Study on properties of bamboo fiber composites with different fiber morphologies based on vacuum-assisted resin transfer molding

-

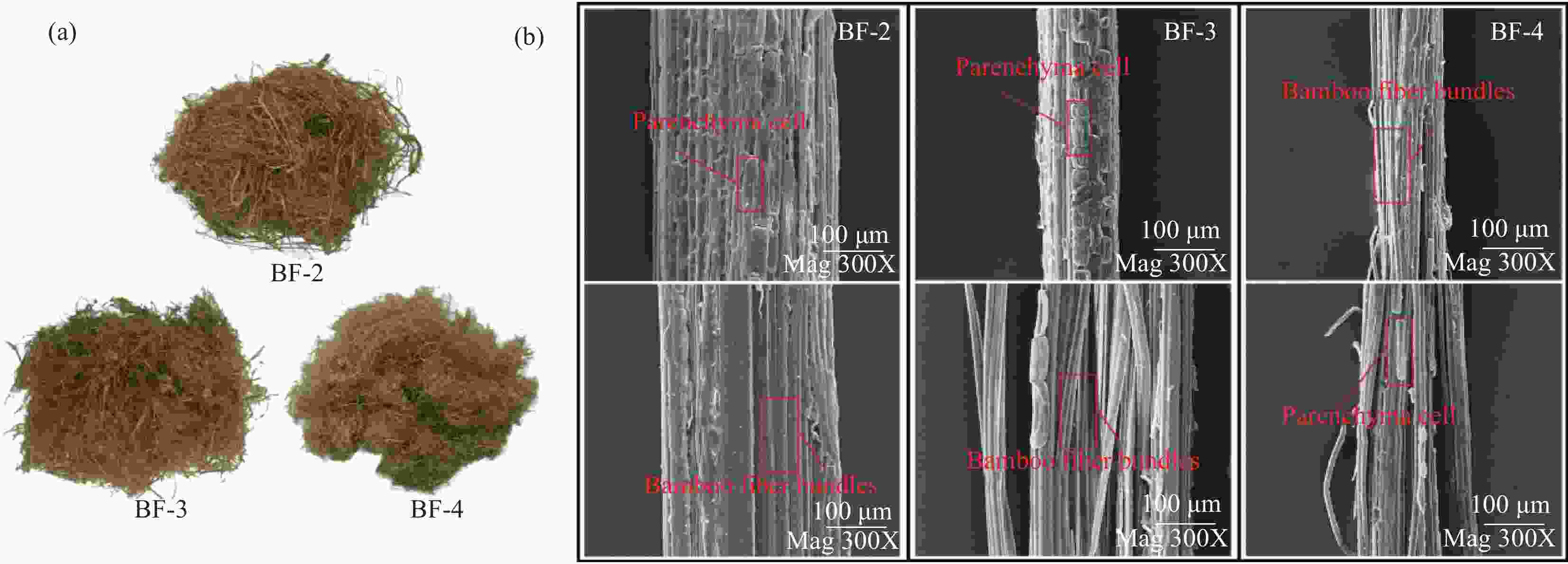

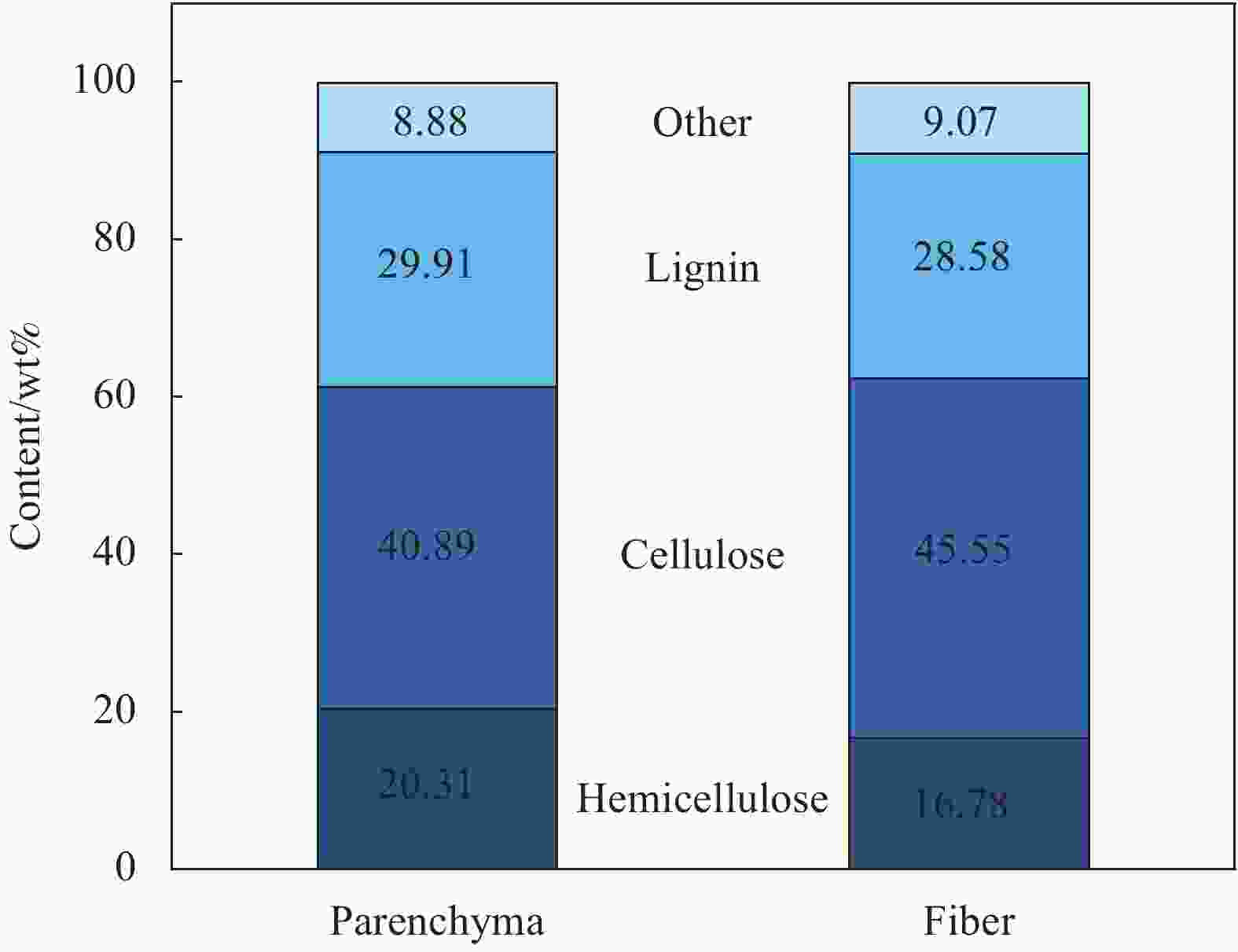

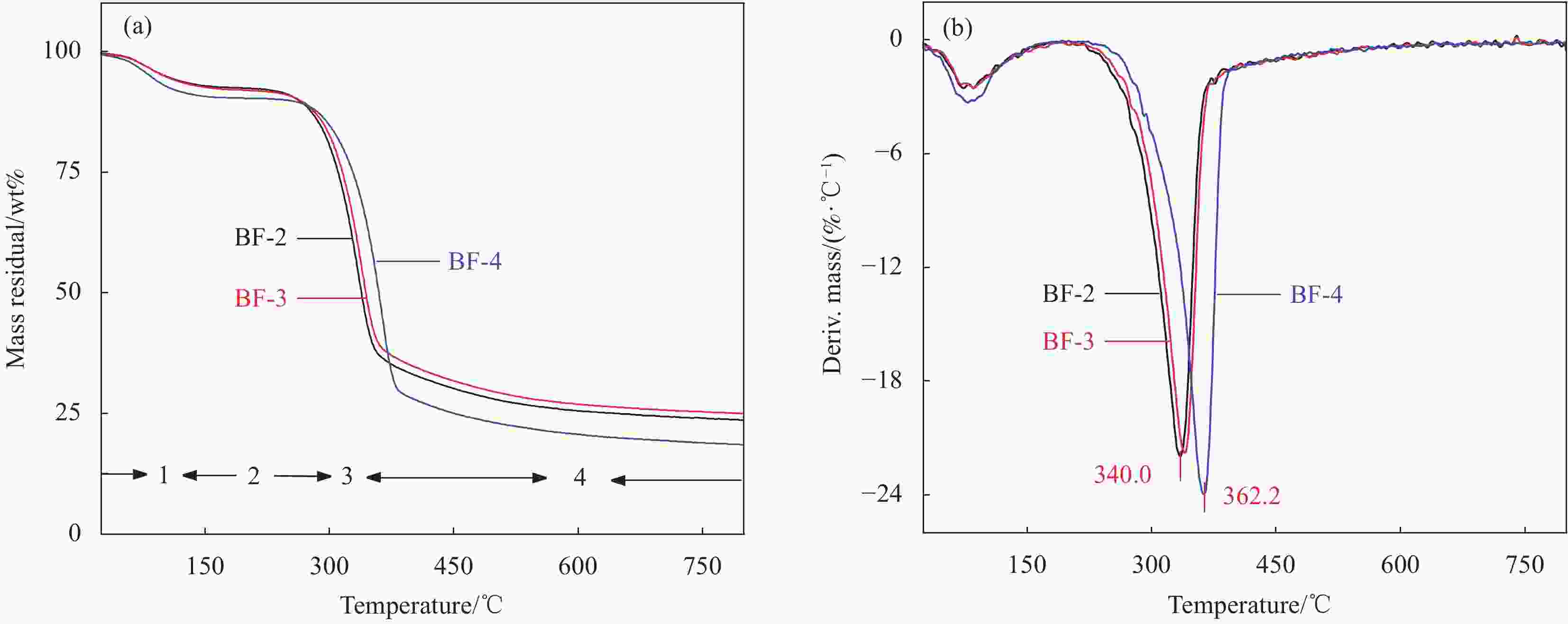

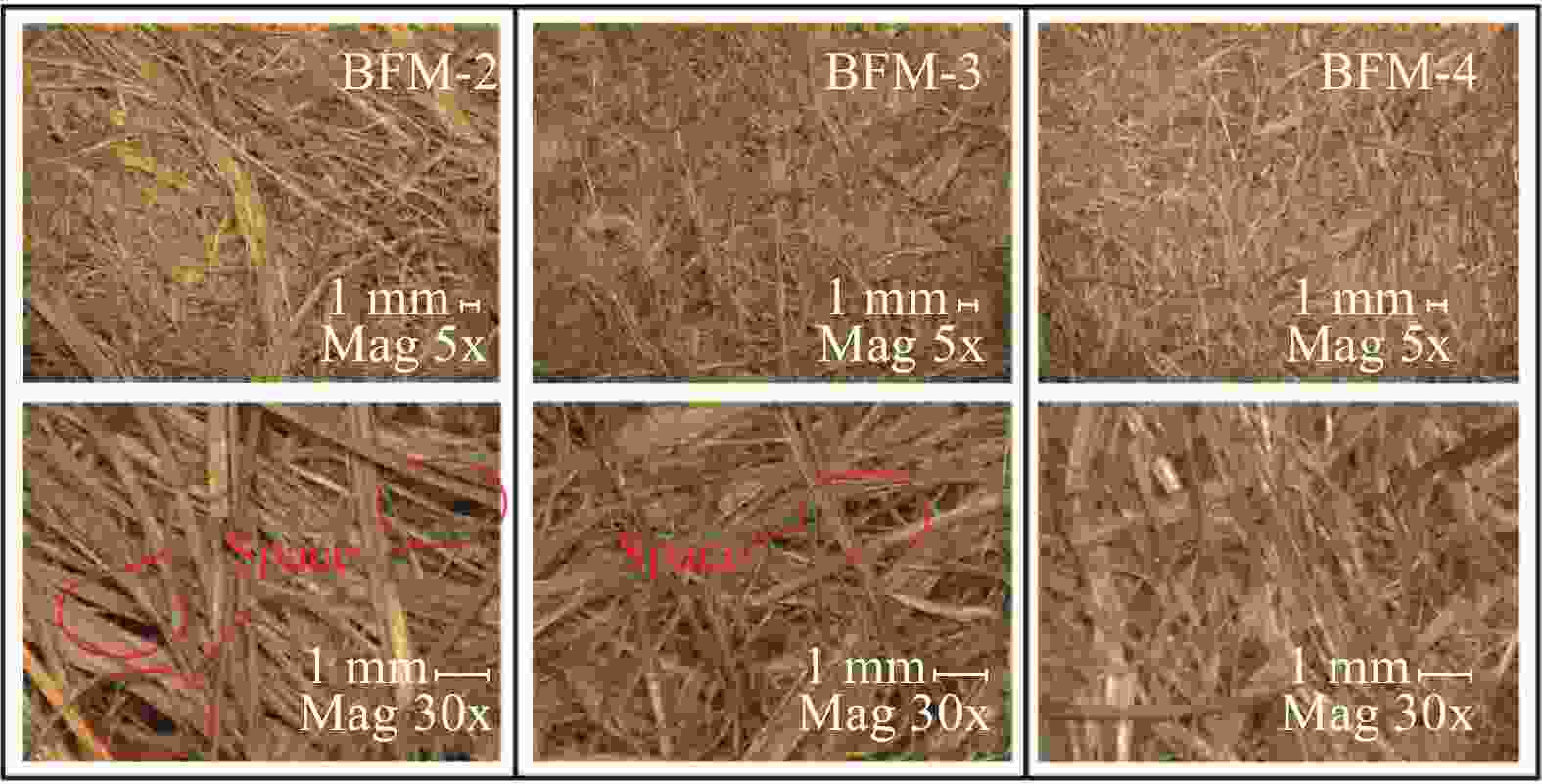

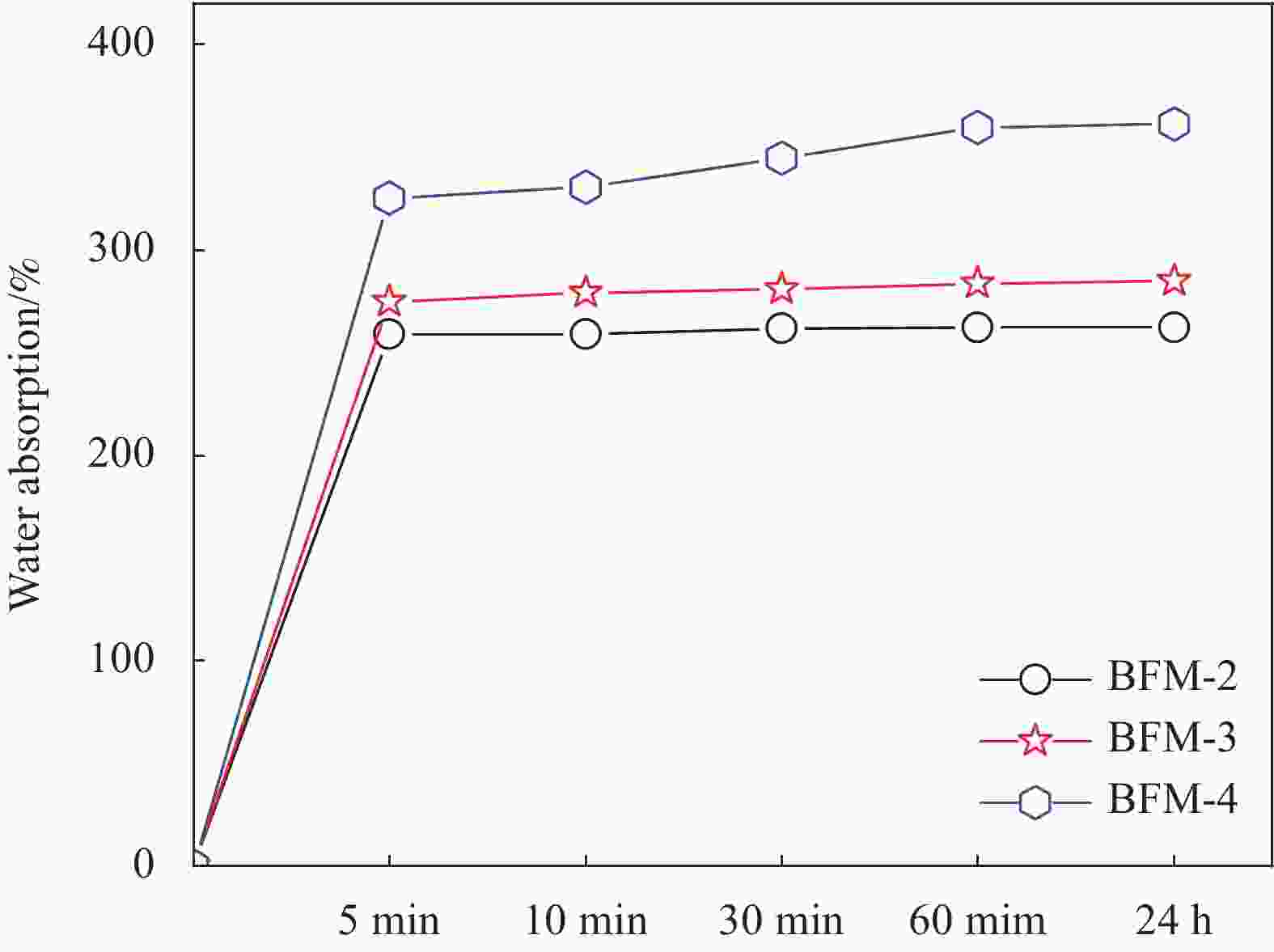

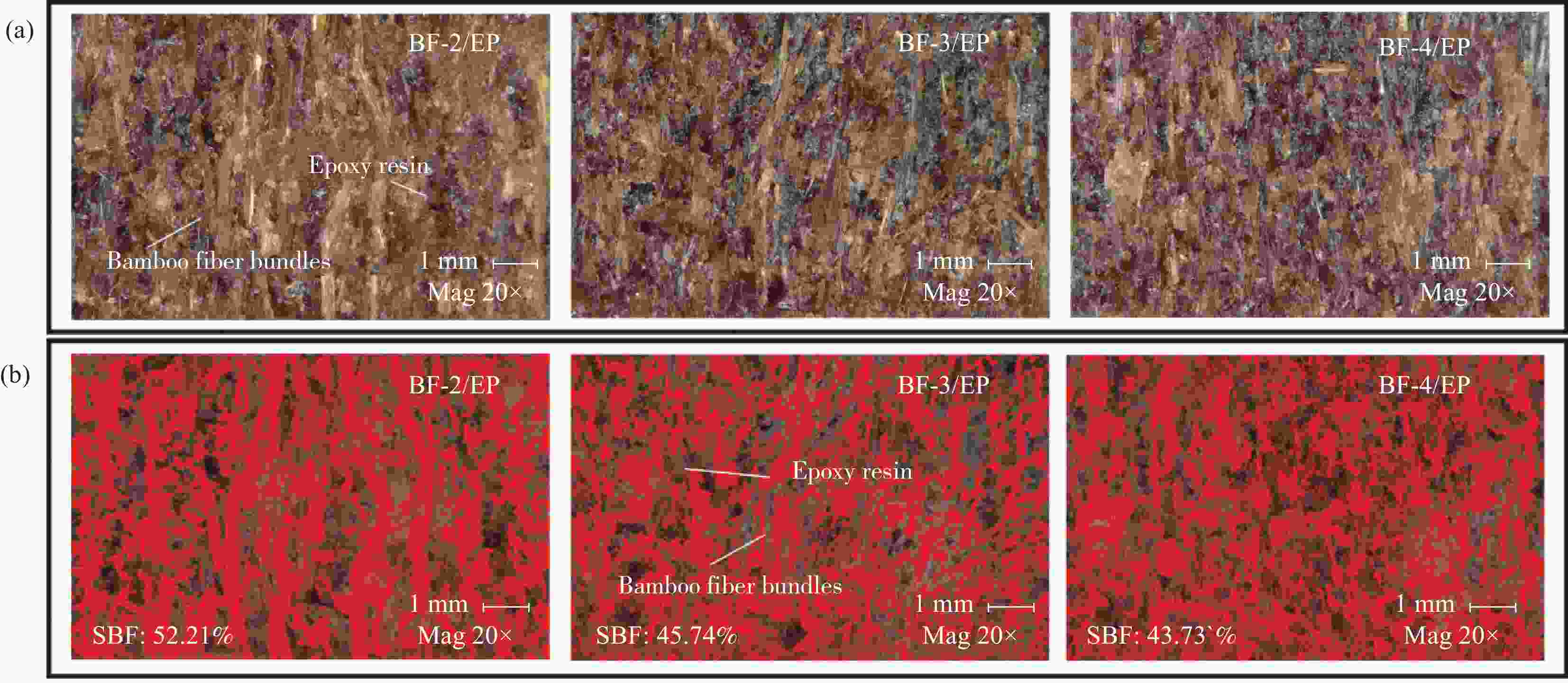

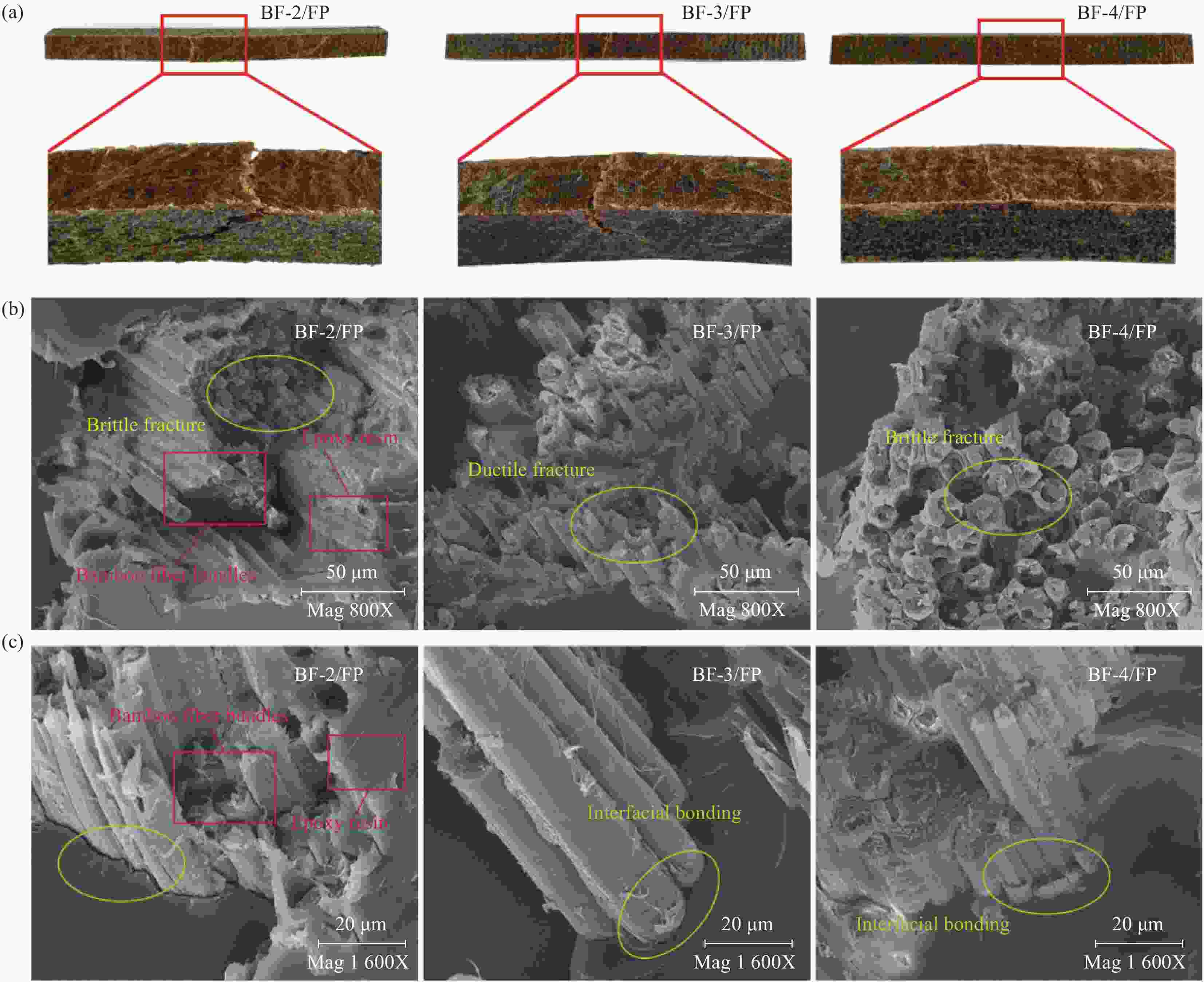

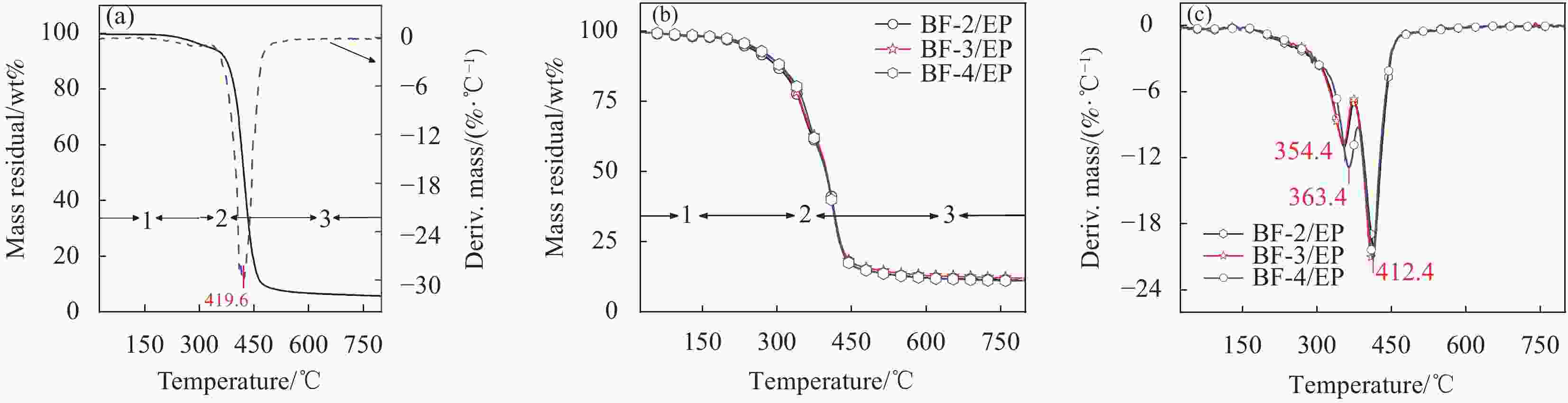

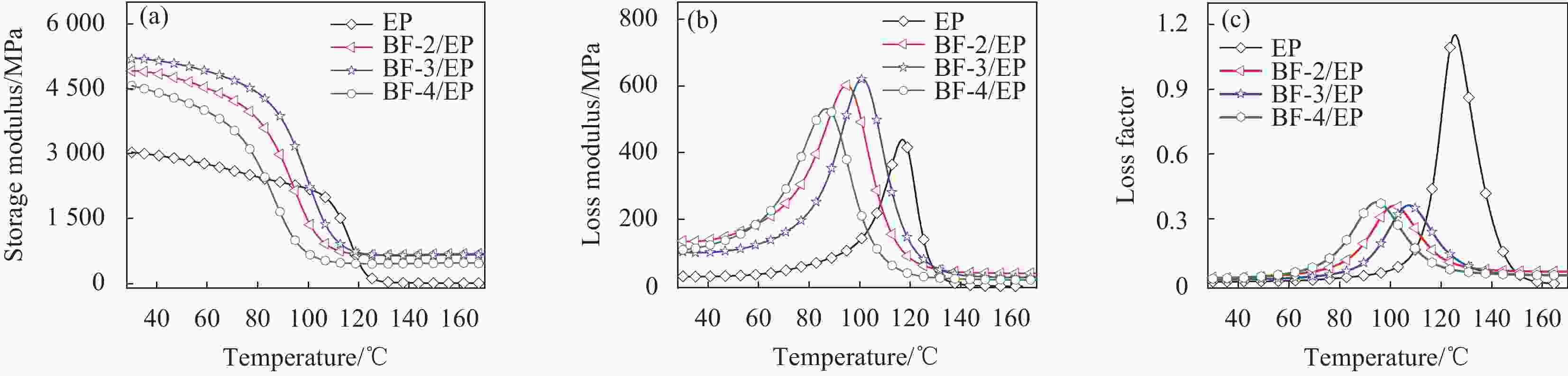

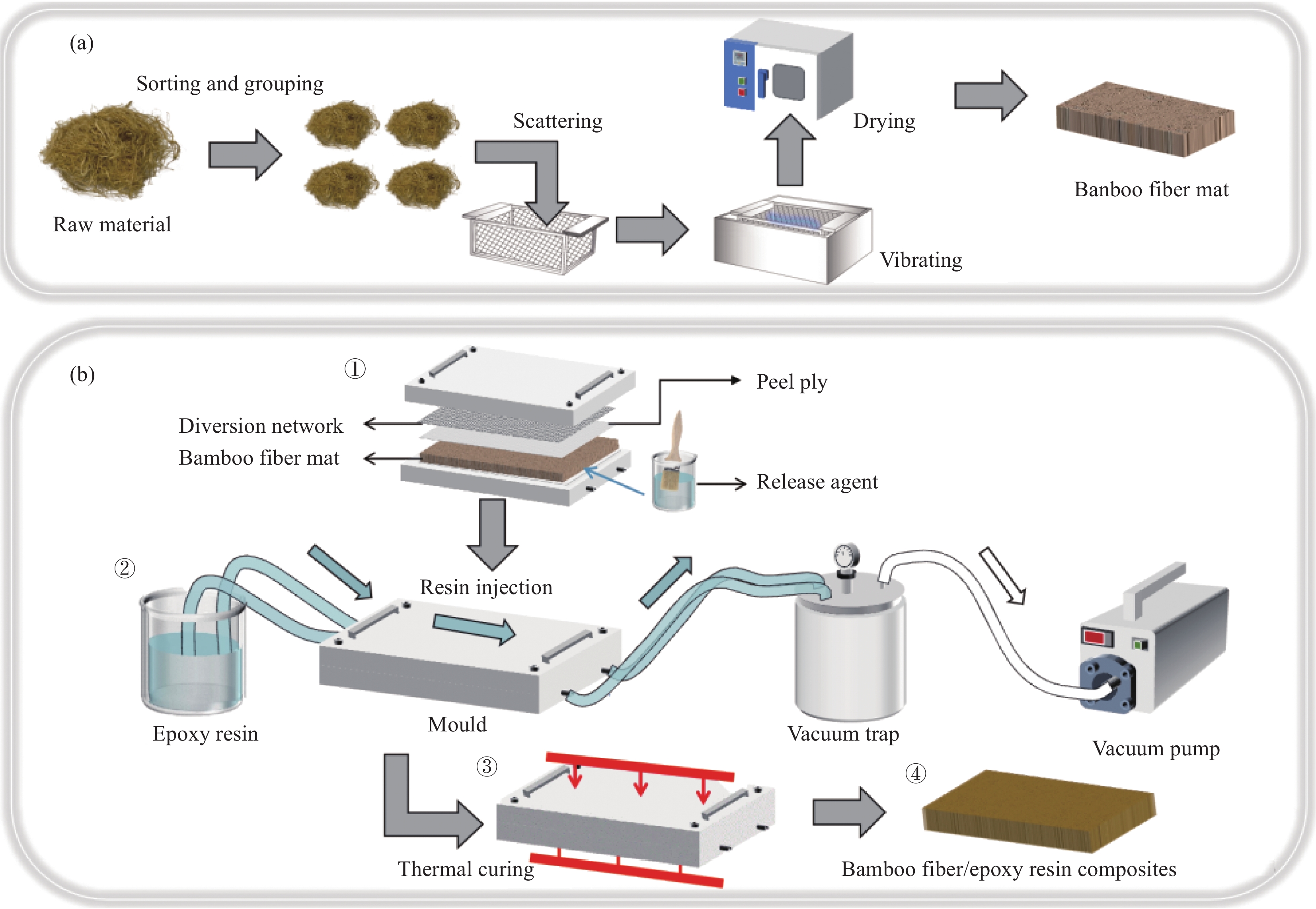

摘要: 为探索不同形态竹纤维(BF)对真空辅助树脂传递模塑成型(VARTM)过程中环氧树脂(EP)浸渍纤维效果及BF/EP复合材料性能的影响,采用经机械碾压2次、3次、4次得到3种不同形态的BF(BF-2、BF-3和BF-4),通过湿法层铺工艺将BF制作成竹纤维毡(BFM),再利用VARTM制备出纤维含量为45wt%的复合材料BF-2/EP、BF-3/EP和BF-4/EP。采用ESEM、超景深显微镜、力学试验机、TG、DMA和Micro-CT对BF、BFM和BF/EP复合材料性能进行表征。研究结果表明:随纤维长度减小、纤维分离度增加,导致湿法层铺成型的BFM蓬松度降低,树脂注射难度增大,BFM-4在树脂注射时会发生纤维堆积,BF-3/EP复合材料吸水率最低。BF-2的长度较长、分离度低,虽保持了BF束自身结构与性能,但是与树脂界面结合性能差,长度与分离度适中的BF-3制备的复合材料力学性能最佳,弯曲强度、弹性模量、剪切强度和冲击韧性分别为97.90 MPa、7.2 GPa、17.01 MPa和8.11 kJ/m2。BF加速了BF/EP复合材料的热解,BF-4/EP复合材料因BF-4中半纤维素含量少,热解温度有所提高。BF能够提升EP的刚性,BF-3与树脂界面结合最佳,孔隙体积占比仅为0.04%,BF-3/EP复合材料储能模量最大值高达5198 MPa。使用VARTM制备BF/EP复合材料时,BF尺寸与分离度是影响纤维与树脂界面结合性能和BF/EP复合材料性能的关键因素。Abstract: The aim of this research was to explore the effect of different morphologies of bamboo fiber (BF) on epoxy resin (EP) impregnation in vacuum-assisted resin transfer molding (VARTM) process and the properties of BF/EP composites. Three types of BF with different morphologies (BF-2, BF-3 and BF-4) were obtained by mechanical rolling with 2, 3 and 4 times, respectively. The BF were made into bamboo fiber mat (BFM) by wet layering process, and then produced into BF-2/EP, BF-3/EP and BF-4/EP composites with fiber content of 45wt% by VARTM. The properties of BF, BFMs and BF/EP composites were characterized with ESEM, ultra-depth-of-field microscope, mechanical testing machine, TG, DMA and micro-CT. The results show that the fluffy degree of BFMs by wet layering decreases and the difficulty of resin injection increases when the fiber length decreases and the fiber separation increases. The fiber accumulation occurs during resin injection of BFM-4, and BF-3/EP composite has the lowest water absorption. The BF-2 with longer length and lower dispersion can easily lead to poor interfacial bonding with resin, although it can maintain the structure and properties of BF. The mechanical properties of the composite prepared by BF-3 with moderate length and separation are the best, and the flexural strength, flexural modulus, shear strength and impact toughness are 97.90 MPa, 7.2 GPa, 17.01 MPa and 8.11 kJ/m2, respectively. BF accelerates the pyrolysis of BF/EP composites. The BF-4/EP composite has a higher pyrolysis temperature because BF-4 has lower hemicellulose content compared with other BF. BF can improve the rigidity of EP. The interface bonding between BF-3 and resin is the best, and the proportion of pores volume is only 0.04%. The maximum storage modulus of BF-3/EP composites is 5198 MPa. When BF/EP composites are prepared by VARTM, the appropriate BF size and separation degree are the key factors that affect the interfacial bonding and properties.

-

Key words:

- bamboo fiber /

- wet layering process /

- VARTM /

- fiber morphology /

- bamboo fiber composites

-

表 1 不同纤维形态竹纤维(BF)的尺寸

Table 1. Size of bamboo fiber (BF) with different morphologies

Material Length/cm Diameter/mm Aspect ratio Average Range Average Range BF-2 23.97 (7.04) 11.20-41.00 0.50 (0.24) 0.19-1.14 479 BF-3 3.43 (0.75) 1.94-5.37 0.37 (0.21) 0.10-1.17 93 BF-4 2.54 (1.03) 1.28-6.02 0.25 (0.12) 0.13-0.55 102 Note: Standard deviation in brackets. 表 2 不同纤维形态BF/EP复合材料密度

Table 2. Densities of BF/EP composites prepared with different fiber morphologies

BF/EP composite EP BF-2/EP BF-3/EP BF-4/EP Density/(g·cm−3) 1.210 1.245 1.259 1.251 -

[1] ZHANG J, CHEVALI V S, WANG H, et al. Current status of carbon fibre and carbon fibre composites recycling[J]. Composites Part B: Engineering,2020,193:108053. doi: 10.1016/j.compositesb.2020.108053 [2] MORAMPUDI P, NAMALA K K, GAJJELA Y K, et al. Review on glass fiber reinforced polymer composites[J]. Mater-ials Today: Proceedings,2021,43:314-319. doi: 10.1016/j.matpr.2020.11.669 [3] ZHANG Zhongsen, CAI Shenming, LI Yan, et al. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures[J]. Composites Science and Technology,2020,194:108151. doi: 10.1016/j.compscitech.2020.108151 [4] LIU D, SONG J, ANDERSON D P, et al. Bamboo fiber and its reinforced composites: Structure and properties[J]. Cellulose,2012,19(5):1449-1480. doi: 10.1007/s10570-012-9741-1 [5] DEPUYDT D E, SWEYERS N, APPELS L, et al. Bamboo fibres sourced from three global locations: A microstructural, mechanical and chemical composition study[J]. Jour-nal of Reinforced Plastics and Composites,2019,38(9):397-412. doi: 10.1177/0731684419828532 [6] ZAKIKHANI P, ZAHARI R, SULTAN M, et al. Extraction and preparation of bamboo fibre-reinforced composites[J]. Materials & Design,2014,63:820-828. [7] 李岩, 于涛, 沈轶鸥. 植物纤维增强复合材料[M]. 北京: 科学出版社, 2021.LI Yan, YU Tao, SHEN Yiou. Plant fiber reinforced compo-sites[M]. Beijing: Science Press, 2021(in Chinese). [8] XIA C, SHI S Q, CAI L, et al. Property enhancement of kenaf fiber composites by means of vacuum-assisted resin transfer molding (VARTM)[J]. Holzforschung,2015,69(3):307-312. doi: 10.1515/hf-2014-0054 [9] KIM H, OKUBO K, FUJII T, et al. Influence of fiber extraction and surface modification on mechanical properties of green composites with bamboo fiber[J]. Journal of Adhesion Science & Technology,2013,27(12):1348-1358. [10] WANG D, BAI T, CHENG W, et al. Surface modification of bamboo fibers to enhance the interfacial adhesion of epoxy resin-based composites prepared by resin transfer molding[J]. Polymers,2019,11(12):2107. [11] ISHIKAWA H, TAKAGI H, NAKAGAITO A N, et al. Effect of surface treatments on the mechanical properties of natural fiber textile composites made by VARTM method[J]. Composite Interfaces,2014,21(4):329-336. doi: 10.1080/15685543.2013.876322 [12] 徐灿, 陆继倾, 白天, 等. 纳米SiO2改性竹纤维/乙烯基树脂复合材料界面相容性[J]. 复合材料学报, 2021, 38(9):2776-2786.XU Can, LU Jiqing, BAI Tian, et al. Study on interfacial compatibility of nano-SiO2 modified bamboo fiber/vinyl ester resin composites[J]. Acta Materiae Compositae Sinica,2021,38(9):2776-2786(in Chinese). [13] 范豪. VARTM中树脂充模过程的数值模拟与实验研究[D]. 哈尔滨: 东北林业大学, 2017.FAN Hao. Numerical simulation and experimental study on resin filling process in VARTM[D]. Haerbing: Northeast Forestry University, 2017(in Chinese). [14] 薛昊. 竹纤维/环氧树脂复合材料的RTM成型工艺及界面改性研究[D]. 哈尔滨: 东北林业大学, 2020.XUE Hao. VARTM process and interfacial modification of bamboo fiber/epoxy composite[D]. Harbing: Northeast Forestry University, 2020(in Chinese). [15] CHEN H, CHENG H T, WANG G, et al. Tensile properties of bamboo in different sizes[J]. Journal of Wood Science,2015,61(6):552-561. doi: 10.1007/s10086-015-1511-x [16] 潘明珠. 麦秸纤维/聚丙烯复合材料制造工艺与性能研究[D]. 南京: 南京林业大学, 2008.PAN Mingzhu. Preparation and properties of wheat straw fiber/polypropylene composites[D]. Nanjing: Nanjing Forestry University, 2008(in Chinese). [17] 王春红, 刘胜凯, 任子龙, 等. 表面改性对竹纤维与聚丙烯纤维混杂毡平铺复合材料湿热老化影响[J]. 塑料, 2016, 45(4):50-54.WANG Chunhong, LIU Shengkai, REN Zilong, et al. Effect of surface modification on hygrothermal ageing behavior of bamboo fiber and polypropylene fiber hybrid compo-site[J]. Plastics,2016,45(4):50-54(in Chinese). [18] 郭卫昂. 针刺工艺中机织基布纱线损伤问题的研究[D].上海: 东华大学, 2013.GUO Weiang. The analysis of yarn damage on base cloth in the needle-punching process[D]. Shanghai: Donghua University, 2013(in Chinese). [19] 施江靖, 陈红, 张文福, 等. 纤维含量对VARTM制备竹纤维/环氧树脂复合材料性能影响[J]. 复合材料学报, 2022, 39(3): 1249-1258.SHI J J, CHEN H, ZHANG W F, et al. Effect of fiber content on the properties of bamboo fiber/epoxy resin composites prepared by VARTM [J]. Acta Materiae Compositae Sinica, 2020, 39(3): 1249-1258(in Chinese). [20] SLUITER A, HAMES B, RUIZ R O, et al. Determination of structural carbohydrates and lignin in biomass[J]. Laboratory Analytical Procedure,2008,1617(1):1-16. [21] 中国国家标准化管理委员会. 纤维增强塑料密度和相对密度试验方法: GB/T 1463—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test methods for density and relative of fiber reinforced plastics: GB/T 1463—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [22] 中国国家标准化管理委员会. 木材吸水性测试方法: GB/T 1934.1—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Method for determination of water absorption of wood: GB/T 1934.1—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [23] 中国国家标准化管理委员会. 纤维增强塑料吸水性试验方法: GB/T 1462—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test methods for water absorption of fiber reinforced plastics: GB/T 1462—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [24] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites—Determination of flexural poperties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [25] ASTM. Standard test method for short beam strength of polymer matrix composite materials and their laminates: ASTM D2344/ D2344M—16[S]. West Conshohocken: ASTM International, 2016. [26] 中国国家标准化管理委员会. 纤维增强塑料简支梁式冲击韧性试验方法: GB/T 1451—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites—Determination of charpy impact properties: GB/T 1451—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [27] ROCKY B P, THOMPSON A J. Production of natural bamboo fibers-1: Experimental approaches to different processes and analyses[J]. The Journal of the Textile Institute,2018,109(10):1381-1391. doi: 10.1080/00405000.2018.1482639 [28] 董庆, 张书平, 张理, 等. 竹材热解动力学特性分析[J]. 过程工程学报, 2015, 15(1):89-93.DONG Qing, ZHANG Shuping, ZHANG Li, et al. Study on pyrolysis kinetics of bamboo[J]. The Chinese Journal of Process Engineering,2015,15(1):89-93(in Chinese). [29] GUPTA A. Synthesis, chemical resistance, and water absorption of bamboo fiber reinforced epoxy composites[J]. Polymer Composites,2016,37(1):141-145. doi: 10.1002/pc.23164 [30] KHAN Z, YOUSIF B F, ISLAM M D. Fracture behaviour of bamboo fiber reinforced epoxy composites[J]. Compo-sites Part B: Engineering,2017,116:186-199. doi: 10.1016/j.compositesb.2017.02.015 [31] 陈祥宝. 先进复合材料技术导论[M]. 北京: 航空工业出版社, 2017.CHEN Xiangbao. Introduction of advanced composite technology[M]. Beijing: Aviation Industry Press, 2017(in Chinese). [32] 付盼, 谭欣, 肖来辉, 等. 高性能桐油基酸酐类环氧固化剂研究[J]. 热固性树脂, 2021, 36(2):22-30.FU Pan, TAN Xin, XIAO Laihui, et al. Study on high-performance tung oil-based anhydride epoxy curing agent[J]. Thermosetting Resin,2021,36(2):22-30(in Chinese). [33] SONG K, REN X, ZHANG L. Bamboo fiber-polymer composites: Overview of fabrications, mechanical characterizations and applications[M]. Cham: Springer International Publishing, 2017. [34] WANG C, WANG G, CHENG H, et al. CaCO3 in situ treated bamboo pulp fiber reinforced composites obtained by vacuum-assisted resin infusion[J]. Wood Science & Technology,2017,51(3):571-584. -

下载:

下载: