Effect of ablation time on ablation mechanism of C/C-SiC composites in hypersonic and oxygen-enriched environment

-

摘要: 为了研究烧蚀时间对C/C-SiC复合材料在高超声速富氧环境下烧蚀机制的影响规律,采用富氧环境下的高超声速烧蚀试验技术,对“化学气相渗透+先驱体浸渍裂解”混合工艺制备的针刺C/C-SiC复合材料动态烧蚀机制进行研究,并采用电子扫描显微镜观察烧蚀表面形貌。研究表明:在极端苛刻的高超声速富氧烧蚀环境下,C/C-SiC复合材料能够短时抵抗高温、高压、高超声速燃气射流的氧化工作环境。材料经高超声速富氧烧蚀10 s、20 s、30 s、40 s及50 s后的质量烧蚀率分别为0.021 g/s、0.025 g/s、0.027 g/s、0.026 g/s与0.034 g/s。C/C-SiC复合材料在高超声速富氧环境下的动态烧蚀行为主要受热化学烧蚀与机械剥蚀两种烧蚀机制共同作用。在初始阶段,SiO2保护膜的存在有效阻止了氧化性组分向基体内部的扩散,仅材料中心区域存在轻微热化学烧蚀;烧蚀试验中期,材料的烧蚀主要表现为热化学烧蚀与机械剥蚀联合作用,并由热化学烧蚀向机械剥蚀呈渐变性转变;烧蚀试验后期,基体的深度反应使得材料的烧蚀主要表现为纤维与基体的大面积片状剥落。

-

关键词:

- C/C-SiC复合材料 /

- 高超声速 /

- 富氧烧蚀 /

- 烧蚀时间 /

- 烧蚀机制

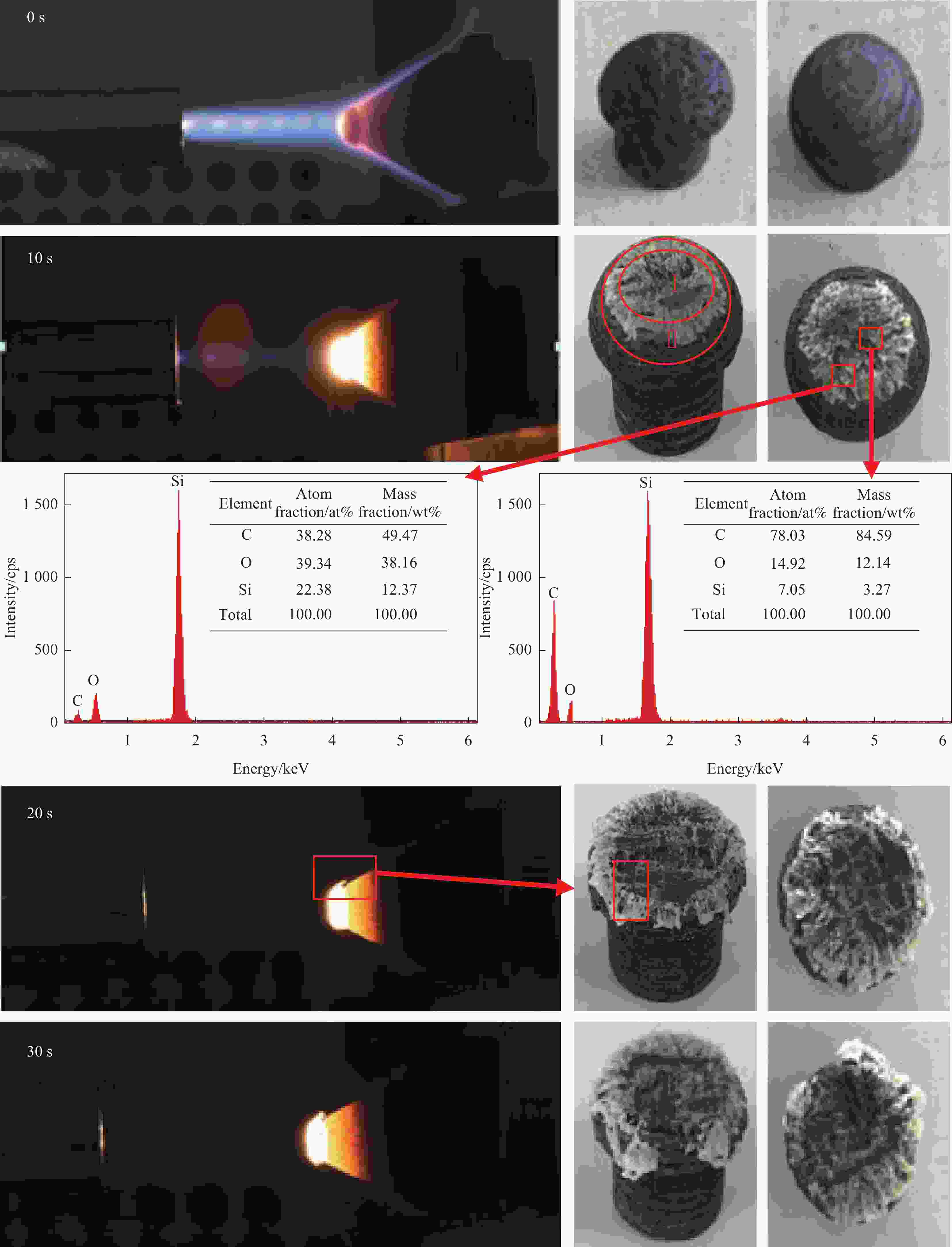

Abstract: In order to study the effect of ablation time on the ablation mechanism of C/C-SiC composites under a hypersonic oxygen-rich environment, the dynamic ablation mechanism of the needled carbon/carbon-silicon carbide composites prepared by “chemical vapor infiltration + precursor immersion pyrolysis” hybrid process was studied by the hypersonic oxygen-enriched ablation test technology in this paper, and the ablation surface morphology of the composites were investigated by scanning electron microscopy. The results show that, the C/C-SiC composites can resist the oxidation working environment of high temperature, high pressure and hypersonic gas jets in a short time under the extremely harsh hypersonic oxygen-enriched ablation environment. The mass ablation rate of C/C-SiC composites after 10 s, 20 s, 30 s, 40 s and 50 s ablation by hypersonic oxygen-enriched ablation are 0.021 g/s, 0.025 g/s, 0.027 g/s, 0.026 g/s and 0.034 g/s, respectively. The dynamic ablation behavior of the C/C-SiC composites under the hypersonic oxygen-enriched environment is synergistic effects of thermo-oxidation ablation and mechanical erosion. In the initial stage, the existence of the SiO2 protective film effectively prevents the diffusion of oxidizing components into the matrix, and only the central area of the material is slightly thermal oxidative ablation. In the middle test, the ablation of the material is mainly manifested in the combined effect of thermo-oxidation ablation and mechanical erosion, and gradually transition from mainly thermal oxidative ablation to mainly mechanical erosion. In the later stage of the ablation test, the further reaction of the matrix makes the ablation mechanism of the material mainly manifested as the large-area flaking of the fiber and matrix.-

Key words:

- C/C-SiC composites /

- hypersonic /

- oxygen-enriched ablation /

- ablation time /

- ablation mechanism

-

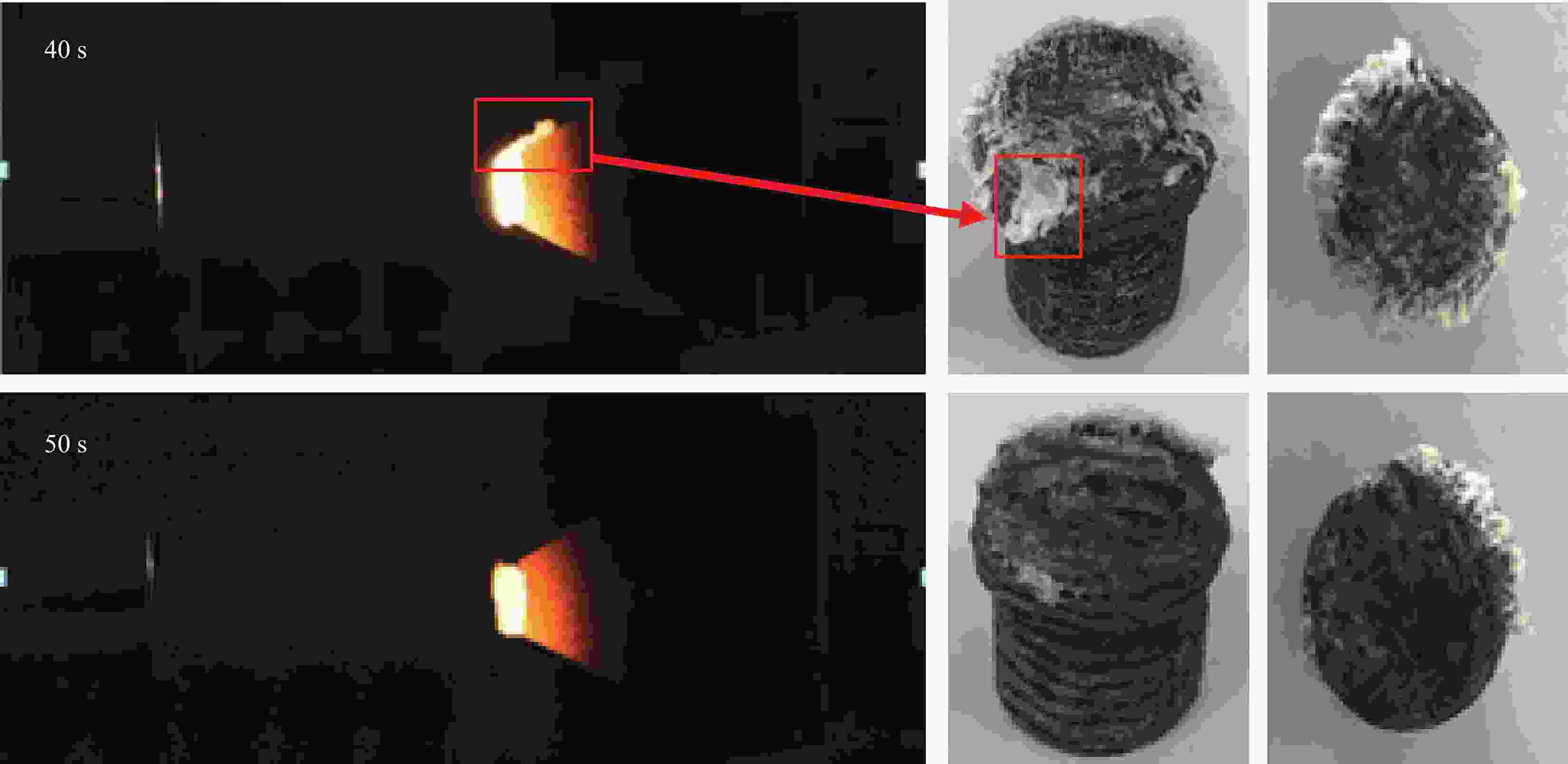

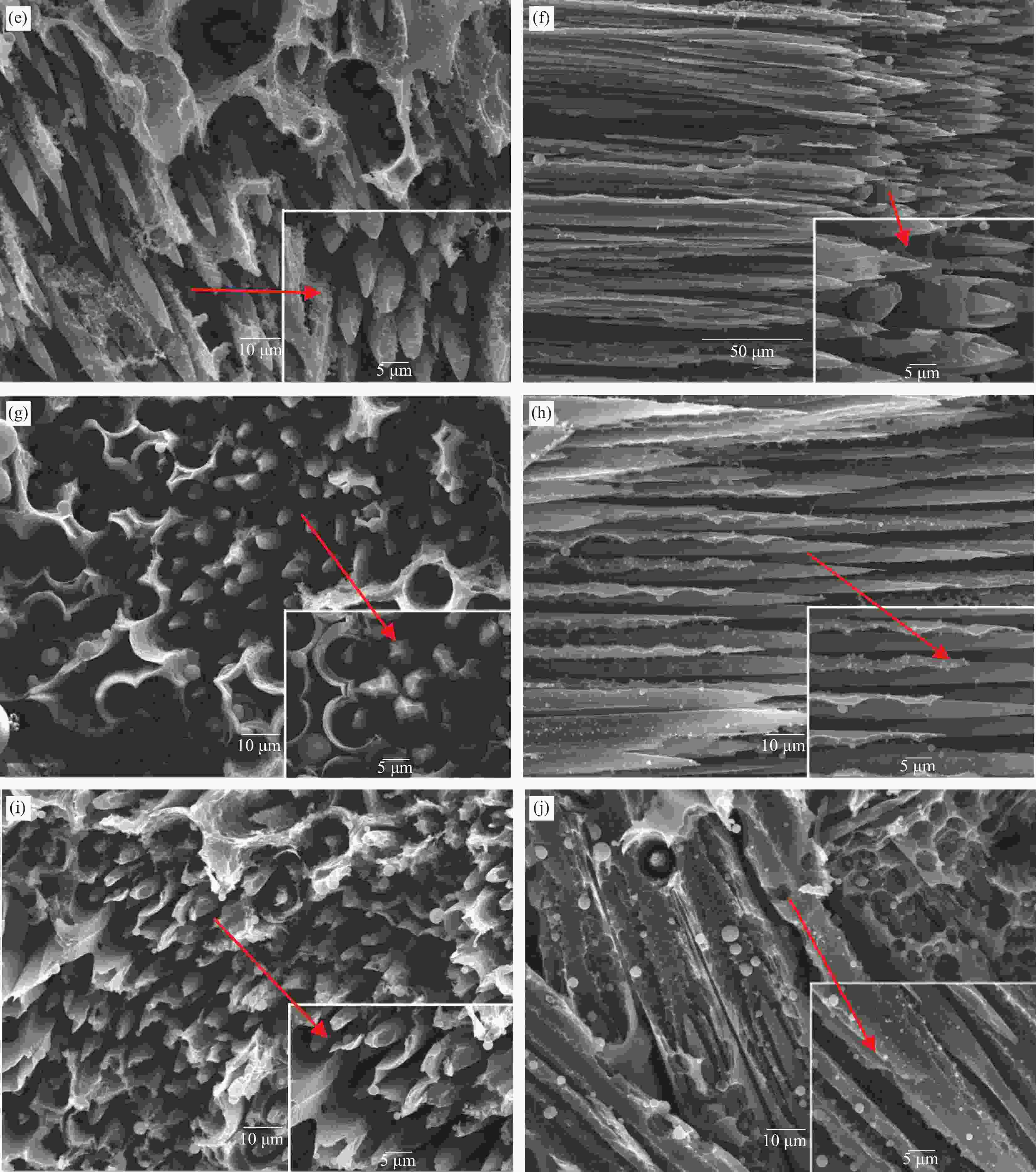

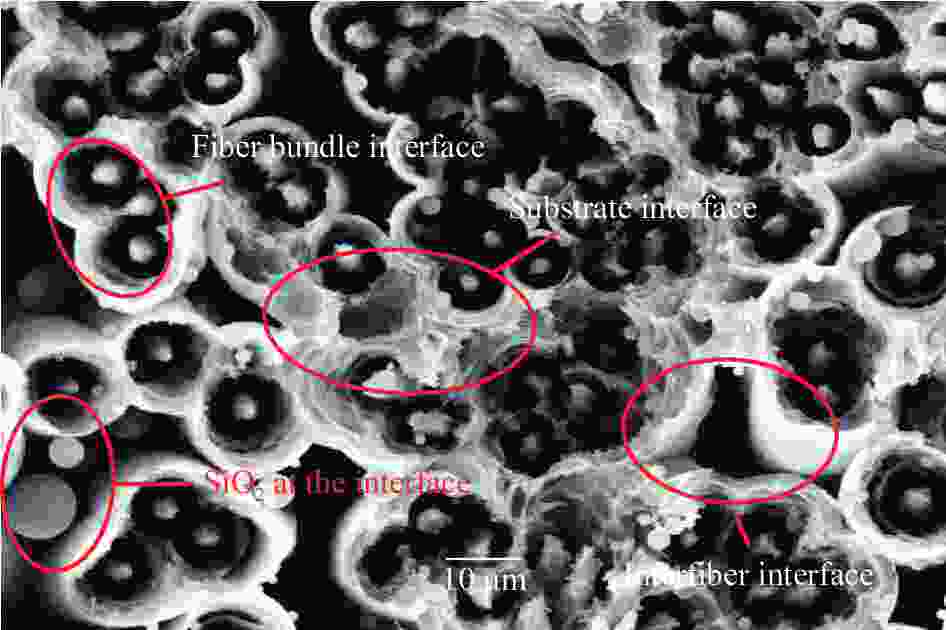

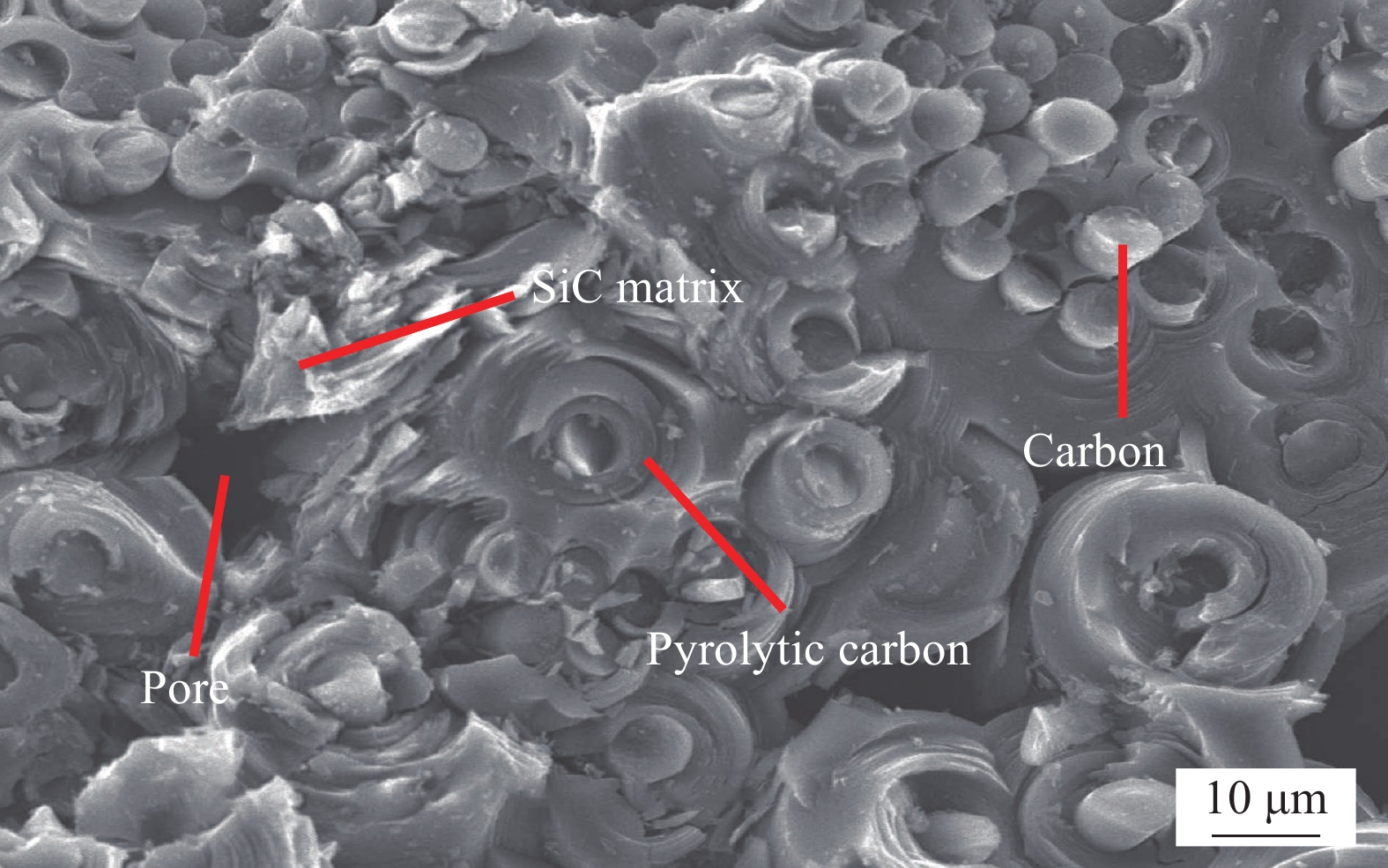

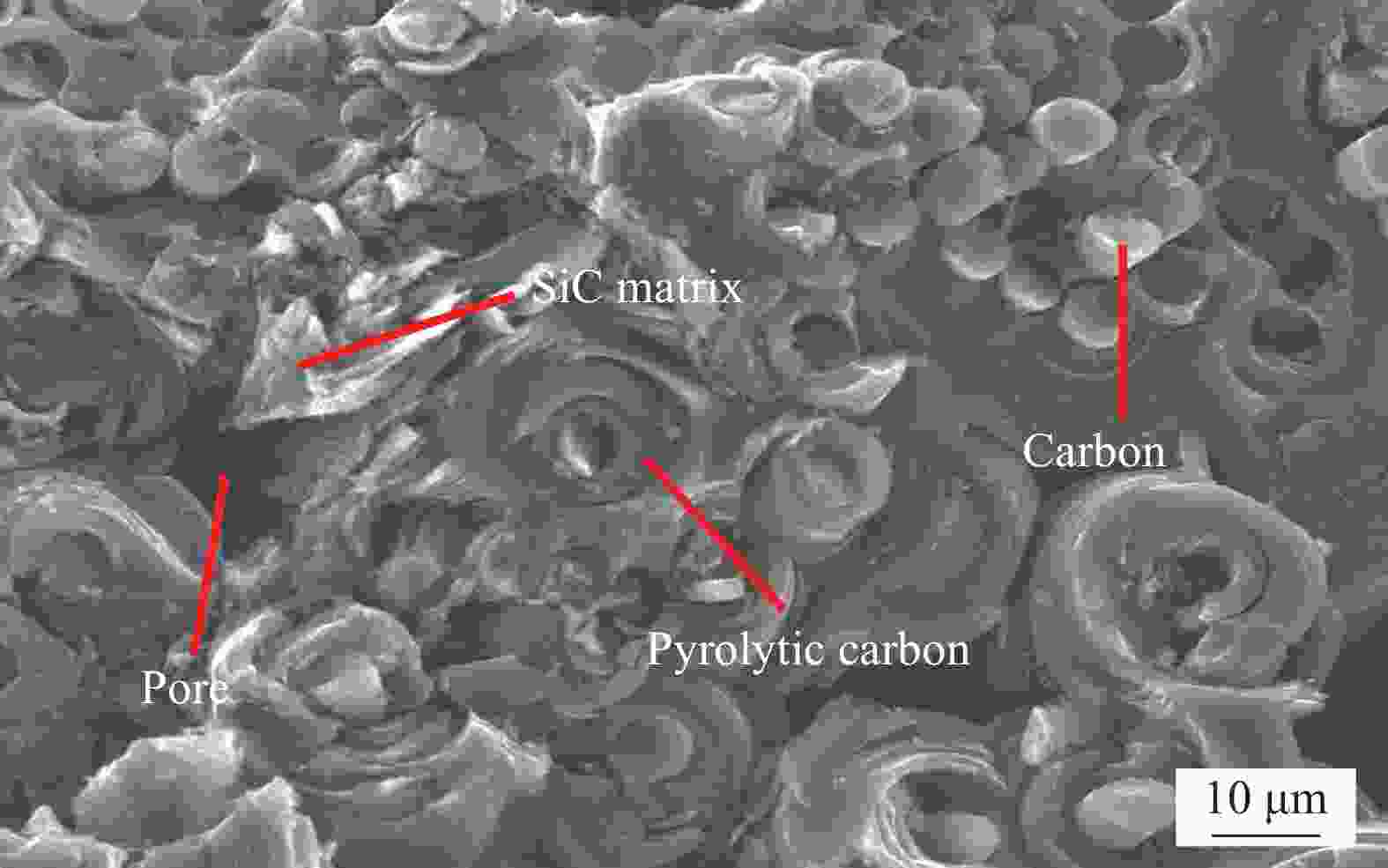

图 7 C/C-SiC复合材料在不同烧蚀时刻的微观形貌:((a)、(b)) 烧蚀10 s后的微观形貌;((c)、(d)) 烧蚀20 s后的微观形貌;((e)、(f)) 烧蚀30 s后的微观形貌;((g)、(h)) 烧蚀40 s后的微观形貌;((i)、(j)) 烧蚀50 s后的微观形貌

Figure 7. Micro-morphologies of C/C-SiC composites at different ablation moments: ((a), (b)) Micro-morphologies after 10 s ablation; ((c), (d)) Micro-morphology after 20 s ablation; ((e), (f)) Micro-morphologies after 30 s ablation; ((g), (h)) Micro-morphologies after 40 s ablation; ((i), (j)) Micro-morphologies after 50 s ablation

图 8 C/C-SiC复合材料轴向与径向纤维在不同烧蚀时刻的微观形貌:((a)、(b)) 烧蚀10 s后的轴向与径向纤维;((c)、(d)) 烧蚀20 s后的轴向与径向纤维;((e)、(f)) 烧蚀30 s后的轴向与径向纤维;((g)、(h)) 烧蚀40 s后的轴向与径向纤维;((i)、(j)) 烧蚀50 s后的轴向与径向纤维

Figure 8. Microscopic morphology for axial and radial fibers of C/C-SiC composites at different ablation time: ((a), (b)) Axial and radial fibers after 10 s ablation; ((c), (d)) Axial and radial fibers after 20 s ablation; ((e), (f)) Axial and radial fibers after 30 s ablation; ((g), (h)) Axial and radial fibers after 40 s ablation; ((i), (j)) Axial and radial fibers after 50s ablation

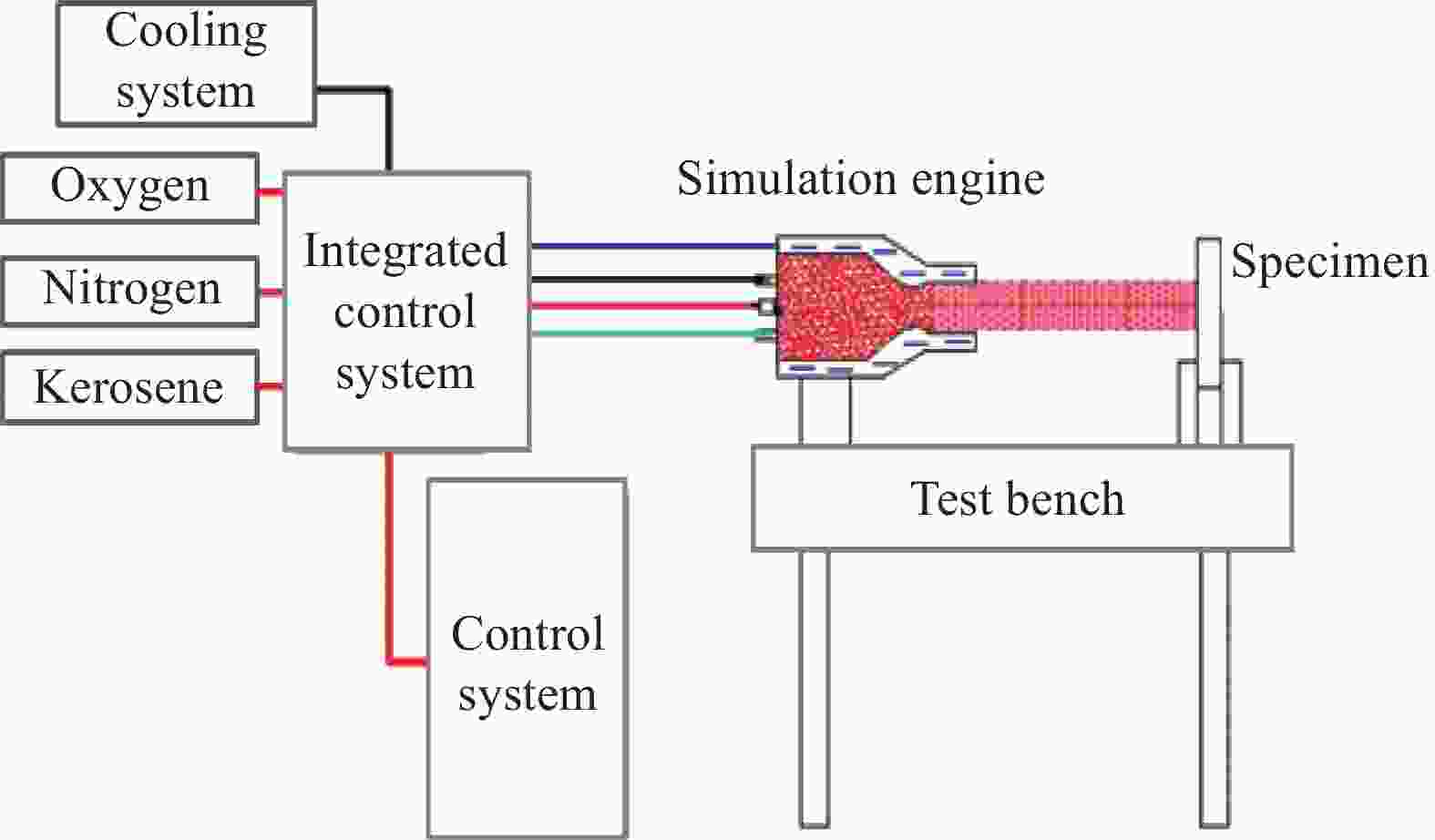

表 1 C/C-SiC复合材料在极端苛刻高超声速富氧环境下的烧蚀试验参数

Table 1. Ablation test parameters of C/C-SiC composites in extremely harsh hypersonic oxygen-enriched environment

Sample Flow of kerosene/

(kg·min−1)Flow of

oxygen/SLMOxygen enrichment

degree/vol%Combustion chamber

pressure/MPaDistance/mm Time/s 1# 0.2 500 5.0 1.00 80 10 2# 0.2 500 5.0 1.00 80 20 3# 0.2 500 5.0 1.00 80 30 4# 0.2 500 5.0 1.00 80 40 5# 0.2 500 5.0 1.00 80 50 Note: SLM—Standard liters per minute. 表 2 针刺C/C-SiC复合材料性能

Table 2. Properties of needle punched C/C-SiC composites

Density/

(g·cm−3)Thermal

conductivity/

(W·m−1·K−1)Compressive

strength/

MPaIn-plane shear

strength/

MPaBending

strength/

MPaTime/s Mass ablation

rate/(g·s−1)Rate of change

in mass ablation

rate/%1.85 10.21 205 18.7 180 10 0.021(~10 s) — 20 0.025(10-20 s) 20.24 30 0.027(20-30 s) 10.83 40 0.026(30-40 s) 5.32 50 0.034(40-50 s) 30.00 -

[1] GLASS D E. Ceramic matrix composite (CMC) thermal protection systems (TPS) and hot structures for hypersonic vehicles[C]//15th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. Dayton, Ohio, 2008: 2682. [2] 李崇俊. X-43A高超声速飞行器C/C热防护涂层结构分析[J]. 高科技纤维与应用, 2015, 40(4):26-40. doi: 10.3969/j.issn.1007-9815.2015.04.004LI Chongjun. Thermal protection coatings of C/C composites in X-43A hypersonic vehicles[J]. Hi-Tech Fiber & Application,2015,40(4):26-40(in Chinese). doi: 10.3969/j.issn.1007-9815.2015.04.004 [3] 王璐, 王友利. 高超声速飞行器热防护技术研究进展和趋势分析[J]. 宇航材料工艺, 2016, 46(1):1-6. doi: 10.3969/j.issn.1007-2330.2016.01.001WANG Lu, WANG Youli. Research progress and trend analysis of hypersonic vehicle thermal protection technology[J]. Aerospace Materials & Technology,2016,46(1):1-6(in Chinese). doi: 10.3969/j.issn.1007-2330.2016.01.001 [4] JOHNSON S M, GASCH M J, LEISER D, et al. Development of new TPS at NASA ames research center[C]//15th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. Dayton, Ohio, 2008: 2560. [5] GLASS D E. Physical challenges and limitations confronting the use of UHTSs on hypersonic vehicles[C]//17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. San Francisco, California, 2011: 2304. [6] WALKER S P, SULLWAN B J. Sharp refractory composite leading edges on hypersonic vehicles[C]. 12th AIAA International Space Planes and Hypersonic Systems and Technologies. Norfolk, VA, 2003: 6915. [7] BOUQUET C, FISCHER R, LARRIEU J M, et al. Composite technologies development status for scramjet applications[C]. 12th AIAA International Space Planes and Hypersonic Systems and Technologies. Norfolk, VA, 2003: 6917. [8] BOUQUET C, FISCHER R, THEBAULT J, et al. Composite technologies development status for scramjet[C]. 13th AIAA/CIRA International Space Planes and Hypersonics Systems and Technologies. Capua, Italy, 2005: 3431. [9] ZHANG L, FU Q G, TAN B Y, et al. Ablation behaviour of C/C and C/C-ZrC-SiC composites with cone-shaped holes under an oxyacetylene flame[J]. Corrosion Science,2016,102:84-92. doi: 10.1016/j.corsci.2015.09.022 [10] LIU L P, YANG L W, ZHAO C H, et al. Oxide-scale evolution and dynamic oxidation mechanism of ZrB2-SiC in high-enthalpy plasma wind tunnel[J]. Journal of the European Ceramic Society,2021,41(7):3911-3921. doi: 10.1016/j.jeurceramsoc.2021.02.006 [11] JIA J H, XIAO J, XIONG D G, et al. Ablation properties of Cf/SiCp-Al self-transpiration cooling composites[J]. Materials Letters,2021,285:129022. doi: 10.1016/j.matlet.2020.129022 [12] SILVA R J, MACIEL H S, ESSIPTCHOUK A M. Comparison of the ablation mechanism of C/C-SiC composite under atmospheric and low pressure[C]. 13th International Ceramics Congress. Montecatini Terme, Italy: Trans Tech Publishers, 2014: 134-139. [13] SHI Y A, ZHA B L, SU Q D, et al. Thermal performance and ablation characteristics of C/C-SiC for thermal protection of hypersonic vehicle[J]. Journal of the European Ceramic Society,2021,41(11):5427-5436. doi: 10.1016/j.jeurceramsoc.2021.03.015 [14] 王玲玲, 嵇阿琳, 黄寒星, 等. 三维针刺C/C-SiC复合材料的烧蚀性能[J]. 固体火箭技术, 2012, 35(4):532-535.WANG Lingling, JI Alin, HUANG Hanxing, et al. Ablation properties of three dimensional needled C/C-SiC composites[J]. Journal of Solid Rocket Technology,2012,35(4):532-535(in Chinese). [15] 王玲玲, 吴玉燕, 嵇阿琳, 等. 固体冲压发动机环境下C/C-SiC喷管的烧蚀行为及重复性使用分析[J]. 复合材料学报, 2017, 34(7):1569-1574.WANG Lingling, WU Yuyan, JI Alin, et al. Ablation behavior and repetitive-use analysis of the C/C-SiC composites nozzle for solid propellant ramjet[J]. Acta Materiae Compositae Sinica,2017,34(7):1569-1574(in Chinese). [16] GLASS D E, CAPRIOTTI D, REIMER T, et al. Testing of DLR C/C-SiC and C/C for HIFiRE 8 scramjet combustor[C]. 19th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. Atlanta, GA, 2014: 3089. [17] SHI Y A, ZHA B L, SU Q D, et al. Effects of oxygen content on the ablation behavior of silicone rubber-based insulation material[J]. International Journal of Aerospace Engineering, 2019, 2019: 6592972. [18] WU X J, YANG J, ZHEN R, et al. Effect of ablation profile structure on plasma ablation performance of needle punched C/C throat lining prepared by CVI+HPIC process[J]. Journal of Inorganic Materials,2020,35(6):654-660. [19] 高勇, 查柏林, 王金金, 等. 固体火箭发动机C/C复合材料烧蚀试验技术研究[J]. 高科技纤维与应用, 2020, 45(4):1-7. doi: 10.3969/j.issn.1007-9815.2020.04.001GAO Yong, ZHA Bailin, WANG Jinjin, et al. Research on ablation test technology of C/C composites in solid rocket motor[J]. Hi-Tech Fiber and Application,2020,45(4):1-7(in Chinese). doi: 10.3969/j.issn.1007-9815.2020.04.001 [20] 喻成璋, 刘卫华. 高超声速飞行器气动热预测技术研究进展[J]. 航空科学技术, 2021, 32(2):14-21.YU Chengzhang, LIU Weihua. Research status of aero- heating prediction technology for hypersonic aircraft[J]. Aeronautical Science & Technology,2021,32(2):14-21(in Chinese). [21] 王亮, 周玲. 基于改进的k-ω-γ转捩模式预测高超声速飞行器气动特性[J]. 空气动力学学报, 2021, 39(3):51-61. doi: 10.7638/kqdlxxb-2019.0146WANG Liang, ZHOU Ling. Prediction of characteristics of hypersonic vehicle by improved k-ω-γ transition model[J]. Acta Aerodynamica Sinica,2021,39(3):51-61(in Chinese). doi: 10.7638/kqdlxxb-2019.0146 [22] 党文伟, 李晓升. 高超声速飞行器烧蚀型防热涂层研究进展[J]. 涂料技术与文摘, 2020, 41(3):33-36.DANG Wenwei, LI Xiaosheng. Research progress in ablative thermal protection coatings for hypersonic vehicle[J]. Coating and Protection,2020,41(3):33-36(in Chinese). [23] 黄礼铿, 胡广军, 胡豹, 等. 固体火箭超燃冲压发动机燃烧试验研究[J]. 固体火箭技术, 2020, 43(5):549-553.HUANG Likeng, HU Guangjun, HU Bao, et al. Experiment on combustion of solid rocket scramjet[J]. Journal of Solid Rocket Technology,2020,43(5):549-553(in Chinese). [24] 王金金. 多相流环境下硅橡胶复合材料烧蚀机理研究[D]. 西安: 火箭军工程大学, 2019.WANG Jinjin. Research on ablation mechanism of silicone rubber composites in multiphase flow environment[D]. Xi'an: Rocket Force University of Engineering, 2019(in Chinese). [25] 尹健, 熊翔, 张红波, 等. 3D C/C复合材料的电弧驻点烧蚀及机理分析[J]. 中南大学学报(自然科学版), 2007, 38(1):14-18. doi: 10.3969/j.issn.1672-7207.2007.01.003YIN Jian, XIONG Xiang, ZHANG Hongbo, et al. Ablation performance and mechanism of 3D C/C composites[J]. Journal of Central South University (Science and Technology),2007,38(1):14-18(in Chinese). doi: 10.3969/j.issn.1672-7207.2007.01.003 -

下载:

下载: