Implosion response and anti-explosion performance of fabric bags

-

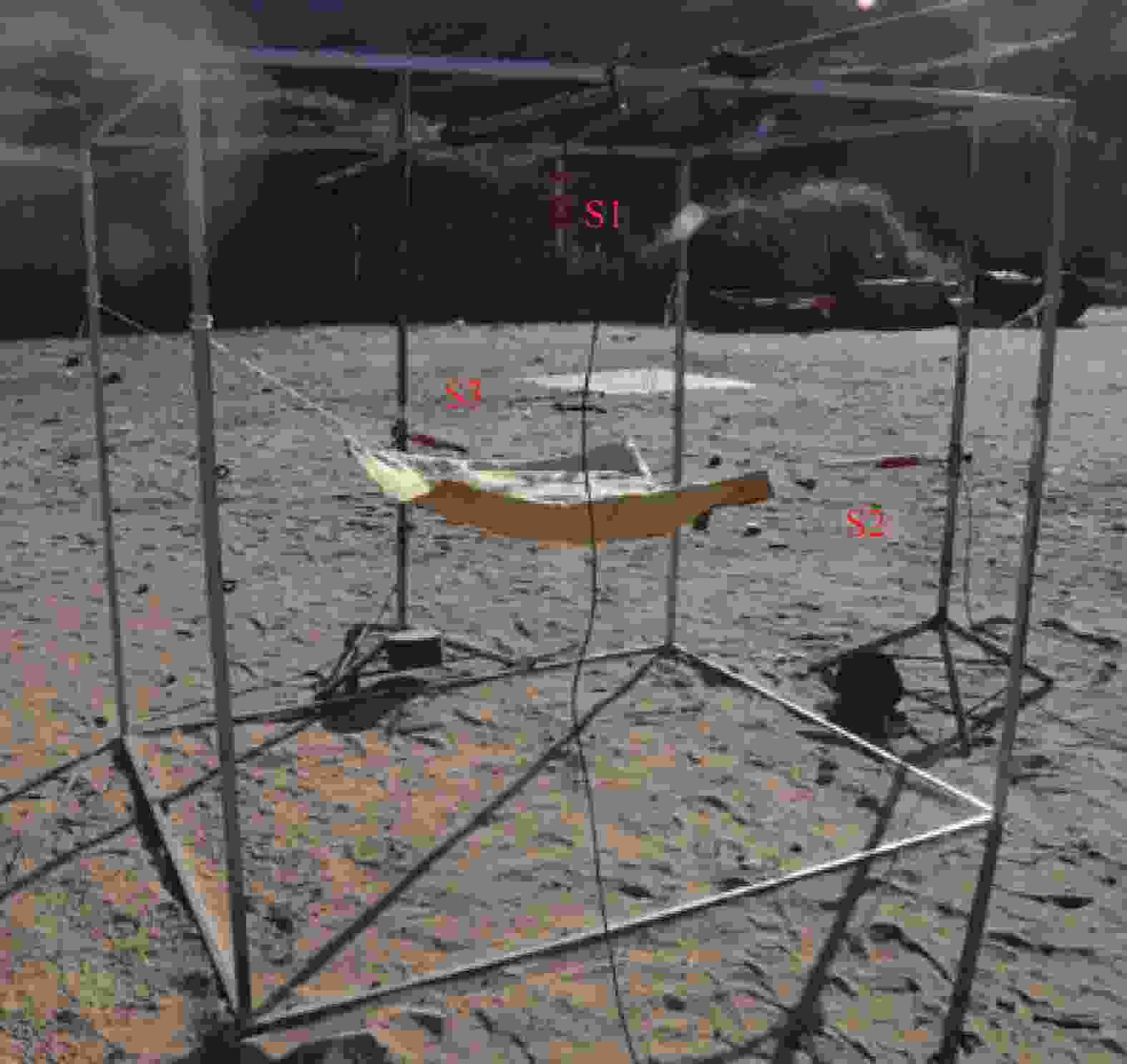

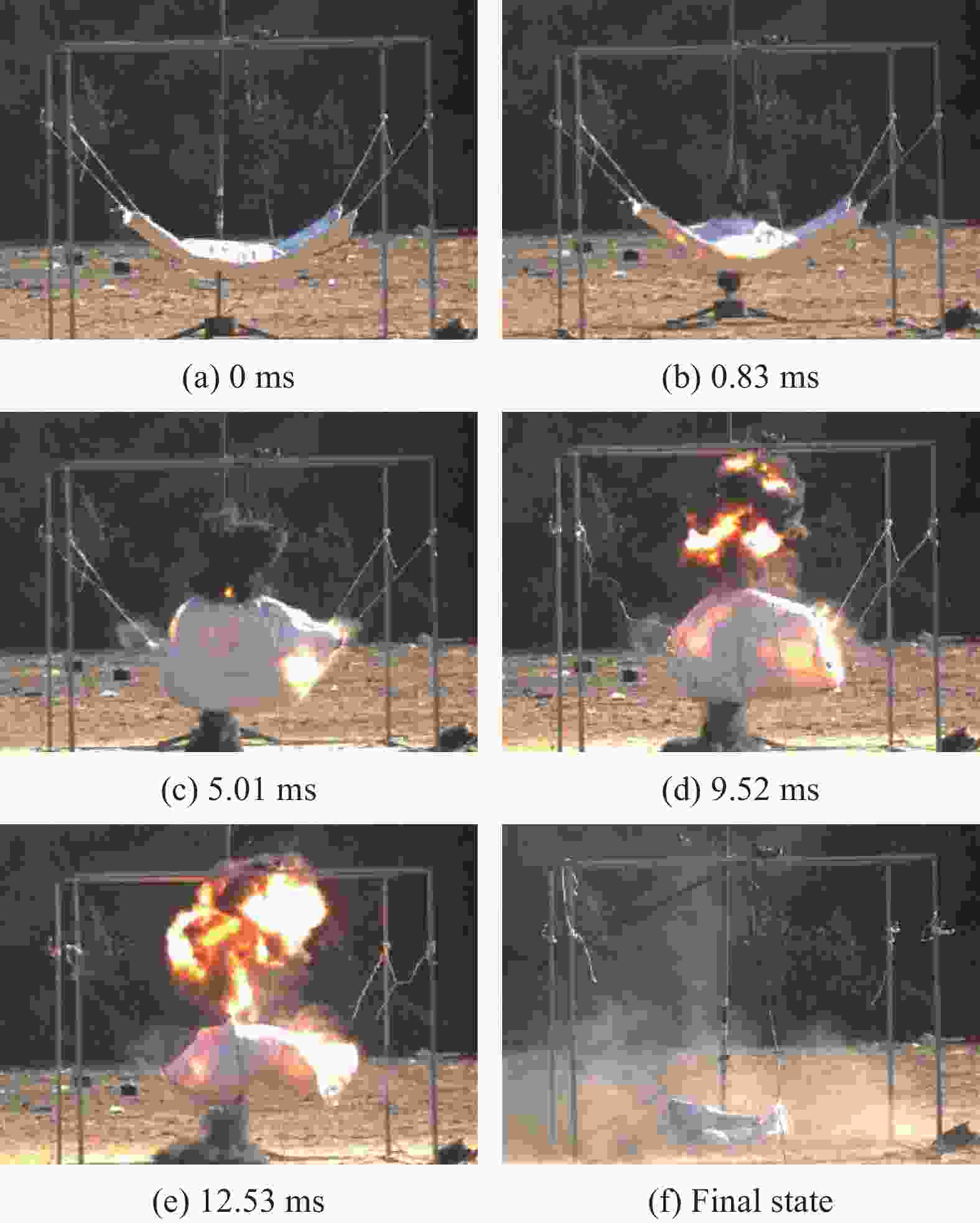

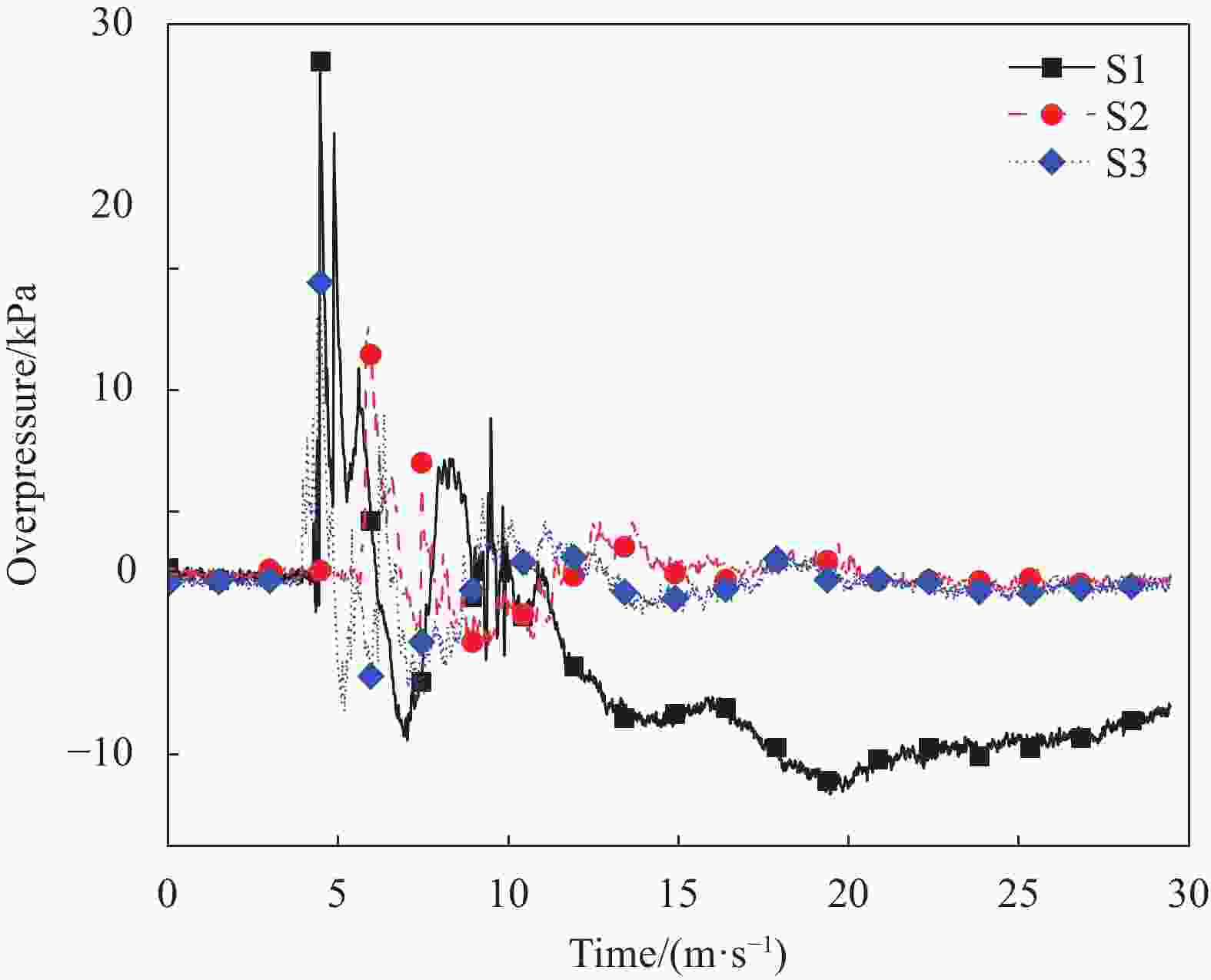

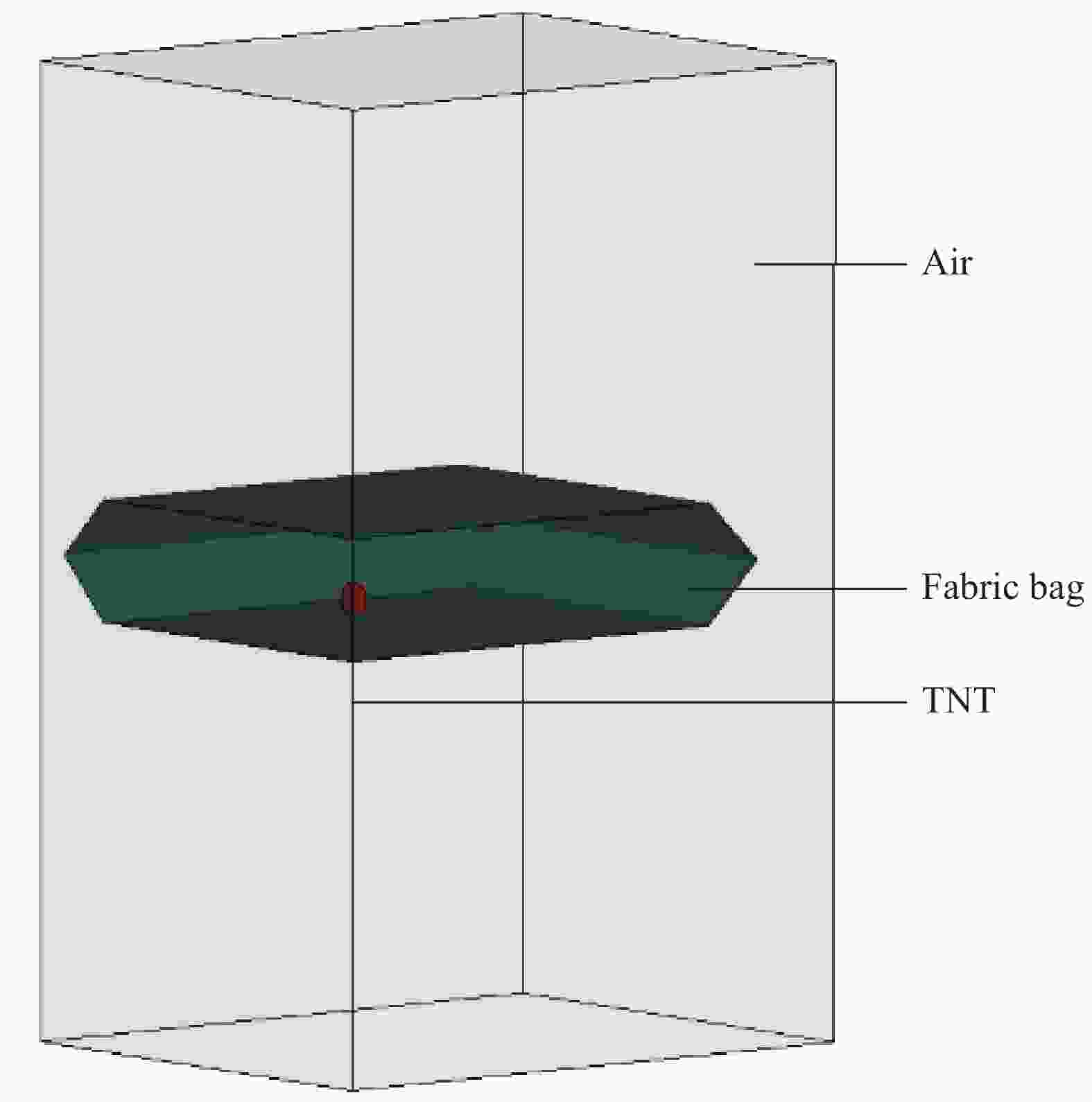

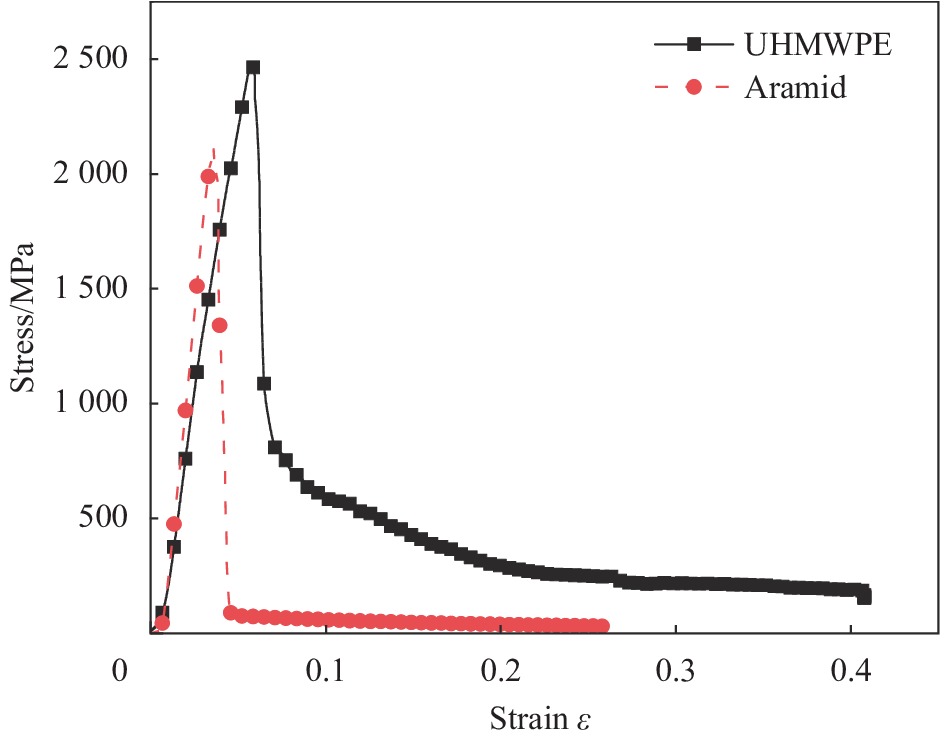

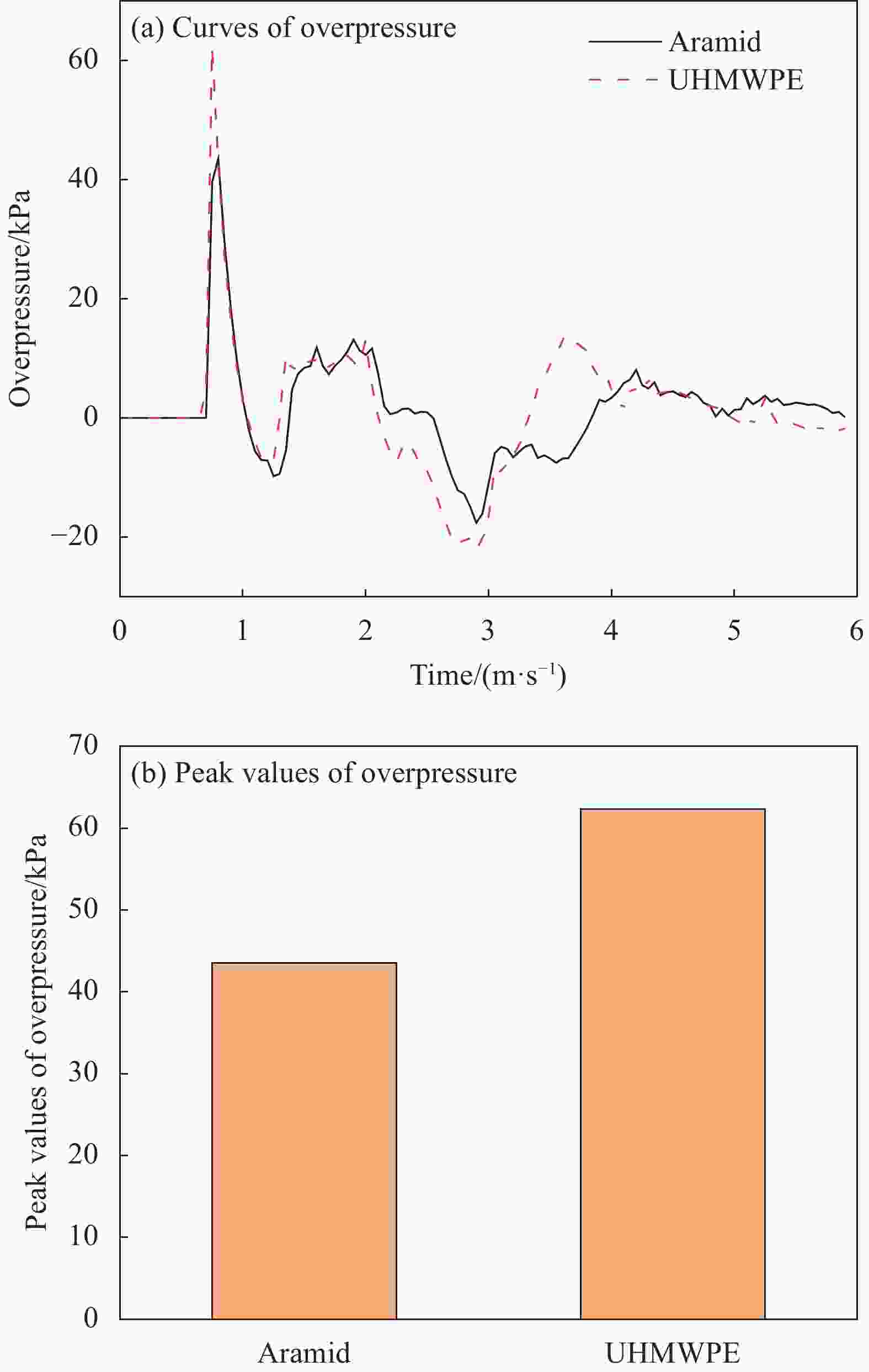

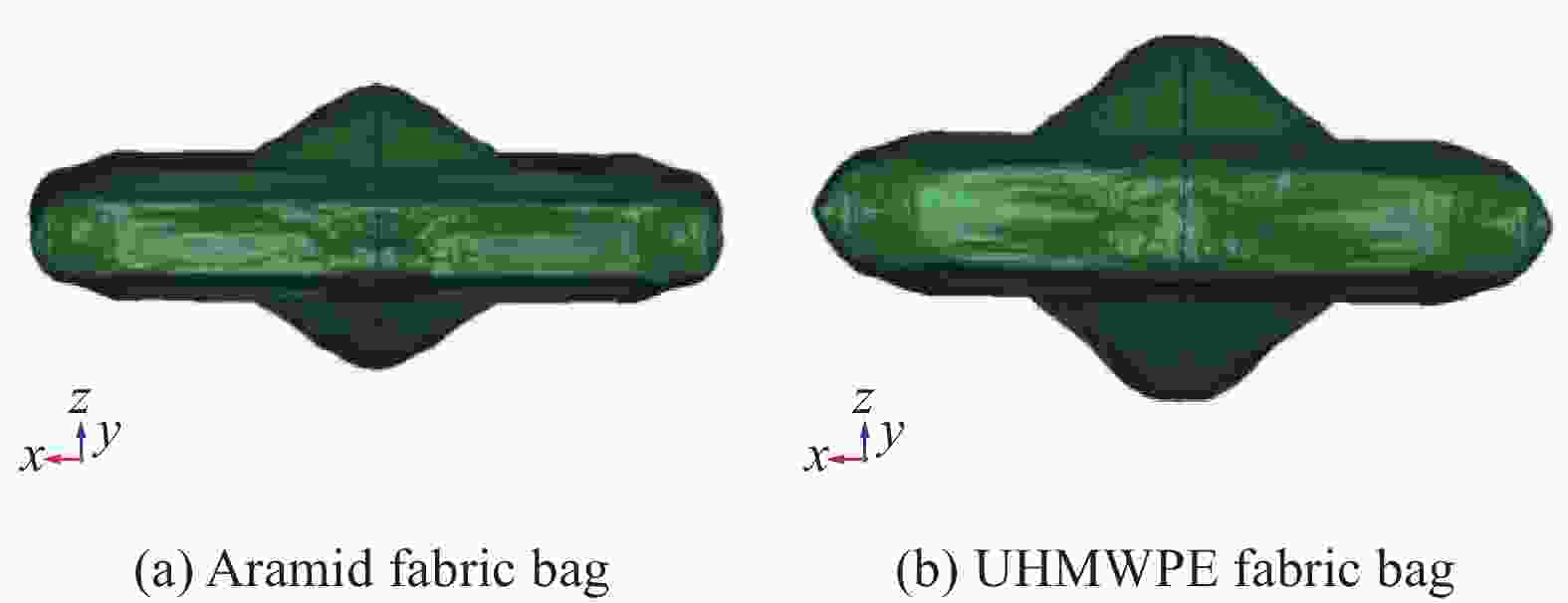

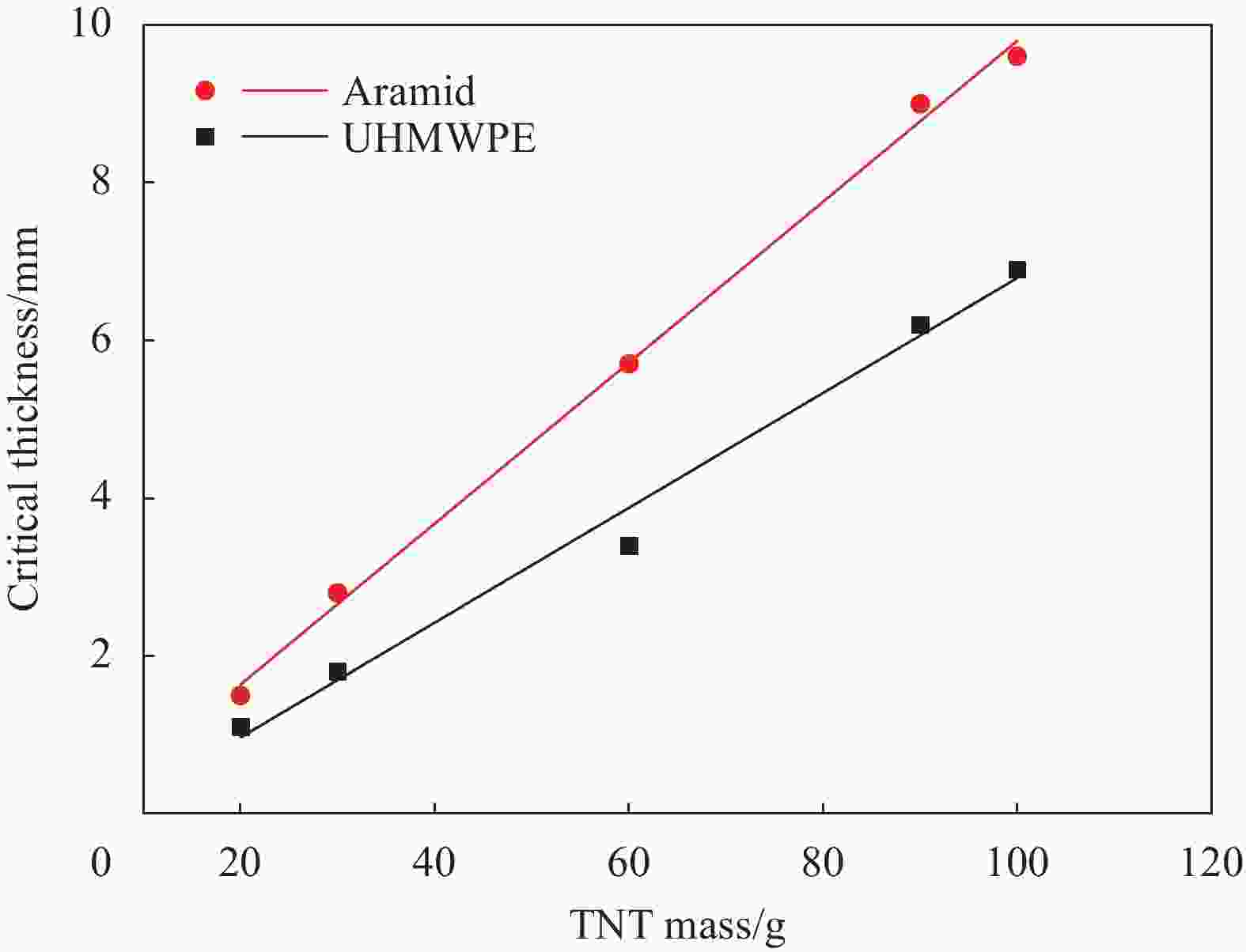

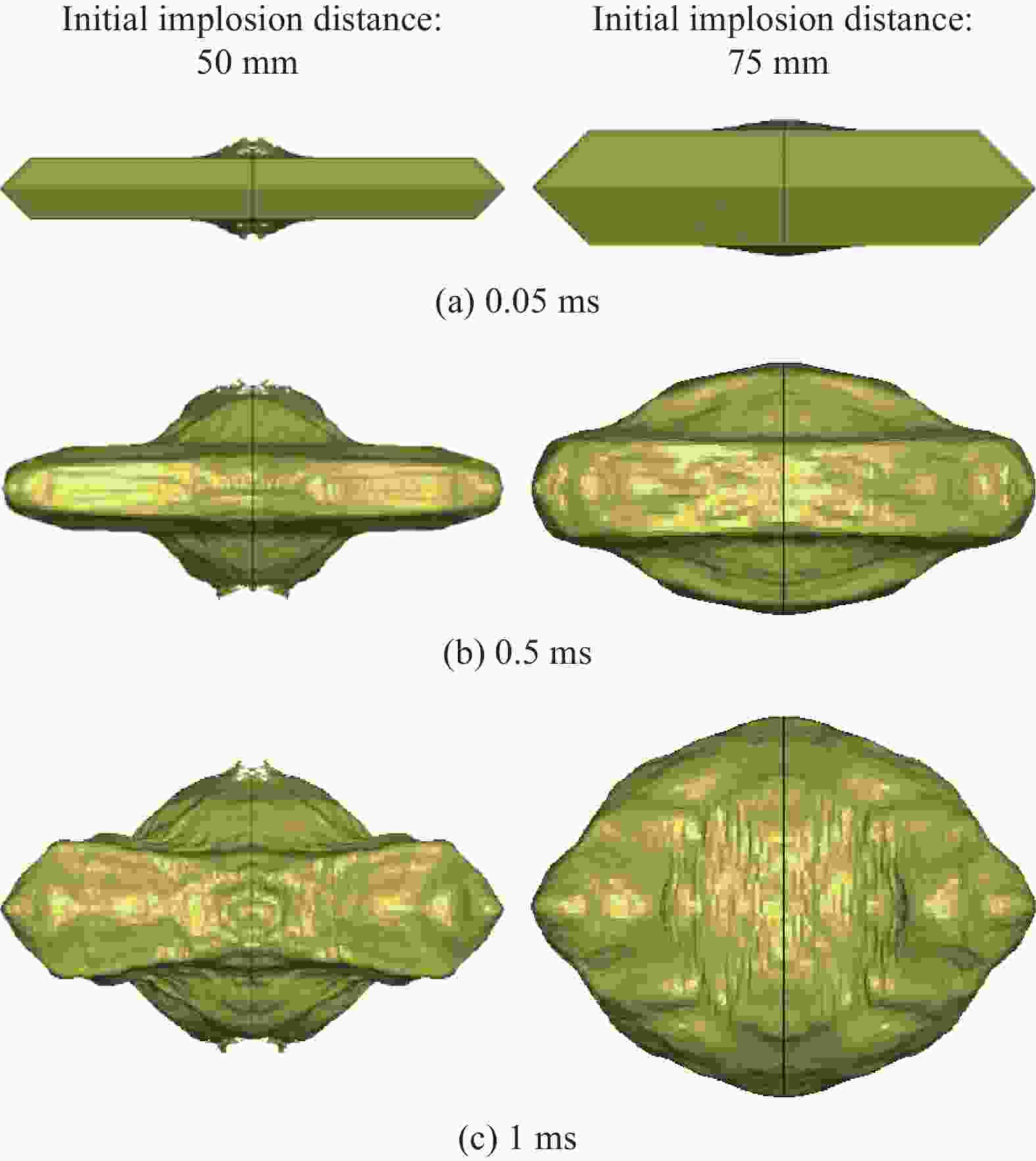

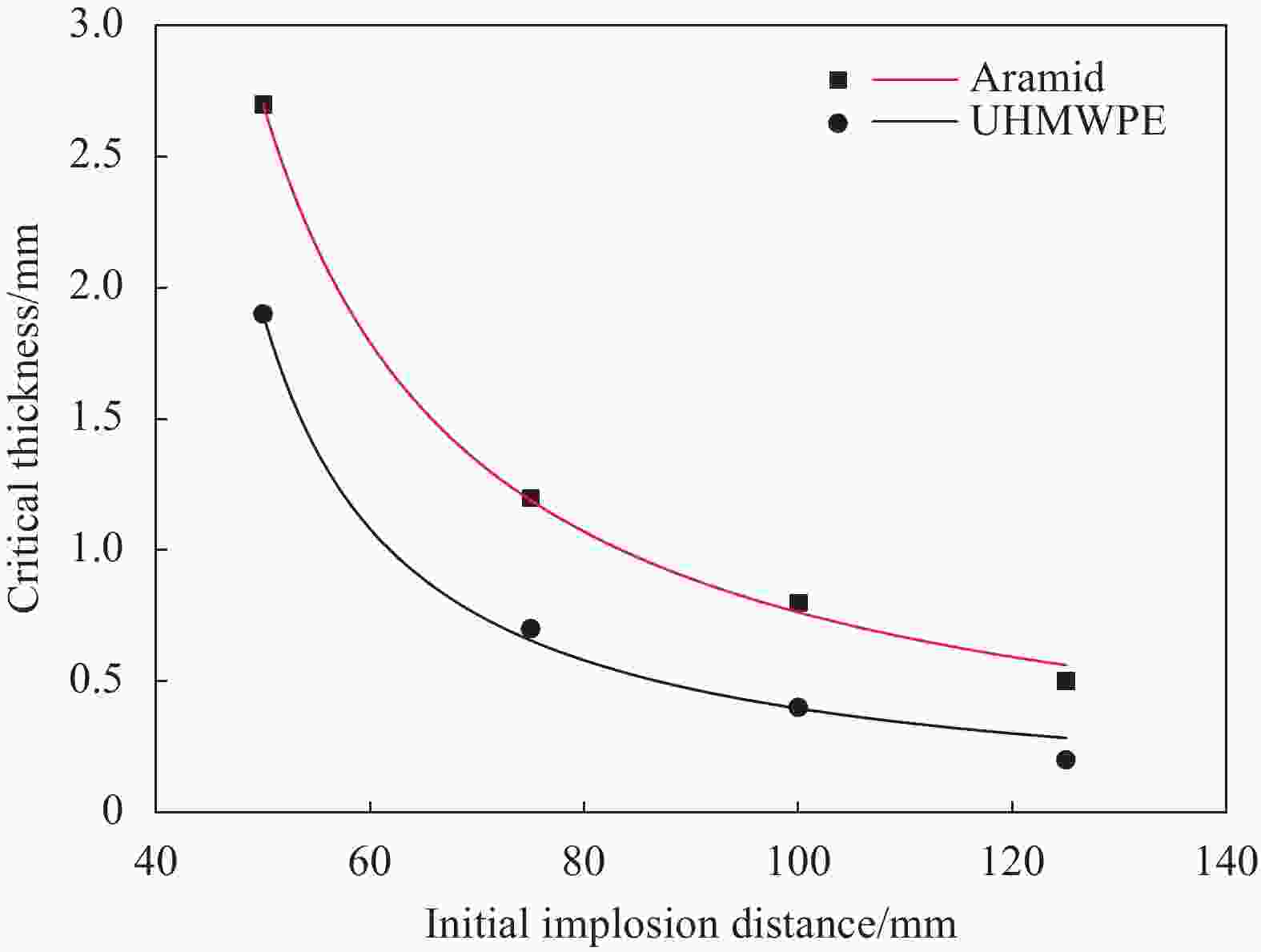

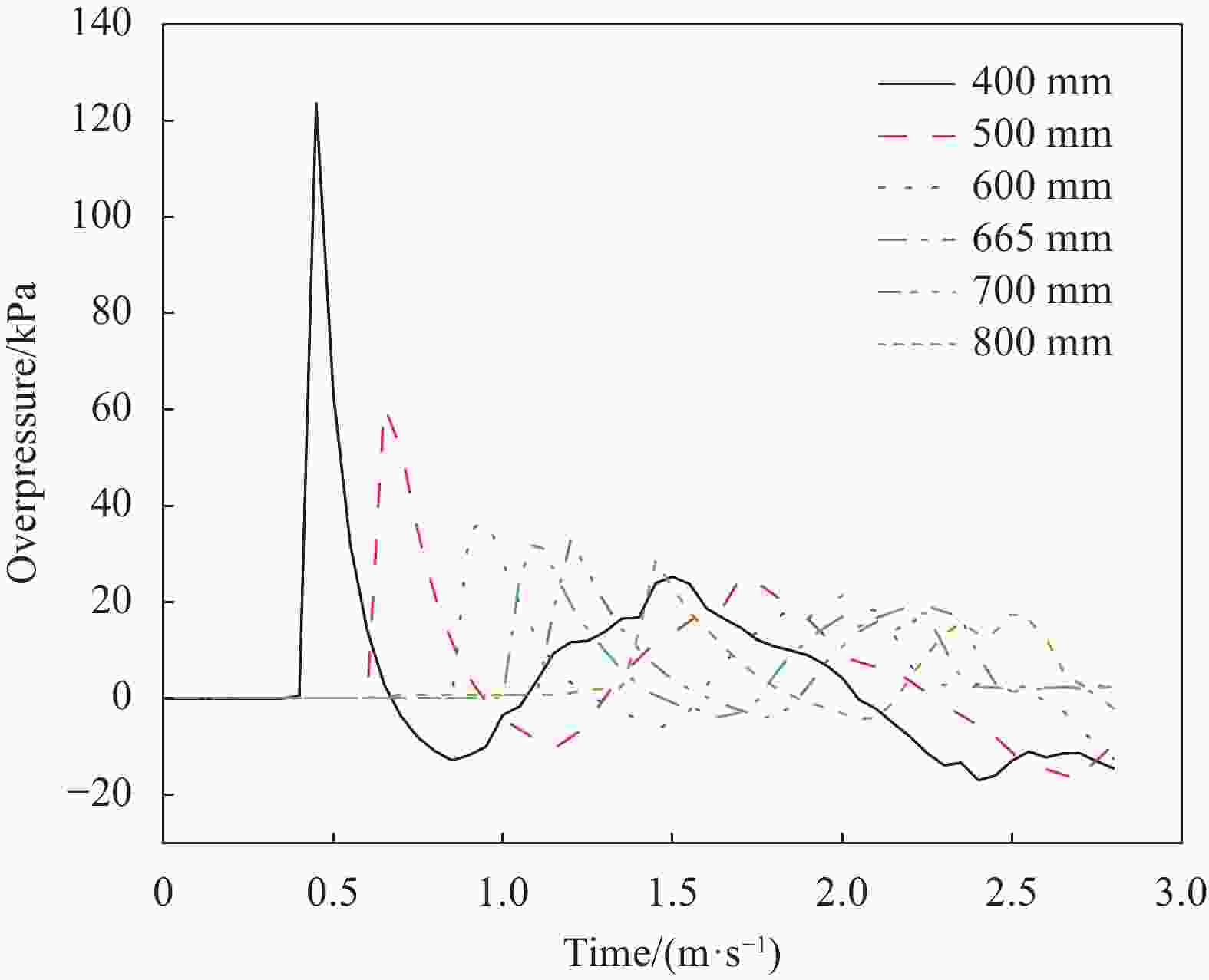

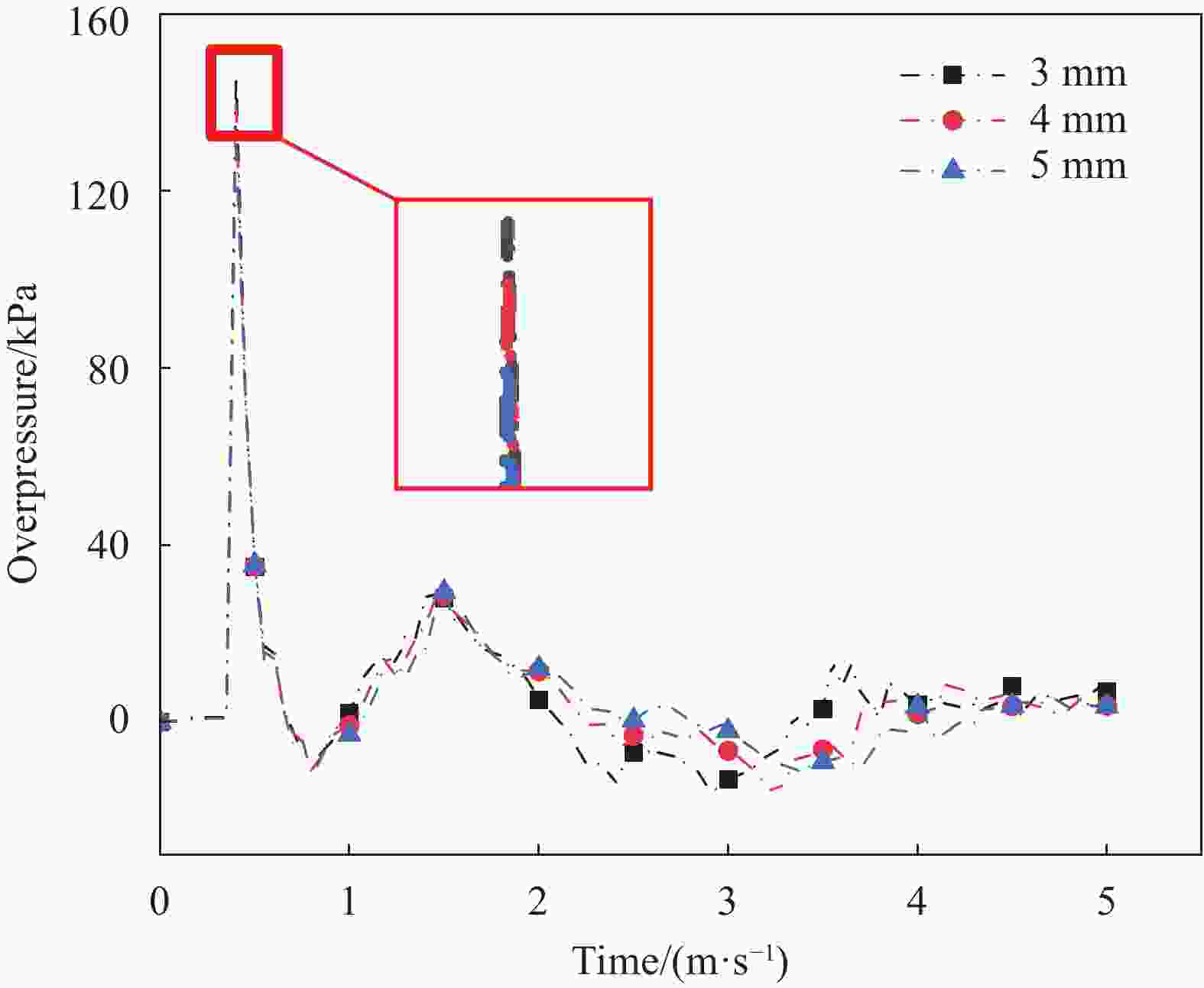

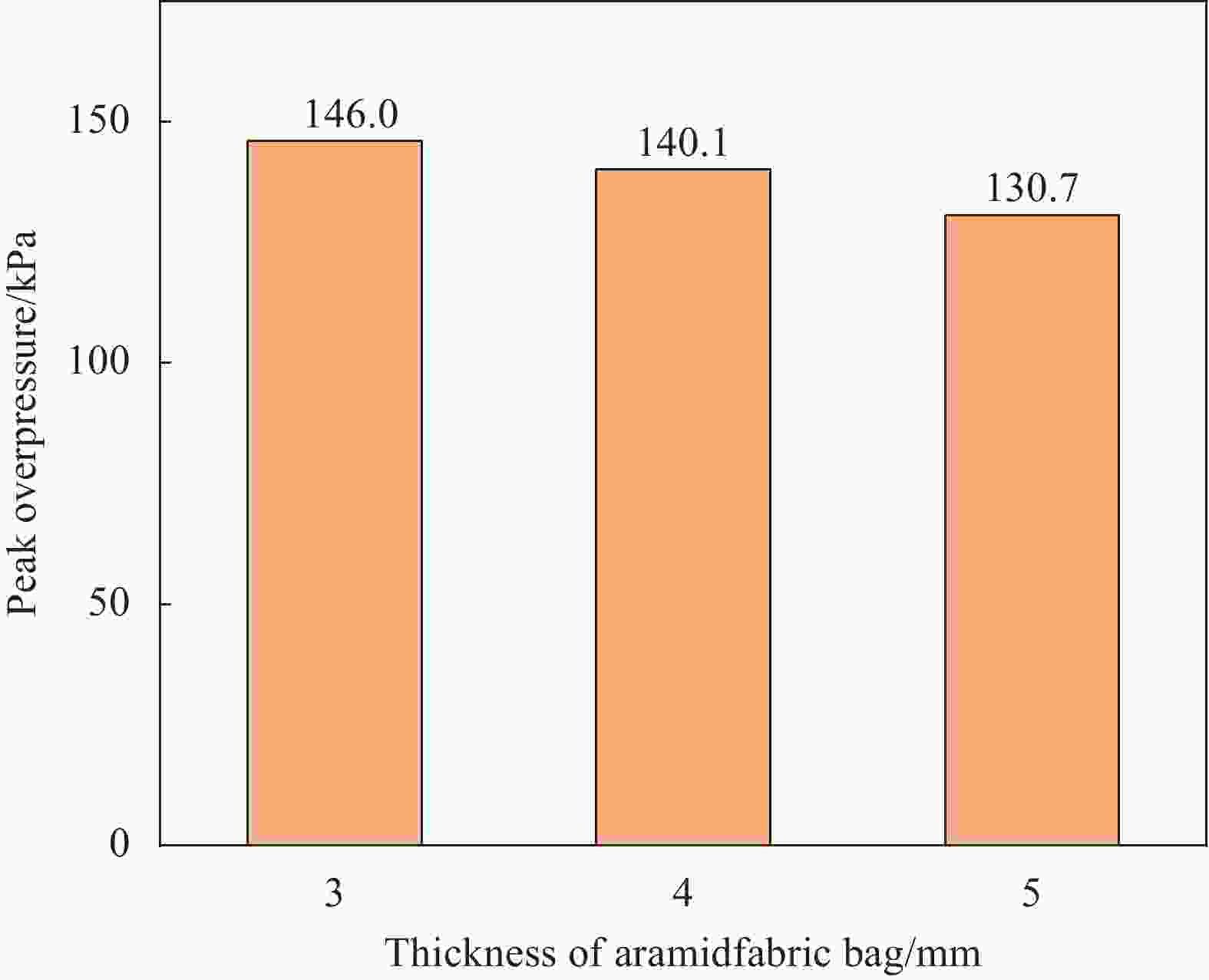

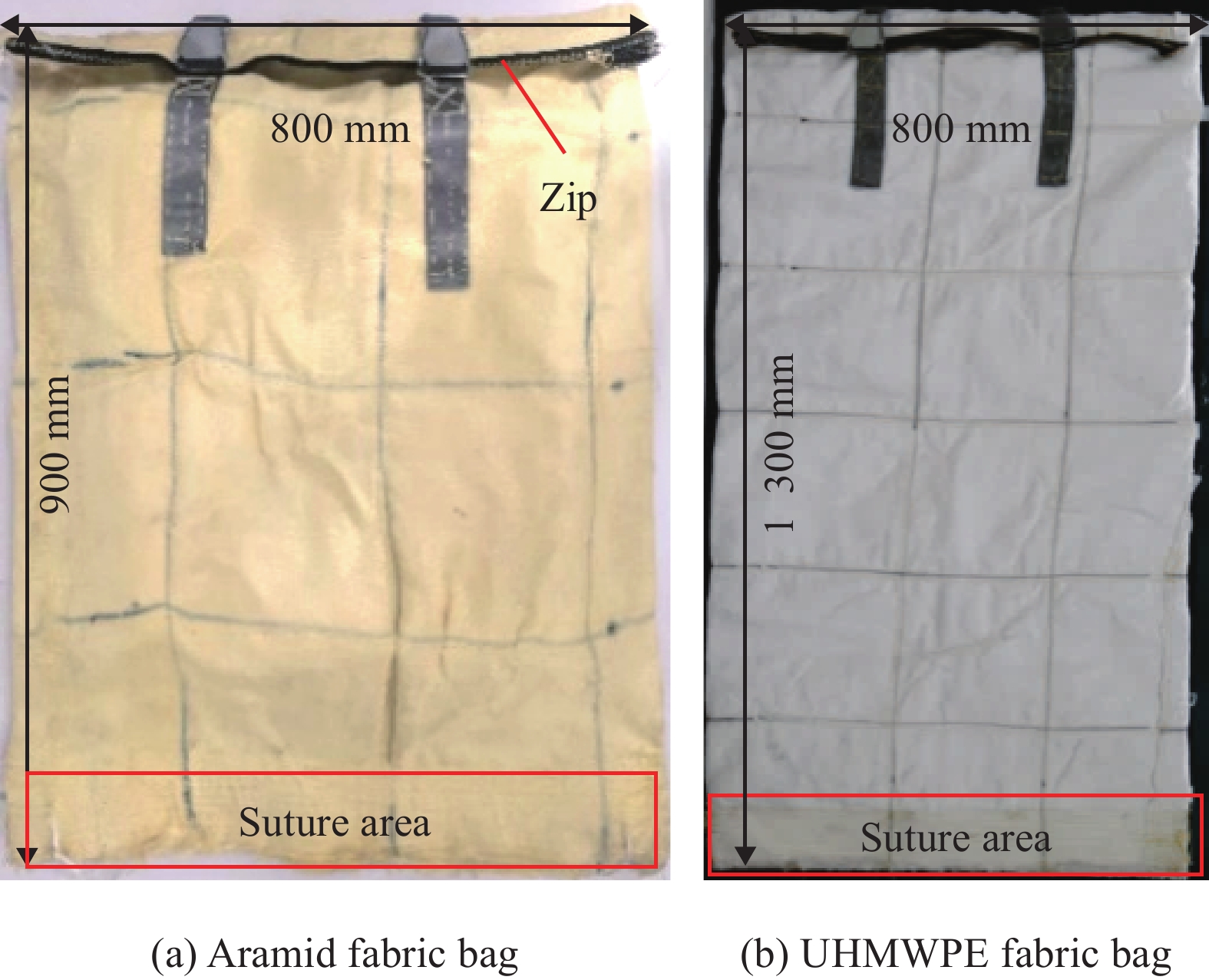

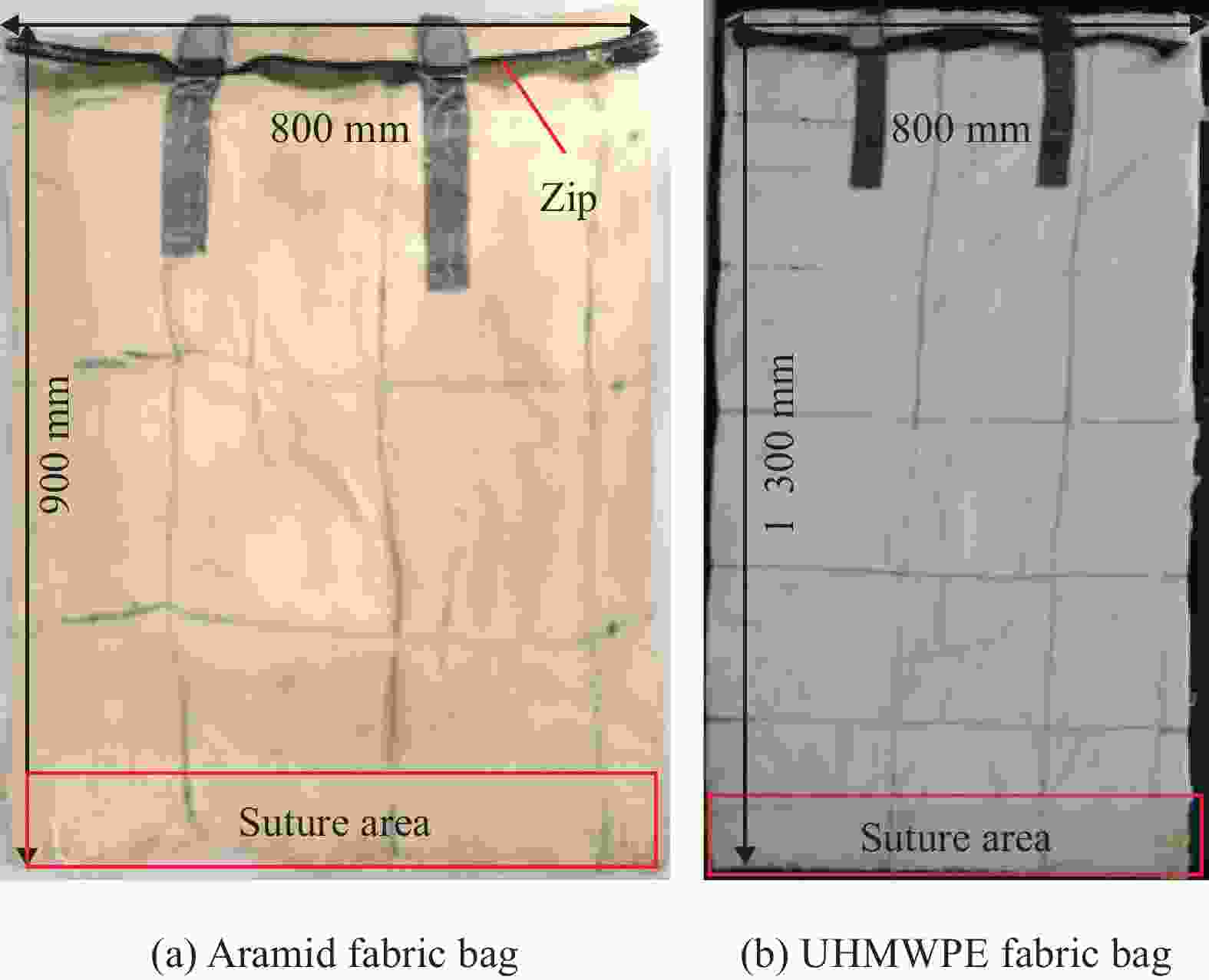

摘要: 针对小型简易爆炸装置,设计了芳纶和超高分子量聚乙烯(UHMWPE)纤维织物防爆袋,开展了织物袋内爆试验,同时建立了织物袋内爆数值分析模型。从外部超压和临界厚度两个角度对比了两种材料织物袋的抗爆能力,分析了初始内爆距离和织物袋厚度对织物袋抗爆性能的影响。结果表明:内爆载荷下织物袋的主要失效模式为中心区域破孔和封口拉链失效。在20~100 g药量范围内,织物袋的临界厚度与药量近似呈线性增长关系。同一药量下,芳纶织物袋的临界厚度明显大于UHMWPE织物袋,在不考虑爆炸火球对织物烧蚀的影响时,UHMWPE织物袋具有更好的抗爆效果。厚度相同时,芳纶织物袋外部的超压峰值更小,表明芳纶织物袋的超压衰减能力更强。随着织物袋初始内爆距离的增大,织物袋的临界厚度减小。织物袋外部一定范围内存在高于人体能够承受的超压,以30 g TNT、3 mm厚芳纶织物袋为例,在距织物袋中心665 mm处的超压为34.2 kPa,超过鼓膜损伤阈值。Abstract: Aramid and ultra-high molecular weight polyethylene (UHMWPE) fiber fabric bags were designed for the disposal of improvised explosive device (IED). The implosion test was carried out, and a finite element (FE) model of fabric bag implosion was established. The anti-explosion abilities of the two fabric bags were compared from the perspectives of external overpressure and critical thickness, and the effects of the initial implosion distance and the thickness of the fabric bag on the anti-explosion ability were analyzed. The results show that the main failure modes of the fabric bag under implosion load are broken hole in the center area and the failure of the sealing zipper. The critical thickness of the fabric bag increases approximately linearly with the charge in the range of 20-100 g TNT charge. The critical thickness of the aramid fabric bag is significantly larger than that of the UHMWPE fabric bag when the charges are the same. The UHMWPE fabric bag has a better anti-explosion ability without considering the influence of the explosion fireball. When the thicknesses are the same, the overpressure outside the aramid fabric bag is smaller, indicating that the overpressure attenuation ability of the aramid fabric bag is better. As the initial implosion distance of the fabric bag increases, the critical thickness decreases. There is an overpressure higher than the human body which can withstand within a certain range outside the fabric bag. Taking the 30 g TNT, 3 mm aramid fabric bag condition as an example, the overpressure at 665 mm from the center of the fabric bag is 34.2 kPa, exceeding the eardrum damage threshold.

-

Key words:

- fiber fabric bag /

- implosion load /

- dynamic response /

- shock wave overpressure /

- FEM

-

表 1 各织物的主要物理参数

Table 1. Main physical parameters of fabrics

Material Aramid UHMWPE Grade F-268 ZTZ 24 Yarn fineness/tex 166 126±10 Yarn body density/(g·cm−3) 1.44 0.97 Yarn breaking elongation/% ≥3.2 3-3.5 Yarn tensile modulus/GPa ≥125 105-110 Fabric thickness/mm 0.3 0.55 Weave count/(yarns·(10 cm)−1) 65×65 87×87 Areal density/(g·m−2) 210-220 235-245 Note: UHMWPE—Ultra-high molecular weight polyethylene. 表 2 TNT参数

Table 2. Parameters of TNT

Parameter Value Density/(kg·cm−3) 1.63×103 Detonation velocity/(m·s−1) 6930 Detonation pressure/GPa 21 A/GPa 374 B/GPa 3.74 R1 4.15 R2 1.4 ω 0.35 E0/(MJ·m−3) 7×103 Notes: A, B, R1, R2, ω—Constants characterizing TNT properties; E0—Detonation energy per unit volume. 表 3 空气参数

Table 3. Parameters of air

Parameter Value Density/(kg·m−3) 1.29 C4 0.4 C5 0.4 C1, C2, C3, C6 0 E0/(MJ·m−3) 0.25 Notes: C0-C6—Polynomial equation coefficients. 表 4 不同药量下织物袋的临界厚度

Table 4. Critical thickness of fabric bags at different charges

Charge/g Critical thickness/mm Aramid fiber UHMWPE 20 1.5 1.1 30 2.8 1.8 60 5.7 3.4 90 9.0 6.2 100 9.6 6.9 表 5 30 g TNT作用下,不同初始内爆距离的织物袋的临界厚度

Table 5. Critical thickness of fabric bags with different initial implosion distances under the condition of 30 g TNT

Size/mm Initial implosion distance/mm Charge/g Critical thickness/mm Aramid UHMWPE 900×800 50 30 2.8 1.9 75 1.2 0.7 100 0.8 0.4 125 0.5 0.2 表 6 30 g TNT作用下3 mm厚芳纶织物袋外部不同位置处的超压峰值

Table 6. Overpressure peaks at different positions outside the 3 mm aramid fabric bag under the condition of 30 g TNT

Distance from measuring

point to explosive/mmCharge/g Overpressure

peak/kPa400 30 123.9 500 60.7 600 37.7 665 34.2 700 32.8 800 28.6 -

[1] Federal Aviation Administration. Least risk bomb location: FAA. AC 25.795-6[S]. Washington: Federal Aviation Administration, 2008. [2] FALLAH A S, MICALLEF K, LANGDON G S, et al. Dynamic response of Dyneema HB26 plates to localised blast loading[J]. International Journal of Impact Engineering,2014,73(11):91-100. [3] GARGANO A, PINGKARAWAT K, BLACKLOCK M. Comparative assessment of the explosive blast performance of carbon and glass fibre-polymer composites used in naval ship structures[J]. Composite Structures,2017,171(1):306-316. [4] ZHANG Y, YAN D J, NIAN X Z, et al. Numerical analysis of rigid and flexible reflection of air shock wave[J]. Applied Mechanics & Materials,2014,638-640:2010-2014. [5] ZHANG B, NIAN X Z, JIN F, et al. Failure analyses of flexible ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced anti-blast wall under explosion[J]. Composite Structures,2018,184:759-774. doi: 10.1016/j.compstruct.2017.10.037 [6] 赵敏, 赵睿昕, 沈永明, 等. CFR嵌片对超高分子质量聚乙烯多层复合织物防爆性能的影响[J]. 纺织学报, 2014, 35(3):37-40.ZHAO Min, ZHAO Ruixin, SHEN Yongming, et al. The effect of CFR inserts on the explosion-proof properties of ultra-high molecular weight polyethylene multilayer composite fabrics[J]. Journal of Textile Research,2014,35(3):37-40(in Chinese). [7] 解江, 姜超, 高斌元, 等. 高性能纤维织物抗爆性能试验研究[J]. 应用力学学报, 2022, 39(1):35-43.XIE Jiang, JIANG Chao, GAO Binyuan, et al. Experimental study on anti-explosion performance of high-performance fiber fabrics[J]. Chinese Journal of Applied Mechanics,2022,39(1):35-43(in Chinese). [8] 冯振宇, 姜超, 高斌元, 等. 芳纶纤维平纹织布在爆炸载荷下的动态响应与失效行为的数值分析[J]. 应用数学和力学, 2021, 42(11):1113-1125.FENG Zhenyu, JIANG Chao, GAO Binyuan, et al. Numerical analysis of dynamic response and failure behavior of aramid fiber plain weave under blast load[J]. Applied Mathematics and Mechanics,2021,42(11):1113-1125(in Chinese). [9] 解江, 高斌元, 甄婷婷, 等. 爆炸载荷下机织物的动态响应与失效行为[J]. 复合材料学报, 2022, 39(10): 4949-4960.XIE Jiang, GAO Binyuan, ZHEN Tingting, et al. Dynamic response and failure behaviors of woven fabrics under blast load[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4949-4960(in Chinese). [10] CHUN S, KAPOOR H, KAPANIA R, et al. Nonlinear fluid-structure interaction in a flexible shelter under blast loading[C]//46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Virginia, 2005. [11] MARKERT F, THOMMESEN J. Blast worthy textile-based luggage containers for aviation safety[J]. Safety and Security Analysis,2011,40:213557. [12] ZANGANI D, AMBROSETTI S, BOZZOLO A, et al. Textile-based luggage containers for onboard blast protection[J]. Sae International Journal of Aerospace,2011,4(2):690-698. doi: 10.4271/2011-01-2517 [13] GIOVANELLE M L. Advanced technologies for bombproof cargo containers and blast containment units for the retrofitting of passenger airplanes[J]. International Journal of Aviation Systems, Operations and Training, 2015, 2(1): 33-47. [14] POLAK J, REDLICH G, WITCZAK E. The reaction of cylinder fibrous cover to explosion of charge with fragments[J]. Central European Journal of Energetic Materials,2009,6(2):137-148. [15] POLAK J, ROMEK R, WIŚNIEWSKI A. Lightweight covers for attenuating the explosion of the charges and the methodology of their protective performance assay[J]. Problemy Techniki Uzbrojenia,2008,37(107):15-24. [16] ZHU W, HUANG G Y, LIU H, et al. Experimental and numerical investigation of a hollow cylindrical water based barrier against internal blast induced fragment loading[J]. International Journal of Impact Engineering,2020,138:103503. doi: 10.1016/j.ijimpeng.2020.103503 [17] MASI F, MARIA M P, VANNUCCI P. Blast actions in aircrafts: An integrated methodology for designing protection devices[J]. Engineering Structures,2018,175:895-911. doi: 10.1016/j.engstruct.2018.08.082 [18] 蔡军锋, 易建政. 新型危险品防爆运输箱设计及抗爆试验研究[J]. 包装工程, 2012, 33(5):6-8, 55.CAI Junfeng, YI Jianzheng. Design and anti-explosion test of new explosion-proof transport case for dangerous article[J]. Packaging Engineering,2012,33(5):6-8, 55(in Chinese). [19] 蔡军锋, 傅孝忠, 易建政. 超高分子量聚乙烯-聚氨酯泡沫复合材料的抗爆实验与数值模拟[J]. 高分子材料科学与工程, 2013, 29(11):79-83. doi: 10.16865/j.cnki.1000-7555.2013.11.019CAI Junfeng, FU Xiaozhong, YI Jianzheng. Anti-explosion experiment and numerical simulation of ultra-high molecular weight polyethylene-polyurethane foam composites[J]. Polymer Materials Science and Engineering,2013,29(11):79-83(in Chinese). doi: 10.16865/j.cnki.1000-7555.2013.11.019 [20] 何泽侃. 芳纶纤维布缠绕增强软壁机匣包容性研究[D]. 杭州: 浙江大学, 2018.HE Zekan. Research on the containment of soft wall casing wrapped with aramid fiber fabric[D]. Hangzhou: Zhejiang University, 2018(in Chinese). [21] 孙艳馥, 王欣. 爆炸冲击波对人体损伤与防护分析[J]. 火炸药学报, 2008, 31(4):50-53. doi: 10.3969/j.issn.1007-7812.2008.04.013SUN Yanfu, WANG Xin. Analysis of human body injury and protection by explosion shock wave[J]. Journal of Explosives,2008,31(4):50-53(in Chinese). doi: 10.3969/j.issn.1007-7812.2008.04.013 -

下载:

下载: