Preparation and anticorrosive performance of covalently functionalized silicon carbide-sulfonated polyaniline/epoxy resin anticorrosive composite coating

-

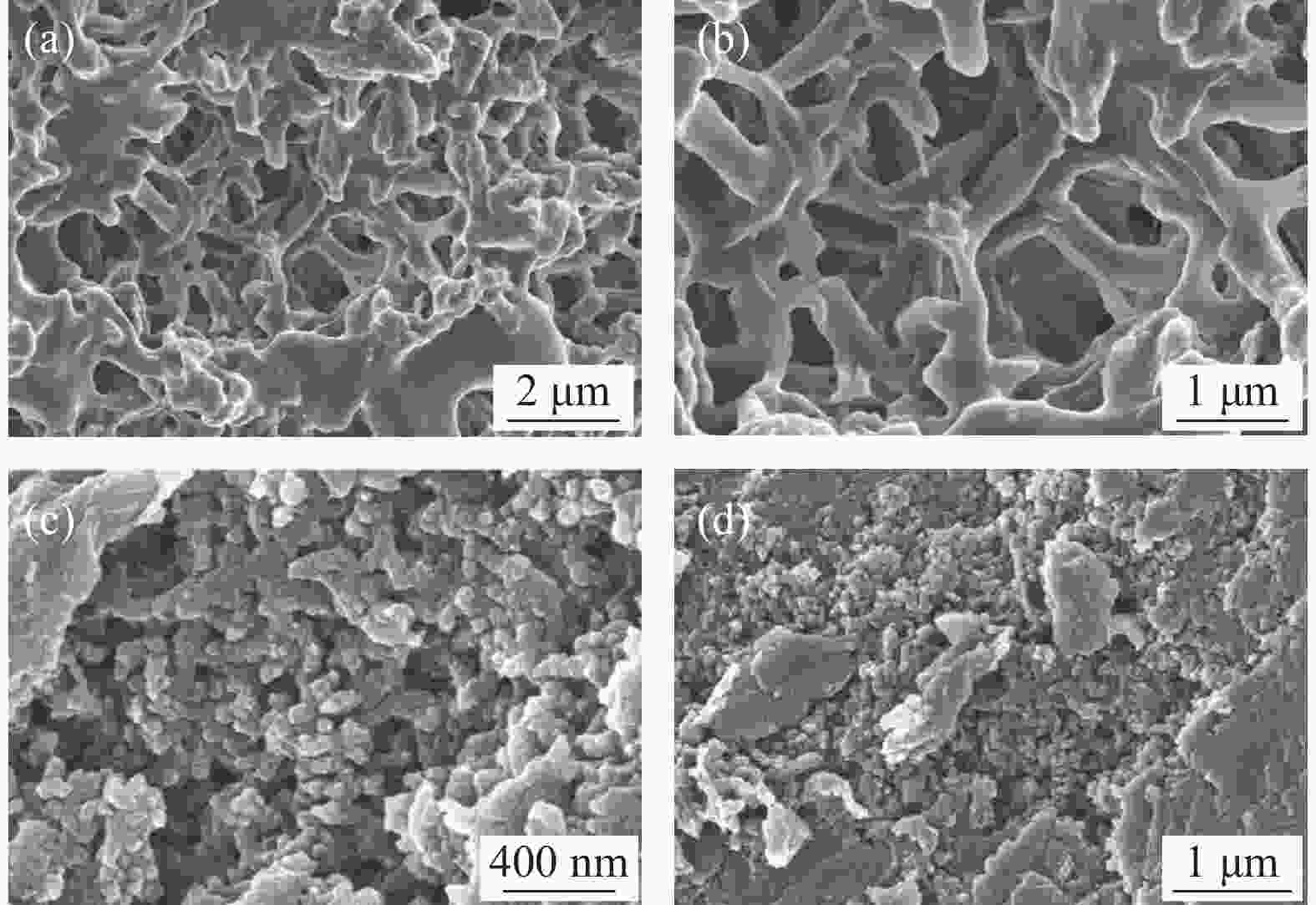

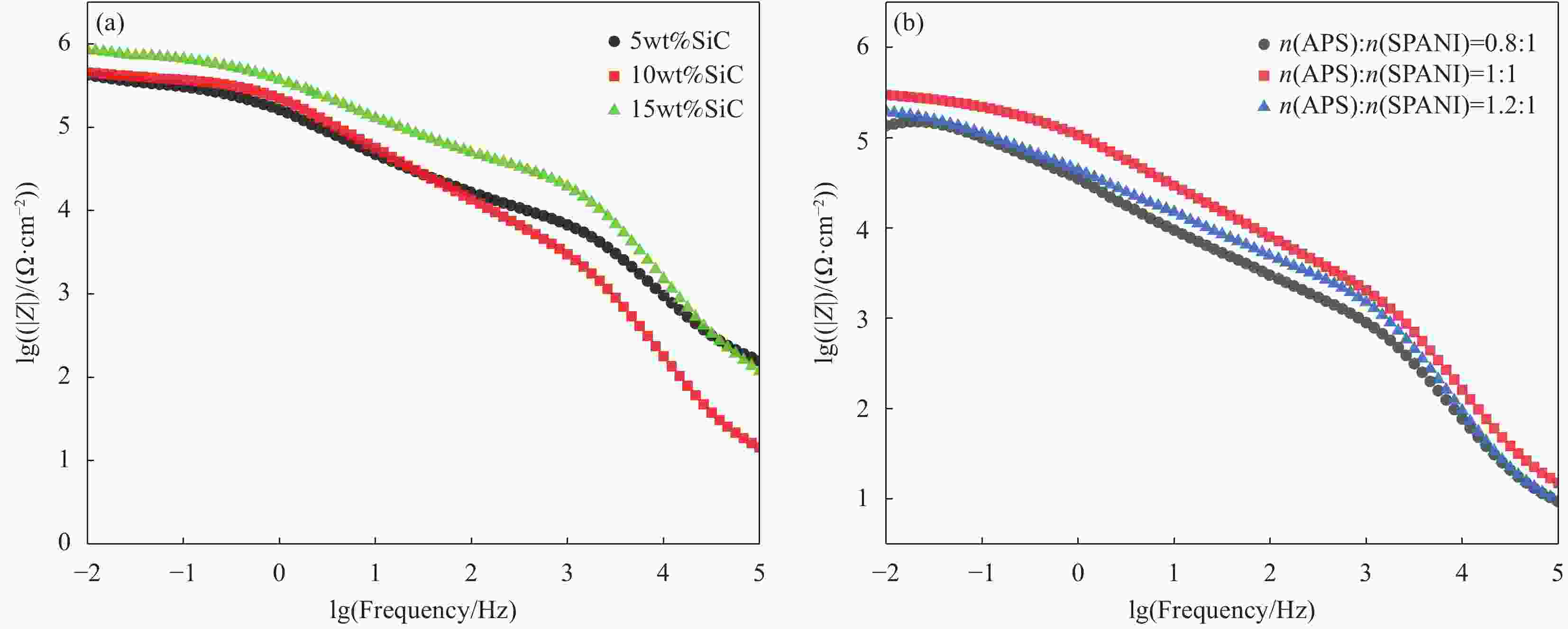

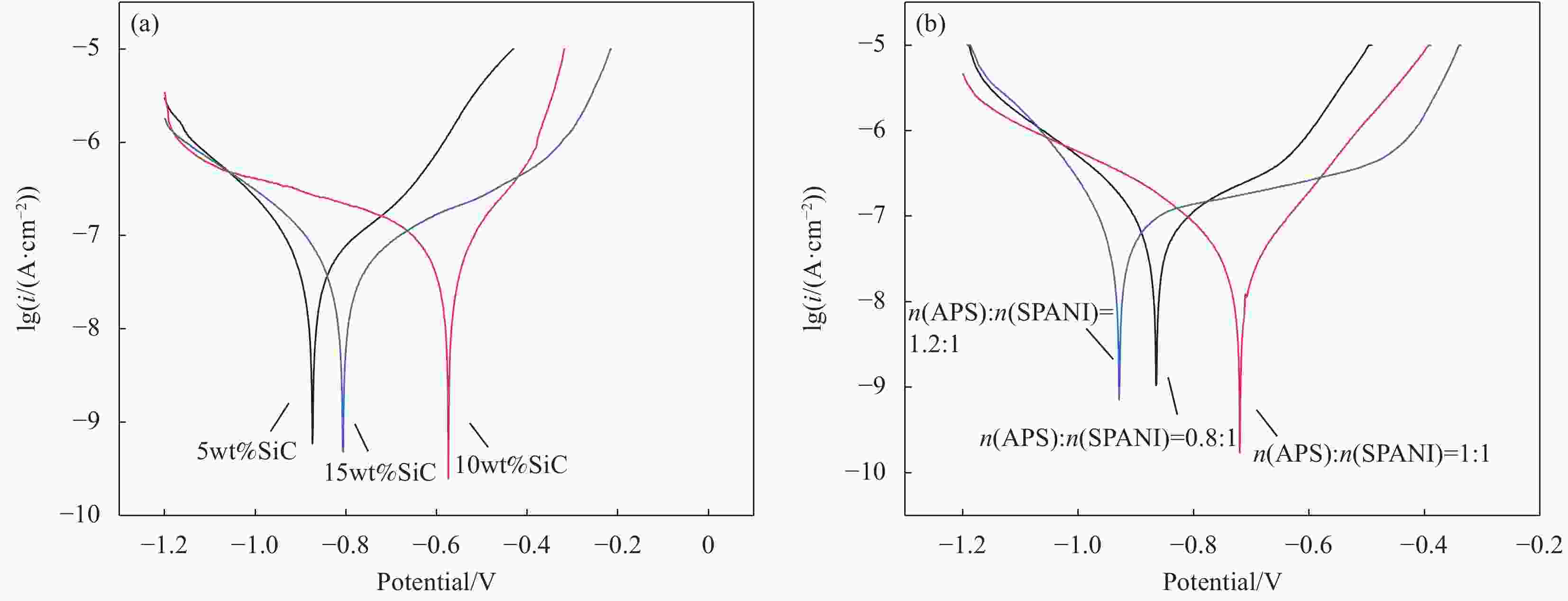

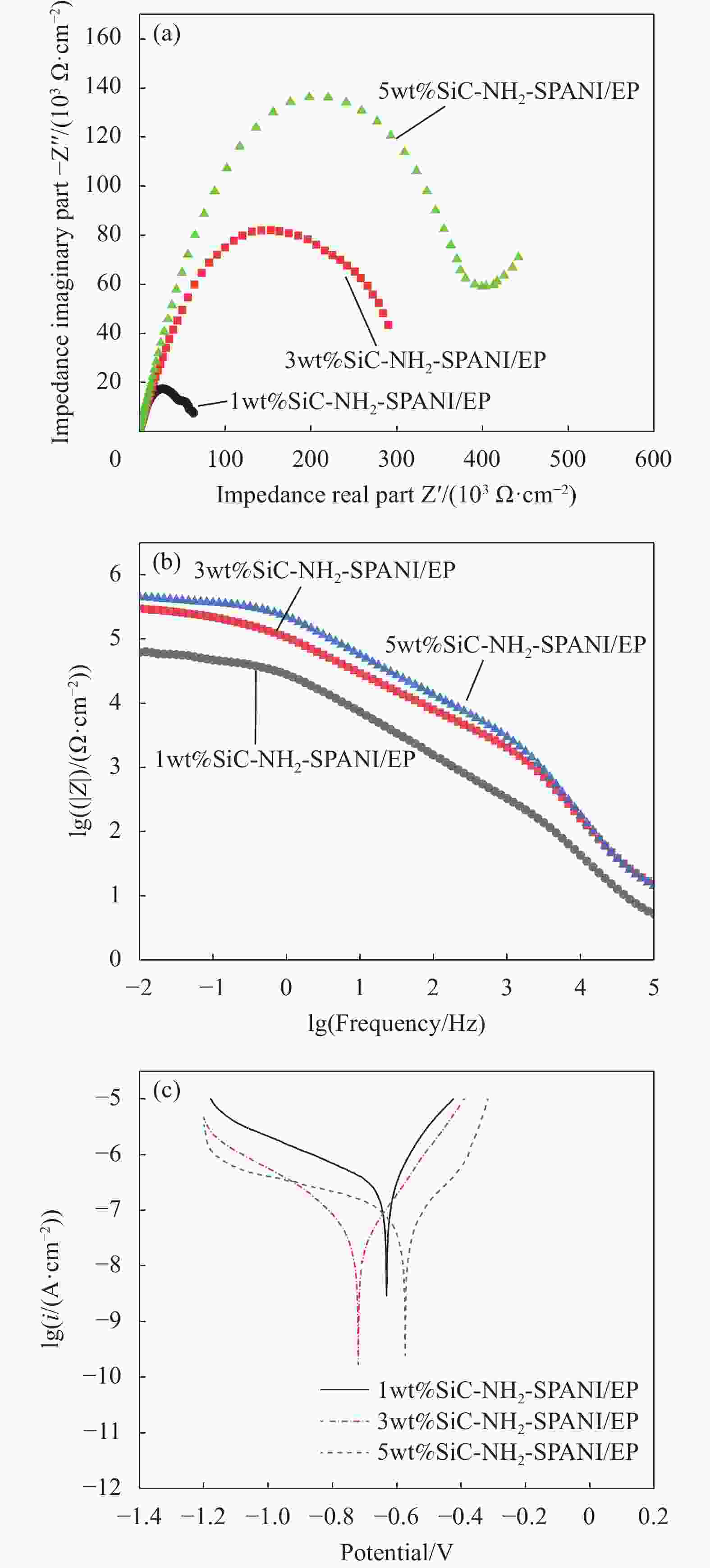

摘要: 聚合物/无机物纳米复合材料由于其独特的性能成为目前材料研究的热点之一。为得到疏水性能及防腐性能俱优的碳化硅 (SiC) 防腐复合涂层材料,利用硅烷偶联剂 (KH-550) 对碳化硅 (SiC) 纳米粒子进行氨基化处理,然后以苯胺、氨基苯磺酸和氨基化SiC纳米粒子为原料,通过一步法氧化聚合反应合成共价功能化碳化硅-磺化聚苯胺 (SiC-NH2-SPANI) 复合材料,采用FT-IR、UV-vis、XRD 和SEM对复合材料的微观结构和形貌进行表征分析。最后通过喷涂法将SiC-NH2-SPANI复合涂层材料涂覆于基材上并对其进行性能测试,主要研究涂层的疏水性能和防腐性能;并探讨了不同SiC纳米粒子和过硫酸铵(APS)的反应量以及复合材料加入量对共价功能化碳化硅-磺化聚苯胺/环氧树脂 (SiC-NH2-SPANI/EP) 防腐复合涂层的影响。研究结果表明,加入质量分数为3wt%SiC-NH2-SPANI的复合涂层具备较优的疏水性能,接触角(CA)值达到99.87°。SiC纳米粒子和过硫酸铵反应量对涂层防腐性能研究结果表明,当SiC-NH2用量为15wt%时,采用过硫酸铵与含氨基单体(苯胺和氨基苯磺酸)摩尔比为1∶1时所制备的SiC-NH2-SPANI/EP涂层的防腐性能最好。掺杂不同材料的复合涂层 (SiC/EP、SiC-NH2/EP和SiC-NH2-SPANI/EP) 中,SiC-NH2/EP涂层的接触角最大,疏水性能最好,防腐性能表现最好。由此也说明涂层疏水性能与防腐性能存在关系,疏水性能越好,防腐性能越好。随浸泡时间增加,质量分数为3wt%SiC-NH2-SPANI/EP复合涂层展现出更优异的长期稳定性和防腐性能。Abstract: Polymer/inorganic nanocomposites have attracted extensive research interests due to their unique properties. In order to obtain SiC composite coating material with excellent hydrophobic and anticorrosive performance, silicon carbide (SiC) nanoparticles were ammoniated by silane coupling agent (KH-550), and then the covalently functionalized SiC-sulfonated polyaniline (SiC-NH2-SPANI) composites were synthesized by one-step oxidative polymerization of aniline, aminobenzenesulfonic acid and aminated SiC nanoparticles, the microstructure and morphology of the composites were characterizated by FT-IR, UV-vis, XRD and SEM. Finally, the SiC-NH2-SPANI epoxy coating was coated on the substrate by spraying method and the hydrophobic and anticorrosion performance of the prepared coating was studied. The effects of the amount of different SiC nanoparticle, ammonium persulfate and the amount of the composite materials on the covalently functionalized silicon carbide-sulfonated polyaniline/epoxy resin anticorrosive composite coating (SiC-NH2-SPANI/EP) was investigated. The results of hydrophobic property show that the contact angle value of the composite coating with 3wt%SiC-NH2-SPANI reaches 99.87°, which is higher than that of the composite coating that used the pristine SiC substituted for SiC-NH2. With regard to the influence of different reaction amount of SiC and ammonium persulfate, the anticorrosion performance of SiC-NH2-SPANI/EP is the best when the mass ratio of 15wt%SiC-NH2 to ammonium persulfate (APS) is 1 : 1. Among the composite coatings doped with different materials (SiC/EP, SiC-NH2/EP and SiC-NH2-SPANI/EP), the SiC-NH2/EP coating has the largest contact angle, the best hydrophobic performance and anticorrosion performance. It also shows that there is a relationship between hydrophobic property and anticorrosion pro-perty and the hydrophobic performance is directly proportional to anticorrosive performance. With regard to the influence of the content of composite coatings, the long-term stability and corrosion resistance are more excellent when the addition of SiC-NH2-SPANI/EP is 3wt%.

-

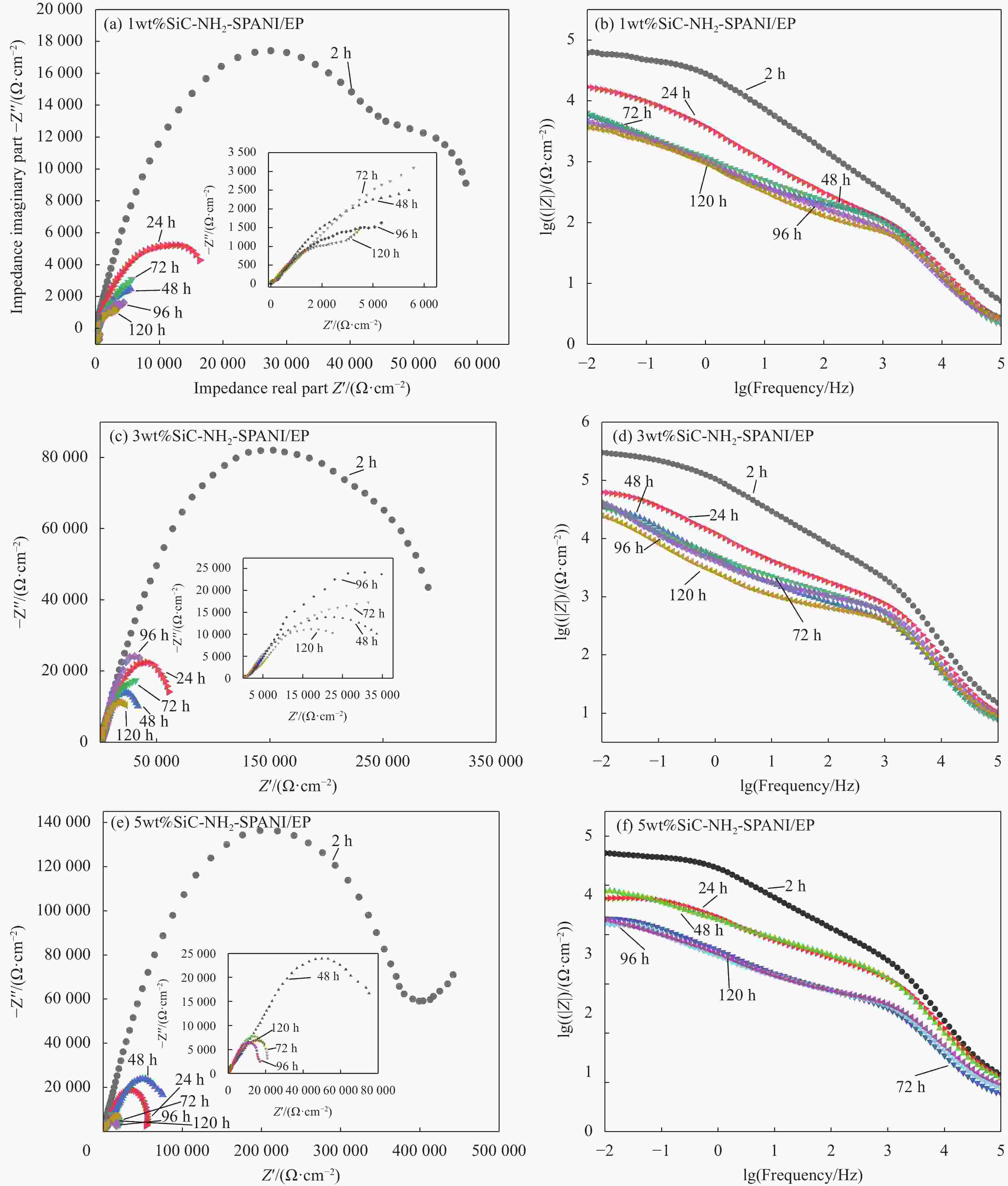

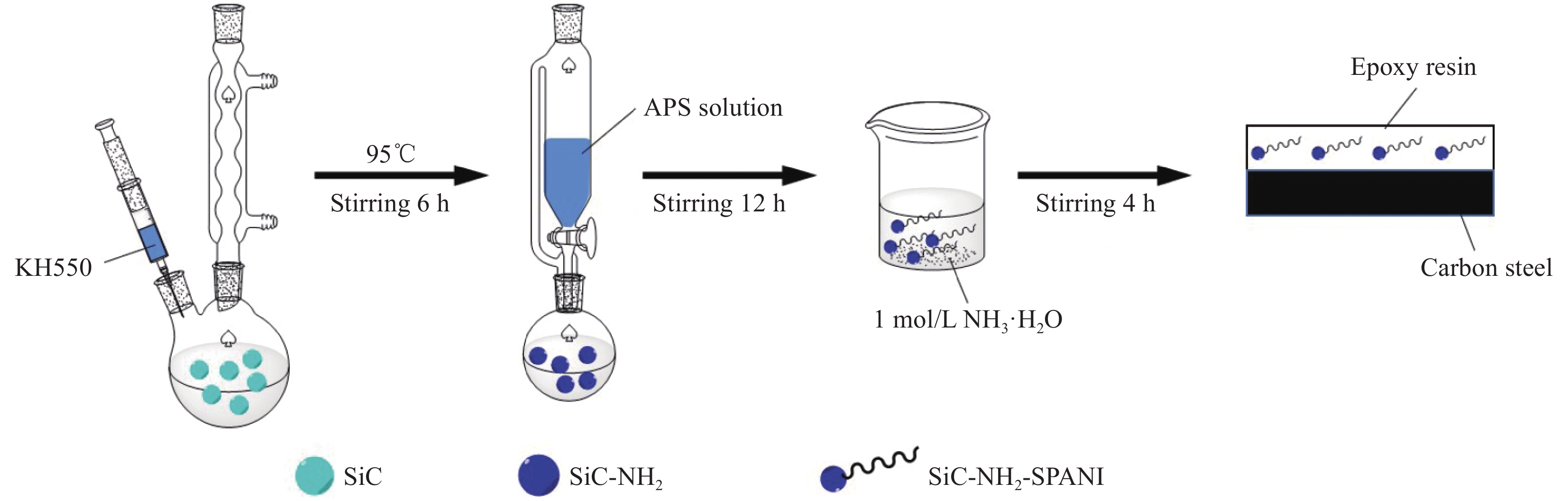

图 1 共价功能化碳化硅-磺化聚苯胺/环氧树脂 (SiC-NH2-SPANI/EP) 防腐复合涂层制备过程示意图

Figure 1. Schematic illustrating process for the preparation of covalently functionalized silicon carbide-sulfonated polyaniline/epoxy resin (SiC-NH2-SPANI/EP) anticorrosive composite coating

APS—Ammonium persulfate; KH550—3-Aminopropyltriethoxysilane

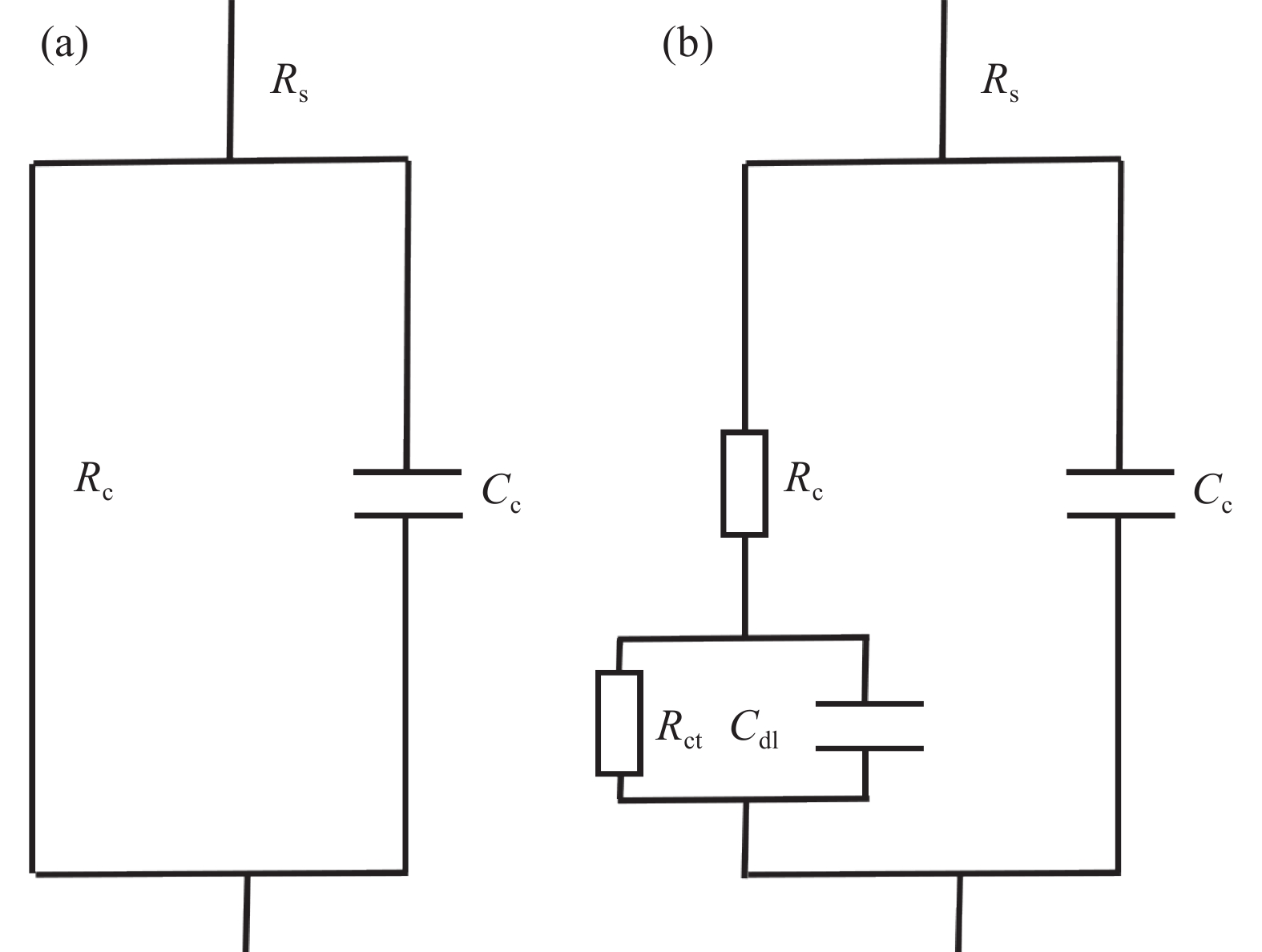

表 1 Q235钢涂覆涂层电极在3.5wt%NaCl溶液中的电化学参数

Table 1. Electrochemical parameters of Q235 steel coated electrode in 3.5wt% NaCl solution

Coating βc/(mV·dec−1) βa/(mV·dec−1) lgic lgia icorr/A Ecorr/V lgicorr Rp/Ω 5wt%SiC 6.505 4.575 −7.386 −7.450 5.023×10−8 −0.869 −7.415 781163 10wt%SiC 4.058 6.501 −7.326 −7.337 6.136×10−5 −0.575 −7.335 671055 15wt%SiC 5.993 4.544 −7.509 −7.548 3.976×10−8 −0.800 −7.531 103779 n(APS) : n(SPANI)=0.8 : 1 6.554 4.432 −7.151 −7.228 9.340×10−8 −0.856 −7.193 423726 n(APS) : n(SPANI)=1 : 1 5.994 8.231 −7.557 −7.700 3.027×10−8 −0.708 −7.598 100981 n(APS) : n(SPANI)=1.2 : 1 9.244 2.803 −7.225 −7.193 7.668×10−8 −0.932 −7.208 470681 Notes: Ecorr—Corrosion potential; icorr—Corrosion current density; βa—Anode slope; βc—Cathode slope; Rp—Polarization resistance; ic , ia—Current density;n : n—Mole ratio. 表 2 三种复合涂层电极在3.5wt%NaCl溶液中的电化学参数

Table 2. Electrochemical parameters of three epoxy-coated electrodes in 3.5wt%NaCl solution

Coating βc/(mV·dec−1) βa/(mV·dec−1) lgic lgia icorr/A Ecorr/V lgi Rp/Ω SiC 6.777 5.852 −7.272 −7.251 6.956×10−8 −0.792 −7.262 494930 SiC-NH2-SPANI 4.058 6.501 −7.326 −7.337 6.136×10−8 −0.575 −7.335 671055 SiC-NH2 5.963 6.663 −7.098 −7.025 1.087×10−7 −0.716 −7.047 319574 表 3 不同含量SiC-NH2-SPANI复合涂层电极在3.5wt%NaCl溶液中的电化学参数

Table 3. Electrochemical parameters of SiC-NH2-SPANI epoxy coated electrodes with different contents in 3.5wt%NaCl solution

Coating βc/(mV·dec−1) βa/(mV·dec−1) lgic lgia icorr/A Ecorr/V lgi Rp/Ω 1wt%SiC-NH2-SPANI 3.170 9.283 −6.656 −6.664 2.780×10−7 −0.634 −6.661 125590 3wt%SiC-NH2-SPANI 5.994 8.231 −7.557 −7.700 3.027×10−8 −0.708 −7.598 100981 5wt%SiC-NH2-SPANI 4.058 6.501 −7.326 −7.337 6.136×10−8 −0.575 −7.335 671055 -

[1] KHODABAKHSHI J, MAHDAVI H. Silica-poly(2-ethyl-2-oxazoline) hairy nanoparticle with high organic content as a material for anticorrosion nanocomposite coatings[J]. Journal of Applied Polymer Science,2021,138(8):49873-49887. doi: 10.1002/app.49873 [2] WANG H, DUAN Y, MA X, et al. Polyisocyanate bridged environmental graphene/epoxy nanocomposite coatings with excellent anticorrosion performance[J]. Progress in Organic Coatings,2021,153:106167. doi: 10.1016/j.porgcoat.2021.106167 [3] JING L V, YUE Q X, DING R, et al. Intelli-gent anti-corrosion and corrosion detection coatings based on layered supramolecules intercalated by fluo-rescent off-on probes[J]. Journal of the Taiwan Institute of Chemical Engineers,2021,118:309-324. doi: 10.1016/j.jtice.2020.12.032 [4] HEJJAJ C, AGHZZAF A, BOUALI I, et al. Layered aluminum tri-polyphosphate as intercalation host for 6-aminohexanoic acid-Synthesis, characterization and application as corrosion protection inhibitor for low carbon steel[J]. Corrosion Science,2021,181:109239. doi: 10.1016/j.corsci.2021.109239 [5] MIN M, WONG J, HONG N. Improvement of anticorrosion coating properties in bio-based polymer epoxy acrylate incorporated with nano zinc oxide particles[J]. Industrial and Engineering Chemistry Research,2020,59(5):1753-1763. doi: 10.1021/acs.iecr.9b05639 [6] YAN G, WANG M, SUN T, et al. Anti-corrosion property of glass flake reinforced chemically bonded phosphate ceramic coatings[J]. Materials,2019,12(13):2082-2095. doi: 10.3390/ma12132082 [7] FAYOMI O, POPOOLA A, KANYANE L R, et al. Development of reinforced in-situ anti-corrosion and wear Zn-TiO2/ZnTiB2 coatings on mild steel[J]. Results in Physics,2017,7:644-650. doi: 10.1016/j.rinp.2017.01.021 [8] GOLABADI M, ALIOFKHAZRAEI M, TOORANI M, et al. Corrosion and cathodic disbondment resistance of epoxy coating on zinc phosphate conversion coating containing Ni2+ and Co2+[J]. Journal of Industrial and Engineering Chemistry,2017,47:154-168. doi: 10.1016/j.jiec.2016.11.027 [9] LI J, GE S, WANG J, et al. Water-based rust converter and its polymer composites for surface anticorrosion[J]. Colloids and Surfaces, A Physicochemical and Engi-neering Aspects,2017,537(20):334-342. [10] LI P, HE X, HUANG T C, et al. Highly effective anti-corrosion epoxy spray coatings containing self-assembled clay in smectic order[J]. Journal of Materials Chemistry A,2015,3:2669-2676. doi: 10.1039/C4TA06221C [11] HAI H, YI H, ZHI H L, et al. Synergistic effect of functional carbon nanotubes and graphene oxide on the anti-corrosion performance of epoxy coating[J]. Polymers for Advanced Technologies,2017,28(6):754-762. doi: 10.1002/pat.3977 [12] LONG C, HUI L, ZHAN Q L, et al. Thermal conductivity and anti-corrosion of epoxy resin based composite coatings doped with graphene and graphene oxide[J]. Composites Part C: Open Access,2021,5:100124. doi: 10.1016/j.jcomc.2021.100124 [13] MOUSTAFA E B, TAHA M A. Evaluation of the micro-structure, thermal and mechanical properties of Cu/SiC nanocomposites fabricated by mechanical alloying[J]. International Journal of Minerals, Metallurgy and Materials,2021,28(3):475-486. doi: 10.1007/s12613-020-2176-z [14] KUKUSHKIN S A, OSIPOV A V. The optical properties, energy band structure, and interfacial conductance of a 3C-SiC(111)/Si(111) heterostructure grown by the method of atomic substitution[J]. Technical Physics Letters,2020,46(11):1103-1106. doi: 10.1134/S1063785020110243 [15] ZHANG Y, ZHOU J, XIE Y, et al. Dual-mode hybrid quasi-SAW/BAW resonators with high effective coupling coefficient[J]. Instituteof Electrical and Electronics Engineers,2020,67(9):1916-1921. [16] JING L, OUCHUAN L, CHENG C, et al. Fabrication of a Ni/SiC composite coating on steel surface with excellent corrosion inhibition performance[J]. Journal of Materials Processing Technology,2020,290:116987. [17] QIN C H, HE J L, XUE M Y, et al. Effects of PyC shell thickness on the microstructure, ablation resistance of SiCnws/PyC-C/C-ZrC-SiC composites[J]. Journal of Materials Science and Technology,2021,71(30):55-66. [18] FAZLI-SHOKOUHI S, NASIRPOURI F, KHATAMIAN M. Epoxy-matrix polyaniline/p-phenylenediamine-functionalised graphene oxide coatings with dual anti-corrosion and anti-fouling performance[J]. RSC Advances,2021,11(19):11627-11641. doi: 10.1039/D0RA10665H [19] SWATI G, HARIOM G, PRAFULLA K J, et al. Enhanced electrochemical performance of stable SPES/SPANI composite polymer electrolyte membranes by enriched ionic nanochannels[J]. ACS Omega,2017,2(9):5831-5839. doi: 10.1021/acsomega.7b00687 [20] WANG H H , PAN Z, GUI Q F, et al. Design and properties of environmental anticorrosion coating based on m-aminobenzenesulfonic acid/aniline/p-phenylenediamine terpolymer[J]. Progress in Organic Coatings,2019,137(3):105274-105274. [21] NIU F X, WANG Y X, ZHANG Y T, et al. A hierarchical architecture of PANI/APTES/SiC nano-composites with tunable dielectric for lightweight and strong microwave absorption[J]. Journal of Materials Science,2019,54(3):2181-2193. doi: 10.1007/s10853-018-2957-1 [22] SHARIQUE A, ADIL S, FAIZ M. Rapid response and excellent recovery of a polyaniline/silicon carbide nanocompo-site for cigarette smoke sensing with enhanced thermally stable DC electrical conductivity[J]. RSC Advances,2016,6:59728-59736. doi: 10.1039/C6RA12655C [23] 段俊, 欧宝立, 郭艳. 共价功能化POSS/PDMS防腐复合涂层的研究[J]. 功能材料, 2021, 52(3):3115-3121. doi: 10.3969/j.issn.1001-9731.2021.03.017DUAN Jun, OU Baoli, GUO Yan. Research on covalent functionalized POSS/PDMS anticorrosive composite coating[J]. Journal of Functional Materials,2021,52(3):3115-3121(in Chinese). doi: 10.3969/j.issn.1001-9731.2021.03.017 [24] 汪雨微, 欧宝立, 鲁忆, 等.功能化纳米TiO2/环氧树脂超疏水防腐复合涂层的制备与性能[J]. 复合材料学报, 2021, 38(12): 3971-3985.WANG Yuwei, OU Baoli, LU Yi, et al. Preparation and pro-perties of functionalized nano-TiO2/epoxy resin super hydrophobic anticorrosive composite coating[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 3971-3985(in Chinese). -

下载:

下载: