Small angle X-ray scattering in polymers and polymer composites

-

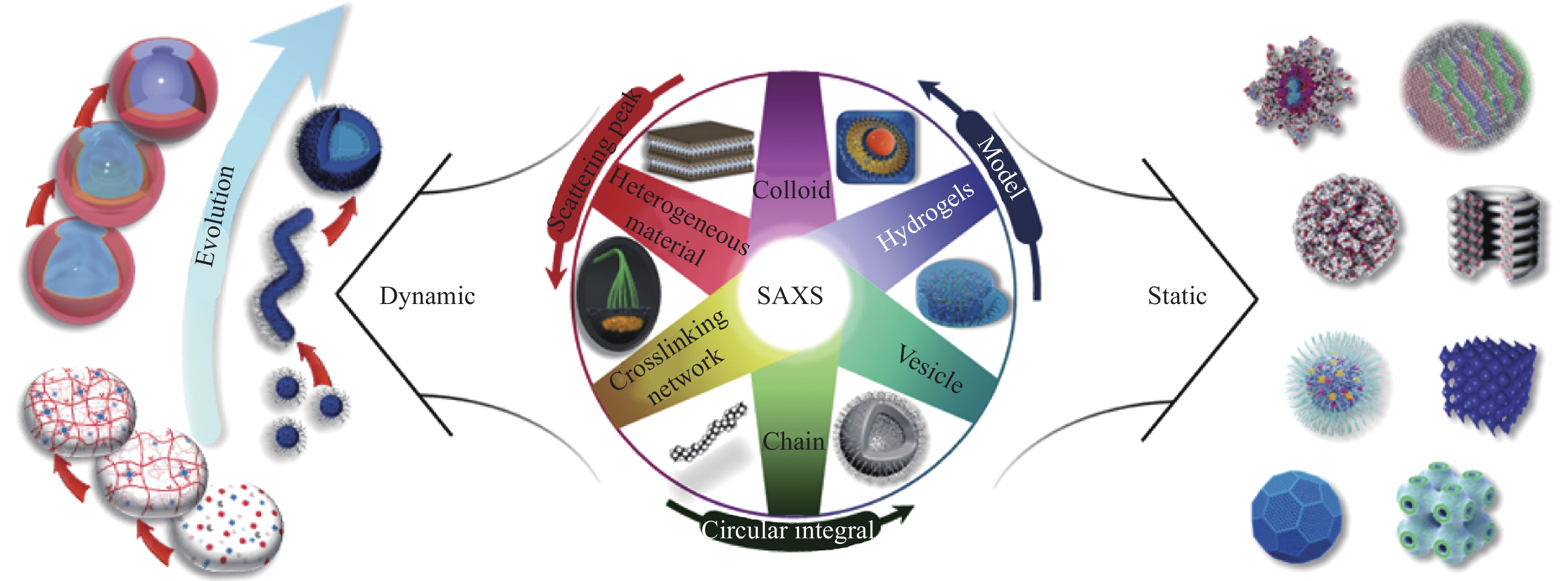

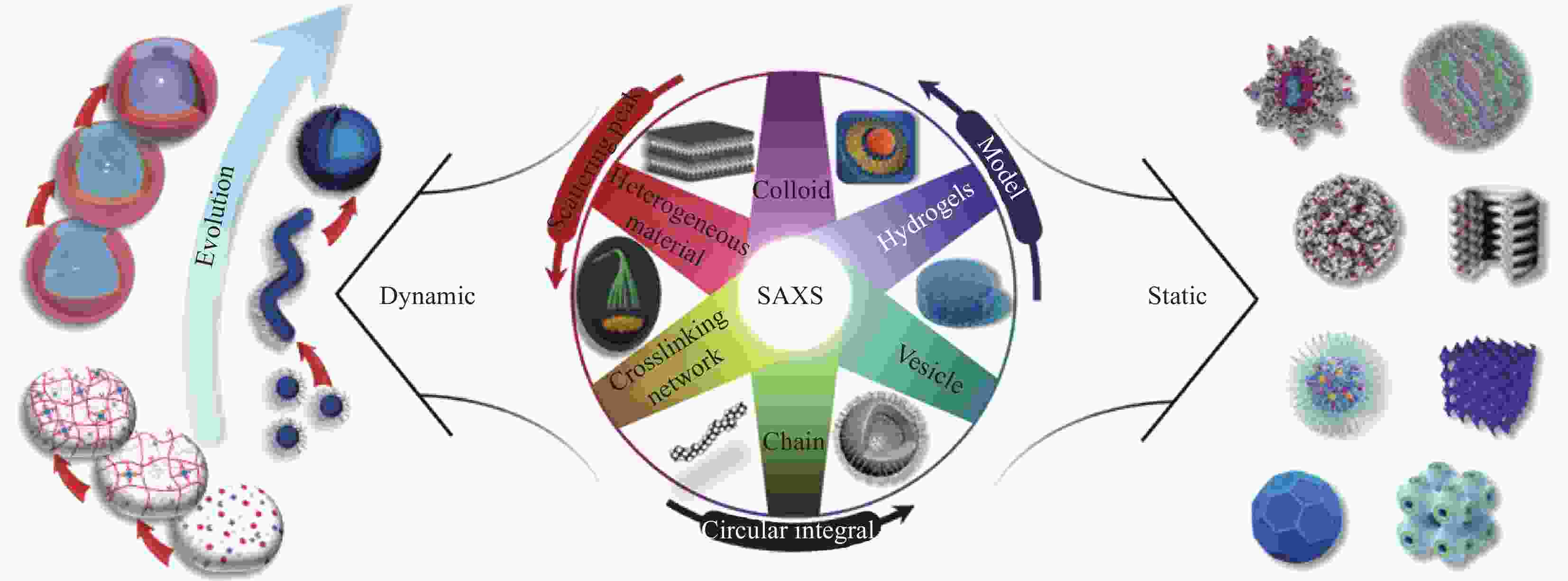

摘要: 在聚合物及其复合材料的合成过程中,实时、动态的观察材料结构的演变并且为性能预测提供启示是当前研究的热点并且面临一定的挑战。小角X射线散射(Small angle X-ray scattering,SAXS)技术作为研究物质微观、亚微观结构的表征手段之一,能够反应出独特的微观构象信息,并且能系统地研究链状、网状、层状高聚物的形貌特征及其形成过程,这对聚合物及其复合材料聚集态结构形成的机制解析、宏观性能预测至关重要。本文从高分子聚合物SAXS研究中常见的峰值观测、模型拟合、环形积分3种方法切入,阐述SAXS在聚合物及其复合材料,特别是天然高聚物材料研究中发挥的实际应用,如动态观测微观结构演变过程、在大范围内获得具有统计学意义的微观结构特征与平均参数。通过对SAXS在聚合物及其复合材料中应用的归纳,总结出SAXS技术在该领域的优势与面临的困难,方便明确不同种类的聚合物及其复合材料研究中SAXS可表征的内容,以期让这一表征技术能够解决更多实际问题。

-

关键词:

- 小角X射线散射(SAXS) /

- 聚合物及其复合材料 /

- 演变过程 /

- 形成机制 /

- 微观构象

Abstract: In the synthesis of polymers and polymer composites, it is still a challenge to observe the real-time and dynamic evolution of material structure and provide implications for property prediction. As one of the methods to characterize the microscopic and submicroscopic structures of substances, small angle X-ray Scattering (SAXS) technology can reflect unique microscopic conformational information, and can systematically study the morphological characteristics and formation process of chain-like, network-like, and layered polymers. The analysis of the formation mechanism of the aggregated structure of molecular materials, and their macroscopic performance prediction are very important. In this paper, three common methods for SAXS applications in current polymer materials research were presented, i.e., the peak observation, the model fitting, and the annular integration. Based on the above three methods, this paper introduced the practical functions of SAXS in studying different polymer materials, such as dynamic observation of the microstructural evolution process, and obtaining large-scale and statistically significant microstructural parameters. After comparing and evaluating the application methods and influences of SAXS in different polymer materials, it was concluded that SAXS plays a comprehensive role that is difficult to replicate in the study of complex polymer materials. It was hoped that this paper could serve as a primer to attract researchers' attention to understand SAXS technology, provide alternative research methods for the investigation of complex polymers, and expand the application of SAXS in wider fields to solve more problems. -

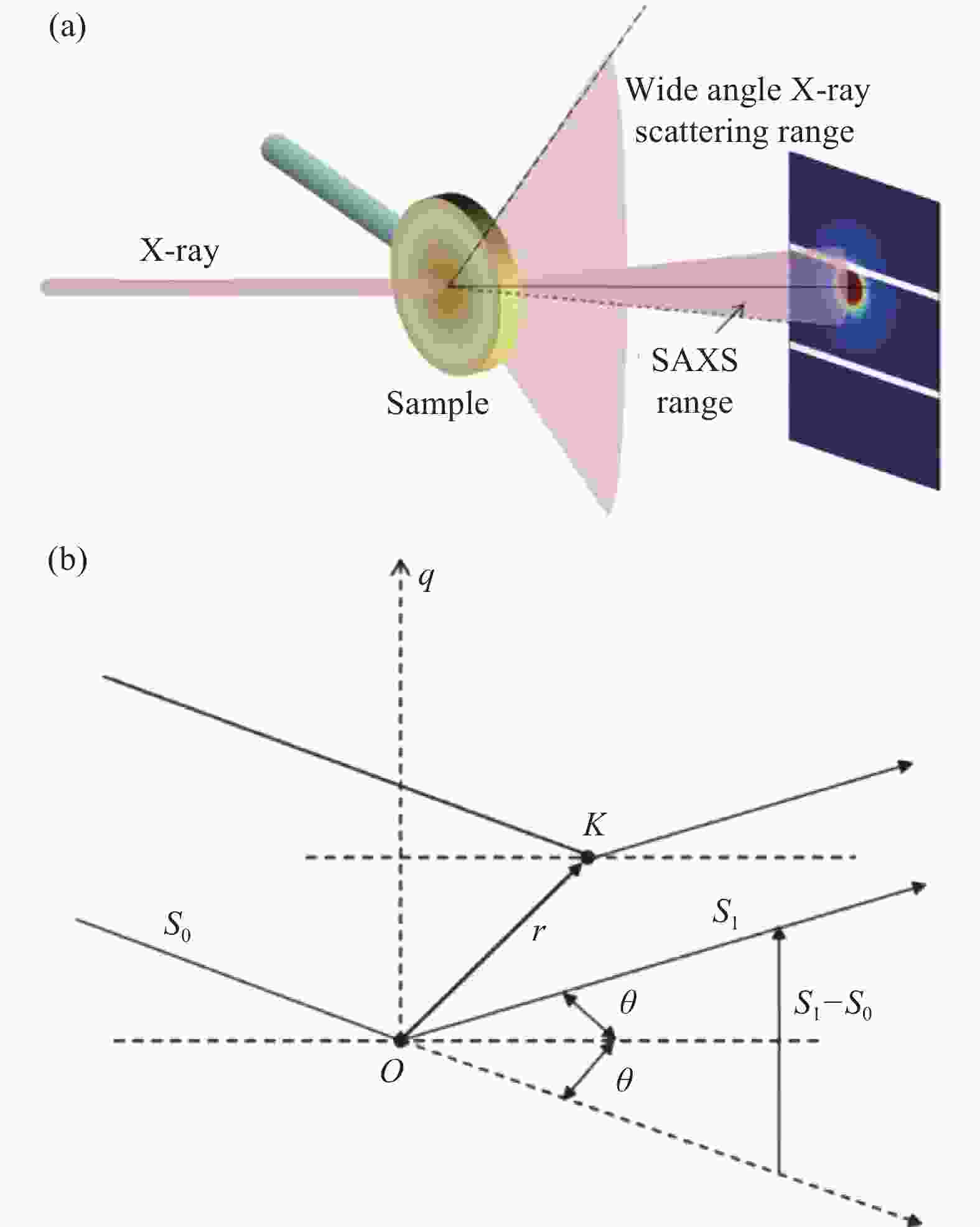

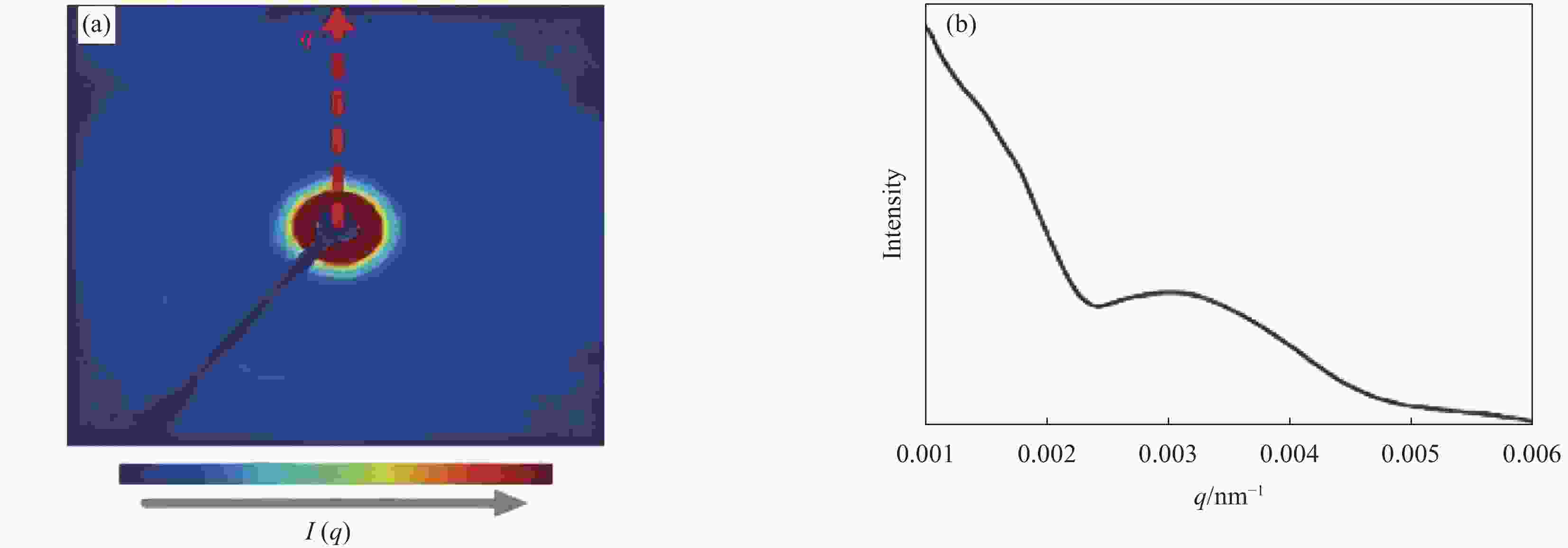

图 2 SAXS原理图:(a)穿透样品后的X射线;(b)小角度X射线散射显微图

S0 and S1—Wave vectors of the incident and scattered X-rays; θ—Angle; K point—Electron with the bit vector r from the O point; q—Scattering vector

Figure 2. Principle diagram of the SAXS: (a) X-rays after penetration of the sample; (b) Microscopic diagram of small angle X-ray scattering

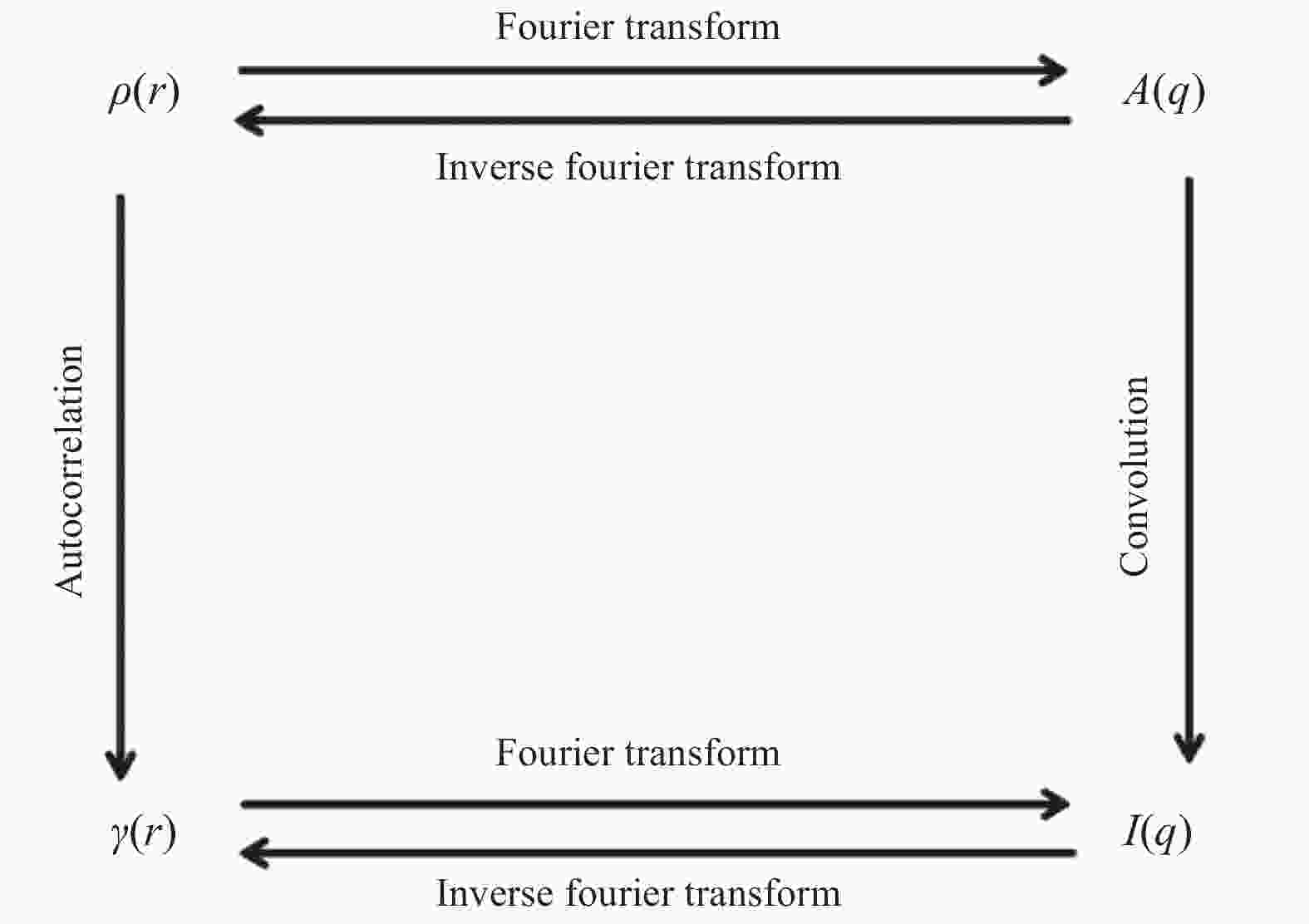

图 3

$ \rho {(}{r}{)} $ 、$ \gamma {(}{r}{)、}\;{}{A}{(}{q}{)} $ 和$ {I}{(}{q}{)} $ 之间的转化关系ρ(r)—Electron density; γ(r)—Autocorrelation function of electron density ρ(r); I(q)—Scattering intensity; A(q)—Sum of the amplitudes at each position

Figure 3. Relationships among

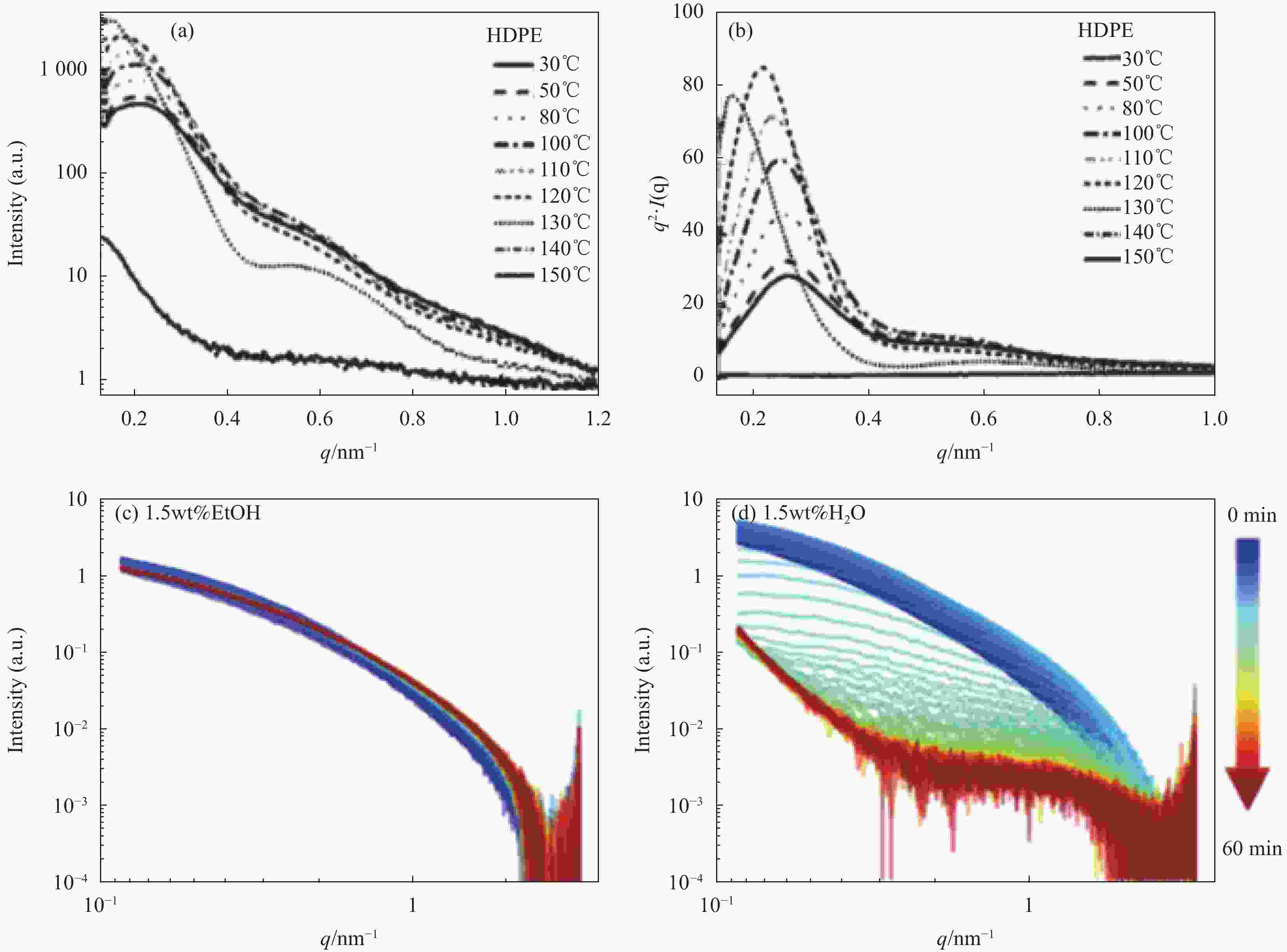

$ \rho {(}{r}{)} $ ,$ \gamma{(}{r}{),}\;{}{A}{(}{q}{)} $ and$ {I}{(}{q}{)} $ 图 5 峰值观测法观察的SAXS一维曲线:(a) 不同温度下HDPE的SAXS一维曲线;(b) 不同温度下HDPE的SAXS一维曲线的洛伦兹校正图[31];(c) 低浓度纤维素乙醇凝胶珠干燥过程的SAXS曲线;(d) 低浓度纤维素水凝胶珠干燥过程的SAXS曲线[32]

HDPE—High density polyethylene

Figure 5. SAXS 1D curves observed by the peak observation method: (a) SAXS 1D curves of HDPE at different temperatures; (b) Lorentz correction of SAXS measurements of HDPE at different temperatures[31]; (c) SAXS 1D curve of low concentration cellulose ethanol gel during the drying process; (d) SAXS 1D curve of low concentration cellulose hydrogel bead gel during the drying process[32]

图 6 环形积分法示意图:(a) 各向异性散射体的形态示意;(b) 各向异性散射体的SAXS散射图像;(c) 环形积分后各向异性散射体的一维曲线

D—Scatterer width; L—Scatterer length; φ—Orientation angle of the scatterer

Figure 6. Schematic diagram of the annular integration method: (a) Existence of anisotropic scatterers; (b) Scattering image of anisotropic scatterers; (c) 1D curve of anisotropic scatterers after circular integration

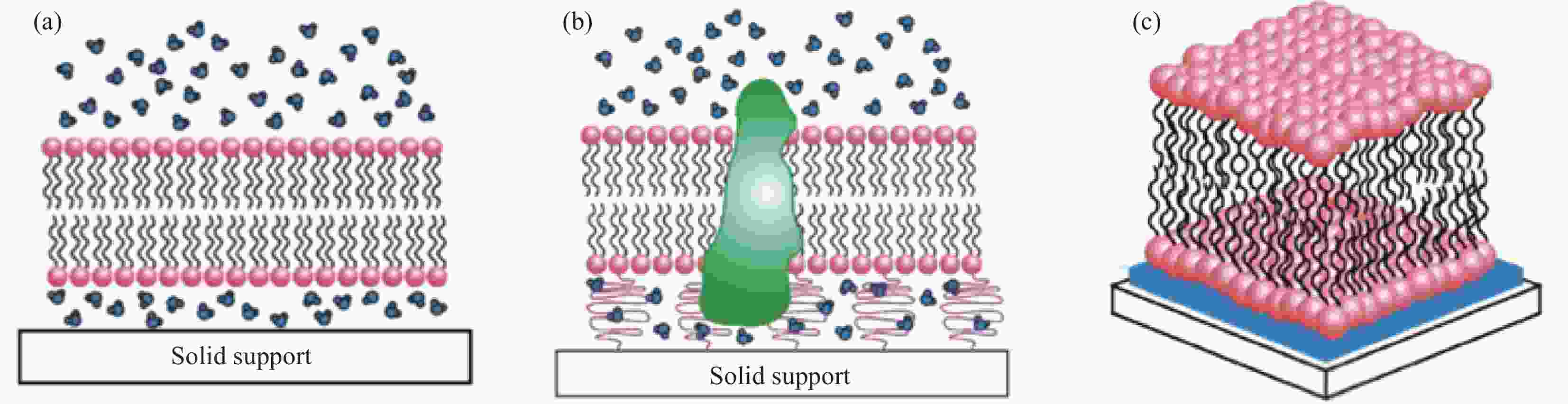

图 7 脂质聚合膜示意图:(a) 水相中脂质膜的形成过程;(b) 脂质膜与底物接触时的状态;(c) 水相中脂质膜的三维结构示意[49]

Figure 7. Schematic diagram of lipid polymeric membrane: (a) Formation of a lipid membrane in an aqueous phase; (b) State of the lipid membrane when in contact with the substrate; (c) 3D structure of lipid membrane in the aqueous phase[49]

图 9 嵌段共聚物研究中所涉及的概念及设备示意图:(a) 临界堆积参数P的计算方法及P的大小与嵌段共聚物微观形貌间的关系;(b) 原位SAXS测试实验装置[63];(c) 不同聚合程度的嵌段共聚物微观形貌模拟示意图[62]

P—Critical packing parameter; V—Volume; lc—Length; a0—Effective are

Figure 9. Concepts and equipment diagram of block copolymer part: (a) Critical packing parameter P calculation method, relationship between P and morphology of block copolymer; (b) In situ SAXS experimental device[63]; (c) Schematic diagram of the microstructure of block copolymer at different degrees of polymerization[62]

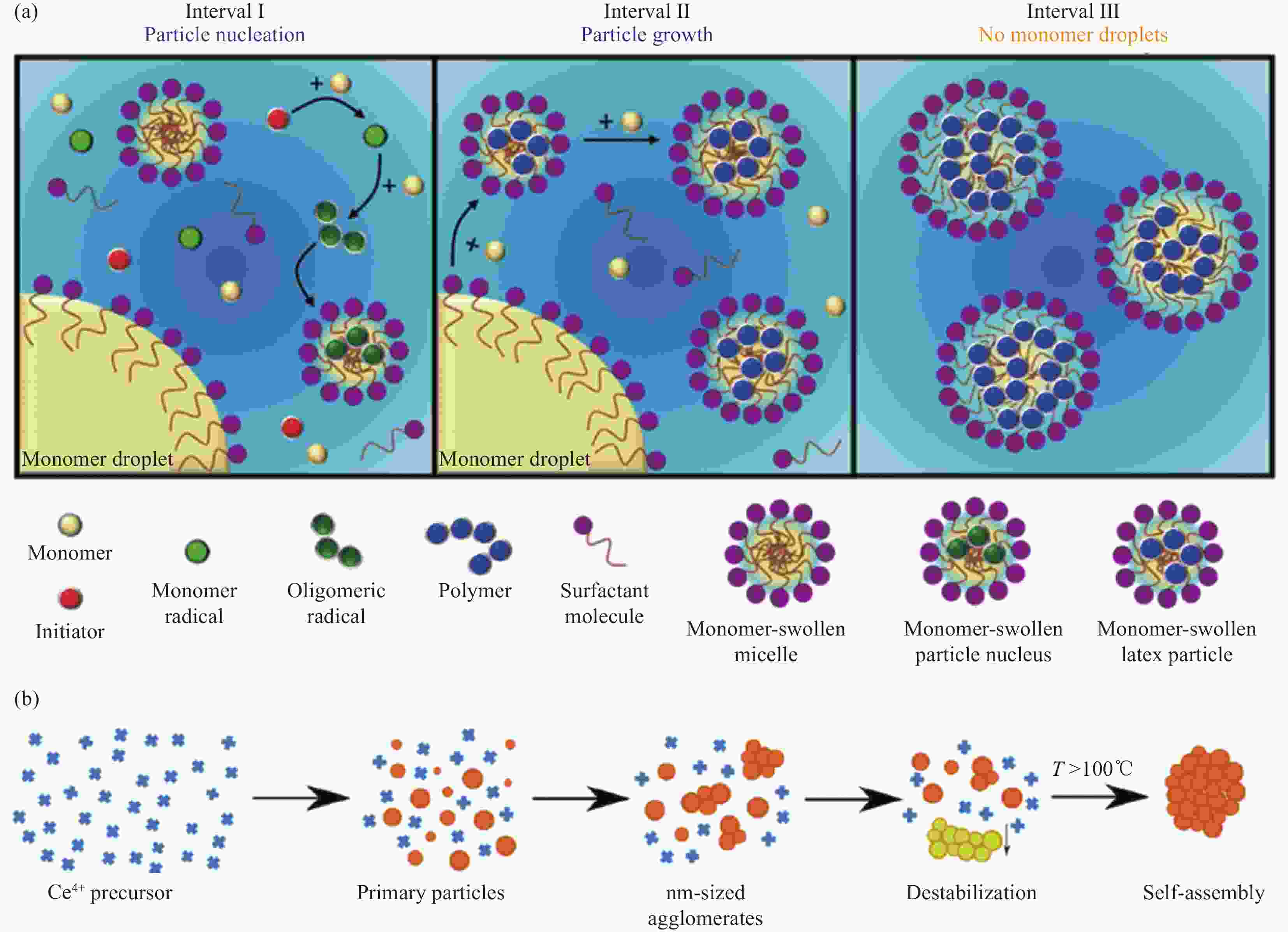

图 8 水乳液聚合和胶体聚合机制示意图:(a) 水乳液聚合过程中疏水相单体聚合的3个阶段[52];(b) 氧化铈胶体形成团聚体的形成机制[53]

T—Temperature

Figure 8. Schematic diagram of water emulsion polymerization and colloid polymerization mechanism: (a) Representation of the three main intervals (I, II, and III) that occur during the aqueous emulsion polymerization of a water-immiscible monomer[52]; (b) Formation mechanism of colloidal aggregates of cerium oxide[53]

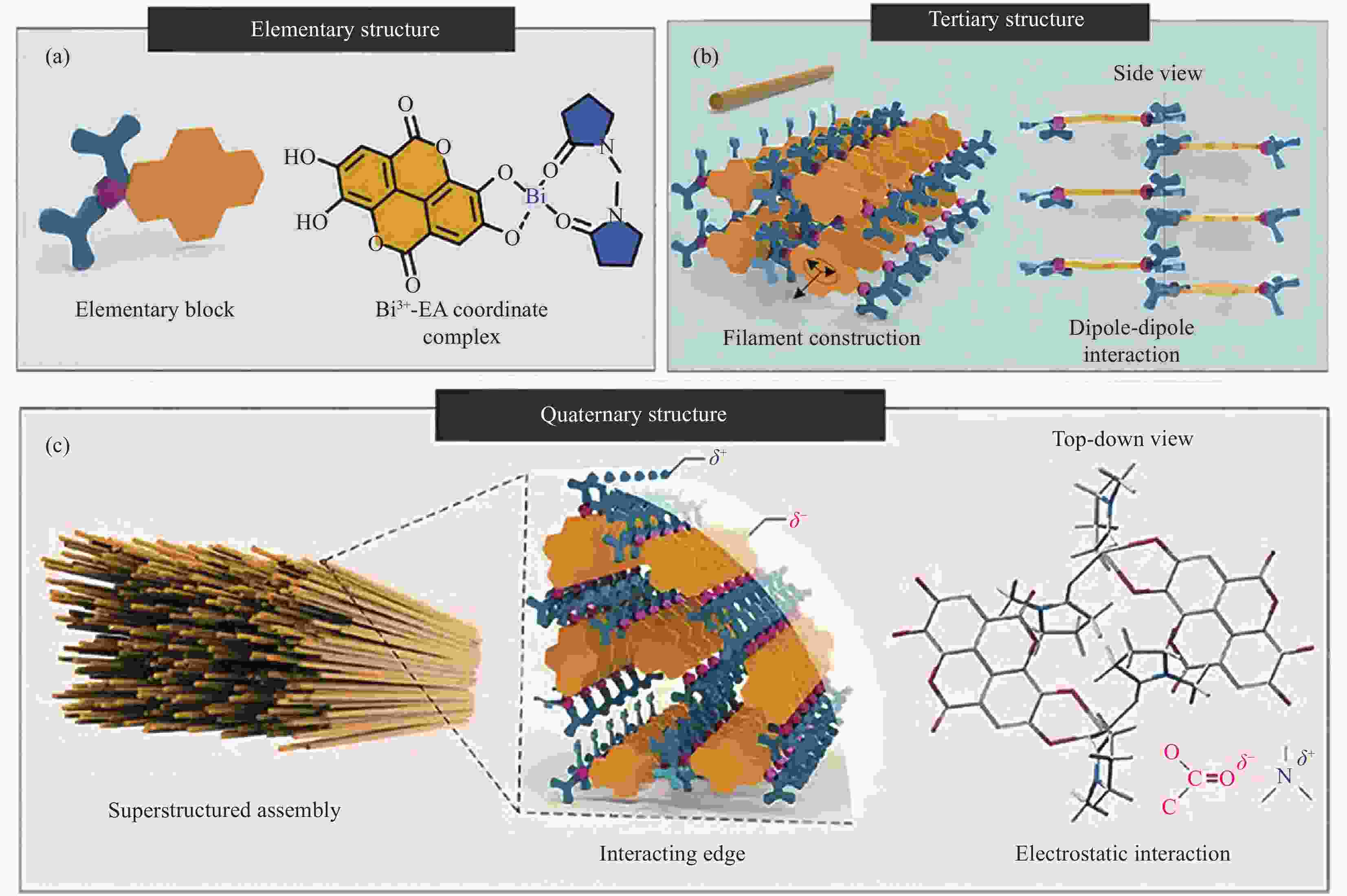

图 10 多级介晶各级结构示意图:(a) Bi3+、EA和NMP合成的基本结构;(b) 由基础结构经过偶极-偶极相互作用所形成的细长纳米丝;(c) 纳米细丝间通过静电作用形成的Bi-EA介晶结构[64]

Figure 10. Schematic diagram of each level of multistage structure monocrystals: (a) Basic structure of Bi3+, EA, and NMP synthesis; (b) Nanofilaments formed by dipole-dipole interaction of the infrastructure; (c) Bi-EA mesocrystals formed by electrostatic action of the filaments[64]

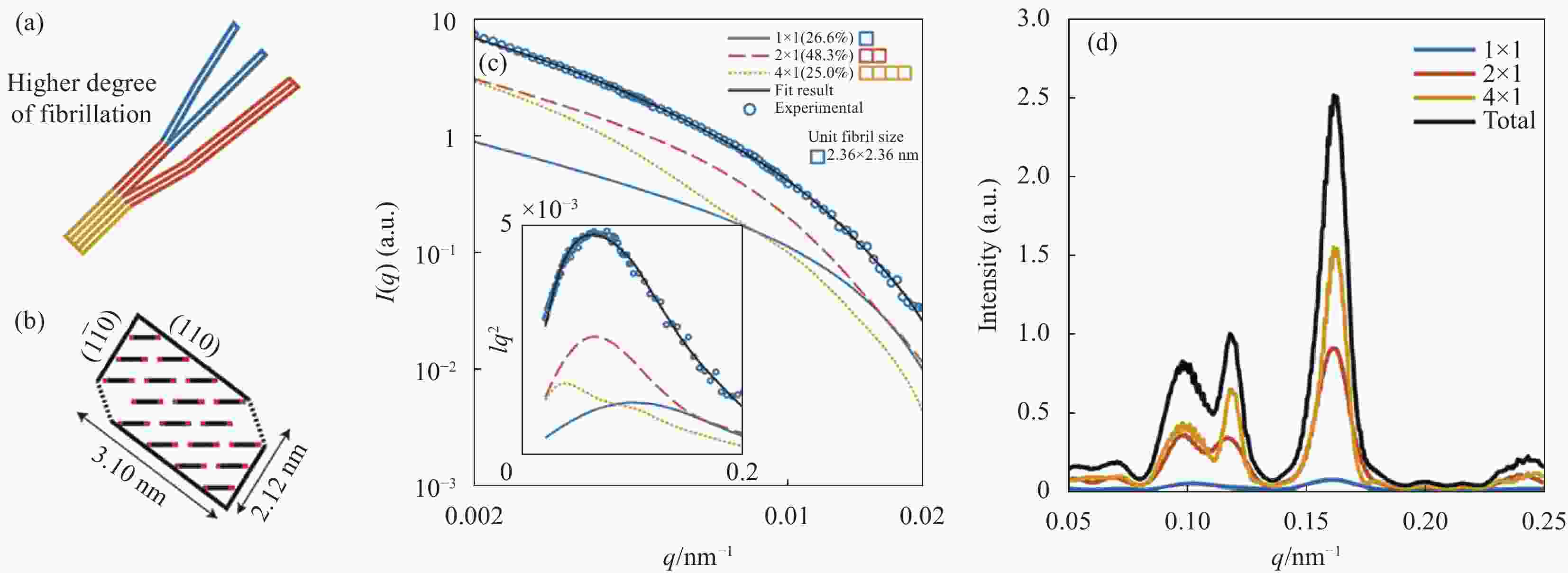

图 11 纤维素纳米纤维(CNF)模型示意图、模拟和实际测试所得到的SAXS数据:(a) 符合理想假设的CNF模型;(b) CNF横切面上主平面与晶体平面示意图;(c) 实测的单根CNF的SAXS一维曲线、模拟CNF的SAXS曲线及三者对强度的贡献曲线;(d) 实验测量3种组分CNF在广角X射线衍射(WAXD)中对散射强度的贡献情况[66]

Figure 11. Schematic diagram of cellulose nanofibers (CNF) ideal model with simulation and actual experimental data: (a) CNF model schematic diagram; (b) Relation between the principal plane and crystal plane on the CNF cross-section; (c) Measured SAXS 1D curve , the simulated SAXS 1D curve , and the contribution of the three parts to the strength; (d) Experimentally measured wide-angle X-ray diffraction (WAXD) curve and the contribution of scattering intensity in three-part WAXD[66]

图 12 部分天然材料中的组织结构分布图:(a) 毛竹显微CT重建切片影像,1区域为维管束区,2区域为薄壁组织区;(b) 毛竹的SAXS二维散射图,其中Ⅰ区域的散射强度主要由维管束贡献,Ⅱ区域的散射强度主要由薄壁细胞贡献;由区域Ⅰ (c) 和区域Ⅱ (d) 重构的散射分布图[75];((e)~(h)) 在冻融干燥法制备泡沫结构材料中CNF的实际取向情况,色轮的颜色代表CNF的实际取向,虚线箭头代表了冻结过程开始的主方向[76]

q2—Relative standard deviation of the scattering vector q

Figure 12. Tissue structure distribution of some natural materials: (a) Microscopic CT reconstruction section of phyllostachys edulis, 1 represented the vascular bundle region, 2 represented the parenchyma region; (b) SAXS 2D scattering diagram of Phyllostachys edulis, region Ⅰ was contributed by the vascular bundle and region Ⅱ was contributed by parenchyma cells; Slice of scattering distribution reconstructed from region Ⅰ (c) and region Ⅱ (d)[75]; ((e)-(h)) True orientation of CNF in foam structure materials prepared by freeze-thawing-drying, the colors of the color wheel represents the true orientation of the CNF, the dotted arrows indicate the main direction of the freezing front[76]

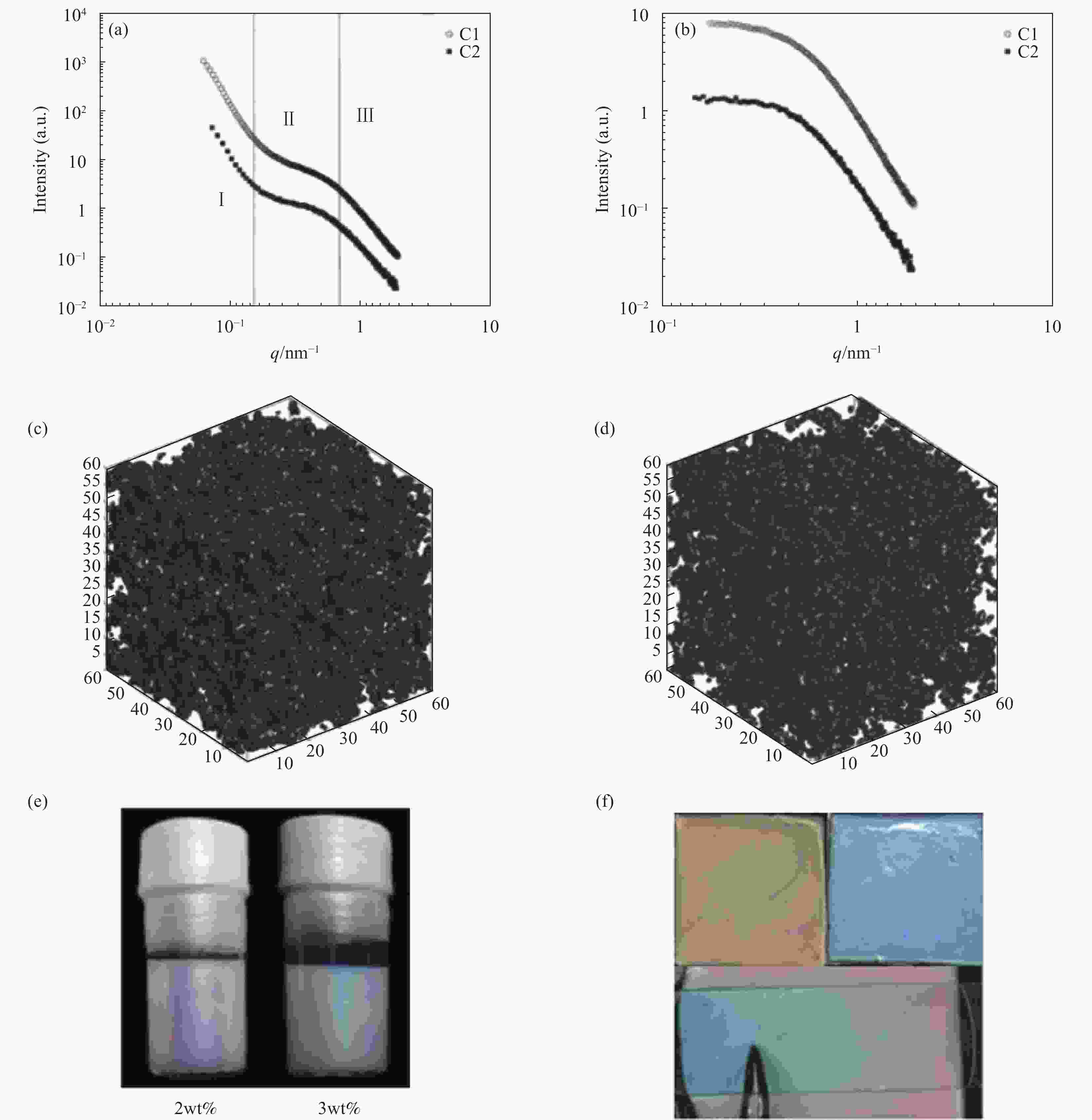

图 13 聚烯烃催化剂与钙钛矿纳米片层水凝胶:(a) 聚烯烃催化剂的SAXS一维曲线;(b) 从总散射曲线中分离得到的关于催化剂孔隙的SAXS一维曲线;通过截断高斯场法对催化剂C1 (c) 与催化剂C2 (d) 的三维模型重构[81];(e) 2.0wt%和3.0wt%钙钛矿纳米片凝胶溶液;(f) 橙色和蓝色钙钛矿纳米片水凝胶[82]

Figure 13. Polyolefin catalyst and perovskite nanosheet hydrogels: (a) SAXS 1D curve of catalyst; (b) SAXS 1D curve of catalyst pores; 3D reconstruction model of catalysts C1 (c) and C2 (d) by correlated Gaussian random filed method[81]; (e) 2.0wt% and 3.0wt% perovskite nanosheet gel solution; (f) Orange and blue perovskite nanosheet hydrogels[82]

图 14 HDPE横截面上的空洞:((a), (b)) 当

${ \varepsilon }_{\text{H}} $ 小于0.5时HDPE内部电镜显示空洞的数量较少且尺寸较小;((c), (d)) 当$ { \varepsilon }_{\text{H}} $ 增大时HDPE内部空洞的数量和尺寸同步增加与扩大[37]εH—True strain defined by Hencky

Figure 14. Cavities on HDPE fracture surface: ((a), (b))When

$ { \varepsilon }_{\text{H}} $ was less than 0.5, the HDPE internal electron microscope showed that the number and size of cavities were small; ((c), (d)) When$ { \varepsilon }_{\text{H}} $ increased, the number and size of HDPE holes increased synchronously[37] -

[1] ZHU Y, ZHENG W, WANG W, et al. When polymerization meets coordination-driven self-assembly: Metallo-supramolecular polymers based on supramolecular coordination complexes[J]. Chemical Society Reviews,2021,50(13):7395-7417. doi: 10.1039/D0CS00654H [2] JUNG K, CORRIGAN N, WONG E H H, et al. Bioactive synthetic polymers[J]. Advanced Materials, 2022, 34(2): e2105063. [3] WONG C K, QIANG X L, MULLER A H E, et al. Self-assembly of block copolymers into internally ordered microparticles[J]. Progress in Polymer Science,2020,102:101211. [4] MEZHUEV Y O, KORSHAK Y V, SHTILMAN M I, et al. Electronic and crystal structures of nitrogen-containing electroconductive and electroactive polymers[J]. Journal of Structural Chemistry,2019,60(4):583-601. doi: 10.1134/S0022476619040097 [5] ZHU M, LI J, YU J, et al. Superstable and intrinsically self-healing fibrous membrane with bionic confined protective structure for breathable electronic skin[J]. Angewandte Chemie International Edition,2022,61(22):e202200226. [6] ZENG X, WANG Y, HAN J, et al. Fighting against drug-resistant tumors using a dual-responsive Pt(IV)/Ru(II) bimetallic polymer[J]. Advanced Materials, 2020, 32(43): 2004766. [7] USSIA M, PUMERA M. Towards micromachine intelligence: Potential of polymers[J]. Chemical Society Reviews,2022,51(5):1558-1572. doi: 10.1039/D1CS00587A [8] AGUILA B, SUN Q, PERMAN J A, et al. Efficient mercury capture using functionalized porous organic polymer[J]. Advanced Materials, 2017, 29(31): 1700665. [9] CHEN Y, ZHANG Y, LI H, et al. Dynamic circularly polarized luminescence with tunable handedness and intensity enabled by achiral dichroic dyes in cholesteric liquid crystal medium[J]. Advanced Materials, 2022, 34(28): 2202309. [10] HUI S Y, HYUNGJU A, SANGSUL L, et al. Universal alignment of graphene oxide in suspensions and fibers[J]. ACS Nano,2021,15(8):13453-13462. doi: 10.1021/acsnano.1c03954 [11] LI T, ANDREW J S, LEE B. Small angle X-ray scattering for nanoparticle research[J]. Chemical Reviews,2016,116(18):11128-11180. doi: 10.1021/acs.chemrev.5b00690 [12] NGUYEN V T, NGUYEN V D, HAUG G C, et al. Alkene synthesis by photocatalytic chemoenzymatically compatible dehydrodecarboxylation of carboxylic acids and biomass[J]. ACS Catalysis,2019,9(10):9485-9498. doi: 10.1021/acscatal.9b02951 [13] 吕冬, 卢影, 门永锋. 小角X射线散射技术在高分子表征中的应用[J]. 高分子学报, 2021, 52(7):822-839. doi: 10.11777/j.issn1000-3304.2020.20249LYU Dong, LU Ying, MEN Yongfeng. Application of small angle X-ray scattering technique in polymer characterization[J]. Acta Polymerica Sinica,2021,52(7):822-839(in Chinese). doi: 10.11777/j.issn1000-3304.2020.20249 [14] 田宇, 朱才镇, 龚静华, 等. 纤维结构形态的原位同步辐射X射线散射及衍射研究[J]. 化学进展, 2013, 25(10):1751-1762. doi: 10.7536/PC130135TIAN Yu, ZHU Caizhen, GONG Jinghua, et al. In situ synchrotron radiation X-ray scattering and diffraction measurement studies on structure and morphology of fibers[J]. Progress in Chemistry,2013,25(10):1751-1762(in Chinese). doi: 10.7536/PC130135 [15] 乔治, 陈刚. 同步辐射原位X射线散射技术在纳米与能源材料中的应用[J]. 中国材料进展, 2021, 40(2):105-111.QIAO Zhi, CHEN Gang. Application of synchrotron radiation in-situ X-ray scattering technology in nano and energy materials research[J]. Materials China,2021,40(2):105-111(in Chinese). [16] 朱育平. 小角X射线散射—理论、测试、计算及应用[M]. 北京: 化学工业出版社, 2008.ZHU Yuping. Small angle X-ray scattering—Theory, testing, calculation and application[M]. Beijing: Chemical Industry Press, 2008(in Chinese). [17] MARIANNE L, MARIOS G, ANDREAS M, et al. Nanostructure surveys of macroscopic specimens by small-angle scattering tensor tomography[J]. Nature,2015,527(7578):349-353. doi: 10.1038/nature16056 [18] THOMAS Z, MATHEW R S, SÖNKE S, et al. Absolute intramolecular distance measurements with angstrom-resolution using anomalous small-angle X-ray scattering[J]. Nano Letters,2016,16(9):1-5. [19] FANG L, SOENKE S, WINANS R E, et al. Understanding synthesis and structural variation of nanomaterials through in situ/operando XAS and SAXS[J]. Small (Weinheim an der Bergstrasse, Germany),2022,18(19):e2106017. [20] VENDITTI V, EGNER T K, CLORE G M. Hybrid approaches to structural characterization of conformational ensembles of complex macromolecular systems combining NMR residual dipolar couplings and solution X-ray scattering[J]. Chemical Reviews, 2016, 116(11): 6305-6322. [21] WANG X, WU L, WANG G, et al. Dynamic crystallization and phase transition in evaporating colloidal droplets[J]. Nano Letters,2019,19(11):8225-8233. doi: 10.1021/acs.nanolett.9b03633 [22] LIAM P D R, DERRY M J, ALESSANDRO I, et al. A single thermoresponsive diblock copolymer can form spheres, worms or vesicles in aqueous solution[J]. Angewandte Chemie International Edition,2019,131(52):18964-18970. [23] LYU X L, TANG Z H, XIAO A Q, et al. Temperature-controlled formation of inverse mesophases assembled from a rod-coil block copolymer[J]. Polymer Chemistry,2019,10(44):6031-6036. doi: 10.1039/C9PY01257E [24] 朱才镇, 刘小芳, 马敬红, 等. 取向体系的二维小角X射线散射分析理论研究进展[J]. 高分子通报, 2013(10): 7-11.ZHU Caizhen, LIU Xiaofang, MA Jinghong, et al. An overview of theoretical analysis for orientation systems based on two-dimensional small angle scattering of X-ray[J]. Chinese Polymer Bulletin, 2013(10): 7-11(in Chinese). [25] HOU J, BADRI A, JOHN J T, et al. Saxsdom: Modeling multidomain protein structures using small-angle X-ray scattering data[J]. Proteins,2020,88(6):1-13. [26] 杨春明, 洪春霞, 周平, 等. 同步辐射小角X射线散射及其在材料研究中的应用[J]. 中国材料进展, 2021, 40(2):111-119. doi: 10.7502/j.issn.1674-3962.202009018YANG Chunming, HONG Chunxia, ZHOU Ping, et al. Synchrotron radiation small angle X-ray scattering in materials research[J]. Materials China,2021,40(2):111-119(in Chinese). doi: 10.7502/j.issn.1674-3962.202009018 [27] 李登华, 吕春祥, 杨禹, 等. 碳纤维微观结构表征: 小角X射线散射[J]. 材料导报, 2021, 35(7):7077-7086. doi: 10.11896/cldb.19070264LI Denghua, LYU Chunxiang, YANG Yu, et al. Characterization of the microstructure of carbon fibers: Small angle X-ray scattering[J]. Materials Reports,2021,35(7):7077-7086(in Chinese). doi: 10.11896/cldb.19070264 [28] 田恐虎, 吴阳, 盛绍顶, 等. 聚合物基绝缘导热复合材料中碳系填料的研究进展[J]. 复合材料学报, 2021, 38(4):1054-1065. doi: 10.13801/j.cnki.fhclxb.20201224.001TIAN Konghu, WU Yang, SHENG Shaoding, et al. Research progress of carbon-based fillers in polymer matrix insulating and thermally conductive composites[J]. Acta Materiae Compositae Sinica,2021,38(4):1054-1065(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201224.001 [29] LUDESCHER L, MORAK R, BRAXMEIER S, et al. Hierarchically organized materials with ordered mesopores: Adsorption isotherm and adsorption-induced deformation from small-angle scattering[J]. Physical Chemistry Chemical Physics,2020,22(22):12713-12723. doi: 10.1039/D0CP01026J [30] NAGINI M, PRADEEP K G, VIJAY R, et al. A combined electron microscopy, atom probe tomography and small angle X-ray scattering study of oxide dispersion strengthened 18 CR ferritic steel[J]. Materials Characterization,2020,164:1-9. [31] 海洋, 柳义, 陈西良, 等. 小角X射线散射法测定高密度聚乙烯微观结构随温度的变化[J]. 高分子材料科学与工程, 2015, 31(9):117-121. doi: 10.16865/j.cnki.1000-7555.2015.09.023HAI Yang, LIU Yi, CHEN Xiliang, et al. Determination of microstructures of high-density polyethylene with temperature by small angle X-ray scattering method[J]. Polymer Materials Science and Engineerig,2015,31(9):117-121(in Chinese). doi: 10.16865/j.cnki.1000-7555.2015.09.023 [32] LI H, KRUTEVA M, DULLE M, et al. Understanding the drying behavior of regenerated cellulose gel beads: The effects of concentration and nonsolvents[J]. ACS Nano,2022,16(2):2608-2620. doi: 10.1021/acsnano.1c09338 [33] YANG J, SATO T. Conformation of pullulan in aqueous solution studied by small-angle X-ray scattering[J]. Polymers,2020,12(6):1-11. [34] CANDIA C F, STROM A, GÓMEZ-MASCARAQUE L G, et al. Understanding nanostructural differences in hydrogels from commercial carrageenans: Combined small angle X-ray scattering and rheological studies[J]. Algal Research,2020,47:1-14. [35] RAHMAN T, PETRUS E, SEGADO M, et al. Predicting the solubility of inorganic ions pairs in water[J]. Angewandte Chemie International Edition,2022,61(19):e202117839. [36] 武海娟, 翟红生, 杨春明, 等. 小角X射线散射法研究枣树的微孔结构[J]. 光散射学报, 2020, 32(4):328-334. doi: 10.13883/j.issn1004-5929.202004006WU Haijuan, QU Hongsheng, YANG Chunming, et al. SAXS study on the micropore structure of jujube[J]. The Journal of Light Scattering,2020,32(4):328-334(in Chinese). doi: 10.13883/j.issn1004-5929.202004006 [37] RAHMANIAN V, GALESKI A. Cavitation in strained polyethylene/nanographene nanocomposites[J]. Polymer,2021,232(6):124158. [38] CHEN R, LU Y, JIANG Z Y, et al. Cavitation in poly(4-methyl-1-pentene) during tensile deformation[J]. Journal of Physical Chemistry B,2018,122(14):4159-4168. doi: 10.1021/acs.jpcb.8b00060 [39] ZHANG C, LIU G, SONG Y, et al. Structural evolution of beta-IPP during uniaxial stretching studied by in-situ WAXS and SAXS[J]. Polymer,2014,55(26):6915-6923. doi: 10.1016/j.polymer.2014.10.049 [40] LANASA J A, NEUMAN A, RIGGLEMAN R A, et al. Investi-gating nanoparticle organization in polymer matrices during reaction-induced phase transitions and material processing[J]. ACS Applied Materials & Interfaces,2021,13(35):42104-42113. [41] MARTINS I C B, AL-SABBAGH D, BENTRUP U, et al. Formation mechanism of a nano-ring of bismuth cations and mono-lacunary Keggin-type phosphomolybdate[J]. Chemistry-A European Journal,2022,28(27):1-6. [42] ANKER A S, CHRISTIANSEN T L, WEBER M, et al. Structural changes during the growth of atomically precise metal oxido nanoclusters from combined pair distribution function and small-angle X-ray scattering analysis[J]. Angewandte Chemie International Edition,2021,60(37):20407-20416. doi: 10.1002/anie.202103641 [43] FANG L, SEIFERT S, WINANS R E, et al. Understanding synthesis and structural variation of nanomaterials through in situ/operando XAS and SAXS[J]. Small,2022,18(19):1-12. [44] YANG Y, ROH I, LOUISIA S, et al. Operando resonant soft X-ray scattering studies of chemical environment and interparticle dynamics of Cu nanocatalysts for CO2 electroreduction[J]. Journal of the American Chemical Society,2022,144(20):8927-8931. doi: 10.1021/jacs.2c03662 [45] CHEN Q, YAO Y, LIAO J, et al. Subnanometer ion channel anion exchange membranes having a rigid benzimidazole structure for selective anion separation[J]. ACS Nano,2022,16(3):4629-4641. doi: 10.1021/acsnano.1c11264 [46] OH E J, PARK D G, LIM Y S, et al. Structural transition of reverse cylindrical micelles to reverse vesicles by mixtures of lecithin and inorganic salts[J]. Journal of Colloid and Interface Science,2022,615:768-777. doi: 10.1016/j.jcis.2022.02.015 [47] ROYES J, BJORNESTAD V A, BRUN G, et al. Transition kinetics of mixed lipid: Photosurfactant assemblies studied by time-resolved small angle X-ray scattering[J]. Journal of Colloid and Interface Science,2022,610:830-841. doi: 10.1016/j.jcis.2021.11.133 [48] KANG M, TUTEJA M, CENTRONE A, et al. Nanostructured lipid-based films for substrate mediated applications in biotechnology[J]. Advanced Functional Materials,2018,28:1-20. [49] CASTELLANA E T, CREMER P S. Solid supported lipid bilayers: From biophysical studies to sensor design[J]. Surface Science Reports,2006,61(10):429-444. doi: 10.1016/j.surfrep.2006.06.001 [50] HERRERA D, CHEVALIER T, FROT D, et al. Monitoring the formation kinetics of a bicontinuous microemulsion[J]. Journal of Colloid and Interface Science,2022,609:200-211. doi: 10.1016/j.jcis.2021.12.011 [51] WU H, TING J M, WEISS T M, et al. Interparticle interactions in dilute solutions of polyelectrolyte complex micelles[J]. ACS Macro Letters,2019,8(7):819-825. doi: 10.1021/acsmacrolett.9b00226 [52] CZAJKA A, ARMES S P. Time-resolved small-angle X-ray scattering studies during aqueous emulsion polymerization[J]. Journal of the American Chemical Society,2021,143(3):1474-1484. doi: 10.1021/jacs.0c11183 [53] ELIFKÜBRA Ö, FELIX B, PASCAL C, et al. Peering into the formation of cerium oxide colloidal particles in solution by in-situ small-angle X-ray scattering[J]. Langmuir,2020,36(31):9175-9190. doi: 10.1021/acs.langmuir.0c01463 [54] DORDOVIC V, UCHMAN M, ZHIGUNOV A, et al. Compartmentalization in hybrid metallacarborane nanoparticles formed by block copolymers with star-like architecture[J]. ACS Macro Letters,2014,3(11):1151-1155. doi: 10.1021/mz5004757 [55] HANCOX E, DERRY M J, GREENALL M J, et al. Heterotelechelic homopolymers mimicking high CHI- ultralow n block copolymers with sub-2 nm domain size[J]. Chemical Science,2022,13(14):4019-4028. doi: 10.1039/D2SC00720G [56] ANDREOZZI P, SIMO C, MORETTI P, et al. Novel core-shell polyamine phosphate nanoparticles self-assembled from pegylated poly(allylamine hydrochloride) with low toxicity and increased in vivo circulation time[J]. Small,2021,17(35):1-10. [57] KARAVOLIAS M G, ELDER J B, NESS E M, et al. Order-to-disorder transitions in lamellar melt self-assembled core-shell bottlebrush polymers[J]. ACS Macro Letters,2019,8(12):1617-1622. doi: 10.1021/acsmacrolett.9b00782 [58] PARK J, NAM J, SEO M, et al. Side-chain density driven morphology transition in brush-linear diblock copolymers[J]. ACS Macro Letters,2022,11(4):468-474. doi: 10.1021/acsmacrolett.2c00068 [59] KIM S, CHO Y, KIM J H, et al. Structural analysis of bottle brush block copolymer micelles using small-angle X-ray scattering[J]. ACS Macro Letters,2020,9(9):1261-1266. doi: 10.1021/acsmacrolett.0c00442 [60] RAPHAEL E, DERRY M J, HIPPLER M, et al. Tuning the properties of hydrogen-bonded block copolymer worm gels prepared via polymerization-induced self-assembly[J]. Chemical Science,2021,12(36):12082-12091. doi: 10.1039/D1SC03156B [61] BROTHERTON E E, HATTON F L, COCKRAM A A, et al. In situ small-angle X-ray scattering studies during reversible addition-fragmentation chain transfer aqueous emulsion polymerization[J]. Journal of the American Chemical Society,2019,141(34):13664-13675. doi: 10.1021/jacs.9b06788 [62] BO F, JING W, JIALI Z, et al. Triggered degradable colloidal particles with ordered inverse bicontinuous cubic and hexagonal mesophases[J]. ACS Nano,2021,15(3):4688-4698. doi: 10.1021/acsnano.0c09166 [63] CZAJKA A, ARMES S P. In situ SAXS studies of a prototypical raft aqueous dispersion polymerization formulation: Monitoring the evolution in copolymer morphology during polymerization-induced self-assembly[J]. Chemical Science,2020,11(42):11443-11454. doi: 10.1039/D0SC03411H [64] QIU X, WANG X, HE Y, et al. Superstructured mesocrystals through multiple inherent molecular interactions for highly reversible sodium ion batteries[J]. Science Advances,2021,7(37):1-10. [65] MALIN W, TOBIAS B, LARS W, et al. Cellulose and the role of hydrogen bonds: Not in charge of everything[J]. Cellulose,2022,29(1):1-23. doi: 10.1007/s10570-021-04325-4 [66] TOMAS R, HE H, WANG R, et al. Cross-sections of nanocellulose from wood analyzed by quantized polydispersity of elementary microfibrils[J]. ACS Nano,2020,14(12):16743-16754. [67] SUZUKI M, ORIDO T, TAKANO A, et al. The largest quasicrystalline tiling with dodecagonal symmetry from a single pentablock quarterpolymer of the AB1 CB2 D type[J]. ACS Nano,2022,16(4):6111-6117. [68] JANAS K, ŁATKIEWICZ A, PARNELL A, et al. Differential effects of early growth conditions on colour-producing nanostructures revealed through small angle X-ray scattering (SAXS) and electron microscopy[J]. The Journal of Experimental Biology,2020,223:228387. [69] ZHOU L, KOH J J, HOU X, et al. Crystallization of decanoic acid/dopamine supramolecular self-assemblies in the presence of coacervates[J]. Journal of Colloid and Interface Science,2022,615:759-767. doi: 10.1016/j.jcis.2022.02.016 [70] GAO Y, ZHOU Y, XU X, et al. Fabrication of oriented colloidal crystals from capillary assembly of polymer-tethered gold nanoparticles[J]. Small,2022,18(13):1-9. [71] LIU C, TANG X, WANG Y, et al. Ionic conductivity enhancement of polymer electrolytes by directed crystallization[J]. ACS Macro Letters,2022,11(4):595-602. doi: 10.1021/acsmacrolett.2c00040 [72] ZHU Y, ZENG S, LI B, et al. Liquid-crystalline thermally activated delayed fluorescence: Design, synthesis, and application in solution-processed organic light-emitting diodes[J]. ACS Applied Materials & Interfaces,2022,14(13):15437-15447. [73] KONISHI T, OKAMOTO D, TADOKORO D, et al. Kinetics of polymer crystallization with aggregating small crystallites[J]. Physical Review Letters, 2022, 128(10): 107801. [74] DONG K, PENG X, WANG Z L. Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence[J]. Advanced Materials,2020,32(5):1-43. [75] 胡涛, 滑文强, 王玉丹, 等. 基于Kirkpatrick-Baez镜聚焦的X射线小角散射显微层析成像[J]. 光学学报, 2018, 38(1):392-398.HU Tao, HUA Wenqiang, WANG Yudan, et al. Samll-angle X-ray scattering tomography based on micro-focusing Kirkpatrick-Baez mirrors[J]. Acta Optica Sinica,2018,38(1):392-398(in Chinese). [76] LUTZ-BUENO V, DIAZ A, WU T, et al. Hierarchical structure of cellulose nanofibril-based foams explored by multimodal X-ray scattering[J]. Biomacromolecules,2022,23(3):676-686. doi: 10.1021/acs.biomac.1c00521 [77] KUMAR R K, MISHCHENKO A, CHEN X, et al. High-order fractal states in graphene superlattices[J]. Proceedings of the National Academy of Sciences of the United States of America,2018,115(20):5135-5139. doi: 10.1073/pnas.1804572115 [78] XIAO Y X, YING J, TIAN G, et al. Hierarchically fractal PTPDCU sponges and their directed mass- and electron-transfer effects[J]. Nano Letters,2021,21(18):7870-7878. doi: 10.1021/acs.nanolett.1c02268 [79] 王春红, 赵玲, 李姗. 利用小角X射线散射技术研究改性处理对苎麻/热固性聚乳酸复合材料界面特性和分形特征的影响[J]. 天津工业大学学报, 2014, 33(6):21-24. doi: 10.3969/j.issn.1671-024X.2014.06.005WANG Chunhong, ZHAO Lin, LI Shan. Influence of modification on interface and fractal characteristics of ramie/PLA composites by SAXS[J]. Journal of Tianjin Polytechnic University,2014,33(6):21-24(in Chinese). doi: 10.3969/j.issn.1671-024X.2014.06.005 [80] MAI H, LE T C, CHEN D, et al. Machine learning for electrocatalyst and photocatalyst design and discovery[J]. Chemical Reviews, 2022, 122(16): 13478-13515. [81] 岑为, 夏先知, 刘月祥, 等. 基于小角X射线散射聚烯烃催化剂三维模型重构[J]. 高分子通报, 2014(11):83-89. doi: 10.14028/j.cnki.1003-3726.2014.11.011CEN Wei, XIA Xianzhi, LIU Yuexiang, et al. Reconstruction of polyolefin catalyst 3D model based on small angle X-ray scattering[J]. Polymer Bulletin,2014(11):83-89(in Chinese). doi: 10.14028/j.cnki.1003-3726.2014.11.011 [82] MICHELSEN H A, CAMPBELL M F, TRAN I C, et al. Distinguishing gas-phase and nanoparticle contributions to small-angle X-ray scattering in reacting aerosol flows[J]. The Journal of Physical Chemistry A,2022,126(19):3015-3026. doi: 10.1021/acs.jpca.2c00454 [83] YANG W, SHINYA Y, KEIICHIRO S, et al. Perovskite nanosheet hydrogels with mechanochromic structural color[J]. Angewandte Chemie International Edition,2021,60(15):8466-8471. doi: 10.1002/anie.202015982 [84] 付莲莲, 卢影, 姜志勇, 等. 基于同步辐射超小角X射线散射的高密度聚乙烯空洞化行为研究[J]. 高分子学报, 2021, 52(2):204-213. doi: 10.11777/j.issn1000-3304.2020.20147FU Lianlian, LU Ying, JIANG Zhiyong, et al. Cavitation behavior of high-density polyethylene based on ultra-small angle X-ray scattering by synchrotron radiation[J]. Acta Polymerica Sinica,2021,52(2):204-213(in Chinese). doi: 10.11777/j.issn1000-3304.2020.20147 -

下载:

下载: