,50 mT@200 kHz条件下的总损耗为1181 kW/m3,1 MHz条件下的品质因数Q可达到46.2。BMI树脂包覆形成的绝缘层可以起到应力缓冲的作用,减少压制过程中的内应力形成,降低磁粉芯的总损耗。傅里叶红外光谱分析证明磁粉芯的老化是由磁粉的氧化引起的,通过磷化处理和BMI树脂包覆能有效减缓磁粉氧化并提高磁粉芯的高温可靠性,经过180℃长期加速老化试验后,磁性能保持稳定。Abstract: Electronic devices are developing towards miniaturization, integration, and high frequency with the development of electronic industry. The soft magnetic cores require better loss characteristics and higher reliability becaues their magnetic properties would decline due to the sharply increased magnetic loss and serious heating with the high-frequency application. In this work, high-performance soft magnetic composites with phosphate-bismaleimide@Fe structure were prepared by phosphating treatment and bismaleimide (BMI) coating, and the effects of insulation coating methods on the reliability of soft magnetic composites were investigated. The results indicate that the excellent comprehensive magnetic properties of soft magnetic composites have been obtained as the content of BMI resin is 2wt% and the compaction pressure is 800 MPa, the effective permeability is 32.2, the total loss is 1181 kW/m3 under the condition of 50 mT@200 kHz and the quality factor Q can reach 46.2 at 1 MHz. Moreover, it is found that the resin layer between iron powder particles can play a role of stress buffer to reduce the formation of internal stress and the total loss of soft magnetic composites. The aging of soft magnetic composites due to the oxidation of the magnetic powders which was proved by flourier infrared spectrum analysis. The phosphating treatment and BMI coating can effectively slow down the aging to improve the high-temperature reliability of soft magnetic composites and perform stable magnetic properties after long-term accelerated aging test at 180℃.

-

Key words:

- magnetic material /

- bismaleimide /

- phosphate /

- heat resistance /

- magnetic loss /

- soft magnetic core

-

表 1 磁粉样品的工艺参数

Table 1. Process parameters of magnetic powder samples

Sample number Phosphoric acid solution concentration/wt% BMI

addition/wt%CIP 0 0 PCIP 0.7 0 PCIP@1wt%BMI 0.7 1.0 PCIP@2wt%BMI 0.7 2.0 PCIP@3wt%BMI 0.7 3.0 CIP@2wt%BMI 0 2.0 Notes: BMI—Bismaleimide; CIP—Carbonyl iron powder; PCIP—Phosphatized carbonyl iron powder. 表 2 800 MPa压制压力下磁粉芯的性能数据

Table 2. Properties data of soft magnetic composites prepared under 800 MPa

Sample number ρ/(g·cm−3) μe Q(1 MHz) Ps/(kW·m−3)@50 mT 100 kHz 200 kHz 300 kHz CIP 6.92 69.9 18.2 3358 18410 — CIP@2wt%BMI 6.69 45.5 53.3 569 1171 1829 PCIP 6.80 52.7 62.2 630 1313 2013 PCIP@1wt%BMI 6.72 40.7 44.5 594 1123 1766 PCIP@2wt%BMI 6.43 32.2 46.2 612 1181 1858 PCIP@3wt%BMI 6.20 21.9 41.4 656 1290 2065 表 3 高温加速老化实验前后磁粉芯磁性能

Table 3. Magnetic performance of soft magnetic composites before and after high-temperature accelerated aging test

Sample Parameter Aging

time 0 hAging

time 100 hChange

ratePCIP μe 44.6 43.8 1.7% Q(1 MHz) 62.2 24.2 61.1% CIP@2wt%

BMIμe 37.2 36.3 2.4% Q(1 MHz) 53.3 33.5 37.1% PCIP@2wt%

BMIμe 29.3 28.7 2.0% Q(1 MHz) 46.2 45.6 1.3% -

[1] 吴深, 李杰超, 王晓威, 等. 高频低损耗软磁复合材料的研究进展[J]. 轻功学报, 2020, 35(5):61-70.WU Shen, LI Jiechao, WANG Xiaowei, et al. Development of high-frequency low-loss soft magnetic composites[J]. Journal of Light Industry,2020,35(5):61-70(in Chinese). [2] SHOKROLLAHI H, JANGHORBAN K. Soft magnetic composite materials (SMCs)[J]. Journal of Materials Processing Technology,2007,189(1-3):1-12. doi: 10.1016/j.jmatprotec.2007.02.034 [3] SUNDAY K J, TAHERI M L. Soft magnetic composites: Recent advancements in the technology[J]. Metal Powder Report,2017,72(6):425-429. doi: 10.1016/j.mprp.2016.08.003 [4] PÉRIGO E A, WEIDENFELLER B, KOLLÁR P, et al. Past, present, and future of soft magnetic composites[J]. Applied Physics Reviews,2018,5:031301. doi: 10.1063/1.5027045 [5] SILVEYRA J M, FERRARA E, HUBER D L, et al. Soft magnetic materials for a sustainable and electrified world[J]. Science,2018,362(6413):418. [6] LI K, CHENG D, YU H, et al. Process optimization and magnetic properties of soft magnetic composite cores based on phosphated and mixed resin coated Fe powders[J]. Journal of Magnetism and Magnetic Materials,2020,501:166455. doi: 10.1016/j.jmmm.2020.166455 [7] PAN Y, QIAN L, WANG X, et al. Hybrid phosphate-alumina iron-based core-shell soft magnetic composites fabricated by sol-gel method and ball milling method[J]. Metals,2020,10(2):257. doi: 10.3390/met10020257 [8] HSIANG H, FAN L, HUNG J. Effects of the sodium stearate addition on the corrosion resistance and electromagnetic properties of phosphatized iron-based SMCs[J]. Journal of Magnetism and Magnetic Materials,2019,490:165532. doi: 10.1016/j.jmmm.2019.165532 [9] TAGHVAEI A H, SHOKROLLAHI H, JANGHORBAN K, et al. Eddy current and total power loss separation in the iron-phosphate-polyepoxy soft magnetic composites[J]. Materials and Design,2009,30(10):3989-3995. doi: 10.1016/j.matdes.2009.05.026 [10] HUANG M, WU C, JIANG Y, et al. Evolution of phosphate coatings during high-temperature annealing and its influence on the Fe and FeSiAl soft magnetic composites[J]. Journal of Alloys and Compounds,2015,644:124-130. doi: 10.1016/j.jallcom.2015.04.201 [11] PAN Y, PENG J, QIAN L, et al. Effects of compaction and heat treatment on the soft magnetic properties of iron-based soft magnetic composites[J]. Materials Research Express,2020,7:016115. doi: 10.1088/2053-1591/ab6acc [12] CHEN D, LI K, YU H, et al. Effects of secondary particle size distribution on the magnetic properties of carbonyl iron powder cores[J]. Journal of Magnetism and Magnetic Materials,2020,497:166062. doi: 10.1016/j.jmmm.2019.166062 [13] SUGIMURA K, MIYAJIMA Y, SONEHARA M, et al. Formation of high electrical-resistivity thin surface layer on carbonyl-iron powder (CIP) and thermal stability of nanocrystalline structure and vortex magnetic structure of CIP[J]. AIP Advances,2016,6:055932. doi: 10.1063/1.4944705 [14] WANG J, FAN X A, WU Z, et al. Intergranular insulated Fe/SiO2 soft magnetic composite for decreased core loss[J]. Advanced Powder Technology,2016,27(4):1189-1194. doi: 10.1016/j.apt.2016.04.002 [15] YAGHTIN M, TAGHVAEI A H, HASHEMI B, et al. Structural and magnetic properties of Fe-Al2O3 soft magnetic composites prepared using the sol-gel method[J]. International Journal of Materials Research,2014,105(5):474-479. doi: 10.3139/146.111040 [16] SUNDAY K J, DARLING K A, HANEJKO F G, et al. Al2O3 "self-coated” iron powder composites via mechanical milling[J]. Journal of Alloys and Compounds,2015,653:61-68. doi: 10.1016/j.jallcom.2015.08.260 [17] ZHENG J, ZHENG H, LEI J, et al. Magnetic properties and microstructure of iron-based soft magnetic composites with Al2O3 insulating coating by one-pot synthesis method[J]. Journal of Magnetism and Magnetic Materials,2020,499:166255. doi: 10.1016/j.jmmm.2019.166255 [18] TAGHVAEI A H, SHOKROLLAHI H, GHAFFARI M, et al. Influence of particle size and compaction pressure on the magnetic properties of iron-phenolic soft magnetic composites[J]. Journal of Physics and Chemistry of Solids,2010,71(1):7-11. doi: 10.1016/j.jpcs.2009.08.008 [19] PFUTZNER H, SCHONHUBER P, ERBIL B, et al. Problems of loss separation for crystalline and consolidated amorphous soft magnetic materials[J]. IEEE Transactions on Magnetics,1991,27(3):3426-3432. doi: 10.1109/20.79085 [20] IREDALE R J, WARD C, HAMERTON I. Modern advances in bismaleimide resin technology: A 21st century perspective on the chemistry of addition polyimides[J]. Progress in Polymer Science,2017,69:1-21. doi: 10.1016/j.progpolymsci.2016.12.002 [21] GOUZMAN I, GROSSMAN E, VERKER R, et al. Advances in polyimide-based materials for space applications[J]. Advanced Materials,2019,31(18):1807738. doi: 10.1002/adma.201807738 [22] HSIANG H I, FAN L F, HUNG J J. Phosphoric acid addition effect on the microstructure and magnetic properties of iron-based soft magnetic composites[J]. Journal of Magnetism and Magnetic Materials,2018,447:1-8. doi: 10.1016/j.jmmm.2017.08.096 [23] WANG D, XIONG X, REN R, et al. Characterization and properties of high-temperature resistant structure adhesive based on novel toughened bismaleimide resins[J]. High Performance Polymers,2020,33(5):488-496. [24] HEIM L, FARSHCHI M, MORGENEYER M, et al. Adhesion of carbonyl iron powder particles studied by atomic force microscopy[J]. Journal of Adhesion Science and Technology,2005,19(3-5):199-213. doi: 10.1163/1568561054352658 [25] LUKSHINA V A, DMITRIEVA N V, VOLKOVA E G, et al. Magnetic properties of the Fe63.5Ni10Cu1Nb3Si13.5B9 alloy nanocrystallized in the presence of tensile stresses[J]. Physics of Metals and Metallography,2019,120(4):320-324. doi: 10.1134/S0031918X19040070 [26] 潘贇, 刘天成, 李广敏, 等. 张力退火感生各向异性对纳米晶合金磁性能的影响[J]. 材料研究学报, 2020, 34(10):753-760. doi: 10.11901/1005.3093.2020.137PAN Yun, LIU Tiancheng, LI Guangmin, et al. Effect of tension annealing induced-anisotropy on magnetic properties of nanocrystalline alloy[J]. Chinese Journal of Materials Research,2020,34(10):753-760(in Chinese). doi: 10.11901/1005.3093.2020.137 [27] REE M. High performance polyimides for applications in microelectronics and flat panel displays[J]. Macromolecular Research,2006,14(1):1-33. doi: 10.1007/BF03219064 [28] ZHAO Y, LI J, ZHAO L, et al. Synthesis of amidoxime-functionalized Fe3O4@SiO2 core-shell magnetic microspheres for highly efficient sorption of U(VI)[J]. Chemical Engineering Journal,2014,235:275-283. doi: 10.1016/j.cej.2013.09.034 [29] LIU D, WU C, YAN M, et al. Correlating the microstructure, growth mechanism and magnetic properties of FeSiAl soft magnetic composites fabricated via HNO3 oxidation[J]. Acta Materialia,2018,146:294-303. doi: 10.1016/j.actamat.2018.01.001 [30] HOU Z, YAN P, SUN B, et al. An excellent soft magnetic Fe/Fe3O4-FeSiAl composite with high permeability and low core loss[J]. Results in Physics,2019,14:102498. doi: 10.1016/j.rinp.2019.102498 [31] SCHWERTMANN U, CORNELL R M. Iron oxides in the laboratory preparation and characterization[M]. Weinheim: VCH Verlagsgesellschaft, 1992: 68-127. -

下载:

下载: